b6c4093642f1197ee9a948670cd9ace2.ppt

- Количество слайдов: 20

Chapter 5 Overview b Casting die is the other major component b Casting die has four functions: • Hold molten metal in shape of desired casting • Provide means for molten metal to get into the space where it is held in desired shape • Remove heat from molten metal to 1 solidify it

Chapter 5 Objectives b Identify the four types of casting dies b Identify the three major casting die modules b Identify the purpose of each major die component 2

New Terms b Cavity • The void or empty space in the die that fills with metal to make the casting b Gate • The smallest restriction in the alloy flow path, located at the edge of the casting b OEM • Acronym for Original Equipment Manufacturer b Overflows/lifters • Small pockets of alloy located around the edge of 3 the casting

New Terms cont. b Runner • Die cast alloy distribution system within the casting die b Shot • All the injected material b Vacuum vent • Helps get the air out of the die cavity. b Vent • Path from the die cavity to outside the die 4

Die Ownership b The OEM owns the tooling required to make the die casting • If GM opted to purchase casting from a custom producer, the custom producer would buy casting die from a toolmaker and then sell the die to GM • If GM opted to manufacturer the casting in its own plant, GM would buy the die from a toolmaker directly 5

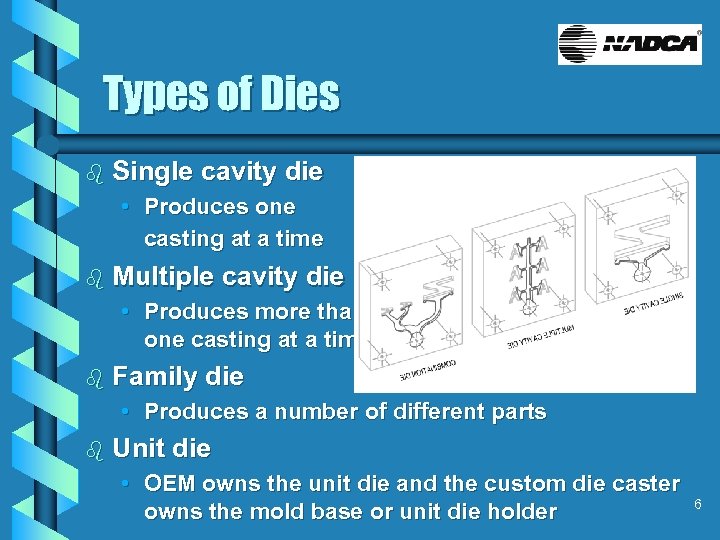

Types of Dies b Single cavity die • Produces one casting at a time b Multiple cavity die • Produces more than one casting at a time b Family die • Produces a number of different parts b Unit die • OEM owns the unit die and the custom die caster owns the mold base or unit die holder 6

Unit Die System b Advantages • • • Lower tooling costs Shorter lead times Potentially lower piece part costs b Disadvantages • Reduced flexibility in part design • Limited size • Possible problem moving tooling from one vendor to another without additional tooling costs 7

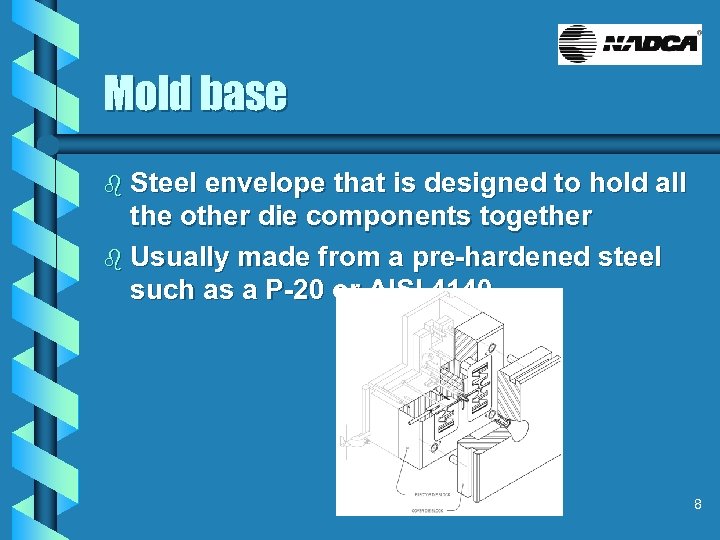

Mold base b Steel envelope that is designed to hold all the other die components together b Usually made from a pre-hardened steel such as a P-20 or AISI 4140 8

Stationary half mold base b Acts as container for stationary die cavities b Provides means for attaching stationary die half to machine b Couples injection system to the die b Provides a means for aligning to two die halves b Has several components 9

Stationary Half Mold Base Components b Clamp slots b Guide pins b Pryslots b Mounting/clamp plate 10

Moving half mold base b Acts as container for the die cavities b Couples ejection system to the cavities b Provides means for aligning the two die halves b Components include: • Guide bushings 11

Ejector box b Provides a means for mounting moving half mold base to moving machine platen b Supports moving half mold base against machine closing force and force of injection b Couples machine ejector system to die ejector system b Has several components 12

Ejector Box Components b Parallels/rails b Clamp plate b Support pillars 13

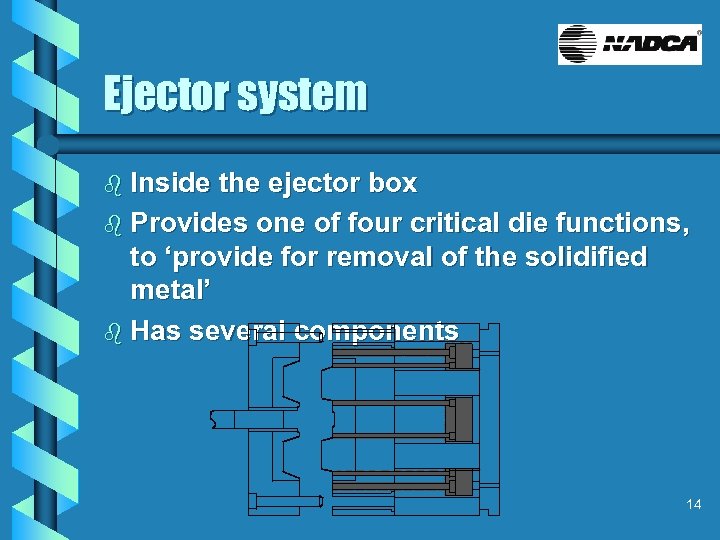

Ejector system b Inside the ejector box b Provides one of four critical die functions, to ‘provide for removal of the solidified metal’ b Has several components 14

Ejector System Components b Ejector pins b Return pins b Ejector plate b Ejector return plate b Guided ejection 15

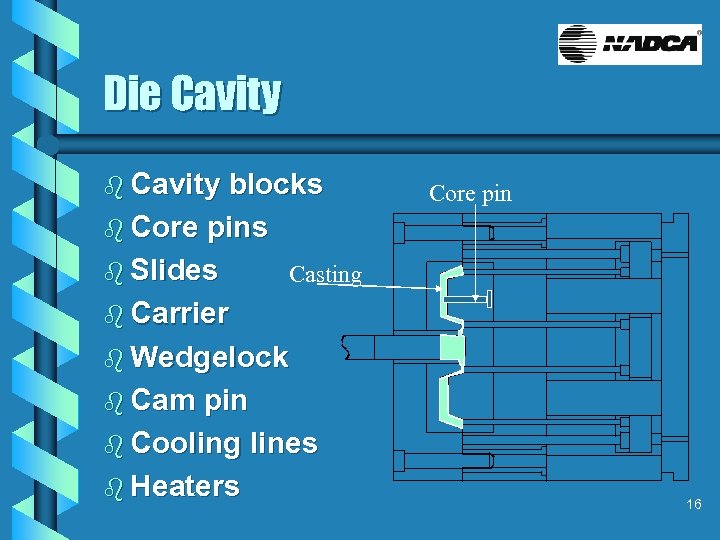

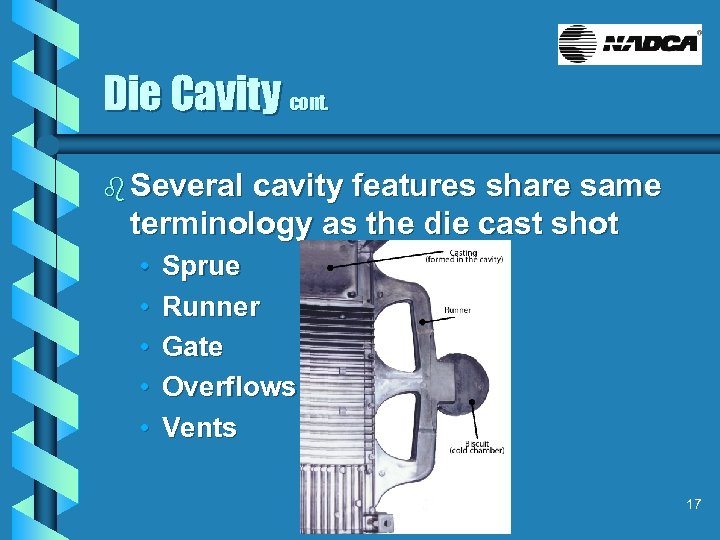

Die Cavity blocks b Core pins b Slides Casting b Carrier b Wedgelock b Cam pin b Cooling lines b Heaters Core pin 16

Die Cavity cont. b Several cavity features share same terminology as the die cast shot • • • Sprue Runner Gate Overflows Vents 17

Miscellaneous Components b Biscuit block b Sprue bushing b Sprue post b Stop buttons b Quick eject cam and pins 18

Summary b Casting die is the other major component • Has four functions b Castings can be manufactured by the OEM or purchased from a custom producer b 4 casting die forms: single cavity, multiple cavity, family and unit 19 b A typical die contains 3 modules:

Summary cont. b Unit dies are not complete dies; have certain advantages and disadvantages for the OEM b There are many components to casting dies • • Mold base Stationary half mold base Moving half mold base Ejector box 20

b6c4093642f1197ee9a948670cd9ace2.ppt