45fa72e80e71cf11db6444d2fcc04925.ppt

- Количество слайдов: 28

Chapter 6 Light vehicle chassis systems © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 1

Chapter 6 Light vehicle chassis systems © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 1

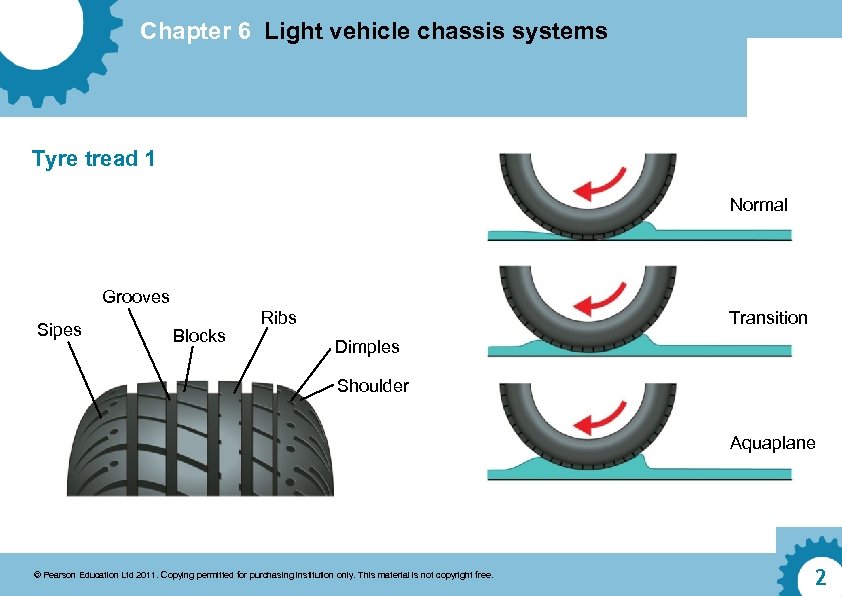

Chapter 6 Light vehicle chassis systems Tyre tread 1 Normal Grooves Sipes Blocks Transition Ribs Dimples Shoulder Aquaplane © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 2

Chapter 6 Light vehicle chassis systems Tyre tread 1 Normal Grooves Sipes Blocks Transition Ribs Dimples Shoulder Aquaplane © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 2

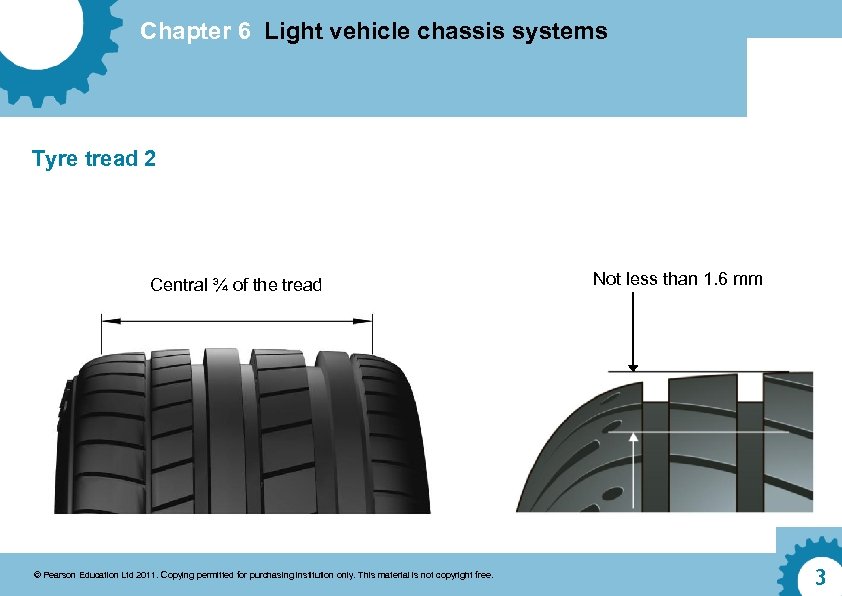

Chapter 6 Light vehicle chassis systems Tyre tread 2 Central ¾ of the tread © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Not less than 1. 6 mm 3

Chapter 6 Light vehicle chassis systems Tyre tread 2 Central ¾ of the tread © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Not less than 1. 6 mm 3

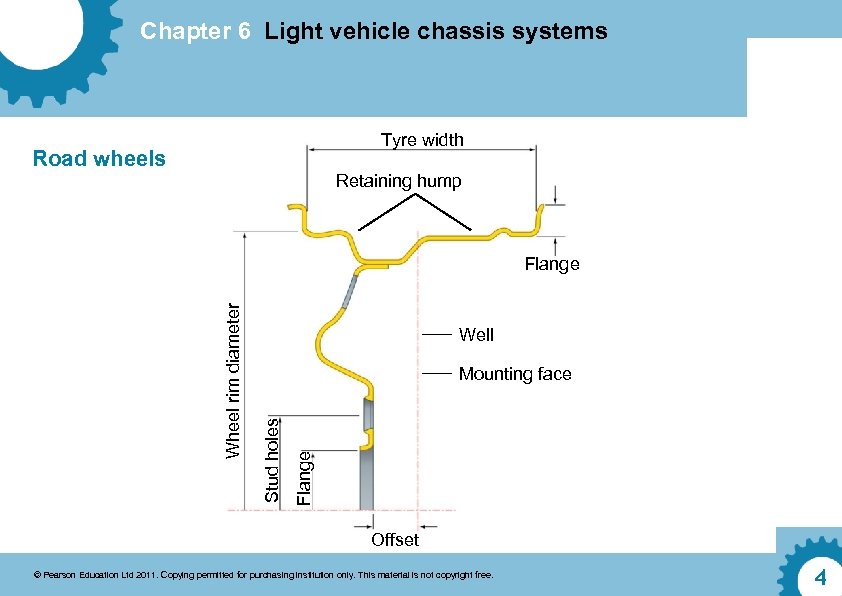

Chapter 6 Light vehicle chassis systems Tyre width Road wheels Retaining hump Well Flange Mounting face Stud holes Wheel rim diameter Flange Offset © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 4

Chapter 6 Light vehicle chassis systems Tyre width Road wheels Retaining hump Well Flange Mounting face Stud holes Wheel rim diameter Flange Offset © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 4

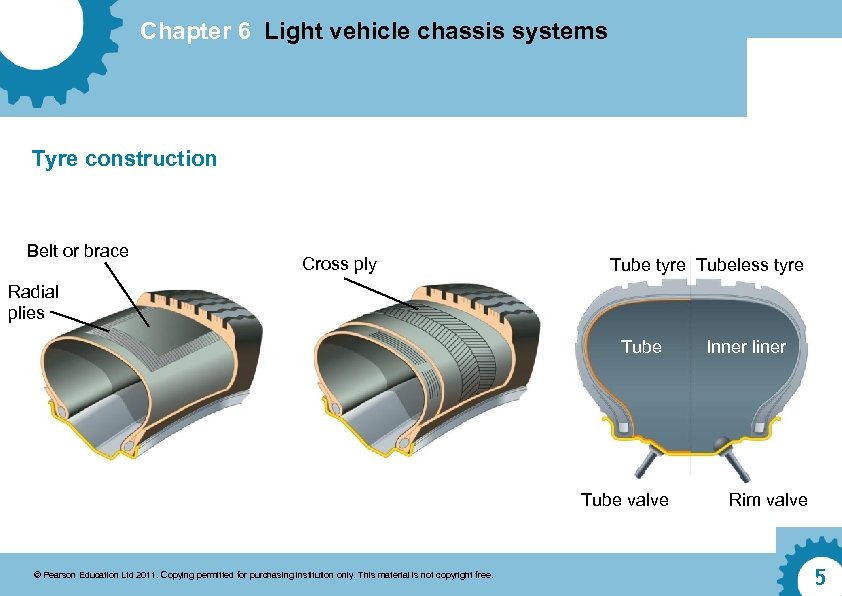

Chapter 6 Light vehicle chassis systems Tyre construction Belt or brace Cross ply Tube tyre Tubeless tyre Radial plies Tube valve © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Inner liner Rim valve 5

Chapter 6 Light vehicle chassis systems Tyre construction Belt or brace Cross ply Tube tyre Tubeless tyre Radial plies Tube valve © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Inner liner Rim valve 5

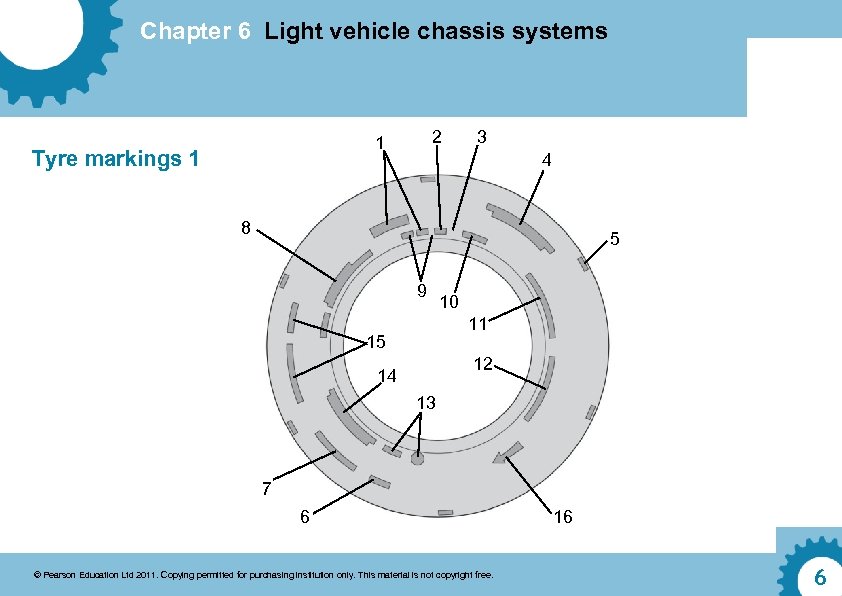

Chapter 6 Light vehicle chassis systems 2 1 Tyre markings 1 3 4 8 5 9 10 11 15 12 14 13 7 6 © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 16 6

Chapter 6 Light vehicle chassis systems 2 1 Tyre markings 1 3 4 8 5 9 10 11 15 12 14 13 7 6 © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 16 6

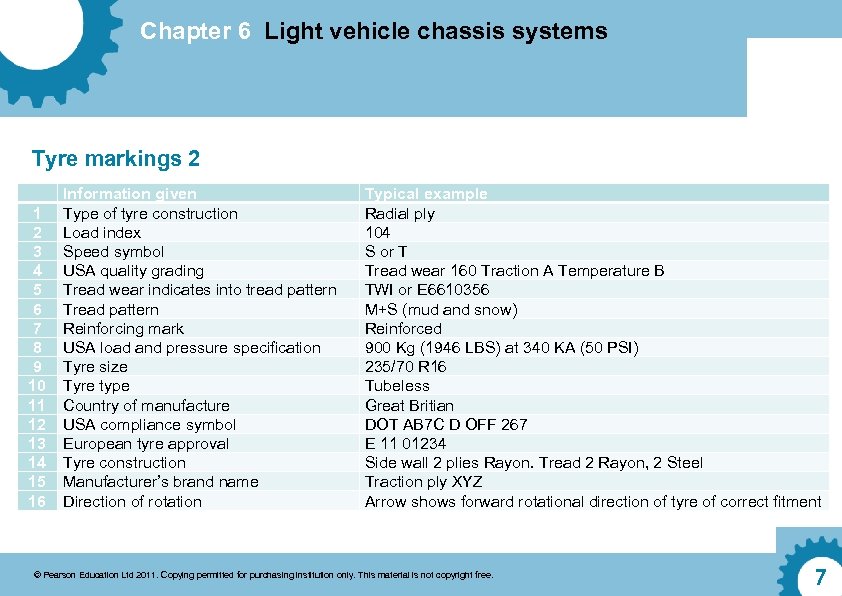

Chapter 6 Light vehicle chassis systems Tyre markings 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Information given Type of tyre construction Load index Speed symbol USA quality grading Tread wear indicates into tread pattern Tread pattern Reinforcing mark USA load and pressure specification Tyre size Tyre type Country of manufacture USA compliance symbol European tyre approval Tyre construction Manufacturer’s brand name Direction of rotation Typical example Radial ply 104 S or T Tread wear 160 Traction A Temperature B TWI or E 6610356 M+S (mud and snow) Reinforced 900 Kg (1946 LBS) at 340 KA (50 PSI) 235/70 R 16 Tubeless Great Britian DOT AB 7 C D OFF 267 E 11 01234 Side wall 2 plies Rayon. Tread 2 Rayon, 2 Steel Traction ply XYZ Arrow shows forward rotational direction of tyre of correct fitment © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 7

Chapter 6 Light vehicle chassis systems Tyre markings 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Information given Type of tyre construction Load index Speed symbol USA quality grading Tread wear indicates into tread pattern Tread pattern Reinforcing mark USA load and pressure specification Tyre size Tyre type Country of manufacture USA compliance symbol European tyre approval Tyre construction Manufacturer’s brand name Direction of rotation Typical example Radial ply 104 S or T Tread wear 160 Traction A Temperature B TWI or E 6610356 M+S (mud and snow) Reinforced 900 Kg (1946 LBS) at 340 KA (50 PSI) 235/70 R 16 Tubeless Great Britian DOT AB 7 C D OFF 267 E 11 01234 Side wall 2 plies Rayon. Tread 2 Rayon, 2 Steel Traction ply XYZ Arrow shows forward rotational direction of tyre of correct fitment © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 7

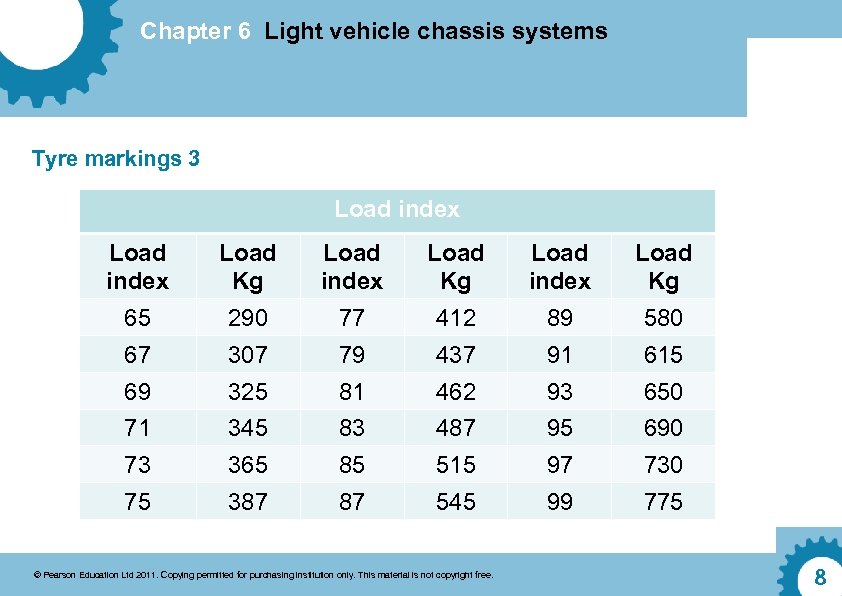

Chapter 6 Light vehicle chassis systems Tyre markings 3 Load index Load Kg 65 290 77 412 89 580 67 307 79 437 91 615 69 325 81 462 93 650 71 345 83 487 95 690 73 365 85 515 97 730 75 387 87 545 99 775 © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 8

Chapter 6 Light vehicle chassis systems Tyre markings 3 Load index Load Kg 65 290 77 412 89 580 67 307 79 437 91 615 69 325 81 462 93 650 71 345 83 487 95 690 73 365 85 515 97 730 75 387 87 545 99 775 © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 8

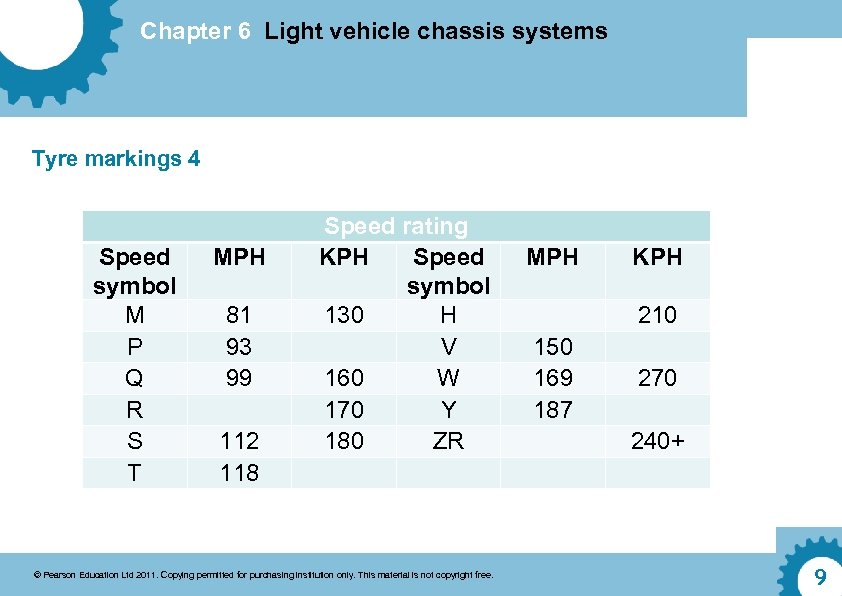

Chapter 6 Light vehicle chassis systems Tyre markings 4 Speed symbol M P Q R S T MPH 81 93 99 112 118 Speed rating KPH Speed symbol 130 H V 160 W 170 Y 180 ZR © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. MPH KPH 210 150 169 187 270 240+ 9

Chapter 6 Light vehicle chassis systems Tyre markings 4 Speed symbol M P Q R S T MPH 81 93 99 112 118 Speed rating KPH Speed symbol 130 H V 160 W 170 Y 180 ZR © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. MPH KPH 210 150 169 187 270 240+ 9

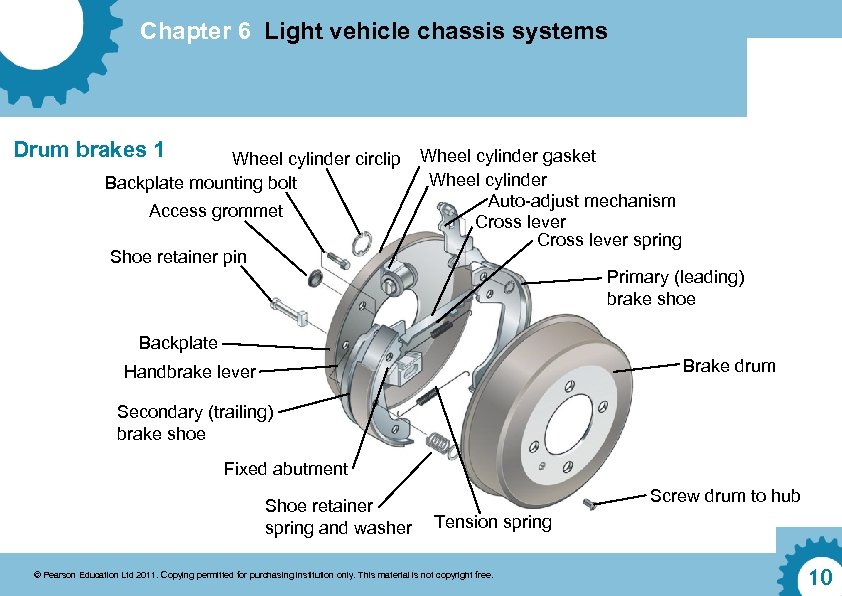

Chapter 6 Light vehicle chassis systems Drum brakes 1 Wheel cylinder circlip Backplate mounting bolt Access grommet Shoe retainer pin Wheel cylinder gasket Wheel cylinder Auto-adjust mechanism Cross lever spring Primary (leading) brake shoe Backplate Brake drum Handbrake lever Secondary (trailing) brake shoe Fixed abutment Shoe retainer spring and washer Screw drum to hub Tension spring © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 10

Chapter 6 Light vehicle chassis systems Drum brakes 1 Wheel cylinder circlip Backplate mounting bolt Access grommet Shoe retainer pin Wheel cylinder gasket Wheel cylinder Auto-adjust mechanism Cross lever spring Primary (leading) brake shoe Backplate Brake drum Handbrake lever Secondary (trailing) brake shoe Fixed abutment Shoe retainer spring and washer Screw drum to hub Tension spring © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 10

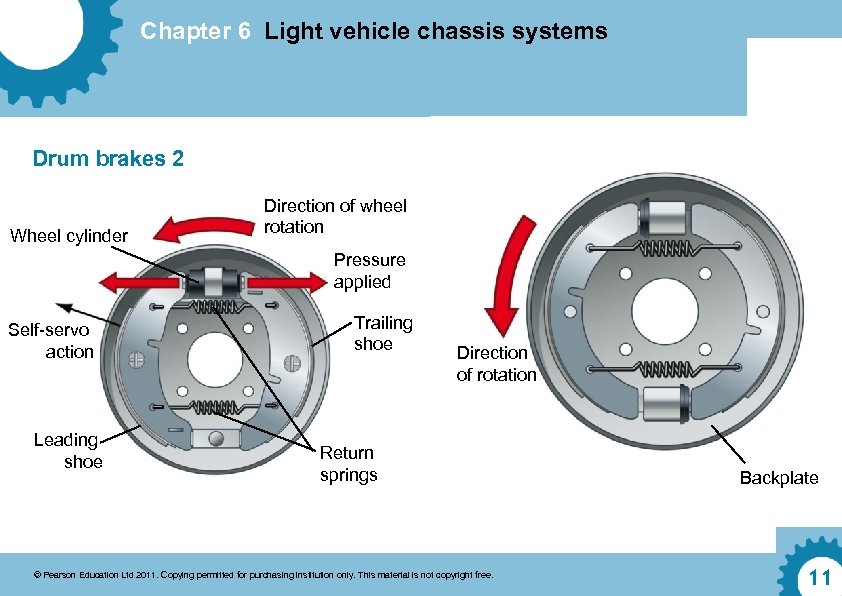

Chapter 6 Light vehicle chassis systems Drum brakes 2 Wheel cylinder Direction of wheel rotation Pressure applied Self-servo action Leading shoe Trailing shoe Direction of rotation Return springs © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Backplate 11

Chapter 6 Light vehicle chassis systems Drum brakes 2 Wheel cylinder Direction of wheel rotation Pressure applied Self-servo action Leading shoe Trailing shoe Direction of rotation Return springs © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Backplate 11

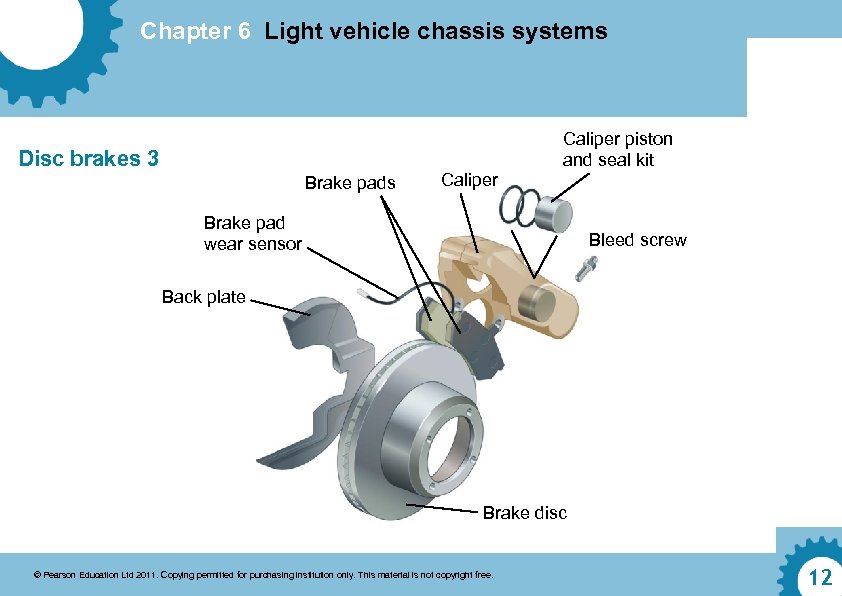

Chapter 6 Light vehicle chassis systems Disc brakes 3 Brake pads Caliper piston and seal kit Brake pad wear sensor Bleed screw Back plate Brake disc © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 12

Chapter 6 Light vehicle chassis systems Disc brakes 3 Brake pads Caliper piston and seal kit Brake pad wear sensor Bleed screw Back plate Brake disc © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 12

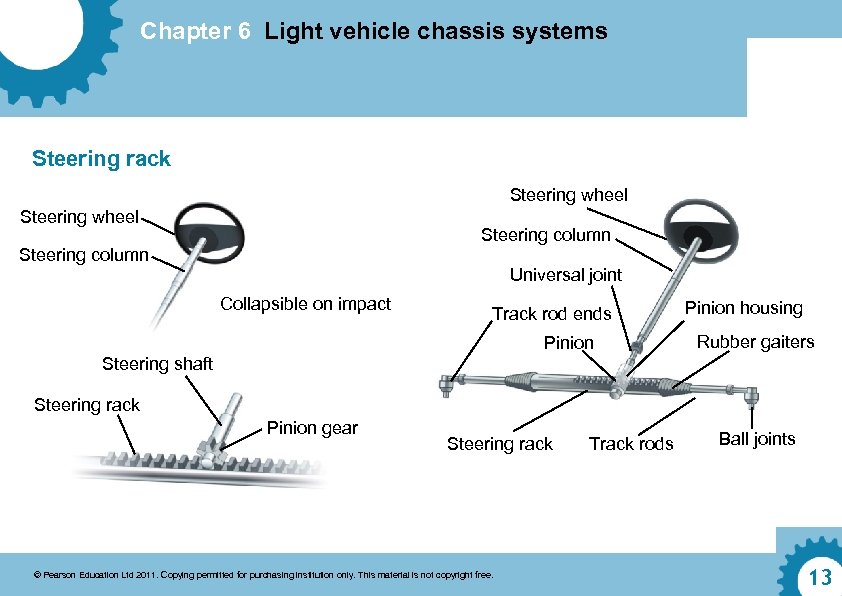

Chapter 6 Light vehicle chassis systems Steering rack Steering wheel Steering column Universal joint Collapsible on impact Track rod ends Pinion housing Rubber gaiters Steering shaft Steering rack Pinion gear Steering rack © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Track rods Ball joints 13

Chapter 6 Light vehicle chassis systems Steering rack Steering wheel Steering column Universal joint Collapsible on impact Track rod ends Pinion housing Rubber gaiters Steering shaft Steering rack Pinion gear Steering rack © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Track rods Ball joints 13

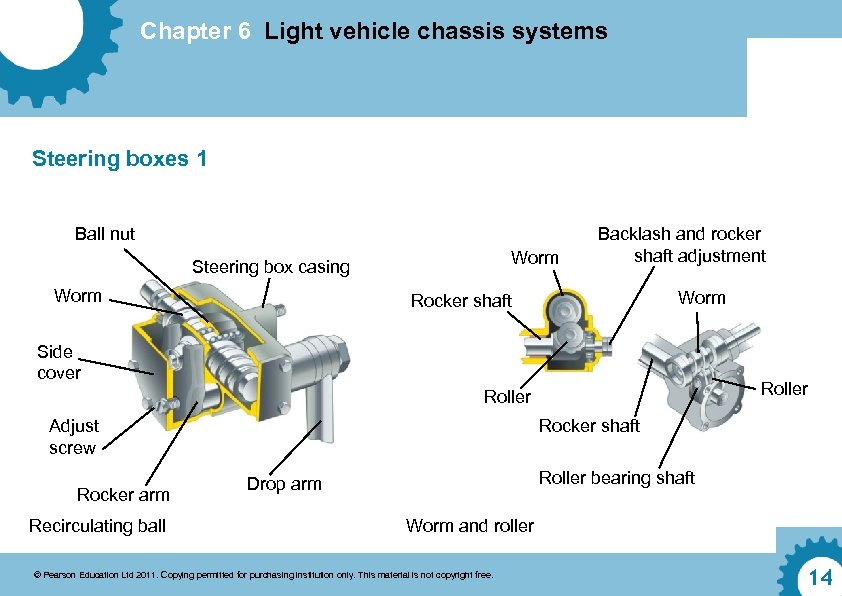

Chapter 6 Light vehicle chassis systems Steering boxes 1 Ball nut Worm Steering box casing Worm Backlash and rocker shaft adjustment Worm Rocker shaft Side cover Roller Rocker shaft Adjust screw Rocker arm Recirculating ball Roller bearing shaft Drop arm Worm and roller © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 14

Chapter 6 Light vehicle chassis systems Steering boxes 1 Ball nut Worm Steering box casing Worm Backlash and rocker shaft adjustment Worm Rocker shaft Side cover Roller Rocker shaft Adjust screw Rocker arm Recirculating ball Roller bearing shaft Drop arm Worm and roller © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 14

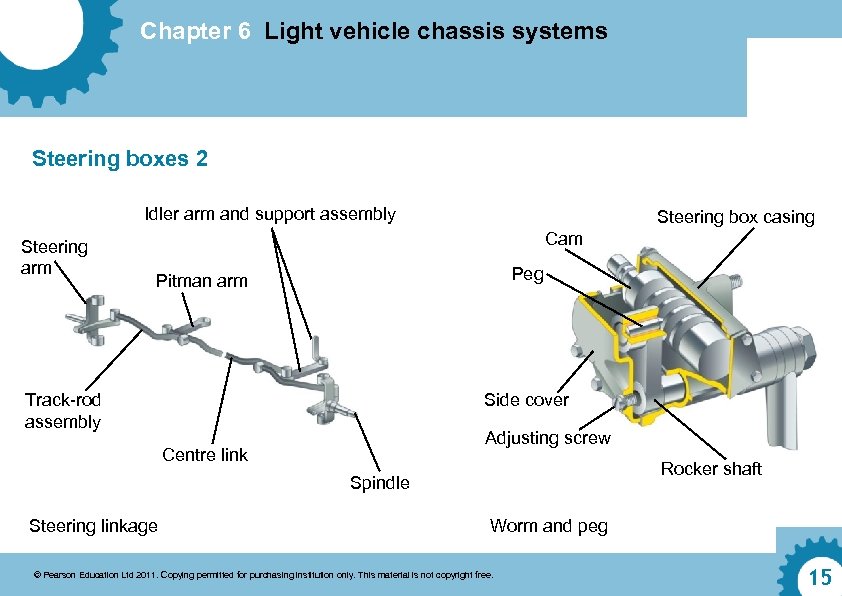

Chapter 6 Light vehicle chassis systems Steering boxes 2 Idler arm and support assembly Steering arm Steering box casing Cam Peg Pitman arm Side cover Track-rod assembly Adjusting screw Centre link Rocker shaft Spindle Steering linkage Worm and peg © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 15

Chapter 6 Light vehicle chassis systems Steering boxes 2 Idler arm and support assembly Steering arm Steering box casing Cam Peg Pitman arm Side cover Track-rod assembly Adjusting screw Centre link Rocker shaft Spindle Steering linkage Worm and peg © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 15

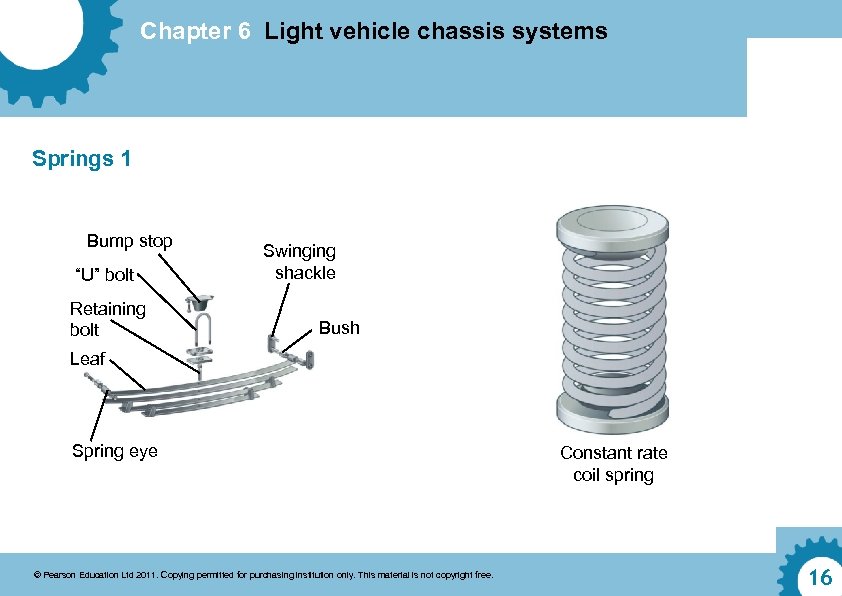

Chapter 6 Light vehicle chassis systems Springs 1 Bump stop “U” bolt Retaining bolt Swinging shackle Bush Leaf Spring eye © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Constant rate coil spring 16

Chapter 6 Light vehicle chassis systems Springs 1 Bump stop “U” bolt Retaining bolt Swinging shackle Bush Leaf Spring eye © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Constant rate coil spring 16

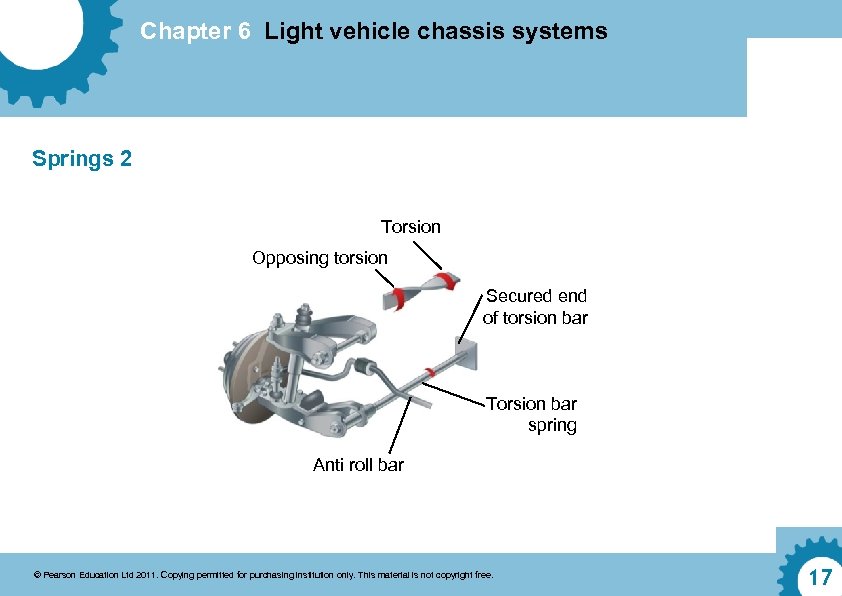

Chapter 6 Light vehicle chassis systems Springs 2 Torsion Opposing torsion Secured end of torsion bar Torsion bar spring Anti roll bar © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 17

Chapter 6 Light vehicle chassis systems Springs 2 Torsion Opposing torsion Secured end of torsion bar Torsion bar spring Anti roll bar © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 17

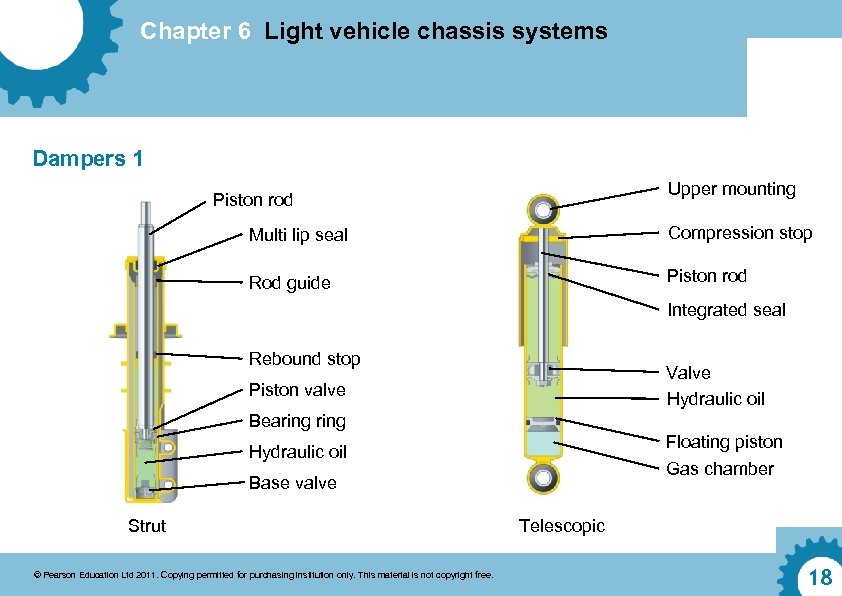

Chapter 6 Light vehicle chassis systems Dampers 1 Upper mounting Piston rod Multi lip seal Compression stop Rod guide Piston rod Integrated seal Rebound stop Valve Hydraulic oil Piston valve Bearing Floating piston Hydraulic oil Gas chamber Base valve Strut © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Telescopic 18

Chapter 6 Light vehicle chassis systems Dampers 1 Upper mounting Piston rod Multi lip seal Compression stop Rod guide Piston rod Integrated seal Rebound stop Valve Hydraulic oil Piston valve Bearing Floating piston Hydraulic oil Gas chamber Base valve Strut © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Telescopic 18

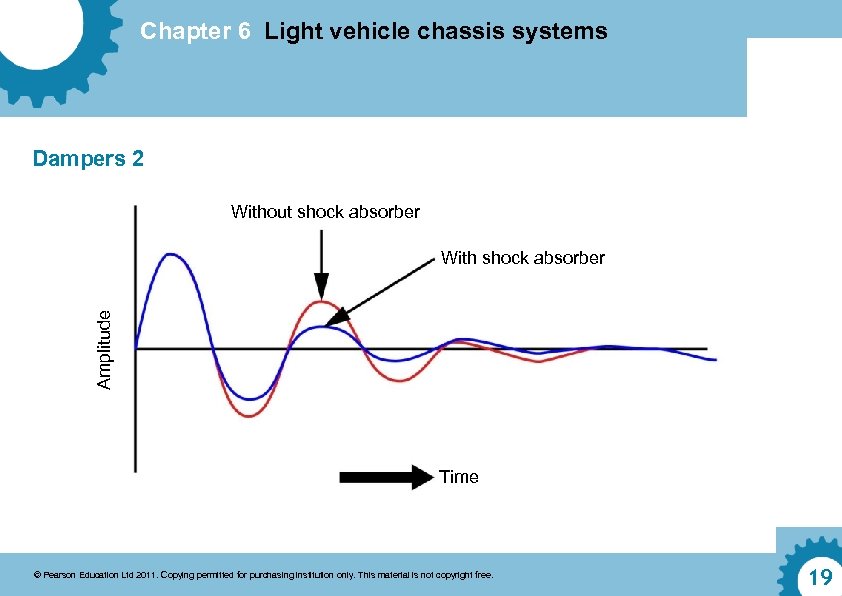

Chapter 6 Light vehicle chassis systems Dampers 2 Without shock absorber Amplitude With shock absorber Time © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 19

Chapter 6 Light vehicle chassis systems Dampers 2 Without shock absorber Amplitude With shock absorber Time © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 19

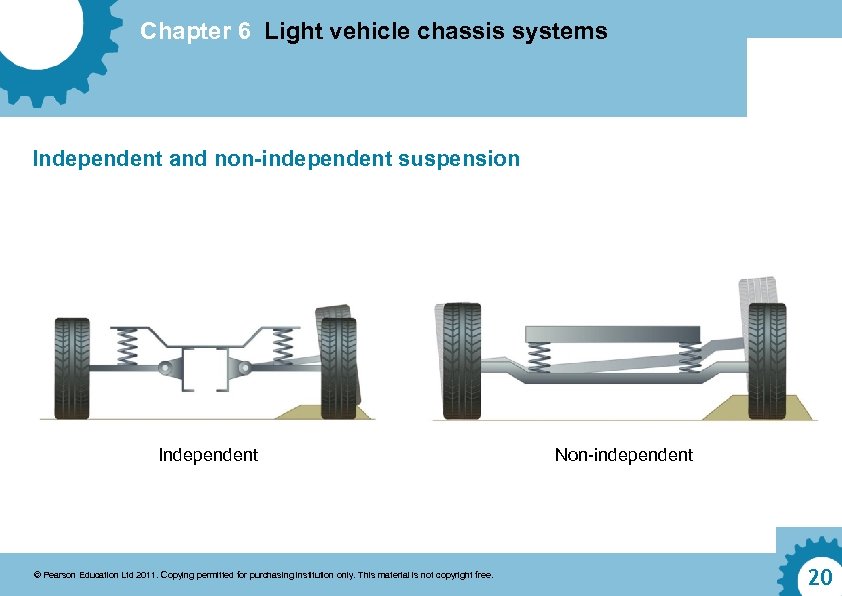

Chapter 6 Light vehicle chassis systems Independent and non-independent suspension Independent © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Non-independent 20

Chapter 6 Light vehicle chassis systems Independent and non-independent suspension Independent © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Non-independent 20

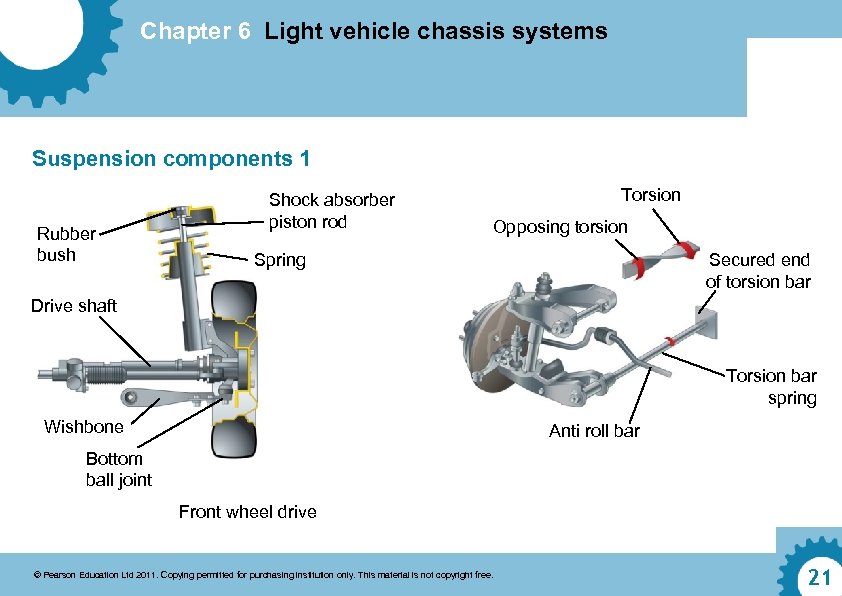

Chapter 6 Light vehicle chassis systems Suspension components 1 Rubber bush Spring Shock absorber piston rod Torsion Opposing torsion Secured end of torsion bar Spring Drive shaft Torsion bar spring Wishbone Anti roll bar Bottom ball joint Front wheel drive © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 21

Chapter 6 Light vehicle chassis systems Suspension components 1 Rubber bush Spring Shock absorber piston rod Torsion Opposing torsion Secured end of torsion bar Spring Drive shaft Torsion bar spring Wishbone Anti roll bar Bottom ball joint Front wheel drive © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 21

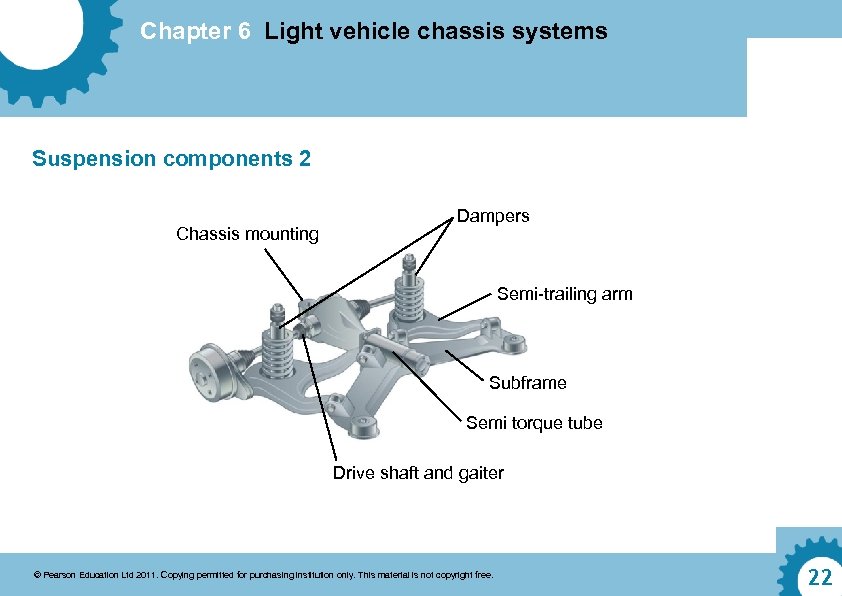

Chapter 6 Light vehicle chassis systems Suspension components 2 Chassis mounting Dampers Semi-trailing arm Subframe Semi torque tube Drive shaft and gaiter © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 22

Chapter 6 Light vehicle chassis systems Suspension components 2 Chassis mounting Dampers Semi-trailing arm Subframe Semi torque tube Drive shaft and gaiter © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 22

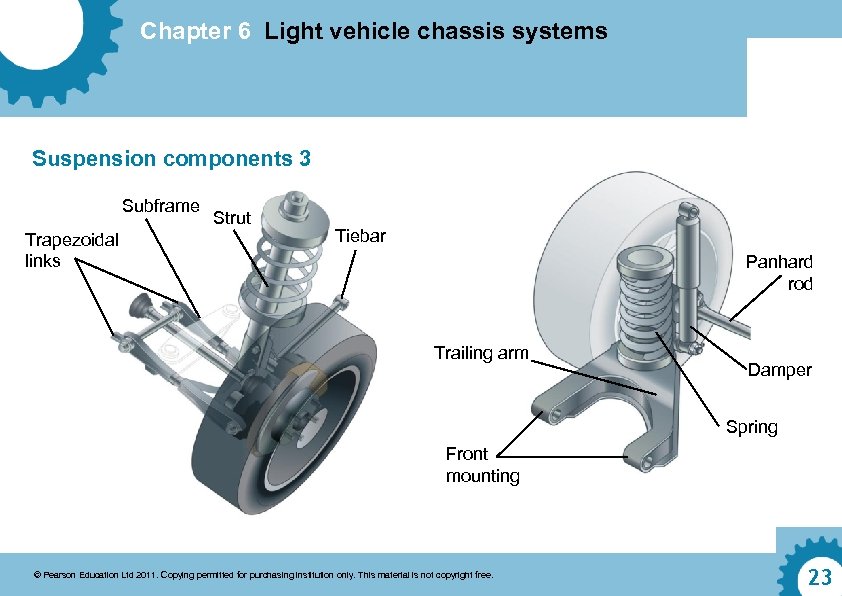

Chapter 6 Light vehicle chassis systems Suspension components 3 Subframe Trapezoidal links Strut Tiebar Panhard rod Trailing arm Damper Spring Front mounting © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 23

Chapter 6 Light vehicle chassis systems Suspension components 3 Subframe Trapezoidal links Strut Tiebar Panhard rod Trailing arm Damper Spring Front mounting © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 23

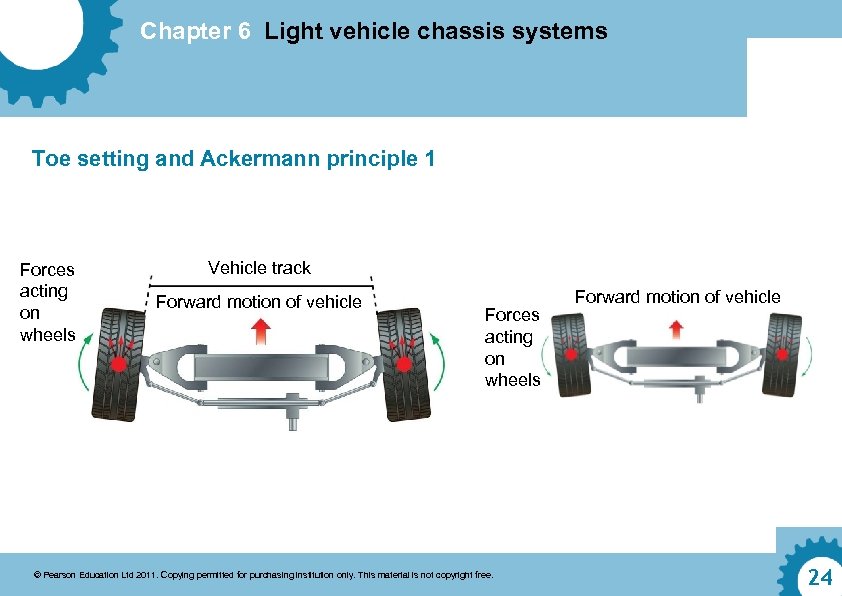

Chapter 6 Light vehicle chassis systems Toe setting and Ackermann principle 1 Forces acting on wheels Vehicle track Forward motion of vehicle Forces acting on wheels © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Forward motion of vehicle 24

Chapter 6 Light vehicle chassis systems Toe setting and Ackermann principle 1 Forces acting on wheels Vehicle track Forward motion of vehicle Forces acting on wheels © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. Forward motion of vehicle 24

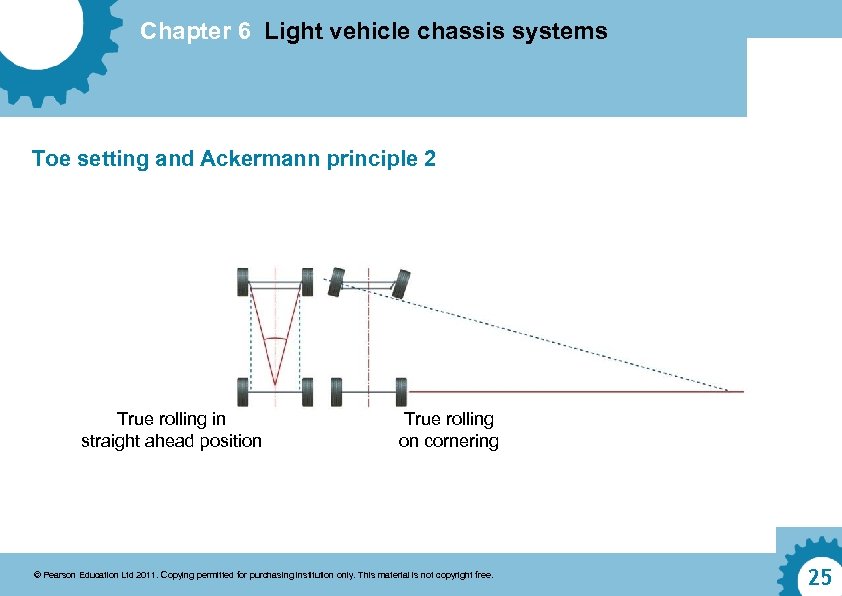

Chapter 6 Light vehicle chassis systems Toe setting and Ackermann principle 2 True rolling in straight ahead position True rolling on cornering © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 25

Chapter 6 Light vehicle chassis systems Toe setting and Ackermann principle 2 True rolling in straight ahead position True rolling on cornering © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 25

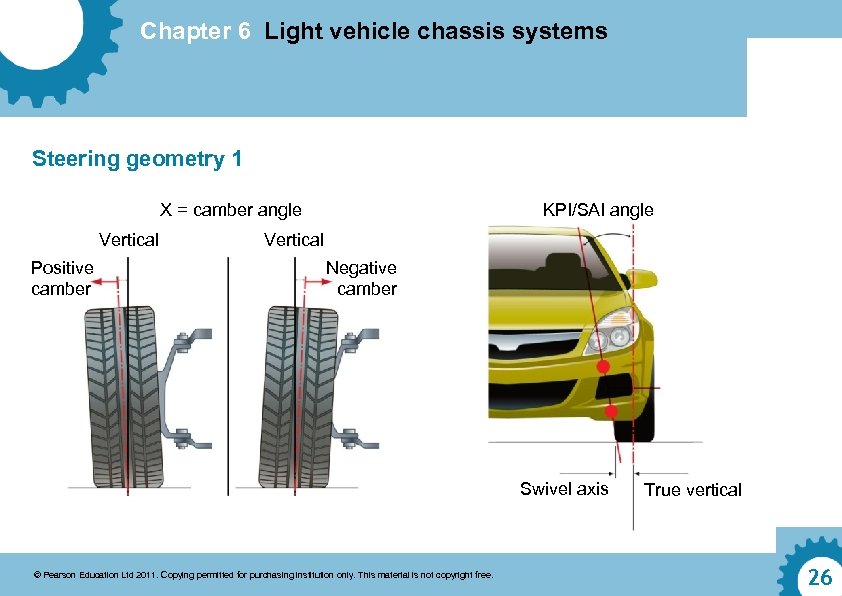

Chapter 6 Light vehicle chassis systems Steering geometry 1 X = camber angle Vertical Positive camber KPI/SAI angle Vertical Negative camber Swivel axis © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. True vertical 26

Chapter 6 Light vehicle chassis systems Steering geometry 1 X = camber angle Vertical Positive camber KPI/SAI angle Vertical Negative camber Swivel axis © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. True vertical 26

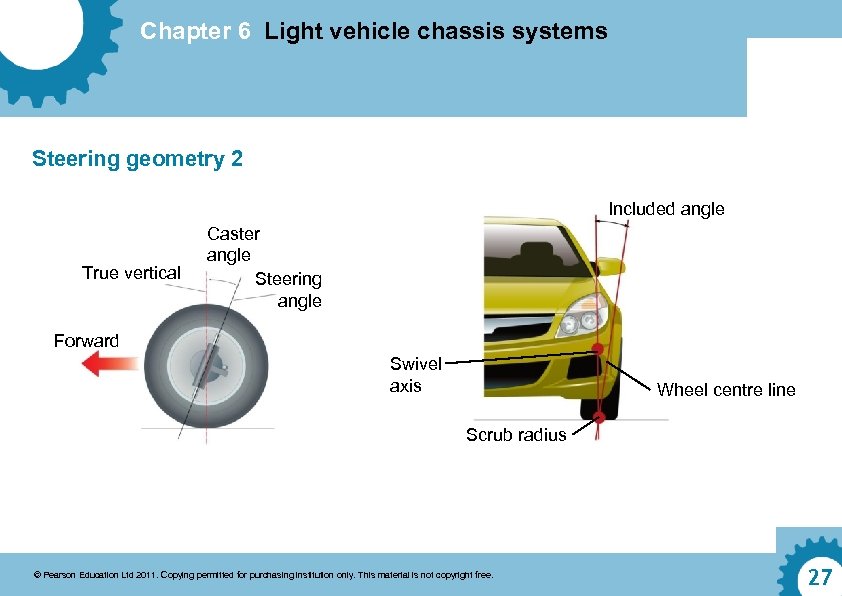

Chapter 6 Light vehicle chassis systems Steering geometry 2 Included angle True vertical Caster angle Steering angle Forward Swivel axis Wheel centre line Scrub radius © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 27

Chapter 6 Light vehicle chassis systems Steering geometry 2 Included angle True vertical Caster angle Steering angle Forward Swivel axis Wheel centre line Scrub radius © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 27

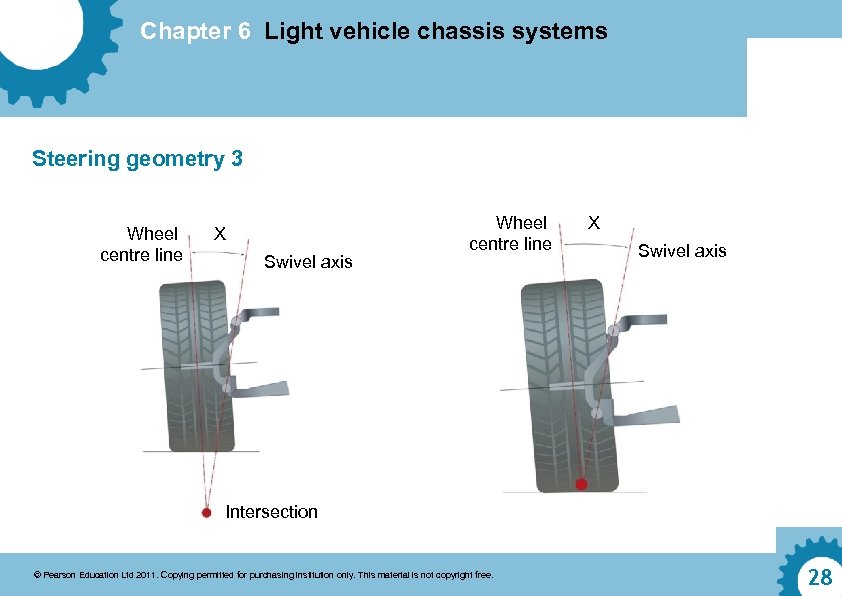

Chapter 6 Light vehicle chassis systems Steering geometry 3 Wheel centre line X Swivel axis Intersection © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 28

Chapter 6 Light vehicle chassis systems Steering geometry 3 Wheel centre line X Swivel axis Intersection © Pearson Education Ltd 2011. Copying permitted for purchasing institution only. This material is not copyright free. 28