cc6b4f808b4979a97b3d58ad9419408f.ppt

- Количество слайдов: 60

Chapter 15 Order Fulfillment, Logistics, and Supply Chain Management 1

Chapter 15 Order Fulfillment, Logistics, and Supply Chain Management 1

Order Fulfillment Problems u How much do I need? u Delivery: time and cost ü Fierce competition ü Where are my goods? Track and Trace û One shipment or many, for an order ü When will it arrive? û Variability, uncertainty û Late delivery u Delays costs low satisfaction u In-land overseas delivery CK Farn 2

Order Fulfillment Problems u How much do I need? u Delivery: time and cost ü Fierce competition ü Where are my goods? Track and Trace û One shipment or many, for an order ü When will it arrive? û Variability, uncertainty û Late delivery u Delays costs low satisfaction u In-land overseas delivery CK Farn 2

Order Fulfillment: Overview u Introduction ü Taking orders may be the easiest part ü Factors responsible for delays in deliveries: û Inability to accurately forecast demand û Ineffective supply chains û Pull type manufacturing û Customized products CK Farn 3

Order Fulfillment: Overview u Introduction ü Taking orders may be the easiest part ü Factors responsible for delays in deliveries: û Inability to accurately forecast demand û Ineffective supply chains û Pull type manufacturing û Customized products CK Farn 3

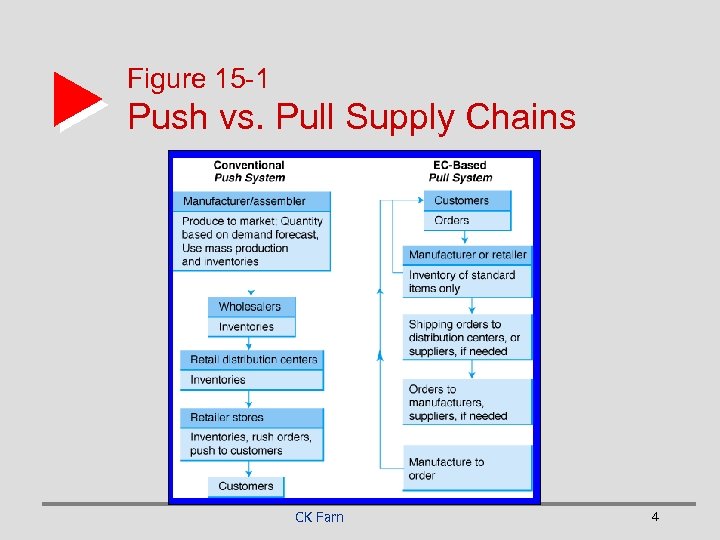

Figure 15 -1 Push vs. Pull Supply Chains CK Farn 4

Figure 15 -1 Push vs. Pull Supply Chains CK Farn 4

Major Concepts u Order fulfillment: Deliver right order on time u Front office operations: ü Order taking ü Advertisement ü CRM u Back office operations ü Accounting ü Finance ü Inventory Packaging Logistics CK Farn 5

Major Concepts u Order fulfillment: Deliver right order on time u Front office operations: ü Order taking ü Advertisement ü CRM u Back office operations ü Accounting ü Finance ü Inventory Packaging Logistics CK Farn 5

Major Concepts (cont. ) u Definitions of logistics: ü Managing the flow of goods, information and money along the supply chain ü Aspect of military science dealing with procurement, maintenance, and transportation ü Management of details of an operation ü All activities involved in management of product movement û Right product û Right place û Right time CK Farn 6

Major Concepts (cont. ) u Definitions of logistics: ü Managing the flow of goods, information and money along the supply chain ü Aspect of military science dealing with procurement, maintenance, and transportation ü Management of details of an operation ü All activities involved in management of product movement û Right product û Right place û Right time CK Farn 6

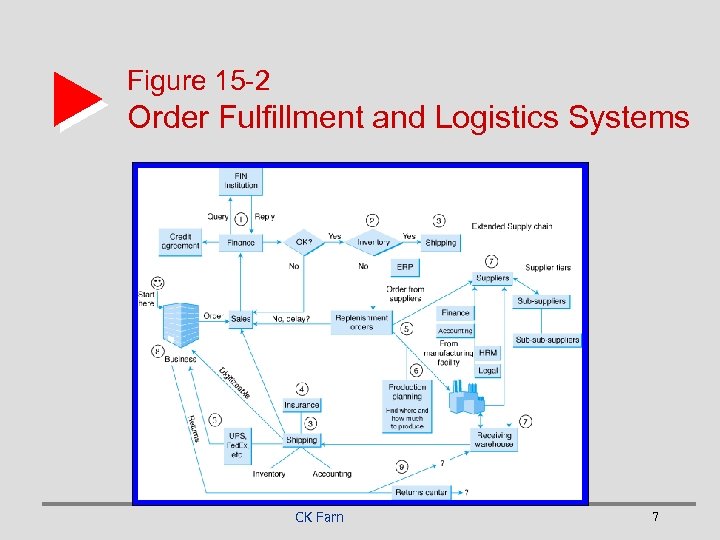

Figure 15 -2 Order Fulfillment and Logistics Systems CK Farn 7

Figure 15 -2 Order Fulfillment and Logistics Systems CK Farn 7

The Steps of Order Fulfillment 1. Payment Clearance 2. In-stock availability 3. Packaging, shipment 4. Insuring 5. Production (planning, execution) 6. Plant services CK Farn 7. Purchasing, warehousing 8. Customer contacts 9. Returns (Reverse logistics) 10. Demand forecast 11. Accounting, billing 12. Reverse logistics 8

The Steps of Order Fulfillment 1. Payment Clearance 2. In-stock availability 3. Packaging, shipment 4. Insuring 5. Production (planning, execution) 6. Plant services CK Farn 7. Purchasing, warehousing 8. Customer contacts 9. Returns (Reverse logistics) 10. Demand forecast 11. Accounting, billing 12. Reverse logistics 8

Shipping a Tropical Fish 1. Placing order, payment 2. Transfer order to Petstore. com, check stock 3. Use a wholesaler to get the fish 4. Supplier finds fish, ships to wholesalers 5. Wholesalers rush to Petstore 6. Petstore uses Fed. Ex to ship to customer with copy of credit card payment Discussion: What is the contribution of EC? CK Farn 9

Shipping a Tropical Fish 1. Placing order, payment 2. Transfer order to Petstore. com, check stock 3. Use a wholesaler to get the fish 4. Supplier finds fish, ships to wholesalers 5. Wholesalers rush to Petstore 6. Petstore uses Fed. Ex to ship to customer with copy of credit card payment Discussion: What is the contribution of EC? CK Farn 9

Supply Chain Management u SCM: u Definition: ü Integration of the ü Flow of material, business processes information, money, along the chain, etc. from raw material Planning, Organizing, suppliers through control of many factories to customers activities u It includes: u Activities: ü organizations, ü Purchasing, delivery, procedures, people packaging, checking, warehousing, etc. CK Farn 10

Supply Chain Management u SCM: u Definition: ü Integration of the ü Flow of material, business processes information, money, along the chain, etc. from raw material Planning, Organizing, suppliers through control of many factories to customers activities u It includes: u Activities: ü organizations, ü Purchasing, delivery, procedures, people packaging, checking, warehousing, etc. CK Farn 10

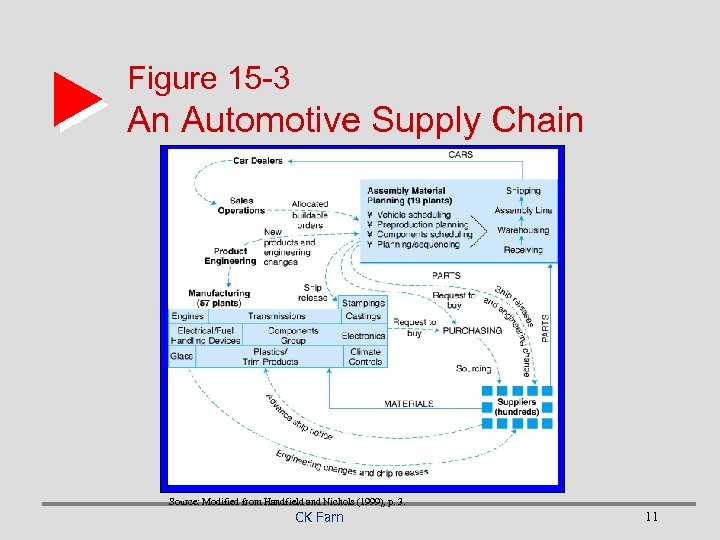

Figure 15 -3 An Automotive Supply Chain Source: Modified from Handfield and Nichols (1999), p. 3. CK Farn 11

Figure 15 -3 An Automotive Supply Chain Source: Modified from Handfield and Nichols (1999), p. 3. CK Farn 11

Benefits of SCM u Reduce uncertainty along the chain u Proper inventory levels in the chain u Minimize delays u Eliminate rush (unplanned) activities u Provide superb customer service u Major contributor of success (ever survival) CK Farn 12

Benefits of SCM u Reduce uncertainty along the chain u Proper inventory levels in the chain u Minimize delays u Eliminate rush (unplanned) activities u Provide superb customer service u Major contributor of success (ever survival) CK Farn 12

Global Supply Chain u Can be very long u Possible cross-border problems ü Customs clearance, tax, different regulations u Need information technology support of: ü Communication ü Collaboration u Possible delays due to: customs, tax, translations, politics CK Farn 13

Global Supply Chain u Can be very long u Possible cross-border problems ü Customs clearance, tax, different regulations u Need information technology support of: ü Communication ü Collaboration u Possible delays due to: customs, tax, translations, politics CK Farn 13

Typical Problems Along the Supply Chain u Delays in production, distribution, etc. u Expensive Inventories u Lack of partners’ coordination u Uncertainties in deliveries u Poor demand forecast u Interference with production u Poor quality CK Farn 14

Typical Problems Along the Supply Chain u Delays in production, distribution, etc. u Expensive Inventories u Lack of partners’ coordination u Uncertainties in deliveries u Poor demand forecast u Interference with production u Poor quality CK Farn 14

More Difficulties u Virtual companies do not have logistics infrastructures u One company is a member of several supply chain u Conventional warehouses are too expensive u Need automatic warehouses with robots as pickers CK Farn 15

More Difficulties u Virtual companies do not have logistics infrastructures u One company is a member of several supply chain u Conventional warehouses are too expensive u Need automatic warehouses with robots as pickers CK Farn 15

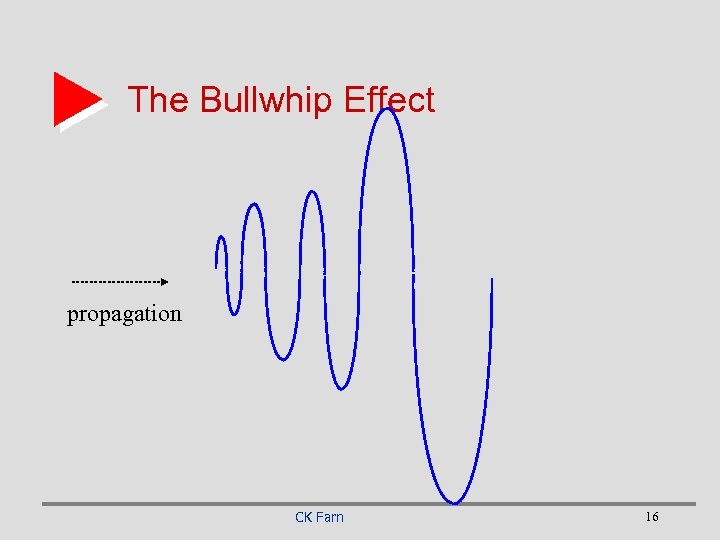

The Bullwhip Effect propagation CK Farn 16

The Bullwhip Effect propagation CK Farn 16

Bullwhip Effect and Information Sharing u Flow of information to and from all participating entities u Information sharing between retailers and their suppliers ü Bullwhip effect refers to erratic shifts in orders up and down supply chain ü Distorted information leads to: û Inefficiencies Ineffective shipments û Excessive inventories Poor customer service û Missed production schedules CK Farn 17

Bullwhip Effect and Information Sharing u Flow of information to and from all participating entities u Information sharing between retailers and their suppliers ü Bullwhip effect refers to erratic shifts in orders up and down supply chain ü Distorted information leads to: û Inefficiencies Ineffective shipments û Excessive inventories Poor customer service û Missed production schedules CK Farn 17

The Bullwhip Effect u Slight changes in actual demand create problems u Partners build “just in case” inventories u Lack of trust among partners u Stockpiling results in huge cost u The manufacturers cannot plan production u Cannot order material from suppliers CK Farn 18

The Bullwhip Effect u Slight changes in actual demand create problems u Partners build “just in case” inventories u Lack of trust among partners u Stockpiling results in huge cost u The manufacturers cannot plan production u Cannot order material from suppliers CK Farn 18

Avoiding the Sting of the Bullwhip u How to do it? ü Information sharing is a must and is facilitated by EDI, extranets, and groupware technologies u Trust and agreements in regard to: ü Ordering and inventory decisions ü Placing supply chain ahead of individual entities within the corporation u Sharing information could save $30 Billion/year just in the grocery industry CK Farn 19

Avoiding the Sting of the Bullwhip u How to do it? ü Information sharing is a must and is facilitated by EDI, extranets, and groupware technologies u Trust and agreements in regard to: ü Ordering and inventory decisions ü Placing supply chain ahead of individual entities within the corporation u Sharing information could save $30 Billion/year just in the grocery industry CK Farn 19

Preliminary Activities u Understand the supply chain (flow charts) u Study internal and external parts u Performance measurement are a must (Benchmarking) u Multidimension performance analysis u A BPR may be needed u People’s relationships are a must CK Farn 20

Preliminary Activities u Understand the supply chain (flow charts) u Study internal and external parts u Performance measurement are a must (Benchmarking) u Multidimension performance analysis u A BPR may be needed u People’s relationships are a must CK Farn 20

Areas of Opportunities u u Manufacturing processes Warehousing operation Packaging and delivery Material inspection/receiving u Inbound and outbound transportation CK Farn u Reverse logistics (return) u In-plant material handling u Vendor management program u Customer order processing 21

Areas of Opportunities u u Manufacturing processes Warehousing operation Packaging and delivery Material inspection/receiving u Inbound and outbound transportation CK Farn u Reverse logistics (return) u In-plant material handling u Vendor management program u Customer order processing 21

Areas of Opportunities (cont. ) u Use of teams and u Invoicing, auditing and empowerment of other accounting activities employees u Collaboration procedures u Automation of with partners processes u Employee training and u Use of software for deployments facilitating all the above u Labor scheduling u Inventory management and control CK Farn 22

Areas of Opportunities (cont. ) u Use of teams and u Invoicing, auditing and empowerment of other accounting activities employees u Collaboration procedures u Automation of with partners processes u Employee training and u Use of software for deployments facilitating all the above u Labor scheduling u Inventory management and control CK Farn 22

Using Inventories u The classical MAGIC u Insurance against stock out u Can be in several places u Can be excessive u Can be insufficient CK Farn 23

Using Inventories u The classical MAGIC u Insurance against stock out u Can be in several places u Can be excessive u Can be insufficient CK Farn 23

Using Inventories u Using inventories to solve supply chain shortages: ü Building inventories as insurance against uncertainty—products and parts flow smoothly ü Very difficult to correctly determine inventory levels for each product and part û Customized finished products can only stock components û Excessive levels are costly to store û Insufficient levels cannot protect against high demand or slow delivery times CK Farn 24

Using Inventories u Using inventories to solve supply chain shortages: ü Building inventories as insurance against uncertainty—products and parts flow smoothly ü Very difficult to correctly determine inventory levels for each product and part û Customized finished products can only stock components û Excessive levels are costly to store û Insufficient levels cannot protect against high demand or slow delivery times CK Farn 24

Using Inventories (cont. ) u Example: Littlewoods Stores; UK ü Retail clothing industry is very competitive ü Littlewoods instituted an IT-supported initiative to support supply chain efficiency; specifically, to deal with the overstocking problem CK Farn 25

Using Inventories (cont. ) u Example: Littlewoods Stores; UK ü Retail clothing industry is very competitive ü Littlewoods instituted an IT-supported initiative to support supply chain efficiency; specifically, to deal with the overstocking problem CK Farn 25

Littlewoods Stores (cont. ) u Use a Web-Based performance reporting system that analyzes daily: ü ü Marketing and financial data Merchandising Space planning Purchasing data CK Farn 26

Littlewoods Stores (cont. ) u Use a Web-Based performance reporting system that analyzes daily: ü ü Marketing and financial data Merchandising Space planning Purchasing data CK Farn 26

Littlewoods Stores (cont. ) u Using data warehouse, DSS and other enduser oriented software system has helped: ü Reduce backup inventory expenses ü Increased the ability to strategically price merchandise differently in different stores ü Reduced the need for stock liquidations ü Cut marketing distribution costs significantly ü Increased the number of Web-based users CK Farn 27

Littlewoods Stores (cont. ) u Using data warehouse, DSS and other enduser oriented software system has helped: ü Reduce backup inventory expenses ü Increased the ability to strategically price merchandise differently in different stores ü Reduced the need for stock liquidations ü Cut marketing distribution costs significantly ü Increased the number of Web-based users CK Farn 27

Proper SCM u Proper SCM and inventory management requires coordination of all activities and links in the supply chain to: ü Ensure that goods move smoothly and on time from suppliers to customers ü Keep inventories low ü Keep costs down CK Farn 28

Proper SCM u Proper SCM and inventory management requires coordination of all activities and links in the supply chain to: ü Ensure that goods move smoothly and on time from suppliers to customers ü Keep inventories low ü Keep costs down CK Farn 28

Proper SCM (cont. ) u Coordination is needed because: ü Supply chain partners depend on each other ü Partners don’t always work together toward the same goal u To properly control uncertainties it is necessary to: ü Understand the causes/problems ü Determine how uncertainties will affect other activities up and down the supply chain ü Formulate ways to eliminate or reduce uncertainties CK Farn 29

Proper SCM (cont. ) u Coordination is needed because: ü Supply chain partners depend on each other ü Partners don’t always work together toward the same goal u To properly control uncertainties it is necessary to: ü Understand the causes/problems ü Determine how uncertainties will affect other activities up and down the supply chain ü Formulate ways to eliminate or reduce uncertainties CK Farn 29

Proper SCM (cont. ) u Information flow is a u Support is needed key: communications to ensure this between business communication and partners should be: is enabled by: ü Effective ü Efficient ü IT support ü EC support CK Farn 30

Proper SCM (cont. ) u Information flow is a u Support is needed key: communications to ensure this between business communication and partners should be: is enabled by: ü Effective ü Efficient ü IT support ü EC support CK Farn 30

EC Solutions Along the Supply Chain u Automate order taking (e-procurement) ü Use EDI/Internet ü Web-based ordering; intelligent agents u Electronic payments u Inventory reduction (made-to-order pull process) ü Improved inventory management ü Decreased administrative costs CK Farn 31

EC Solutions Along the Supply Chain u Automate order taking (e-procurement) ü Use EDI/Internet ü Web-based ordering; intelligent agents u Electronic payments u Inventory reduction (made-to-order pull process) ü Improved inventory management ü Decreased administrative costs CK Farn 31

EC Solutions Along the Supply Chain (cont. ) u Digitization of products u Collaborative commerce among members of the —instant order supply chain fulfillment ü Shortens cycle time u Back-office interface ü Minimizes delays ü Shortens cycle time ü Eliminates errors CK Farn and work interruptions ü Lower inventories ü Lower administrative costs 32

EC Solutions Along the Supply Chain (cont. ) u Digitization of products u Collaborative commerce among members of the —instant order supply chain fulfillment ü Shortens cycle time u Back-office interface ü Minimizes delays ü Shortens cycle time ü Eliminates errors CK Farn and work interruptions ü Lower inventories ü Lower administrative costs 32

Innovative Solutions to Order Fulfillment Problem u Examples of solutions to order fulfillment: ü Real-time video (Webcam) û Move inventory 70 times/year û FAO Schwartz demonstrates famous store in New York ü Mail. Boxes Etc. and Innotrac Corp. û Comprehensive system û Software connects e-tailers and order management systems CK Farn 33

Innovative Solutions to Order Fulfillment Problem u Examples of solutions to order fulfillment: ü Real-time video (Webcam) û Move inventory 70 times/year û FAO Schwartz demonstrates famous store in New York ü Mail. Boxes Etc. and Innotrac Corp. û Comprehensive system û Software connects e-tailers and order management systems CK Farn 33

Innovative Solutions to Order Fulfillment Problem (cont. ) u Role of 7 -Eleven & convenience stores ü ü Can be used as a collection point for returns Can be used as a pick-up place Can be used as a place for order placing Can pay in cash/card to the store ü Returns are a problem: up to 30% CK Farn 34

Innovative Solutions to Order Fulfillment Problem (cont. ) u Role of 7 -Eleven & convenience stores ü ü Can be used as a collection point for returns Can be used as a pick-up place Can be used as a place for order placing Can pay in cash/card to the store ü Returns are a problem: up to 30% CK Farn 34

Innovative Solutions to Order Fulfillment Problem (cont. ) u Relysoftware. com helps find: ü “Forwarders”—intermediaries that prepare goods for shipping for companies u Relysoftware. com also helps: ü Forwarders find the best prices on air carriers ü Carriers fill up empty cargo space by bidding it up CK Farn 35

Innovative Solutions to Order Fulfillment Problem (cont. ) u Relysoftware. com helps find: ü “Forwarders”—intermediaries that prepare goods for shipping for companies u Relysoftware. com also helps: ü Forwarders find the best prices on air carriers ü Carriers fill up empty cargo space by bidding it up CK Farn 35

Same Day, Even Same Hour Delivery u Role of Fed. Ex and similar shippers ü ü ü From a delivery to all-logistics Many services (see Box 13. 4) Complete inventory control Packaging, warehousing, reordering, etc. Tracking services to customers CK Farn 36

Same Day, Even Same Hour Delivery u Role of Fed. Ex and similar shippers ü ü ü From a delivery to all-logistics Many services (see Box 13. 4) Complete inventory control Packaging, warehousing, reordering, etc. Tracking services to customers CK Farn 36

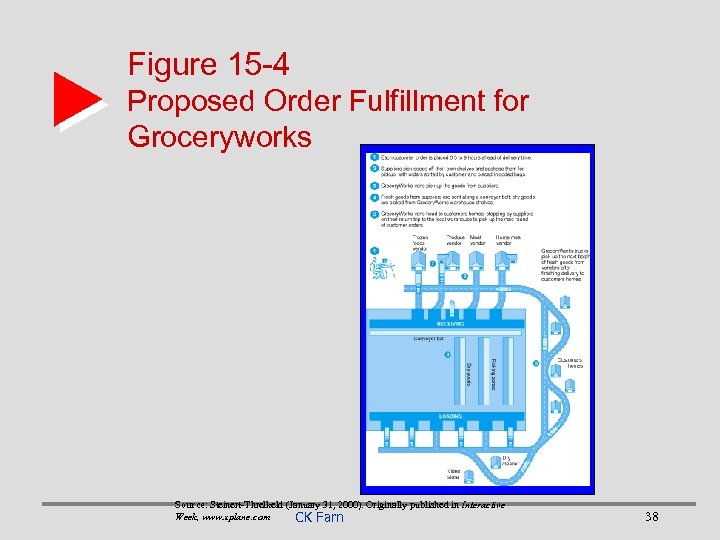

Same Day, Even Same Hour Delivery (cont. ) u Supermarket deliveries ü Transport of fresh food to people who are in homes only at specific hours ü Distribution systems are critical ü Fresh food may be spoiled CK Farn 37

Same Day, Even Same Hour Delivery (cont. ) u Supermarket deliveries ü Transport of fresh food to people who are in homes only at specific hours ü Distribution systems are critical ü Fresh food may be spoiled CK Farn 37

Figure 15 -4 Proposed Order Fulfillment for Groceryworks Source: Steinert-Threlkeld (January 31, 2000). Originally published in Interactive Week, www. xplane. com CK Farn 38

Figure 15 -4 Proposed Order Fulfillment for Groceryworks Source: Steinert-Threlkeld (January 31, 2000). Originally published in Interactive Week, www. xplane. com CK Farn 38

Automated Warehouses u B 2 C order fulfillment—send small quantities to a large number of individuals ü Step 1: retailers contract Fingerhut to stock products and deliver Web orders ü Step 2: merchandise stored SKU warehouse ü Step 3: orders arrive ü Step 4: computer program consolidates orders from all vendors into “pick waves” CK Farn 39

Automated Warehouses u B 2 C order fulfillment—send small quantities to a large number of individuals ü Step 1: retailers contract Fingerhut to stock products and deliver Web orders ü Step 2: merchandise stored SKU warehouse ü Step 3: orders arrive ü Step 4: computer program consolidates orders from all vendors into “pick waves” CK Farn 39

Automated Warehouses (cont. ) ü Step 5: picked items moved by conveyors to packing area; computer configures size and type of packing; types special packing instructions ü Step 6: conveyer takes packages to scanning station (weighed) ü Step 7: scan destination; moved by conveyer to waiting trucks ü Step 8: full trucks depart for Post Offices CK Farn 40

Automated Warehouses (cont. ) ü Step 5: picked items moved by conveyors to packing area; computer configures size and type of packing; types special packing instructions ü Step 6: conveyer takes packages to scanning station (weighed) ü Step 7: scan destination; moved by conveyer to waiting trucks ü Step 8: full trucks depart for Post Offices CK Farn 40

Handling Returns u Necessary for maintaining customer trust and loyalty ü Return item to place it was purchased ü Separate logistics of returns from logistics of delivery ü Allow customer to physically drop returned items at collection stations ü Completely outsource returns CK Farn 41

Handling Returns u Necessary for maintaining customer trust and loyalty ü Return item to place it was purchased ü Separate logistics of returns from logistics of delivery ü Allow customer to physically drop returned items at collection stations ü Completely outsource returns CK Farn 41

Outsourcing Logistics (3 PL): The UPS Strategy u UPS provides broad EC services: ü Electronic tracking of packages ü Electronic supply chain services for corporate customers by industry including: û Portal page with industry-related information û Statistics ü Calculators for computing shipping fees ü Help customers manage electronic supply chains CK Farn 42

Outsourcing Logistics (3 PL): The UPS Strategy u UPS provides broad EC services: ü Electronic tracking of packages ü Electronic supply chain services for corporate customers by industry including: û Portal page with industry-related information û Statistics ü Calculators for computing shipping fees ü Help customers manage electronic supply chains CK Farn 42

The UPS Strategy (cont. ) u UPS provides broad EC services ü Improved inventory management, warehousing, and delivery ü Integration with shipping management system ü Notify customers by e-mail of: û Delivery status û Expected time of arrival of incoming packages CK Farn 43

The UPS Strategy (cont. ) u UPS provides broad EC services ü Improved inventory management, warehousing, and delivery ü Integration with shipping management system ü Notify customers by e-mail of: û Delivery status û Expected time of arrival of incoming packages CK Farn 43

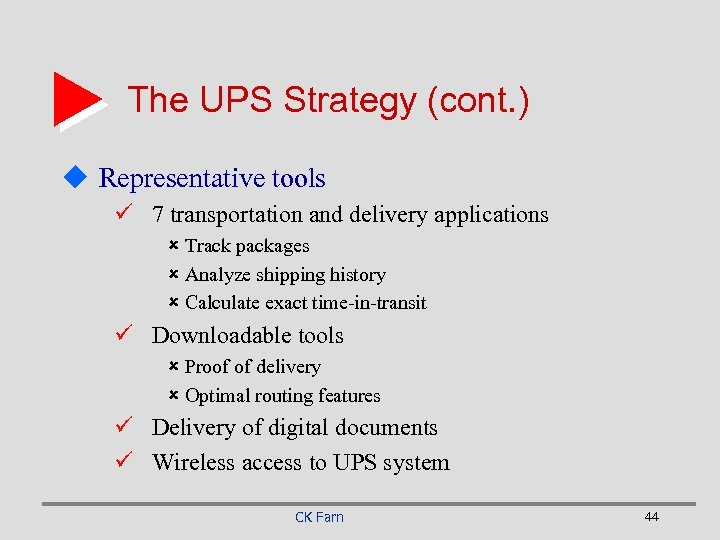

The UPS Strategy (cont. ) u Representative tools ü 7 transportation and delivery applications û Track packages û Analyze shipping history û Calculate exact time-in-transit ü Downloadable tools û Proof of delivery û Optimal routing features ü Delivery of digital documents ü Wireless access to UPS system CK Farn 44

The UPS Strategy (cont. ) u Representative tools ü 7 transportation and delivery applications û Track packages û Analyze shipping history û Calculate exact time-in-transit ü Downloadable tools û Proof of delivery û Optimal routing features ü Delivery of digital documents ü Wireless access to UPS system CK Farn 44

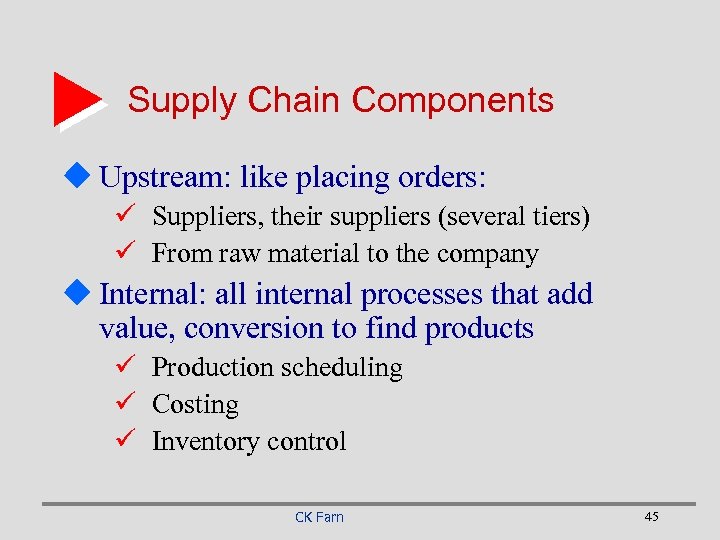

Supply Chain Components u Upstream: like placing orders: ü Suppliers, their suppliers (several tiers) ü From raw material to the company u Internal: all internal processes that add value, conversion to find products ü Production scheduling ü Costing ü Inventory control CK Farn 45

Supply Chain Components u Upstream: like placing orders: ü Suppliers, their suppliers (several tiers) ü From raw material to the company u Internal: all internal processes that add value, conversion to find products ü Production scheduling ü Costing ü Inventory control CK Farn 45

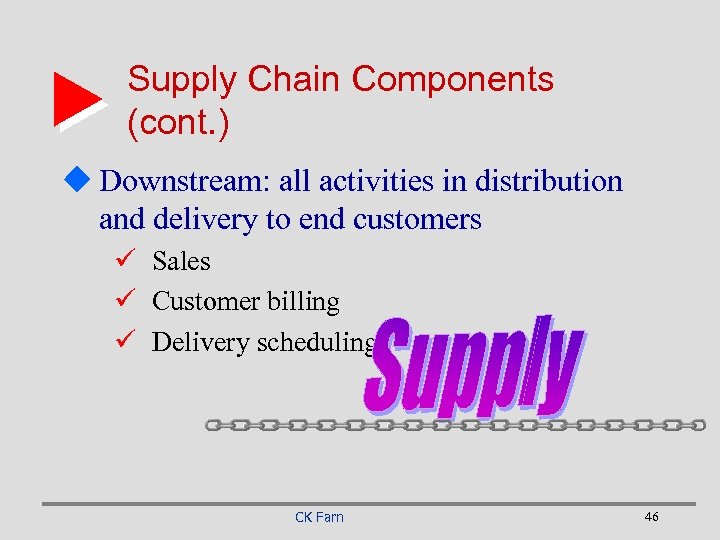

Supply Chain Components (cont. ) u Downstream: all activities in distribution and delivery to end customers ü Sales ü Customer billing ü Delivery scheduling CK Farn 46

Supply Chain Components (cont. ) u Downstream: all activities in distribution and delivery to end customers ü Sales ü Customer billing ü Delivery scheduling CK Farn 46

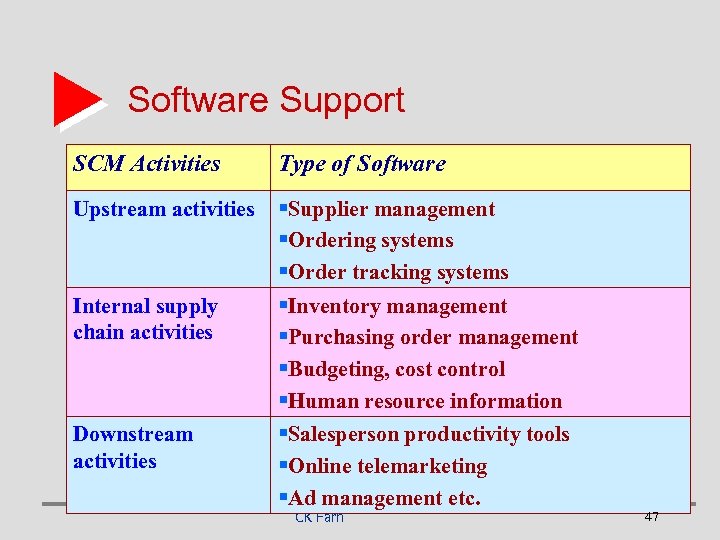

Software Support SCM Activities Type of Software Upstream activities §Supplier management §Ordering systems §Order tracking systems §Inventory management §Purchasing order management §Budgeting, cost control §Human resource information §Salesperson productivity tools §Online telemarketing §Ad management etc. Internal supply chain activities Downstream activities CK Farn 47

Software Support SCM Activities Type of Software Upstream activities §Supplier management §Ordering systems §Order tracking systems §Inventory management §Purchasing order management §Budgeting, cost control §Human resource information §Salesperson productivity tools §Online telemarketing §Ad management etc. Internal supply chain activities Downstream activities CK Farn 47

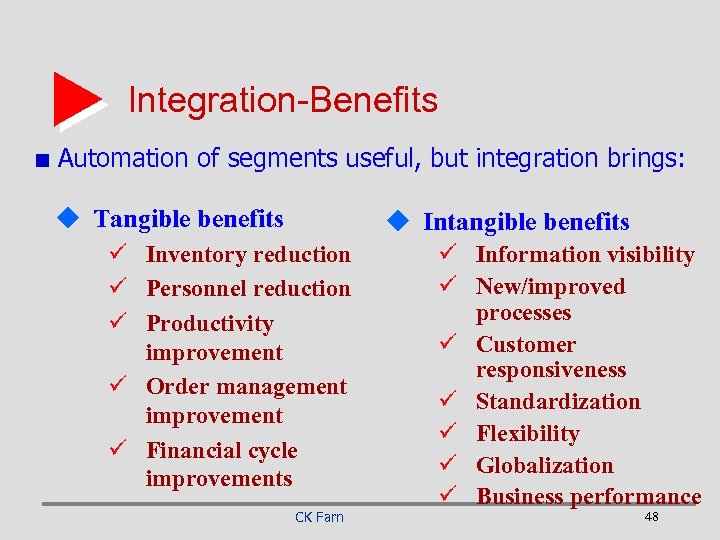

Integration-Benefits Automation of segments useful, but integration brings: u Tangible benefits u Intangible benefits ü Inventory reduction ü Personnel reduction ü Productivity improvement ü Order management improvement ü Financial cycle improvements CK Farn ü Information visibility ü New/improved processes ü Customer responsiveness ü Standardization ü Flexibility ü Globalization ü Business performance 48

Integration-Benefits Automation of segments useful, but integration brings: u Tangible benefits u Intangible benefits ü Inventory reduction ü Personnel reduction ü Productivity improvement ü Order management improvement ü Financial cycle improvements CK Farn ü Information visibility ü New/improved processes ü Customer responsiveness ü Standardization ü Flexibility ü Globalization ü Business performance 48

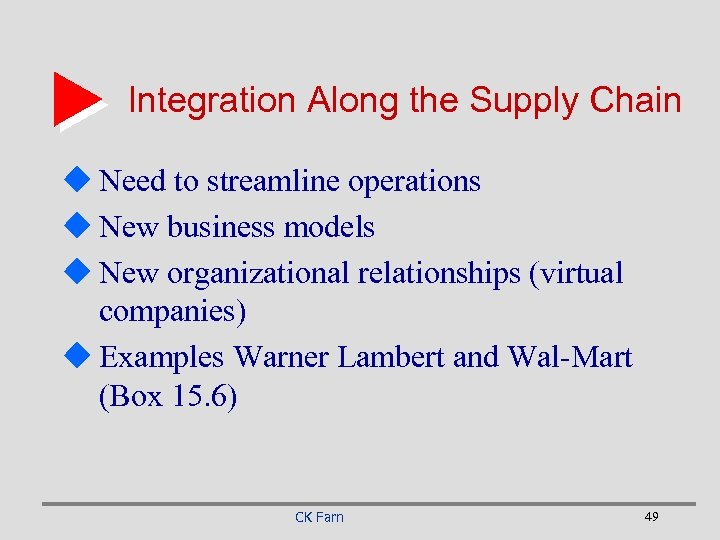

Integration Along the Supply Chain u Need to streamline operations u New business models u New organizational relationships (virtual companies) u Examples Warner Lambert and Wal-Mart (Box 15. 6) CK Farn 49

Integration Along the Supply Chain u Need to streamline operations u New business models u New organizational relationships (virtual companies) u Examples Warner Lambert and Wal-Mart (Box 15. 6) CK Farn 49

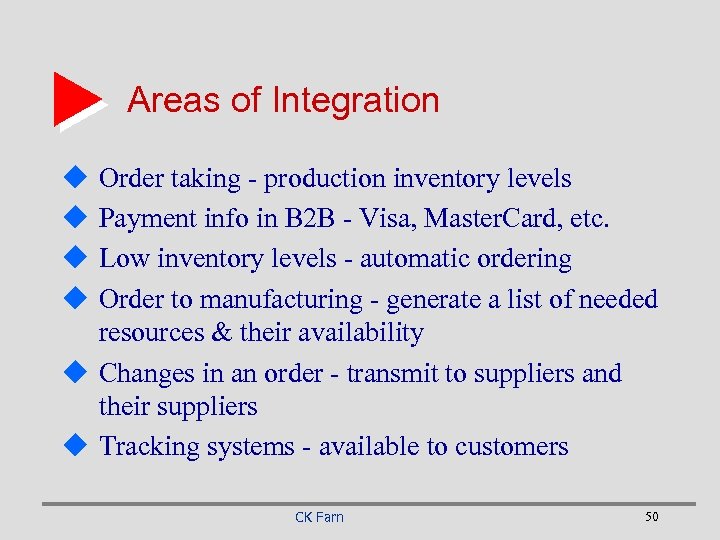

Areas of Integration u u Order taking - production inventory levels Payment info in B 2 B - Visa, Master. Card, etc. Low inventory levels - automatic ordering Order to manufacturing - generate a list of needed resources & their availability u Changes in an order - transmit to suppliers and their suppliers u Tracking systems - available to customers CK Farn 50

Areas of Integration u u Order taking - production inventory levels Payment info in B 2 B - Visa, Master. Card, etc. Low inventory levels - automatic ordering Order to manufacturing - generate a list of needed resources & their availability u Changes in an order - transmit to suppliers and their suppliers u Tracking systems - available to customers CK Farn 50

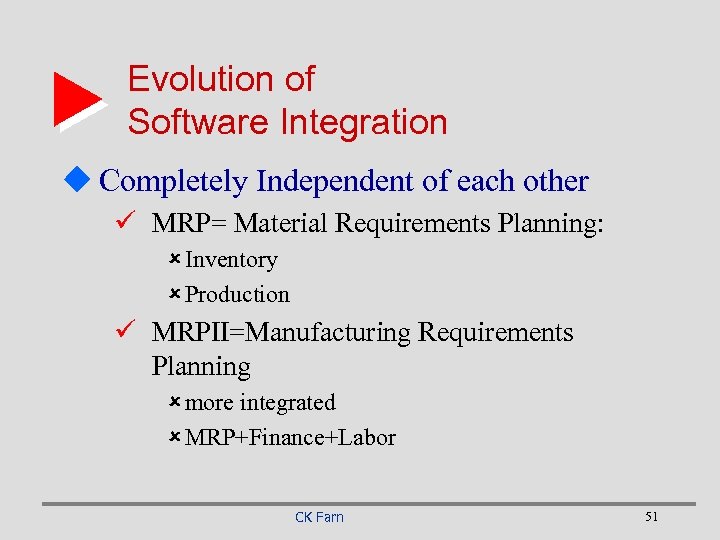

Evolution of Software Integration u Completely Independent of each other ü MRP= Material Requirements Planning: û Inventory û Production ü MRPII=Manufacturing Requirements Planning û more integrated û MRP+Finance+Labor CK Farn 51

Evolution of Software Integration u Completely Independent of each other ü MRP= Material Requirements Planning: û Inventory û Production ü MRPII=Manufacturing Requirements Planning û more integrated û MRP+Finance+Labor CK Farn 51

Evolution of Software Integration (cont. ) u Completely Independent of each other ü ERP=Enterprise Resources Planning û All functional areas ü Extended ERP includes û Suppliers û Customers CK Farn 52

Evolution of Software Integration (cont. ) u Completely Independent of each other ü ERP=Enterprise Resources Planning û All functional areas ü Extended ERP includes û Suppliers û Customers CK Farn 52

From SAP to my. SAP. com u SAP = Traditional ERP = Automate and Integrate transactions u My. SAP. com = Web-based comprehensive system ü Workplace - a personalized, role-based interface ü Marketplace - one stop destination for business professionals to collaborate ü Business Scenarios - products for the Internet and intranet ü Application-hosing - hosting Web applications for SMEs CK Farn 53

From SAP to my. SAP. com u SAP = Traditional ERP = Automate and Integrate transactions u My. SAP. com = Web-based comprehensive system ü Workplace - a personalized, role-based interface ü Marketplace - one stop destination for business professionals to collaborate ü Business Scenarios - products for the Internet and intranet ü Application-hosing - hosting Web applications for SMEs CK Farn 53

ERP Benefits u ERP = Integrating business processes and activities in real time u Solves many supply chain problems u Necessary for medium to large corporations u Helpful also for some SMEs CK Farn 54

ERP Benefits u ERP = Integrating business processes and activities in real time u Solves many supply chain problems u Necessary for medium to large corporations u Helpful also for some SMEs CK Farn 54

ERP Implementation u Need to interface with EC order taking system u Manages all routine transactions in the enterprise u Recently extended to suppliers and customers CK Farn 55

ERP Implementation u Need to interface with EC order taking system u Manages all routine transactions in the enterprise u Recently extended to suppliers and customers CK Farn 55

Developing ERP Systems u Do-it-yourself, from scratch (only few will) u Use Integrated packages such as R/3 from SAP u “Best of Bread” approach, using integrating software u Rent in from ASP service CK Farn 56

Developing ERP Systems u Do-it-yourself, from scratch (only few will) u Use Integrated packages such as R/3 from SAP u “Best of Bread” approach, using integrating software u Rent in from ASP service CK Farn 56

Post-ERP (2 nd Generation) u 1 st generation - transaction processing orientation u 2 nd generation ü Including decision-making capabilities ü EC requires decision support ü EC requires business intelligence u SCM software: Production Planning, Manpower utilization, Profitability models, market analysis u Integration of SCM capabilities u APS function: advanced planning and scheduling u Other added functionalities: CRM, KM CK Farn 57

Post-ERP (2 nd Generation) u 1 st generation - transaction processing orientation u 2 nd generation ü Including decision-making capabilities ü EC requires decision support ü EC requires business intelligence u SCM software: Production Planning, Manpower utilization, Profitability models, market analysis u Integration of SCM capabilities u APS function: advanced planning and scheduling u Other added functionalities: CRM, KM CK Farn 57

ASP and ERP Outsourcing u Why ASP or lease? ü ü Leasing information systems application Back to the days of “time-sharing” A risk prevention strategy Very popular with ERP (expensive, cumbersome) CK Farn 58

ASP and ERP Outsourcing u Why ASP or lease? ü ü Leasing information systems application Back to the days of “time-sharing” A risk prevention strategy Very popular with ERP (expensive, cumbersome) CK Farn 58

Managerial Issues u Planning for order fulfillment is a critical task, especially for virtual EC vendors u Dealing with returns can be a complex issue u Partnerships and alliances can improve logistics and alleviate supply chain problems u Many software products are available to improve SCM and logistics u EC must be tightly connected with back-office operations CK Farn 59

Managerial Issues u Planning for order fulfillment is a critical task, especially for virtual EC vendors u Dealing with returns can be a complex issue u Partnerships and alliances can improve logistics and alleviate supply chain problems u Many software products are available to improve SCM and logistics u EC must be tightly connected with back-office operations CK Farn 59

Managerial Issues (cont. ) u It is necessary to integrate it with EC frontoffice operations u Importance of creation of logistics system for EC and how to use EC applications to improve the supply chain u Software integration may require considerable time and money CK Farn 60

Managerial Issues (cont. ) u It is necessary to integrate it with EC frontoffice operations u Importance of creation of logistics system for EC and how to use EC applications to improve the supply chain u Software integration may require considerable time and money CK Farn 60