54291893b2f5a977fed9570b93ae7f84.ppt

- Количество слайдов: 23

Chapter 20 Controlling logistics performance Chapter 11: Strategic Leadership

Chapter 20 Controlling logistics performance Chapter 11: Strategic Leadership

Outline • Logistics performance should be continuously monitored to ensure efficient use of resources and financial control. • Control can take place at technical, tactical and strategic levels. • The concept of quality is related to customer service, with TQM often being used to achieve continuous improvement. • Various types of performance measures can be used to track certain processes in the logistics framework. • Benchmarking can be used to compare performance against competitors or best-in-class businesses. • SCOR integrates business-process engineering, benchmarking and process measurement into a crossfunctional framework. Chapter 11: Strategic Leadership

Outline • Logistics performance should be continuously monitored to ensure efficient use of resources and financial control. • Control can take place at technical, tactical and strategic levels. • The concept of quality is related to customer service, with TQM often being used to achieve continuous improvement. • Various types of performance measures can be used to track certain processes in the logistics framework. • Benchmarking can be used to compare performance against competitors or best-in-class businesses. • SCOR integrates business-process engineering, benchmarking and process measurement into a crossfunctional framework. Chapter 11: Strategic Leadership

Learning outcomes • The cyclical nature of planning and control • ISO standards applicable to logistics management • Types of performance measures • Specific performance measures used in various functional areas of logistics management • Benchmarking exercises • The SCOR model • The role that BI can play in supply chain management Chapter 11: Strategic Leadership

Learning outcomes • The cyclical nature of planning and control • ISO standards applicable to logistics management • Types of performance measures • Specific performance measures used in various functional areas of logistics management • Benchmarking exercises • The SCOR model • The role that BI can play in supply chain management Chapter 11: Strategic Leadership

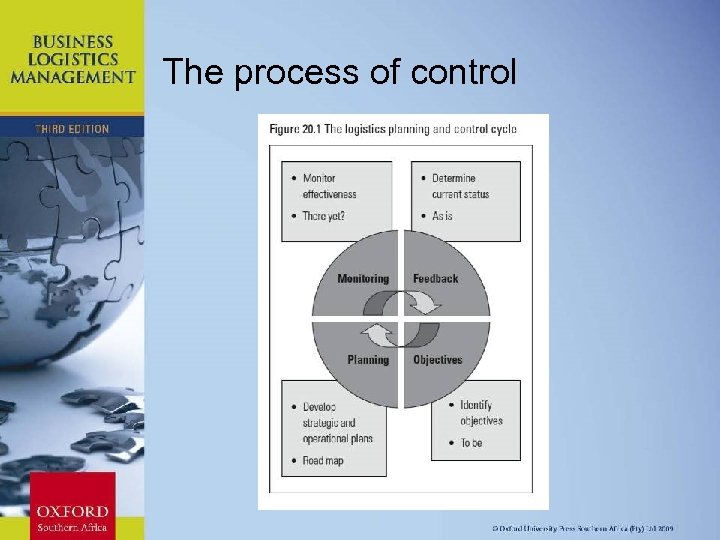

The process of control Chapter 11: Strategic Leadership

The process of control Chapter 11: Strategic Leadership

Control processes and systems (1) Aims of control systems: • Strategic control: achieve organisational objectives • Tactical control: improve short-term performance • Technical control: perform according to standards Strategic and tactical control: • are predictive in nature; • are wide in focus; • consider future changes in cause-and-effect relationships; • trigger entrepreneurial plans; and • include budgetary control. Chapter 11: Strategic Leadership

Control processes and systems (1) Aims of control systems: • Strategic control: achieve organisational objectives • Tactical control: improve short-term performance • Technical control: perform according to standards Strategic and tactical control: • are predictive in nature; • are wide in focus; • consider future changes in cause-and-effect relationships; • trigger entrepreneurial plans; and • include budgetary control. Chapter 11: Strategic Leadership

Control processes and systems (2) Technical control: • Actual current performance • Trigger corrective actions • Narrow focus Technical control systems: • Yardsticks • Standards • Range of satisfactory performance • Frequency of measurement • Reporting system Chapter 11: Strategic Leadership

Control processes and systems (2) Technical control: • Actual current performance • Trigger corrective actions • Narrow focus Technical control systems: • Yardsticks • Standards • Range of satisfactory performance • Frequency of measurement • Reporting system Chapter 11: Strategic Leadership

Quality Concept of quality: • Closely related to customer service excellence • Unseen process with impact on customer satisfaction • Give customers what they want at price they will pay • Consistent service/quality at contained cost • Examples of quality control systems: – TQM – ISO 9000 – Six sigma Chapter 11: Strategic Leadership

Quality Concept of quality: • Closely related to customer service excellence • Unseen process with impact on customer satisfaction • Give customers what they want at price they will pay • Consistent service/quality at contained cost • Examples of quality control systems: – TQM – ISO 9000 – Six sigma Chapter 11: Strategic Leadership

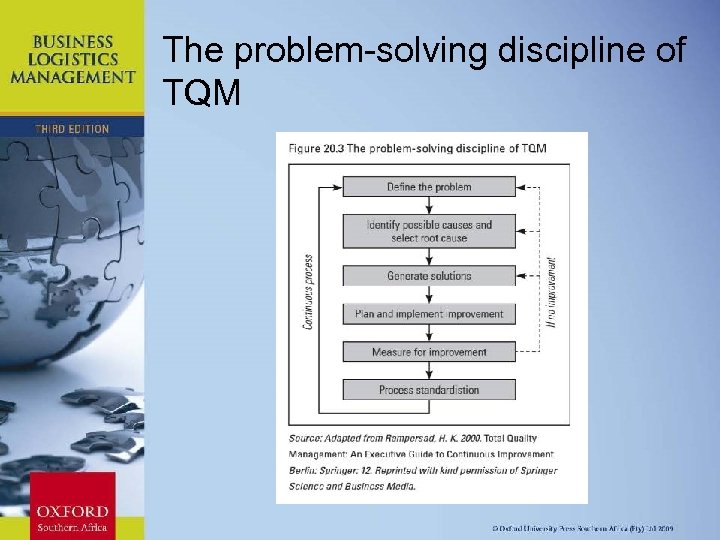

Total quality management (TQM) • Definition of TQM: see p. 442 • Quality principles of TQM: • Customer focus and customer involvement • Involvement of all employees • Process-oriented • Consistency of purpose • Act according to facts • Focus on continuous improvement • Use problem-solving discipline (PSD) for systematic, gradual, team-based problem solving Chapter 11: Strategic Leadership

Total quality management (TQM) • Definition of TQM: see p. 442 • Quality principles of TQM: • Customer focus and customer involvement • Involvement of all employees • Process-oriented • Consistency of purpose • Act according to facts • Focus on continuous improvement • Use problem-solving discipline (PSD) for systematic, gradual, team-based problem solving Chapter 11: Strategic Leadership

The problem-solving discipline of TQM Chapter 11: Strategic Leadership

The problem-solving discipline of TQM Chapter 11: Strategic Leadership

Quality-control system: ISO 9000 ISO (International Organization for Standardization): • Network of national standards institutes • Consistent application of specifications and criteria • Facilitates trade and transfer of technology • Assurance about quality, safety and reliability ISO 9000: • Quality requirements in business-to-business dealings • ISO 9001: 2000 – conformity assessment • Ensure consistency and regulatory compliance • Various requirements Chapter 11: Strategic Leadership

Quality-control system: ISO 9000 ISO (International Organization for Standardization): • Network of national standards institutes • Consistent application of specifications and criteria • Facilitates trade and transfer of technology • Assurance about quality, safety and reliability ISO 9000: • Quality requirements in business-to-business dealings • ISO 9001: 2000 – conformity assessment • Ensure consistency and regulatory compliance • Various requirements Chapter 11: Strategic Leadership

Performance measurement • Performance: efficiency, effectiveness and adaptability • Quantify strategic, tactical and operational actions • Objectives: monitor, control and direct • Purpose of performance management system: – Support decision making – Monitor effect of strategic plans – Stakeholder requirements – Advance warning – Part of continuous improvement – Motivate workforce – ID performance gap – Record-keeping Chapter 11: Strategic Leadership

Performance measurement • Performance: efficiency, effectiveness and adaptability • Quantify strategic, tactical and operational actions • Objectives: monitor, control and direct • Purpose of performance management system: – Support decision making – Monitor effect of strategic plans – Stakeholder requirements – Advance warning – Part of continuous improvement – Motivate workforce – ID performance gap – Record-keeping Chapter 11: Strategic Leadership

Performance measures Types: • Hard direct and fact-based – financial vs. non-financial • Soft intangible and indirectly measured Dimensions of performance: • Achievement: how was my past performance? • Diagnostic: how am I performing now? • Competence: how will I perform in the future? Hierarchy of performance measures Chapter 11: Strategic Leadership

Performance measures Types: • Hard direct and fact-based – financial vs. non-financial • Soft intangible and indirectly measured Dimensions of performance: • Achievement: how was my past performance? • Diagnostic: how am I performing now? • Competence: how will I perform in the future? Hierarchy of performance measures Chapter 11: Strategic Leadership

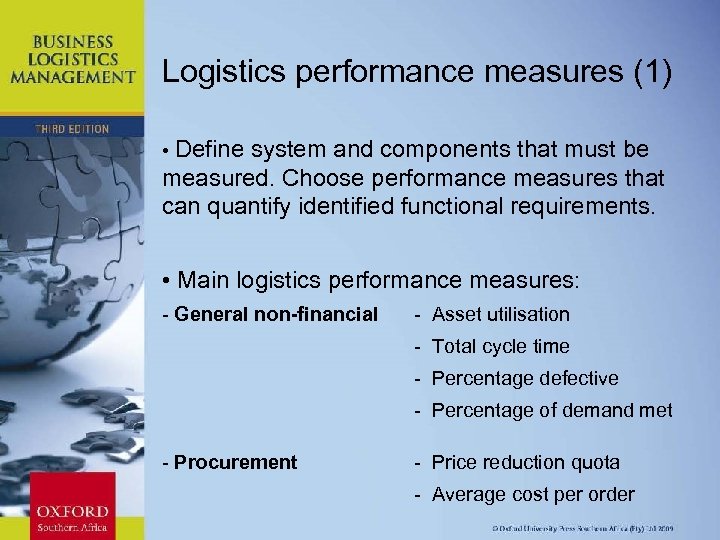

Logistics performance measures (1) • Define system and components that must be measured. Choose performance measures that can quantify identified functional requirements. • Main logistics performance measures: - General non-financial - Asset utilisation - Total cycle time - Percentage defective - Percentage of demand met - Procurement - Price reduction quota - Average cost per order Chapter 11: Strategic Leadership

Logistics performance measures (1) • Define system and components that must be measured. Choose performance measures that can quantify identified functional requirements. • Main logistics performance measures: - General non-financial - Asset utilisation - Total cycle time - Percentage defective - Percentage of demand met - Procurement - Price reduction quota - Average cost per order Chapter 11: Strategic Leadership

Logistics performance measures (2) Supplier selection - Delivery reliability - Complete shipments - Percentage good parts Inventory control - Inventory turnover - Demand not met - Inventory-carrying cost Warehousing - Order picking time - Warehouse throughput - Utilisation of equipment Chapter 11: Strategic Leadership

Logistics performance measures (2) Supplier selection - Delivery reliability - Complete shipments - Percentage good parts Inventory control - Inventory turnover - Demand not met - Inventory-carrying cost Warehousing - Order picking time - Warehouse throughput - Utilisation of equipment Chapter 11: Strategic Leadership

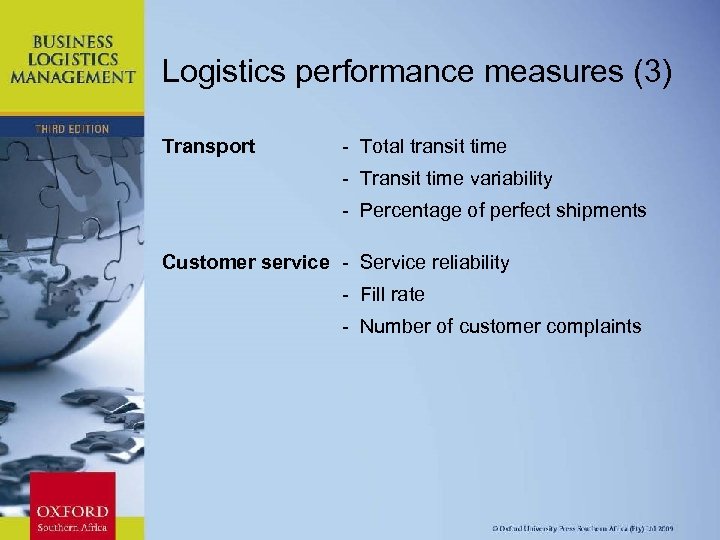

Logistics performance measures (3) Transport - Total transit time - Transit time variability - Percentage of perfect shipments Customer service - Service reliability - Fill rate - Number of customer complaints Chapter 11: Strategic Leadership

Logistics performance measures (3) Transport - Total transit time - Transit time variability - Percentage of perfect shipments Customer service - Service reliability - Fill rate - Number of customer complaints Chapter 11: Strategic Leadership

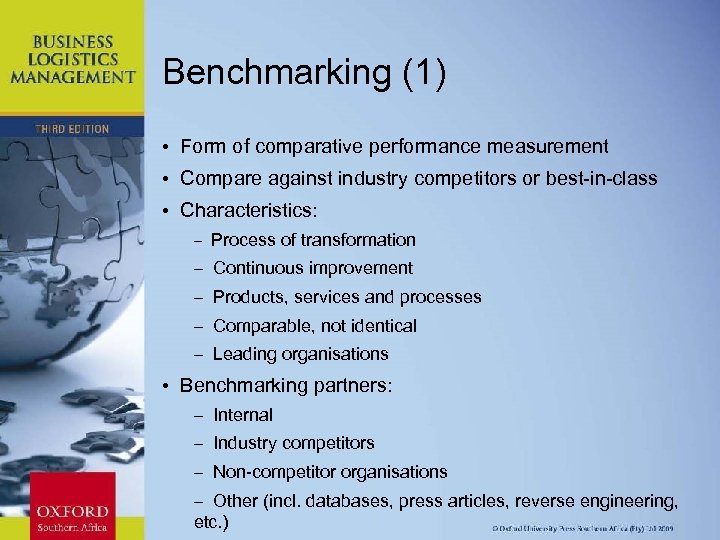

Benchmarking (1) • Form of comparative performance measurement • Compare against industry competitors or best-in-class • Characteristics: – Process of transformation – Continuous improvement – Products, services and processes – Comparable, not identical – Leading organisations • Benchmarking partners: – Internal – Industry competitors – Non-competitor organisations – Other (incl. databases, press articles, reverse engineering, Chapter 11: Strategic Leadership etc. )

Benchmarking (1) • Form of comparative performance measurement • Compare against industry competitors or best-in-class • Characteristics: – Process of transformation – Continuous improvement – Products, services and processes – Comparable, not identical – Leading organisations • Benchmarking partners: – Internal – Industry competitors – Non-competitor organisations – Other (incl. databases, press articles, reverse engineering, Chapter 11: Strategic Leadership etc. )

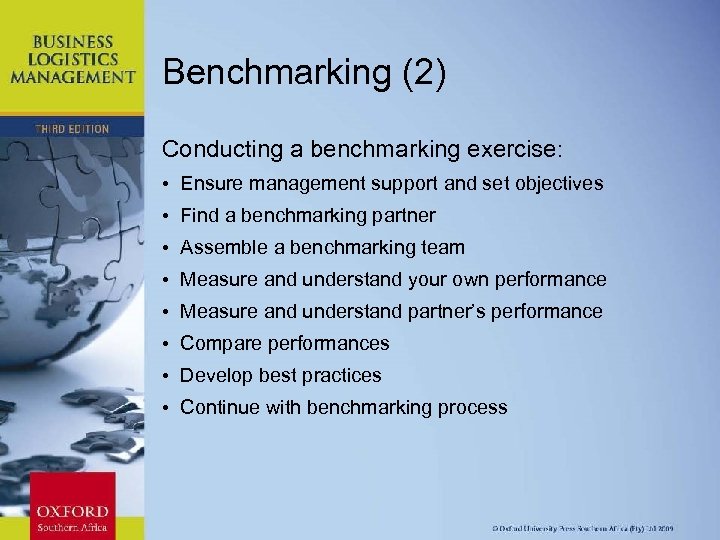

Benchmarking (2) Conducting a benchmarking exercise: • Ensure management support and set objectives • Find a benchmarking partner • Assemble a benchmarking team • Measure and understand your own performance • Measure and understand partner’s performance • Compare performances • Develop best practices • Continue with benchmarking process Chapter 11: Strategic Leadership

Benchmarking (2) Conducting a benchmarking exercise: • Ensure management support and set objectives • Find a benchmarking partner • Assemble a benchmarking team • Measure and understand your own performance • Measure and understand partner’s performance • Compare performances • Develop best practices • Continue with benchmarking process Chapter 11: Strategic Leadership

The SCOR model (1) Supply-chain operations reference model (SCOR): • Integration of: – business-process engineering; – benchmarking; and – process measurement. • Describes supply chains in a common language • Identifies performance requirements • Sets targets and measures performance • ID improvement opportunities • ID best practices and share learning Chapter 11: Strategic Leadership

The SCOR model (1) Supply-chain operations reference model (SCOR): • Integration of: – business-process engineering; – benchmarking; and – process measurement. • Describes supply chains in a common language • Identifies performance requirements • Sets targets and measures performance • ID improvement opportunities • ID best practices and share learning Chapter 11: Strategic Leadership

The SCOR model (2) Types of level 1 SCOR processes: • Plan (P) – match resources to requirements • Source (S) – connect with suppliers • Make (M) – transform materials • Deliver (D) – connect with customers • Return (R) – return from customers or to suppliers Enablers required to support above processes (e. g. transportation management must support delivery) Chapter 11: Strategic Leadership

The SCOR model (2) Types of level 1 SCOR processes: • Plan (P) – match resources to requirements • Source (S) – connect with suppliers • Make (M) – transform materials • Deliver (D) – connect with customers • Return (R) – return from customers or to suppliers Enablers required to support above processes (e. g. transportation management must support delivery) Chapter 11: Strategic Leadership

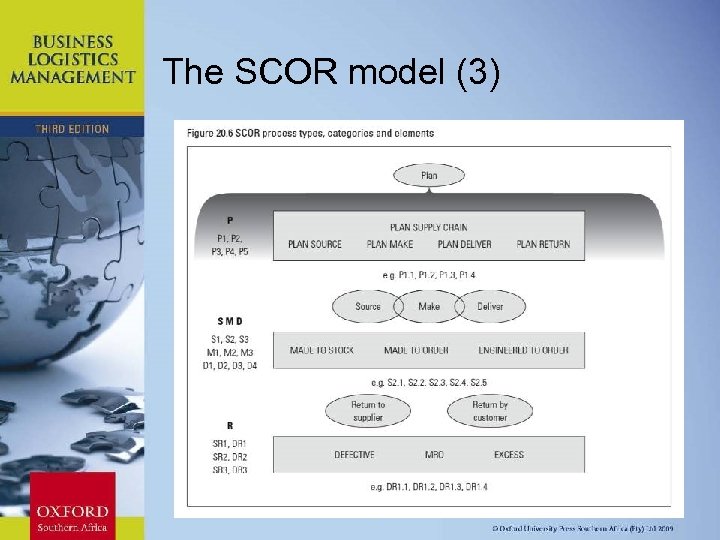

The SCOR model (3) Chapter 11: Strategic Leadership

The SCOR model (3) Chapter 11: Strategic Leadership

The SCOR model (4) Basis of supply chain competition (performance attributes): • Reliability • Responsiveness • Agility • Cost • Asset management • Performance measures developed by Supply-Chain Council (SCC) to measure achievement of goals • Use thread diagrams to assist with configuration (see pp. 454– 5) Chapter 11: Strategic Leadership

The SCOR model (4) Basis of supply chain competition (performance attributes): • Reliability • Responsiveness • Agility • Cost • Asset management • Performance measures developed by Supply-Chain Council (SCC) to measure achievement of goals • Use thread diagrams to assist with configuration (see pp. 454– 5) Chapter 11: Strategic Leadership

Business intelligence (BI) • Use software to collect, integrate, analyse and present business information from various sources • QRA expanded to advanced analytics • Data from various sources pulled into data warehouse • Use queries to extract data that meets selected criteria • Support decision making • Use dashboards to consolidate, aggregate and arrange • Automate way of rendering information from existing data • Quality of output depends on quality and availability of supply chain data Chapter 11: Strategic Leadership

Business intelligence (BI) • Use software to collect, integrate, analyse and present business information from various sources • QRA expanded to advanced analytics • Data from various sources pulled into data warehouse • Use queries to extract data that meets selected criteria • Support decision making • Use dashboards to consolidate, aggregate and arrange • Automate way of rendering information from existing data • Quality of output depends on quality and availability of supply chain data Chapter 11: Strategic Leadership