155430745628a7b3a37b51e572074358.ppt

- Количество слайдов: 26

Chapter 5 Lecture 8 capacity planning For products and services

Chapter 5 Lecture 8 capacity planning For products and services

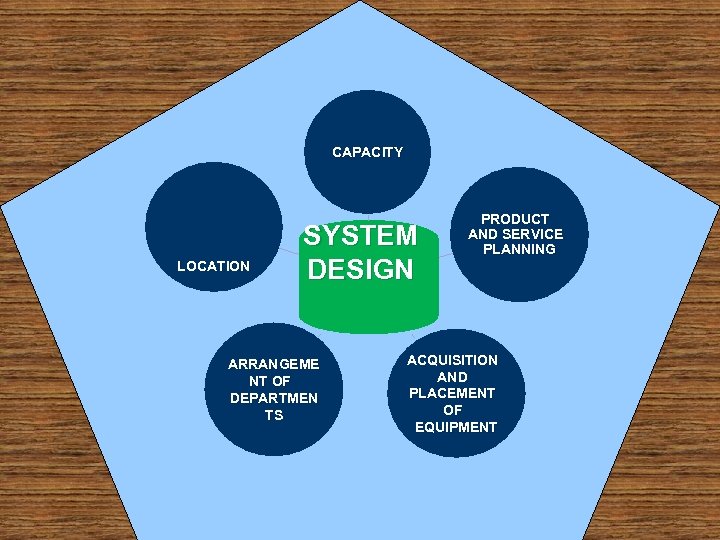

CAPACITY LOCATION SYSTEM DESIGN ARRANGEME NT OF DEPARTMEN TS PRODUCT AND SERVICE PLANNING ACQUISITION AND PLACEMENT OF EQUIPMENT

CAPACITY LOCATION SYSTEM DESIGN ARRANGEME NT OF DEPARTMEN TS PRODUCT AND SERVICE PLANNING ACQUISITION AND PLACEMENT OF EQUIPMENT

Definitions Capacity refers to : The upper limit or ceiling on the load that an operating unit can handle Operating units might be: • Plant department • Machine • Store • worker

Definitions Capacity refers to : The upper limit or ceiling on the load that an operating unit can handle Operating units might be: • Plant department • Machine • Store • worker

Definitions Capacity planning aims to : Achieve a match between supply capabilities and the predicted level of demand Strategic capacity planning: It is a long-term capacity planning

Definitions Capacity planning aims to : Achieve a match between supply capabilities and the predicted level of demand Strategic capacity planning: It is a long-term capacity planning

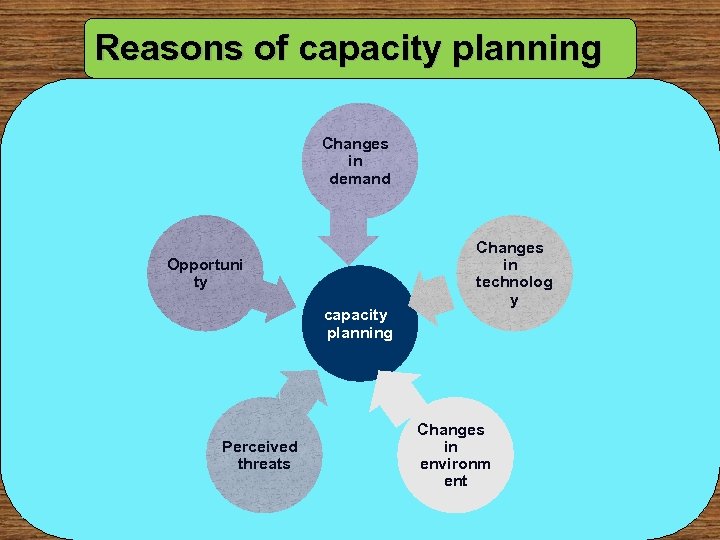

Reasons of capacity planning Changes in demand Opportuni ty capacity planning Perceived threats Changes in technolog y Changes in environm ent

Reasons of capacity planning Changes in demand Opportuni ty capacity planning Perceived threats Changes in technolog y Changes in environm ent

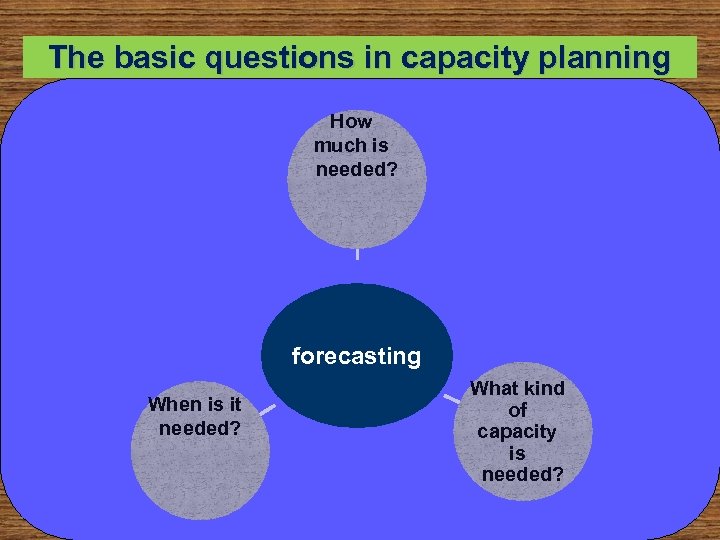

The basic questions in capacity planning How much is needed? forecasting When is it needed? What kind of capacity is needed?

The basic questions in capacity planning How much is needed? forecasting When is it needed? What kind of capacity is needed?

When capacity planning ? It is made infrequently and in others, it is made regularly depends on the following factors : Ø Equipment and product design • The stability of demand • The rate of technological change Ø Competitive factors Ø Others factors • The type of product and services • Whether styles changes are important

When capacity planning ? It is made infrequently and in others, it is made regularly depends on the following factors : Ø Equipment and product design • The stability of demand • The rate of technological change Ø Competitive factors Ø Others factors • The type of product and services • Whether styles changes are important

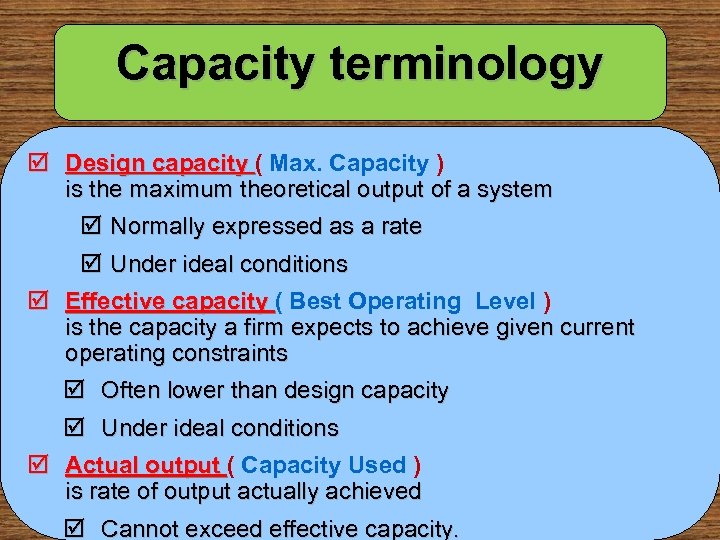

Capacity terminology þ Design capacity ( Max. Capacity ) is the maximum theoretical output of a system þ Normally expressed as a rate þ Under ideal conditions þ Effective capacity ( Best Operating Level ) is the capacity a firm expects to achieve given current operating constraints þ Often lower than design capacity þ Under ideal conditions þ Actual output ( Capacity Used ) is rate of output actually achieved þ Cannot exceed effective capacity.

Capacity terminology þ Design capacity ( Max. Capacity ) is the maximum theoretical output of a system þ Normally expressed as a rate þ Under ideal conditions þ Effective capacity ( Best Operating Level ) is the capacity a firm expects to achieve given current operating constraints þ Often lower than design capacity þ Under ideal conditions þ Actual output ( Capacity Used ) is rate of output actually achieved þ Cannot exceed effective capacity.

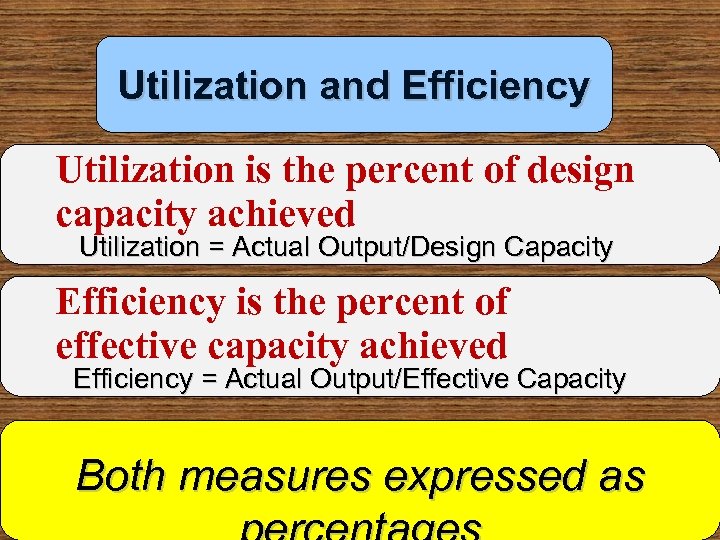

Utilization and Efficiency Utilization is the percent of design capacity achieved Utilization = Actual Output/Design Capacity Efficiency is the percent of effective capacity achieved Efficiency = Actual Output/Effective Capacity Both measures expressed as

Utilization and Efficiency Utilization is the percent of design capacity achieved Utilization = Actual Output/Design Capacity Efficiency is the percent of effective capacity achieved Efficiency = Actual Output/Effective Capacity Both measures expressed as

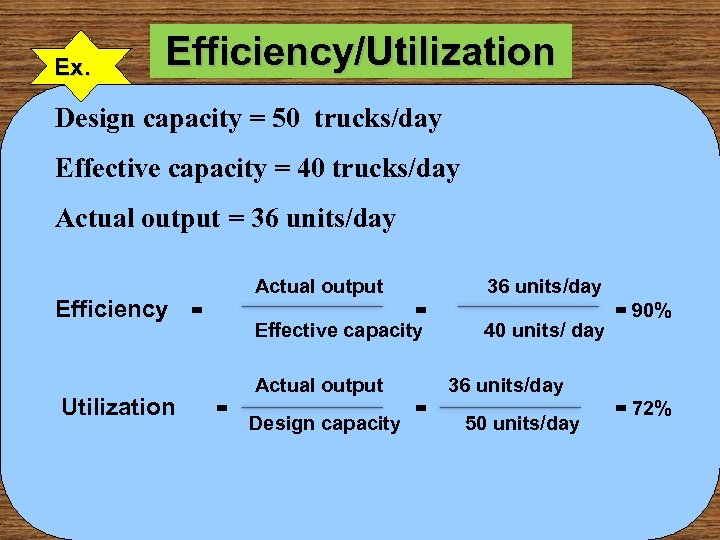

Ex. Efficiency/Utilization Design capacity = 50 trucks/day Effective capacity = 40 trucks/day Actual output = 36 units/day Actual output Efficiency = Utilization 36 units/day = Effective capacity Actual output = Design capacity 40 units/ day = 90% 36 units/day = 50 units/day = 72%

Ex. Efficiency/Utilization Design capacity = 50 trucks/day Effective capacity = 40 trucks/day Actual output = 36 units/day Actual output Efficiency = Utilization 36 units/day = Effective capacity Actual output = Design capacity 40 units/ day = 90% 36 units/day = 50 units/day = 72%

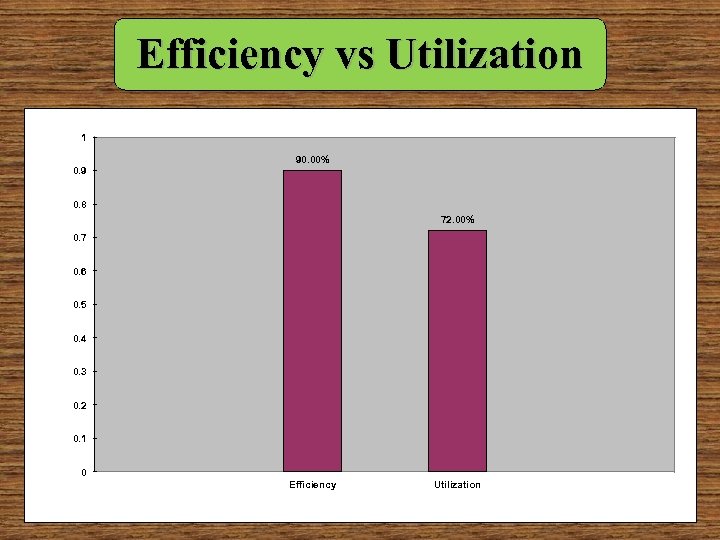

Efficiency vs Utilization 1 90. 00% 0. 9 0. 8 72. 00% 0. 7 0. 6 0. 5 0. 4 0. 3 0. 2 0. 1 0 Efficiency Utilization

Efficiency vs Utilization 1 90. 00% 0. 9 0. 8 72. 00% 0. 7 0. 6 0. 5 0. 4 0. 3 0. 2 0. 1 0 Efficiency Utilization

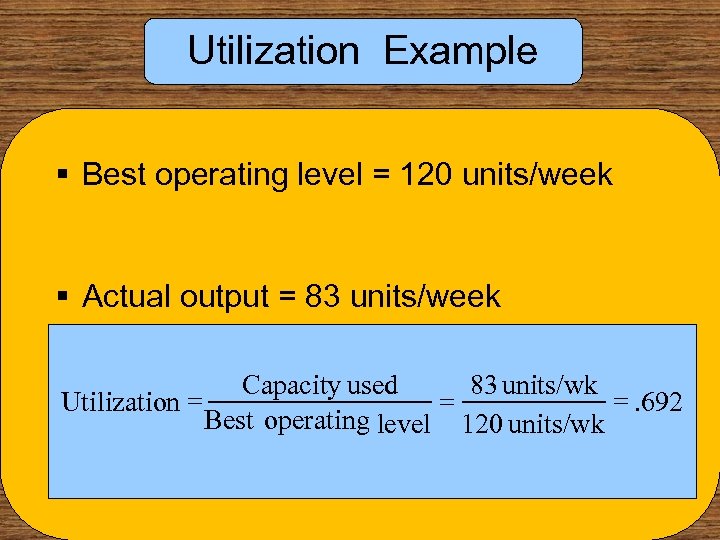

Utilization Example § Best operating level = 120 units/week § Actual output = 83 units/week Capacity used 83 units/wk =. 692 Utilization = = Best ? § Utilization = operating level 120 units/wk

Utilization Example § Best operating level = 120 units/week § Actual output = 83 units/week Capacity used 83 units/wk =. 692 Utilization = = Best ? § Utilization = operating level 120 units/wk

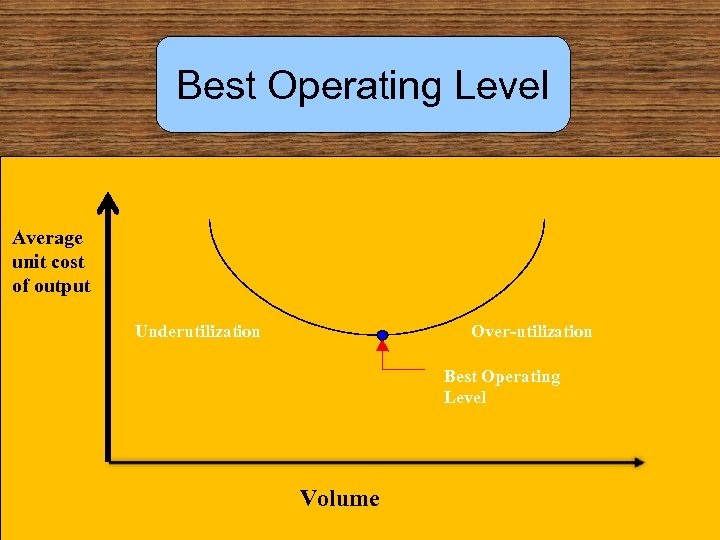

Best Operating Level Average unit cost of output Underutilization Over-utilization Best Operating Level Volume

Best Operating Level Average unit cost of output Underutilization Over-utilization Best Operating Level Volume

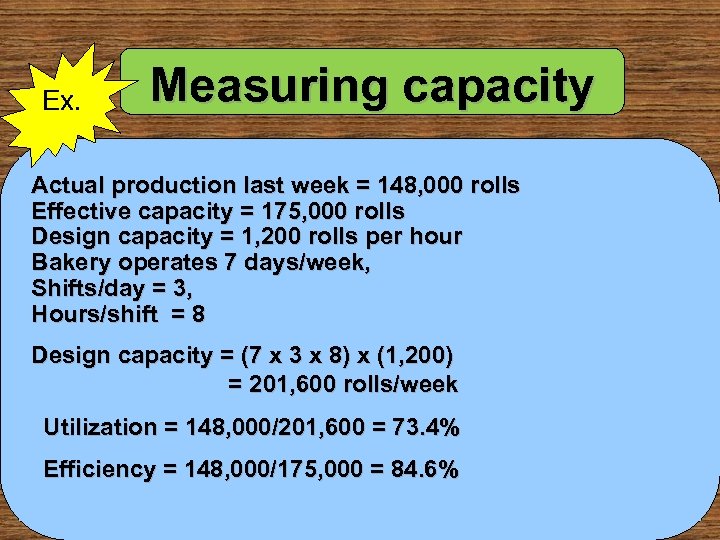

Ex. Measuring capacity Actual production last week = 148, 000 rolls Effective capacity = 175, 000 rolls Design capacity = 1, 200 rolls per hour Bakery operates 7 days/week, Shifts/day = 3, Hours/shift = 8 Design capacity = (7 x 3 x 8) x (1, 200) = 201, 600 rolls/week Utilization = 148, 000/201, 600 = 73. 4% Efficiency = 148, 000/175, 000 = 84. 6%

Ex. Measuring capacity Actual production last week = 148, 000 rolls Effective capacity = 175, 000 rolls Design capacity = 1, 200 rolls per hour Bakery operates 7 days/week, Shifts/day = 3, Hours/shift = 8 Design capacity = (7 x 3 x 8) x (1, 200) = 201, 600 rolls/week Utilization = 148, 000/201, 600 = 73. 4% Efficiency = 148, 000/175, 000 = 84. 6%

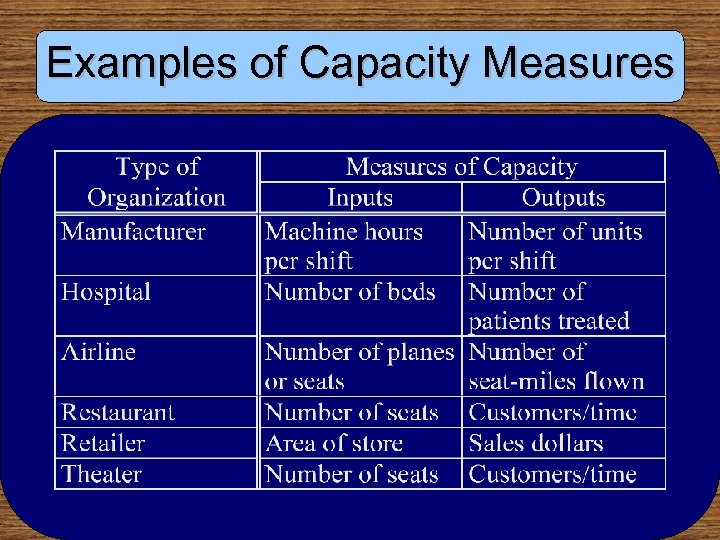

Examples of Capacity Measures

Examples of Capacity Measures

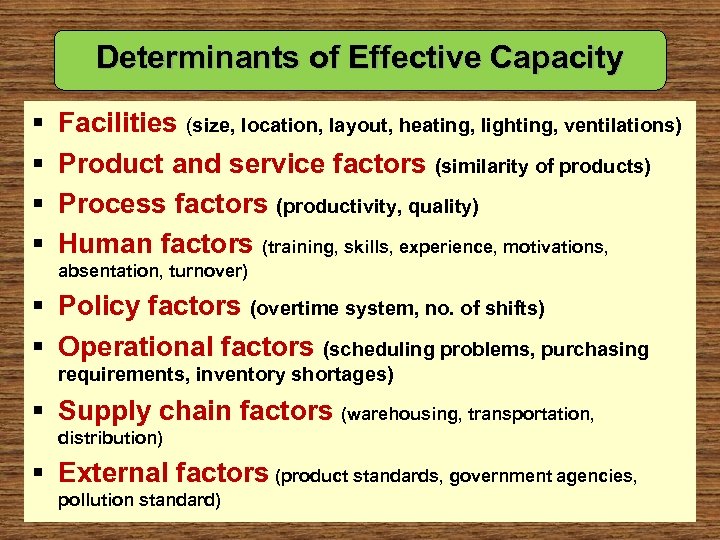

Determinants of Effective Capacity § § Facilities (size, location, layout, heating, lighting, ventilations) Product and service factors (similarity of products) Process factors (productivity, quality) Human factors (training, skills, experience, motivations, absentation, turnover) § Policy factors (overtime system, no. of shifts) § Operational factors (scheduling problems, purchasing requirements, inventory shortages) § Supply chain factors (warehousing, transportation, distribution) § External factors (product standards, government agencies, pollution standard)

Determinants of Effective Capacity § § Facilities (size, location, layout, heating, lighting, ventilations) Product and service factors (similarity of products) Process factors (productivity, quality) Human factors (training, skills, experience, motivations, absentation, turnover) § Policy factors (overtime system, no. of shifts) § Operational factors (scheduling problems, purchasing requirements, inventory shortages) § Supply chain factors (warehousing, transportation, distribution) § External factors (product standards, government agencies, pollution standard)

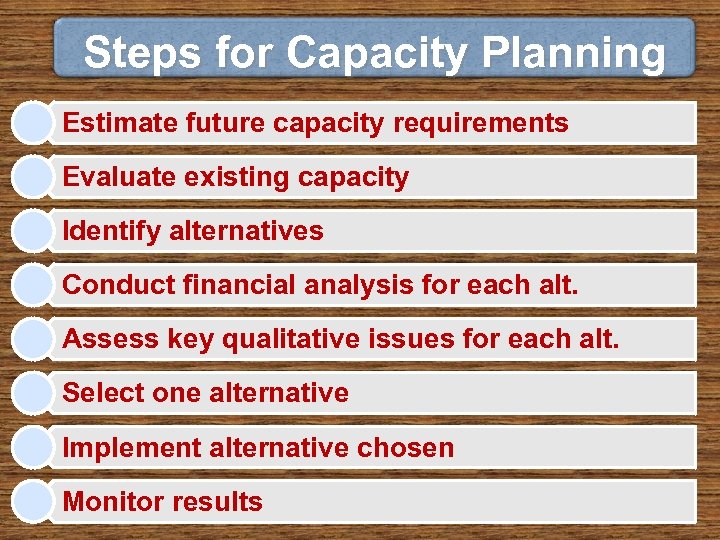

Steps for Capacity Planning Estimate future capacity requirements Evaluate existing capacity Identify alternatives Conduct financial analysis for each alt. Assess key qualitative issues for each alt. Select one alternative Implement alternative chosen Monitor results

Steps for Capacity Planning Estimate future capacity requirements Evaluate existing capacity Identify alternatives Conduct financial analysis for each alt. Assess key qualitative issues for each alt. Select one alternative Implement alternative chosen Monitor results

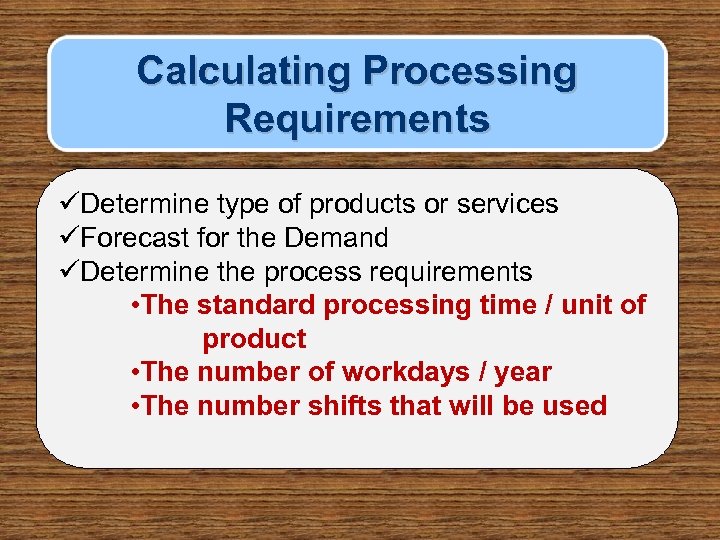

Calculating Processing Requirements üDetermine type of products or services üForecast for the Demand üDetermine the process requirements • The standard processing time / unit of product • The number of workdays / year • The number shifts that will be used

Calculating Processing Requirements üDetermine type of products or services üForecast for the Demand üDetermine the process requirements • The standard processing time / unit of product • The number of workdays / year • The number shifts that will be used

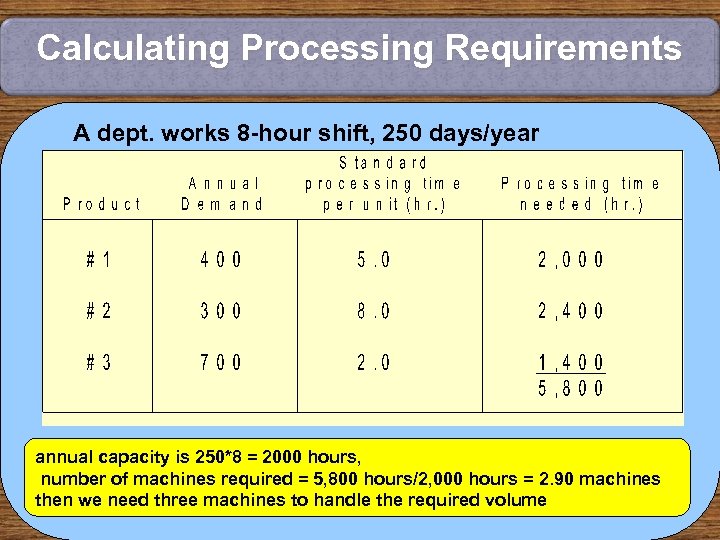

Calculating Processing Requirements A dept. works 8 -hour shift, 250 days/year annual capacity is 250*8 = 2000 hours, number of machines required = 5, 800 hours/2, 000 hours = 2. 90 machines then we need three machines to handle the required volume

Calculating Processing Requirements A dept. works 8 -hour shift, 250 days/year annual capacity is 250*8 = 2000 hours, number of machines required = 5, 800 hours/2, 000 hours = 2. 90 machines then we need three machines to handle the required volume

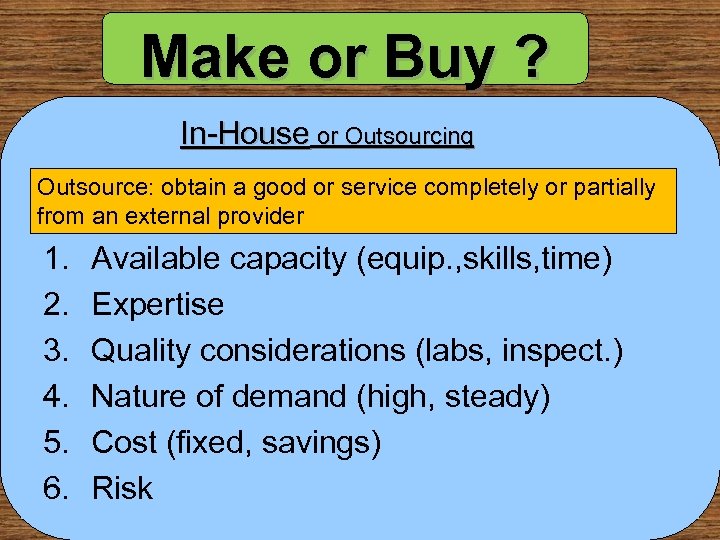

Make or Buy ? In-House or Outsourcing Outsource: obtain a good or service completely or partially from an external provider 1. 2. 3. 4. 5. 6. Available capacity (equip. , skills, time) Expertise Quality considerations (labs, inspect. ) Nature of demand (high, steady) Cost (fixed, savings) Risk

Make or Buy ? In-House or Outsourcing Outsource: obtain a good or service completely or partially from an external provider 1. 2. 3. 4. 5. 6. Available capacity (equip. , skills, time) Expertise Quality considerations (labs, inspect. ) Nature of demand (high, steady) Cost (fixed, savings) Risk

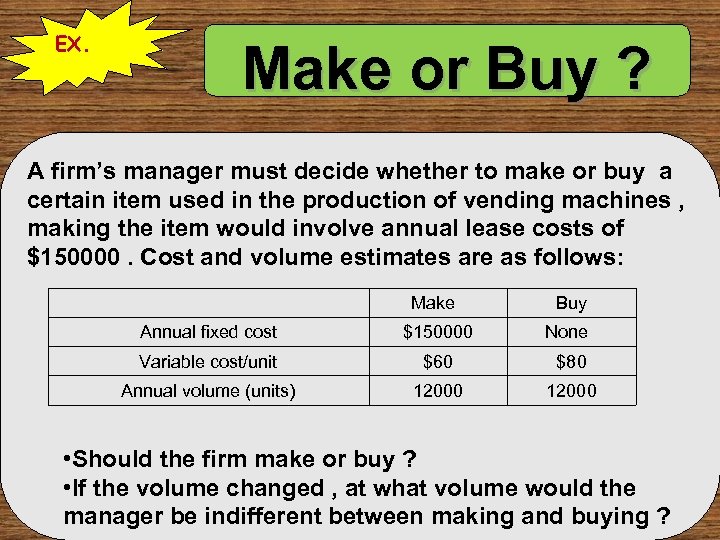

EX. Make or Buy ? A firm’s manager must decide whether to make or buy a certain item used in the production of vending machines , making the item would involve annual lease costs of $150000. Cost and volume estimates are as follows: Make Buy Annual fixed cost $150000 None Variable cost/unit $60 $80 Annual volume (units) 12000 • Should the firm make or buy ? • If the volume changed , at what volume would the manager be indifferent between making and buying ?

EX. Make or Buy ? A firm’s manager must decide whether to make or buy a certain item used in the production of vending machines , making the item would involve annual lease costs of $150000. Cost and volume estimates are as follows: Make Buy Annual fixed cost $150000 None Variable cost/unit $60 $80 Annual volume (units) 12000 • Should the firm make or buy ? • If the volume changed , at what volume would the manager be indifferent between making and buying ?

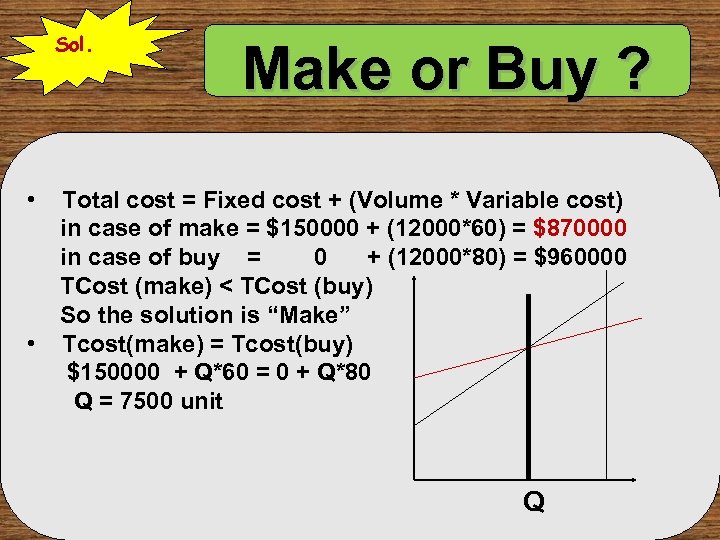

Sol. • • Make or Buy ? Total cost = Fixed cost + (Volume * Variable cost) in case of make = $150000 + (12000*60) = $870000 in case of buy = 0 + (12000*80) = $960000 TCost (make) < TCost (buy) So the solution is “Make” Tcost(make) = Tcost(buy) $150000 + Q*60 = 0 + Q*80 Q = 7500 unit Q

Sol. • • Make or Buy ? Total cost = Fixed cost + (Volume * Variable cost) in case of make = $150000 + (12000*60) = $870000 in case of buy = 0 + (12000*80) = $960000 TCost (make) < TCost (buy) So the solution is “Make” Tcost(make) = Tcost(buy) $150000 + Q*60 = 0 + Q*80 Q = 7500 unit Q

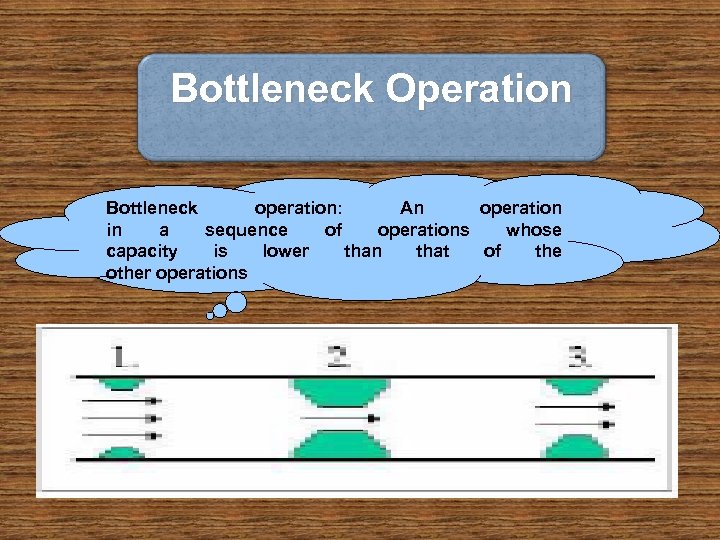

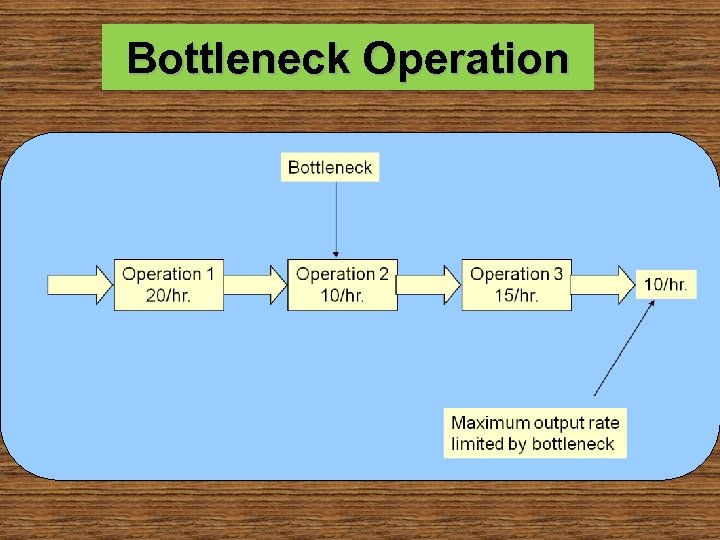

Bottleneck Operation Bottleneck operation: An operation in a sequence of operations whose capacity is lower than that of the other operations

Bottleneck Operation Bottleneck operation: An operation in a sequence of operations whose capacity is lower than that of the other operations

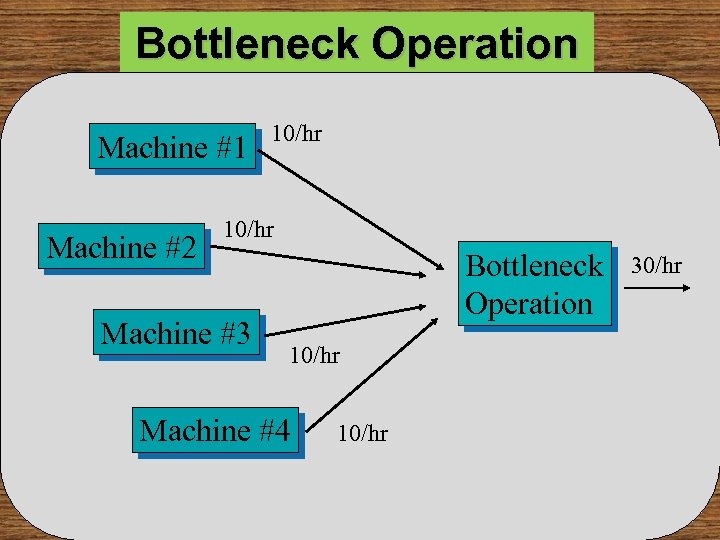

Bottleneck Operation Machine #1 Machine #2 10/hr Machine #3 Bottleneck Operation 10/hr Machine #4 10/hr 30/hr

Bottleneck Operation Machine #1 Machine #2 10/hr Machine #3 Bottleneck Operation 10/hr Machine #4 10/hr 30/hr

Bottleneck Operation

Bottleneck Operation

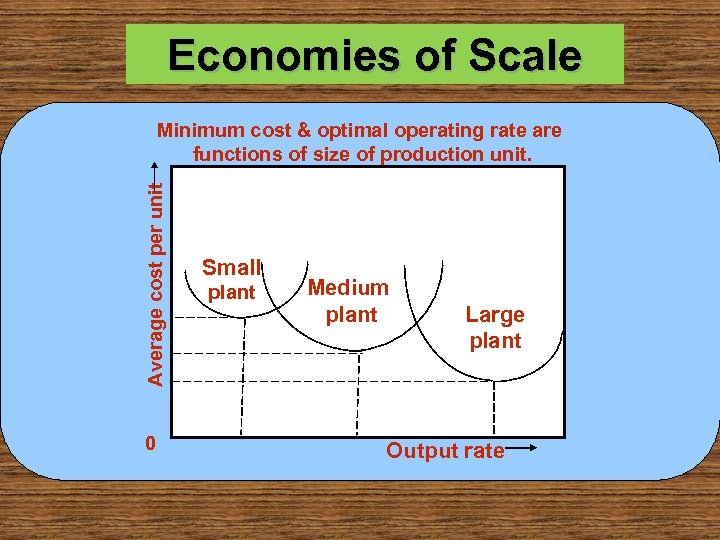

Economies of Scale Average cost per unit Minimum cost & optimal operating rate are functions of size of production unit. 0 Small plant Medium plant Large plant Output rate

Economies of Scale Average cost per unit Minimum cost & optimal operating rate are functions of size of production unit. 0 Small plant Medium plant Large plant Output rate