de73815ae2075e2ec41e9497c7482a51.ppt

- Количество слайдов: 27

Chapter 16 - Lean Systems To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Chapter 16 - Lean Systems To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Characteristics of Lean Systems: Just-in-Time · Pull method of materials flow (internal client supplier relations dictated by the client) · Consistently high quality · Small lot sizes · Uniform workstation loads (line balanced; keep the monthly proportion in daily basis) · Standardized components and work methods (repeatability; commonality; reducing the parts variation) · Close supplier ties (reliable; pare suppliers; local suppliers; advance information, ) · Flexible workforce (relieving bottlenecks; avoiding absenteeism consequences, increasing flexibility and minimizing boredom) · Line flows · Automated production · Preventive maintenance To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Characteristics of Lean Systems: Just-in-Time · Pull method of materials flow (internal client supplier relations dictated by the client) · Consistently high quality · Small lot sizes · Uniform workstation loads (line balanced; keep the monthly proportion in daily basis) · Standardized components and work methods (repeatability; commonality; reducing the parts variation) · Close supplier ties (reliable; pare suppliers; local suppliers; advance information, ) · Flexible workforce (relieving bottlenecks; avoiding absenteeism consequences, increasing flexibility and minimizing boredom) · Line flows · Automated production · Preventive maintenance To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

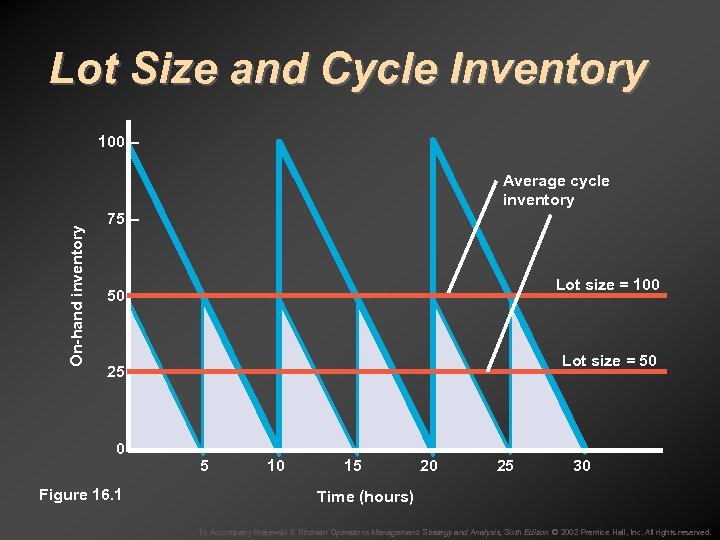

Lot Size and Cycle Inventory 100 – On-hand inventory Average cycle inventory 75 – Lot size = 100 50 – Lot size = 50 25 – 0– Figure 16. 1 5 10 15 20 25 30 Time (hours) To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Lot Size and Cycle Inventory 100 – On-hand inventory Average cycle inventory 75 – Lot size = 100 50 – Lot size = 50 25 – 0– Figure 16. 1 5 10 15 20 25 30 Time (hours) To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

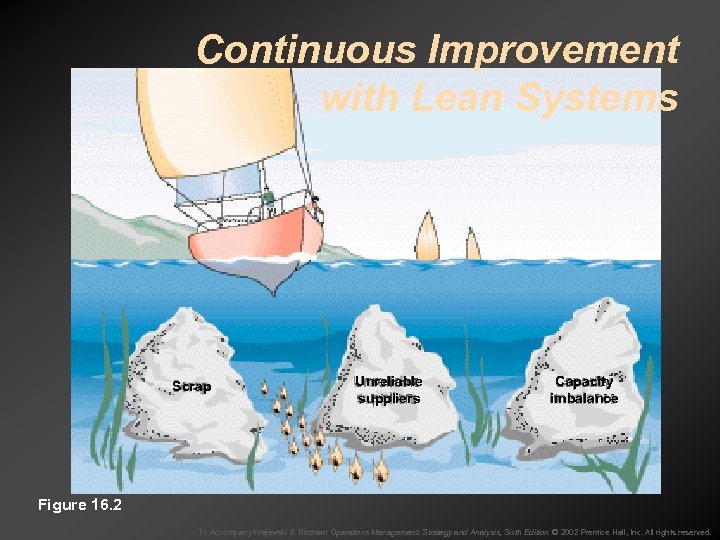

Continuous Improvement with Lean Systems Scrap Unreliable suppliers Capacity imbalance Figure 16. 2 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Continuous Improvement with Lean Systems Scrap Unreliable suppliers Capacity imbalance Figure 16. 2 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

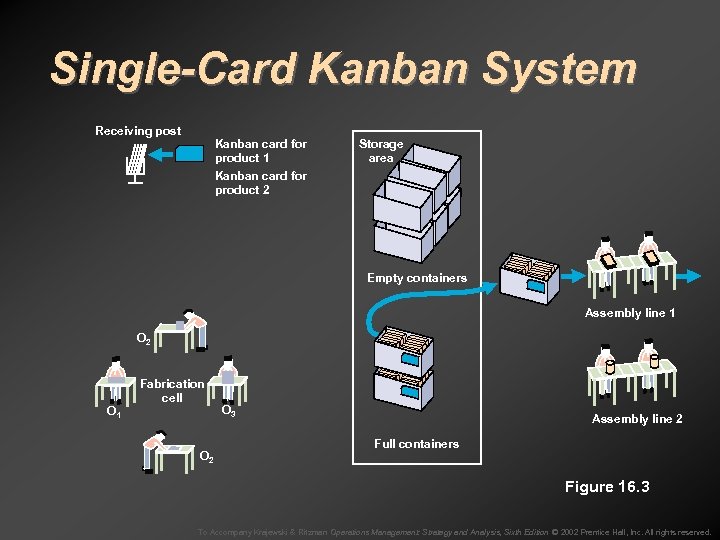

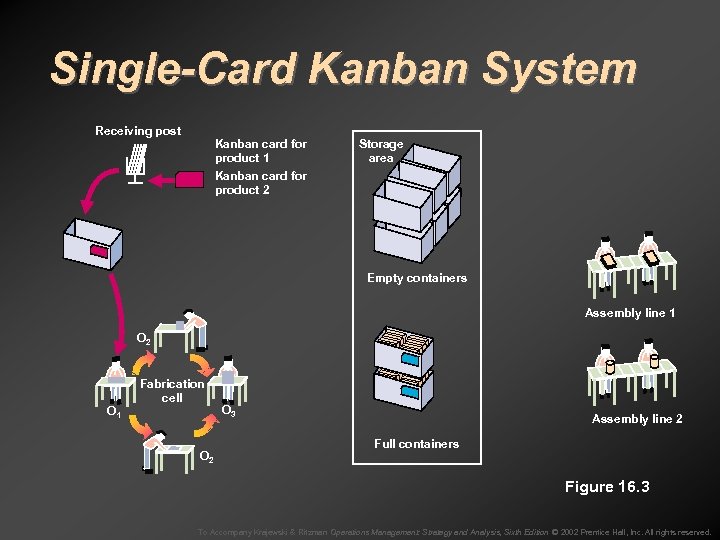

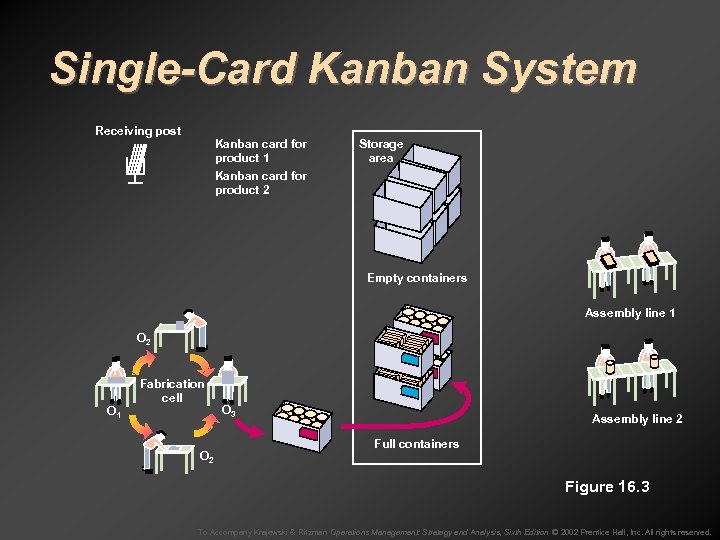

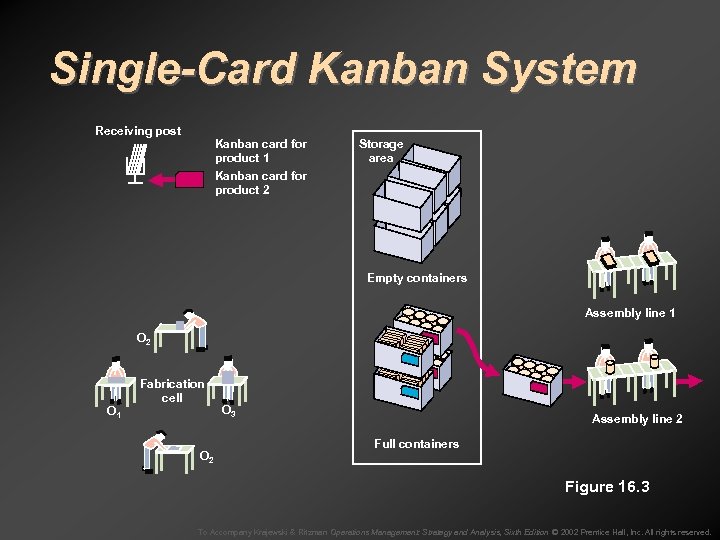

Single-Card Kanban System To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

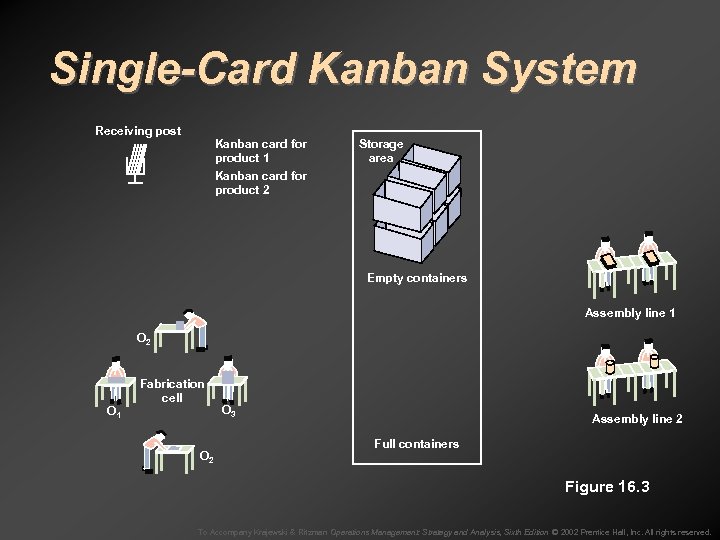

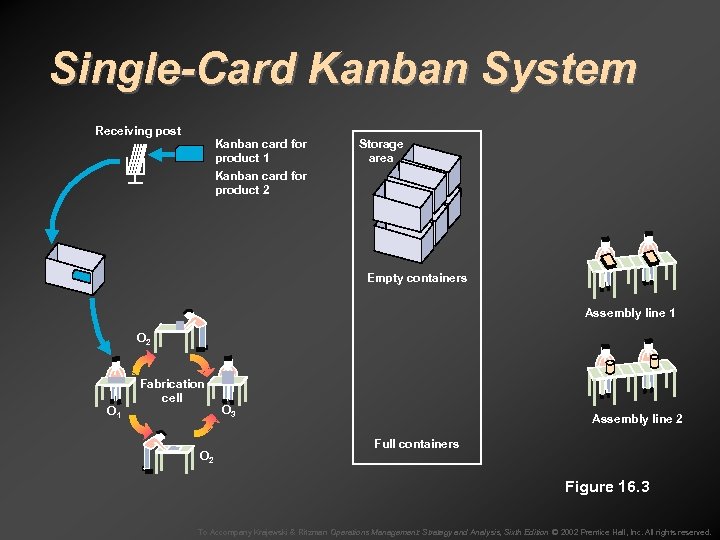

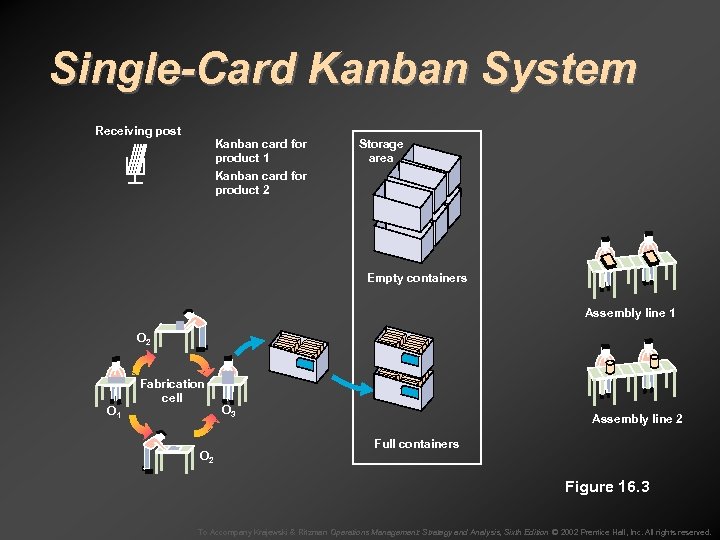

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Receiving post Kanban card for product 1 Kanban card for product 2 Storage area Empty containers Assembly line 1 O 2 O 1 Fabrication cell O 2 O 3 Assembly line 2 Full containers Figure 16. 3 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

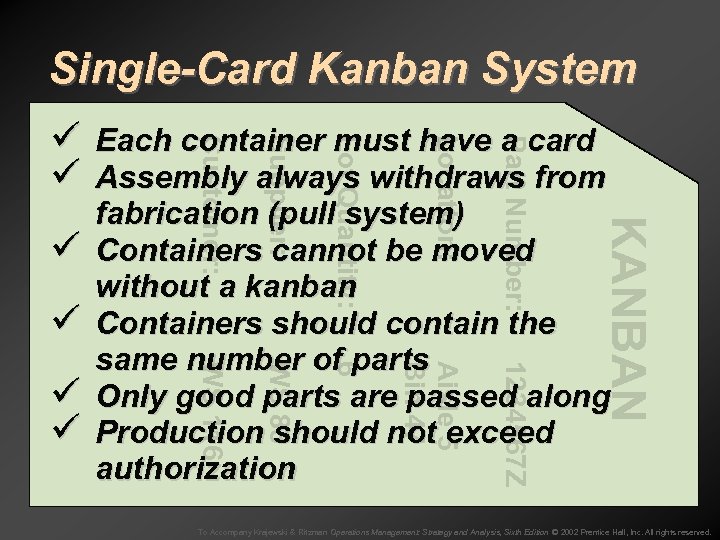

Single-Card Kanban System Location: Part Number: 6 Aisle 5 Bin 47 1234567 Z KANBAN Lot Quantity: WS 83 ü ü Supplier: ü WS 116 ü Each container must have a card Assembly always withdraws from fabrication (pull system) Containers cannot be moved without a kanban Containers should contain the same number of parts Only good parts are passed along Production should not exceed authorization Customer: ü ü To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Single-Card Kanban System Location: Part Number: 6 Aisle 5 Bin 47 1234567 Z KANBAN Lot Quantity: WS 83 ü ü Supplier: ü WS 116 ü Each container must have a card Assembly always withdraws from fabrication (pull system) Containers cannot be moved without a kanban Containers should contain the same number of parts Only good parts are passed along Production should not exceed authorization Customer: ü ü To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

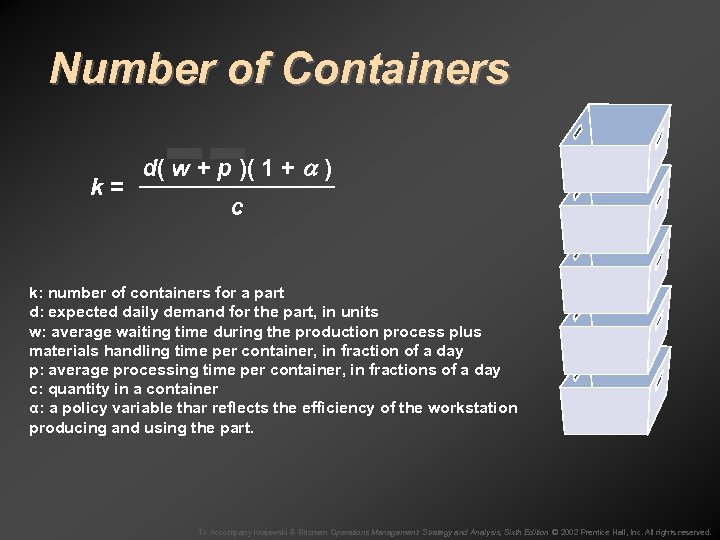

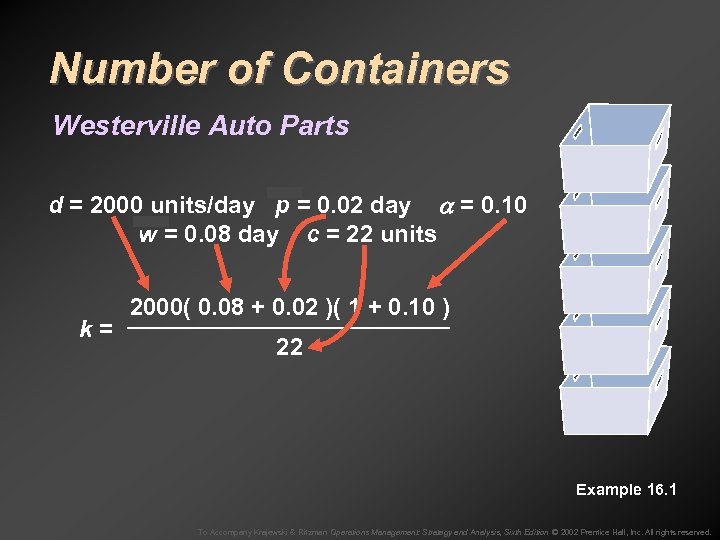

Number of Containers k= d( w + p )( 1 + a ) c k: number of containers for a part d: expected daily demand for the part, in units w: average waiting time during the production process plus materials handling time per container, in fraction of a day p: average processing time per container, in fractions of a day c: quantity in a container α: a policy variable thar reflects the efficiency of the workstation producing and using the part. To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers k= d( w + p )( 1 + a ) c k: number of containers for a part d: expected daily demand for the part, in units w: average waiting time during the production process plus materials handling time per container, in fraction of a day p: average processing time per container, in fractions of a day c: quantity in a container α: a policy variable thar reflects the efficiency of the workstation producing and using the part. To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

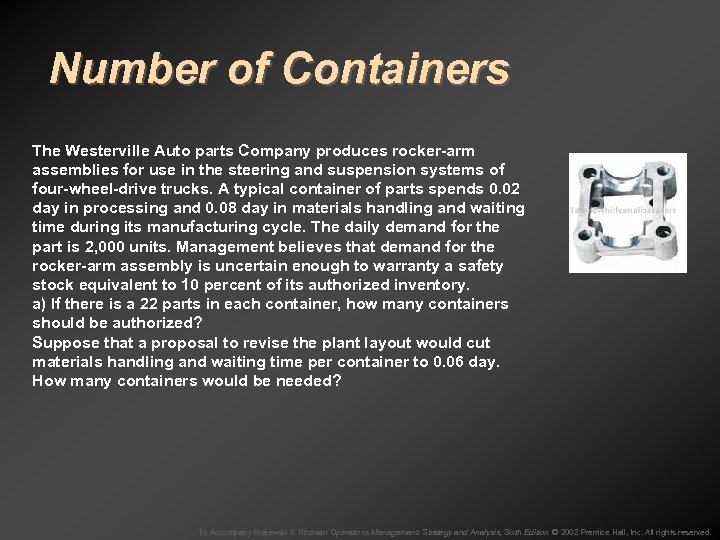

Number of Containers The Westerville Auto parts Company produces rocker-arm assemblies for use in the steering and suspension systems of four-wheel-drive trucks. A typical container of parts spends 0. 02 day in processing and 0. 08 day in materials handling and waiting time during its manufacturing cycle. The daily demand for the part is 2, 000 units. Management believes that demand for the rocker-arm assembly is uncertain enough to warranty a safety stock equivalent to 10 percent of its authorized inventory. a) If there is a 22 parts in each container, how many containers should be authorized? Suppose that a proposal to revise the plant layout would cut materials handling and waiting time per container to 0. 06 day. How many containers would be needed? To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers The Westerville Auto parts Company produces rocker-arm assemblies for use in the steering and suspension systems of four-wheel-drive trucks. A typical container of parts spends 0. 02 day in processing and 0. 08 day in materials handling and waiting time during its manufacturing cycle. The daily demand for the part is 2, 000 units. Management believes that demand for the rocker-arm assembly is uncertain enough to warranty a safety stock equivalent to 10 percent of its authorized inventory. a) If there is a 22 parts in each container, how many containers should be authorized? Suppose that a proposal to revise the plant layout would cut materials handling and waiting time per container to 0. 06 day. How many containers would be needed? To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

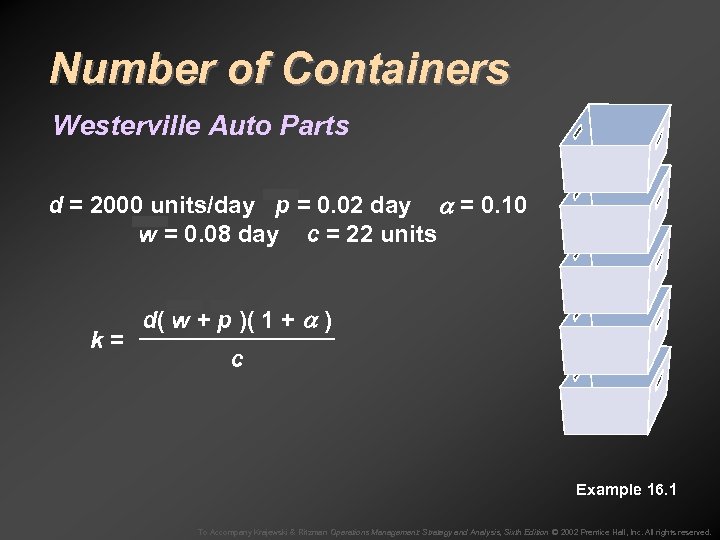

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 08 day c = 22 units k= d( w + p )( 1 + a ) c Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 08 day c = 22 units k= d( w + p )( 1 + a ) c Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

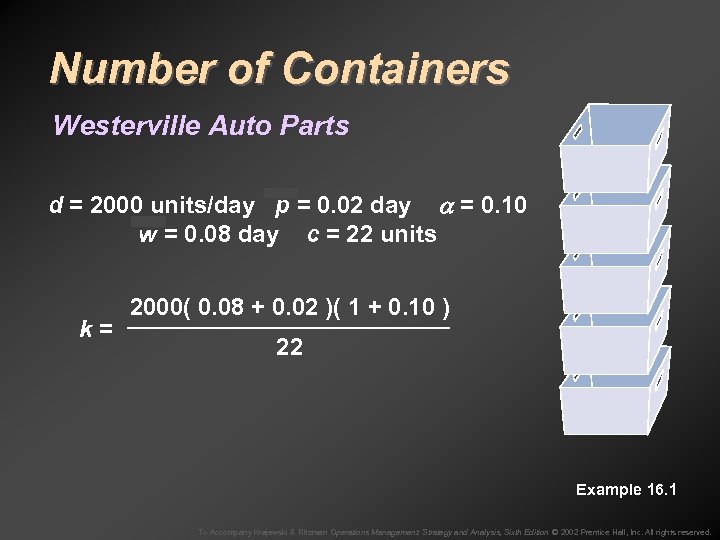

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 08 day c = 22 units k= 2000( 0. 08 + 0. 02 )( 1 + 0. 10 ) 22 Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 08 day c = 22 units k= 2000( 0. 08 + 0. 02 )( 1 + 0. 10 ) 22 Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 08 day c = 22 units k= 2000( 0. 08 + 0. 02 )( 1 + 0. 10 ) 22 Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 08 day c = 22 units k= 2000( 0. 08 + 0. 02 )( 1 + 0. 10 ) 22 Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

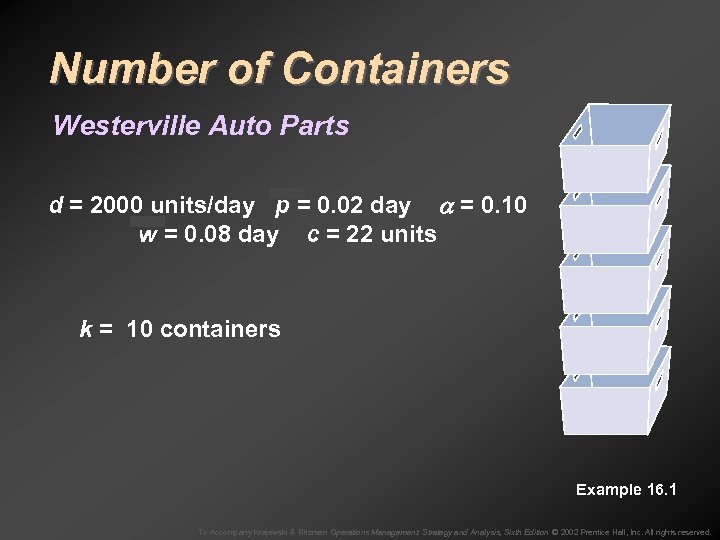

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 08 day c = 22 units k = 10 containers Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 08 day c = 22 units k = 10 containers Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

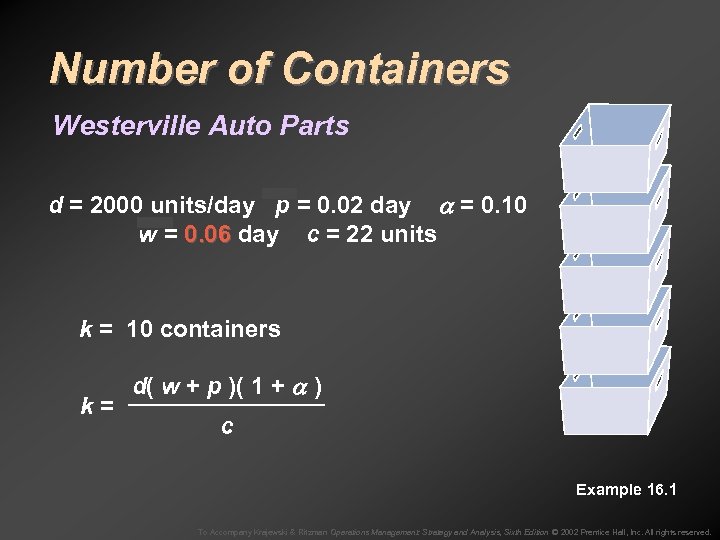

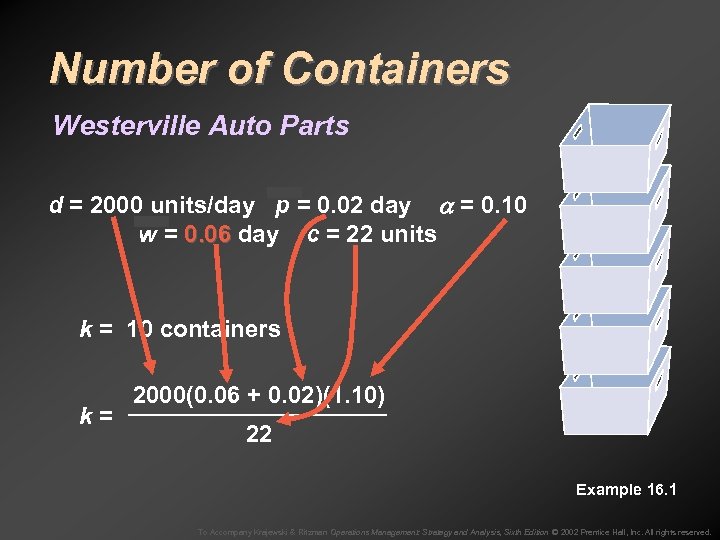

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 06 day c = 22 units k = 10 containers k= d( w + p )( 1 + a ) c Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 06 day c = 22 units k = 10 containers k= d( w + p )( 1 + a ) c Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

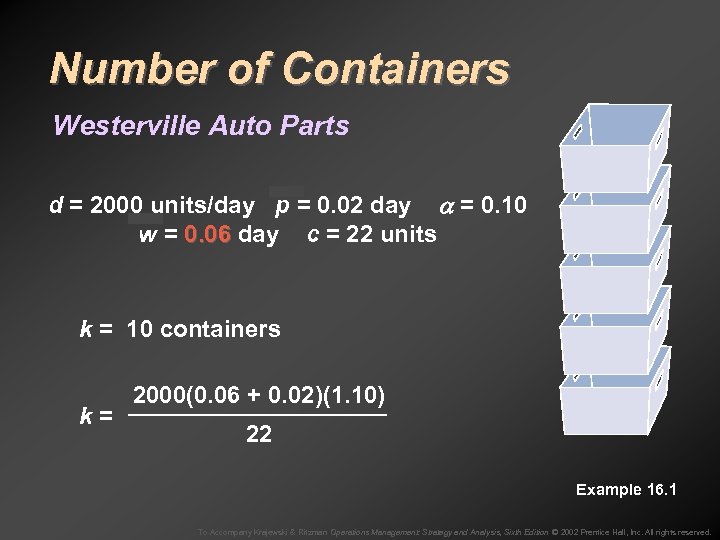

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 06 day c = 22 units k = 10 containers k= 2000(0. 06 + 0. 02)(1. 10) 22 Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 06 day c = 22 units k = 10 containers k= 2000(0. 06 + 0. 02)(1. 10) 22 Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 06 day c = 22 units k = 10 containers k= 2000(0. 06 + 0. 02)(1. 10) 22 Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 06 day c = 22 units k = 10 containers k= 2000(0. 06 + 0. 02)(1. 10) 22 Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

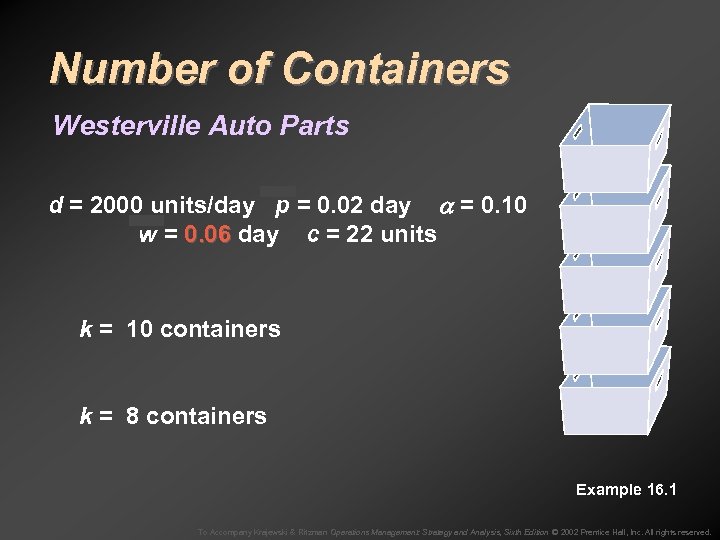

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 06 day c = 22 units k = 10 containers k = 8 containers Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Number of Containers Westerville Auto Parts d = 2000 units/day p = 0. 02 day a = 0. 10 w = 0. 06 day c = 22 units k = 10 containers k = 8 containers Example 16. 1 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Lean Systems in Services · Consistently high quality · Uniform facility loads · Standardized work methods · Close supplier ties · Flexible workforce · Automation · Preventive maintenance · Pull method of materials flow · Line flows To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Lean Systems in Services · Consistently high quality · Uniform facility loads · Standardized work methods · Close supplier ties · Flexible workforce · Automation · Preventive maintenance · Pull method of materials flow · Line flows To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Operational Benefits · Reduce space requirements · Reduce inventory investment · Reduce lead times · Increase labor productivity · Increase equipment utilization · Reduce paperwork and simple · · · planning systems Valid priorities for scheduling Workforce participation Increase product quality To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

Operational Benefits · Reduce space requirements · Reduce inventory investment · Reduce lead times · Increase labor productivity · Increase equipment utilization · Reduce paperwork and simple · · · planning systems Valid priorities for scheduling Workforce participation Increase product quality To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

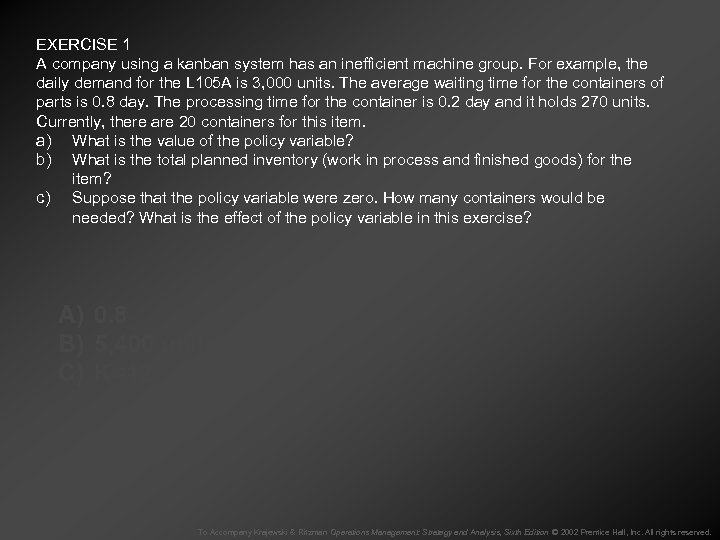

EXERCISE 1 A company using a kanban system has an inefficient machine group. For example, the daily demand for the L 105 A is 3, 000 units. The average waiting time for the containers of parts is 0. 8 day. The processing time for the container is 0. 2 day and it holds 270 units. Currently, there are 20 containers for this item. a) What is the value of the policy variable? b) What is the total planned inventory (work in process and finished goods) for the item? c) Suppose that the policy variable were zero. How many containers would be needed? What is the effect of the policy variable in this exercise? A) 0. 8 B) 5, 400 units C) K=12 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

EXERCISE 1 A company using a kanban system has an inefficient machine group. For example, the daily demand for the L 105 A is 3, 000 units. The average waiting time for the containers of parts is 0. 8 day. The processing time for the container is 0. 2 day and it holds 270 units. Currently, there are 20 containers for this item. a) What is the value of the policy variable? b) What is the total planned inventory (work in process and finished goods) for the item? c) Suppose that the policy variable were zero. How many containers would be needed? What is the effect of the policy variable in this exercise? A) 0. 8 B) 5, 400 units C) K=12 To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

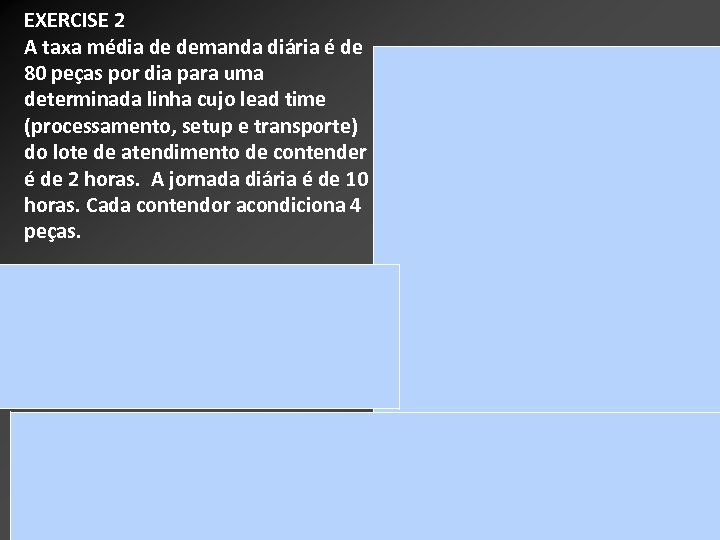

EXERCISE 2 A taxa média de demanda diária é de 80 peças por dia para uma determinada linha cujo lead time (processamento, setup e transporte) do lote de atendimento de contender é de 2 horas. A jornada diária é de 10 horas. Cada contendor acondiciona 4 peças. Os kanbans referem-se ao ciclo O ciclo é definido pelo lead time de fornecimento LT: Lead Time do Ciclo 1 Ciclo 2 Ciclo 3 Ciclo 4 Ciclo 5 LT=2 h Jornada = 10 h To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.

EXERCISE 2 A taxa média de demanda diária é de 80 peças por dia para uma determinada linha cujo lead time (processamento, setup e transporte) do lote de atendimento de contender é de 2 horas. A jornada diária é de 10 horas. Cada contendor acondiciona 4 peças. Os kanbans referem-se ao ciclo O ciclo é definido pelo lead time de fornecimento LT: Lead Time do Ciclo 1 Ciclo 2 Ciclo 3 Ciclo 4 Ciclo 5 LT=2 h Jornada = 10 h To Accompany Krajewski & Ritzman Operations Management: Strategy and Analysis, Sixth Edition © 2002 Prentice Hall, Inc. All rights reserved.