3d0c457bdc31915acc9bccf9fa7d3b25.ppt

- Количество слайдов: 39

CHAPTER 18: OPERATIONS MANAGEMENT Putting It All Together

CHAPTER 18: OPERATIONS MANAGEMENT Putting It All Together

OPERATIONS MANAGEMENT: IT ISN’T GLAMOROUS, BUT IT MATTERS…. Operations Management – all of the activities involved in creating goods and services and distributing them to customers.

OPERATIONS MANAGEMENT: IT ISN’T GLAMOROUS, BUT IT MATTERS…. Operations Management – all of the activities involved in creating goods and services and distributing them to customers.

GOOD OPERATIONS MANAGEMENT Most efficient and effective processes Produce the right goods and services Produce the right quantities Distribute products to the right customers at the right time

GOOD OPERATIONS MANAGEMENT Most efficient and effective processes Produce the right goods and services Produce the right quantities Distribute products to the right customers at the right time

THE COST OF GOODS FOR SALE Unit cost the cost to make one sensor (car, computer, cup of coffee, etc. ) Material the cost of the “stuff” you use to make your sensor smaller, faster, more reliable = higher cost Labor cost … plus … cost the cost to assemble your product

THE COST OF GOODS FOR SALE Unit cost the cost to make one sensor (car, computer, cup of coffee, etc. ) Material the cost of the “stuff” you use to make your sensor smaller, faster, more reliable = higher cost Labor cost … plus … cost the cost to assemble your product

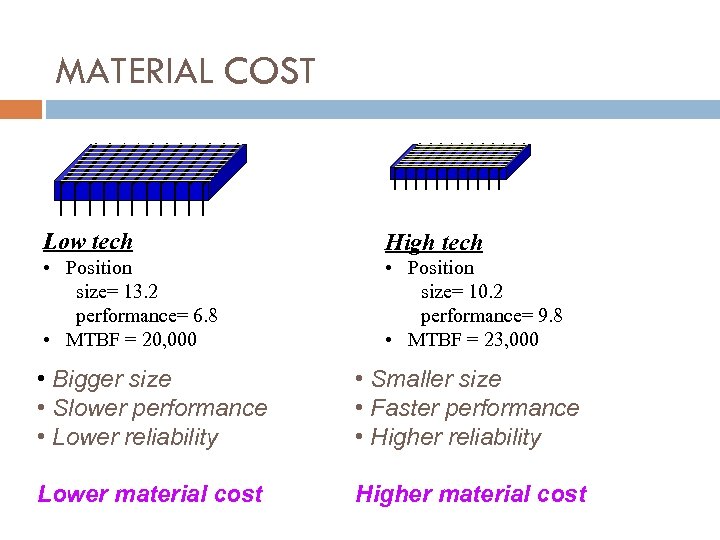

MATERIAL COST Low tech High tech • Position size= 13. 2 performance= 6. 8 • MTBF = 20, 000 • Position size= 10. 2 performance= 9. 8 • MTBF = 23, 000 • Bigger size • Slower performance • Lower reliability • Smaller size • Faster performance • Higher reliability Lower material cost Higher material cost

MATERIAL COST Low tech High tech • Position size= 13. 2 performance= 6. 8 • MTBF = 20, 000 • Position size= 10. 2 performance= 9. 8 • MTBF = 23, 000 • Bigger size • Slower performance • Lower reliability • Smaller size • Faster performance • Higher reliability Lower material cost Higher material cost

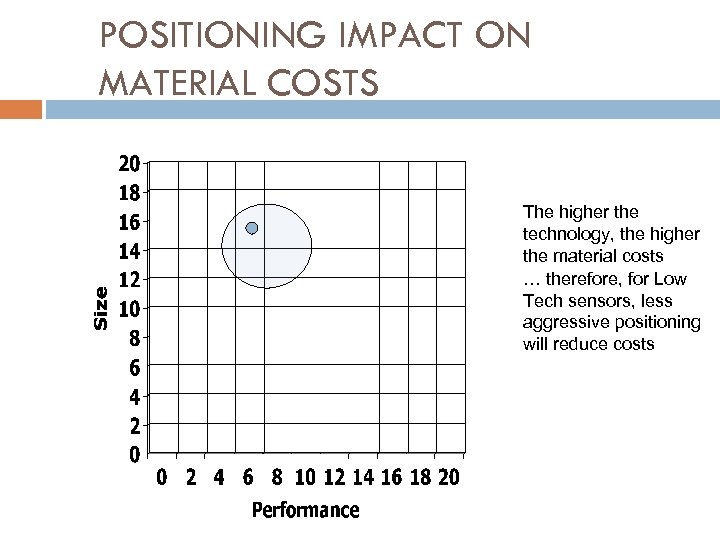

POSITIONING IMPACT ON MATERIAL COSTS The higher the technology, the higher the material costs … therefore, for Low Tech sensors, less aggressive positioning will reduce costs

POSITIONING IMPACT ON MATERIAL COSTS The higher the technology, the higher the material costs … therefore, for Low Tech sensors, less aggressive positioning will reduce costs

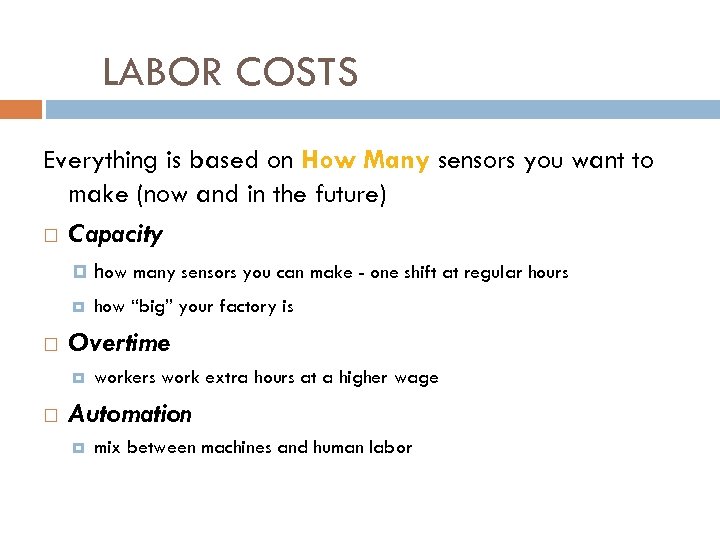

LABOR COSTS Everything is based on How Many sensors you want to make (now and in the future) Capacity how many sensors you can make - one shift at regular hours Overtime how “big” your factory is workers work extra hours at a higher wage Automation mix between machines and human labor

LABOR COSTS Everything is based on How Many sensors you want to make (now and in the future) Capacity how many sensors you can make - one shift at regular hours Overtime how “big” your factory is workers work extra hours at a higher wage Automation mix between machines and human labor

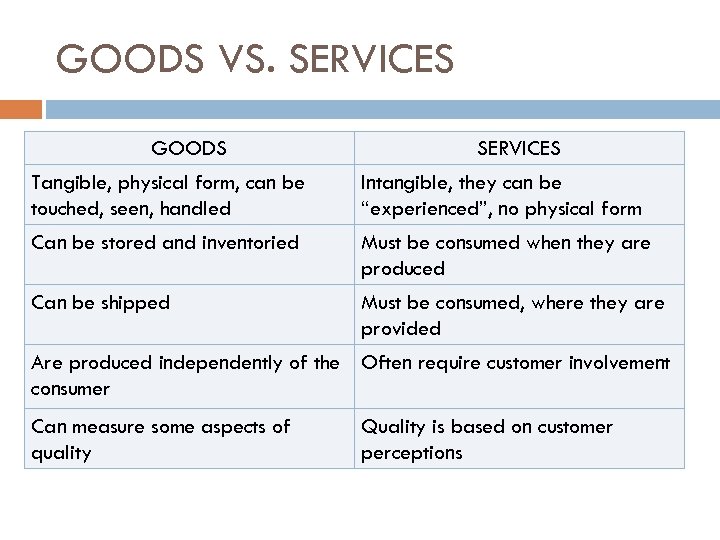

GOODS VS. SERVICES GOODS SERVICES Tangible, physical form, can be touched, seen, handled Intangible, they can be “experienced”, no physical form Can be stored and inventoried Must be consumed when they are produced Can be shipped Must be consumed, where they are provided Are produced independently of the Often require customer involvement consumer Can measure some aspects of quality Quality is based on customer perceptions

GOODS VS. SERVICES GOODS SERVICES Tangible, physical form, can be touched, seen, handled Intangible, they can be “experienced”, no physical form Can be stored and inventoried Must be consumed when they are produced Can be shipped Must be consumed, where they are provided Are produced independently of the Often require customer involvement consumer Can measure some aspects of quality Quality is based on customer perceptions

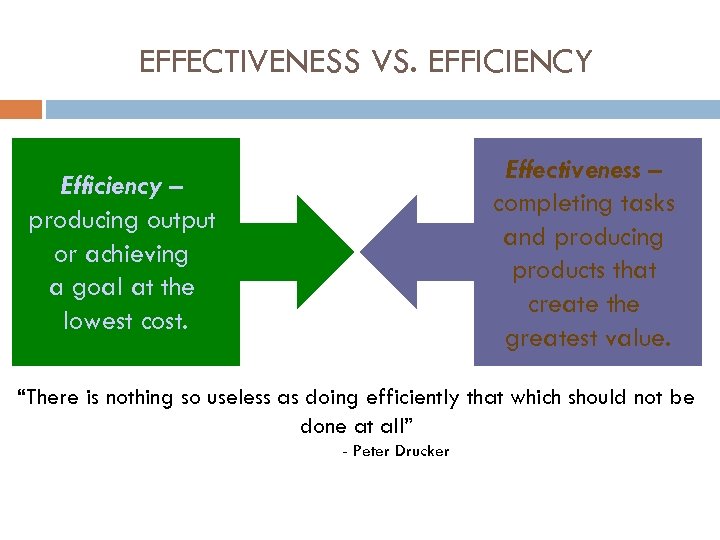

EFFECTIVENESS VS. EFFICIENCY Effectiveness – completing tasks and producing products that create the greatest value. Efficiency – producing output or achieving a goal at the lowest cost. “There is nothing so useless as doing efficiently that which should not be done at all” - Peter Drucker

EFFECTIVENESS VS. EFFICIENCY Effectiveness – completing tasks and producing products that create the greatest value. Efficiency – producing output or achieving a goal at the lowest cost. “There is nothing so useless as doing efficiently that which should not be done at all” - Peter Drucker

WHAT DO OPERATIONS MANAGERS DO? Facility Location Process Selection and Facility Layout Inventory Control Scheduling

WHAT DO OPERATIONS MANAGERS DO? Facility Location Process Selection and Facility Layout Inventory Control Scheduling

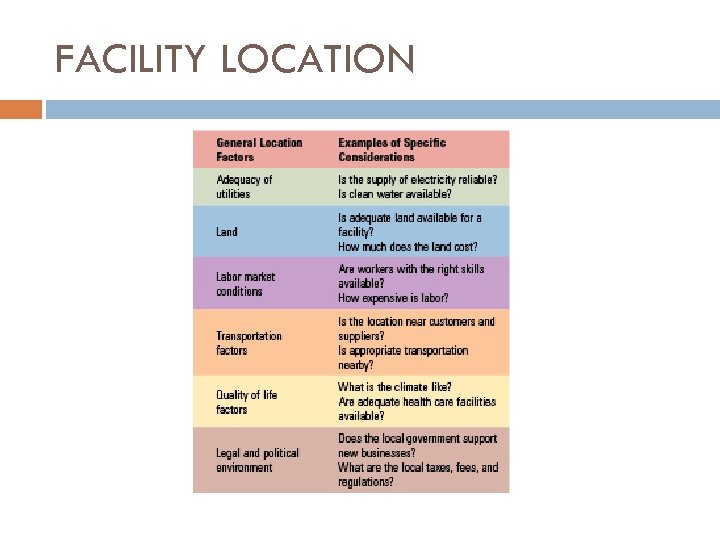

FACILITY LOCATION

FACILITY LOCATION

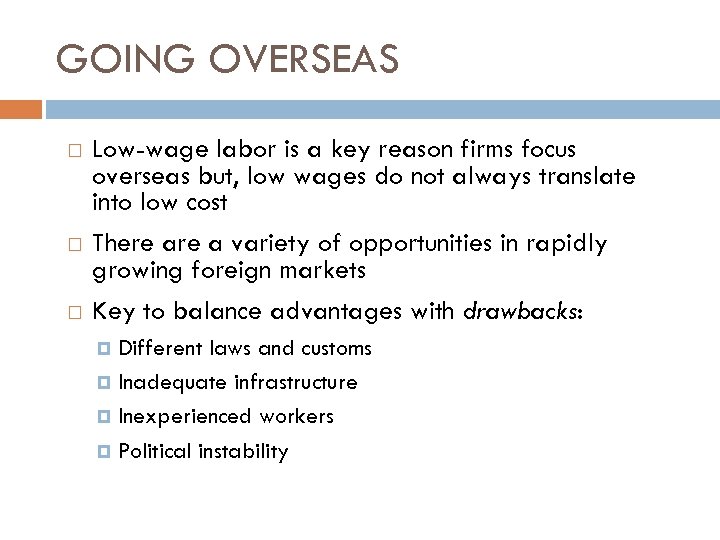

GOING OVERSEAS Low-wage labor is a key reason firms focus overseas but, low wages do not always translate into low cost There a variety of opportunities in rapidly growing foreign markets Key to balance advantages with drawbacks: Different laws and customs Inadequate infrastructure Inexperienced workers Political instability

GOING OVERSEAS Low-wage labor is a key reason firms focus overseas but, low wages do not always translate into low cost There a variety of opportunities in rapidly growing foreign markets Key to balance advantages with drawbacks: Different laws and customs Inadequate infrastructure Inexperienced workers Political instability

PROCESS SELECTION AND FACILITY LAYOUT Flow Shops Produce Large Batches Standardized Products Specialized Machinery Standardized Tasks Assembly Line is a Flow Shop Process Job Shops Produce Small Batches Variety of Products General-purpose Machinery Flexible Processes

PROCESS SELECTION AND FACILITY LAYOUT Flow Shops Produce Large Batches Standardized Products Specialized Machinery Standardized Tasks Assembly Line is a Flow Shop Process Job Shops Produce Small Batches Variety of Products General-purpose Machinery Flexible Processes

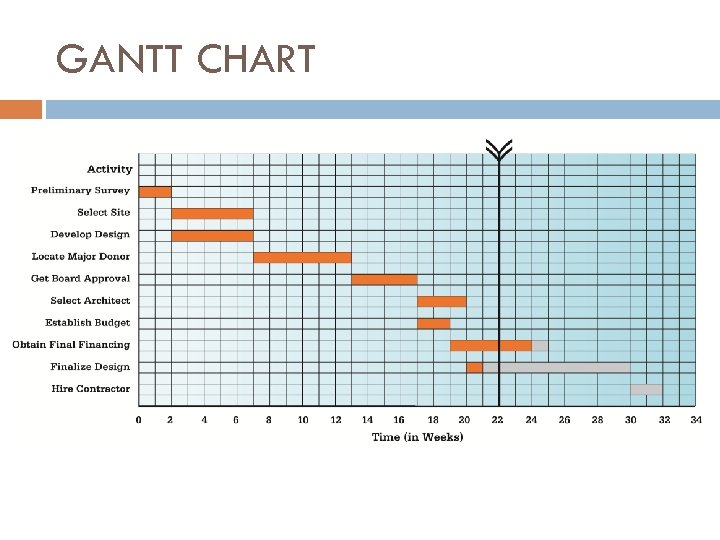

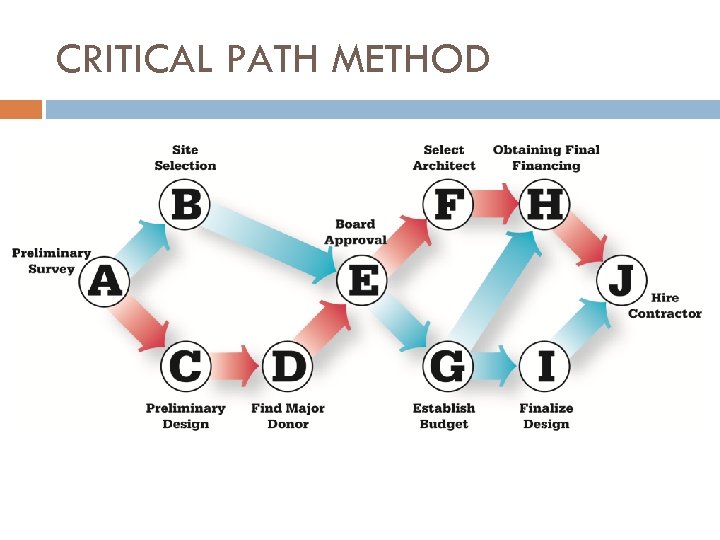

MANAGING PROJECTS Production of some products are projects Projects are usually complex and expensive New House/Building Filming a Movie Managers use Gantt charts and critical path method to manage projects

MANAGING PROJECTS Production of some products are projects Projects are usually complex and expensive New House/Building Filming a Movie Managers use Gantt charts and critical path method to manage projects

INVENTORY CONTROL: DON’T JUST SIT THERE Why hold inventories… Smooth out production schedules Meet demand increases Reduce switching costs Compensate errors forecast Why not… Unsold funds inventory ties up Inventory must be warehoused and managed Risk of losses due to spoilage, obsolescence and pilferage

INVENTORY CONTROL: DON’T JUST SIT THERE Why hold inventories… Smooth out production schedules Meet demand increases Reduce switching costs Compensate errors forecast Why not… Unsold funds inventory ties up Inventory must be warehoused and managed Risk of losses due to spoilage, obsolescence and pilferage

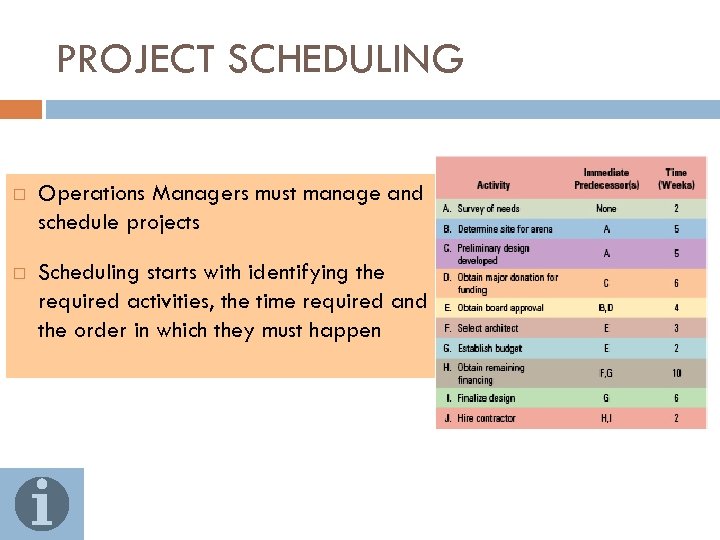

PROJECT SCHEDULING Operations Managers must manage and schedule projects Scheduling starts with identifying the required activities, the time required and the order in which they must happen

PROJECT SCHEDULING Operations Managers must manage and schedule projects Scheduling starts with identifying the required activities, the time required and the order in which they must happen

GANTT CHART

GANTT CHART

CRITICAL PATH METHOD

CRITICAL PATH METHOD

AUTOMATION: LET THE MACHINES DO IT Automation – replacing human operations and control of machinery and equipment with some form of programmed control. Robot – a programmable machine that is capable of manipulating materials in order to perform tasks.

AUTOMATION: LET THE MACHINES DO IT Automation – replacing human operations and control of machinery and equipment with some form of programmed control. Robot – a programmable machine that is capable of manipulating materials in order to perform tasks.

ROBOTS • Robots are well suited for dangerous, tedious, dirty and physically demanding tasks. • Robots don’t get tired • Robots are flexible

ROBOTS • Robots are well suited for dangerous, tedious, dirty and physically demanding tasks. • Robots don’t get tired • Robots are flexible

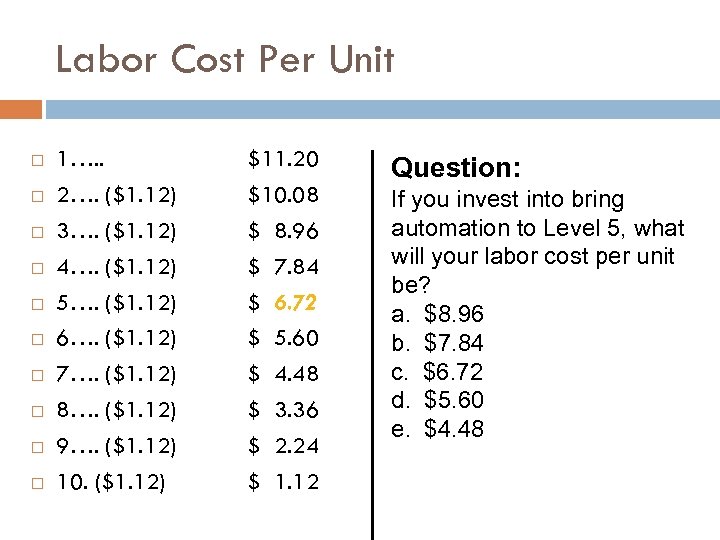

Machinery: Automation Level of robotics: from 1 – 10 Automation level of 1 Labor cost of $11. 20 per unit

Machinery: Automation Level of robotics: from 1 – 10 Automation level of 1 Labor cost of $11. 20 per unit

Machinery: Automation Level of robotics: from 1 – 10 Automation level of 1 - $11. 20 per unit Automation level of 2 Labor cost is 10% ($1. 12) lower… $10. 08

Machinery: Automation Level of robotics: from 1 – 10 Automation level of 1 - $11. 20 per unit Automation level of 2 Labor cost is 10% ($1. 12) lower… $10. 08

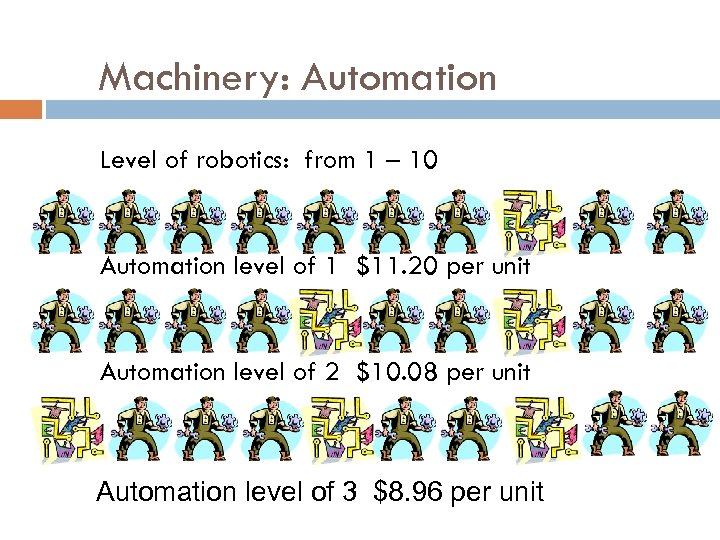

Machinery: Automation Level of robotics: from 1 – 10 Automation level of 1 $11. 20 per unit Automation level of 2 $10. 08 per unit Automation level of 3 $8. 96 per unit

Machinery: Automation Level of robotics: from 1 – 10 Automation level of 1 $11. 20 per unit Automation level of 2 $10. 08 per unit Automation level of 3 $8. 96 per unit

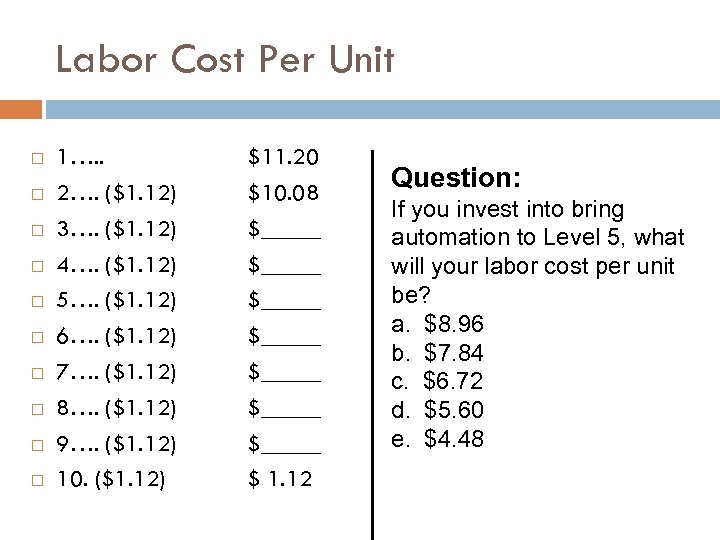

Labor Cost Per Unit 1…. . 2…. ($1. 12) 3…. ($1. 12) 4…. ($1. 12) 5…. ($1. 12) 6…. ($1. 12) 7…. ($1. 12) 8…. ($1. 12) 9…. ($1. 12) 10. ($1. 12) $11. 20 $10. 08 $_____ $_____ $ 1. 12 Question: If you invest into bring automation to Level 5, what will your labor cost per unit be? a. $8. 96 b. $7. 84 c. $6. 72 d. $5. 60 e. $4. 48

Labor Cost Per Unit 1…. . 2…. ($1. 12) 3…. ($1. 12) 4…. ($1. 12) 5…. ($1. 12) 6…. ($1. 12) 7…. ($1. 12) 8…. ($1. 12) 9…. ($1. 12) 10. ($1. 12) $11. 20 $10. 08 $_____ $_____ $ 1. 12 Question: If you invest into bring automation to Level 5, what will your labor cost per unit be? a. $8. 96 b. $7. 84 c. $6. 72 d. $5. 60 e. $4. 48

Labor Cost Per Unit 1…. . 2…. ($1. 12) 3…. ($1. 12) 4…. ($1. 12) 5…. ($1. 12) 6…. ($1. 12) 7…. ($1. 12) 8…. ($1. 12) 9…. ($1. 12) 10. ($1. 12) $11. 20 $10. 08 $ 8. 96 $ 7. 84 $ 6. 72 $ 5. 60 $ 4. 48 $ 3. 36 $ 2. 24 $ 1. 12 Question: If you invest into bring automation to Level 5, what will your labor cost per unit be? a. $8. 96 b. $7. 84 c. $6. 72 d. $5. 60 e. $4. 48

Labor Cost Per Unit 1…. . 2…. ($1. 12) 3…. ($1. 12) 4…. ($1. 12) 5…. ($1. 12) 6…. ($1. 12) 7…. ($1. 12) 8…. ($1. 12) 9…. ($1. 12) 10. ($1. 12) $11. 20 $10. 08 $ 8. 96 $ 7. 84 $ 6. 72 $ 5. 60 $ 4. 48 $ 3. 36 $ 2. 24 $ 1. 12 Question: If you invest into bring automation to Level 5, what will your labor cost per unit be? a. $8. 96 b. $7. 84 c. $6. 72 d. $5. 60 e. $4. 48

MANAGING SUPPLY CHAINS Supply chains can be complex Wide range of functions Involve many firms Heavy use of technology

MANAGING SUPPLY CHAINS Supply chains can be complex Wide range of functions Involve many firms Heavy use of technology

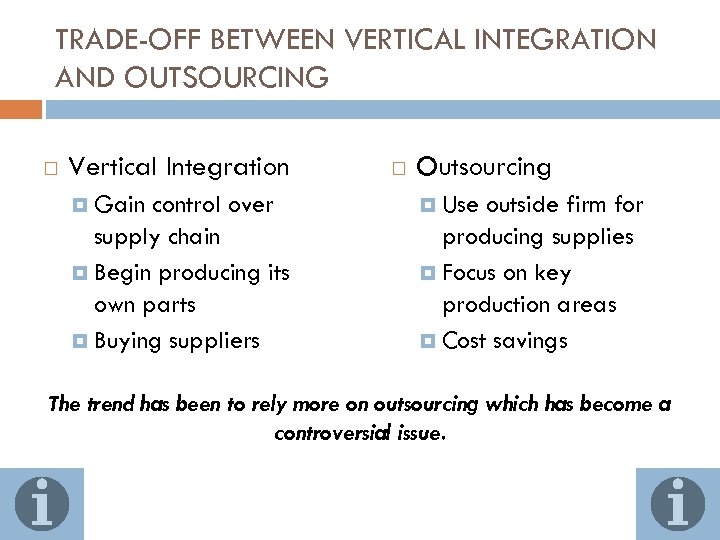

TRADE-OFF BETWEEN VERTICAL INTEGRATION AND OUTSOURCING Vertical Integration Gain control over supply chain Begin producing its own parts Buying suppliers Outsourcing Use outside firm for producing supplies Focus on key production areas Cost savings The trend has been to rely more on outsourcing which has become a controversial issue.

TRADE-OFF BETWEEN VERTICAL INTEGRATION AND OUTSOURCING Vertical Integration Gain control over supply chain Begin producing its own parts Buying suppliers Outsourcing Use outside firm for producing supplies Focus on key production areas Cost savings The trend has been to rely more on outsourcing which has become a controversial issue.

ENTERPRISE RESOURCE PLANNING (ERP) : CREATING ONE BIG SYSTEM The goal of ERP is to integrate the flow of information ERP systems can be costly and challenging to implement Most firms that complete implementation of ERP systems, report being satisfied with the results

ENTERPRISE RESOURCE PLANNING (ERP) : CREATING ONE BIG SYSTEM The goal of ERP is to integrate the flow of information ERP systems can be costly and challenging to implement Most firms that complete implementation of ERP systems, report being satisfied with the results

FOCUS ON QUALITY Quality improves effectiveness and efficiency Quality helps achieve competitive advantage Lower costs, increases value Poor quality costs

FOCUS ON QUALITY Quality improves effectiveness and efficiency Quality helps achieve competitive advantage Lower costs, increases value Poor quality costs

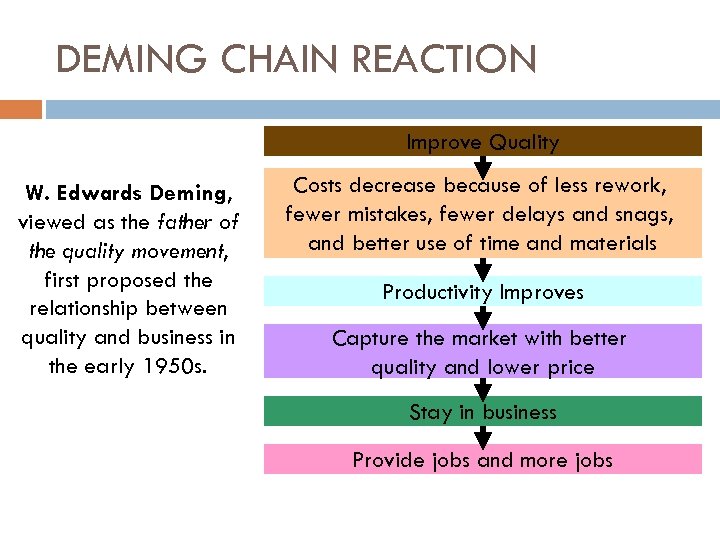

DEMING CHAIN REACTION Improve Quality W. Edwards Deming, viewed as the father of the quality movement, first proposed the relationship between quality and business in the early 1950 s. Costs decrease because of less rework, fewer mistakes, fewer delays and snags, and better use of time and materials Productivity Improves Capture the market with better quality and lower price Stay in business Provide jobs and more jobs

DEMING CHAIN REACTION Improve Quality W. Edwards Deming, viewed as the father of the quality movement, first proposed the relationship between quality and business in the early 1950 s. Costs decrease because of less rework, fewer mistakes, fewer delays and snags, and better use of time and materials Productivity Improves Capture the market with better quality and lower price Stay in business Provide jobs and more jobs

HOW AMERICAN FIRMS RESPONDED TO THE QUALITY CHALLENGE A broad concept of quality: Total Quality Management: Customer Focus Build quality throughout the organization Empowerment of employees Focus on prevention of errors Long-run commitment to continuous improvement

HOW AMERICAN FIRMS RESPONDED TO THE QUALITY CHALLENGE A broad concept of quality: Total Quality Management: Customer Focus Build quality throughout the organization Empowerment of employees Focus on prevention of errors Long-run commitment to continuous improvement

POKA-YOKES Japanese term for “mistake proofing” Procedures built into the production process that prevent workers from making mistakes… …or catch and correct mistakes

POKA-YOKES Japanese term for “mistake proofing” Procedures built into the production process that prevent workers from making mistakes… …or catch and correct mistakes

SIX SIGMA Focus on quality improvement and commitment Standard is no more that one error (defect) per 3. 4 million opportunities Requires a high level of expertise Focus on employee training

SIX SIGMA Focus on quality improvement and commitment Standard is no more that one error (defect) per 3. 4 million opportunities Requires a high level of expertise Focus on employee training

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION Founded in 1947 Network of national standards institutes in 150 nations ISO 9000 Certification Generic quality standards Updated and modified, latest version is ISO 9000: 2005 Environmental management focused standards: ISO 14000

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION Founded in 1947 Network of national standards institutes in 150 nations ISO 9000 Certification Generic quality standards Updated and modified, latest version is ISO 9000: 2005 Environmental management focused standards: ISO 14000

THE BALDRIGE NATIONAL QUALITY PROGRAM Created by Congress in 1987 to encourage global competition Participating firms are extensively evaluated Detailed reports of company strengths and weaknesses

THE BALDRIGE NATIONAL QUALITY PROGRAM Created by Congress in 1987 to encourage global competition Participating firms are extensively evaluated Detailed reports of company strengths and weaknesses

LEAN PRODUCTION: CUTTING WASTE TO IMPROVE PERFORMANCE Strategies and practices to eliminate waste Remove activities that don’t contribute value

LEAN PRODUCTION: CUTTING WASTE TO IMPROVE PERFORMANCE Strategies and practices to eliminate waste Remove activities that don’t contribute value

VALUE STREAM MAPPING A tool used to show the flows of materials and information in the production process to identify waste.

VALUE STREAM MAPPING A tool used to show the flows of materials and information in the production process to identify waste.

REDUCING INVESTMENT IN INVENTORY: JUSTIN-TIME TO THE RESCUE Produce goods and services to meet actual demand. Minimize inventories at all stages of the supply chain through coordination.

REDUCING INVESTMENT IN INVENTORY: JUSTIN-TIME TO THE RESCUE Produce goods and services to meet actual demand. Minimize inventories at all stages of the supply chain through coordination.

LEAN THINKING IN THE SERVICE SECTOR ü Standardize ü Minimize costs ü High utilization ü Simplified processes

LEAN THINKING IN THE SERVICE SECTOR ü Standardize ü Minimize costs ü High utilization ü Simplified processes