175cb46068e22c5d2213c12994e32af7.ppt

- Количество слайдов: 56

Chapter 5 Products and Services Operations Management - 5 th Edition Roberta Russell & Bernard W. Taylor, III Copyright 2006 John Wiley & Sons, Inc. Beni Asllani University of Tennessee at Chattanooga

Chapter 5 Products and Services Operations Management - 5 th Edition Roberta Russell & Bernard W. Taylor, III Copyright 2006 John Wiley & Sons, Inc. Beni Asllani University of Tennessee at Chattanooga

Relevant WEB Sites w Click Here Copyright 2006 John Wiley & Sons, Inc. 2

Relevant WEB Sites w Click Here Copyright 2006 John Wiley & Sons, Inc. 2

Lecture Outline w Design Process w Reducing Time-to-Market w Improving Quality of Design w Special Considerations in Service Design Copyright 2006 John Wiley & Sons, Inc. 3

Lecture Outline w Design Process w Reducing Time-to-Market w Improving Quality of Design w Special Considerations in Service Design Copyright 2006 John Wiley & Sons, Inc. 3

Design Process w Effective design can provide a competitive edge n n matches product or service characteristics with customer requirements ensures that customer requirements are met in the simplest and least costly manner reduces time required to design a new product or service minimizes revisions necessary to make a design workable Copyright 2006 John Wiley & Sons, Inc. 4

Design Process w Effective design can provide a competitive edge n n matches product or service characteristics with customer requirements ensures that customer requirements are met in the simplest and least costly manner reduces time required to design a new product or service minimizes revisions necessary to make a design workable Copyright 2006 John Wiley & Sons, Inc. 4

Design Process (cont. ) w Product design n n defines appearance of product sets standards for performance specifies which materials are to be used determines dimensions and tolerances Copyright 2006 John Wiley & Sons, Inc. w Service design n n specifies what physical items, sensual benefits, and psychological benefits customer is to receive from service defines environment in which service will take place 5

Design Process (cont. ) w Product design n n defines appearance of product sets standards for performance specifies which materials are to be used determines dimensions and tolerances Copyright 2006 John Wiley & Sons, Inc. w Service design n n specifies what physical items, sensual benefits, and psychological benefits customer is to receive from service defines environment in which service will take place 5

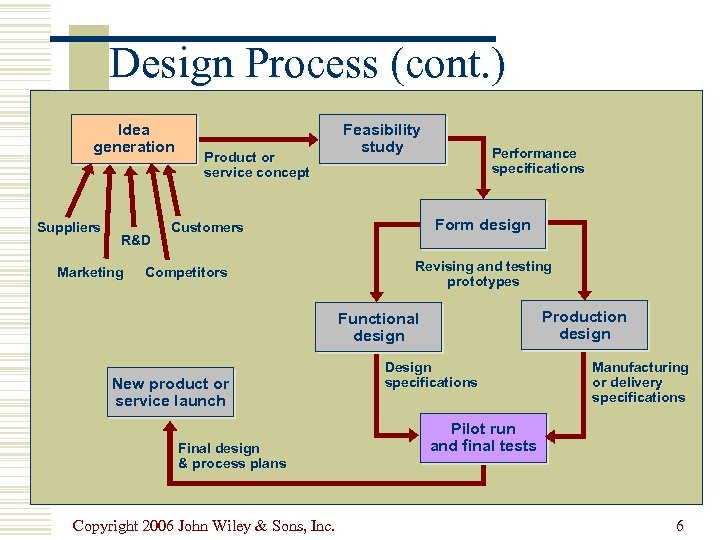

Design Process (cont. ) Idea generation Suppliers R&D Marketing Product or service concept Feasibility study Form design Customers Competitors Performance specifications Revising and testing prototypes Production design Functional design New product or service launch Final design & process plans Copyright 2006 John Wiley & Sons, Inc. Design specifications Manufacturing or delivery specifications Pilot run and final tests 6

Design Process (cont. ) Idea generation Suppliers R&D Marketing Product or service concept Feasibility study Form design Customers Competitors Performance specifications Revising and testing prototypes Production design Functional design New product or service launch Final design & process plans Copyright 2006 John Wiley & Sons, Inc. Design specifications Manufacturing or delivery specifications Pilot run and final tests 6

Idea Generation Sources w Company’s own R&D department w Customer complaints or suggestions w Marketing research w Suppliers Copyright 2006 John Wiley & Sons, Inc. w Salespersons in the field w Factory workers w New technological developments w Competitors 7

Idea Generation Sources w Company’s own R&D department w Customer complaints or suggestions w Marketing research w Suppliers Copyright 2006 John Wiley & Sons, Inc. w Salespersons in the field w Factory workers w New technological developments w Competitors 7

Idea Generation Sources (cont. ) § Perceptual Maps § Visual comparison of customer perceptions § Benchmarking § Comparing product/service against best-in-class § Reverse engineering § Dismantling competitor’s product to improve your own product Copyright 2006 John Wiley & Sons, Inc. 8

Idea Generation Sources (cont. ) § Perceptual Maps § Visual comparison of customer perceptions § Benchmarking § Comparing product/service against best-in-class § Reverse engineering § Dismantling competitor’s product to improve your own product Copyright 2006 John Wiley & Sons, Inc. 8

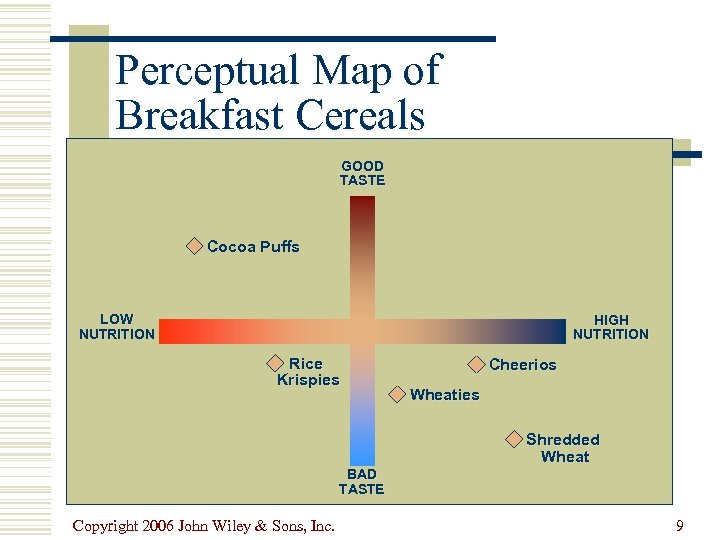

Perceptual Map of Breakfast Cereals GOOD TASTE Cocoa Puffs LOW NUTRITION HIGH NUTRITION Rice Krispies Cheerios Wheaties Shredded Wheat BAD TASTE Copyright 2006 John Wiley & Sons, Inc. 9

Perceptual Map of Breakfast Cereals GOOD TASTE Cocoa Puffs LOW NUTRITION HIGH NUTRITION Rice Krispies Cheerios Wheaties Shredded Wheat BAD TASTE Copyright 2006 John Wiley & Sons, Inc. 9

Feasibility Study w Market analysis w Economic analysis w Technical/strategic analysis w Performance specifications Copyright 2006 John Wiley & Sons, Inc. 10

Feasibility Study w Market analysis w Economic analysis w Technical/strategic analysis w Performance specifications Copyright 2006 John Wiley & Sons, Inc. 10

Rapid Prototyping w Build a prototype n n n form design functional design production design w Test prototype w Revise design w Retest Copyright 2006 John Wiley & Sons, Inc. 11

Rapid Prototyping w Build a prototype n n n form design functional design production design w Test prototype w Revise design w Retest Copyright 2006 John Wiley & Sons, Inc. 11

Form and Functional Design w Form Design n how product will look? w Functional Design n Copyright 2006 John Wiley & Sons, Inc. reliability maintainability usability 12

Form and Functional Design w Form Design n how product will look? w Functional Design n Copyright 2006 John Wiley & Sons, Inc. reliability maintainability usability 12

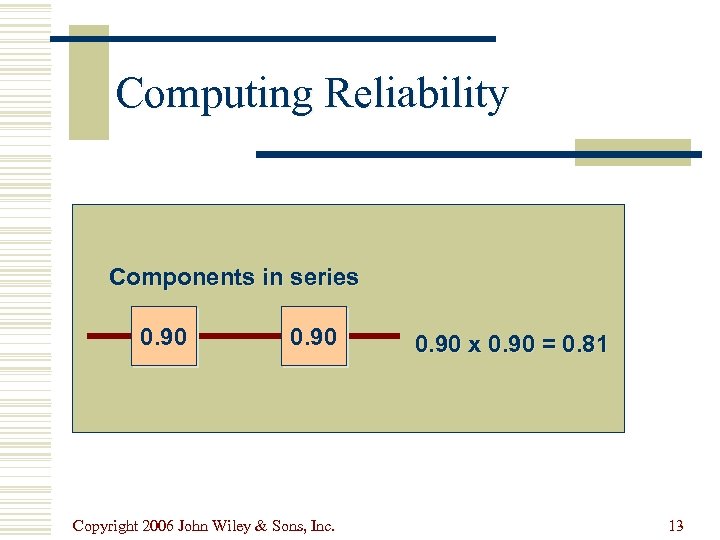

Computing Reliability Components in series 0. 90 Copyright 2006 John Wiley & Sons, Inc. 0. 90 x 0. 90 = 0. 81 13

Computing Reliability Components in series 0. 90 Copyright 2006 John Wiley & Sons, Inc. 0. 90 x 0. 90 = 0. 81 13

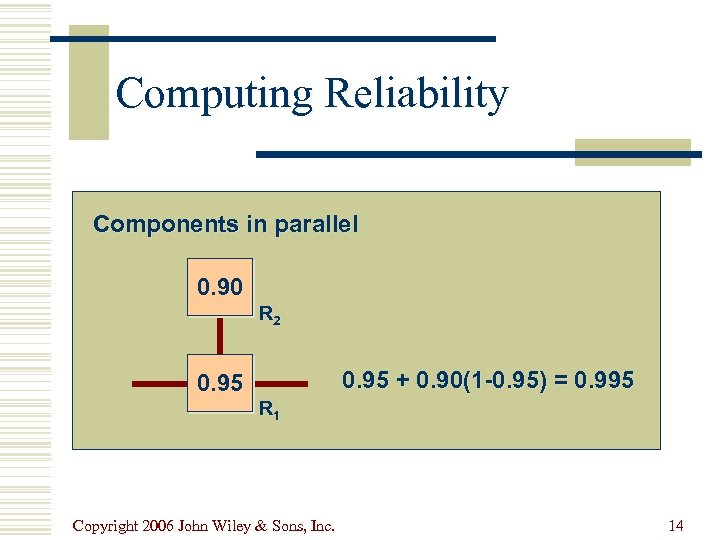

Computing Reliability Components in parallel 0. 90 R 2 0. 95 + 0. 90(1 -0. 95) = 0. 995 0. 95 R 1 Copyright 2006 John Wiley & Sons, Inc. 14

Computing Reliability Components in parallel 0. 90 R 2 0. 95 + 0. 90(1 -0. 95) = 0. 995 0. 95 R 1 Copyright 2006 John Wiley & Sons, Inc. 14

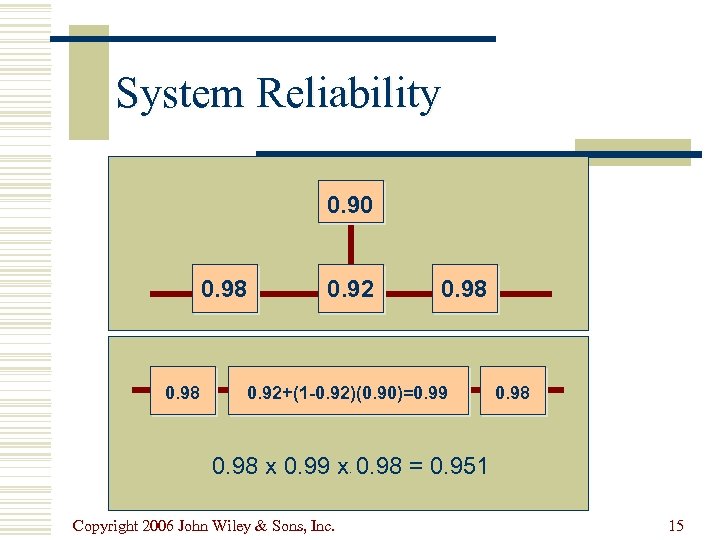

System Reliability 0. 90 0. 98 0. 92+(1 -0. 92)(0. 90)=0. 99 0. 98 x 0. 99 x 0. 98 = 0. 951 Copyright 2006 John Wiley & Sons, Inc. 15

System Reliability 0. 90 0. 98 0. 92+(1 -0. 92)(0. 90)=0. 99 0. 98 x 0. 99 x 0. 98 = 0. 951 Copyright 2006 John Wiley & Sons, Inc. 15

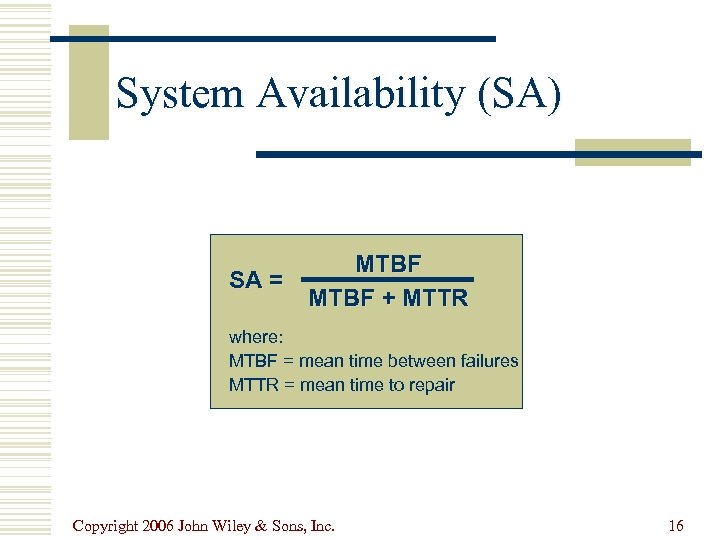

System Availability (SA) SA = MTBF + MTTR where: MTBF = mean time between failures MTTR = mean time to repair Copyright 2006 John Wiley & Sons, Inc. 16

System Availability (SA) SA = MTBF + MTTR where: MTBF = mean time between failures MTTR = mean time to repair Copyright 2006 John Wiley & Sons, Inc. 16

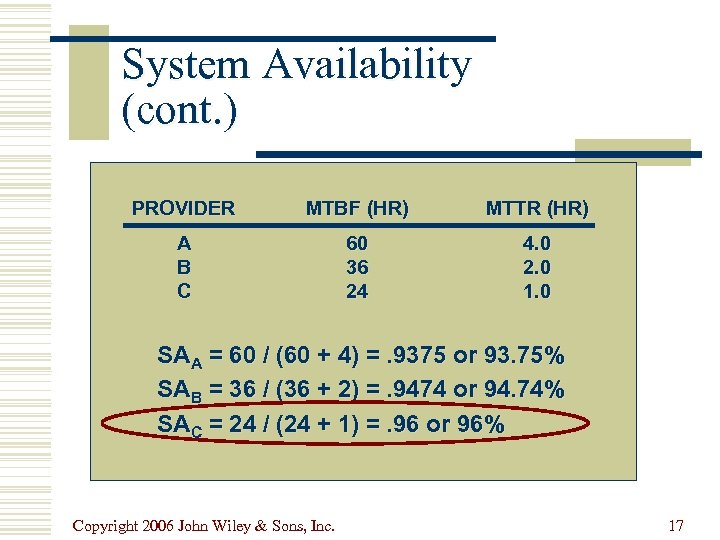

System Availability (cont. ) PROVIDER MTBF (HR) MTTR (HR) A B C 60 36 24 4. 0 2. 0 1. 0 SAA = 60 / (60 + 4) =. 9375 or 93. 75% SAB = 36 / (36 + 2) =. 9474 or 94. 74% SAC = 24 / (24 + 1) =. 96 or 96% Copyright 2006 John Wiley & Sons, Inc. 17

System Availability (cont. ) PROVIDER MTBF (HR) MTTR (HR) A B C 60 36 24 4. 0 2. 0 1. 0 SAA = 60 / (60 + 4) =. 9375 or 93. 75% SAB = 36 / (36 + 2) =. 9474 or 94. 74% SAC = 24 / (24 + 1) =. 96 or 96% Copyright 2006 John Wiley & Sons, Inc. 17

Usability w Ease of use of a product or service n n n ease of learning ease of use ease of remembering how to use frequency and severity of errors user satisfaction with experience Copyright 2006 John Wiley & Sons, Inc. 18

Usability w Ease of use of a product or service n n n ease of learning ease of use ease of remembering how to use frequency and severity of errors user satisfaction with experience Copyright 2006 John Wiley & Sons, Inc. 18

Production Design § Simplification n reducing number of parts, assemblies, or options in a product § Standardization n using commonly available and interchangeable parts § Modularity n combining standardized building blocks, or modules, to create unique finished products Copyright 2006 John Wiley & Sons, Inc. 19

Production Design § Simplification n reducing number of parts, assemblies, or options in a product § Standardization n using commonly available and interchangeable parts § Modularity n combining standardized building blocks, or modules, to create unique finished products Copyright 2006 John Wiley & Sons, Inc. 19

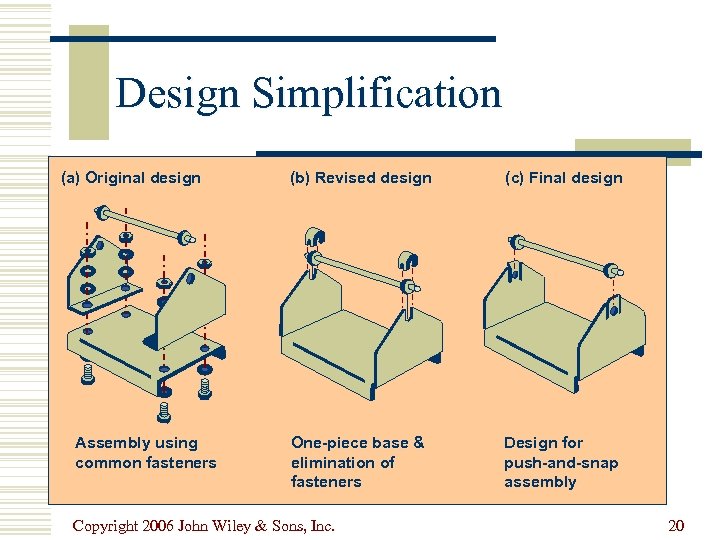

Design Simplification (a) Original design Assembly using common fasteners (b) Revised design (c) Final design One-piece base & elimination of fasteners Design for push-and-snap assembly Copyright 2006 John Wiley & Sons, Inc. 20

Design Simplification (a) Original design Assembly using common fasteners (b) Revised design (c) Final design One-piece base & elimination of fasteners Design for push-and-snap assembly Copyright 2006 John Wiley & Sons, Inc. 20

Final Design and Process Plans w Final design n detailed drawings and specifications for new product or service w Process plans n workable instructions l l Copyright 2006 John Wiley & Sons, Inc. necessary equipment and tooling component sourcing recommendations job descriptions and procedures computer programs for automated machines 21

Final Design and Process Plans w Final design n detailed drawings and specifications for new product or service w Process plans n workable instructions l l Copyright 2006 John Wiley & Sons, Inc. necessary equipment and tooling component sourcing recommendations job descriptions and procedures computer programs for automated machines 21

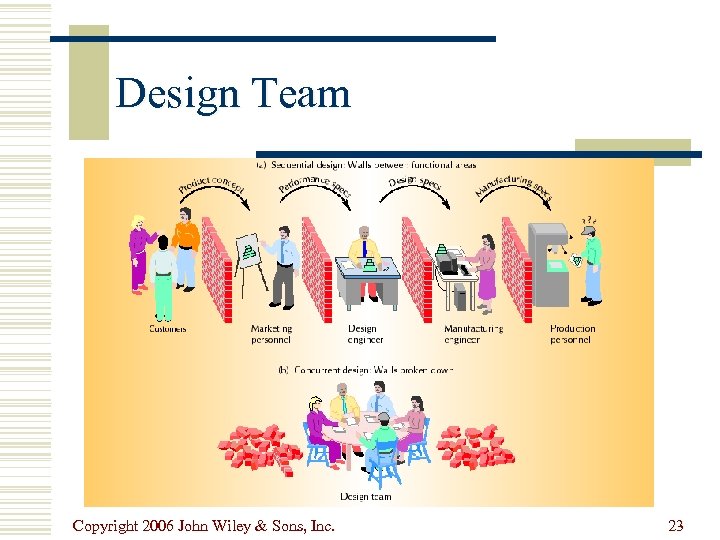

Reducing Time-to. Market w Establish multifunctional design teams w Make design decisions concurrently rather than sequentially w Design for manufacture and assembly w Use technology in the design process w Engage in collaborative design Copyright 2006 John Wiley & Sons, Inc. 22

Reducing Time-to. Market w Establish multifunctional design teams w Make design decisions concurrently rather than sequentially w Design for manufacture and assembly w Use technology in the design process w Engage in collaborative design Copyright 2006 John Wiley & Sons, Inc. 22

Design Team Copyright 2006 John Wiley & Sons, Inc. 23

Design Team Copyright 2006 John Wiley & Sons, Inc. 23

Concurrent Design w A new approach to design that involves simultaneous design of products and processes by design teams Copyright 2006 John Wiley & Sons, Inc. w Improves quality of early design decisions w Involves suppliers w Incorporates production process w Uses a price-minus system w Scheduling and management can be complex as tasks are done in parallel 24

Concurrent Design w A new approach to design that involves simultaneous design of products and processes by design teams Copyright 2006 John Wiley & Sons, Inc. w Improves quality of early design decisions w Involves suppliers w Incorporates production process w Uses a price-minus system w Scheduling and management can be complex as tasks are done in parallel 24

Design for Manufacture and Assembly (DFMA) § Design for manufacture § design a product for easy and economical production w Design for assembly n a set of procedures for: l l l Copyright 2006 John Wiley & Sons, Inc. reducing number of parts in an assembly evaluating methods of assembly determining an assembly sequence 25

Design for Manufacture and Assembly (DFMA) § Design for manufacture § design a product for easy and economical production w Design for assembly n a set of procedures for: l l l Copyright 2006 John Wiley & Sons, Inc. reducing number of parts in an assembly evaluating methods of assembly determining an assembly sequence 25

DFM Guidelines w Minimize number of parts and subassemblies w Avoid tools, separate fasteners, and adjustments w Use standard parts when possible and repeatable, well -understood processes w Design parts for many uses, and modules that can be combined in different ways w Design for ease of assembly, minimal handling, and proper presentation w Allow for efficient and adequate testing and replacement of parts Copyright 2006 John Wiley & Sons, Inc. 26

DFM Guidelines w Minimize number of parts and subassemblies w Avoid tools, separate fasteners, and adjustments w Use standard parts when possible and repeatable, well -understood processes w Design parts for many uses, and modules that can be combined in different ways w Design for ease of assembly, minimal handling, and proper presentation w Allow for efficient and adequate testing and replacement of parts Copyright 2006 John Wiley & Sons, Inc. 26

Technology in the Design Process w Computer Aided Design (CAD) n n assists in creation, modification, and analysis of a design includes l computer-aided engineering (CAE) w tests and analyzes designs on computer screen l computer-aided manufacturing (CAM) w ultimate design-to-manufacture connection Copyright 2006 John Wiley & Sons, Inc. 27

Technology in the Design Process w Computer Aided Design (CAD) n n assists in creation, modification, and analysis of a design includes l computer-aided engineering (CAE) w tests and analyzes designs on computer screen l computer-aided manufacturing (CAM) w ultimate design-to-manufacture connection Copyright 2006 John Wiley & Sons, Inc. 27

Collaborative Design w A software system for collaborative design and development among trading partners w Follows life cycle of the product w Accelerates product development, helps to resolve product launch issues, and improves quality of the design w Designers can n n conduct virtual review sessions test “what if” scenarios assign and track design issues communicate with multiple tiers of suppliers create, store, and manage project documents Copyright 2006 John Wiley & Sons, Inc. 28

Collaborative Design w A software system for collaborative design and development among trading partners w Follows life cycle of the product w Accelerates product development, helps to resolve product launch issues, and improves quality of the design w Designers can n n conduct virtual review sessions test “what if” scenarios assign and track design issues communicate with multiple tiers of suppliers create, store, and manage project documents Copyright 2006 John Wiley & Sons, Inc. 28

Improving Quality of Design w Review designs to prevent failures and ensure value w Design for environment w Measure design quality w Use quality function deployment w Design for robustness Copyright 2006 John Wiley & Sons, Inc. 29

Improving Quality of Design w Review designs to prevent failures and ensure value w Design for environment w Measure design quality w Use quality function deployment w Design for robustness Copyright 2006 John Wiley & Sons, Inc. 29

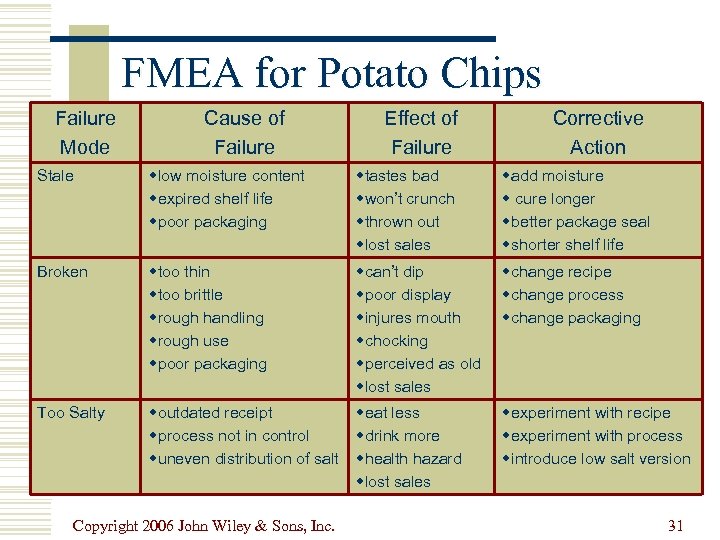

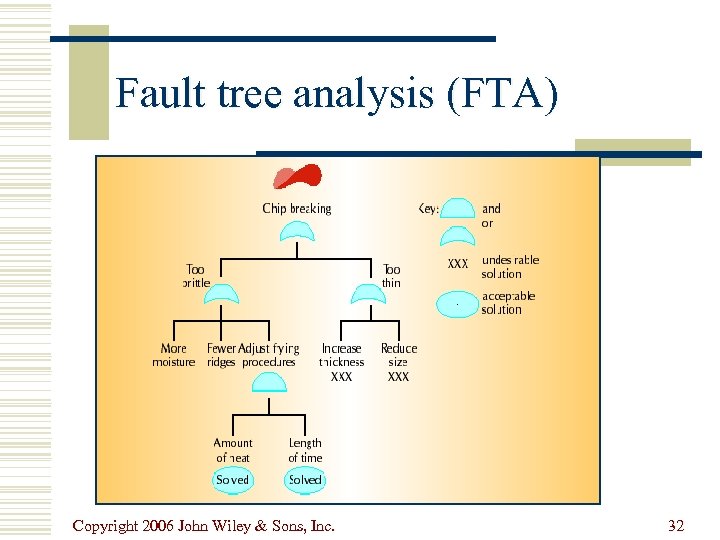

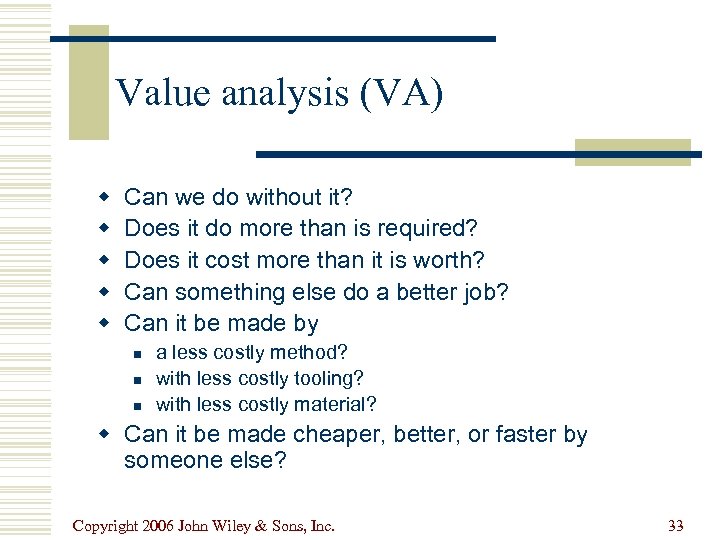

Design Review w Failure mode and effects analysis (FMEA) n a systematic method of analyzing product failures w Fault tree analysis (FTA) n a visual method for analyzing interrelationships among failures w Value analysis (VA) n helps eliminate unnecessary features and functions Copyright 2006 John Wiley & Sons, Inc. 30

Design Review w Failure mode and effects analysis (FMEA) n a systematic method of analyzing product failures w Fault tree analysis (FTA) n a visual method for analyzing interrelationships among failures w Value analysis (VA) n helps eliminate unnecessary features and functions Copyright 2006 John Wiley & Sons, Inc. 30

FMEA for Potato Chips Failure Mode Cause of Failure Effect of Failure Corrective Action Stale wlow moisture content wexpired shelf life wpoor packaging wtastes bad wwon’t crunch wthrown out wlost sales wadd moisture w cure longer wbetter package seal wshorter shelf life Broken wtoo thin wtoo brittle wrough handling wrough use wpoor packaging wcan’t dip wpoor display winjures mouth wchocking wperceived as old wlost sales wchange recipe wchange process wchange packaging Too Salty woutdated receipt weat less wprocess not in control wdrink more wuneven distribution of salt whealth hazard wlost sales Copyright 2006 John Wiley & Sons, Inc. wexperiment with recipe wexperiment with process wintroduce low salt version 31

FMEA for Potato Chips Failure Mode Cause of Failure Effect of Failure Corrective Action Stale wlow moisture content wexpired shelf life wpoor packaging wtastes bad wwon’t crunch wthrown out wlost sales wadd moisture w cure longer wbetter package seal wshorter shelf life Broken wtoo thin wtoo brittle wrough handling wrough use wpoor packaging wcan’t dip wpoor display winjures mouth wchocking wperceived as old wlost sales wchange recipe wchange process wchange packaging Too Salty woutdated receipt weat less wprocess not in control wdrink more wuneven distribution of salt whealth hazard wlost sales Copyright 2006 John Wiley & Sons, Inc. wexperiment with recipe wexperiment with process wintroduce low salt version 31

Fault tree analysis (FTA) Copyright 2006 John Wiley & Sons, Inc. 32

Fault tree analysis (FTA) Copyright 2006 John Wiley & Sons, Inc. 32

Value analysis (VA) w w w Can we do without it? Does it do more than is required? Does it cost more than it is worth? Can something else do a better job? Can it be made by n n n a less costly method? with less costly tooling? with less costly material? w Can it be made cheaper, better, or faster by someone else? Copyright 2006 John Wiley & Sons, Inc. 33

Value analysis (VA) w w w Can we do without it? Does it do more than is required? Does it cost more than it is worth? Can something else do a better job? Can it be made by n n n a less costly method? with less costly tooling? with less costly material? w Can it be made cheaper, better, or faster by someone else? Copyright 2006 John Wiley & Sons, Inc. 33

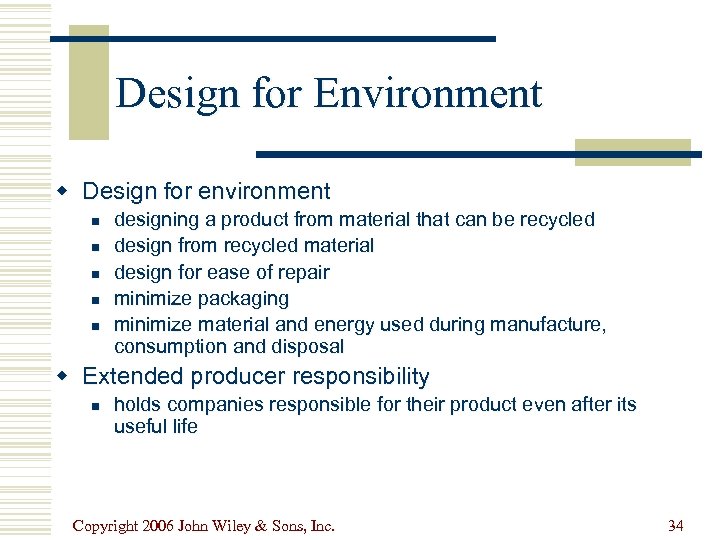

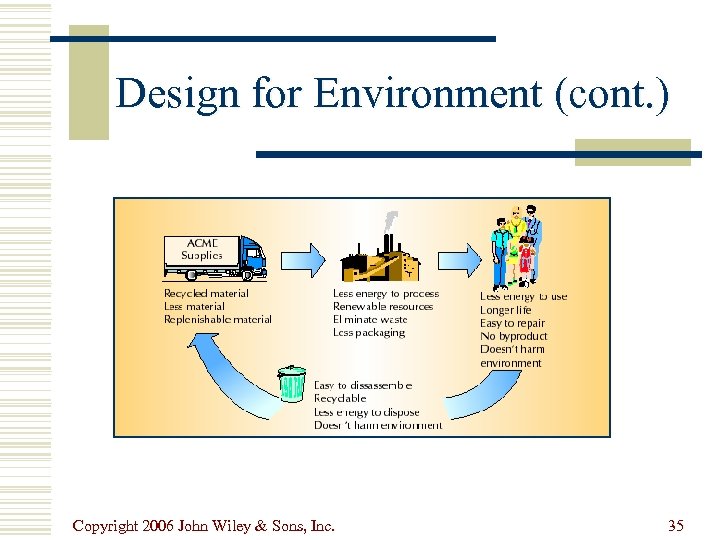

Design for Environment w Design for environment n n n designing a product from material that can be recycled design from recycled material design for ease of repair minimize packaging minimize material and energy used during manufacture, consumption and disposal w Extended producer responsibility n holds companies responsible for their product even after its useful life Copyright 2006 John Wiley & Sons, Inc. 34

Design for Environment w Design for environment n n n designing a product from material that can be recycled design from recycled material design for ease of repair minimize packaging minimize material and energy used during manufacture, consumption and disposal w Extended producer responsibility n holds companies responsible for their product even after its useful life Copyright 2006 John Wiley & Sons, Inc. 34

Design for Environment (cont. ) Copyright 2006 John Wiley & Sons, Inc. 35

Design for Environment (cont. ) Copyright 2006 John Wiley & Sons, Inc. 35

Measure Design Quality w % of revenue from new products or services w % of products capturing 50% or more of market w % of process initiatives yielding a 50% or more improvement in effectiveness w % of suppliers engaged in collaborative design Copyright 2006 John Wiley & Sons, Inc. w % of parts that can be recycled w % of parts used in multiple products w % of parts with no engineering change orders w Average number of components per product w Things gone wrong (TGW) 36

Measure Design Quality w % of revenue from new products or services w % of products capturing 50% or more of market w % of process initiatives yielding a 50% or more improvement in effectiveness w % of suppliers engaged in collaborative design Copyright 2006 John Wiley & Sons, Inc. w % of parts that can be recycled w % of parts used in multiple products w % of parts with no engineering change orders w Average number of components per product w Things gone wrong (TGW) 36

Quality Function Deployment (QFD) w Translates voice of customer into technical design requirements w Displays requirements in matrix diagrams n n first matrix called “house of quality” series of connected houses Copyright 2006 John Wiley & Sons, Inc. 37

Quality Function Deployment (QFD) w Translates voice of customer into technical design requirements w Displays requirements in matrix diagrams n n first matrix called “house of quality” series of connected houses Copyright 2006 John Wiley & Sons, Inc. 37

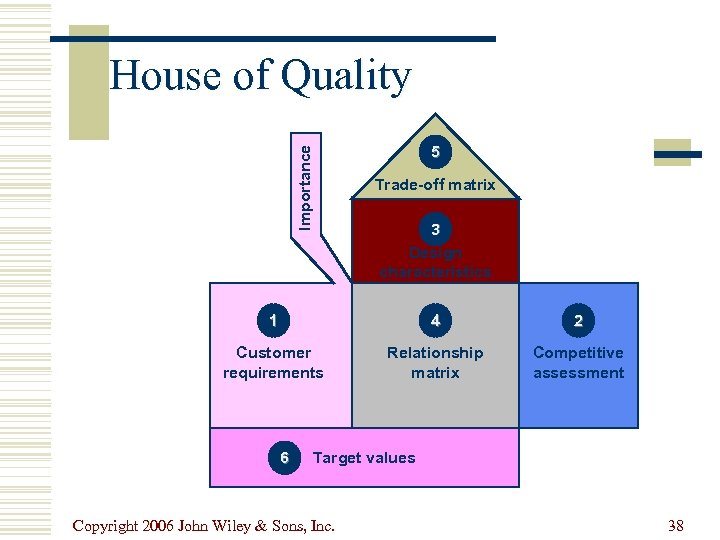

Importance House of Quality 5 Trade-off matrix 3 Design characteristics 1 4 2 Customer requirements Relationship matrix Competitive assessment 6 Target values Copyright 2006 John Wiley & Sons, Inc. 38

Importance House of Quality 5 Trade-off matrix 3 Design characteristics 1 4 2 Customer requirements Relationship matrix Competitive assessment 6 Target values Copyright 2006 John Wiley & Sons, Inc. 38

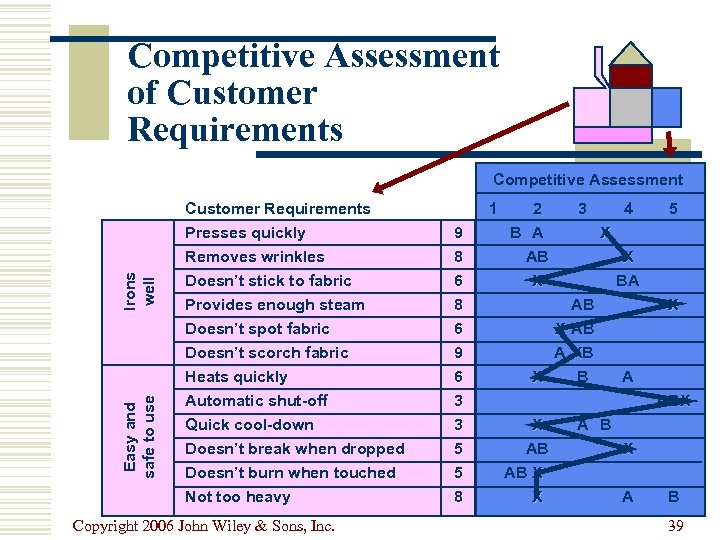

Competitive Assessment of Customer Requirements Competitive Assessment Easy and safe to use Irons well Customer Requirements Presses quickly 9 Removes wrinkles Doesn’t stick to fabric Provides enough steam Doesn’t spot fabric Doesn’t scorch fabric Heats quickly Automatic shut-off Quick cool-down Doesn’t break when dropped Doesn’t burn when touched Not too heavy 8 6 9 6 3 3 5 5 8 Copyright 2006 John Wiley & Sons, Inc. 1 2 B A 3 4 5 X AB X X BA AB X AB A XB X A ABX X AB AB X X A B 39

Competitive Assessment of Customer Requirements Competitive Assessment Easy and safe to use Irons well Customer Requirements Presses quickly 9 Removes wrinkles Doesn’t stick to fabric Provides enough steam Doesn’t spot fabric Doesn’t scorch fabric Heats quickly Automatic shut-off Quick cool-down Doesn’t break when dropped Doesn’t burn when touched Not too heavy 8 6 9 6 3 3 5 5 8 Copyright 2006 John Wiley & Sons, Inc. 1 2 B A 3 4 5 X AB X X BA AB X AB A XB X A ABX X AB AB X X A B 39

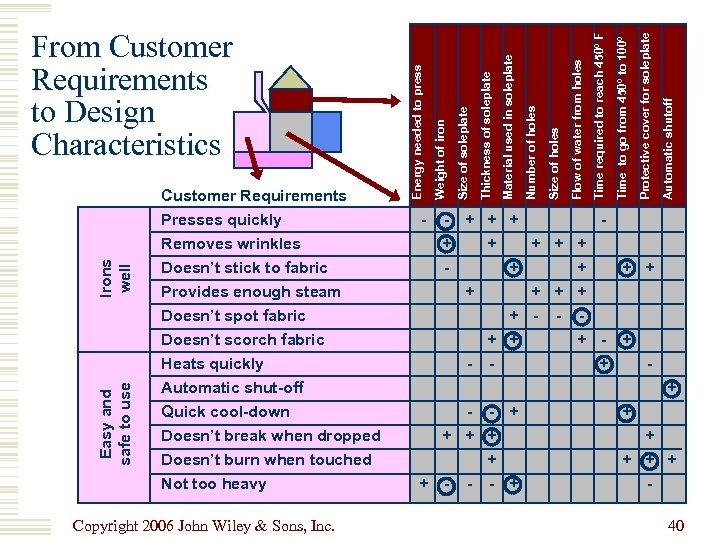

Easy and safe to use Irons well Removes wrinkles Doesn’t stick to fabric Provides enough steam Doesn’t spot fabric Doesn’t scorch fabric Heats quickly Automatic shut-off Quick cool-down Doesn’t break when dropped Doesn’t burn when touched Not too heavy Copyright 2006 John Wiley & Sons, Inc. - - + + - Automatic shutoff Protective cover for soleplate Time to go from 450º to 100º Time required to reach 450º F Flow of water from holes Size of holes Number of holes Material used in soleplate Thickness of soleplate Size of soleplate Weight of iron Customer Requirements Presses quickly Energy needed to press From Customer Requirements to Design Characteristics - + + + + - - + + + - - + + + - - - + + + 40

Easy and safe to use Irons well Removes wrinkles Doesn’t stick to fabric Provides enough steam Doesn’t spot fabric Doesn’t scorch fabric Heats quickly Automatic shut-off Quick cool-down Doesn’t break when dropped Doesn’t burn when touched Not too heavy Copyright 2006 John Wiley & Sons, Inc. - - + + - Automatic shutoff Protective cover for soleplate Time to go from 450º to 100º Time required to reach 450º F Flow of water from holes Size of holes Number of holes Material used in soleplate Thickness of soleplate Size of soleplate Weight of iron Customer Requirements Presses quickly Energy needed to press From Customer Requirements to Design Characteristics - + + + + - - + + + - - + + + - - - + + + 40

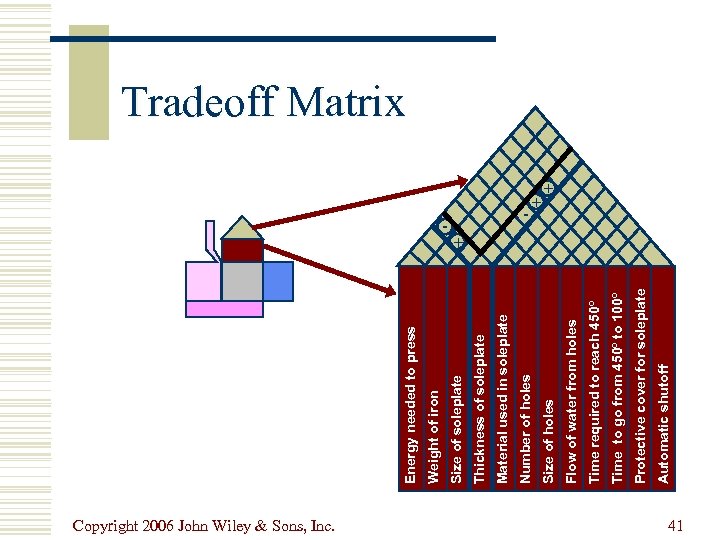

Copyright 2006 John Wiley & Sons, Inc. Automatic shutoff Protective cover for soleplate Time to go from 450º to 100º Time required to reach 450º + Flow of water from holes - Size of holes Number of holes Material used in soleplate - Thickness of soleplate Size of soleplate Weight of iron Energy needed to press Tradeoff Matrix + + 41

Copyright 2006 John Wiley & Sons, Inc. Automatic shutoff Protective cover for soleplate Time to go from 450º to 100º Time required to reach 450º + Flow of water from holes - Size of holes Number of holes Material used in soleplate - Thickness of soleplate Size of soleplate Weight of iron Energy needed to press Tradeoff Matrix + + 41

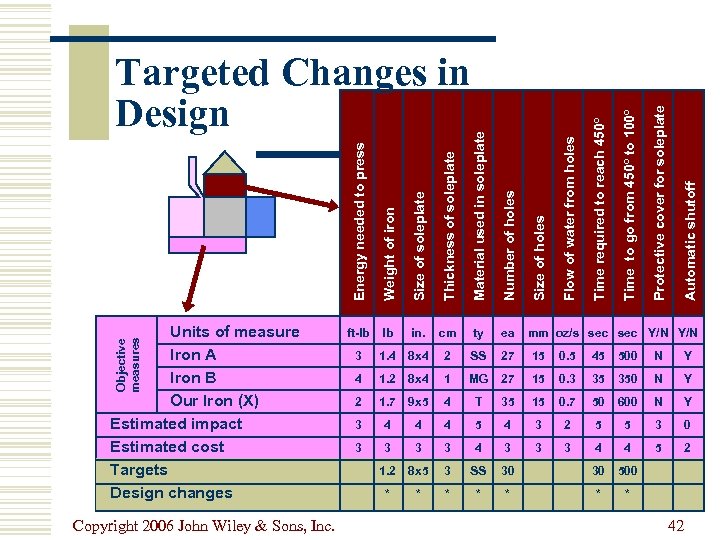

Copyright 2006 John Wiley & Sons, Inc. lb in. cm ty ea 3 1. 4 8 x 4 2 SS 27 15 0. 5 45 500 N Y 4 1. 2 8 x 4 1 MG 27 15 0. 3 35 350 N Y 2 1. 7 9 x 5 4 T 35 15 0. 7 50 600 N Y 3 4 4 4 5 4 3 2 5 5 3 0 3 3 4 3 3 3 4 4 5 2 1. 2 8 x 5 3 SS 30 30 500 * * * * Automatic shutoff Number of holes Protective cover for soleplate Material used in soleplate Time to go from 450º to 100º Thickness of soleplate Time required to reach 450º Size of soleplate ft-lb Flow of water from holes Weight of iron Objective measures Units of measure Iron A Iron B Our Iron (X) Estimated impact Estimated cost Targets Design changes Size of holes Energy needed to press Targeted Changes in Design mm oz/s sec Y/N 42

Copyright 2006 John Wiley & Sons, Inc. lb in. cm ty ea 3 1. 4 8 x 4 2 SS 27 15 0. 5 45 500 N Y 4 1. 2 8 x 4 1 MG 27 15 0. 3 35 350 N Y 2 1. 7 9 x 5 4 T 35 15 0. 7 50 600 N Y 3 4 4 4 5 4 3 2 5 5 3 0 3 3 4 3 3 3 4 4 5 2 1. 2 8 x 5 3 SS 30 30 500 * * * * Automatic shutoff Number of holes Protective cover for soleplate Material used in soleplate Time to go from 450º to 100º Thickness of soleplate Time required to reach 450º Size of soleplate ft-lb Flow of water from holes Weight of iron Objective measures Units of measure Iron A Iron B Our Iron (X) Estimated impact Estimated cost Targets Design changes Size of holes Energy needed to press Targeted Changes in Design mm oz/s sec Y/N 42

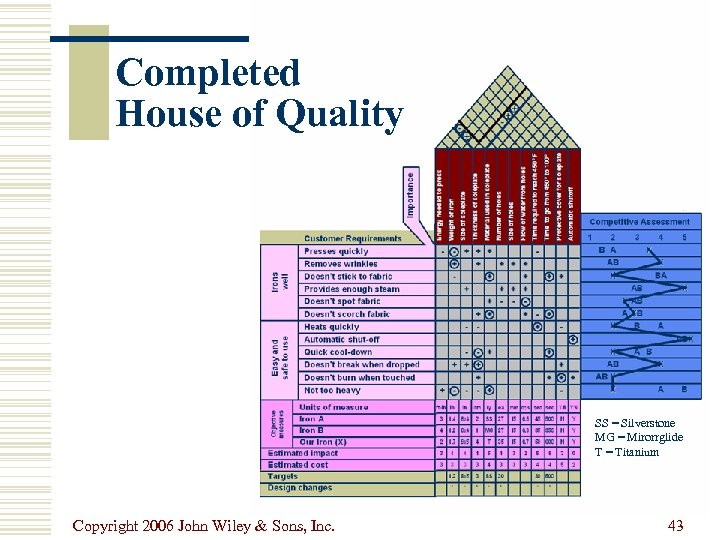

Completed House of Quality SS = Silverstone MG = Mirorrglide T = Titanium Copyright 2006 John Wiley & Sons, Inc. 43

Completed House of Quality SS = Silverstone MG = Mirorrglide T = Titanium Copyright 2006 John Wiley & Sons, Inc. 43

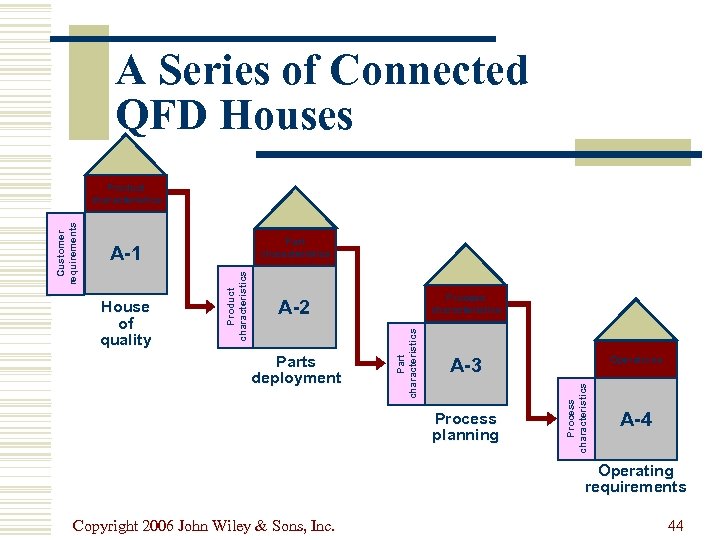

A Series of Connected QFD Houses Part characteristics Process characteristics A-2 Parts deployment A-3 Process planning Operations Process characteristics House of quality Part characteristics A-1 Product characteristics Customer requirements Product characteristics A-4 Operating requirements Copyright 2006 John Wiley & Sons, Inc. 44

A Series of Connected QFD Houses Part characteristics Process characteristics A-2 Parts deployment A-3 Process planning Operations Process characteristics House of quality Part characteristics A-1 Product characteristics Customer requirements Product characteristics A-4 Operating requirements Copyright 2006 John Wiley & Sons, Inc. 44

Benefits of QFD § Promotes better understanding of customer demands § Promotes better understanding of design interactions § Involves manufacturing in design process § Breaks down barriers between functions and departments § Provides documentation of design process Copyright 2006 John Wiley & Sons, Inc. 45

Benefits of QFD § Promotes better understanding of customer demands § Promotes better understanding of design interactions § Involves manufacturing in design process § Breaks down barriers between functions and departments § Provides documentation of design process Copyright 2006 John Wiley & Sons, Inc. 45

Design for Robustness w Robust product n designed to withstand variations in environmental and operating conditions w Robust design n yields a product or service designed to withstand variations w Controllable factors n design parameters such as material used, dimensions, and form of processing w Uncontrollable factors n user’s control (length of use, maintenance, settings Copyright 2006 John Wiley & Sons, Inc. 46

Design for Robustness w Robust product n designed to withstand variations in environmental and operating conditions w Robust design n yields a product or service designed to withstand variations w Controllable factors n design parameters such as material used, dimensions, and form of processing w Uncontrollable factors n user’s control (length of use, maintenance, settings Copyright 2006 John Wiley & Sons, Inc. 46

Tolerance and Consistency w Tolerance n allowable ranges of variation in the dimension of a part w Consistency n n n consistent errors are easier to correct than random errors parts within tolerances may yield assemblies that are not within limits consumers prefer product characteristics near their ideal values Copyright 2006 John Wiley & Sons, Inc. 47

Tolerance and Consistency w Tolerance n allowable ranges of variation in the dimension of a part w Consistency n n n consistent errors are easier to correct than random errors parts within tolerances may yield assemblies that are not within limits consumers prefer product characteristics near their ideal values Copyright 2006 John Wiley & Sons, Inc. 47

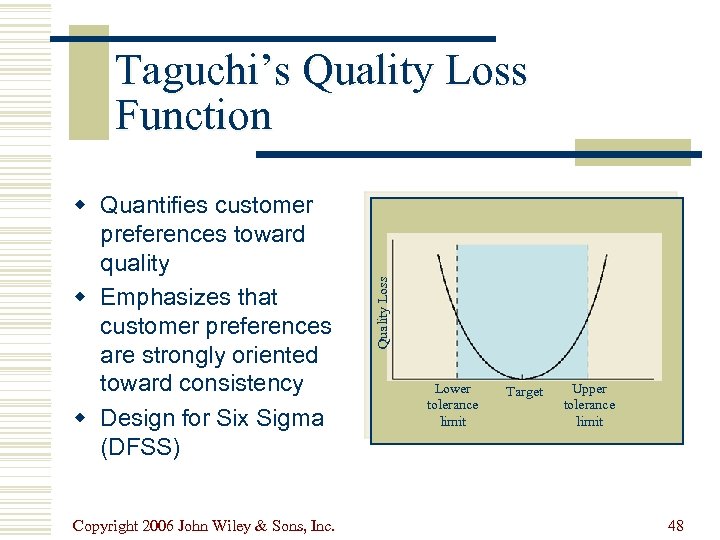

w Quantifies customer preferences toward quality w Emphasizes that customer preferences are strongly oriented toward consistency w Design for Six Sigma (DFSS) Copyright 2006 John Wiley & Sons, Inc. Quality Loss Taguchi’s Quality Loss Function Lower tolerance limit Target Upper tolerance limit 48

w Quantifies customer preferences toward quality w Emphasizes that customer preferences are strongly oriented toward consistency w Design for Six Sigma (DFSS) Copyright 2006 John Wiley & Sons, Inc. Quality Loss Taguchi’s Quality Loss Function Lower tolerance limit Target Upper tolerance limit 48

Special Considerations in Service Design w w Services are intangible Service output is variable Service have higher customer contact Services are perishable Copyright 2006 John Wiley & Sons, Inc. w Service inseparable from delivery w Services tend to be decentralized and dispersed w Services are consumed more often than products w Services can be easily emulated 49

Special Considerations in Service Design w w Services are intangible Service output is variable Service have higher customer contact Services are perishable Copyright 2006 John Wiley & Sons, Inc. w Service inseparable from delivery w Services tend to be decentralized and dispersed w Services are consumed more often than products w Services can be easily emulated 49

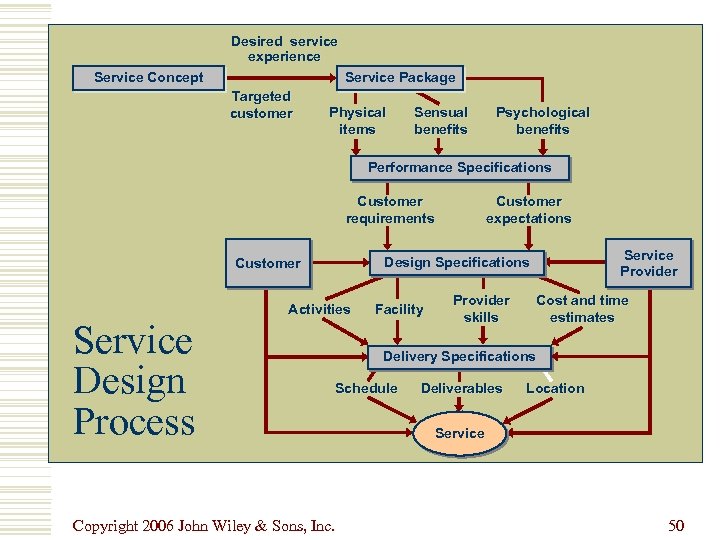

Desired service experience Service Concept Service Package Targeted customer Physical items Sensual benefits Psychological benefits Performance Specifications Customer requirements Service Provider Design Specifications Customer Service Design Process Customer expectations Activities Facility Provider skills Cost and time estimates Delivery Specifications Schedule Copyright 2006 John Wiley & Sons, Inc. Deliverables Location Service 50

Desired service experience Service Concept Service Package Targeted customer Physical items Sensual benefits Psychological benefits Performance Specifications Customer requirements Service Provider Design Specifications Customer Service Design Process Customer expectations Activities Facility Provider skills Cost and time estimates Delivery Specifications Schedule Copyright 2006 John Wiley & Sons, Inc. Deliverables Location Service 50

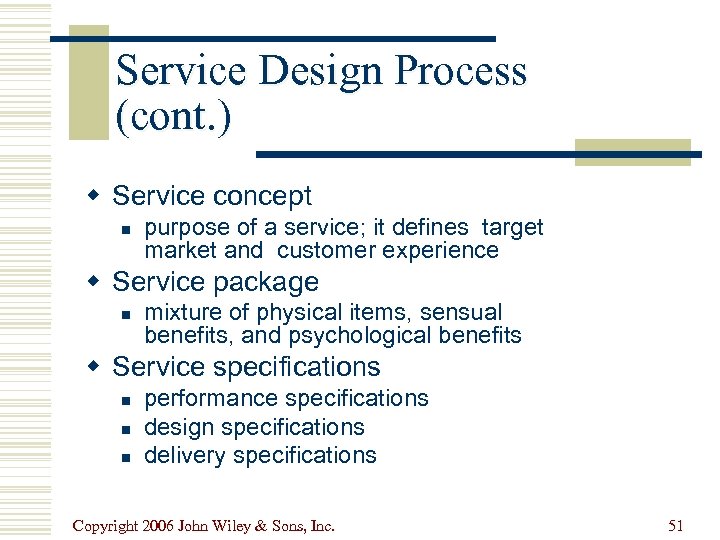

Service Design Process (cont. ) w Service concept n purpose of a service; it defines target market and customer experience w Service package n mixture of physical items, sensual benefits, and psychological benefits w Service specifications n n n performance specifications design specifications delivery specifications Copyright 2006 John Wiley & Sons, Inc. 51

Service Design Process (cont. ) w Service concept n purpose of a service; it defines target market and customer experience w Service package n mixture of physical items, sensual benefits, and psychological benefits w Service specifications n n n performance specifications design specifications delivery specifications Copyright 2006 John Wiley & Sons, Inc. 51

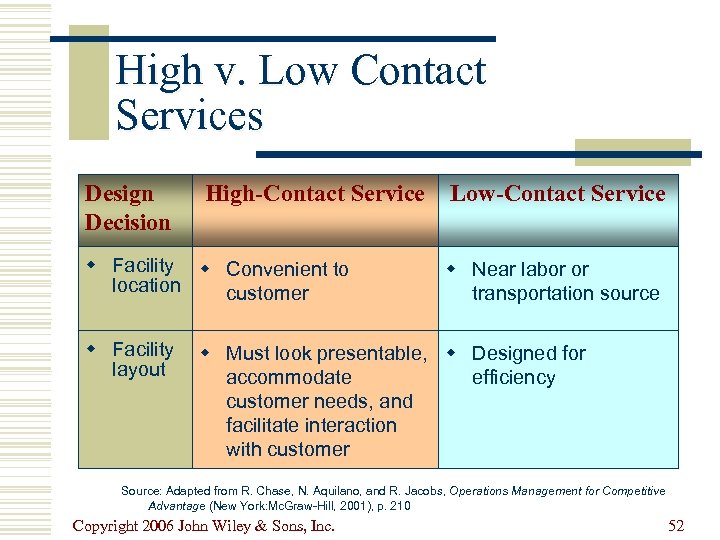

High v. Low Contact Services Design Decision High-Contact Service w Facility w Convenient to location customer w Facility layout Low-Contact Service w Near labor or transportation source w Must look presentable, w Designed for accommodate efficiency customer needs, and facilitate interaction with customer Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 52

High v. Low Contact Services Design Decision High-Contact Service w Facility w Convenient to location customer w Facility layout Low-Contact Service w Near labor or transportation source w Must look presentable, w Designed for accommodate efficiency customer needs, and facilitate interaction with customer Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 52

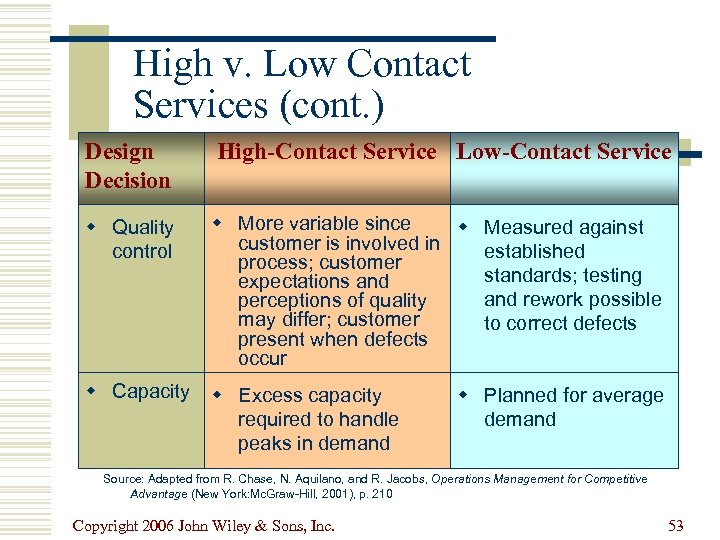

High v. Low Contact Services (cont. ) Design Decision High-Contact Service Low-Contact Service w Quality control w More variable since w Measured against customer is involved in established process; customer standards; testing expectations and rework possible perceptions of quality may differ; customer to correct defects present when defects occur w Capacity w Excess capacity required to handle peaks in demand w Planned for average demand Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 53

High v. Low Contact Services (cont. ) Design Decision High-Contact Service Low-Contact Service w Quality control w More variable since w Measured against customer is involved in established process; customer standards; testing expectations and rework possible perceptions of quality may differ; customer to correct defects present when defects occur w Capacity w Excess capacity required to handle peaks in demand w Planned for average demand Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 53

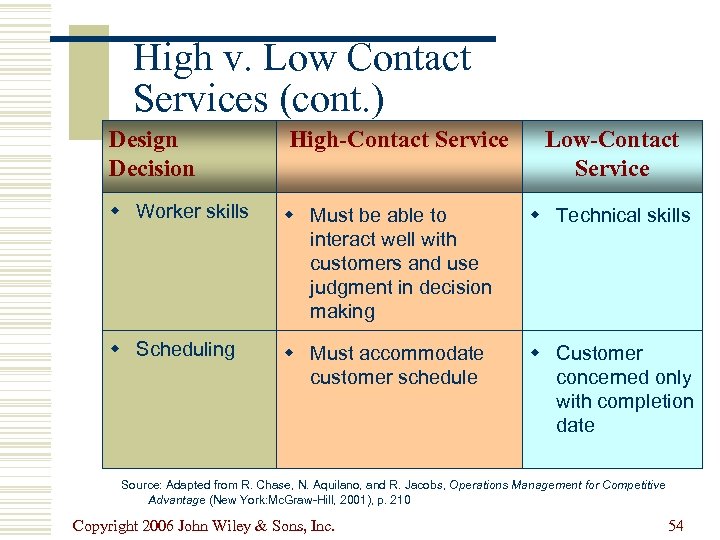

High v. Low Contact Services (cont. ) Design Decision High-Contact Service Low-Contact Service w Worker skills w Must be able to interact well with customers and use judgment in decision making w Technical skills w Scheduling w Must accommodate customer schedule w Customer concerned only with completion date Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 54

High v. Low Contact Services (cont. ) Design Decision High-Contact Service Low-Contact Service w Worker skills w Must be able to interact well with customers and use judgment in decision making w Technical skills w Scheduling w Must accommodate customer schedule w Customer concerned only with completion date Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 54

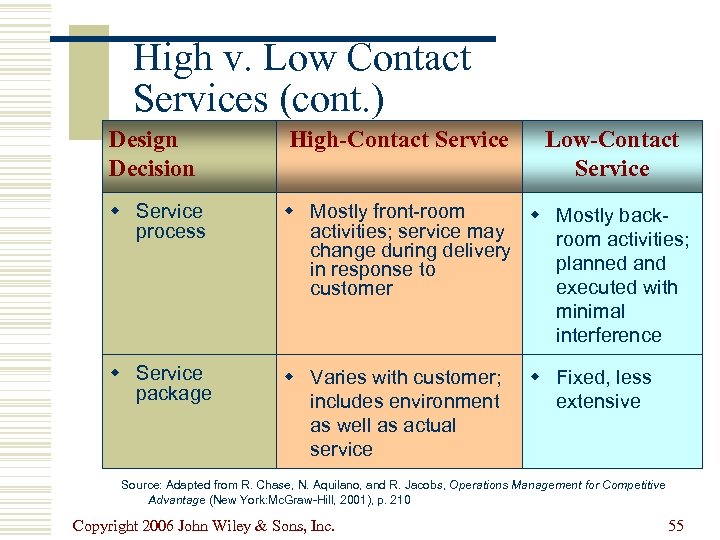

High v. Low Contact Services (cont. ) Design Decision High-Contact Service Low-Contact Service w Service process w Mostly front-room w Mostly backactivities; service may room activities; change during delivery planned and in response to executed with customer minimal interference w Service package w Varies with customer; includes environment as well as actual service w Fixed, less extensive Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 55

High v. Low Contact Services (cont. ) Design Decision High-Contact Service Low-Contact Service w Service process w Mostly front-room w Mostly backactivities; service may room activities; change during delivery planned and in response to executed with customer minimal interference w Service package w Varies with customer; includes environment as well as actual service w Fixed, less extensive Source: Adapted from R. Chase, N. Aquilano, and R. Jacobs, Operations Management for Competitive Advantage (New York: Mc. Graw-Hill, 2001), p. 210 Copyright 2006 John Wiley & Sons, Inc. 55

Copyright 2006 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that permitted in section 117 of the 1976 United States Copyright Act without express permission of the copyright owner is unlawful. Request for further information should be addressed to the Permission Department, John Wiley & Sons, Inc. The purchaser may make back-up copies for his/her own use only and not for distribution or resale. The Publisher assumes no responsibility for errors, omissions, or damages caused by the use of these programs or from the use of the information herein. Copyright 2006 John Wiley & Sons, Inc. 56

Copyright 2006 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that permitted in section 117 of the 1976 United States Copyright Act without express permission of the copyright owner is unlawful. Request for further information should be addressed to the Permission Department, John Wiley & Sons, Inc. The purchaser may make back-up copies for his/her own use only and not for distribution or resale. The Publisher assumes no responsibility for errors, omissions, or damages caused by the use of these programs or from the use of the information herein. Copyright 2006 John Wiley & Sons, Inc. 56