e84d92a85cc28b347cbee7fc37960b1a.ppt

- Количество слайдов: 56

Chapter 4 Processes and Technologies To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved. To Accompany Russell and Taylor, Operations Management, 4 th Edition, 2003 Prentice-Hall, Inc. All rights reserved.

Chapter 4 Processes and Technologies To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved. To Accompany Russell and Taylor, Operations Management, 4 th Edition, 2003 Prentice-Hall, Inc. All rights reserved.

Process Strategy ü Overall approach to producing goods and services ü Defines: ü Capital intensity ü Process flexibility ü Vertical integration ü Customer involvement To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Strategy ü Overall approach to producing goods and services ü Defines: ü Capital intensity ü Process flexibility ü Vertical integration ü Customer involvement To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

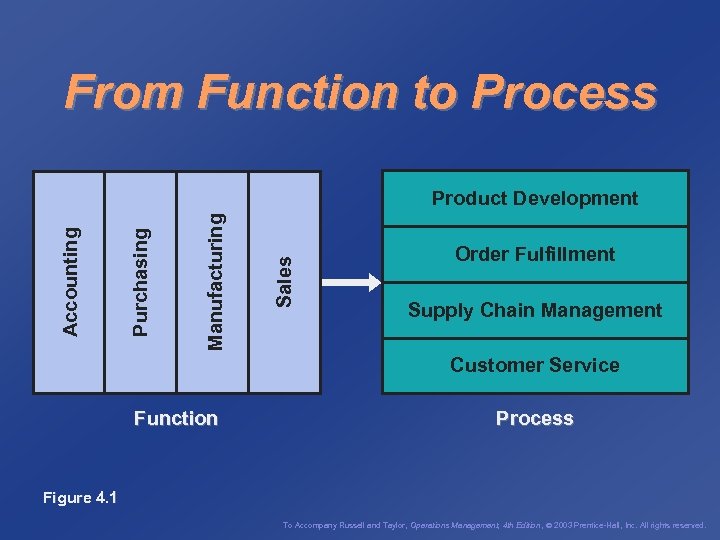

From Function to Process Sales Manufacturing Purchasing Accounting Product Development Order Fulfillment Supply Chain Management Customer Service Function Process Figure 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

From Function to Process Sales Manufacturing Purchasing Accounting Product Development Order Fulfillment Supply Chain Management Customer Service Function Process Figure 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Types of Processes ü Projects ü Batch production ü Mass production ü Continuous production To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Types of Processes ü Projects ü Batch production ü Mass production ü Continuous production To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

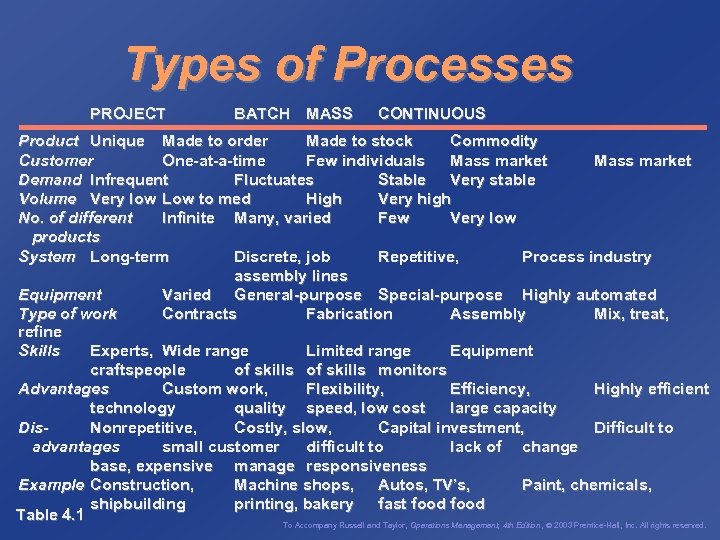

Types of Processes PROJECT BATCH MASS CONTINUOUS Product Unique Made to order Made to stock Commodity Customer One-at-a-time Few individuals Mass market Demand Infrequent Fluctuates Stable Very stable Volume Very low Low to med High Very high No. of different Infinite Many, varied Few Very low products System Long-term Discrete, job Repetitive, Process industry assembly lines Equipment Varied General-purpose Special-purpose Highly automated Type of work Contracts Fabrication Assembly Mix, treat, refine Skills Experts, Wide range Limited range Equipment craftspeople of skills monitors Advantages Custom work, Flexibility, Efficiency, Highly efficient technology quality speed, low cost large capacity Dis. Nonrepetitive, Costly, slow, Capital investment, Difficult to advantages small customer difficult to lack of change base, expensive manage responsiveness Example Construction, Machine shops, Autos, TV’s, Paint, chemicals, shipbuilding printing, bakery fast food Table 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Types of Processes PROJECT BATCH MASS CONTINUOUS Product Unique Made to order Made to stock Commodity Customer One-at-a-time Few individuals Mass market Demand Infrequent Fluctuates Stable Very stable Volume Very low Low to med High Very high No. of different Infinite Many, varied Few Very low products System Long-term Discrete, job Repetitive, Process industry assembly lines Equipment Varied General-purpose Special-purpose Highly automated Type of work Contracts Fabrication Assembly Mix, treat, refine Skills Experts, Wide range Limited range Equipment craftspeople of skills monitors Advantages Custom work, Flexibility, Efficiency, Highly efficient technology quality speed, low cost large capacity Dis. Nonrepetitive, Costly, slow, Capital investment, Difficult to advantages small customer difficult to lack of change base, expensive manage responsiveness Example Construction, Machine shops, Autos, TV’s, Paint, chemicals, shipbuilding printing, bakery fast food Table 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

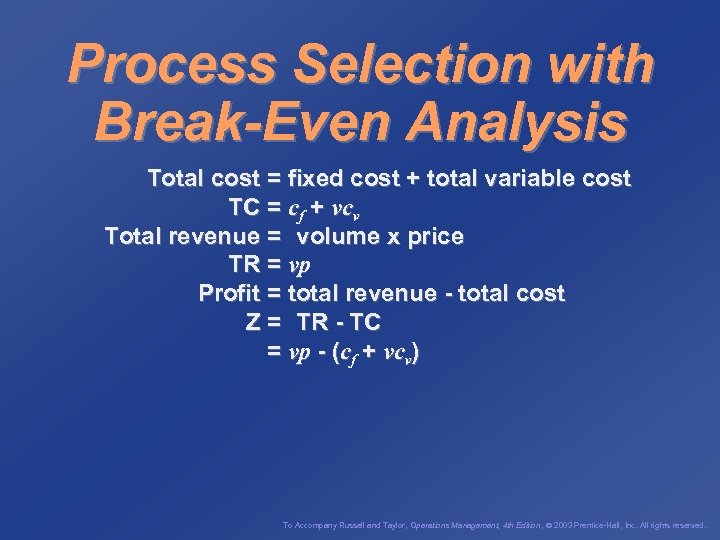

Process Selection with Break-Even Analysis Total cost = fixed cost + total variable cost TC = cf + vcv Total revenue = volume x price TR = vp Profit = total revenue - total cost Z = TR - TC = vp - (cf + vcv) To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Selection with Break-Even Analysis Total cost = fixed cost + total variable cost TC = cf + vcv Total revenue = volume x price TR = vp Profit = total revenue - total cost Z = TR - TC = vp - (cf + vcv) To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

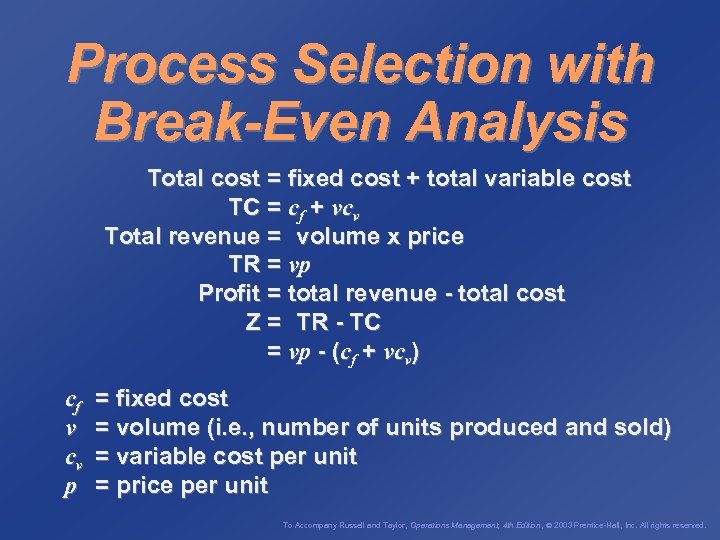

Process Selection with Break-Even Analysis Total cost = fixed cost + total variable cost TC = cf + vcv Total revenue = volume x price TR = vp Profit = total revenue - total cost Z = TR - TC = vp - (cf + vcv) cf v cv p = fixed cost = volume (i. e. , number of units produced and sold) = variable cost per unit = price per unit To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Selection with Break-Even Analysis Total cost = fixed cost + total variable cost TC = cf + vcv Total revenue = volume x price TR = vp Profit = total revenue - total cost Z = TR - TC = vp - (cf + vcv) cf v cv p = fixed cost = volume (i. e. , number of units produced and sold) = variable cost per unit = price per unit To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

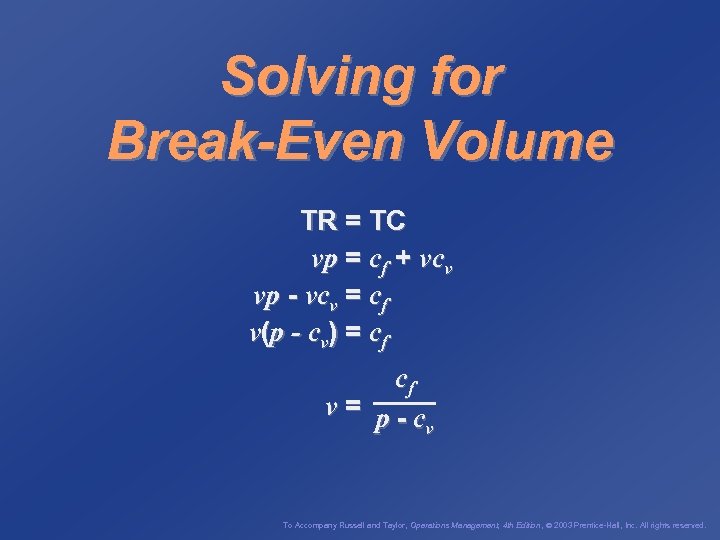

Solving for Break-Even Volume TR = TC vp = cf + vcv vp - vcv = cf v (p - c v ) = c f cf v= p-c v To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Solving for Break-Even Volume TR = TC vp = cf + vcv vp - vcv = cf v (p - c v ) = c f cf v= p-c v To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

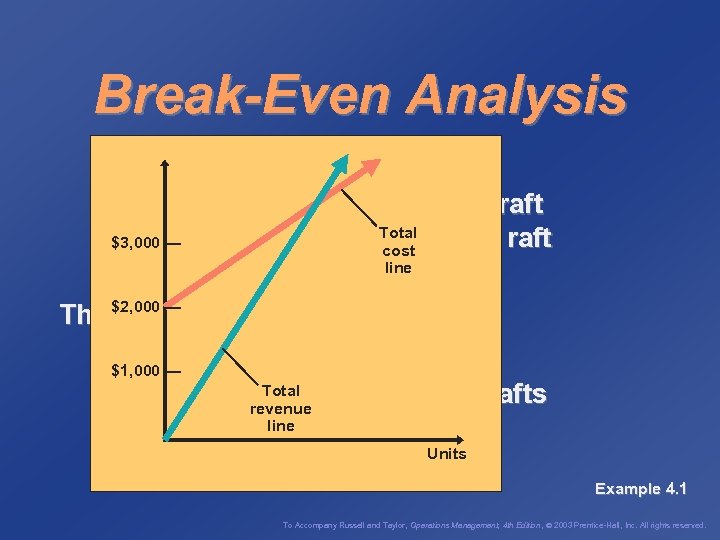

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Price = p = $10 per raft Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Price = p = $10 per raft Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Price = p = $10 per raft The break-even point is cf 2000 v= p-c = = 400 rafts v 10 - 5 Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Price = p = $10 per raft The break-even point is cf 2000 v= p-c = = 400 rafts v 10 - 5 Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Price = p = $10 per raft $3, 000 — The $2, 000 — break-even point is cf 2000 v= p-c = = 400 rafts v 10 - 5 $1, 000 — Units Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Price = p = $10 per raft $3, 000 — The $2, 000 — break-even point is cf 2000 v= p-c = = 400 rafts v 10 - 5 $1, 000 — Units Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

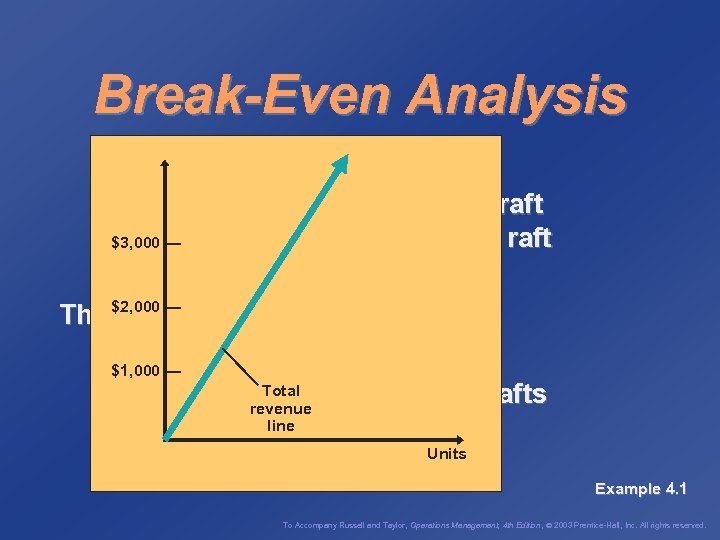

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Price = p = $10 per raft $3, 000 — The $2, 000 — break-even point is cf Total v = p - revenue cv = $1, 000 — line 2000 = 400 rafts 10 - 5 Units Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Price = p = $10 per raft $3, 000 — The $2, 000 — break-even point is cf Total v = p - revenue cv = $1, 000 — line 2000 = 400 rafts 10 - 5 Units Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Total Price = p = $10 per raft $3, 000 — cost line The $2, 000 — break-even point is cf Total v = p - revenue cv = $1, 000 — line 2000 = 400 rafts 10 - 5 Units Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Total Price = p = $10 per raft $3, 000 — cost line The $2, 000 — break-even point is cf Total v = p - revenue cv = $1, 000 — line 2000 = 400 rafts 10 - 5 Units Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

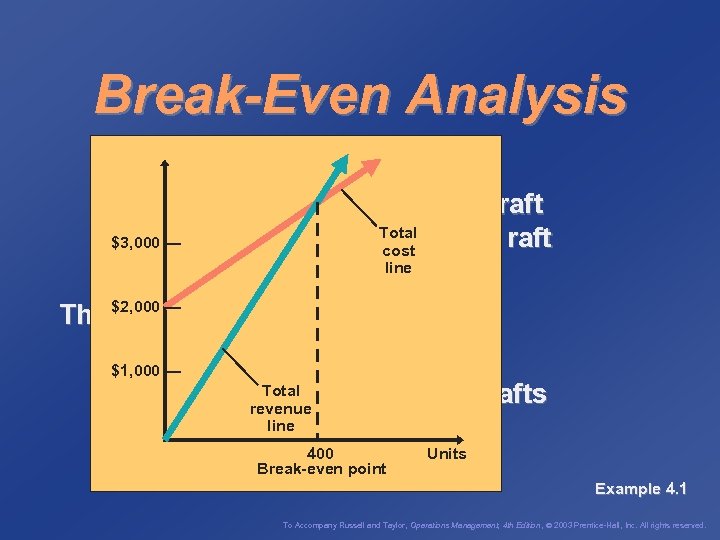

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Total Price = p = $10 per raft $3, 000 — cost line The $2, 000 — break-even point is cf Total v = p - revenue cv = $1, 000 — line 2000 = 400 rafts 10 - 5 400 Break-even point Units Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Break-Even Analysis Fixed cost = cf = $2, 000 Variable cost = cv = $5 per raft Total Price = p = $10 per raft $3, 000 — cost line The $2, 000 — break-even point is cf Total v = p - revenue cv = $1, 000 — line 2000 = 400 rafts 10 - 5 400 Break-even point Units Example 4. 1 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

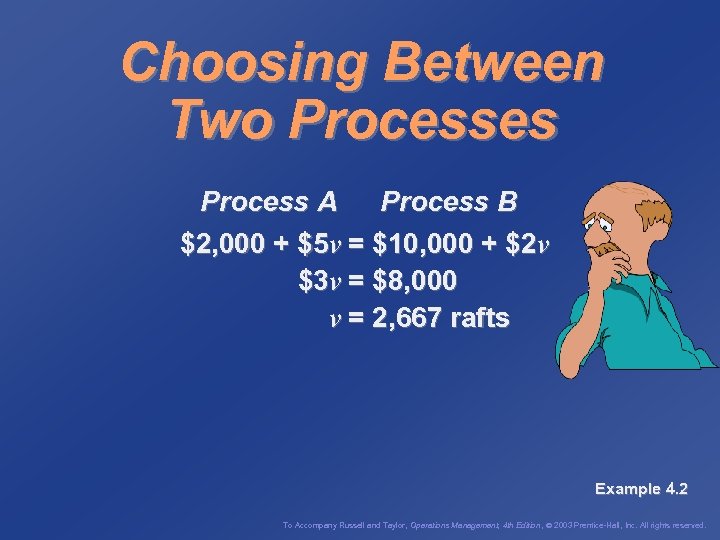

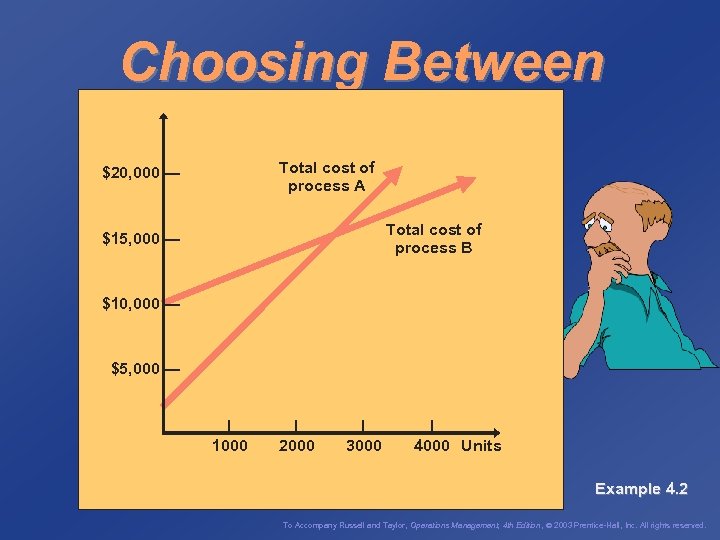

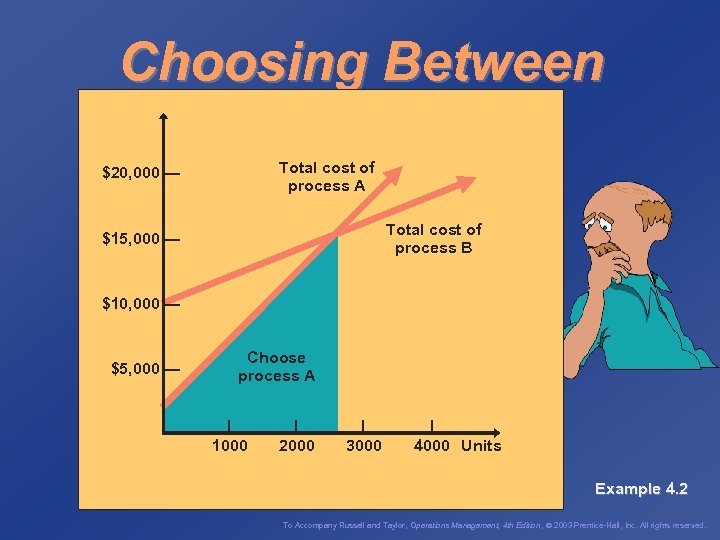

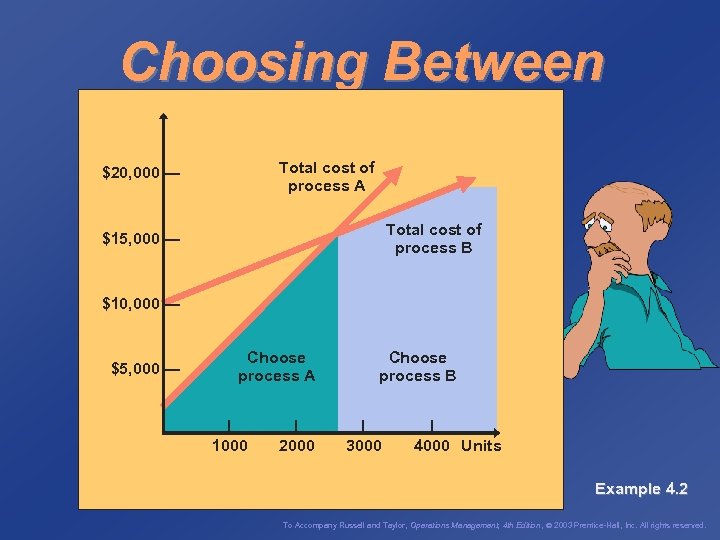

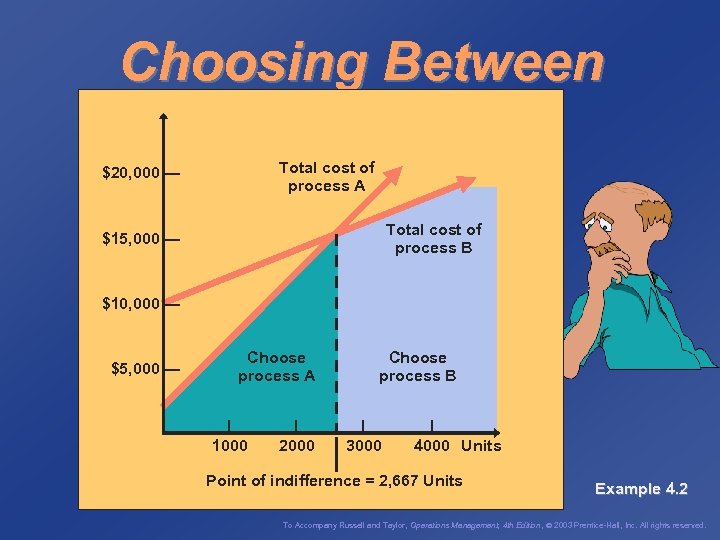

Choosing Between Two Processes Process A Process B $2, 000 + $5 v = $10, 000 + $2 v $3 v = $8, 000 v = 2, 667 rafts Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Process A Process B $2, 000 + $5 v = $10, 000 + $2 v $3 v = $8, 000 v = 2, 667 rafts Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

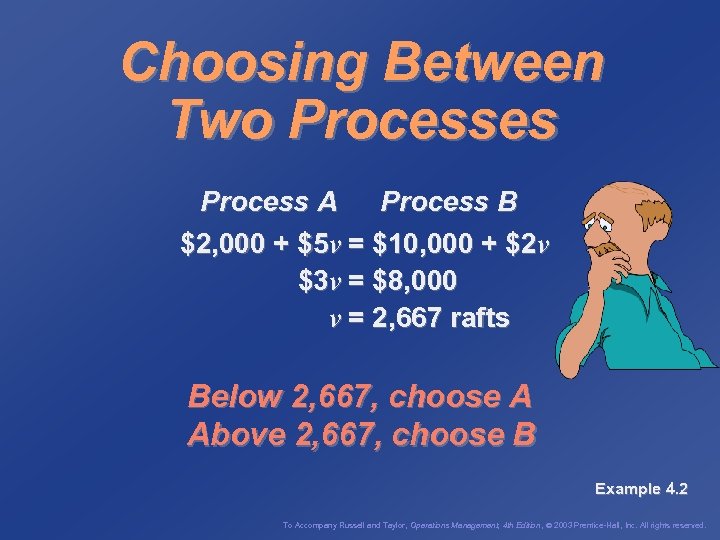

Choosing Between Two Processes Process A Process B $2, 000 + $5 v = $10, 000 + $2 v $3 v = $8, 000 v = 2, 667 rafts Below 2, 667, choose A Above 2, 667, choose B Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Process A Process B $2, 000 + $5 v = $10, 000 + $2 v $3 v = $8, 000 v = 2, 667 rafts Below 2, 667, choose A Above 2, 667, choose B Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes $20, 000 — $15, 000 — $10, 000 — $5, 000 — | 1000 | 2000 | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes $20, 000 — $15, 000 — $10, 000 — $5, 000 — | 1000 | 2000 | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

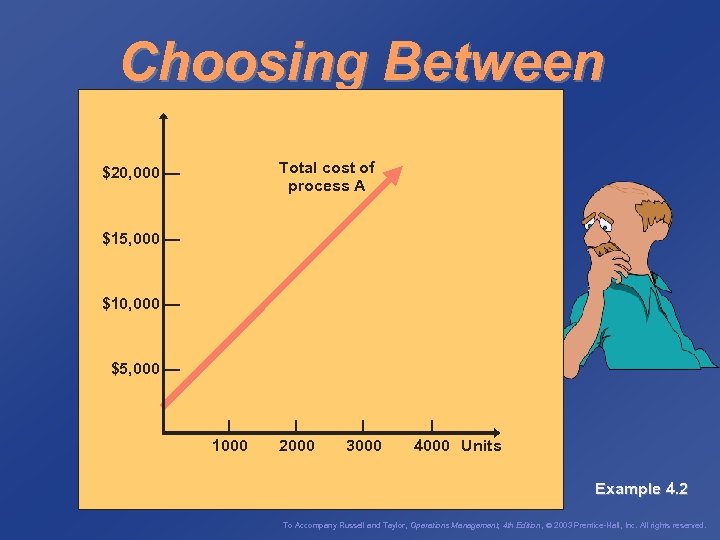

Choosing Between Two Processes Total cost of process A $20, 000 — $15, 000 — $10, 000 — $5, 000 — | 1000 | 2000 | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — $15, 000 — $10, 000 — $5, 000 — | 1000 | 2000 | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — Total cost of process B $15, 000 — $10, 000 — $5, 000 — | 1000 | 2000 | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — Total cost of process B $15, 000 — $10, 000 — $5, 000 — | 1000 | 2000 | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — Total cost of process B $15, 000 — $10, 000 — $5, 000 — Choose process A | 1000 | 2000 | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — Total cost of process B $15, 000 — $10, 000 — $5, 000 — Choose process A | 1000 | 2000 | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — Total cost of process B $15, 000 — $10, 000 — $5, 000 — Choose process A | 1000 | 2000 Choose process B | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — Total cost of process B $15, 000 — $10, 000 — $5, 000 — Choose process A | 1000 | 2000 Choose process B | 3000 | 4000 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — Total cost of process B $15, 000 — $10, 000 — $5, 000 — Choose process A | 1000 | 2000 Choose process B | 3000 | 4000 Units Point of indifference = 2, 667 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Choosing Between Two Processes Total cost of process A $20, 000 — Total cost of process B $15, 000 — $10, 000 — $5, 000 — Choose process A | 1000 | 2000 Choose process B | 3000 | 4000 Units Point of indifference = 2, 667 Units Example 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Point of Indifference ü Volume where cost of A = cost of B ü Rule for choosing process: ü Above point of indifference choose process with lowest variable cost ü Below point of indifference choose process with lowest fixed cost To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Point of Indifference ü Volume where cost of A = cost of B ü Rule for choosing process: ü Above point of indifference choose process with lowest variable cost ü Below point of indifference choose process with lowest fixed cost To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Planning ü Make-or-buy decisions ü Process selection ü Specific equipment selection ü Process plans ü Process analysis To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Planning ü Make-or-buy decisions ü Process selection ü Specific equipment selection ü Process plans ü Process analysis To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Make-or-Buy Decisions 1. 2. 3. 4. 5. 6. Cost Capacity Quality Speed Reliability Expertise Make? Buy? To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Make-or-Buy Decisions 1. 2. 3. 4. 5. 6. Cost Capacity Quality Speed Reliability Expertise Make? Buy? To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Specific Equipment Selection 1. Purchase cost 2. Operating cost 3. Annual savings 4. Revenue enhancement 5. Replacement analysis 6. Risk and uncertainty 7. Piecemeal analysis To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Specific Equipment Selection 1. Purchase cost 2. Operating cost 3. Annual savings 4. Revenue enhancement 5. Replacement analysis 6. Risk and uncertainty 7. Piecemeal analysis To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Plans ü ü ü Blueprints Bill of material Assembly chart / product structure diagram ü Operations process chart ü Routing sheet To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Plans ü ü ü Blueprints Bill of material Assembly chart / product structure diagram ü Operations process chart ü Routing sheet To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

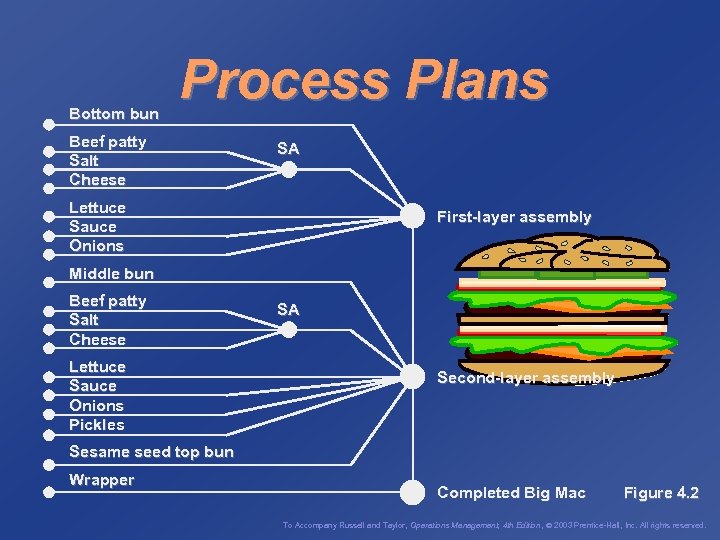

Bottom bun Process Plans Beef patty Salt Cheese SA Lettuce Sauce Onions First-layer assembly Middle bun Beef patty Salt Cheese Lettuce Sauce Onions Pickles SA Second-layer assembly Sesame seed top bun Wrapper Completed Big Mac Figure 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Bottom bun Process Plans Beef patty Salt Cheese SA Lettuce Sauce Onions First-layer assembly Middle bun Beef patty Salt Cheese Lettuce Sauce Onions Pickles SA Second-layer assembly Sesame seed top bun Wrapper Completed Big Mac Figure 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

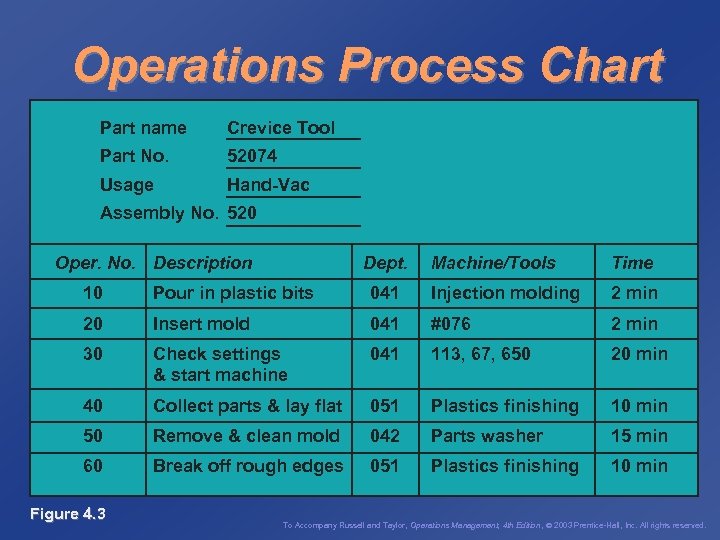

Operations Process Chart Part name Crevice Tool Part No. 52074 Usage Hand-Vac Assembly No. 520 Oper. No. Description Dept. Machine/Tools Time 10 Pour in plastic bits 041 Injection molding 2 min 20 Insert mold 041 #076 2 min 30 Check settings & start machine 041 113, 67, 650 20 min 40 Collect parts & lay flat 051 Plastics finishing 10 min 50 Remove & clean mold 042 Parts washer 15 min 60 Break off rough edges 051 Plastics finishing 10 min Figure 4. 3 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Operations Process Chart Part name Crevice Tool Part No. 52074 Usage Hand-Vac Assembly No. 520 Oper. No. Description Dept. Machine/Tools Time 10 Pour in plastic bits 041 Injection molding 2 min 20 Insert mold 041 #076 2 min 30 Check settings & start machine 041 113, 67, 650 20 min 40 Collect parts & lay flat 051 Plastics finishing 10 min 50 Remove & clean mold 042 Parts washer 15 min 60 Break off rough edges 051 Plastics finishing 10 min Figure 4. 3 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Analysis ü The systematic examination of all aspects of a process to improve its operation ü ü Faster More efficient Less costly More responsive ü Basic tools ü Process flowchart ü Process diagrams ü Process maps To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Analysis ü The systematic examination of all aspects of a process to improve its operation ü ü Faster More efficient Less costly More responsive ü Basic tools ü Process flowchart ü Process diagrams ü Process maps To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

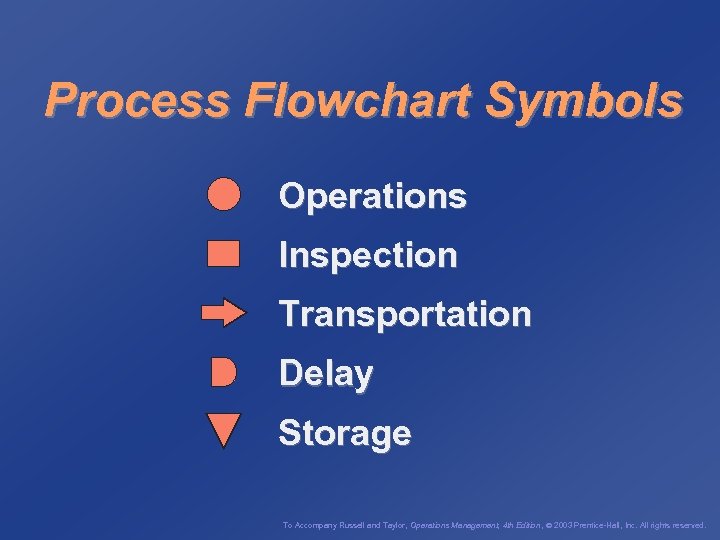

Process Flowchart Symbols Operations Inspection Transportation Delay Storage To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Flowchart Symbols Operations Inspection Transportation Delay Storage To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

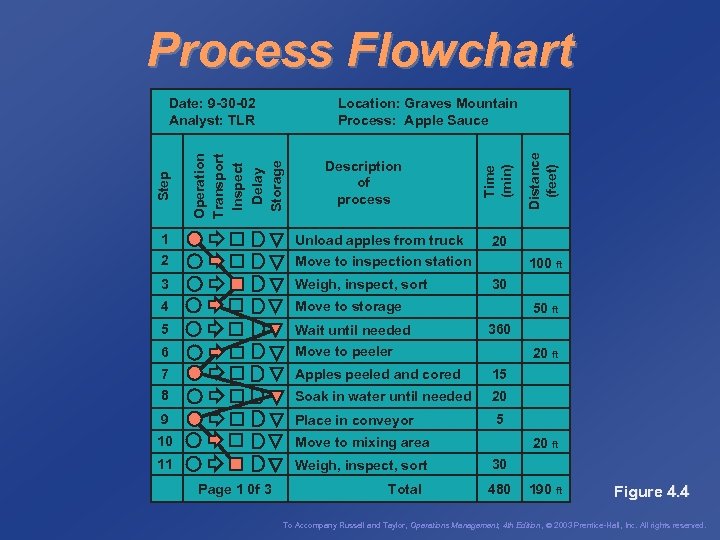

Process Flowchart 1 Unload apples from truck 2 Move to inspection station 3 Weigh, inspect, sort 4 Move to storage 5 Wait until needed 6 Move to peeler 7 Apples peeled and cored 15 8 Soak in water until needed 20 9 Place in conveyor 5 10 Move to mixing area 11 Weigh, inspect, sort Distance (feet) Description of process Time (min) Location: Graves Mountain Process: Apple Sauce Operation Transport Inspect Delay Storage Step Date: 9 -30 -02 Analyst: TLR Page 1 0 f 3 Total 20 100 ft 30 50 ft 360 20 ft 30 480 190 ft Figure 4. 4 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Flowchart 1 Unload apples from truck 2 Move to inspection station 3 Weigh, inspect, sort 4 Move to storage 5 Wait until needed 6 Move to peeler 7 Apples peeled and cored 15 8 Soak in water until needed 20 9 Place in conveyor 5 10 Move to mixing area 11 Weigh, inspect, sort Distance (feet) Description of process Time (min) Location: Graves Mountain Process: Apple Sauce Operation Transport Inspect Delay Storage Step Date: 9 -30 -02 Analyst: TLR Page 1 0 f 3 Total 20 100 ft 30 50 ft 360 20 ft 30 480 190 ft Figure 4. 4 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

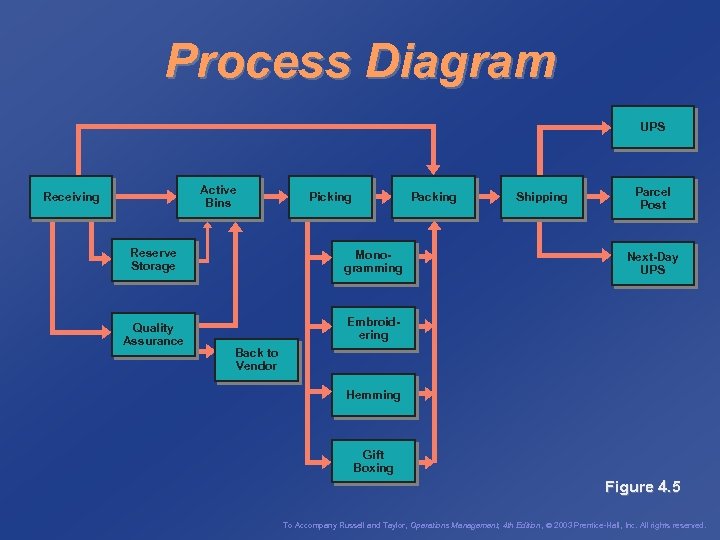

Process Diagram UPS Active Bins Receiving Reserve Storage Quality Assurance Picking Packing Monogramming Shipping Parcel Post Next-Day UPS Embroidering Back to Vendor Hemming Gift Boxing Figure 4. 5 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Diagram UPS Active Bins Receiving Reserve Storage Quality Assurance Picking Packing Monogramming Shipping Parcel Post Next-Day UPS Embroidering Back to Vendor Hemming Gift Boxing Figure 4. 5 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

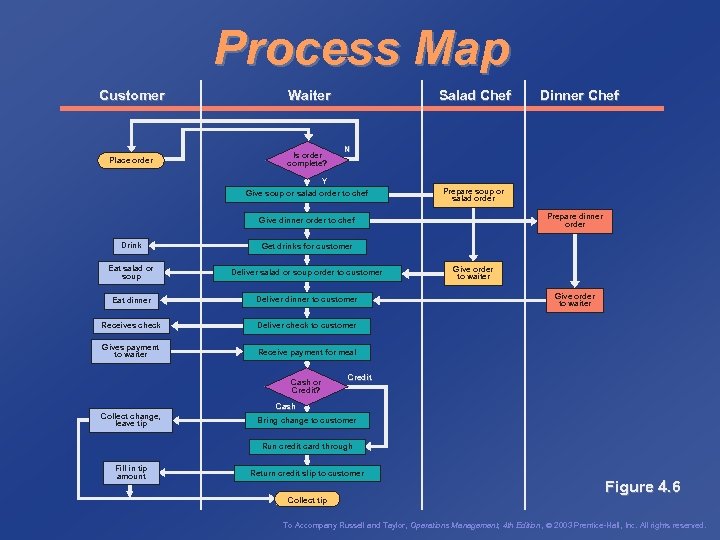

Process Map Customer Waiter Place order Is order complete? Salad Chef Dinner Chef N Y Give soup or salad order to chef Prepare soup or salad order Prepare dinner order Give dinner order to chef Drink Get drinks for customer Eat salad or soup Deliver salad or soup order to customer Eat dinner Deliver dinner to customer Receives check Deliver check to customer Gives payment to waiter Receive payment for meal Cash or Credit? Give order to waiter Credit Cash Collect change, leave tip Bring change to customer Run credit card through Fill in tip amount Return credit slip to customer Figure 4. 6 Collect tip To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Map Customer Waiter Place order Is order complete? Salad Chef Dinner Chef N Y Give soup or salad order to chef Prepare soup or salad order Prepare dinner order Give dinner order to chef Drink Get drinks for customer Eat salad or soup Deliver salad or soup order to customer Eat dinner Deliver dinner to customer Receives check Deliver check to customer Gives payment to waiter Receive payment for meal Cash or Credit? Give order to waiter Credit Cash Collect change, leave tip Bring change to customer Run credit card through Fill in tip amount Return credit slip to customer Figure 4. 6 Collect tip To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

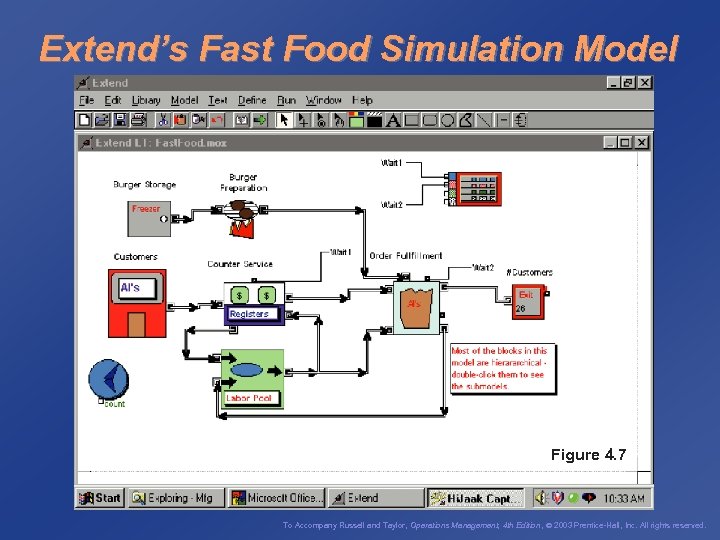

Extend’s Fast Food Simulation Model Figure 4. 7 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Extend’s Fast Food Simulation Model Figure 4. 7 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

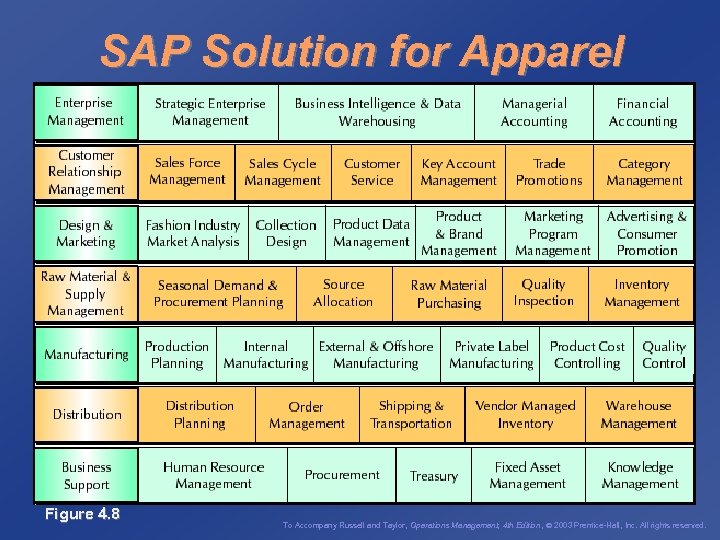

SAP Solution for Apparel Figure 4. 8 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

SAP Solution for Apparel Figure 4. 8 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

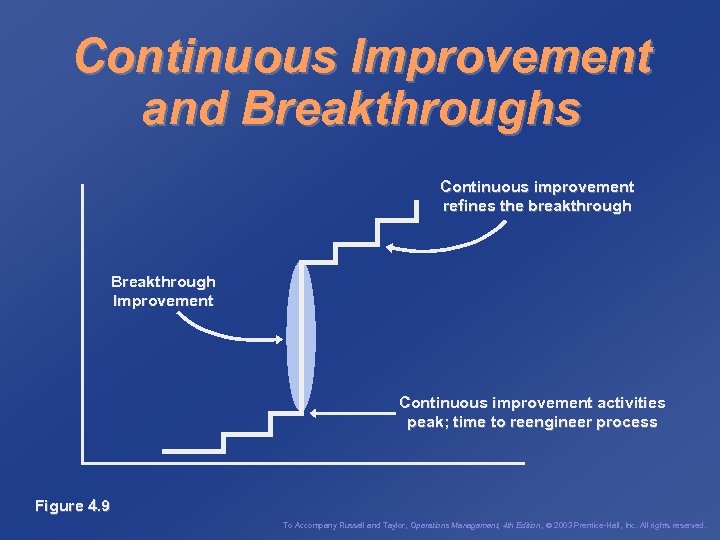

Continuous Improvement and Breakthroughs Continuous improvement refines the breakthrough Breakthrough Improvement Continuous improvement activities peak; time to reengineer process Figure 4. 9 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Continuous Improvement and Breakthroughs Continuous improvement refines the breakthrough Breakthrough Improvement Continuous improvement activities peak; time to reengineer process Figure 4. 9 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

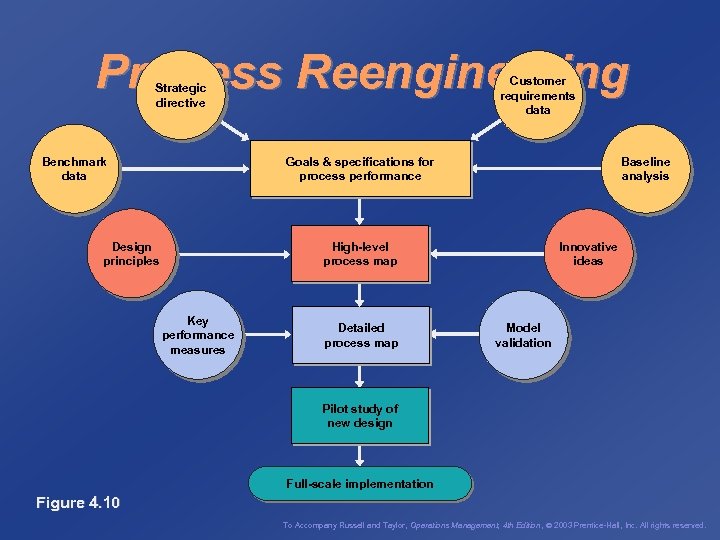

Process Reengineering Customer requirements data Strategic directive Benchmark data Goals & specifications for process performance Design principles Baseline analysis High-level process map Key performance measures Detailed process map Innovative ideas Model validation Pilot study of new design Full-scale implementation Figure 4. 10 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Process Reengineering Customer requirements data Strategic directive Benchmark data Goals & specifications for process performance Design principles Baseline analysis High-level process map Key performance measures Detailed process map Innovative ideas Model validation Pilot study of new design Full-scale implementation Figure 4. 10 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

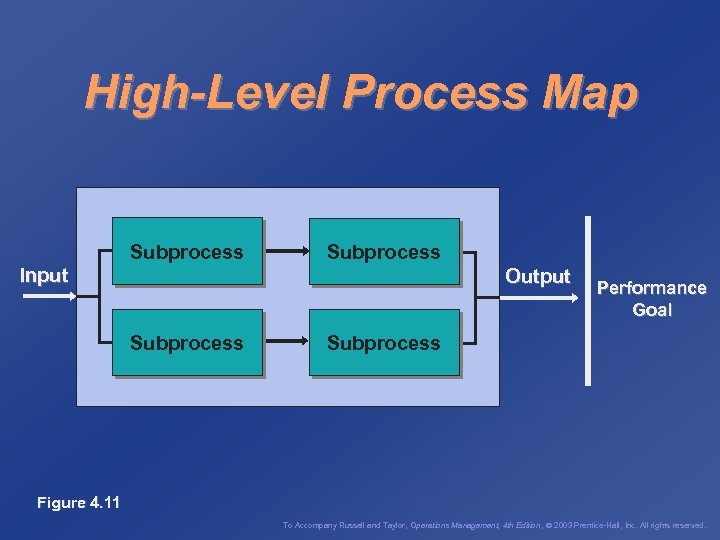

High-Level Process Map Subprocess Input Output Subprocess Performance Goal Subprocess Figure 4. 11 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

High-Level Process Map Subprocess Input Output Subprocess Performance Goal Subprocess Figure 4. 11 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Principles for Redesigning Processes 1. Remove waste, simplify, consolidate 2. Link processes to create value 3. Let the swiftest and most capable execute 4. Flex the process 5. Capture information digitally and propagate Table 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Principles for Redesigning Processes 1. Remove waste, simplify, consolidate 2. Link processes to create value 3. Let the swiftest and most capable execute 4. Flex the process 5. Capture information digitally and propagate Table 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Principles for Redesigning Processes 6. Provide visibility through information about process status 7. Fit the process with sensors and feedback loops 8. Add analytic capabilities 9. Connect, collect and create knowledge around the process 10. Personalize the process Table 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Principles for Redesigning Processes 6. Provide visibility through information about process status 7. Fit the process with sensors and feedback loops 8. Add analytic capabilities 9. Connect, collect and create knowledge around the process 10. Personalize the process Table 4. 2 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Techniques for Generating Innovative Ideas ü ü ü Vary entry point to a problem Draw analogies Change your perspective Try inverse brainstorming Chain forward as far as possible Use attribute brainstorming Table 4. 3 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Techniques for Generating Innovative Ideas ü ü ü Vary entry point to a problem Draw analogies Change your perspective Try inverse brainstorming Chain forward as far as possible Use attribute brainstorming Table 4. 3 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Information Technology ü Management Information Systems (MIS) ü Move large amounts of data ü Decision Support Systems (DSS) ü Add decision making support ü Expert System ü Recommend decision based on expert knowledge To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Information Technology ü Management Information Systems (MIS) ü Move large amounts of data ü Decision Support Systems (DSS) ü Add decision making support ü Expert System ü Recommend decision based on expert knowledge To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

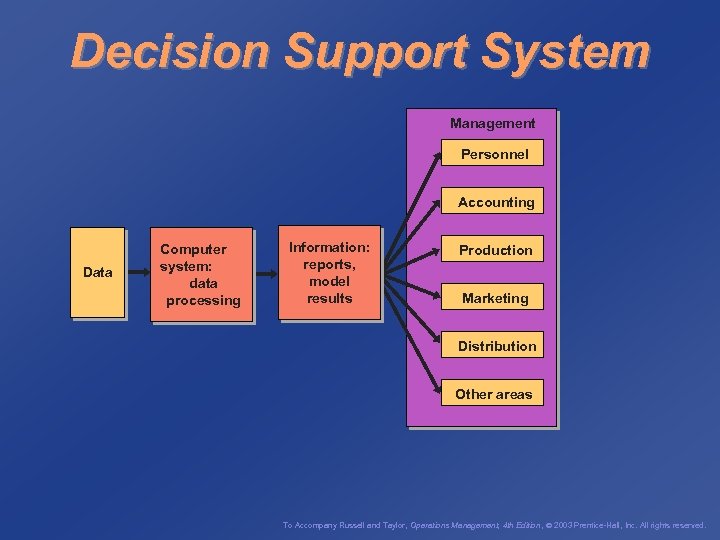

Decision Support System Management Personnel Accounting Data Computer system: data processing Information: reports, model results Production Marketing Distribution Other areas To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Decision Support System Management Personnel Accounting Data Computer system: data processing Information: reports, model results Production Marketing Distribution Other areas To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

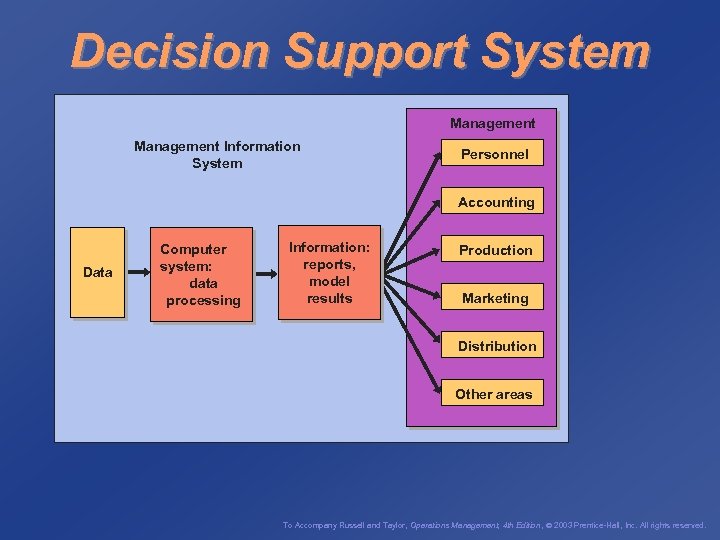

Decision Support System Management Information System Personnel Accounting Data Computer system: data processing Information: reports, model results Production Marketing Distribution Other areas To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Decision Support System Management Information System Personnel Accounting Data Computer system: data processing Information: reports, model results Production Marketing Distribution Other areas To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

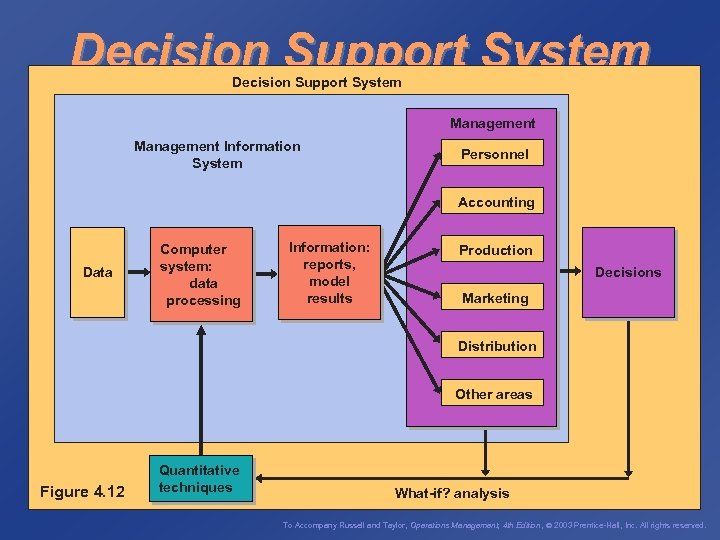

Decision Support System Management Information System Personnel Accounting Data Computer system: data processing Information: reports, model results Production Decisions Marketing Distribution Other areas Figure 4. 12 Quantitative techniques What-if? analysis To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Decision Support System Management Information System Personnel Accounting Data Computer system: data processing Information: reports, model results Production Decisions Marketing Distribution Other areas Figure 4. 12 Quantitative techniques What-if? analysis To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Artificial Intelligence ü Neural networks ü Emulate interconnections in brain ü Genetic algorithms ü Based on adaptive capabilities in nature ü Fuzzy logic ü Simulate human ability to deal with ambiguity To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Artificial Intelligence ü Neural networks ü Emulate interconnections in brain ü Genetic algorithms ü Based on adaptive capabilities in nature ü Fuzzy logic ü Simulate human ability to deal with ambiguity To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Enterprise Software ü Collect, analyze, and make decisions based on data ü ERP - Enterprise Resource Planning ü Managing wide range of processes üHuman resources, materials management, supply chains, accounting, finance, manufacturing, sales force automation, customer service, customer order entry ü Finding hidden patterns through data mining To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Enterprise Software ü Collect, analyze, and make decisions based on data ü ERP - Enterprise Resource Planning ü Managing wide range of processes üHuman resources, materials management, supply chains, accounting, finance, manufacturing, sales force automation, customer service, customer order entry ü Finding hidden patterns through data mining To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Advanced Communications ü ü Electronic data interchange (EDI) Internet, extranets Wireless communications Teleconferencing & telecommuting ü Bar coding, RFT ü Virtual reality To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Advanced Communications ü ü Electronic data interchange (EDI) Internet, extranets Wireless communications Teleconferencing & telecommuting ü Bar coding, RFT ü Virtual reality To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Manufacturing Technology ü Numerically controlled (NC) machines ü Controlled by punched tape ü Computer numerical controlled (CNC) ü Controlled by attached computer ü Direct numerical control (DNC) ü Several NC machines controlled by single computer ü Flexible manufacturing systems (FMS) ü Includes automated material handling To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Manufacturing Technology ü Numerically controlled (NC) machines ü Controlled by punched tape ü Computer numerical controlled (CNC) ü Controlled by attached computer ü Direct numerical control (DNC) ü Several NC machines controlled by single computer ü Flexible manufacturing systems (FMS) ü Includes automated material handling To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Automated Material Handling ü Conveyors ü Automated guided vehicle (AGV) ü Automated storage & retrieval system (ASRS) To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Automated Material Handling ü Conveyors ü Automated guided vehicle (AGV) ü Automated storage & retrieval system (ASRS) To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Flexible Manufacturing Systems (FMS) ü Programmable machine tools ü Controlled by common computer network ü Combines flexibility with efficiency ü Reduces setup & queue times To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Flexible Manufacturing Systems (FMS) ü Programmable machine tools ü Controlled by common computer network ü Combines flexibility with efficiency ü Reduces setup & queue times To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

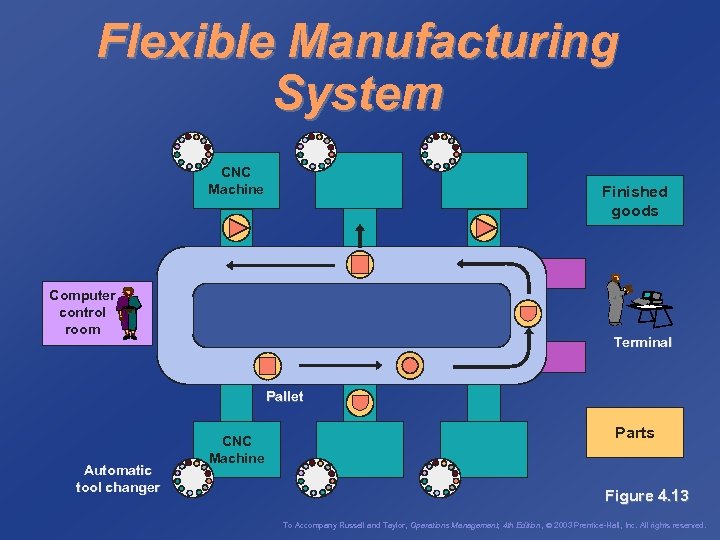

Flexible Manufacturing System CNC Machine Finished goods Computer control room Terminal Pallet Automatic tool changer CNC Machine Parts Figure 4. 13 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Flexible Manufacturing System CNC Machine Finished goods Computer control room Terminal Pallet Automatic tool changer CNC Machine Parts Figure 4. 13 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Robotics ü Programmable manipulators ü Follow specified path ü Better than humans with respect to ü Hostile environments ü Long hours ü Consistency ü Adoption has been slowed by ineffective integration and adaptation of systems To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Robotics ü Programmable manipulators ü Follow specified path ü Better than humans with respect to ü Hostile environments ü Long hours ü Consistency ü Adoption has been slowed by ineffective integration and adaptation of systems To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

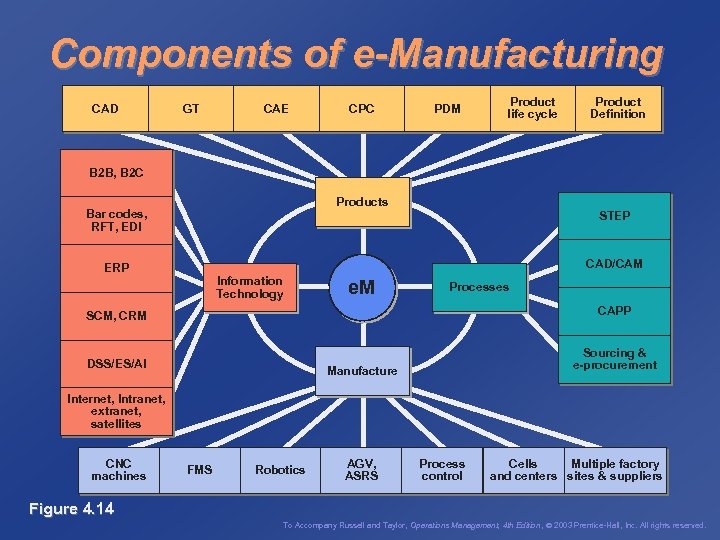

e-Manufacturing ü Real-time sharing of data with trading partners and customers to drive collaborative decisions ü CAD - uses software to create & modify designs ü GT- classifies designs to benefit from prior experience ü STEP - sets standards for communication ü CAPP - creates processing instructions for CAM ü CAM - uses programmable automation in manufacturing To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

e-Manufacturing ü Real-time sharing of data with trading partners and customers to drive collaborative decisions ü CAD - uses software to create & modify designs ü GT- classifies designs to benefit from prior experience ü STEP - sets standards for communication ü CAPP - creates processing instructions for CAM ü CAM - uses programmable automation in manufacturing To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Components of e-Manufacturing CAD GT CAE CPC PDM Product life cycle Product Definition B 2 B, B 2 C Products Bar codes, RFT, EDI STEP CAD/CAM ERP Information Technology e. M Processes SCM, CRM CAPP DSS/ES/AI Sourcing & e-procurement Manufacture Internet, Intranet, extranet, satellites CNC machines FMS Robotics AGV, ASRS Process control Cells Multiple factory and centers sites & suppliers Figure 4. 14 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.

Components of e-Manufacturing CAD GT CAE CPC PDM Product life cycle Product Definition B 2 B, B 2 C Products Bar codes, RFT, EDI STEP CAD/CAM ERP Information Technology e. M Processes SCM, CRM CAPP DSS/ES/AI Sourcing & e-procurement Manufacture Internet, Intranet, extranet, satellites CNC machines FMS Robotics AGV, ASRS Process control Cells Multiple factory and centers sites & suppliers Figure 4. 14 To Accompany Russell and Taylor, Operations Management, 4 th Edition , 2003 Prentice-Hall, Inc. All rights reserved.