7ac0282b3e57a7f6911338335555fa5a.ppt

- Количество слайдов: 76

Chapter 4 Six Sigma for Process and Quality Improvement Chapter 4: Six Sigma for Process and Quality Improvement 1

Chapter 4 Six Sigma for Process and Quality Improvement Chapter 4: Six Sigma for Process and Quality Improvement 1

Quality Management and Six Sigma in Perspective n Two primary sets of costs are involved in quality: ¡ ¡ n control costs failure costs Costs broken into four categories: ¡ ¡ Prevention costs Appraisal costs Internal costs of defects External costs of defects Chapter 4: Six Sigma for Process and Quality Improvement 2

Quality Management and Six Sigma in Perspective n Two primary sets of costs are involved in quality: ¡ ¡ n control costs failure costs Costs broken into four categories: ¡ ¡ Prevention costs Appraisal costs Internal costs of defects External costs of defects Chapter 4: Six Sigma for Process and Quality Improvement 2

Japanese Approaches to Quality n In 1950 the Japanese government invited W. Edwards Deming (then a professor at New York University) to give a series of lectures on quality control to help Japanese engineers reindustrialize the country. Chapter 4: Six Sigma for Process and Quality Improvement 3

Japanese Approaches to Quality n In 1950 the Japanese government invited W. Edwards Deming (then a professor at New York University) to give a series of lectures on quality control to help Japanese engineers reindustrialize the country. Chapter 4: Six Sigma for Process and Quality Improvement 3

W. Edwards Deming n n n Major source of poor quality is variation Quality improvement the responsibility of top management All employees should be trained in use of problem solving tools and especially statistical techniques Chapter 4: Six Sigma for Process and Quality Improvement 4

W. Edwards Deming n n n Major source of poor quality is variation Quality improvement the responsibility of top management All employees should be trained in use of problem solving tools and especially statistical techniques Chapter 4: Six Sigma for Process and Quality Improvement 4

Deming’s 14 Points 1. 2. 3. 4. Create constancy of purpose Adopt the new philosophy Cease dependence on mass inspection End practice of awarding business on basis of price tags 5. Improve constantly and forever 6. Institute modern methods of training Chapter 4: Six Sigma for Process and Quality Improvement 5

Deming’s 14 Points 1. 2. 3. 4. Create constancy of purpose Adopt the new philosophy Cease dependence on mass inspection End practice of awarding business on basis of price tags 5. Improve constantly and forever 6. Institute modern methods of training Chapter 4: Six Sigma for Process and Quality Improvement 5

Deming’s 14 Points continued 7. Institute modern method of supervision 8. Drive out fear 9. Breakdown organizational barriers 10. Eliminate arbitrary numerical goals 11. Eliminate work standards and quotas 12. Remove barriers that reduce pride of workmanship Chapter 4: Six Sigma for Process and Quality Improvement 6

Deming’s 14 Points continued 7. Institute modern method of supervision 8. Drive out fear 9. Breakdown organizational barriers 10. Eliminate arbitrary numerical goals 11. Eliminate work standards and quotas 12. Remove barriers that reduce pride of workmanship Chapter 4: Six Sigma for Process and Quality Improvement 6

Deming’s 14 Points continued 13. Institute a vigorous program of education and training 14. Push the 13 points everyday Chapter 4: Six Sigma for Process and Quality Improvement 7

Deming’s 14 Points continued 13. Institute a vigorous program of education and training 14. Push the 13 points everyday Chapter 4: Six Sigma for Process and Quality Improvement 7

Total Quality Management (TQM) n n Better to produce item right the first time than to try to inspect quality in Quality at the source - responsibility shifted from quality control department to workers Chapter 4: Six Sigma for Process and Quality Improvement 8

Total Quality Management (TQM) n n Better to produce item right the first time than to try to inspect quality in Quality at the source - responsibility shifted from quality control department to workers Chapter 4: Six Sigma for Process and Quality Improvement 8

History of TQM n n Dr. Shewart began using statistical control at the Bell Institute in 1930 s Military standards developed in 1950 s After World War II, Japanese Union of Scientist and Engineers began consulting with Deming Prize introduced in Japan in 1951 Chapter 4: Six Sigma for Process and Quality Improvement 9

History of TQM n n Dr. Shewart began using statistical control at the Bell Institute in 1930 s Military standards developed in 1950 s After World War II, Japanese Union of Scientist and Engineers began consulting with Deming Prize introduced in Japan in 1951 Chapter 4: Six Sigma for Process and Quality Improvement 9

History of TQM n n n n continued Quality assurance concept proposed in 1952 Juran makes first trip to Japan in 1954 Quality becomes Japan’s national slogan in 1956 First quality circles created in 1957 10, 000 quality circles by 1966 100, 000 quality circles by 1977 First U. S. quality circle 1974 Chapter 4: Six Sigma for Process and Quality Improvement 10

History of TQM n n n n continued Quality assurance concept proposed in 1952 Juran makes first trip to Japan in 1954 Quality becomes Japan’s national slogan in 1956 First quality circles created in 1957 10, 000 quality circles by 1966 100, 000 quality circles by 1977 First U. S. quality circle 1974 Chapter 4: Six Sigma for Process and Quality Improvement 10

Five Steps in TQM n n n Determine what customers want Develop products and services Develop production system Monitor the system Include customers and suppliers Chapter 4: Six Sigma for Process and Quality Improvement 11

Five Steps in TQM n n n Determine what customers want Develop products and services Develop production system Monitor the system Include customers and suppliers Chapter 4: Six Sigma for Process and Quality Improvement 11

Joseph Juran n Quality Control Handbook (1951) Employees speak in different languages Quality Trilogy ¡ ¡ ¡ n Quality Planning Quality Control Quality Improvement Need to place more emphasis on planning and improvement Chapter 4: Six Sigma for Process and Quality Improvement 12

Joseph Juran n Quality Control Handbook (1951) Employees speak in different languages Quality Trilogy ¡ ¡ ¡ n Quality Planning Quality Control Quality Improvement Need to place more emphasis on planning and improvement Chapter 4: Six Sigma for Process and Quality Improvement 12

Joseph Juran n continued Organizations progress through four phases ¡ ¡ Minimize prevention and appraisal costs Appraisal costs increased Process control introduced increasing appraisal costs but lowering internal and external failure costs Prevention costs increased in effort to lower total quality costs Chapter 4: Six Sigma for Process and Quality Improvement 13

Joseph Juran n continued Organizations progress through four phases ¡ ¡ Minimize prevention and appraisal costs Appraisal costs increased Process control introduced increasing appraisal costs but lowering internal and external failure costs Prevention costs increased in effort to lower total quality costs Chapter 4: Six Sigma for Process and Quality Improvement 13

A Brief History of Six Sigma n n n The Six Sigma concept was developed by Bill Smith, a senior engineer at Motorola, in 1986 as a way to standardize the way defects were tallied. Sigma is the Greek symbol used in statistics to refer to standard deviation which is a measure of variation. Adding “six” to “sigma” combines a measure of process performance (sigma) with the goal of nearly perfect quality (six). Chapter 4: Six Sigma for Process and Quality Improvement 14

A Brief History of Six Sigma n n n The Six Sigma concept was developed by Bill Smith, a senior engineer at Motorola, in 1986 as a way to standardize the way defects were tallied. Sigma is the Greek symbol used in statistics to refer to standard deviation which is a measure of variation. Adding “six” to “sigma” combines a measure of process performance (sigma) with the goal of nearly perfect quality (six). Chapter 4: Six Sigma for Process and Quality Improvement 14

A Brief History of Six Sigma continued n In the popular book The Six Sigma Way, Six Sigma is defined as: ¡ a comprehensive and flexible system for achieving, sustaining and maximizing business success. Six Sigma is uniquely driven by close understanding of customer needs, disciplined use of facts, data, and statistical analysis, and diligent attention to managing, improving, and reinventing business processes. (p. xi) Chapter 4: Six Sigma for Process and Quality Improvement 15

A Brief History of Six Sigma continued n In the popular book The Six Sigma Way, Six Sigma is defined as: ¡ a comprehensive and flexible system for achieving, sustaining and maximizing business success. Six Sigma is uniquely driven by close understanding of customer needs, disciplined use of facts, data, and statistical analysis, and diligent attention to managing, improving, and reinventing business processes. (p. xi) Chapter 4: Six Sigma for Process and Quality Improvement 15

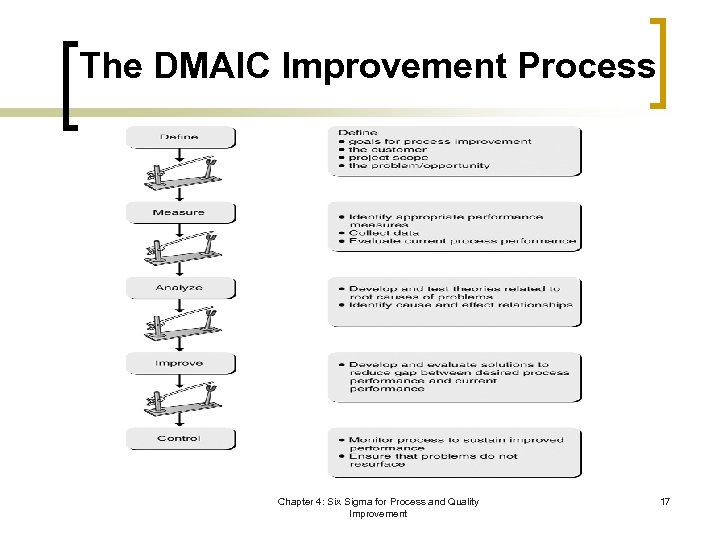

The DMAIC Improvement Process n Six Sigma projects generally follow a well defined process consisting of five phases. define ¡ measure ¡ analyze ¡ improve ¡ control pronounced dey-MAY-ihk ¡ Chapter 4: Six Sigma for Process and Quality Improvement 16

The DMAIC Improvement Process n Six Sigma projects generally follow a well defined process consisting of five phases. define ¡ measure ¡ analyze ¡ improve ¡ control pronounced dey-MAY-ihk ¡ Chapter 4: Six Sigma for Process and Quality Improvement 16

The DMAIC Improvement Process Chapter 4: Six Sigma for Process and Quality Improvement 17

The DMAIC Improvement Process Chapter 4: Six Sigma for Process and Quality Improvement 17

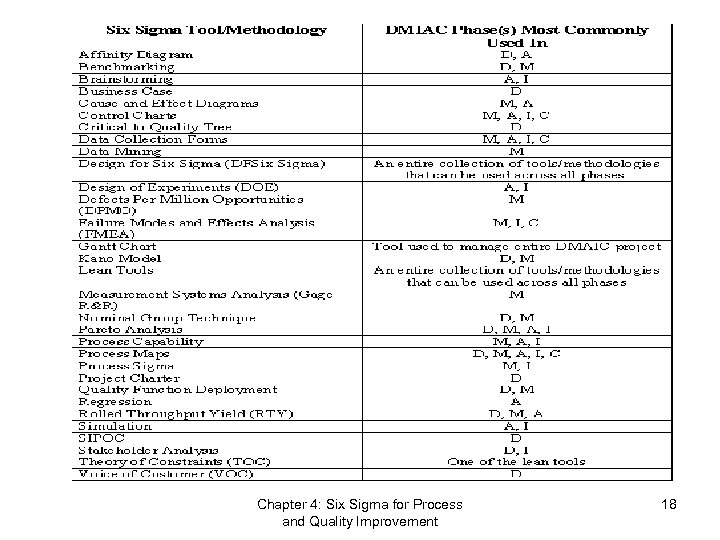

Chapter 4: Six Sigma for Process and Quality Improvement 18

Chapter 4: Six Sigma for Process and Quality Improvement 18

The Define Phase n The define phase of a DMAIC project focuses on clearly specifying the problem or opportunity, what the goals are for the process improvement project, and what the scope of the project is. Identifying who the customer is and their requirements is also critical given that the overarching goal for all Six Sigma projects is improving the organization’s ability to meet the needs of its customers. Chapter 4: Six Sigma for Process and Quality Improvement 19

The Define Phase n The define phase of a DMAIC project focuses on clearly specifying the problem or opportunity, what the goals are for the process improvement project, and what the scope of the project is. Identifying who the customer is and their requirements is also critical given that the overarching goal for all Six Sigma projects is improving the organization’s ability to meet the needs of its customers. Chapter 4: Six Sigma for Process and Quality Improvement 19

Defining and Measuring Quality n n n Conformance to specifications Performance Quick response Quick-change expertise Features Reliability Durability Serviceability Aesthetics Perceived quality Humanity Value Chapter 4: Six Sigma for Process and Quality Improvement 20

Defining and Measuring Quality n n n Conformance to specifications Performance Quick response Quick-change expertise Features Reliability Durability Serviceability Aesthetics Perceived quality Humanity Value Chapter 4: Six Sigma for Process and Quality Improvement 20

Benchmarking n Benchmarking involves comparing an organization's processes with the best practices to be found. Benchmarking is used for a variety of purposes, including: ¡ ¡ Comparing an organization's processes with the best organization's processes. Comparing an organization's products and services with those of other organizations. Chapter 4: Six Sigma for Process and Quality Improvement 21

Benchmarking n Benchmarking involves comparing an organization's processes with the best practices to be found. Benchmarking is used for a variety of purposes, including: ¡ ¡ Comparing an organization's processes with the best organization's processes. Comparing an organization's products and services with those of other organizations. Chapter 4: Six Sigma for Process and Quality Improvement 21

Benchmarking continued n n Identifying the best practices to implement. Projecting trends in order to be able to respond proactively to future challenges and opportunities. Chapter 4: Six Sigma for Process and Quality Improvement 22

Benchmarking continued n n Identifying the best practices to implement. Projecting trends in order to be able to respond proactively to future challenges and opportunities. Chapter 4: Six Sigma for Process and Quality Improvement 22

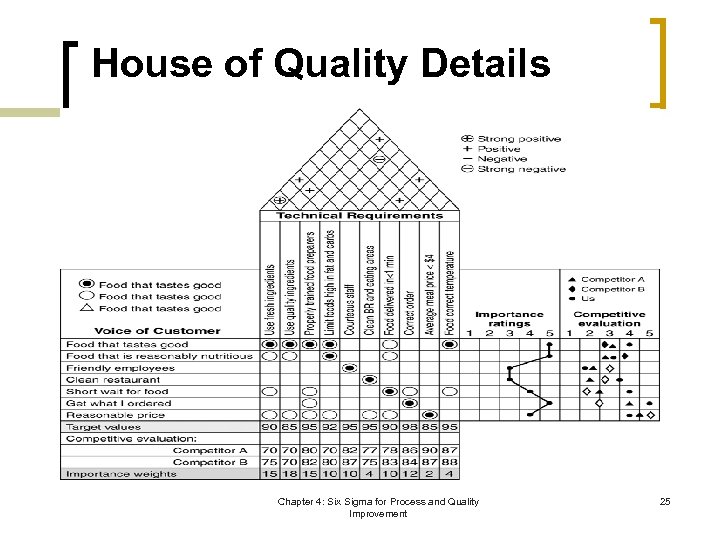

Quality Function Deployment (QFD) n n Two key drivers of an organization’s longterm competitive success are the extent to which its new products or services meet customers’ needs, and having the organizational capabilities to develop and deliver such new products and services. Tools for helping translate customer desires directly into product service attributes. Chapter 4: Six Sigma for Process and Quality Improvement 23

Quality Function Deployment (QFD) n n Two key drivers of an organization’s longterm competitive success are the extent to which its new products or services meet customers’ needs, and having the organizational capabilities to develop and deliver such new products and services. Tools for helping translate customer desires directly into product service attributes. Chapter 4: Six Sigma for Process and Quality Improvement 23

Four Houses of Quality n n Customer requirements Technical requirements Component requirements Process deployment requirements Chapter 4: Six Sigma for Process and Quality Improvement 24

Four Houses of Quality n n Customer requirements Technical requirements Component requirements Process deployment requirements Chapter 4: Six Sigma for Process and Quality Improvement 24

House of Quality Details Chapter 4: Six Sigma for Process and Quality Improvement 25

House of Quality Details Chapter 4: Six Sigma for Process and Quality Improvement 25

The Measure Phase n n n The measure phase begins with the identification of the key process performance metrics. Once the key process performance metrics have been specified, related process and customer data is collected. Two commonly used process performance measures, namely, Defects per Million Opportunities (DPMO) and Process Sigma. Chapter 4: Six Sigma for Process and Quality Improvement 26

The Measure Phase n n n The measure phase begins with the identification of the key process performance metrics. Once the key process performance metrics have been specified, related process and customer data is collected. Two commonly used process performance measures, namely, Defects per Million Opportunities (DPMO) and Process Sigma. Chapter 4: Six Sigma for Process and Quality Improvement 26

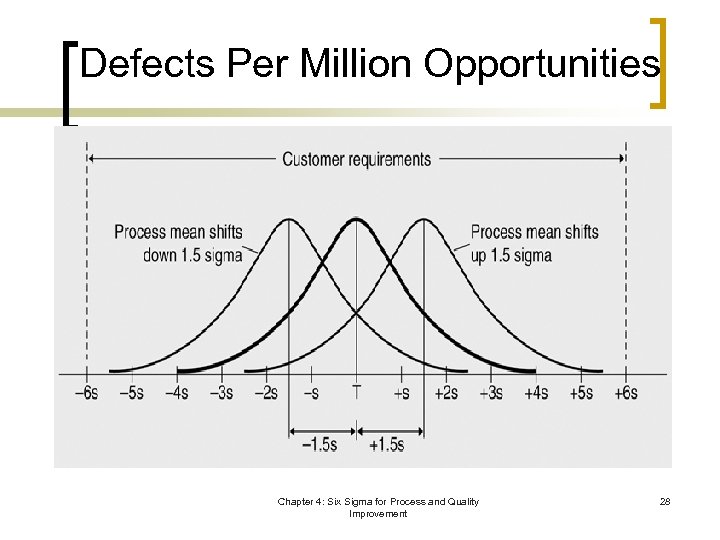

Defects Per Million Opportunities n Earlier it was noted that a literal interpretation of Six Sigma is 3. 4 defects per million opportunities (DPMO). This may have caused some confusion for more statistically inclined readers, which we shall now attempt to reconcile. Chapter 4: Six Sigma for Process and Quality Improvement 27

Defects Per Million Opportunities n Earlier it was noted that a literal interpretation of Six Sigma is 3. 4 defects per million opportunities (DPMO). This may have caused some confusion for more statistically inclined readers, which we shall now attempt to reconcile. Chapter 4: Six Sigma for Process and Quality Improvement 27

Defects Per Million Opportunities Chapter 4: Six Sigma for Process and Quality Improvement 28

Defects Per Million Opportunities Chapter 4: Six Sigma for Process and Quality Improvement 28

Process Sigma n How sigma itself can be used to measure the performance of a process. ¡ One way to measure the performance of a process is to calculate the number of standard deviations the customer requirements are from the process mean or target value. Chapter 4: Six Sigma for Process and Quality Improvement 29

Process Sigma n How sigma itself can be used to measure the performance of a process. ¡ One way to measure the performance of a process is to calculate the number of standard deviations the customer requirements are from the process mean or target value. Chapter 4: Six Sigma for Process and Quality Improvement 29

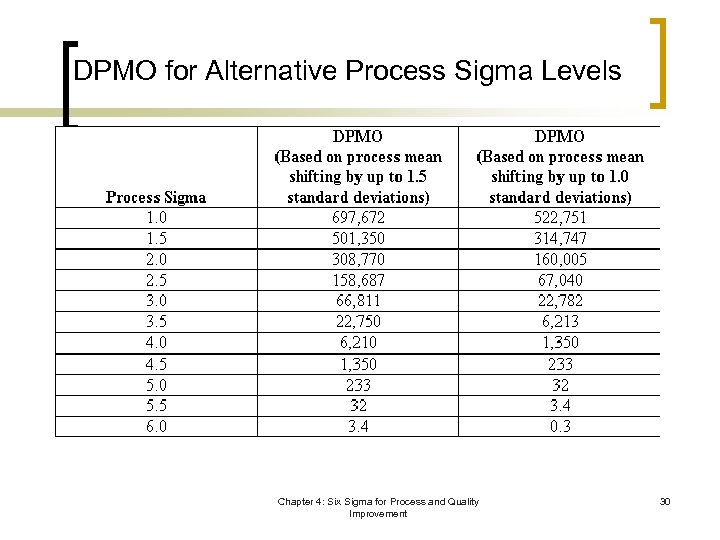

DPMO for Alternative Process Sigma Levels Chapter 4: Six Sigma for Process and Quality Improvement 30

DPMO for Alternative Process Sigma Levels Chapter 4: Six Sigma for Process and Quality Improvement 30

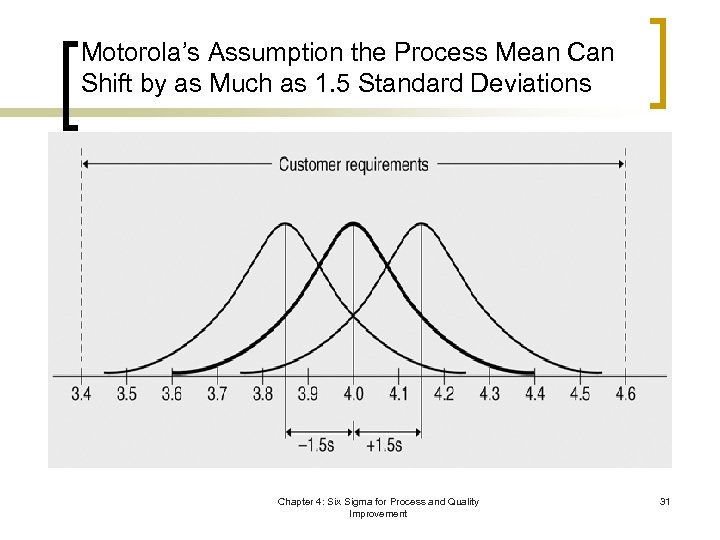

Motorola’s Assumption the Process Mean Can Shift by as Much as 1. 5 Standard Deviations Chapter 4: Six Sigma for Process and Quality Improvement 31

Motorola’s Assumption the Process Mean Can Shift by as Much as 1. 5 Standard Deviations Chapter 4: Six Sigma for Process and Quality Improvement 31

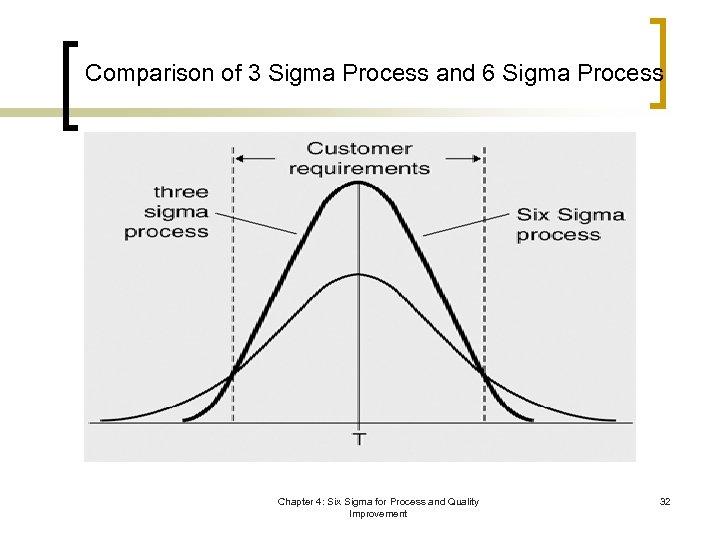

Comparison of 3 Sigma Process and 6 Sigma Process Chapter 4: Six Sigma for Process and Quality Improvement 32

Comparison of 3 Sigma Process and 6 Sigma Process Chapter 4: Six Sigma for Process and Quality Improvement 32

The Analyze Phase n n In this phase our objective is to utilize the data that has been collected to develop and test theories related to the root causes of existing gaps between the process’ current performance and its desired performance. See next slide Table 4. 3 Common tools and methodologies in the Six Sigma toolset. Chapter 4: Six Sigma for Process and Quality Improvement 33

The Analyze Phase n n In this phase our objective is to utilize the data that has been collected to develop and test theories related to the root causes of existing gaps between the process’ current performance and its desired performance. See next slide Table 4. 3 Common tools and methodologies in the Six Sigma toolset. Chapter 4: Six Sigma for Process and Quality Improvement 33

Brainstorming n The brainstorming approach: ¡ ¡ Do not criticize ideas during the brainstorming session. Express all ideas no matter how radical, bizarre, unconventional, ridiculous, or impractical they may seem. Generate as many ideas as possible. Combine, extend, and/or improve on one another’s ideas. Chapter 4: Six Sigma for Process and Quality Improvement 34

Brainstorming n The brainstorming approach: ¡ ¡ Do not criticize ideas during the brainstorming session. Express all ideas no matter how radical, bizarre, unconventional, ridiculous, or impractical they may seem. Generate as many ideas as possible. Combine, extend, and/or improve on one another’s ideas. Chapter 4: Six Sigma for Process and Quality Improvement 34

Brainstorming: Actions to Enhance Team Creativity n n n n n Create diversified teams. Use analogical reasoning. Use brain writing. Use the Nominal Group Technique. Record team ideas. Use trained facilitators to run the brainstorming session. Set high standards. Change the composition of the team. Use electronic brainstorming. Make the workplace a playground. Chapter 4: Six Sigma for Process and Quality Improvement 35

Brainstorming: Actions to Enhance Team Creativity n n n n n Create diversified teams. Use analogical reasoning. Use brain writing. Use the Nominal Group Technique. Record team ideas. Use trained facilitators to run the brainstorming session. Set high standards. Change the composition of the team. Use electronic brainstorming. Make the workplace a playground. Chapter 4: Six Sigma for Process and Quality Improvement 35

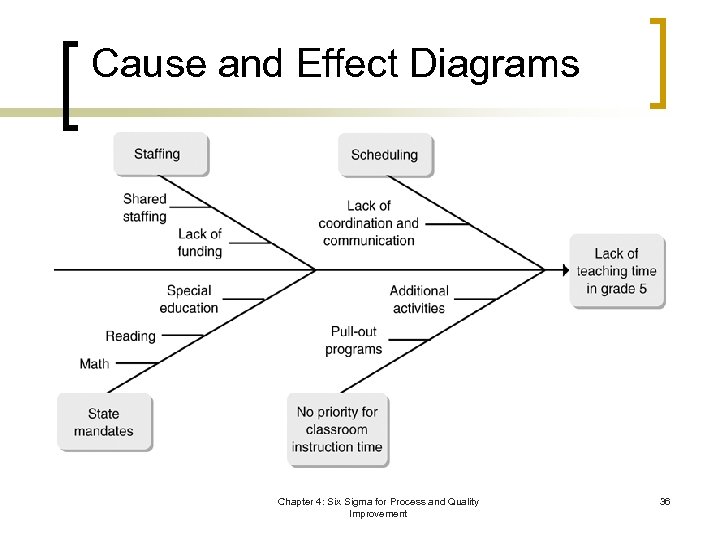

Cause and Effect Diagrams Chapter 4: Six Sigma for Process and Quality Improvement 36

Cause and Effect Diagrams Chapter 4: Six Sigma for Process and Quality Improvement 36

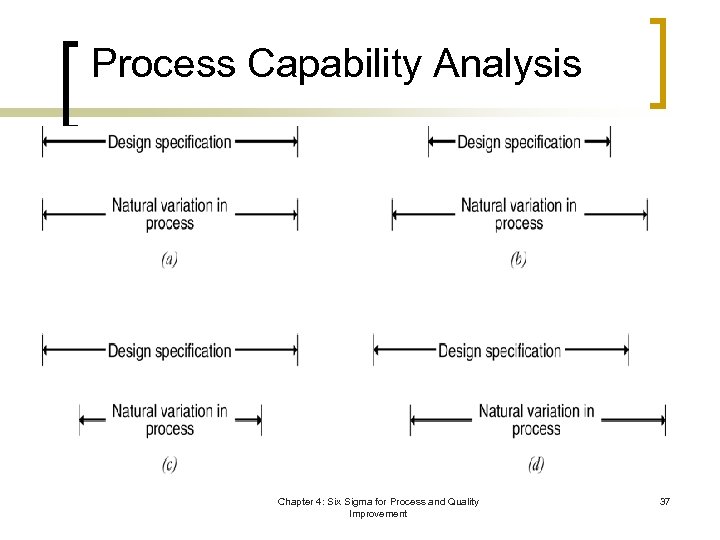

Process Capability Analysis Chapter 4: Six Sigma for Process and Quality Improvement 37

Process Capability Analysis Chapter 4: Six Sigma for Process and Quality Improvement 37

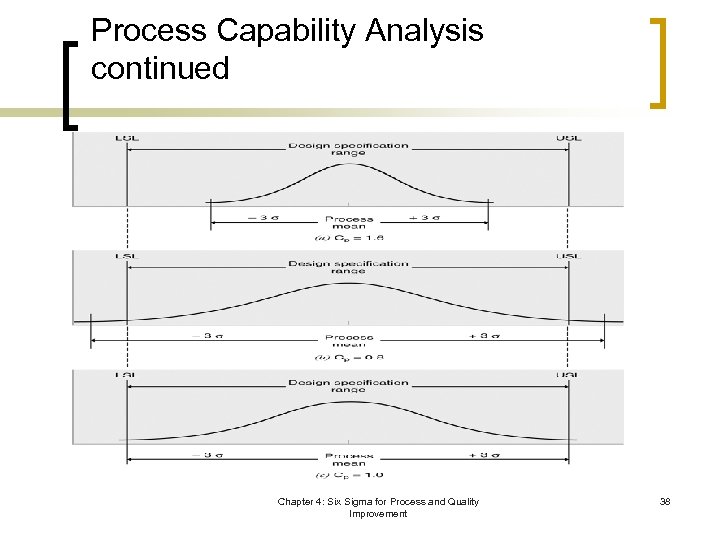

Process Capability Analysis continued Chapter 4: Six Sigma for Process and Quality Improvement 38

Process Capability Analysis continued Chapter 4: Six Sigma for Process and Quality Improvement 38

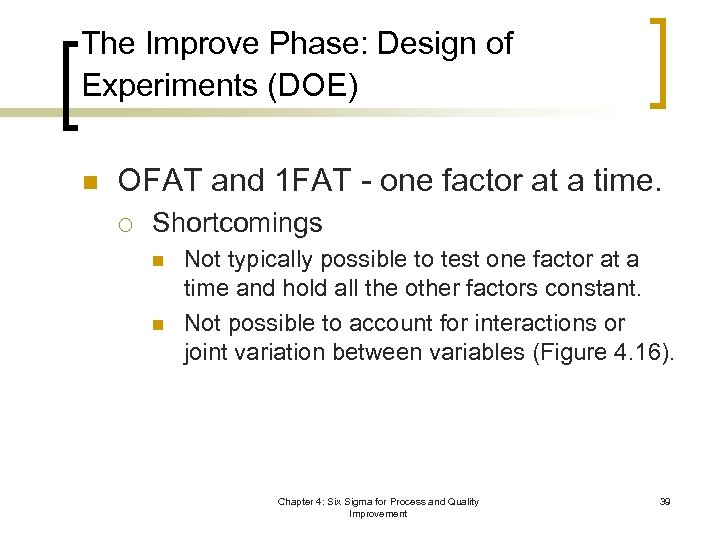

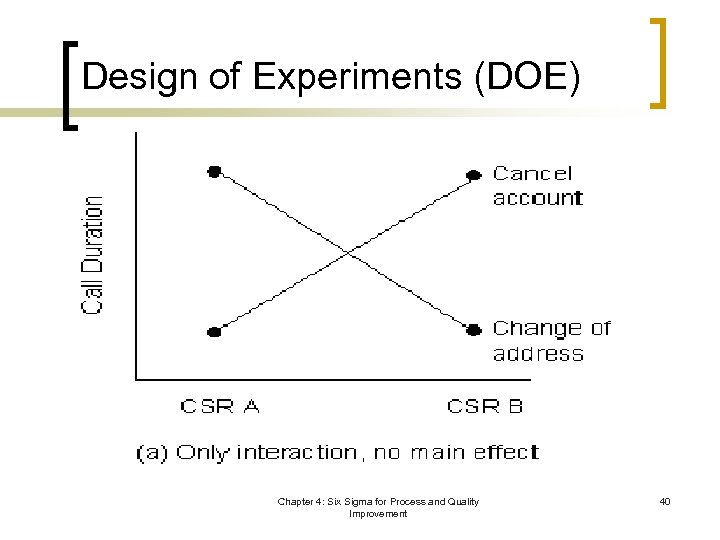

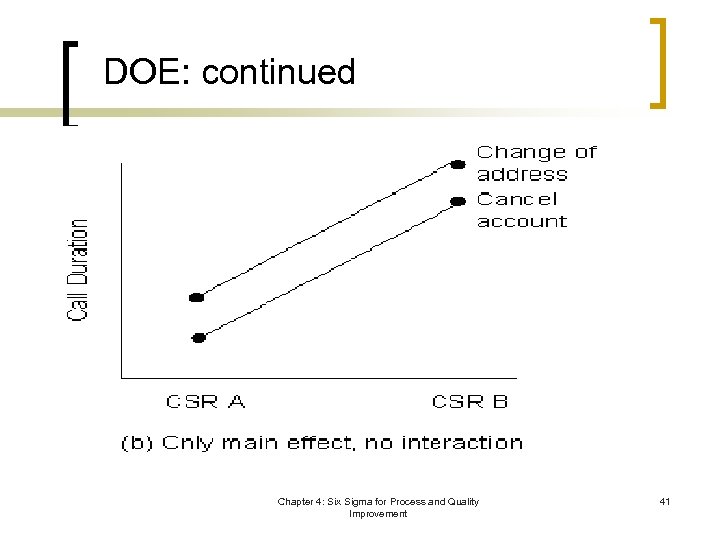

The Improve Phase: Design of Experiments (DOE) n OFAT and 1 FAT - one factor at a time. ¡ Shortcomings n n Not typically possible to test one factor at a time and hold all the other factors constant. Not possible to account for interactions or joint variation between variables (Figure 4. 16). Chapter 4: Six Sigma for Process and Quality Improvement 39

The Improve Phase: Design of Experiments (DOE) n OFAT and 1 FAT - one factor at a time. ¡ Shortcomings n n Not typically possible to test one factor at a time and hold all the other factors constant. Not possible to account for interactions or joint variation between variables (Figure 4. 16). Chapter 4: Six Sigma for Process and Quality Improvement 39

Design of Experiments (DOE) Chapter 4: Six Sigma for Process and Quality Improvement 40

Design of Experiments (DOE) Chapter 4: Six Sigma for Process and Quality Improvement 40

DOE: continued Chapter 4: Six Sigma for Process and Quality Improvement 41

DOE: continued Chapter 4: Six Sigma for Process and Quality Improvement 41

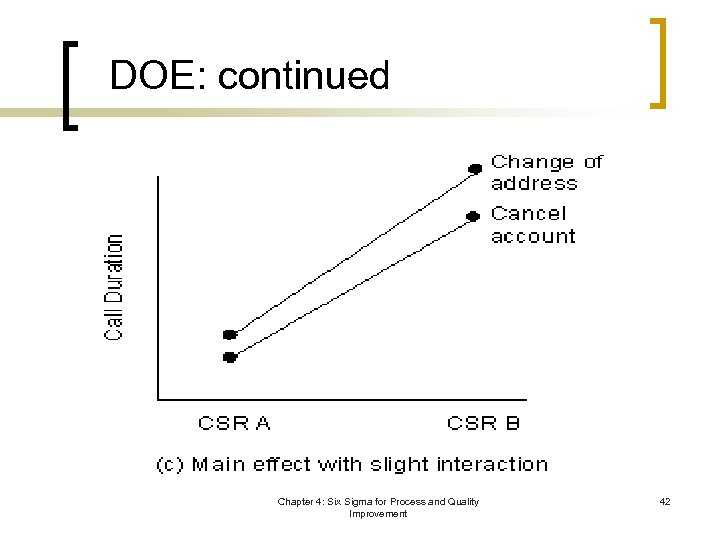

DOE: continued Chapter 4: Six Sigma for Process and Quality Improvement 42

DOE: continued Chapter 4: Six Sigma for Process and Quality Improvement 42

DOE continued n Some of the major considerations associated with DOE include: ¡ ¡ Determining which factors to include in the experiment. Specifying the levels for each factor. Determining how much data to collect. Determining the type of experimental design. Chapter 4: Six Sigma for Process and Quality Improvement 43

DOE continued n Some of the major considerations associated with DOE include: ¡ ¡ Determining which factors to include in the experiment. Specifying the levels for each factor. Determining how much data to collect. Determining the type of experimental design. Chapter 4: Six Sigma for Process and Quality Improvement 43

Taguchi Methods n n Design for Manufacturability (DFM) Procedure for statistical testing to determine best combination of product and transformation system design that will make output relatively independent of normal fluctuations in the production system Chapter 4: Six Sigma for Process and Quality Improvement 44

Taguchi Methods n n Design for Manufacturability (DFM) Procedure for statistical testing to determine best combination of product and transformation system design that will make output relatively independent of normal fluctuations in the production system Chapter 4: Six Sigma for Process and Quality Improvement 44

Statistical Quality Control Chapter 4: Six Sigma for Process and Quality Improvement 45

Statistical Quality Control Chapter 4: Six Sigma for Process and Quality Improvement 45

Chance Versus Assignable Variation n Chance variation is variability built into the system. Assignable variation occurs because some element of the system or some operating condition is out of control. Quality control seeks to identify when assignable variation is present so that corrective action can be taken. Chapter 4: Six Sigma for Process and Quality Improvement 46

Chance Versus Assignable Variation n Chance variation is variability built into the system. Assignable variation occurs because some element of the system or some operating condition is out of control. Quality control seeks to identify when assignable variation is present so that corrective action can be taken. Chapter 4: Six Sigma for Process and Quality Improvement 46

Control Based on Attributes and Variables n n Inspection for Variables: measuring a variable that can be scaled such as weight, length, temperature, and diameter. Inspection of Attributes: determining the existence of a characteristic such as acceptable-defective, timely-late, and right-wrong. Chapter 4: Six Sigma for Process and Quality Improvement 47

Control Based on Attributes and Variables n n Inspection for Variables: measuring a variable that can be scaled such as weight, length, temperature, and diameter. Inspection of Attributes: determining the existence of a characteristic such as acceptable-defective, timely-late, and right-wrong. Chapter 4: Six Sigma for Process and Quality Improvement 47

Control Charts Chapter 4: Six Sigma for Process and Quality Improvement 48

Control Charts Chapter 4: Six Sigma for Process and Quality Improvement 48

Control Charts n Developed in 1920 s to distinguish between chance variation in a system and variation caused by the system’s being out of control - assignable variation. Chapter 4: Six Sigma for Process and Quality Improvement 49

Control Charts n Developed in 1920 s to distinguish between chance variation in a system and variation caused by the system’s being out of control - assignable variation. Chapter 4: Six Sigma for Process and Quality Improvement 49

Control Charts continued n n Repetitive operation will not produce exactly the same outputs. Pattern of variability often described by normal distribution. Random samples that fully represent the population being checked are taken. Sample data plotted on control charts to determine if the process is still under control. Chapter 4: Six Sigma for Process and Quality Improvement 50

Control Charts continued n n Repetitive operation will not produce exactly the same outputs. Pattern of variability often described by normal distribution. Random samples that fully represent the population being checked are taken. Sample data plotted on control charts to determine if the process is still under control. Chapter 4: Six Sigma for Process and Quality Improvement 50

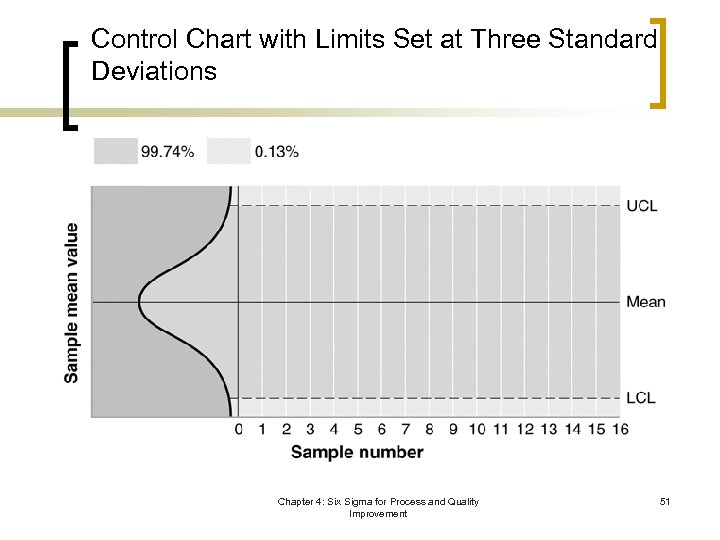

Control Chart with Limits Set at Three Standard Deviations Chapter 4: Six Sigma for Process and Quality Improvement 51

Control Chart with Limits Set at Three Standard Deviations Chapter 4: Six Sigma for Process and Quality Improvement 51

Control Charts for Variables Chapter 4: Six Sigma for Process and Quality Improvement 52

Control Charts for Variables Chapter 4: Six Sigma for Process and Quality Improvement 52

Two Control Charts n n Sample Means Chart Range Chart Chapter 4: Six Sigma for Process and Quality Improvement 53

Two Control Charts n n Sample Means Chart Range Chart Chapter 4: Six Sigma for Process and Quality Improvement 53

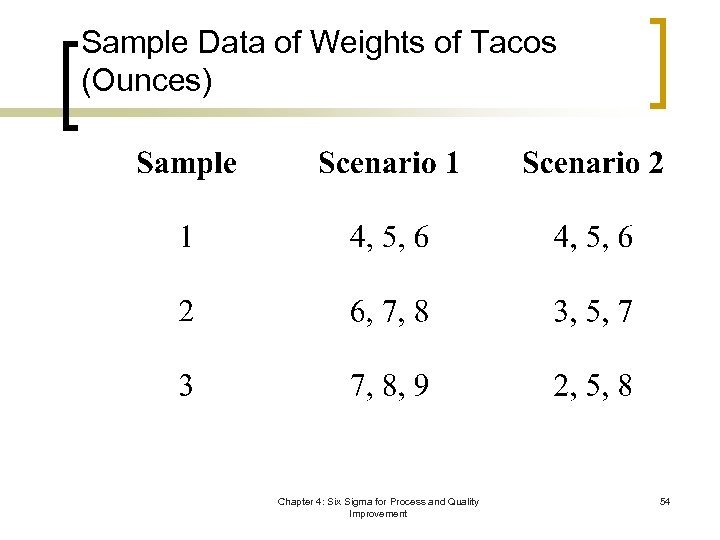

Sample Data of Weights of Tacos (Ounces) Chapter 4: Six Sigma for Process and Quality Improvement 54

Sample Data of Weights of Tacos (Ounces) Chapter 4: Six Sigma for Process and Quality Improvement 54

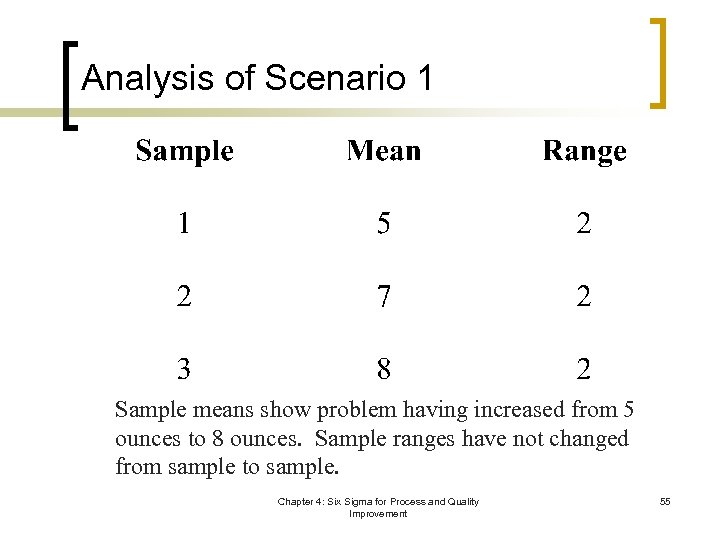

Analysis of Scenario 1 Sample means show problem having increased from 5 ounces to 8 ounces. Sample ranges have not changed from sample to sample. Chapter 4: Six Sigma for Process and Quality Improvement 55

Analysis of Scenario 1 Sample means show problem having increased from 5 ounces to 8 ounces. Sample ranges have not changed from sample to sample. Chapter 4: Six Sigma for Process and Quality Improvement 55

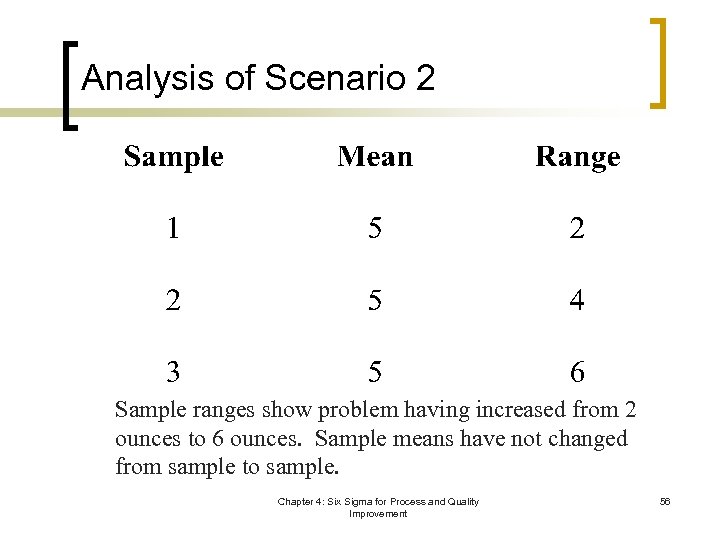

Analysis of Scenario 2 Sample ranges show problem having increased from 2 ounces to 6 ounces. Sample means have not changed from sample to sample. Chapter 4: Six Sigma for Process and Quality Improvement 56

Analysis of Scenario 2 Sample ranges show problem having increased from 2 ounces to 6 ounces. Sample means have not changed from sample to sample. Chapter 4: Six Sigma for Process and Quality Improvement 56

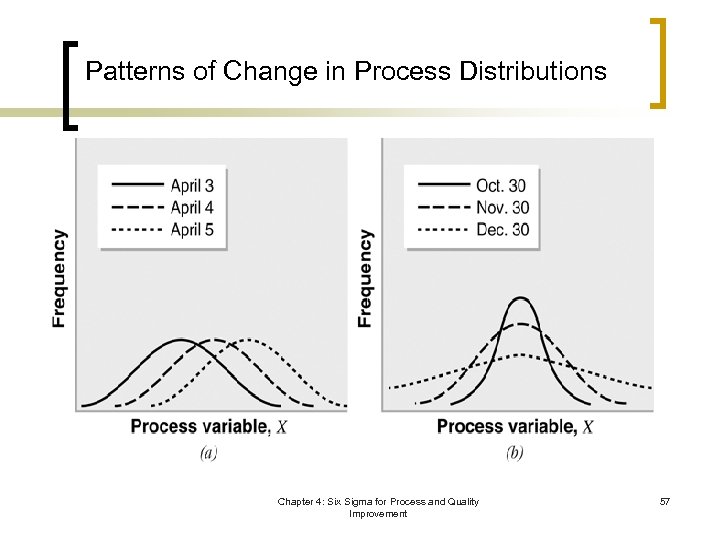

Patterns of Change in Process Distributions Chapter 4: Six Sigma for Process and Quality Improvement 57

Patterns of Change in Process Distributions Chapter 4: Six Sigma for Process and Quality Improvement 57

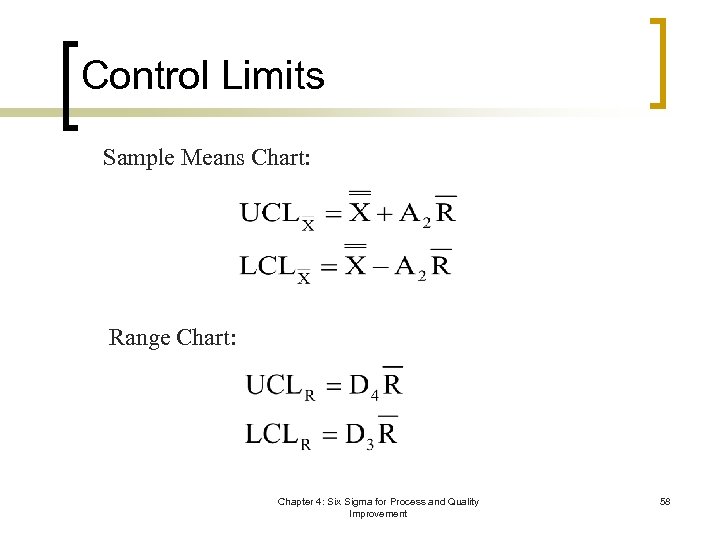

Control Limits Sample Means Chart: Range Chart: Chapter 4: Six Sigma for Process and Quality Improvement 58

Control Limits Sample Means Chart: Range Chart: Chapter 4: Six Sigma for Process and Quality Improvement 58

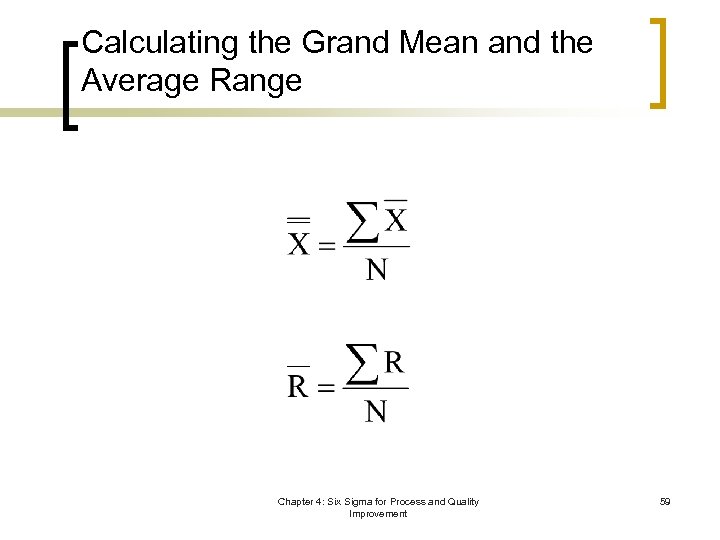

Calculating the Grand Mean and the Average Range Chapter 4: Six Sigma for Process and Quality Improvement 59

Calculating the Grand Mean and the Average Range Chapter 4: Six Sigma for Process and Quality Improvement 59

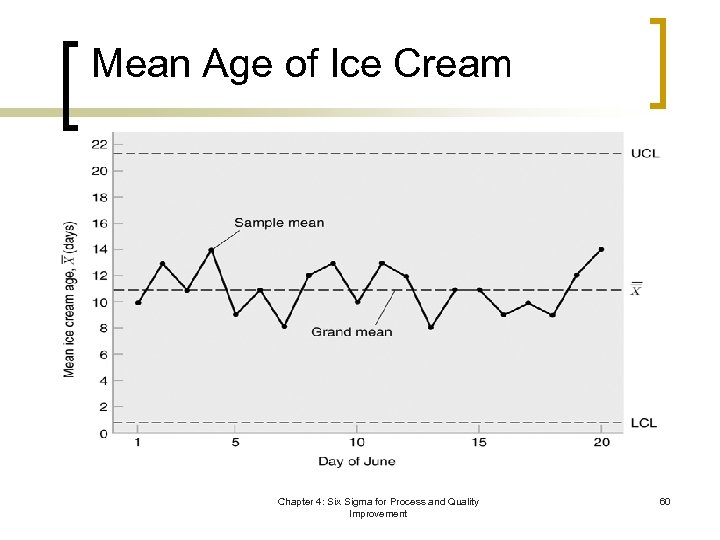

Mean Age of Ice Cream Chapter 4: Six Sigma for Process and Quality Improvement 60

Mean Age of Ice Cream Chapter 4: Six Sigma for Process and Quality Improvement 60

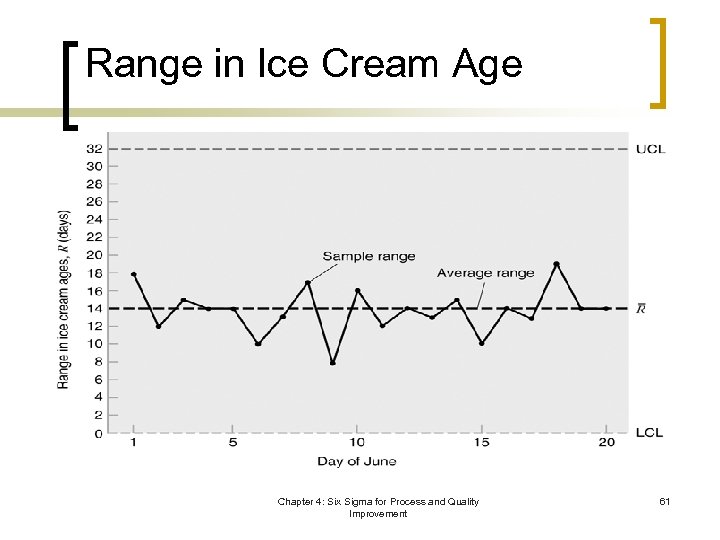

Range in Ice Cream Age Chapter 4: Six Sigma for Process and Quality Improvement 61

Range in Ice Cream Age Chapter 4: Six Sigma for Process and Quality Improvement 61

Control Charts for Attributes Chapter 4: Six Sigma for Process and Quality Improvement 62

Control Charts for Attributes Chapter 4: Six Sigma for Process and Quality Improvement 62

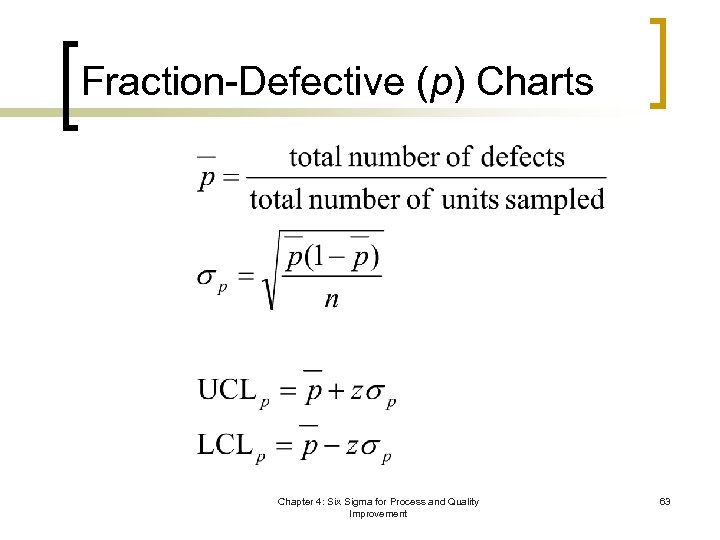

Fraction-Defective (p) Charts Chapter 4: Six Sigma for Process and Quality Improvement 63

Fraction-Defective (p) Charts Chapter 4: Six Sigma for Process and Quality Improvement 63

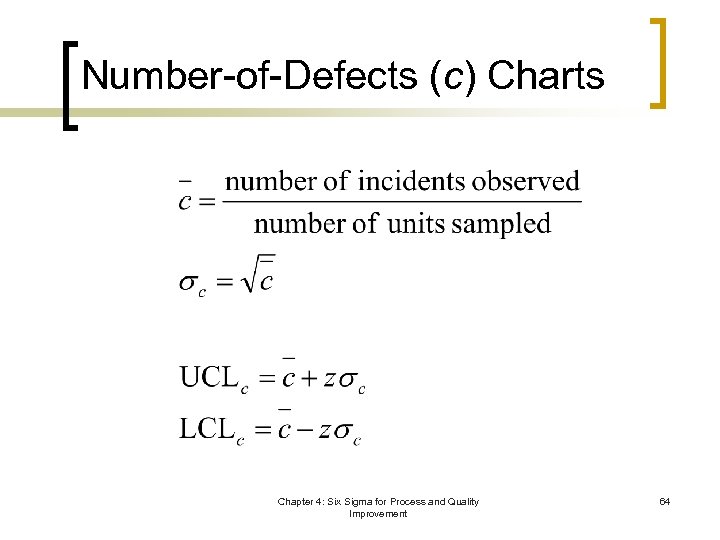

Number-of-Defects (c) Charts Chapter 4: Six Sigma for Process and Quality Improvement 64

Number-of-Defects (c) Charts Chapter 4: Six Sigma for Process and Quality Improvement 64

Six Sigma in Practice n Six Sigma Roles: ¡ ¡ n Master Black Belts. Green Belts. Yellow Belts. Supporting Roles: ¡ ¡ Champions/Sponsors. Process owners. Chapter 4: Six Sigma for Process and Quality Improvement 65

Six Sigma in Practice n Six Sigma Roles: ¡ ¡ n Master Black Belts. Green Belts. Yellow Belts. Supporting Roles: ¡ ¡ Champions/Sponsors. Process owners. Chapter 4: Six Sigma for Process and Quality Improvement 65

Quality in Services n n Measuring is difficult Training in standard procedures often used to improve quality One way to measure quality of services is to use customer satisfaction surveys J. D. Power and Associates uses surveys to rate domestic airlines, hotel chains, and rental car companies. Chapter 4: Six Sigma for Process and Quality Improvement 66

Quality in Services n n Measuring is difficult Training in standard procedures often used to improve quality One way to measure quality of services is to use customer satisfaction surveys J. D. Power and Associates uses surveys to rate domestic airlines, hotel chains, and rental car companies. Chapter 4: Six Sigma for Process and Quality Improvement 66

Rating the Performance of Domestic Airlines n n On-time performance (25%) Airport check-in (11%) Courtesy of flight attendants (11%) Seating comfort (11%) Chapter 4: Six Sigma for Process and Quality Improvement 67

Rating the Performance of Domestic Airlines n n On-time performance (25%) Airport check-in (11%) Courtesy of flight attendants (11%) Seating comfort (11%) Chapter 4: Six Sigma for Process and Quality Improvement 67

Service Defections n Organizations should monitor customer defections ¡ ¡ ¡ feedback from defecting customers can be used to identify problem areas can determine what is needed to win them back changes in defection rate can be used as early warning signal Chapter 4: Six Sigma for Process and Quality Improvement 68

Service Defections n Organizations should monitor customer defections ¡ ¡ ¡ feedback from defecting customers can be used to identify problem areas can determine what is needed to win them back changes in defection rate can be used as early warning signal Chapter 4: Six Sigma for Process and Quality Improvement 68

Quality Awards/Certifications Chapter 4: Six Sigma for Process and Quality Improvement 69

Quality Awards/Certifications Chapter 4: Six Sigma for Process and Quality Improvement 69

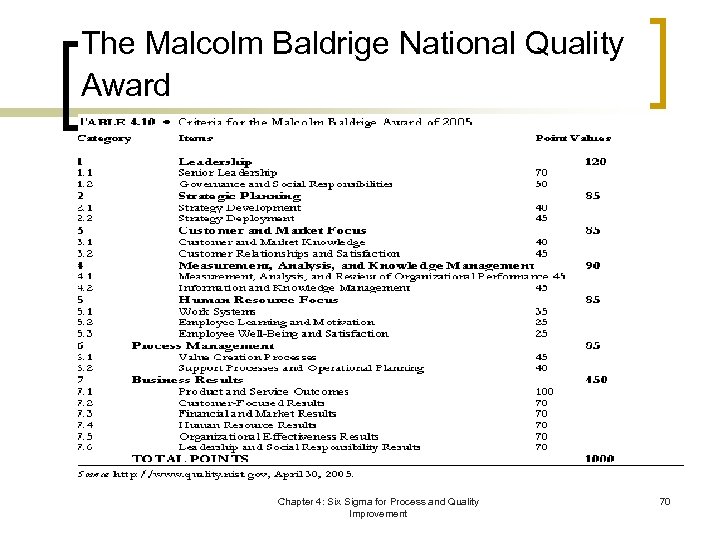

The Malcolm Baldrige National Quality Award Chapter 4: Six Sigma for Process and Quality Improvement 70

The Malcolm Baldrige National Quality Award Chapter 4: Six Sigma for Process and Quality Improvement 70

ISO 9000 n n Guidelines for designing, manufacturing, selling, and servicing products. Selecting an ISO 9000 certified supplier provides some assurance that supplier follows accepted business practices in areas covered by the standard Chapter 4: Six Sigma for Process and Quality Improvement 71

ISO 9000 n n Guidelines for designing, manufacturing, selling, and servicing products. Selecting an ISO 9000 certified supplier provides some assurance that supplier follows accepted business practices in areas covered by the standard Chapter 4: Six Sigma for Process and Quality Improvement 71

Elements of ISO 9000 n n n n n Management Responsibility Quality System Contract Review Design Control Document and Data Control Purchasing Control of Customer Supplied Product Identification and Traceability Process Control Inspection and Testing n n n n n Control of Inspection, Measuring, and Test Equipment Inspection and Test Status Control of Nonconforming Product Corrective and Preventive Action Handling, Storage, Packaging, Preservation, and Delivery Internal Quality Audits Training Servicing Statistical Techniques Chapter 4: Six Sigma for Process and Quality Improvement 72

Elements of ISO 9000 n n n n n Management Responsibility Quality System Contract Review Design Control Document and Data Control Purchasing Control of Customer Supplied Product Identification and Traceability Process Control Inspection and Testing n n n n n Control of Inspection, Measuring, and Test Equipment Inspection and Test Status Control of Nonconforming Product Corrective and Preventive Action Handling, Storage, Packaging, Preservation, and Delivery Internal Quality Audits Training Servicing Statistical Techniques Chapter 4: Six Sigma for Process and Quality Improvement 72

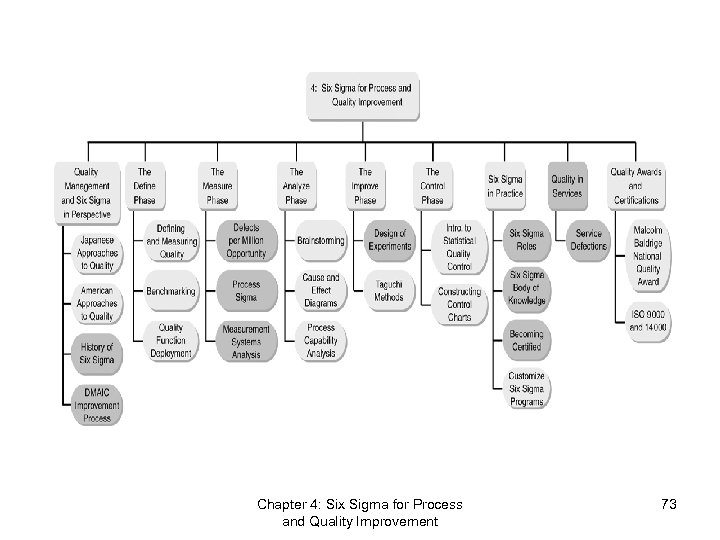

Chapter 4: Six Sigma for Process and Quality Improvement 73

Chapter 4: Six Sigma for Process and Quality Improvement 73

ISO 14000 n n Series of standards covering environmental management systems, environmental auditing, evaluation of environmental performance, environmental labeling, and lifecycle assessment. Intent is to help organizations improve their environmental performance through documentation control, operational control, control of records, training, statistical techniques, and corrective and preventive actions. Chapter 4: Six Sigma for Process and Quality Improvement 74

ISO 14000 n n Series of standards covering environmental management systems, environmental auditing, evaluation of environmental performance, environmental labeling, and lifecycle assessment. Intent is to help organizations improve their environmental performance through documentation control, operational control, control of records, training, statistical techniques, and corrective and preventive actions. Chapter 4: Six Sigma for Process and Quality Improvement 74

Chapter 4: Six Sigma for Process and Quality Improvement 75

Chapter 4: Six Sigma for Process and Quality Improvement 75

Copyright 2006 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that named in Section 117 of the United States Copyright Act without the express written consent of the copyright owner is unlawful. Requests for further information should be addressed to the Permissions Department, John Wiley & Sons, Inc. Adopters of the textbook are granted permission to make back-up copies for their own use only, to make copies for distribution to students of the course the textbook is used in, and to modify this material to best suit their instructional needs. Under no circumstances can copies be made for resale. The Publisher assumes no responsibility for errors, omissions, or damages, caused by the use of these programs or from the use of the information contained herein. Chapter 4: Six Sigma for Process and Quality Improvement 76

Copyright 2006 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that named in Section 117 of the United States Copyright Act without the express written consent of the copyright owner is unlawful. Requests for further information should be addressed to the Permissions Department, John Wiley & Sons, Inc. Adopters of the textbook are granted permission to make back-up copies for their own use only, to make copies for distribution to students of the course the textbook is used in, and to modify this material to best suit their instructional needs. Under no circumstances can copies be made for resale. The Publisher assumes no responsibility for errors, omissions, or damages, caused by the use of these programs or from the use of the information contained herein. Chapter 4: Six Sigma for Process and Quality Improvement 76