706d1c9d7600ca9d4817f8939e504878.ppt

- Количество слайдов: 42

Chapter 17 Scheduling Operations Management - 6 th Edition Roberta Russell & Bernard W. Taylor, III Copyright 2009 John Wiley & Sons, Inc. Beni Asllani University of Tennessee at Chattanooga

Chapter 17 Scheduling Operations Management - 6 th Edition Roberta Russell & Bernard W. Taylor, III Copyright 2009 John Wiley & Sons, Inc. Beni Asllani University of Tennessee at Chattanooga

Lecture Outline w w w w Objectives in Scheduling Sequencing Loading Monitoring Advanced Planning and Scheduling Systems Theory of Constraints Employee Scheduling Copyright 2009 John Wiley & Sons, Inc. 2

Lecture Outline w w w w Objectives in Scheduling Sequencing Loading Monitoring Advanced Planning and Scheduling Systems Theory of Constraints Employee Scheduling Copyright 2009 John Wiley & Sons, Inc. 2

What is Scheduling? w Last stage of planning before production occurs w Specifies when labor, equipment, and facilities are needed to produce a product or provide a service Copyright 2009 John Wiley & Sons, Inc. 3

What is Scheduling? w Last stage of planning before production occurs w Specifies when labor, equipment, and facilities are needed to produce a product or provide a service Copyright 2009 John Wiley & Sons, Inc. 3

Scheduled Operations w Process Industry n n Linear programming EOQ with non-instantaneous replenishment w Mass Production n Assembly line balancing w Batch Production n w Project n Project -scheduling techniques (PERT, CPM) Copyright 2009 John Wiley & Sons, Inc. n Aggregate planning (Sales and Operations Planning) Master scheduling Material requirements planning (MRP) Capacity requirements planning (CRP) 4

Scheduled Operations w Process Industry n n Linear programming EOQ with non-instantaneous replenishment w Mass Production n Assembly line balancing w Batch Production n w Project n Project -scheduling techniques (PERT, CPM) Copyright 2009 John Wiley & Sons, Inc. n Aggregate planning (Sales and Operations Planning) Master scheduling Material requirements planning (MRP) Capacity requirements planning (CRP) 4

Objectives in Scheduling w Meet customer due dates w Minimize job lateness w Minimize response time w Minimize completion time w Minimize time in the system Copyright 2009 John Wiley & Sons, Inc. w Minimize overtime w Maximize machine or labor utilization w Minimize idle time w Minimize work-inprocess inventory 5

Objectives in Scheduling w Meet customer due dates w Minimize job lateness w Minimize response time w Minimize completion time w Minimize time in the system Copyright 2009 John Wiley & Sons, Inc. w Minimize overtime w Maximize machine or labor utilization w Minimize idle time w Minimize work-inprocess inventory 5

Shop Floor Control (SFC) w scheduling and monitoring of day-to-day production in a job shop also called production control and production activity control (PAC) usually performed by production control department w w Loading n l Check availability of material, machines, and labor Sequencing n l Release work orders to shop and issue dispatch lists for individual machines Monitoring n l Maintain progress reports on each job until it is complete Copyright 2009 John Wiley & Sons, Inc. 6

Shop Floor Control (SFC) w scheduling and monitoring of day-to-day production in a job shop also called production control and production activity control (PAC) usually performed by production control department w w Loading n l Check availability of material, machines, and labor Sequencing n l Release work orders to shop and issue dispatch lists for individual machines Monitoring n l Maintain progress reports on each job until it is complete Copyright 2009 John Wiley & Sons, Inc. 6

Loading w Process of assigning work to limited resources w Perform work with most efficient resources w Use assignment method of linear programming to determine allocation Copyright 2009 John Wiley & Sons, Inc. 7

Loading w Process of assigning work to limited resources w Perform work with most efficient resources w Use assignment method of linear programming to determine allocation Copyright 2009 John Wiley & Sons, Inc. 7

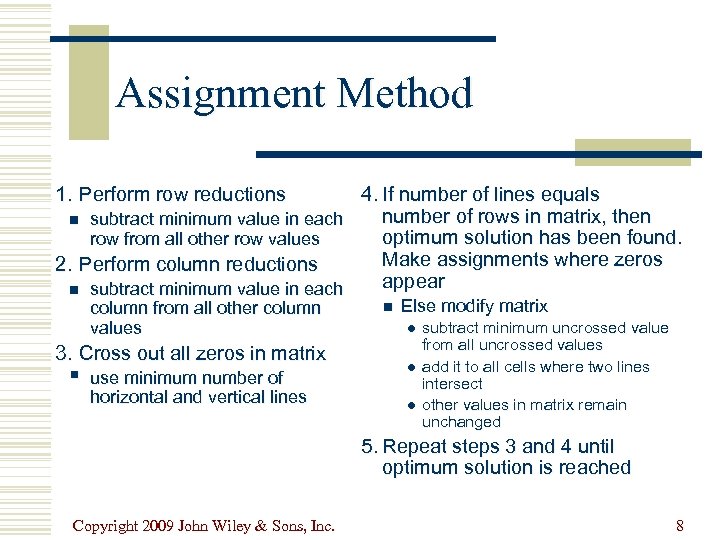

Assignment Method 1. Perform row reductions 4. If number of lines equals number of rows in matrix, then n subtract minimum value in each optimum solution has been found. row from all other row values Make assignments where zeros 2. Perform column reductions appear n subtract minimum value in each column from all other column values 3. Cross out all zeros in matrix § use minimum number of horizontal and vertical lines n Else modify matrix l l l subtract minimum uncrossed value from all uncrossed values add it to all cells where two lines intersect other values in matrix remain unchanged 5. Repeat steps 3 and 4 until optimum solution is reached Copyright 2009 John Wiley & Sons, Inc. 8

Assignment Method 1. Perform row reductions 4. If number of lines equals number of rows in matrix, then n subtract minimum value in each optimum solution has been found. row from all other row values Make assignments where zeros 2. Perform column reductions appear n subtract minimum value in each column from all other column values 3. Cross out all zeros in matrix § use minimum number of horizontal and vertical lines n Else modify matrix l l l subtract minimum uncrossed value from all uncrossed values add it to all cells where two lines intersect other values in matrix remain unchanged 5. Repeat steps 3 and 4 until optimum solution is reached Copyright 2009 John Wiley & Sons, Inc. 8

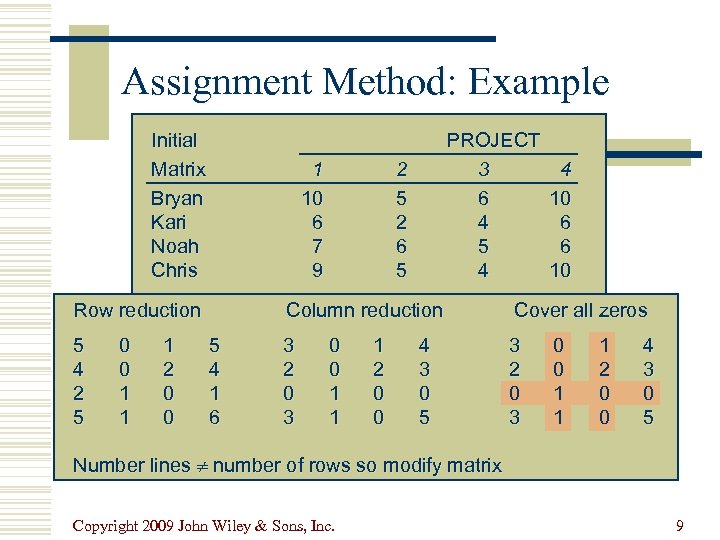

Assignment Method: Example Initial Matrix Bryan Kari Noah Chris 1 10 6 7 9 Row reduction 5 4 2 5 0 0 1 1 1 2 0 0 PROJECT 3 6 4 5 4 2 5 2 6 5 4 10 6 6 10 Column reduction 5 4 1 6 Cover all zeros 3 2 0 3 0 0 1 1 1 2 0 0 4 3 0 5 Number lines number of rows so modify matrix Copyright 2009 John Wiley & Sons, Inc. 9

Assignment Method: Example Initial Matrix Bryan Kari Noah Chris 1 10 6 7 9 Row reduction 5 4 2 5 0 0 1 1 1 2 0 0 PROJECT 3 6 4 5 4 2 5 2 6 5 4 10 6 6 10 Column reduction 5 4 1 6 Cover all zeros 3 2 0 3 0 0 1 1 1 2 0 0 4 3 0 5 Number lines number of rows so modify matrix Copyright 2009 John Wiley & Sons, Inc. 9

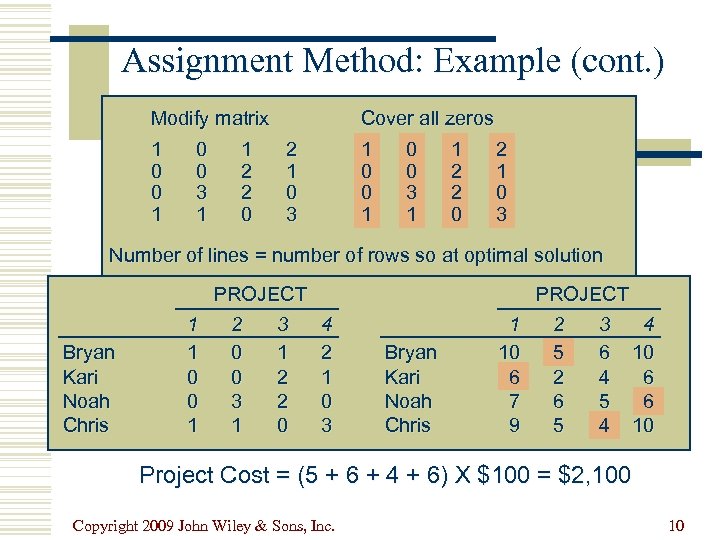

Assignment Method: Example (cont. ) Modify matrix 1 0 0 3 1 1 2 2 0 Cover all zeros 2 1 0 3 1 0 0 3 1 1 2 2 0 2 1 0 3 Number of lines = number of rows so at optimal solution Bryan Kari Noah Chris 1 1 0 0 1 PROJECT 2 3 0 1 0 2 3 2 1 0 4 2 1 0 3 Bryan Kari Noah Chris 1 10 6 7 9 PROJECT 2 3 4 5 6 10 2 4 6 6 5 4 10 Project Cost = (5 + 6 + 4 + 6) X $100 = $2, 100 Copyright 2009 John Wiley & Sons, Inc. 10

Assignment Method: Example (cont. ) Modify matrix 1 0 0 3 1 1 2 2 0 Cover all zeros 2 1 0 3 1 0 0 3 1 1 2 2 0 2 1 0 3 Number of lines = number of rows so at optimal solution Bryan Kari Noah Chris 1 1 0 0 1 PROJECT 2 3 0 1 0 2 3 2 1 0 4 2 1 0 3 Bryan Kari Noah Chris 1 10 6 7 9 PROJECT 2 3 4 5 6 10 2 4 6 6 5 4 10 Project Cost = (5 + 6 + 4 + 6) X $100 = $2, 100 Copyright 2009 John Wiley & Sons, Inc. 10

Sequencing § § § Prioritize jobs assigned to a resource If no order specified use first-come first-served (FCFS) Other Sequencing Rules §FCFS - first-come, first-served §LCFS - last come, first served §DDATE - earliest due date §CUSTPR - highest customer priority §SETUP - similar required setups §SLACK - smallest slack §CR - smallest critical ratio §SPT - shortest processing time §LPT - longest processing time Copyright 2009 John Wiley & Sons, Inc. 11

Sequencing § § § Prioritize jobs assigned to a resource If no order specified use first-come first-served (FCFS) Other Sequencing Rules §FCFS - first-come, first-served §LCFS - last come, first served §DDATE - earliest due date §CUSTPR - highest customer priority §SETUP - similar required setups §SLACK - smallest slack §CR - smallest critical ratio §SPT - shortest processing time §LPT - longest processing time Copyright 2009 John Wiley & Sons, Inc. 11

Minimum Slack and Smallest Critical Ratio § SLACK considers both work and time remaining SLACK = (due date – today’s date) – (processing time) § CR recalculates sequence as processing continues and arranges information in ratio form CR = time remaining work remaining = due date - today’s date remaining processing time If CR > 1, job ahead of schedule If CR < 1, job behind schedule If CR = 1, job on schedule Copyright 2009 John Wiley & Sons, Inc. 12

Minimum Slack and Smallest Critical Ratio § SLACK considers both work and time remaining SLACK = (due date – today’s date) – (processing time) § CR recalculates sequence as processing continues and arranges information in ratio form CR = time remaining work remaining = due date - today’s date remaining processing time If CR > 1, job ahead of schedule If CR < 1, job behind schedule If CR = 1, job on schedule Copyright 2009 John Wiley & Sons, Inc. 12

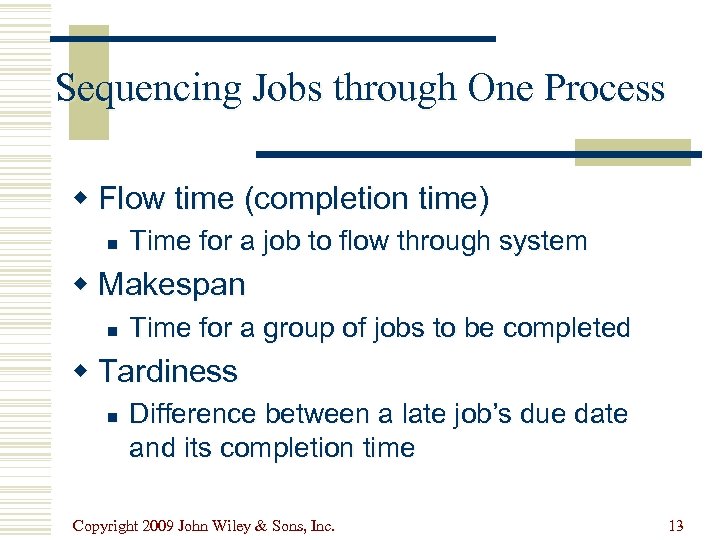

Sequencing Jobs through One Process w Flow time (completion time) n Time for a job to flow through system w Makespan n Time for a group of jobs to be completed w Tardiness n Difference between a late job’s due date and its completion time Copyright 2009 John Wiley & Sons, Inc. 13

Sequencing Jobs through One Process w Flow time (completion time) n Time for a job to flow through system w Makespan n Time for a group of jobs to be completed w Tardiness n Difference between a late job’s due date and its completion time Copyright 2009 John Wiley & Sons, Inc. 13

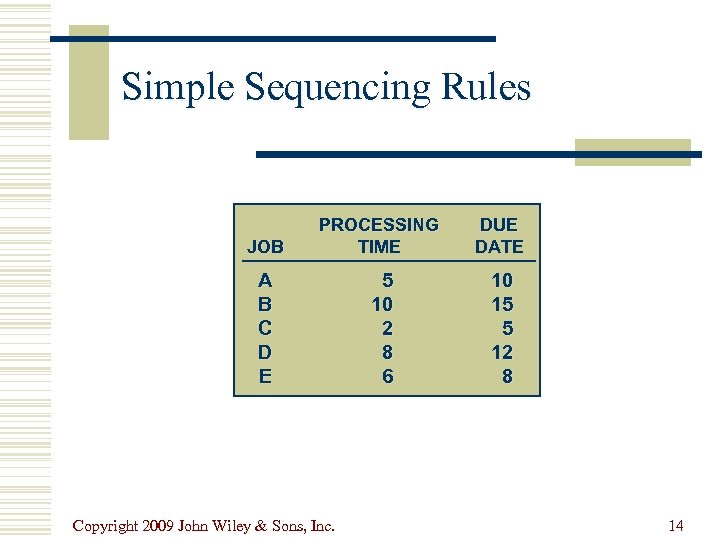

Simple Sequencing Rules JOB PROCESSING TIME DUE DATE A B C D E 5 10 2 8 6 10 15 5 12 8 Copyright 2009 John Wiley & Sons, Inc. 14

Simple Sequencing Rules JOB PROCESSING TIME DUE DATE A B C D E 5 10 2 8 6 10 15 5 12 8 Copyright 2009 John Wiley & Sons, Inc. 14

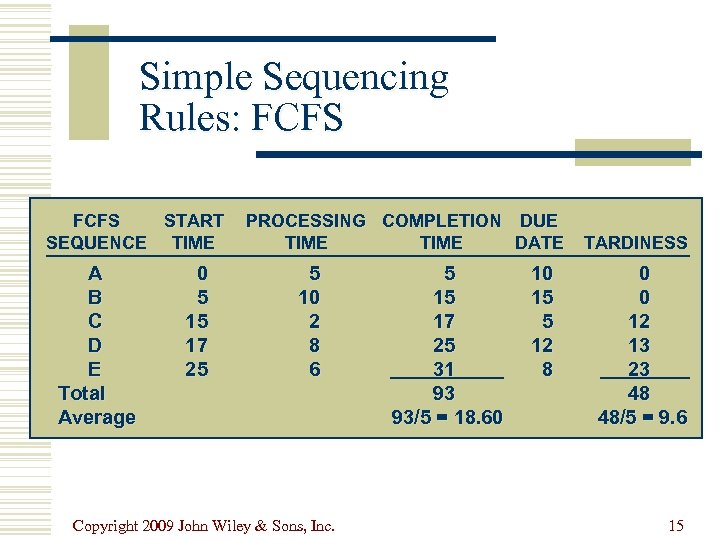

Simple Sequencing Rules: FCFS START SEQUENCE TIME A B C D E Total Average 0 5 15 17 25 PROCESSING COMPLETION DUE TIME DATE 5 10 2 8 6 Copyright 2009 John Wiley & Sons, Inc. 5 15 17 25 31 93 93/5 = 18. 60 10 15 5 12 8 TARDINESS 0 0 12 13 23 48 48/5 = 9. 6 15

Simple Sequencing Rules: FCFS START SEQUENCE TIME A B C D E Total Average 0 5 15 17 25 PROCESSING COMPLETION DUE TIME DATE 5 10 2 8 6 Copyright 2009 John Wiley & Sons, Inc. 5 15 17 25 31 93 93/5 = 18. 60 10 15 5 12 8 TARDINESS 0 0 12 13 23 48 48/5 = 9. 6 15

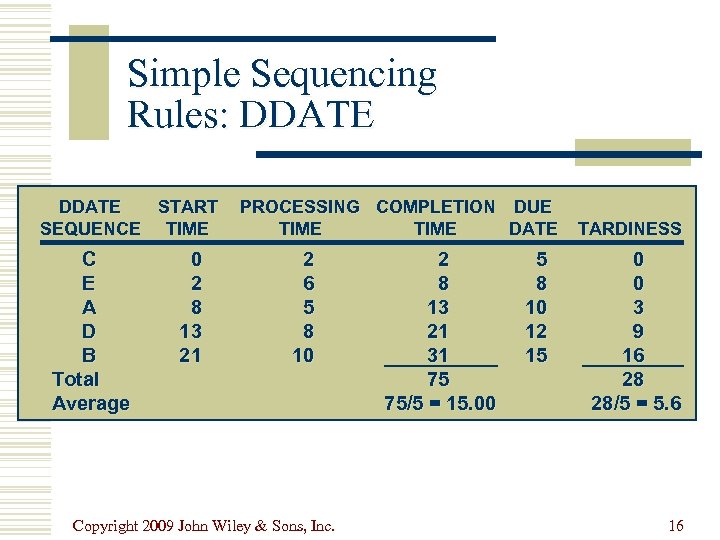

Simple Sequencing Rules: DDATE START SEQUENCE TIME C E A D B Total Average 0 2 8 13 21 PROCESSING COMPLETION DUE TIME DATE 2 6 5 8 10 Copyright 2009 John Wiley & Sons, Inc. 2 8 13 21 31 75 75/5 = 15. 00 5 8 10 12 15 TARDINESS 0 0 3 9 16 28 28/5 = 5. 6 16

Simple Sequencing Rules: DDATE START SEQUENCE TIME C E A D B Total Average 0 2 8 13 21 PROCESSING COMPLETION DUE TIME DATE 2 6 5 8 10 Copyright 2009 John Wiley & Sons, Inc. 2 8 13 21 31 75 75/5 = 15. 00 5 8 10 12 15 TARDINESS 0 0 3 9 16 28 28/5 = 5. 6 16

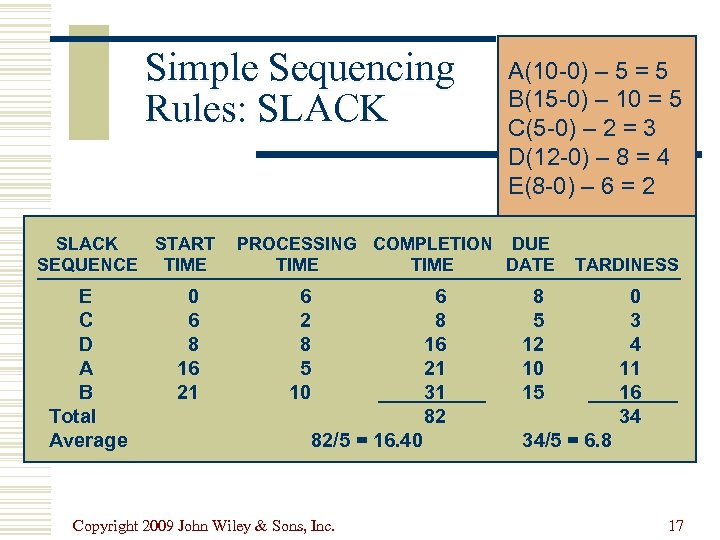

Simple Sequencing Rules: SLACK START SEQUENCE TIME E C D A B Total Average 0 6 8 16 21 A(10 -0) – 5 = 5 B(15 -0) – 10 = 5 C(5 -0) – 2 = 3 D(12 -0) – 8 = 4 E(8 -0) – 6 = 2 PROCESSING COMPLETION DUE TIME DATE 6 2 8 5 10 82/5 = 16. 40 Copyright 2009 John Wiley & Sons, Inc. 6 8 16 21 31 82 TARDINESS 8 5 12 10 15 0 3 4 11 16 34 34/5 = 6. 8 17

Simple Sequencing Rules: SLACK START SEQUENCE TIME E C D A B Total Average 0 6 8 16 21 A(10 -0) – 5 = 5 B(15 -0) – 10 = 5 C(5 -0) – 2 = 3 D(12 -0) – 8 = 4 E(8 -0) – 6 = 2 PROCESSING COMPLETION DUE TIME DATE 6 2 8 5 10 82/5 = 16. 40 Copyright 2009 John Wiley & Sons, Inc. 6 8 16 21 31 82 TARDINESS 8 5 12 10 15 0 3 4 11 16 34 34/5 = 6. 8 17

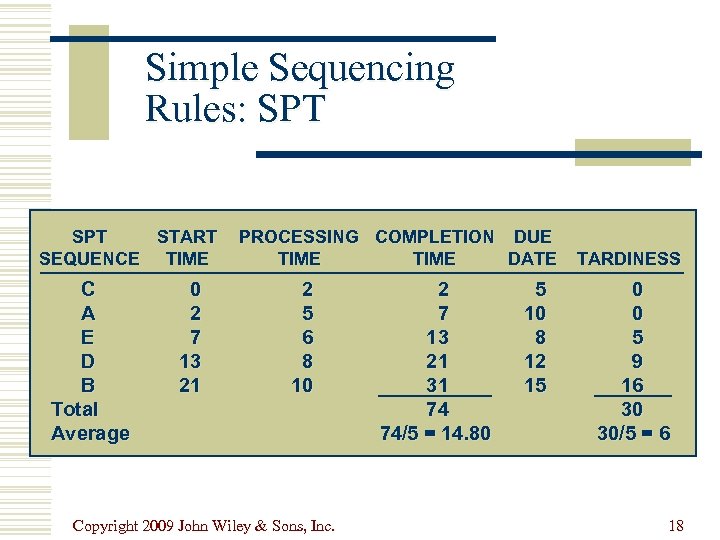

Simple Sequencing Rules: SPT START SEQUENCE TIME C A E D B Total Average 0 2 7 13 21 PROCESSING COMPLETION DUE TIME DATE 2 5 6 8 10 Copyright 2009 John Wiley & Sons, Inc. 2 7 13 21 31 74 74/5 = 14. 80 5 10 8 12 15 TARDINESS 0 0 5 9 16 30 30/5 = 6 18

Simple Sequencing Rules: SPT START SEQUENCE TIME C A E D B Total Average 0 2 7 13 21 PROCESSING COMPLETION DUE TIME DATE 2 5 6 8 10 Copyright 2009 John Wiley & Sons, Inc. 2 7 13 21 31 74 74/5 = 14. 80 5 10 8 12 15 TARDINESS 0 0 5 9 16 30 30/5 = 6 18

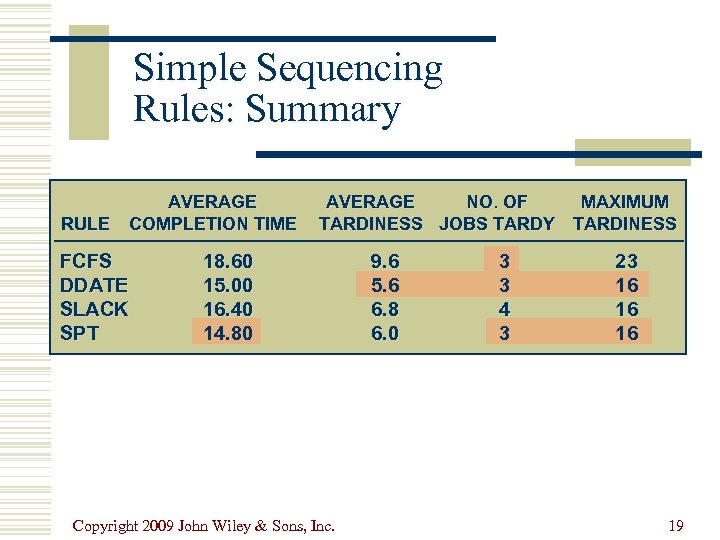

Simple Sequencing Rules: Summary RULE AVERAGE COMPLETION TIME FCFS DDATE SLACK SPT AVERAGE NO. OF MAXIMUM TARDINESS JOBS TARDY TARDINESS 18. 60 15. 00 16. 40 14. 80 Copyright 2009 John Wiley & Sons, Inc. 9. 6 5. 6 6. 8 6. 0 3 3 4 3 23 16 16 16 19

Simple Sequencing Rules: Summary RULE AVERAGE COMPLETION TIME FCFS DDATE SLACK SPT AVERAGE NO. OF MAXIMUM TARDINESS JOBS TARDY TARDINESS 18. 60 15. 00 16. 40 14. 80 Copyright 2009 John Wiley & Sons, Inc. 9. 6 5. 6 6. 8 6. 0 3 3 4 3 23 16 16 16 19

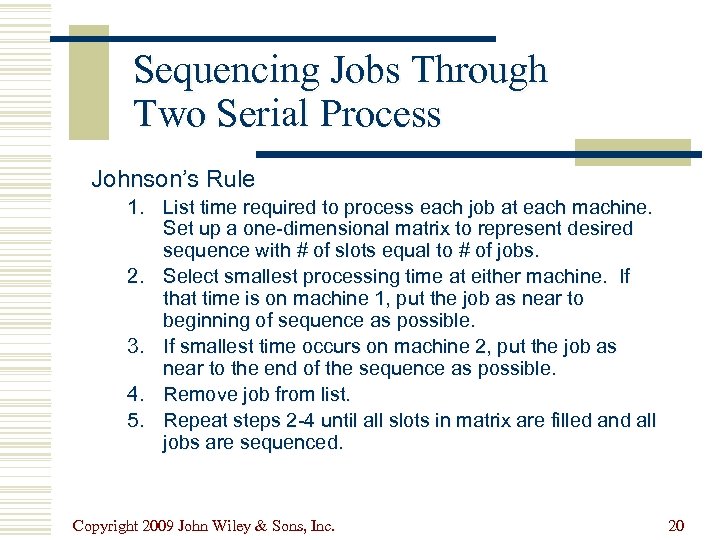

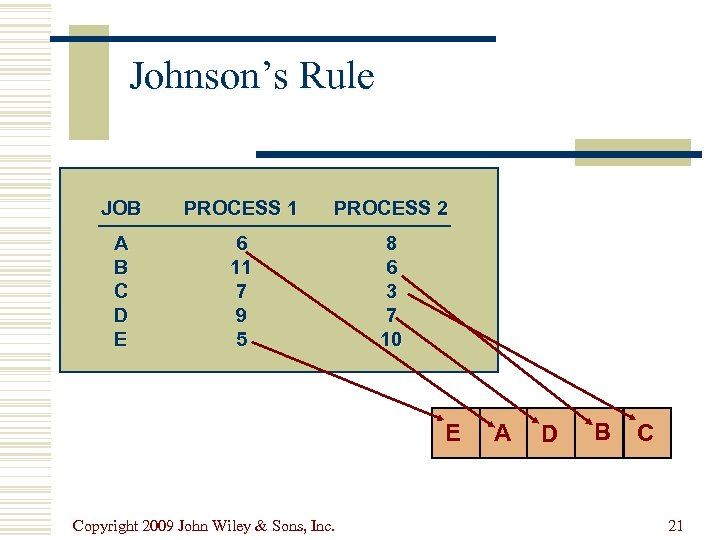

Sequencing Jobs Through Two Serial Process Johnson’s Rule 1. List time required to process each job at each machine. Set up a one-dimensional matrix to represent desired sequence with # of slots equal to # of jobs. 2. Select smallest processing time at either machine. If that time is on machine 1, put the job as near to beginning of sequence as possible. 3. If smallest time occurs on machine 2, put the job as near to the end of the sequence as possible. 4. Remove job from list. 5. Repeat steps 2 -4 until all slots in matrix are filled and all jobs are sequenced. Copyright 2009 John Wiley & Sons, Inc. 20

Sequencing Jobs Through Two Serial Process Johnson’s Rule 1. List time required to process each job at each machine. Set up a one-dimensional matrix to represent desired sequence with # of slots equal to # of jobs. 2. Select smallest processing time at either machine. If that time is on machine 1, put the job as near to beginning of sequence as possible. 3. If smallest time occurs on machine 2, put the job as near to the end of the sequence as possible. 4. Remove job from list. 5. Repeat steps 2 -4 until all slots in matrix are filled and all jobs are sequenced. Copyright 2009 John Wiley & Sons, Inc. 20

Johnson’s Rule JOB PROCESS 1 PROCESS 2 A B C D E 6 11 7 9 5 8 6 3 7 10 E Copyright 2009 John Wiley & Sons, Inc. A D B C 21

Johnson’s Rule JOB PROCESS 1 PROCESS 2 A B C D E 6 11 7 9 5 8 6 3 7 10 E Copyright 2009 John Wiley & Sons, Inc. A D B C 21

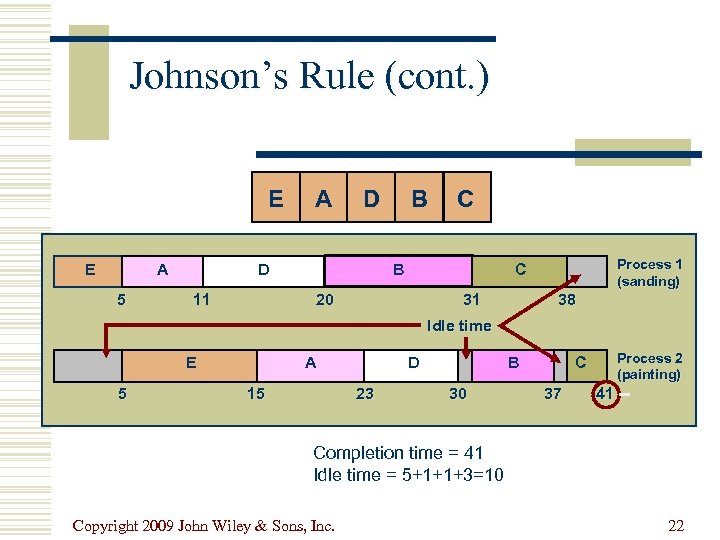

Johnson’s Rule (cont. ) E E A 5 A D D 11 B C B Process 1 (sanding) C 20 31 38 Idle time E 5 A 15 D 23 B 30 Process 2 (painting) C 37 41 Completion time = 41 Idle time = 5+1+1+3=10 Copyright 2009 John Wiley & Sons, Inc. 22

Johnson’s Rule (cont. ) E E A 5 A D D 11 B C B Process 1 (sanding) C 20 31 38 Idle time E 5 A 15 D 23 B 30 Process 2 (painting) C 37 41 Completion time = 41 Idle time = 5+1+1+3=10 Copyright 2009 John Wiley & Sons, Inc. 22

Guidelines for Selecting a Sequencing Rule 1. 2. 3. 4. 5. 6. SPT most useful when shop is highly congested Use SLACK for periods of normal activity Use DDATE when only small tardiness values can be tolerated Use LPT if subcontracting is anticipated Use FCFS when operating at low-capacity levels Do not use SPT to sequence jobs that have to be assembled with other jobs at a later date Copyright 2009 John Wiley & Sons, Inc. 23

Guidelines for Selecting a Sequencing Rule 1. 2. 3. 4. 5. 6. SPT most useful when shop is highly congested Use SLACK for periods of normal activity Use DDATE when only small tardiness values can be tolerated Use LPT if subcontracting is anticipated Use FCFS when operating at low-capacity levels Do not use SPT to sequence jobs that have to be assembled with other jobs at a later date Copyright 2009 John Wiley & Sons, Inc. 23

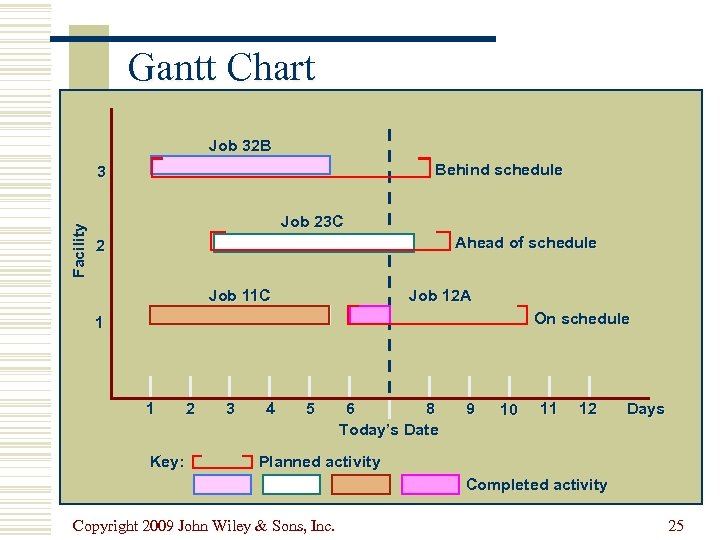

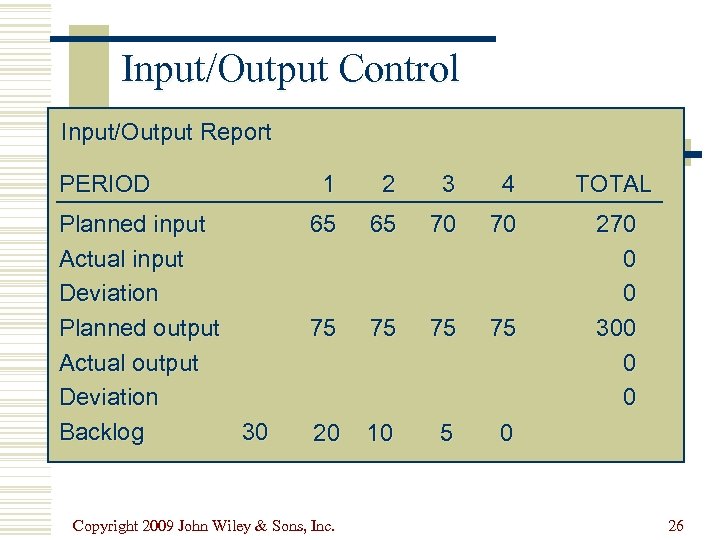

Monitoring w Work package n Shop paperwork that travels with a job w Gantt Chart n Shows both planned and completed activities against a time scale w Input/Output Control n Monitors the input and output from each work center Copyright 2009 John Wiley & Sons, Inc. 24

Monitoring w Work package n Shop paperwork that travels with a job w Gantt Chart n Shows both planned and completed activities against a time scale w Input/Output Control n Monitors the input and output from each work center Copyright 2009 John Wiley & Sons, Inc. 24

Gantt Chart Job 32 B Behind schedule Facility 3 Job 23 C Ahead of schedule 2 Job 11 C Job 12 A On schedule 1 1 Key: 2 3 4 5 6 8 Today’s Date 9 10 11 12 Days Planned activity Completed activity Copyright 2009 John Wiley & Sons, Inc. 25

Gantt Chart Job 32 B Behind schedule Facility 3 Job 23 C Ahead of schedule 2 Job 11 C Job 12 A On schedule 1 1 Key: 2 3 4 5 6 8 Today’s Date 9 10 11 12 Days Planned activity Completed activity Copyright 2009 John Wiley & Sons, Inc. 25

Input/Output Control Input/Output Report PERIOD Planned input Actual input Deviation Planned output Actual output Deviation Backlog 30 1 2 3 4 TOTAL 65 65 70 70 75 75 270 0 0 300 0 0 20 10 5 0 Copyright 2009 John Wiley & Sons, Inc. 26

Input/Output Control Input/Output Report PERIOD Planned input Actual input Deviation Planned output Actual output Deviation Backlog 30 1 2 3 4 TOTAL 65 65 70 70 75 75 270 0 0 300 0 0 20 10 5 0 Copyright 2009 John Wiley & Sons, Inc. 26

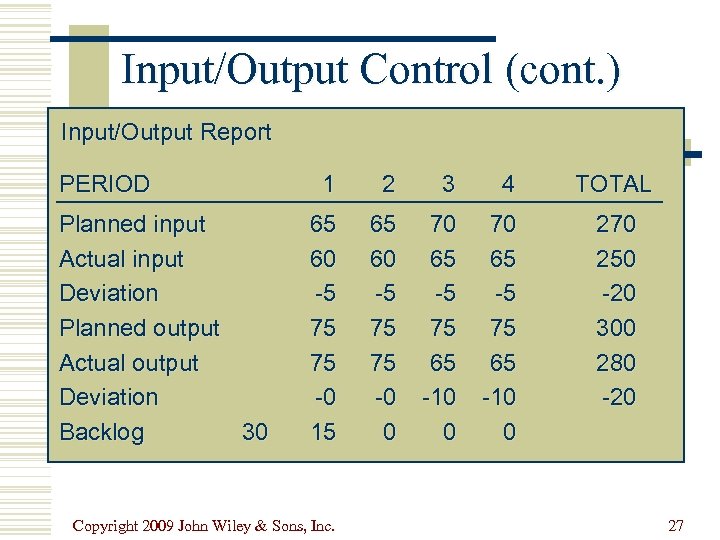

Input/Output Control (cont. ) Input/Output Report PERIOD Planned input Actual input Deviation Planned output Actual output Deviation Backlog 30 1 2 3 4 65 60 -5 75 75 -0 15 65 60 -5 75 75 -0 0 70 65 -5 75 65 -10 0 Copyright 2009 John Wiley & Sons, Inc. TOTAL 270 250 -20 300 280 -20 27

Input/Output Control (cont. ) Input/Output Report PERIOD Planned input Actual input Deviation Planned output Actual output Deviation Backlog 30 1 2 3 4 65 60 -5 75 75 -0 15 65 60 -5 75 75 -0 0 70 65 -5 75 65 -10 0 Copyright 2009 John Wiley & Sons, Inc. TOTAL 270 250 -20 300 280 -20 27

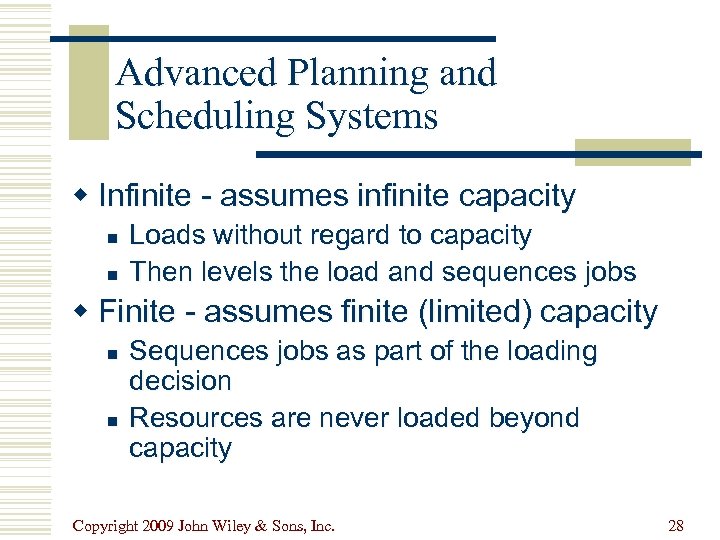

Advanced Planning and Scheduling Systems w Infinite - assumes infinite capacity n n Loads without regard to capacity Then levels the load and sequences jobs w Finite - assumes finite (limited) capacity n n Sequences jobs as part of the loading decision Resources are never loaded beyond capacity Copyright 2009 John Wiley & Sons, Inc. 28

Advanced Planning and Scheduling Systems w Infinite - assumes infinite capacity n n Loads without regard to capacity Then levels the load and sequences jobs w Finite - assumes finite (limited) capacity n n Sequences jobs as part of the loading decision Resources are never loaded beyond capacity Copyright 2009 John Wiley & Sons, Inc. 28

Advanced Planning and Scheduling Systems (cont. ) w Advanced planning and scheduling (APS) n n Add-ins to ERP systems Constraint-based programming (CBP) identifies a solution space and evaluates alternatives Genetic algorithms based on natural selection properties of genetics Manufacturing execution system (MES) monitors status, usage, availability, quality Copyright 2009 John Wiley & Sons, Inc. 29

Advanced Planning and Scheduling Systems (cont. ) w Advanced planning and scheduling (APS) n n Add-ins to ERP systems Constraint-based programming (CBP) identifies a solution space and evaluates alternatives Genetic algorithms based on natural selection properties of genetics Manufacturing execution system (MES) monitors status, usage, availability, quality Copyright 2009 John Wiley & Sons, Inc. 29

Theory of Constraints w w Not all resources are used evenly Concentrate on the” bottleneck” resource Synchronize flow through the bottleneck Use process and transfer batch sizes to move product through facility Copyright 2009 John Wiley & Sons, Inc. 30

Theory of Constraints w w Not all resources are used evenly Concentrate on the” bottleneck” resource Synchronize flow through the bottleneck Use process and transfer batch sizes to move product through facility Copyright 2009 John Wiley & Sons, Inc. 30

Drum-Buffer-Rope w Drum n Bottleneck, beating to set the pace of production for the rest of the system w Buffer n n Inventory placed in front of the bottleneck to ensure it is always kept busy Determines output or throughput of the system w Rope n Communication signal; tells processes upstream when they should begin production Copyright 2009 John Wiley & Sons, Inc. 31

Drum-Buffer-Rope w Drum n Bottleneck, beating to set the pace of production for the rest of the system w Buffer n n Inventory placed in front of the bottleneck to ensure it is always kept busy Determines output or throughput of the system w Rope n Communication signal; tells processes upstream when they should begin production Copyright 2009 John Wiley & Sons, Inc. 31

TOC Scheduling Procedure w Identify bottleneck w Schedule job first whose lead time to bottleneck is less than or equal to bottleneck processing time w Forward schedule bottleneck machine w Backward schedule other machines to sustain bottleneck schedule w Transfer in batch sizes smaller than process batch size Copyright 2009 John Wiley & Sons, Inc. 32

TOC Scheduling Procedure w Identify bottleneck w Schedule job first whose lead time to bottleneck is less than or equal to bottleneck processing time w Forward schedule bottleneck machine w Backward schedule other machines to sustain bottleneck schedule w Transfer in batch sizes smaller than process batch size Copyright 2009 John Wiley & Sons, Inc. 32

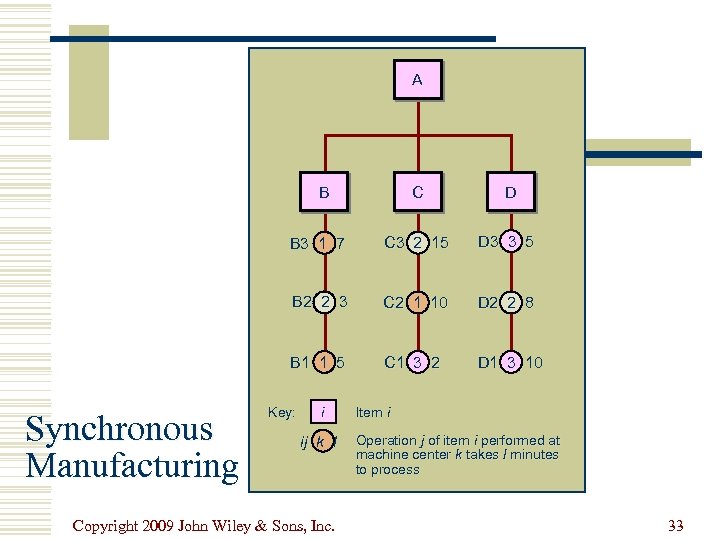

A B D B 3 1 7 C 3 2 15 D 3 3 5 B 2 2 3 C 2 1 10 D 2 2 8 B 1 1 5 Synchronous Manufacturing C C 1 3 2 D 1 3 10 Key: i ij k l Copyright 2009 John Wiley & Sons, Inc. Item i Operation j of item i performed at machine center k takes l minutes to process 33

A B D B 3 1 7 C 3 2 15 D 3 3 5 B 2 2 3 C 2 1 10 D 2 2 8 B 1 1 5 Synchronous Manufacturing C C 1 3 2 D 1 3 10 Key: i ij k l Copyright 2009 John Wiley & Sons, Inc. Item i Operation j of item i performed at machine center k takes l minutes to process 33

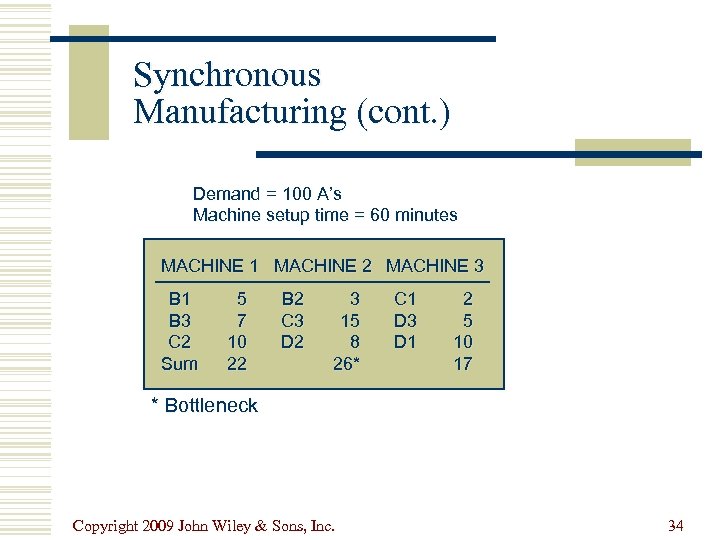

Synchronous Manufacturing (cont. ) Demand = 100 A’s Machine setup time = 60 minutes MACHINE 1 MACHINE 2 MACHINE 3 B 1 B 3 C 2 Sum 5 7 10 22 B 2 C 3 D 2 3 15 8 26* C 1 D 3 D 1 2 5 10 17 * Bottleneck Copyright 2009 John Wiley & Sons, Inc. 34

Synchronous Manufacturing (cont. ) Demand = 100 A’s Machine setup time = 60 minutes MACHINE 1 MACHINE 2 MACHINE 3 B 1 B 3 C 2 Sum 5 7 10 22 B 2 C 3 D 2 3 15 8 26* C 1 D 3 D 1 2 5 10 17 * Bottleneck Copyright 2009 John Wiley & Sons, Inc. 34

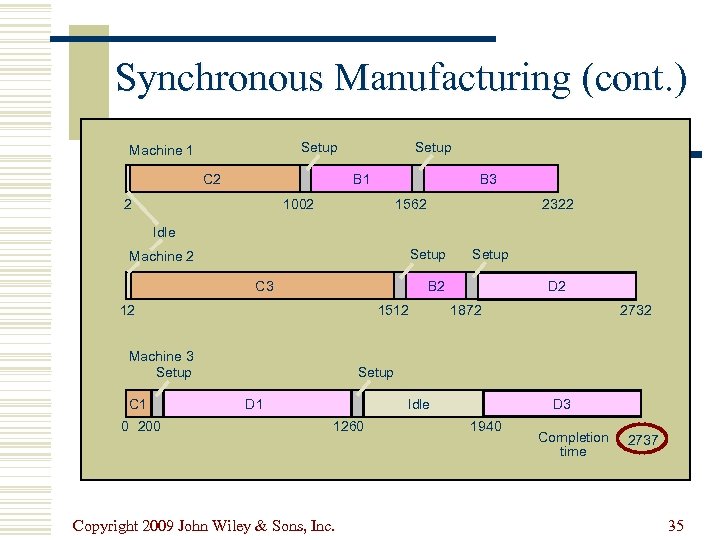

Synchronous Manufacturing (cont. ) Setup Machine 1 C 2 Setup B 1 2 B 3 1002 1562 2322 Idle Setup Machine 2 C 3 B 2 12 1512 Machine 3 Setup C 1 0 200 Setup D 2 1872 2732 Setup D 1 Idle 1260 Copyright 2009 John Wiley & Sons, Inc. D 3 1940 Completion time 2737 35

Synchronous Manufacturing (cont. ) Setup Machine 1 C 2 Setup B 1 2 B 3 1002 1562 2322 Idle Setup Machine 2 C 3 B 2 12 1512 Machine 3 Setup C 1 0 200 Setup D 2 1872 2732 Setup D 1 Idle 1260 Copyright 2009 John Wiley & Sons, Inc. D 3 1940 Completion time 2737 35

Employee Scheduling w Labor is very flexible resource w Scheduling workforce is complicated, repetitive task w Assignment method can be used w Heuristics are commonly used Copyright 2009 John Wiley & Sons, Inc. 36

Employee Scheduling w Labor is very flexible resource w Scheduling workforce is complicated, repetitive task w Assignment method can be used w Heuristics are commonly used Copyright 2009 John Wiley & Sons, Inc. 36

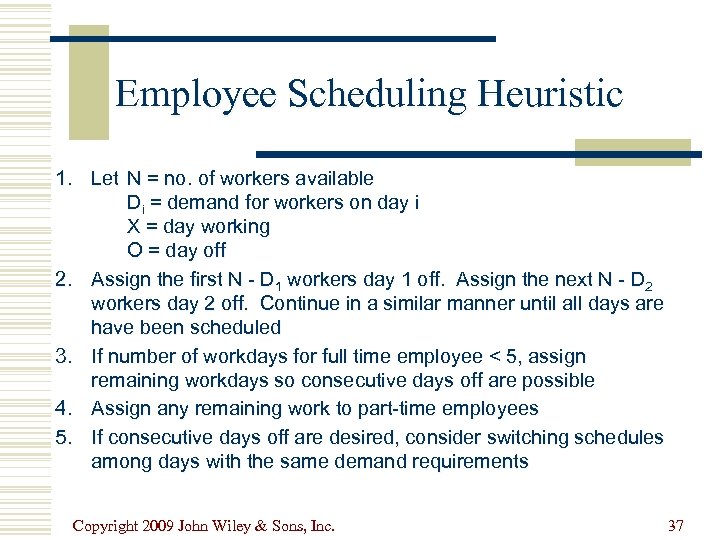

Employee Scheduling Heuristic 1. Let N = no. of workers available Di = demand for workers on day i X = day working O = day off 2. Assign the first N - D 1 workers day 1 off. Assign the next N - D 2 workers day 2 off. Continue in a similar manner until all days are have been scheduled 3. If number of workdays for full time employee < 5, assign remaining workdays so consecutive days off are possible 4. Assign any remaining work to part-time employees 5. If consecutive days off are desired, consider switching schedules among days with the same demand requirements Copyright 2009 John Wiley & Sons, Inc. 37

Employee Scheduling Heuristic 1. Let N = no. of workers available Di = demand for workers on day i X = day working O = day off 2. Assign the first N - D 1 workers day 1 off. Assign the next N - D 2 workers day 2 off. Continue in a similar manner until all days are have been scheduled 3. If number of workdays for full time employee < 5, assign remaining workdays so consecutive days off are possible 4. Assign any remaining work to part-time employees 5. If consecutive days off are desired, consider switching schedules among days with the same demand requirements Copyright 2009 John Wiley & Sons, Inc. 37

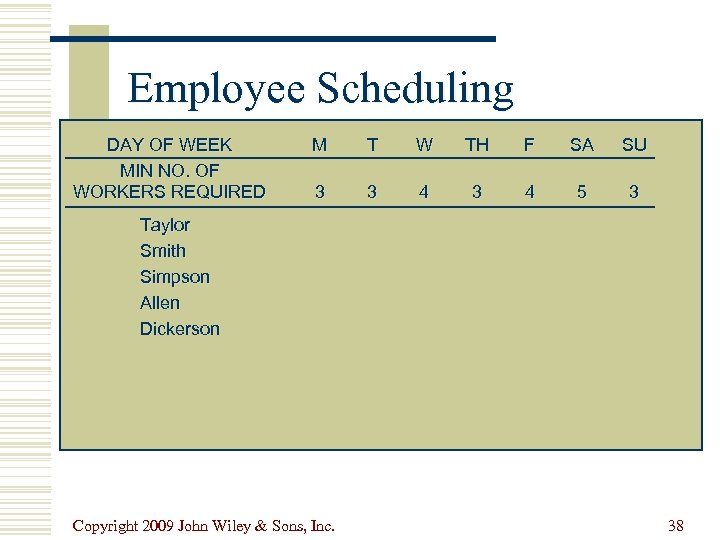

Employee Scheduling DAY OF WEEK MIN NO. OF WORKERS REQUIRED M T W TH F SA SU 3 3 4 5 3 Taylor Smith Simpson Allen Dickerson Copyright 2009 John Wiley & Sons, Inc. 38

Employee Scheduling DAY OF WEEK MIN NO. OF WORKERS REQUIRED M T W TH F SA SU 3 3 4 5 3 Taylor Smith Simpson Allen Dickerson Copyright 2009 John Wiley & Sons, Inc. 38

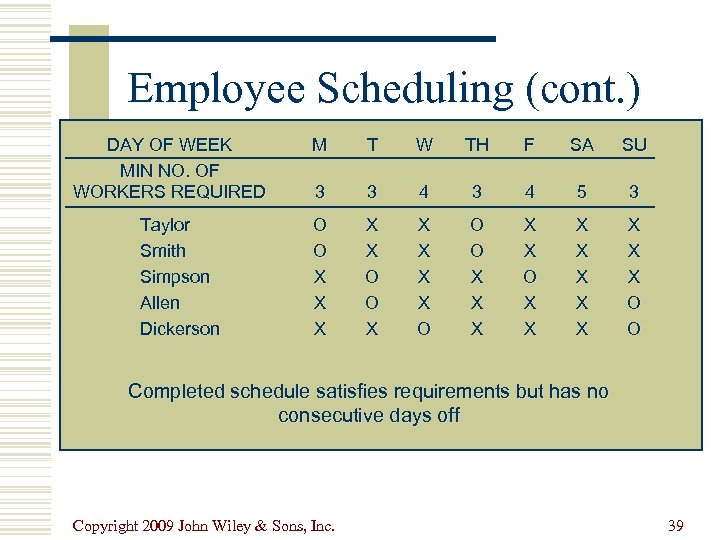

Employee Scheduling (cont. ) DAY OF WEEK MIN NO. OF WORKERS REQUIRED Taylor Smith Simpson Allen Dickerson M T W TH F SA SU 3 3 4 5 3 O O X X X X X O O O X X X X O O Completed schedule satisfies requirements but has no consecutive days off Copyright 2009 John Wiley & Sons, Inc. 39

Employee Scheduling (cont. ) DAY OF WEEK MIN NO. OF WORKERS REQUIRED Taylor Smith Simpson Allen Dickerson M T W TH F SA SU 3 3 4 5 3 O O X X X X X O O O X X X X O O Completed schedule satisfies requirements but has no consecutive days off Copyright 2009 John Wiley & Sons, Inc. 39

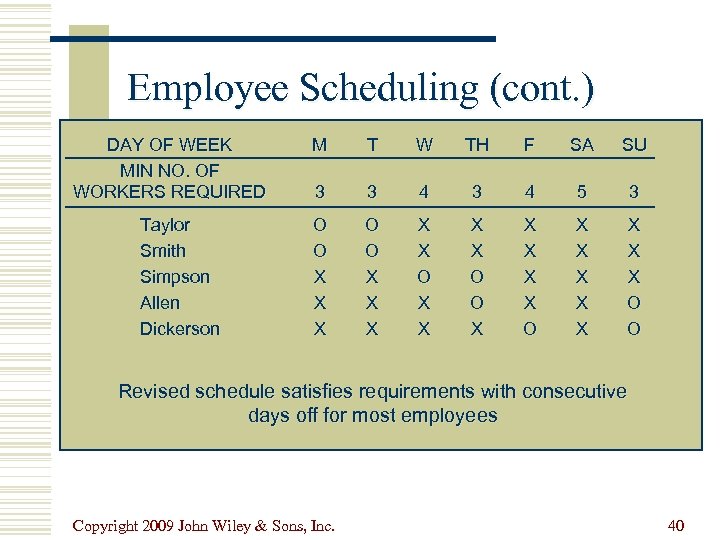

Employee Scheduling (cont. ) DAY OF WEEK MIN NO. OF WORKERS REQUIRED Taylor Smith Simpson Allen Dickerson M T W TH F SA SU 3 3 4 5 3 O O X X X X X O O X X X X O O Revised schedule satisfies requirements with consecutive days off for most employees Copyright 2009 John Wiley & Sons, Inc. 40

Employee Scheduling (cont. ) DAY OF WEEK MIN NO. OF WORKERS REQUIRED Taylor Smith Simpson Allen Dickerson M T W TH F SA SU 3 3 4 5 3 O O X X X X X O O X X X X O O Revised schedule satisfies requirements with consecutive days off for most employees Copyright 2009 John Wiley & Sons, Inc. 40

Automated Scheduling Systems w w w Staff Scheduling Schedule Bidding Schedule Optimization Copyright 2009 John Wiley & Sons, Inc. 41

Automated Scheduling Systems w w w Staff Scheduling Schedule Bidding Schedule Optimization Copyright 2009 John Wiley & Sons, Inc. 41

Copyright 2009 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that permitted in section 117 of the 1976 United States Copyright Act without express permission of the copyright owner is unlawful. Request for further information should be addressed to the Permission Department, John Wiley & Sons, Inc. The purchaser may make back-up copies for his/her own use only and not for distribution or resale. The Publisher assumes no responsibility for errors, omissions, or damages caused by the use of these programs or from the use of the information herein. Copyright 2009 John Wiley & Sons, Inc. 42

Copyright 2009 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that permitted in section 117 of the 1976 United States Copyright Act without express permission of the copyright owner is unlawful. Request for further information should be addressed to the Permission Department, John Wiley & Sons, Inc. The purchaser may make back-up copies for his/her own use only and not for distribution or resale. The Publisher assumes no responsibility for errors, omissions, or damages caused by the use of these programs or from the use of the information herein. Copyright 2009 John Wiley & Sons, Inc. 42