a3cdf94d1b89afb11a728991d3cbc75a.ppt

- Количество слайдов: 53

Chapter 5, Part 1 The TQM Philosophy

Chapter 5, Part 1 The TQM Philosophy

What is Quality? · What do we mean by quality? · Newer, more widely accepted definition of quality is the ability of a product or service to consistently meet or exceed the customer’s expectations. · This definition of quality is “customer driven. ”

What is Quality? · What do we mean by quality? · Newer, more widely accepted definition of quality is the ability of a product or service to consistently meet or exceed the customer’s expectations. · This definition of quality is “customer driven. ”

What is Quality? · Customer driven quality starts with having the customer determine the characteristics of a product or service that are important to them. · What are important characteristics of a · Cake?

What is Quality? · Customer driven quality starts with having the customer determine the characteristics of a product or service that are important to them. · What are important characteristics of a · Cake?

What is Quality? · Technical support? · TV set? · Laptop?

What is Quality? · Technical support? · TV set? · Laptop?

What is Quality? · These characteristics are called quality characteristics. · To insure that they are set at the right levels, we need to quantify them. · We quantify them by having the customer impose acceptable numerical ranges or limits on their values:

What is Quality? · These characteristics are called quality characteristics. · To insure that they are set at the right levels, we need to quantify them. · We quantify them by having the customer impose acceptable numerical ranges or limits on their values:

What is Quality? · How sweet should a cake be? · · It should have between ¼ and ¾ cup of sugar. How moist can it be? · Moisture content can be between 13 and 15 grams. · The diameter of a steering wheel can be between 1. 5 and 2. 5 inches. · The weight of a laptop should be between 3. 5 and 4. 5 lbs.

What is Quality? · How sweet should a cake be? · · It should have between ¼ and ¾ cup of sugar. How moist can it be? · Moisture content can be between 13 and 15 grams. · The diameter of a steering wheel can be between 1. 5 and 2. 5 inches. · The weight of a laptop should be between 3. 5 and 4. 5 lbs.

What is Quality? · The limits on the product’s quality characteristics are called the product’s specification limits, or “specs. ” · Some quality authorities define quality as producing units of a product that fall anywhere within the product’s spec limits. · These units are called conforming (to specs) or non-defective units. · Units that fall outside the specs limits are called nonconforming or defective units.

What is Quality? · The limits on the product’s quality characteristics are called the product’s specification limits, or “specs. ” · Some quality authorities define quality as producing units of a product that fall anywhere within the product’s spec limits. · These units are called conforming (to specs) or non-defective units. · Units that fall outside the specs limits are called nonconforming or defective units.

What is Quality? Thus, according to these authorities, quality is the ability of a product to meet the spec limits. · Other authorities disagree and have a different definition of quality. · Later. ·

What is Quality? Thus, according to these authorities, quality is the ability of a product to meet the spec limits. · Other authorities disagree and have a different definition of quality. · Later. ·

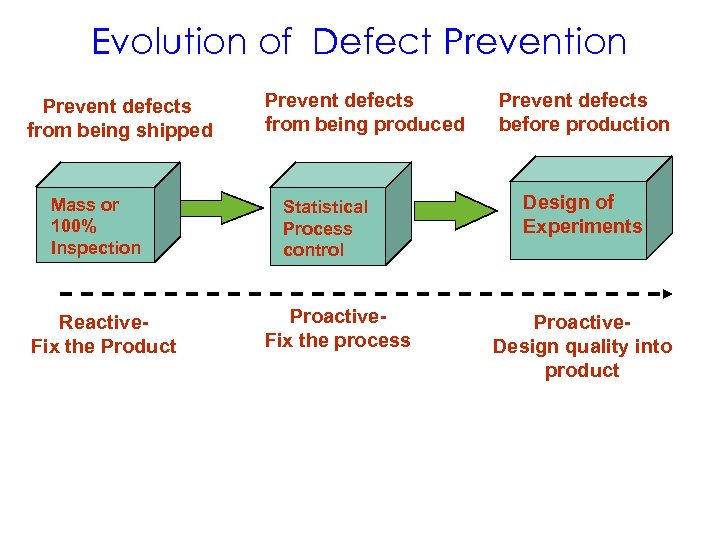

Evolution of Defect Prevention Prevent defects from being shipped Mass or 100% Inspection Reactive. Fix the Product Prevent defects from being produced Statistical Process control Proactive. Fix the process Prevent defects before production Design of Experiments Proactive. Design quality into product

Evolution of Defect Prevention Prevent defects from being shipped Mass or 100% Inspection Reactive. Fix the Product Prevent defects from being produced Statistical Process control Proactive. Fix the process Prevent defects before production Design of Experiments Proactive. Design quality into product

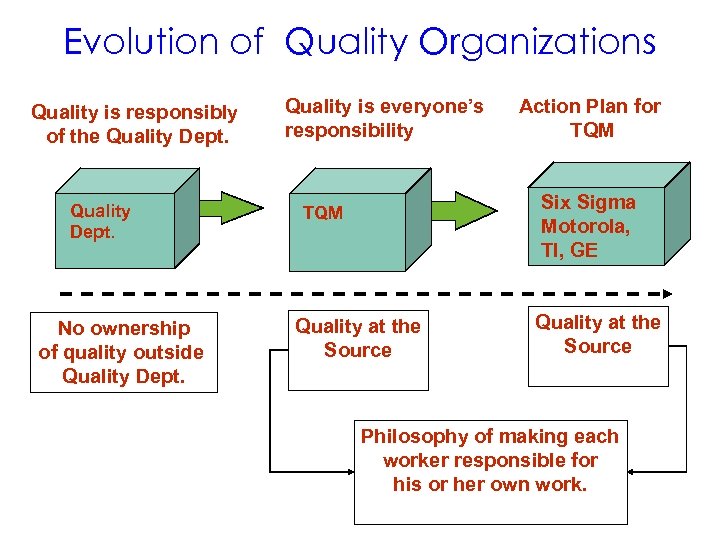

Evolution of Quality Organizations Quality is responsibly of the Quality Dept. No ownership of quality outside Quality Dept. Quality is everyone’s responsibility Action Plan for TQM Six Sigma Motorola, TI, GE TQM Quality at the Source Philosophy of making each worker responsible for his or her own work.

Evolution of Quality Organizations Quality is responsibly of the Quality Dept. No ownership of quality outside Quality Dept. Quality is everyone’s responsibility Action Plan for TQM Six Sigma Motorola, TI, GE TQM Quality at the Source Philosophy of making each worker responsible for his or her own work.

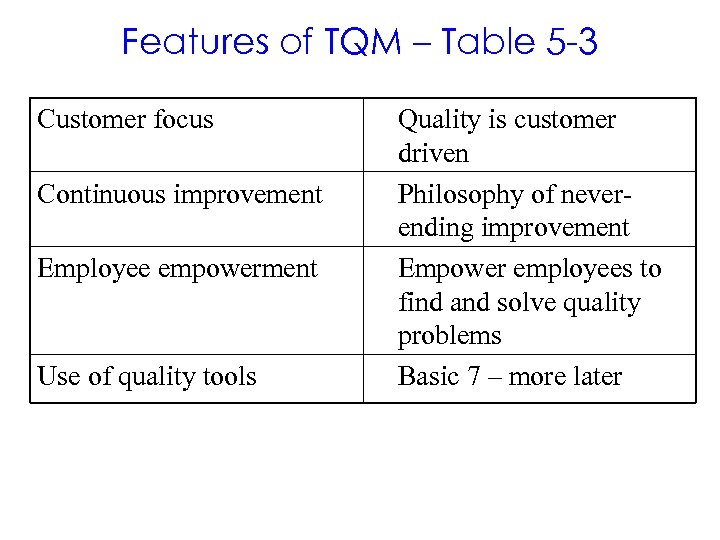

Features of TQM – Table 5 -3 Customer focus Continuous improvement Employee empowerment Use of quality tools Quality is customer driven Philosophy of neverending improvement Empower employees to find and solve quality problems Basic 7 – more later

Features of TQM – Table 5 -3 Customer focus Continuous improvement Employee empowerment Use of quality tools Quality is customer driven Philosophy of neverending improvement Empower employees to find and solve quality problems Basic 7 – more later

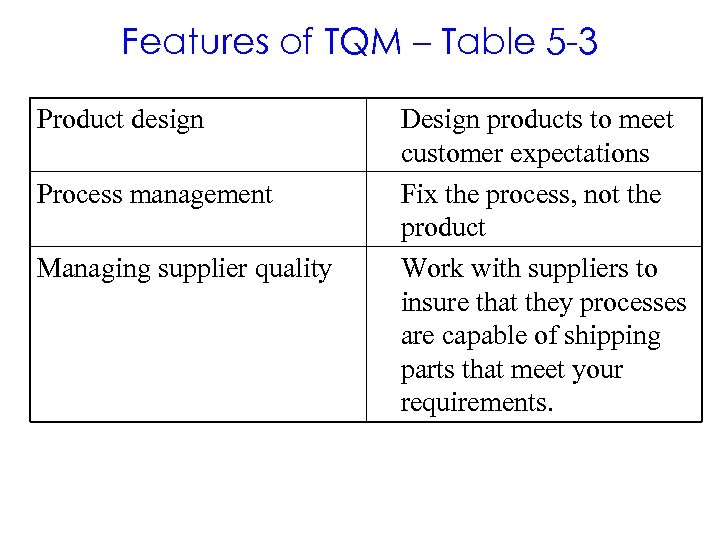

Features of TQM – Table 5 -3 Product design Process management Managing supplier quality Design products to meet customer expectations Fix the process, not the product Work with suppliers to insure that they processes are capable of shipping parts that meet your requirements.

Features of TQM – Table 5 -3 Product design Process management Managing supplier quality Design products to meet customer expectations Fix the process, not the product Work with suppliers to insure that they processes are capable of shipping parts that meet your requirements.

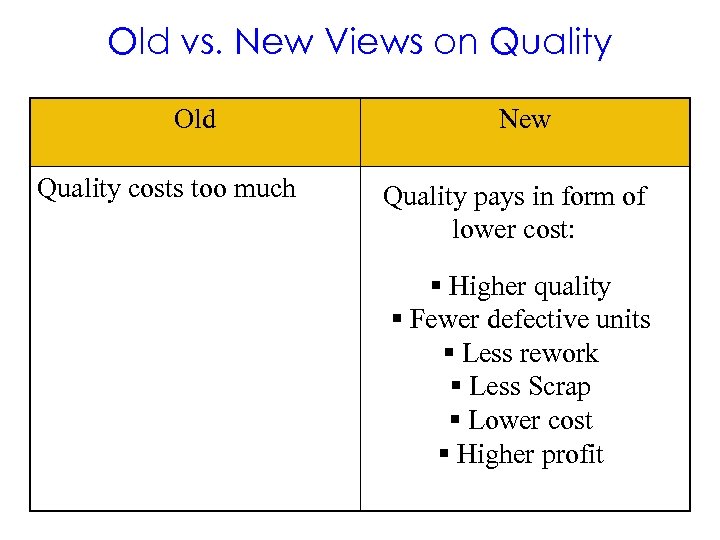

Old vs. New Views on Quality Old Quality costs too much New Quality pays in form of lower cost: § Higher quality § Fewer defective units § Less rework § Less Scrap § Lower cost § Higher profit

Old vs. New Views on Quality Old Quality costs too much New Quality pays in form of lower cost: § Higher quality § Fewer defective units § Less rework § Less Scrap § Lower cost § Higher profit

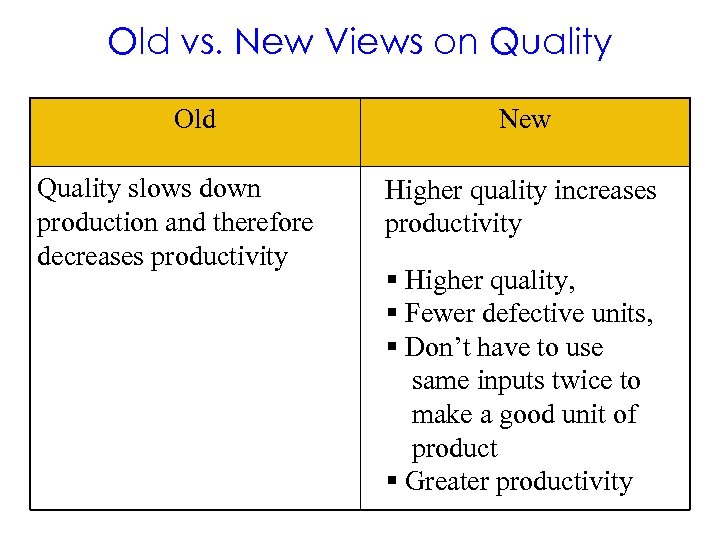

Old vs. New Views on Quality Old Quality slows down production and therefore decreases productivity New Higher quality increases productivity § Higher quality, § Fewer defective units, § Don’t have to use same inputs twice to make a good unit of product § Greater productivity

Old vs. New Views on Quality Old Quality slows down production and therefore decreases productivity New Higher quality increases productivity § Higher quality, § Fewer defective units, § Don’t have to use same inputs twice to make a good unit of product § Greater productivity

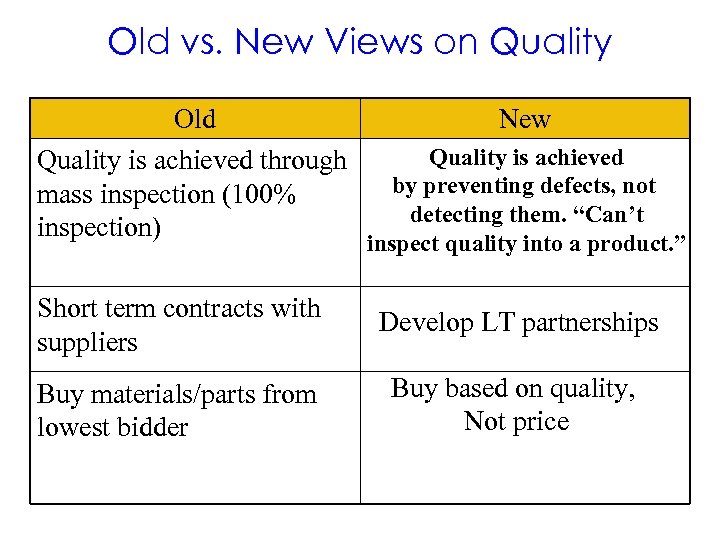

Old vs. New Views on Quality Old Quality is achieved through mass inspection (100% inspection) New Quality is achieved by preventing defects, not detecting them. “Can’t inspect quality into a product. ” Short term contracts with suppliers Develop LT partnerships Buy materials/parts from lowest bidder Buy based on quality, Not price

Old vs. New Views on Quality Old Quality is achieved through mass inspection (100% inspection) New Quality is achieved by preventing defects, not detecting them. “Can’t inspect quality into a product. ” Short term contracts with suppliers Develop LT partnerships Buy materials/parts from lowest bidder Buy based on quality, Not price

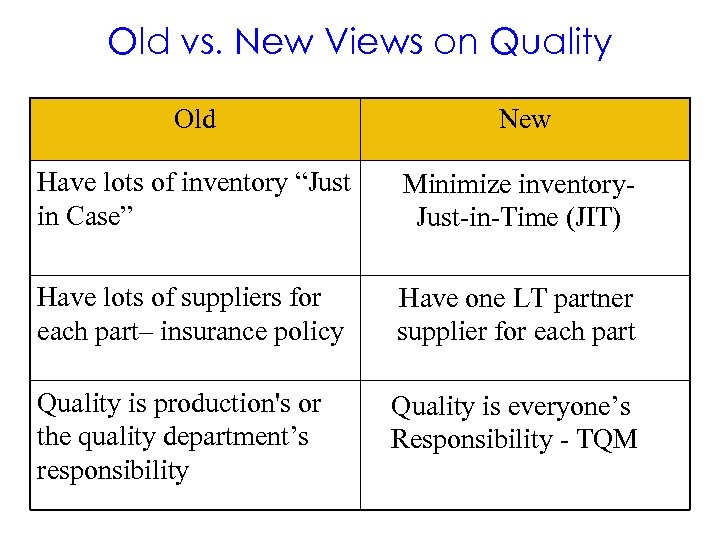

Old vs. New Views on Quality Old New Have lots of inventory “Just in Case” Minimize inventory. Just-in-Time (JIT) Have lots of suppliers for each part– insurance policy Have one LT partner supplier for each part Quality is production's or the quality department’s responsibility Quality is everyone’s Responsibility - TQM

Old vs. New Views on Quality Old New Have lots of inventory “Just in Case” Minimize inventory. Just-in-Time (JIT) Have lots of suppliers for each part– insurance policy Have one LT partner supplier for each part Quality is production's or the quality department’s responsibility Quality is everyone’s Responsibility - TQM

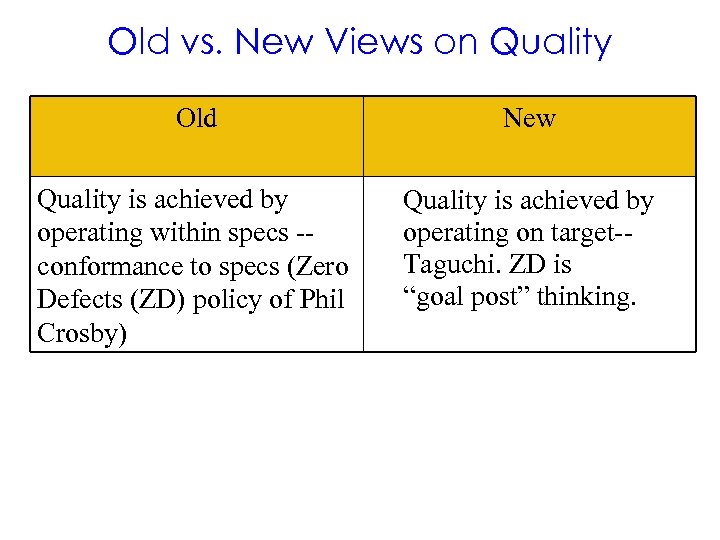

Old vs. New Views on Quality Old New Quality is achieved by operating within specs -conformance to specs (Zero Defects (ZD) policy of Phil Crosby) Quality is achieved by operating on target-Taguchi. ZD is “goal post” thinking.

Old vs. New Views on Quality Old New Quality is achieved by operating within specs -conformance to specs (Zero Defects (ZD) policy of Phil Crosby) Quality is achieved by operating on target-Taguchi. ZD is “goal post” thinking.

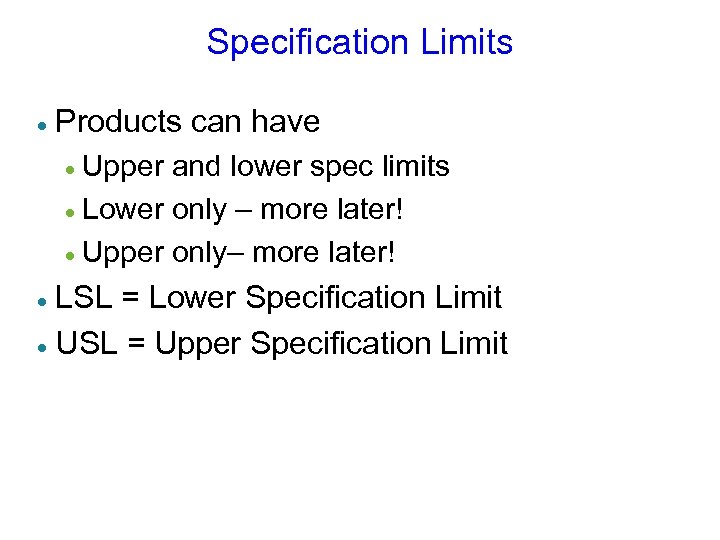

Specification Limits · Products can have Upper and lower spec limits · Lower only – more later! · Upper only– more later! · LSL = Lower Specification Limit · USL = Upper Specification Limit ·

Specification Limits · Products can have Upper and lower spec limits · Lower only – more later! · Upper only– more later! · LSL = Lower Specification Limit · USL = Upper Specification Limit ·

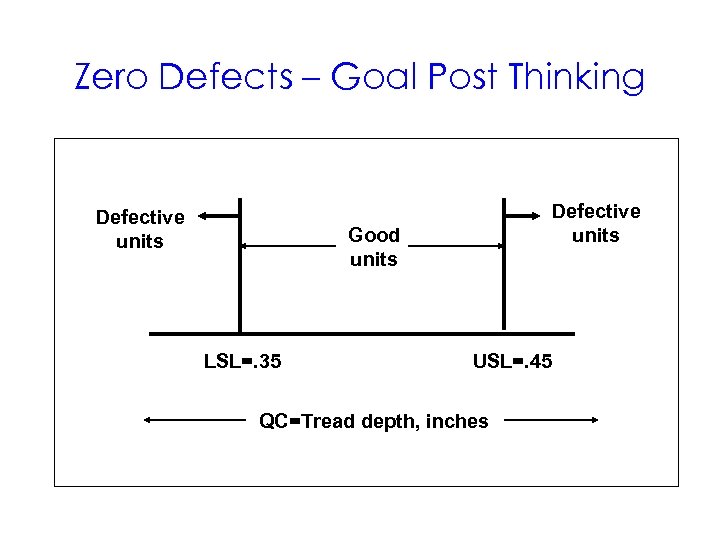

Zero Defects – Goal Post Thinking Defective units Good units LSL=. 35 USL=. 45 QC=Tread depth, inches

Zero Defects – Goal Post Thinking Defective units Good units LSL=. 35 USL=. 45 QC=Tread depth, inches

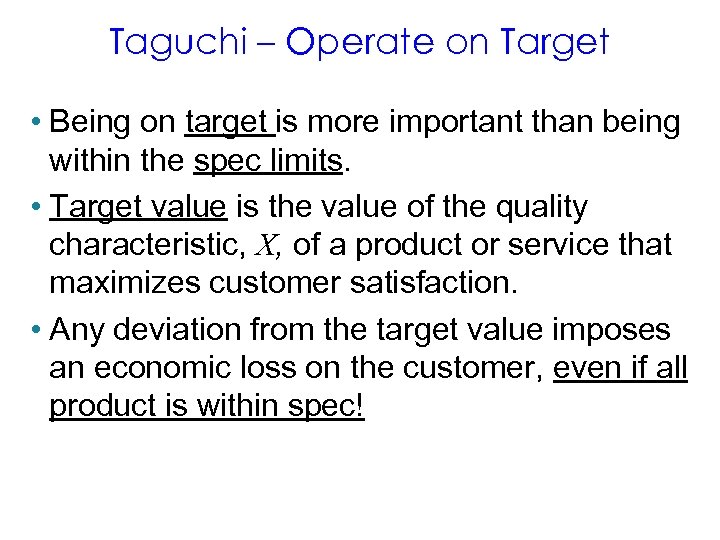

Taguchi – Operate on Target • Being on target is more important than being within the spec limits. • Target value is the value of the quality characteristic, X, of a product or service that maximizes customer satisfaction. • Any deviation from the target value imposes an economic loss on the customer, even if all product is within spec!

Taguchi – Operate on Target • Being on target is more important than being within the spec limits. • Target value is the value of the quality characteristic, X, of a product or service that maximizes customer satisfaction. • Any deviation from the target value imposes an economic loss on the customer, even if all product is within spec!

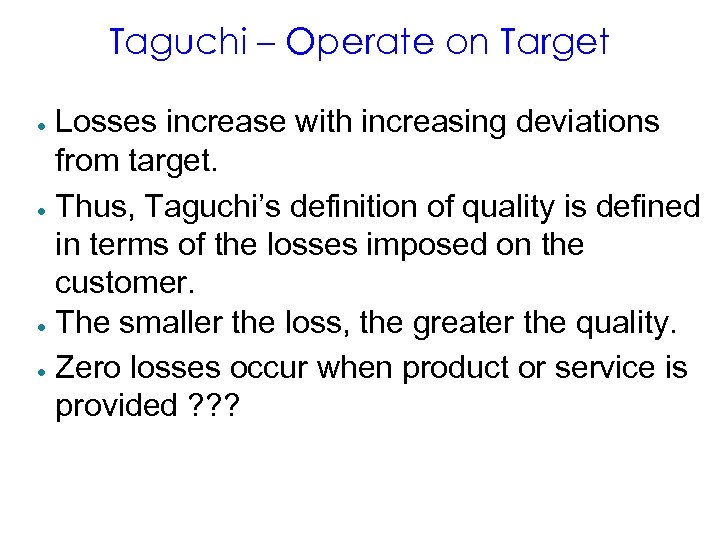

Taguchi – Operate on Target Losses increase with increasing deviations from target. · Thus, Taguchi’s definition of quality is defined in terms of the losses imposed on the customer. · The smaller the loss, the greater the quality. · Zero losses occur when product or service is provided ? ? ? ·

Taguchi – Operate on Target Losses increase with increasing deviations from target. · Thus, Taguchi’s definition of quality is defined in terms of the losses imposed on the customer. · The smaller the loss, the greater the quality. · Zero losses occur when product or service is provided ? ? ? ·

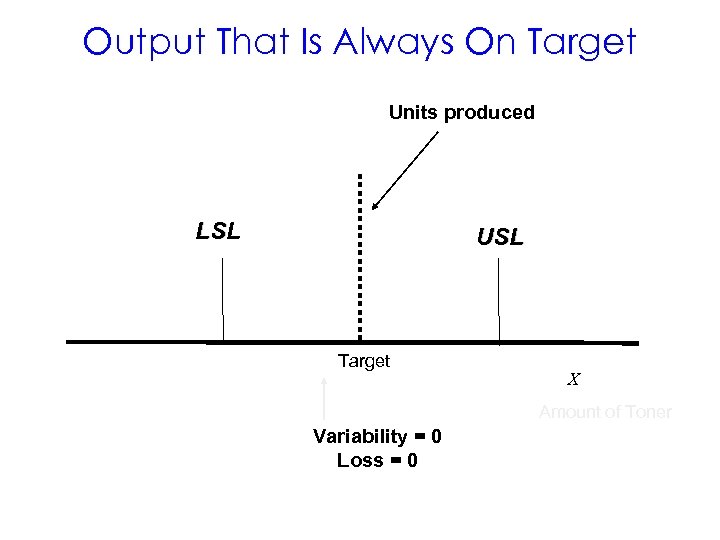

Output That Is Always On Target Units produced LSL USL Target X Amount of Toner Variability = 0 Loss = 0

Output That Is Always On Target Units produced LSL USL Target X Amount of Toner Variability = 0 Loss = 0

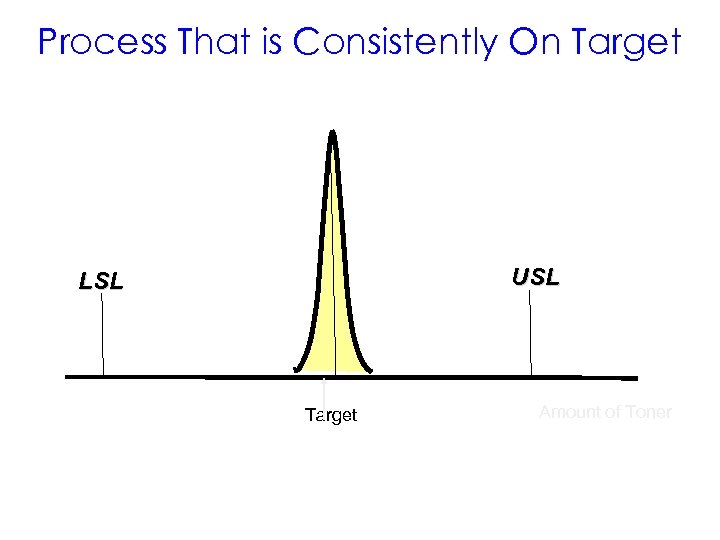

Process That is Consistently On Target USL LSL Target Amount of Toner

Process That is Consistently On Target USL LSL Target Amount of Toner

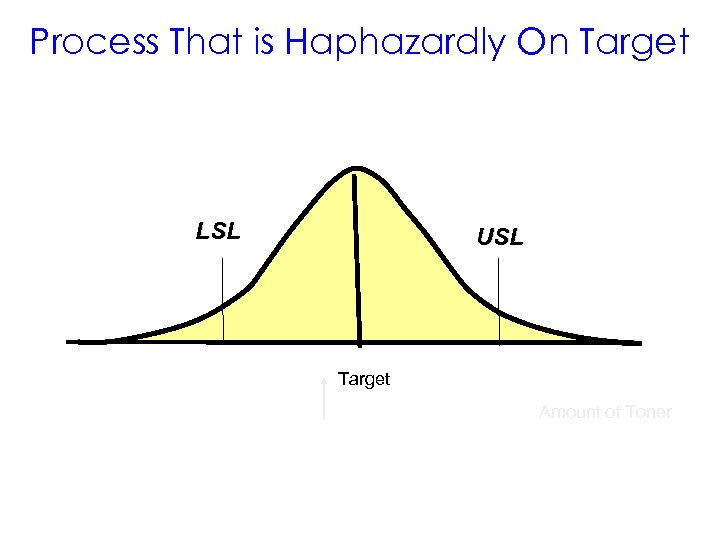

Process That is Haphazardly On Target LSL USL Target Amount of Toner

Process That is Haphazardly On Target LSL USL Target Amount of Toner

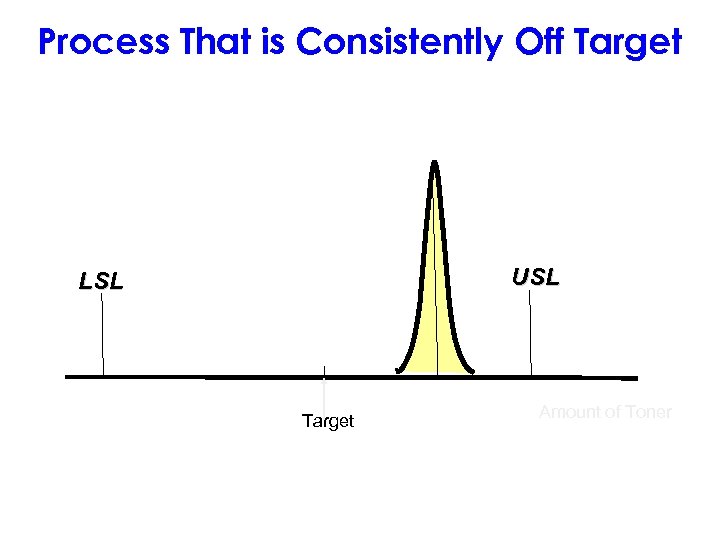

Process That is Consistently Off Target USL LSL Target Amount of Toner

Process That is Consistently Off Target USL LSL Target Amount of Toner

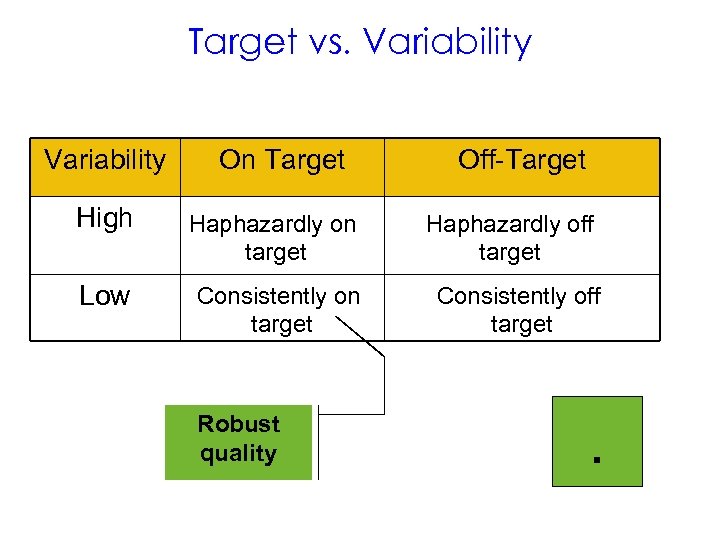

Target vs. Variability On Target Off-Target High Haphazardly on target Haphazardly off target Low Consistently on target Consistently off target Robust quality .

Target vs. Variability On Target Off-Target High Haphazardly on target Haphazardly off target Low Consistently on target Consistently off target Robust quality .

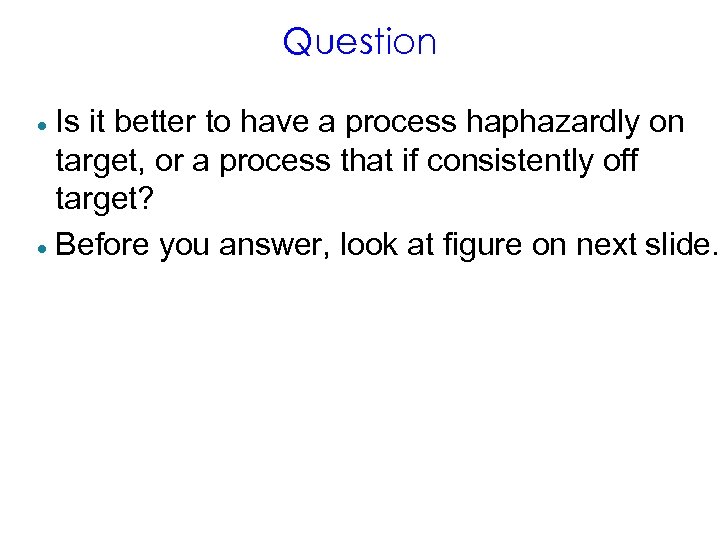

Question Is it better to have a process haphazardly on target, or a process that if consistently off target? · Before you answer, look at figure on next slide. ·

Question Is it better to have a process haphazardly on target, or a process that if consistently off target? · Before you answer, look at figure on next slide. ·

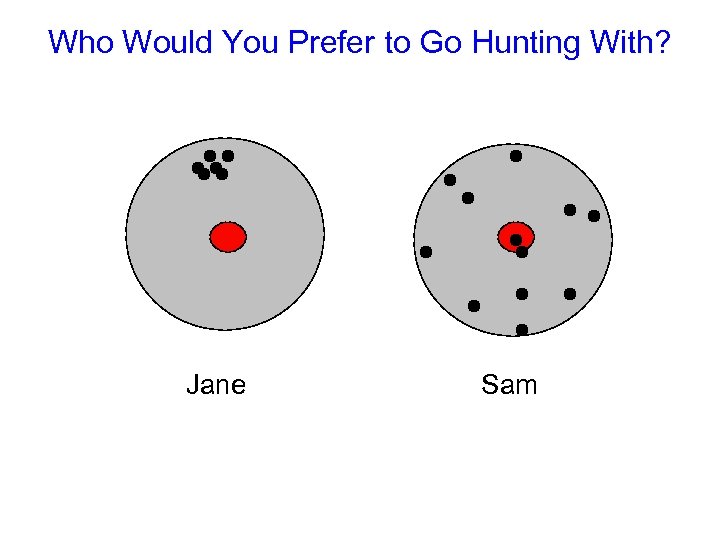

Who Would You Prefer to Go Hunting With? Jane Sam

Who Would You Prefer to Go Hunting With? Jane Sam

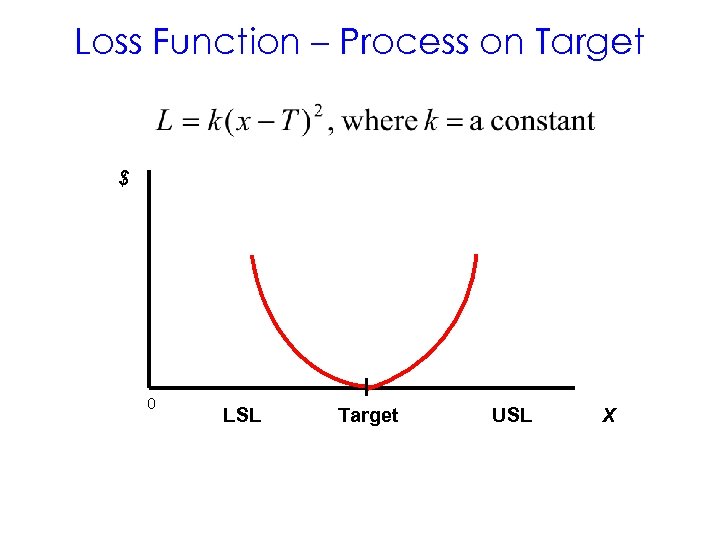

Loss Function – Process on Target $ 0 LSL Target USL X

Loss Function – Process on Target $ 0 LSL Target USL X

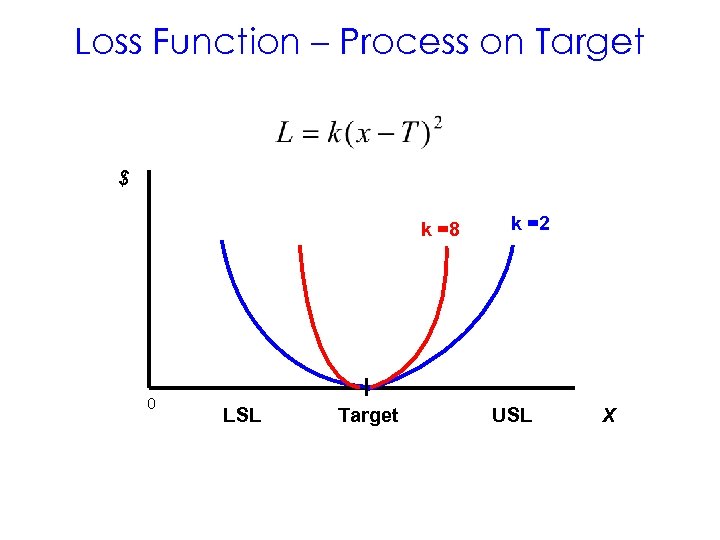

Loss Function – Process on Target $ k =8 0 LSL Target k =2 USL X

Loss Function – Process on Target $ k =8 0 LSL Target k =2 USL X

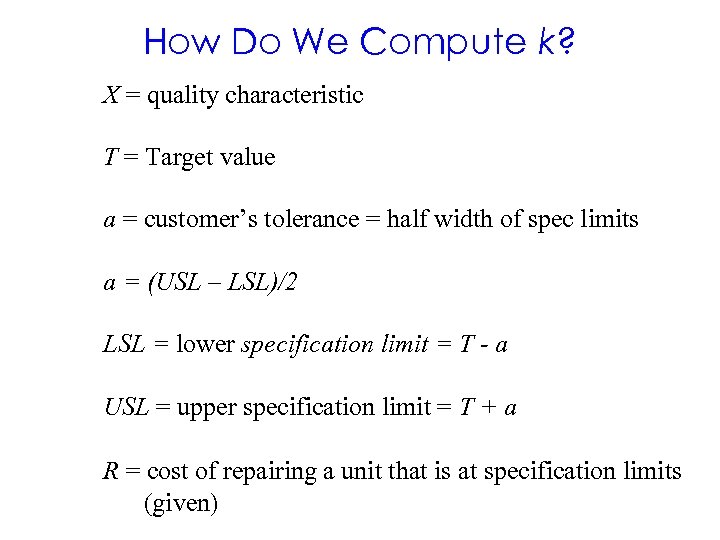

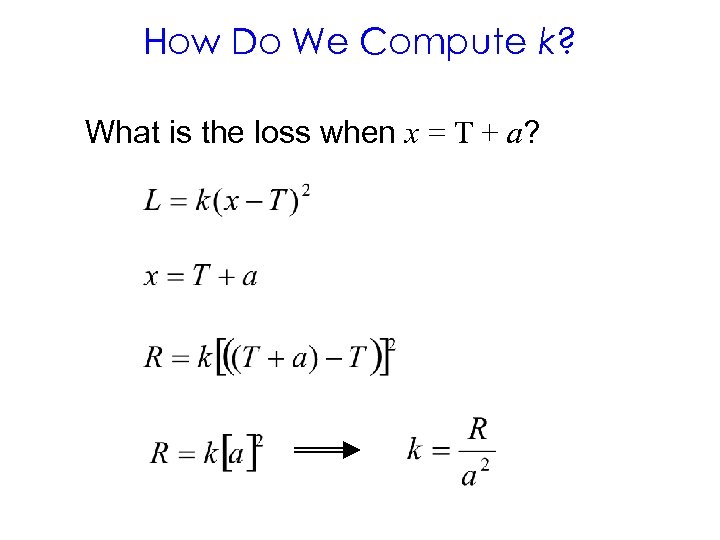

How Do We Compute k? X = quality characteristic T = Target value a = customer’s tolerance = half width of spec limits a = (USL – LSL)/2 LSL = lower specification limit = T - a USL = upper specification limit = T + a R = cost of repairing a unit that is at specification limits (given)

How Do We Compute k? X = quality characteristic T = Target value a = customer’s tolerance = half width of spec limits a = (USL – LSL)/2 LSL = lower specification limit = T - a USL = upper specification limit = T + a R = cost of repairing a unit that is at specification limits (given)

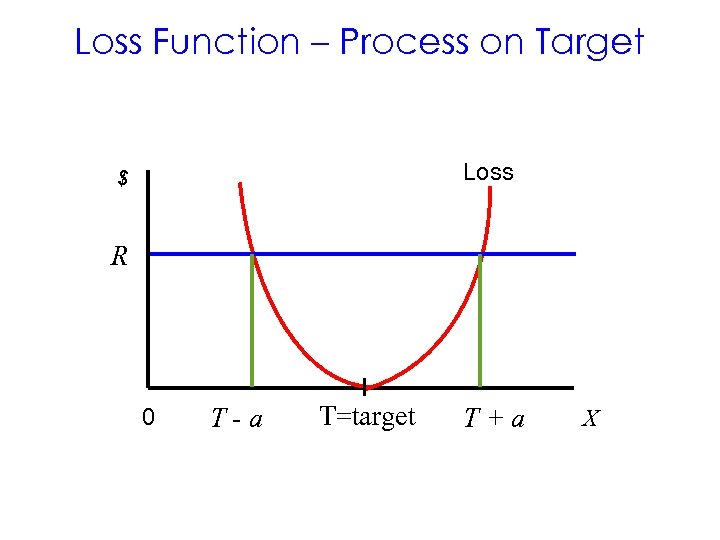

Loss Function – Process on Target Loss $ R 0 T-a T=target T+a X

Loss Function – Process on Target Loss $ R 0 T-a T=target T+a X

How Do We Compute k? What is the loss when x = T + a?

How Do We Compute k? What is the loss when x = T + a?

Affect of k on the Loss Function · As R, cost of repair, increases, it becomes more costly to repair units prior to shipping. This will increase k. · Increases in k increase the losses due to deviations from target. ·

Affect of k on the Loss Function · As R, cost of repair, increases, it becomes more costly to repair units prior to shipping. This will increase k. · Increases in k increase the losses due to deviations from target. ·

Affect of k on the Loss Function · As a increases, k decreases, and so do the losses at all values of X. An increase in a means that the customer’s tolerances are wider, meaning that the acceptable range of product performance has increased. · The wider the range of acceptable performance, the lower the losses due to deviations from target. ·

Affect of k on the Loss Function · As a increases, k decreases, and so do the losses at all values of X. An increase in a means that the customer’s tolerances are wider, meaning that the acceptable range of product performance has increased. · The wider the range of acceptable performance, the lower the losses due to deviations from target. ·

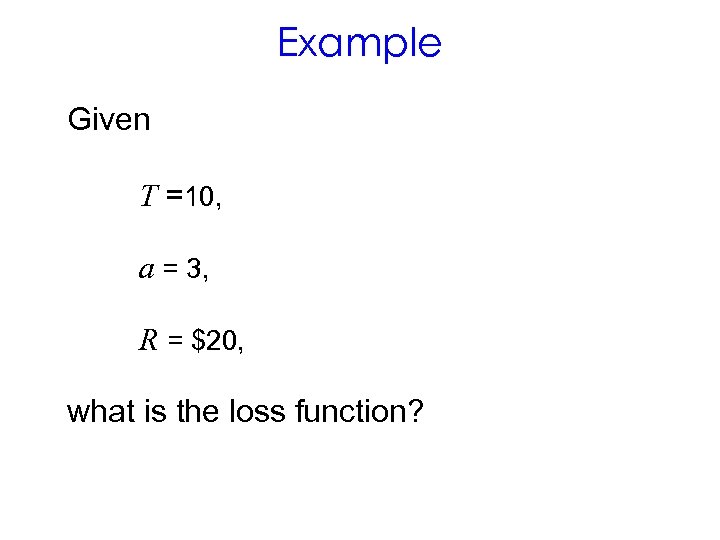

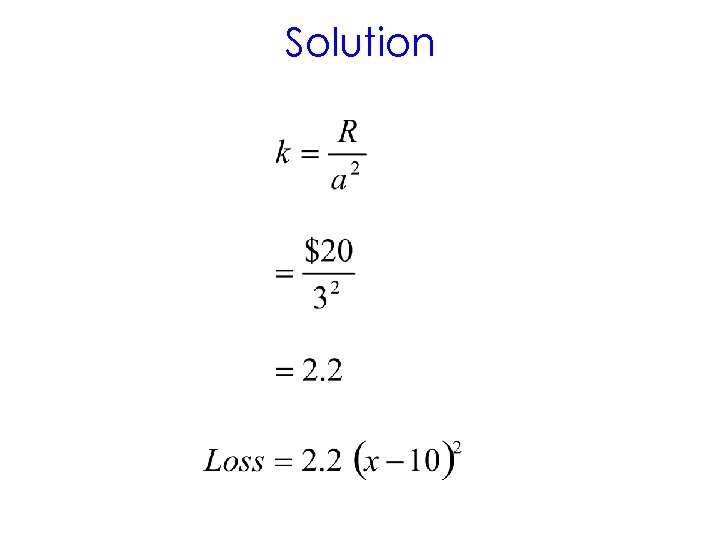

Example Given T =10, a = 3, R = $20, what is the loss function?

Example Given T =10, a = 3, R = $20, what is the loss function?

Solution

Solution

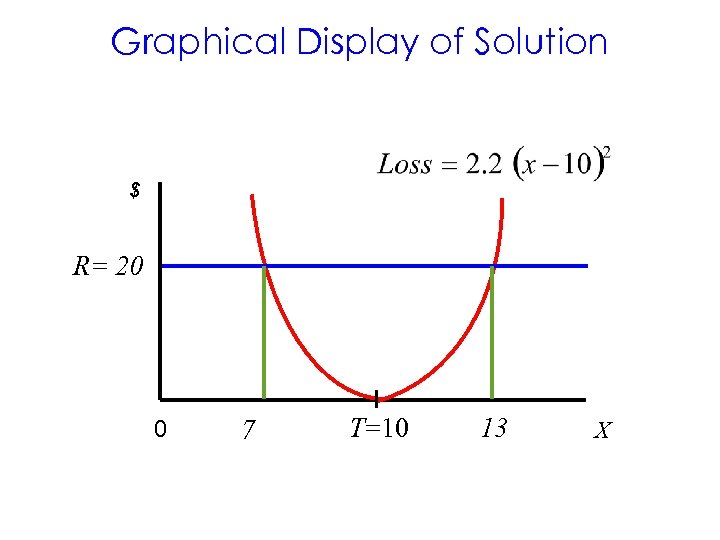

Graphical Display of Solution $ R= 20 0 7 T=10 13 X

Graphical Display of Solution $ R= 20 0 7 T=10 13 X

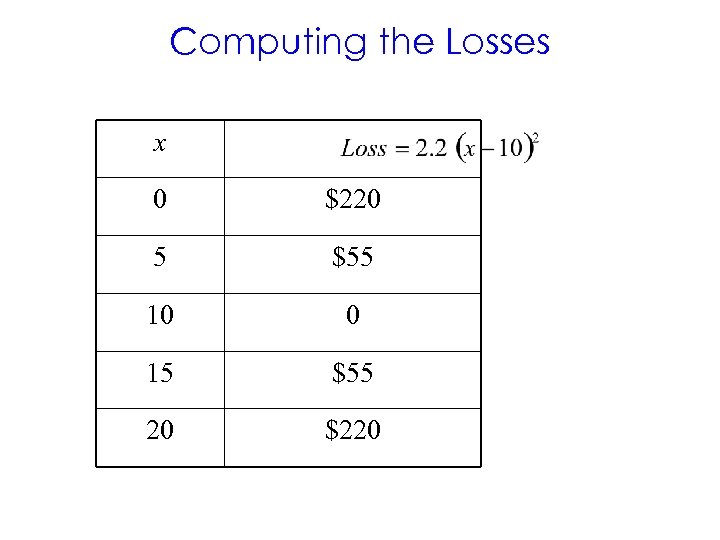

Computing the Losses x 0 $220 5 $55 10 0 15 $55 20 $220

Computing the Losses x 0 $220 5 $55 10 0 15 $55 20 $220

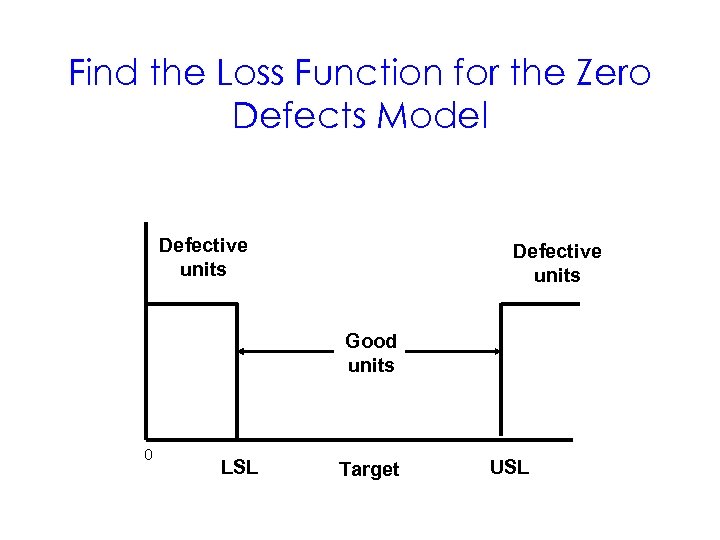

Find the Loss Function for the Zero Defects Model Defective units Good units 0 LSL Target USL

Find the Loss Function for the Zero Defects Model Defective units Good units 0 LSL Target USL

Solution

Solution

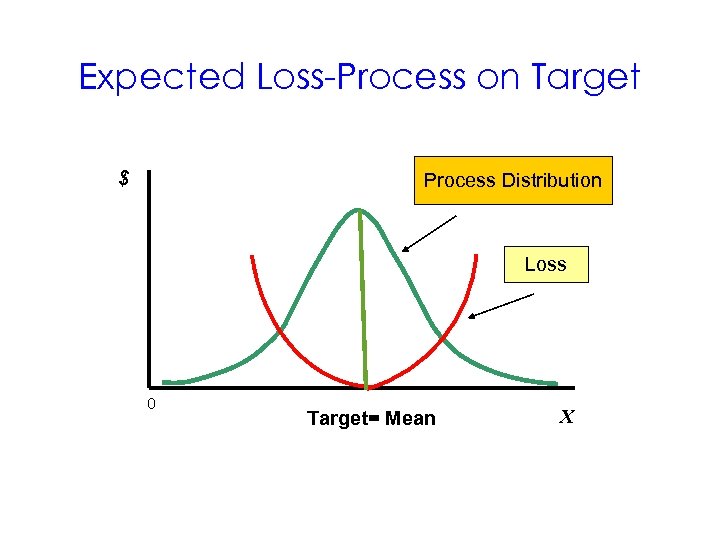

Expected Loss-Process on Target $ Process Distribution Loss 0 Target= Mean X

Expected Loss-Process on Target $ Process Distribution Loss 0 Target= Mean X

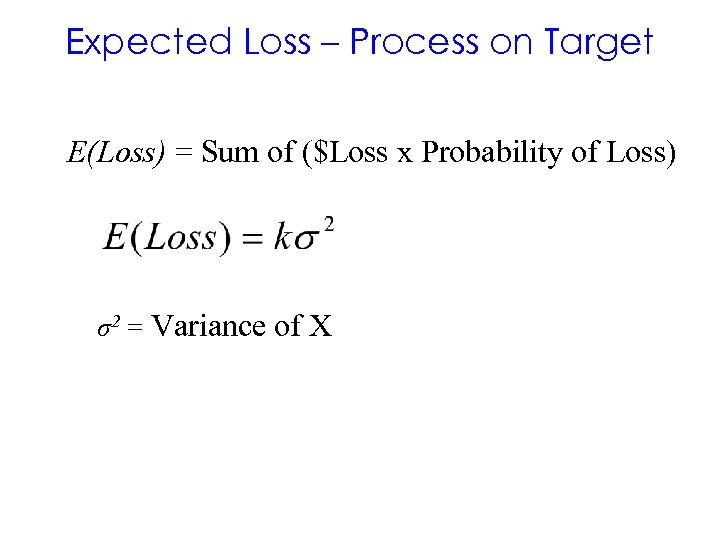

Expected Loss – Process on Target E(Loss) = Sum of ($Loss x Probability of Loss) σ2 = Variance of X

Expected Loss – Process on Target E(Loss) = Sum of ($Loss x Probability of Loss) σ2 = Variance of X

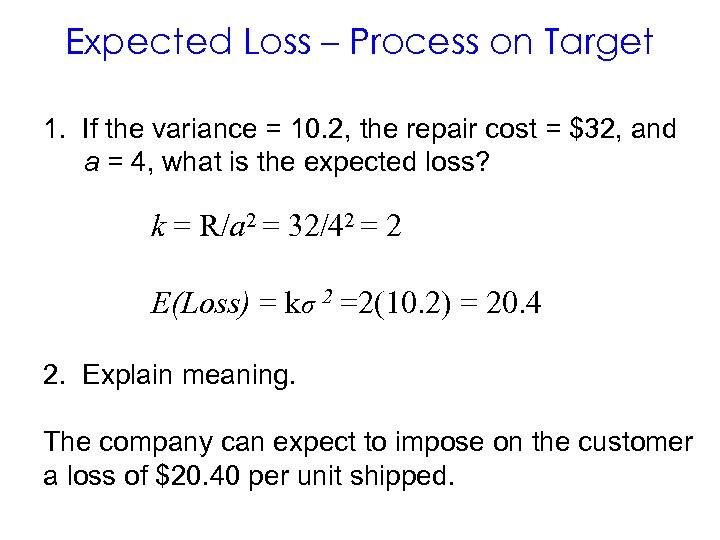

Expected Loss – Process on Target 1. If the variance = 10. 2, the repair cost = $32, and a = 4, what is the expected loss? k = R/a 2 = 32/42 = 2 E(Loss) = kσ 2 =2(10. 2) = 20. 4 2. Explain meaning. The company can expect to impose on the customer a loss of $20. 40 per unit shipped.

Expected Loss – Process on Target 1. If the variance = 10. 2, the repair cost = $32, and a = 4, what is the expected loss? k = R/a 2 = 32/42 = 2 E(Loss) = kσ 2 =2(10. 2) = 20. 4 2. Explain meaning. The company can expect to impose on the customer a loss of $20. 40 per unit shipped.

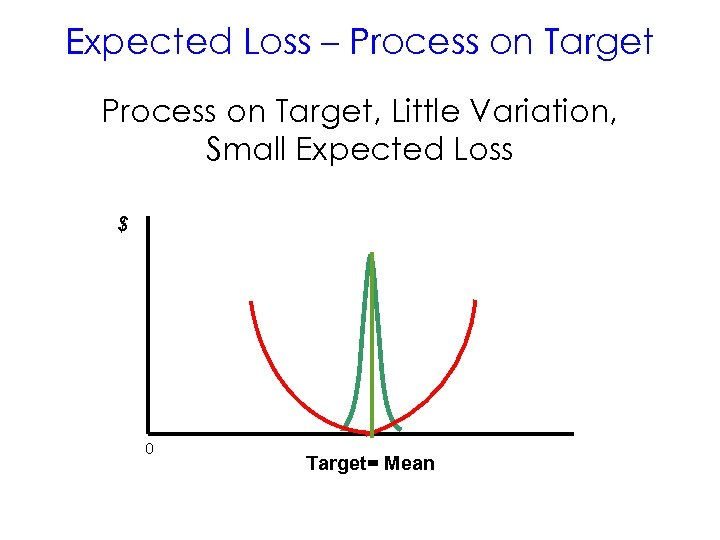

Expected Loss – Process on Target, Little Variation, Small Expected Loss $ 0 Target= Mean

Expected Loss – Process on Target, Little Variation, Small Expected Loss $ 0 Target= Mean

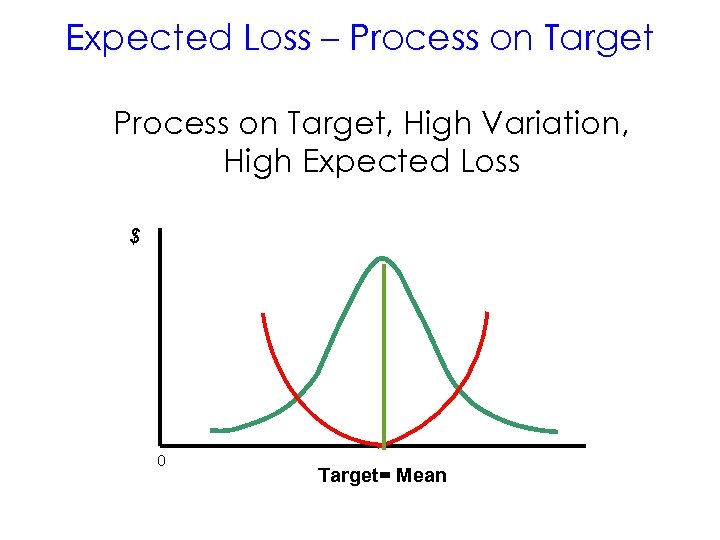

Expected Loss – Process on Target, High Variation, High Expected Loss $ 0 Target= Mean

Expected Loss – Process on Target, High Variation, High Expected Loss $ 0 Target= Mean

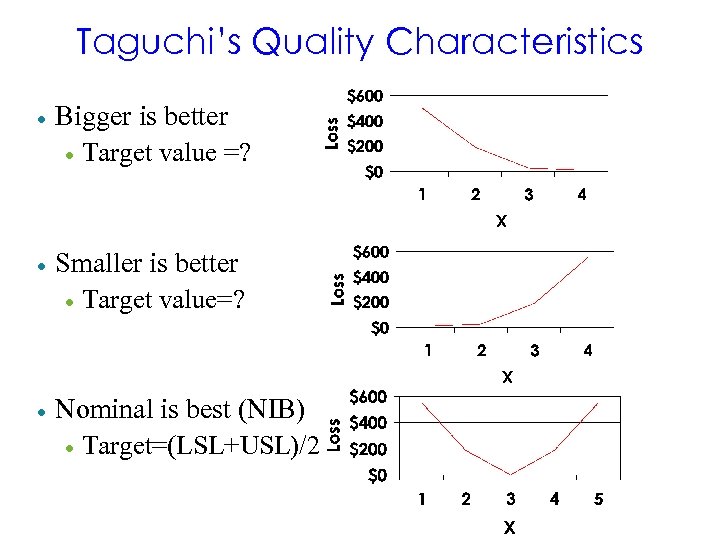

Taguchi’s Quality Characteristics · Bigger is better · Target value =? · Smaller is better · Target value=? · Nominal is best (NIB) · Target=(LSL+USL)/2

Taguchi’s Quality Characteristics · Bigger is better · Target value =? · Smaller is better · Target value=? · Nominal is best (NIB) · Target=(LSL+USL)/2

Provide an Example of Each · Bigger-is-better · Smaller-is-better · Nominal-is-best

Provide an Example of Each · Bigger-is-better · Smaller-is-better · Nominal-is-best

Repair or Ship? It may be more better for a company to ship some off target units without repairing them to target, depending on how far off target they are. · For other off target units, it may be better to repair them prior to shipping. ·

Repair or Ship? It may be more better for a company to ship some off target units without repairing them to target, depending on how far off target they are. · For other off target units, it may be better to repair them prior to shipping. ·

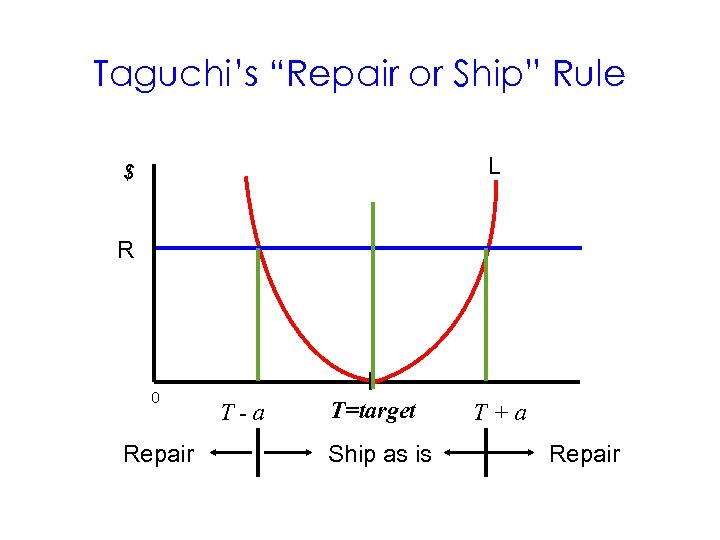

Taguchi’s “Repair or Ship” Rule L $ R 0 Repair T-a T=target Ship as is T+a Repair

Taguchi’s “Repair or Ship” Rule L $ R 0 Repair T-a T=target Ship as is T+a Repair

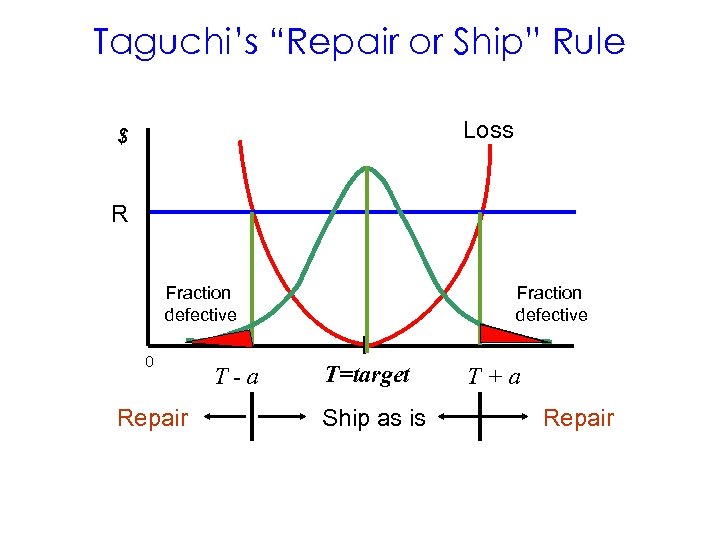

Taguchi’s “Repair or Ship” Rule Loss $ R Fraction defective 0 Repair T-a Fraction defective T=target Ship as is T+a Repair

Taguchi’s “Repair or Ship” Rule Loss $ R Fraction defective 0 Repair T-a Fraction defective T=target Ship as is T+a Repair

Taguchi’s “Repair or Ship” Rule · Explain the logic supporting the decision to ship units “as is. ” · Explain the logic supporting the decision to repair units prior to shipping.

Taguchi’s “Repair or Ship” Rule · Explain the logic supporting the decision to ship units “as is. ” · Explain the logic supporting the decision to repair units prior to shipping.

Taguchi’s “Repair or Ship” Rule · What does rule assume? · If a company is using Taguchi’s rule, when can it stop doing ? ? ?

Taguchi’s “Repair or Ship” Rule · What does rule assume? · If a company is using Taguchi’s rule, when can it stop doing ? ? ?