f1fb993e808483cb858b8ba48f9d3060.ppt

- Количество слайдов: 66

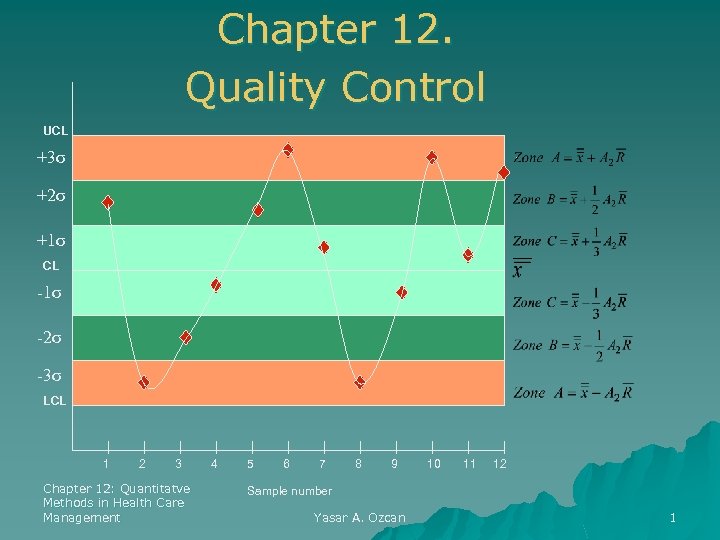

Chapter 12. Quality Control UCL +3σ +2σ +1σ CL -1σ -2σ -3σ LCL 1 2 3 Chapter 12: Quantitatve Methods in Health Care Management 4 5 6 7 8 9 10 11 12 Sample number Yasar A. Ozcan 1

Chapter 12. Quality Control UCL +3σ +2σ +1σ CL -1σ -2σ -3σ LCL 1 2 3 Chapter 12: Quantitatve Methods in Health Care Management 4 5 6 7 8 9 10 11 12 Sample number Yasar A. Ozcan 1

Outline u u u u u Quality in Healthcare Quality Experts Quality Certification TQM & CQI Six-Sigma Monitoring Quality through Control Charts – Control Charts for Attributes – Control Charts for Variables Process improvement Methods for Generating New Ideas Tools for Investigation Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 2

Outline u u u u u Quality in Healthcare Quality Experts Quality Certification TQM & CQI Six-Sigma Monitoring Quality through Control Charts – Control Charts for Attributes – Control Charts for Variables Process improvement Methods for Generating New Ideas Tools for Investigation Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 2

A Broad Definition. . . u u u Quality refers to the ability of a product or service to consistently meet or exceed customer expectations quality in healthcare is evaluated from differing perspectives of providers, recipients and thirdparty payers. Most clinicians accept the Institute of Medicine (1990) definition: “Quality is the extent to which health services for individuals and populations increase the likelihood of desired health outcomes and are consistent with current professional knowledge. ” Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 3

A Broad Definition. . . u u u Quality refers to the ability of a product or service to consistently meet or exceed customer expectations quality in healthcare is evaluated from differing perspectives of providers, recipients and thirdparty payers. Most clinicians accept the Institute of Medicine (1990) definition: “Quality is the extent to which health services for individuals and populations increase the likelihood of desired health outcomes and are consistent with current professional knowledge. ” Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 3

What is quality? You are a world renowned surgeon that has just completed a radical new surgical technique. There were few complications, largely due to the excellence of the hospital’s staff and technological capabilities. QUALITY? Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 4

What is quality? You are a world renowned surgeon that has just completed a radical new surgical technique. There were few complications, largely due to the excellence of the hospital’s staff and technological capabilities. QUALITY? Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 4

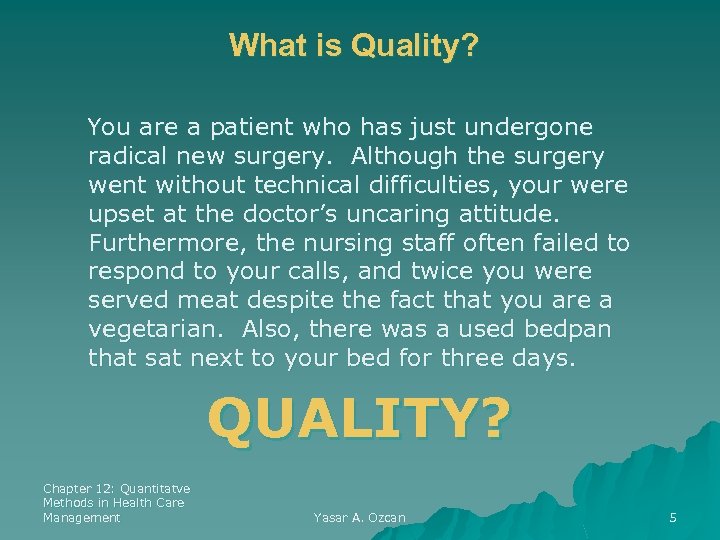

What is Quality? You are a patient who has just undergone radical new surgery. Although the surgery went without technical difficulties, your were upset at the doctor’s uncaring attitude. Furthermore, the nursing staff often failed to respond to your calls, and twice you were served meat despite the fact that you are a vegetarian. Also, there was a used bedpan that sat next to your bed for three days. QUALITY? Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 5

What is Quality? You are a patient who has just undergone radical new surgery. Although the surgery went without technical difficulties, your were upset at the doctor’s uncaring attitude. Furthermore, the nursing staff often failed to respond to your calls, and twice you were served meat despite the fact that you are a vegetarian. Also, there was a used bedpan that sat next to your bed for three days. QUALITY? Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 5

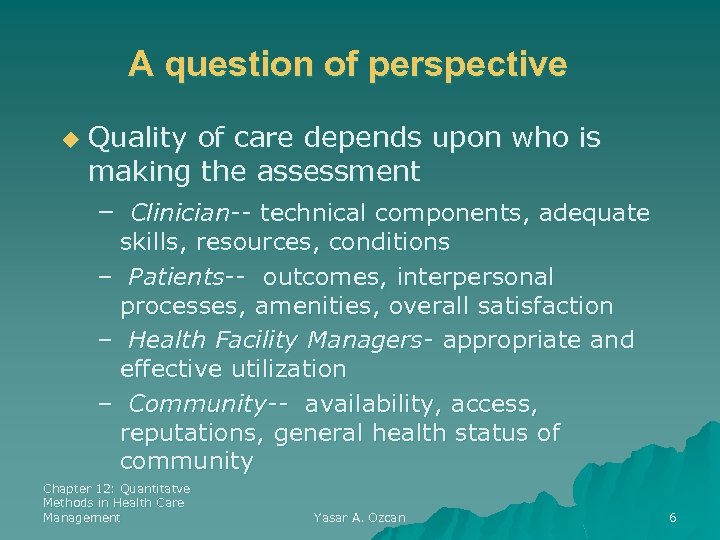

A question of perspective u Quality of care depends upon who is making the assessment – Clinician-- technical components, adequate skills, resources, conditions – Patients-- outcomes, interpersonal processes, amenities, overall satisfaction – Health Facility Managers- appropriate and effective utilization – Community-- availability, access, reputations, general health status of community Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 6

A question of perspective u Quality of care depends upon who is making the assessment – Clinician-- technical components, adequate skills, resources, conditions – Patients-- outcomes, interpersonal processes, amenities, overall satisfaction – Health Facility Managers- appropriate and effective utilization – Community-- availability, access, reputations, general health status of community Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 6

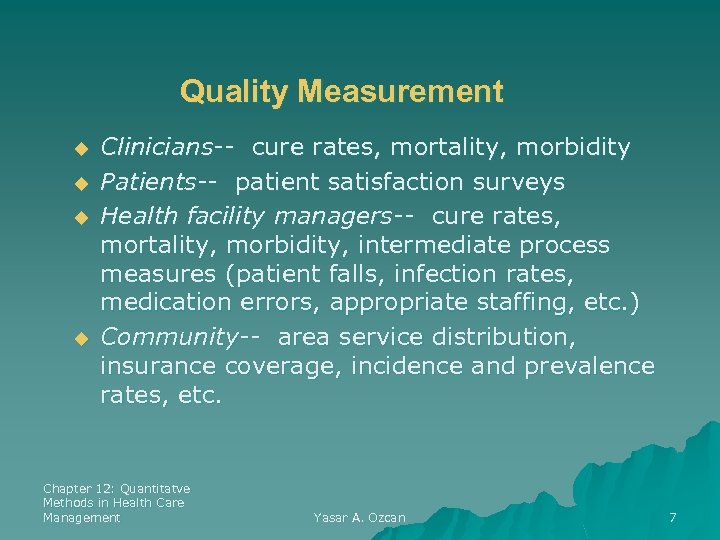

Quality Measurement u u Clinicians-- cure rates, mortality, morbidity Patients-- patient satisfaction surveys Health facility managers-- cure rates, mortality, morbidity, intermediate process measures (patient falls, infection rates, medication errors, appropriate staffing, etc. ) Community-- area service distribution, insurance coverage, incidence and prevalence rates, etc. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 7

Quality Measurement u u Clinicians-- cure rates, mortality, morbidity Patients-- patient satisfaction surveys Health facility managers-- cure rates, mortality, morbidity, intermediate process measures (patient falls, infection rates, medication errors, appropriate staffing, etc. ) Community-- area service distribution, insurance coverage, incidence and prevalence rates, etc. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 7

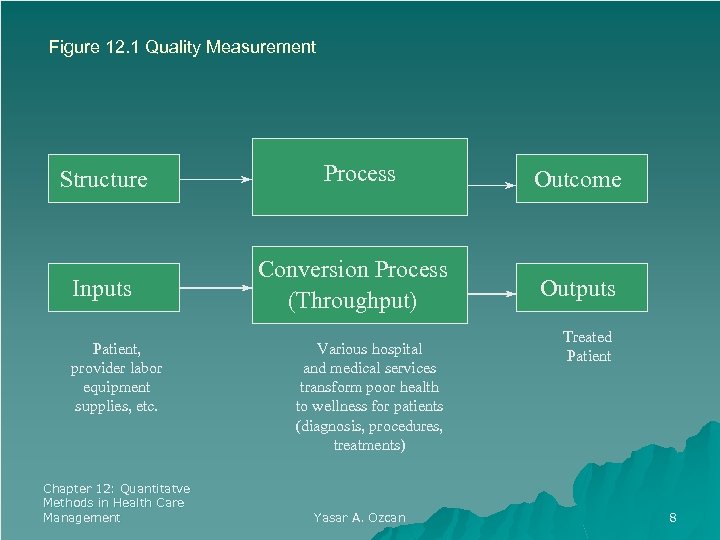

Figure 12. 1 Quality Measurement Structure Inputs Patient, provider labor equipment supplies, etc. Chapter 12: Quantitatve Methods in Health Care Management Process Conversion Process (Throughput) Various hospital and medical services transform poor health to wellness for patients (diagnosis, procedures, treatments) Yasar A. Ozcan Outcome Outputs Treated Patient 8

Figure 12. 1 Quality Measurement Structure Inputs Patient, provider labor equipment supplies, etc. Chapter 12: Quantitatve Methods in Health Care Management Process Conversion Process (Throughput) Various hospital and medical services transform poor health to wellness for patients (diagnosis, procedures, treatments) Yasar A. Ozcan Outcome Outputs Treated Patient 8

Quality Measurement Quality Gaps u. Another way to look at the maintenance of quality is how mistakes are to be avoided – design mistake-proof processes across the whole spectrum of the care, to reduce undesired outcomes. u. Variance in diagnostic and therapeutic interventions and the associated errors hamper the delivery of safe, effective patient care and add to poor outcomes. u. To minimize the variation and the errors – sometimes euphemistically called “quality gaps” – and work toward completely eliminating them are major goals for healthcare systems. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 9

Quality Measurement Quality Gaps u. Another way to look at the maintenance of quality is how mistakes are to be avoided – design mistake-proof processes across the whole spectrum of the care, to reduce undesired outcomes. u. Variance in diagnostic and therapeutic interventions and the associated errors hamper the delivery of safe, effective patient care and add to poor outcomes. u. To minimize the variation and the errors – sometimes euphemistically called “quality gaps” – and work toward completely eliminating them are major goals for healthcare systems. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 9

Quality Measurement Quality Gaps Chassin (1998) classifies the underlying causes of “quality gaps” into three categories: 1) Over-utilization. When the potential benefit of a therapy is less than its risk, overuse of health services affects the quality of care. Pressures for overuse of services may come from either providers or patients. 2) Under-utilization. A patient’s lack of insurance or insurance that has high co-payments and deductibles can cause under-utilization of necessary health care. 3) Miss-utilization. Avoidable complications, negligent care, mistakes, and mishaps create miss- utilization of services. Healthcare providers who generate such conditions harm the quality of patient care and produce poor outcomes; they also waste the organization’s resources and increase lengths of stay. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 10

Quality Measurement Quality Gaps Chassin (1998) classifies the underlying causes of “quality gaps” into three categories: 1) Over-utilization. When the potential benefit of a therapy is less than its risk, overuse of health services affects the quality of care. Pressures for overuse of services may come from either providers or patients. 2) Under-utilization. A patient’s lack of insurance or insurance that has high co-payments and deductibles can cause under-utilization of necessary health care. 3) Miss-utilization. Avoidable complications, negligent care, mistakes, and mishaps create miss- utilization of services. Healthcare providers who generate such conditions harm the quality of patient care and produce poor outcomes; they also waste the organization’s resources and increase lengths of stay. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 10

Quality Measurement u. Healthcare providers do have an arsenal of methods to deal effectively with the problems affecting quality of care. u. They include the programs called quality control (QC), total quality management (TQM), continuous quality improvement (CQI), reengineering, and Six-Sigma. u. All these programs include data gathering, analysis and statistical monitoring to identify the problem and its cause. u. Nevertheless, the crux of the solution to quality problems lies in changing human behavior, changing minds to perform care in new ways. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 11

Quality Measurement u. Healthcare providers do have an arsenal of methods to deal effectively with the problems affecting quality of care. u. They include the programs called quality control (QC), total quality management (TQM), continuous quality improvement (CQI), reengineering, and Six-Sigma. u. All these programs include data gathering, analysis and statistical monitoring to identify the problem and its cause. u. Nevertheless, the crux of the solution to quality problems lies in changing human behavior, changing minds to perform care in new ways. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 11

Quality Experts u u Deming-- poor quality caused by the system, not employees; management’s responsibility to correct system; ” use 14 points to reduce variation caused by special causes (correctable) and not common (random) causes of variation. Juran-- 80% of defects are controllable; three elements: quality planning, quality control, and continual quality improvement Crosby-- zero defects; quality is free Isikawa-- cause and effect diagrams, quality circles Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 12

Quality Experts u u Deming-- poor quality caused by the system, not employees; management’s responsibility to correct system; ” use 14 points to reduce variation caused by special causes (correctable) and not common (random) causes of variation. Juran-- 80% of defects are controllable; three elements: quality planning, quality control, and continual quality improvement Crosby-- zero defects; quality is free Isikawa-- cause and effect diagrams, quality circles Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 12

Quality Certification u Organizations can earn awards or achieve certification/accreditation by international organizations or by their own trade organizations; for instance, hospitals are evaluated periodically by the Joint Commission on Accreditation of Healthcare Organizations (JCAHO). u For the medical group practices, the Medical Group Management Association (MGMA) is the principal voice. MGMA leads the profession and assists members through information, education, networking and advocacy” (MGMA, 2004). u Quality is always a major concern in those advocacy and accreditation bodies. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 13

Quality Certification u Organizations can earn awards or achieve certification/accreditation by international organizations or by their own trade organizations; for instance, hospitals are evaluated periodically by the Joint Commission on Accreditation of Healthcare Organizations (JCAHO). u For the medical group practices, the Medical Group Management Association (MGMA) is the principal voice. MGMA leads the profession and assists members through information, education, networking and advocacy” (MGMA, 2004). u Quality is always a major concern in those advocacy and accreditation bodies. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 13

Quality Certification u ISO 9000 u Set of international standards on quality management and Quality assurance, critical to international Business u ISO 9000 series standards, briefly, require firms to document their quality-control systems at every step (incoming raw materials, product design, in-process monitoring and so forth) so that they’ll be able to identify those areas that are causing quality problems and correct them. u ISO 9000 requires companies to document everything they do that affects the quality of goods and services. – Hierarchical approach to documentation of the Quality Management System Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 14

Quality Certification u ISO 9000 u Set of international standards on quality management and Quality assurance, critical to international Business u ISO 9000 series standards, briefly, require firms to document their quality-control systems at every step (incoming raw materials, product design, in-process monitoring and so forth) so that they’ll be able to identify those areas that are causing quality problems and correct them. u ISO 9000 requires companies to document everything they do that affects the quality of goods and services. – Hierarchical approach to documentation of the Quality Management System Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 14

Total Quality Management u u A philosophy that involves everyone in an organization in the quest for quality, with customer satisfaction as the driving force TQM involves: – finding what customers want – designing services to meet customer needs – designing mistake proof delivery process “pakayoke” – monitoring results and continuous improvement Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 15

Total Quality Management u u A philosophy that involves everyone in an organization in the quest for quality, with customer satisfaction as the driving force TQM involves: – finding what customers want – designing services to meet customer needs – designing mistake proof delivery process “pakayoke” – monitoring results and continuous improvement Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 15

TQM, cont. u u u TQM requires: – continual improvement – competitive benchmarking – employee empowerment – team approaches – knowledge of tools Quality at the source-- each worker responsible for his/her own work Quality function deployment-- involve customers in service design Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 16

TQM, cont. u u u TQM requires: – continual improvement – competitive benchmarking – employee empowerment – team approaches – knowledge of tools Quality at the source-- each worker responsible for his/her own work Quality function deployment-- involve customers in service design Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 16

Controlling Quality u u u Quality control focuses on the conversion of inputs into outputs, i. e. , the processes Goal is to reduce the need for inspection of control efforts Quality assurance efforts occurring during production of services are referred to as statistical process control Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 17

Controlling Quality u u u Quality control focuses on the conversion of inputs into outputs, i. e. , the processes Goal is to reduce the need for inspection of control efforts Quality assurance efforts occurring during production of services are referred to as statistical process control Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 17

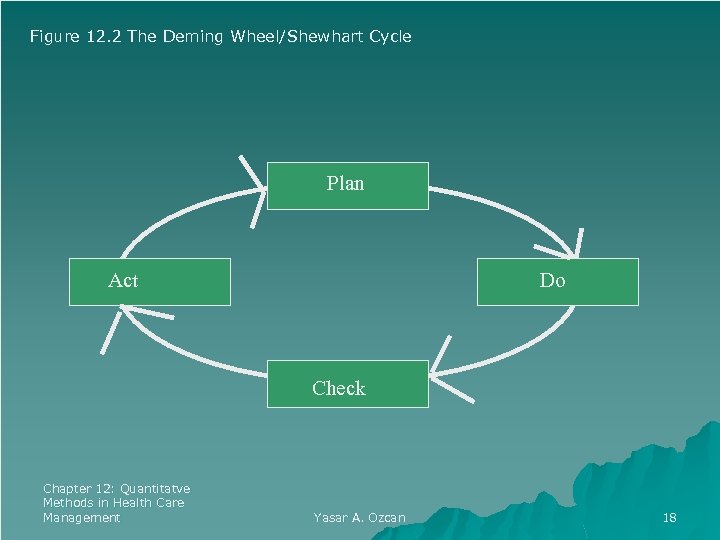

Figure 12. 2 The Deming Wheel/Shewhart Cycle Plan Act Do Check Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 18

Figure 12. 2 The Deming Wheel/Shewhart Cycle Plan Act Do Check Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 18

Continuous Quality Improvement u u u A philosophy seeking to make never-ending improvements to the process of converting inputs into outputs Kaizen-- Japanese term referring to CI Environment must be conducive to CI – appropriate vision statement, strategies, tactics – management style encouraging trust, openness – adherence to stated philosophy – reward/incentive systems Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 19

Continuous Quality Improvement u u u A philosophy seeking to make never-ending improvements to the process of converting inputs into outputs Kaizen-- Japanese term referring to CI Environment must be conducive to CI – appropriate vision statement, strategies, tactics – management style encouraging trust, openness – adherence to stated philosophy – reward/incentive systems Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 19

Continuous Quality Improvement 1) 2) 3) 4) 5) 6) 7) The CQI is a detailed version of a PDSA cycle that comprises: selecting a process that needs an improvement studying and documenting the current process seeking ways to improve it designing an improved process implementing the new process monitoring and evaluation documenting the process if it worked successfully and publicizing it through the healthcare organization if it did not achieve its goals, re-starting from step 1. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 20

Continuous Quality Improvement 1) 2) 3) 4) 5) 6) 7) The CQI is a detailed version of a PDSA cycle that comprises: selecting a process that needs an improvement studying and documenting the current process seeking ways to improve it designing an improved process implementing the new process monitoring and evaluation documenting the process if it worked successfully and publicizing it through the healthcare organization if it did not achieve its goals, re-starting from step 1. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 20

Six-Sigma • Six- Sigma is one of the latest quality improvement concepts to have emerged during the 1990’s. Its name comes from the measure of variation from the normal distribution (six standard deviations). • Adopting a six-sigma strategy as a quality goal sets tolerance levels for errors (defectives) to levels that occur only 3. 4 times per million observations. • The defect rates in healthcare can be defined in such distinct areas as public health, inpatient care, ambulatory care, and so on. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 21

Six-Sigma • Six- Sigma is one of the latest quality improvement concepts to have emerged during the 1990’s. Its name comes from the measure of variation from the normal distribution (six standard deviations). • Adopting a six-sigma strategy as a quality goal sets tolerance levels for errors (defectives) to levels that occur only 3. 4 times per million observations. • The defect rates in healthcare can be defined in such distinct areas as public health, inpatient care, ambulatory care, and so on. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 21

Six-Sigma Healthcare organizations have reduced the deaths caused by anesthesia from 25 -50 per million cases to 5 per million cases since the 1980 s through improved monitoring techniques, adaptation of practice guidelines, and other systematic approaches to reduce errors. This is one area that comes very close to six sigma standards (Chassin, 1998). Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 22

Six-Sigma Healthcare organizations have reduced the deaths caused by anesthesia from 25 -50 per million cases to 5 per million cases since the 1980 s through improved monitoring techniques, adaptation of practice guidelines, and other systematic approaches to reduce errors. This is one area that comes very close to six sigma standards (Chassin, 1998). Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 22

Six-Sigma Deployment of six-sigma to improve the quality of healthcare and delivery performance can be considered in the following areas: a) Clinical excellence b) Service delivery c) Service costs, and d) Patient satisfaction. The deployment can use either of these methodological sequences: DMAIC: define, measure, analyze, improve, and control DMADV: define, measure, analyze, design, and verify. DMAIC is generally used to improve existing systems that have fallen the below six-sigma levels, DMADV is used to design and develop new processes or products at six-sigma levels (Stahl, Shultz, and Pexton, 2003). Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 23

Six-Sigma Deployment of six-sigma to improve the quality of healthcare and delivery performance can be considered in the following areas: a) Clinical excellence b) Service delivery c) Service costs, and d) Patient satisfaction. The deployment can use either of these methodological sequences: DMAIC: define, measure, analyze, improve, and control DMADV: define, measure, analyze, design, and verify. DMAIC is generally used to improve existing systems that have fallen the below six-sigma levels, DMADV is used to design and develop new processes or products at six-sigma levels (Stahl, Shultz, and Pexton, 2003). Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 23

Six-Sigma The essence of six-sigma methodologies is both improvement of the knowledge and capability of employees, and also changes behavior through training. Thus six-sigma employs a classification system that identifies education and training for employees, project managers and executives. Emulating karate honors, certification is granted at Green Belt (GB), Black Belt (BB) and Master Black Belts (MBB) levels. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 24

Six-Sigma The essence of six-sigma methodologies is both improvement of the knowledge and capability of employees, and also changes behavior through training. Thus six-sigma employs a classification system that identifies education and training for employees, project managers and executives. Emulating karate honors, certification is granted at Green Belt (GB), Black Belt (BB) and Master Black Belts (MBB) levels. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 24

Six-Sigma Green Belts (GBs) are the employees who have taken the training courses on implementing the projects. Black Belts (BBs) are the project leaders, whose training may be more intensive; they may complete several projects a year depending upon their size and scope. Master Black Belts (MBBs) are generally assigned to an area that needs improvement (for example, human resources), to ensure that objectives are set, targets are identified, plans are made, and resources are secured to implement the projects in their assigned area. MBBs may oversee many six-sigma projects at a time, working with various BBs. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 25

Six-Sigma Green Belts (GBs) are the employees who have taken the training courses on implementing the projects. Black Belts (BBs) are the project leaders, whose training may be more intensive; they may complete several projects a year depending upon their size and scope. Master Black Belts (MBBs) are generally assigned to an area that needs improvement (for example, human resources), to ensure that objectives are set, targets are identified, plans are made, and resources are secured to implement the projects in their assigned area. MBBs may oversee many six-sigma projects at a time, working with various BBs. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 25

Six-Sigma Six-sigma projects require BBs and MBBs to have expertise in basic statistical tools such as Pareto Diagrams, descriptive and higher level statistics including regression, and statistical modeling techniques as well as control processes. In addition to statistical concepts, they are expected understand project management, finance, leadership, measurement through socio-metric (survey) analysis, reliability and validity. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 26

Six-Sigma Six-sigma projects require BBs and MBBs to have expertise in basic statistical tools such as Pareto Diagrams, descriptive and higher level statistics including regression, and statistical modeling techniques as well as control processes. In addition to statistical concepts, they are expected understand project management, finance, leadership, measurement through socio-metric (survey) analysis, reliability and validity. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 26

Six-Sigma Examples of successful six-sigma deployments in healthcare include: • reduction of emergency room diversions • fewer errors in operating rooms’ cart materials • reduced bloodstream infections in an ICU, and • improved radiology turnaround time (Stahl, Shultz, and Pexton, 2003). Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 27

Six-Sigma Examples of successful six-sigma deployments in healthcare include: • reduction of emergency room diversions • fewer errors in operating rooms’ cart materials • reduced bloodstream infections in an ICU, and • improved radiology turnaround time (Stahl, Shultz, and Pexton, 2003). Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 27

Quality Measurement and Control Techniques Process Variability In the delivery of health care, there are many occasions when an error can happen in the tasks performed by various clinical staff. Often the same task may not even be performed the same way for all patients, though minor alterations within defined limits can be acceptable. When provider performance falls beyond acceptable limits, the errors that occur require investigation and correction. In order to detect noteworthy variations in process, or tendencies that may cause unacceptable levels of errors, healthcare managers must monitor the processes for quality, using various charts. The intent of the monitoring is to distinguish between random and non -random variation. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 28

Quality Measurement and Control Techniques Process Variability In the delivery of health care, there are many occasions when an error can happen in the tasks performed by various clinical staff. Often the same task may not even be performed the same way for all patients, though minor alterations within defined limits can be acceptable. When provider performance falls beyond acceptable limits, the errors that occur require investigation and correction. In order to detect noteworthy variations in process, or tendencies that may cause unacceptable levels of errors, healthcare managers must monitor the processes for quality, using various charts. The intent of the monitoring is to distinguish between random and non -random variation. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 28

Quality Measurement and Control Techniques Process Variability The common variations in process variability that are caused by natural incidences are in general not repetitive, but various minor factors due to chance and are called random variation. If the cause of variation is systematic, not natural, and the source of the variation is identifiable, the process variation is called non-random variation. In healthcare, non-random variation may occur by not following procedures, using defective materials, fatigue, carelessness, or not having appropriate training or orientation to the work situation, among many reasons. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 29

Quality Measurement and Control Techniques Process Variability The common variations in process variability that are caused by natural incidences are in general not repetitive, but various minor factors due to chance and are called random variation. If the cause of variation is systematic, not natural, and the source of the variation is identifiable, the process variation is called non-random variation. In healthcare, non-random variation may occur by not following procedures, using defective materials, fatigue, carelessness, or not having appropriate training or orientation to the work situation, among many reasons. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 29

Quality Measurement and Control Techniques Process Variability Process variation is the range of natural variability in a process for which healthcare managers use control charts to monitor the measurements. If the natural variability or the presence of random variation exceeds tolerances set by control charts, then the process is not meeting the design specifications. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 30

Quality Measurement and Control Techniques Process Variability Process variation is the range of natural variability in a process for which healthcare managers use control charts to monitor the measurements. If the natural variability or the presence of random variation exceeds tolerances set by control charts, then the process is not meeting the design specifications. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 30

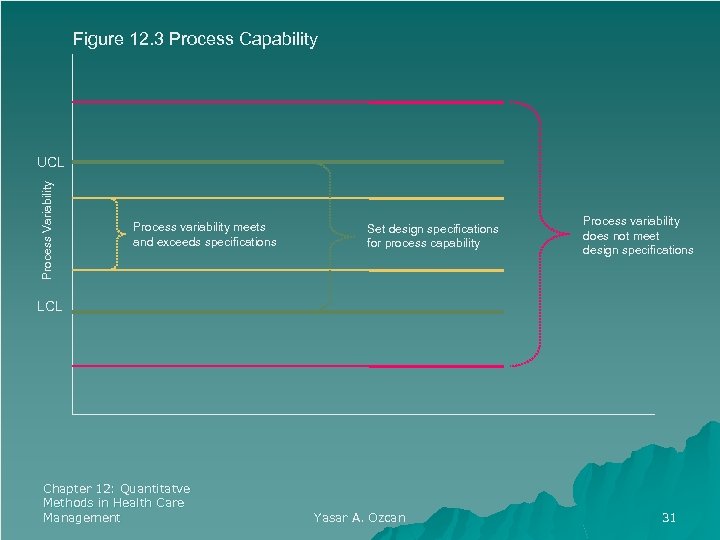

Figure 12. 3 Process Capability Process Variability UCL Process variability meets and exceeds specifications Set design specifications for process capability Process variability does not meet design specifications LCL Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 31

Figure 12. 3 Process Capability Process Variability UCL Process variability meets and exceeds specifications Set design specifications for process capability Process variability does not meet design specifications LCL Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 31

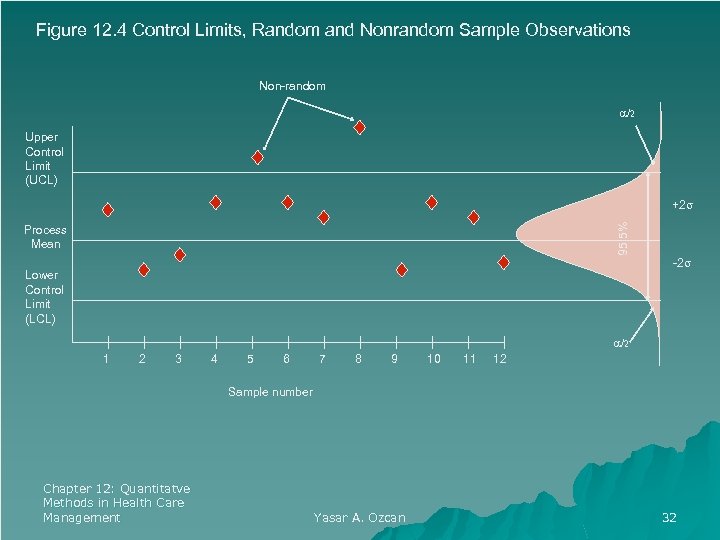

Figure 12. 4 Control Limits, Random and Nonrandom Sample Observations Non-random α/ 2 Upper Control Limit (UCL) 95. 5% +2σ Process Mean Lower Control Limit (LCL) -2σ α/ 2 1 2 3 4 5 6 7 8 9 10 11 12 Sample number Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 32

Figure 12. 4 Control Limits, Random and Nonrandom Sample Observations Non-random α/ 2 Upper Control Limit (UCL) 95. 5% +2σ Process Mean Lower Control Limit (LCL) -2σ α/ 2 1 2 3 4 5 6 7 8 9 10 11 12 Sample number Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 32

Control Charts for Attributes When process characteristics can be counted, attributebased control charts are the appropriate way to display the monitoring process. If the number of occurrences per unit of measure can be counted, or there can be a count of the number of bad occurrences but not of non-occurrences, then a c-chart is the appropriate tool to display monitoring. Counting also can occur for a process with only two outcomes, good or bad (defective); in such cases p-chart is the appropriate control chart. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 33

Control Charts for Attributes When process characteristics can be counted, attributebased control charts are the appropriate way to display the monitoring process. If the number of occurrences per unit of measure can be counted, or there can be a count of the number of bad occurrences but not of non-occurrences, then a c-chart is the appropriate tool to display monitoring. Counting also can occur for a process with only two outcomes, good or bad (defective); in such cases p-chart is the appropriate control chart. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 33

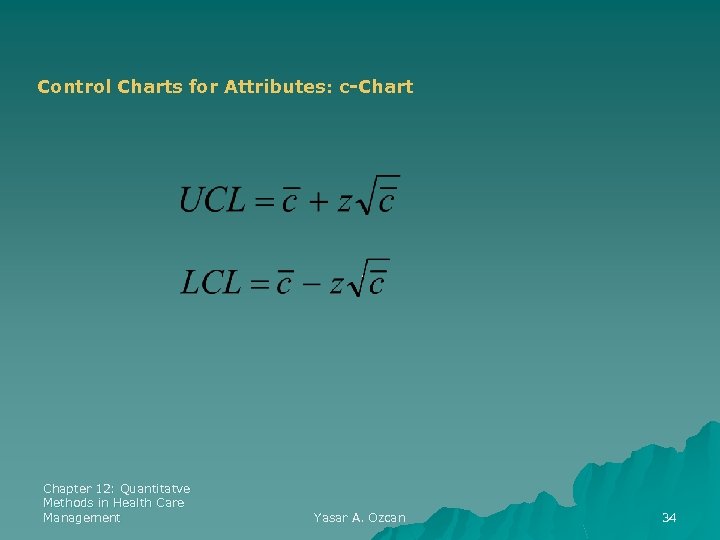

Control Charts for Attributes: c-Chart Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 34

Control Charts for Attributes: c-Chart Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 34

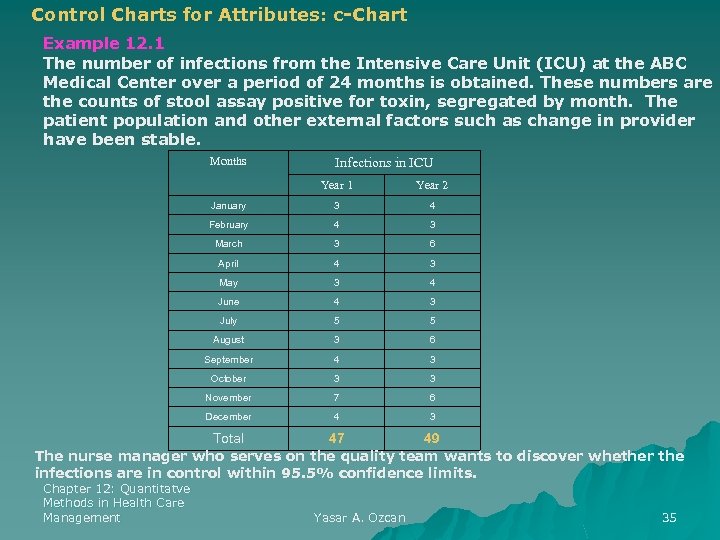

Control Charts for Attributes: c-Chart Example 12. 1 The number of infections from the Intensive Care Unit (ICU) at the ABC Medical Center over a period of 24 months is obtained. These numbers are the counts of stool assay positive for toxin, segregated by month. The patient population and other external factors such as change in provider have been stable. Months Infections in ICU Year 1 Year 2 January 3 4 February 4 3 March 3 6 April 4 3 May 3 4 June 4 3 July 5 5 August 3 6 September 4 3 October 3 3 November 7 6 December 4 3 Total 47 49 The nurse manager who serves on the quality team wants to discover whether the infections are in control within 95. 5% confidence limits. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 35

Control Charts for Attributes: c-Chart Example 12. 1 The number of infections from the Intensive Care Unit (ICU) at the ABC Medical Center over a period of 24 months is obtained. These numbers are the counts of stool assay positive for toxin, segregated by month. The patient population and other external factors such as change in provider have been stable. Months Infections in ICU Year 1 Year 2 January 3 4 February 4 3 March 3 6 April 4 3 May 3 4 June 4 3 July 5 5 August 3 6 September 4 3 October 3 3 November 7 6 December 4 3 Total 47 49 The nurse manager who serves on the quality team wants to discover whether the infections are in control within 95. 5% confidence limits. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 35

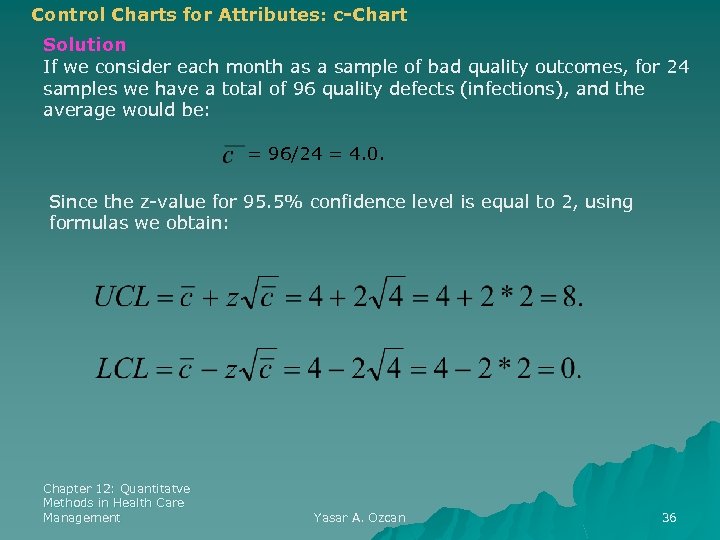

Control Charts for Attributes: c-Chart Solution If we consider each month as a sample of bad quality outcomes, for 24 samples we have a total of 96 quality defects (infections), and the average would be: = 96/24 = 4. 0. Since the z-value for 95. 5% confidence level is equal to 2, using formulas we obtain: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 36

Control Charts for Attributes: c-Chart Solution If we consider each month as a sample of bad quality outcomes, for 24 samples we have a total of 96 quality defects (infections), and the average would be: = 96/24 = 4. 0. Since the z-value for 95. 5% confidence level is equal to 2, using formulas we obtain: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 36

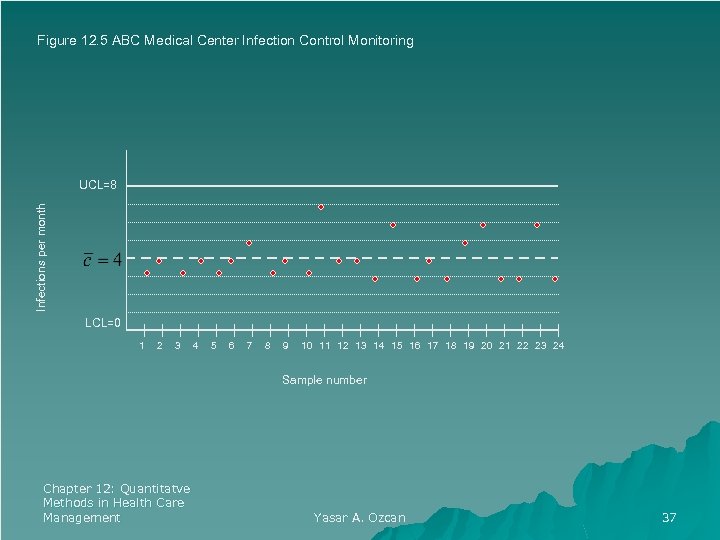

Figure 12. 5 ABC Medical Center Infection Control Monitoring Infections per month UCL=8 LCL=0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Sample number Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 37

Figure 12. 5 ABC Medical Center Infection Control Monitoring Infections per month UCL=8 LCL=0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Sample number Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 37

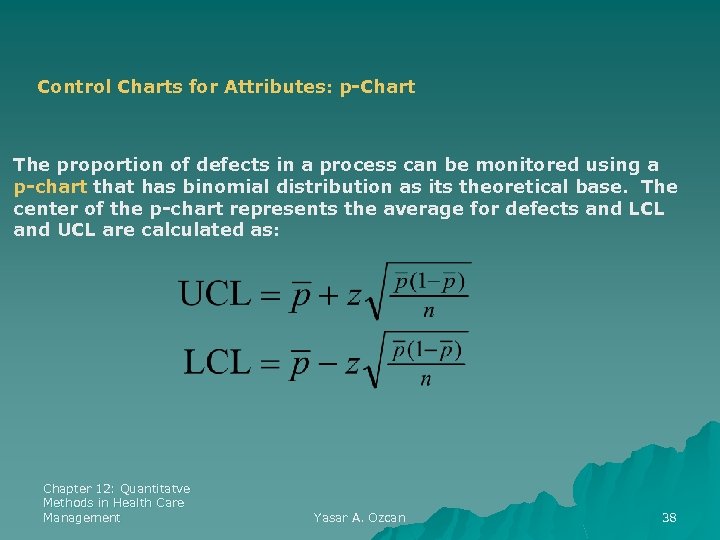

Control Charts for Attributes: p-Chart The proportion of defects in a process can be monitored using a p-chart that has binomial distribution as its theoretical base. The center of the p-chart represents the average for defects and LCL and UCL are calculated as: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 38

Control Charts for Attributes: p-Chart The proportion of defects in a process can be monitored using a p-chart that has binomial distribution as its theoretical base. The center of the p-chart represents the average for defects and LCL and UCL are calculated as: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 38

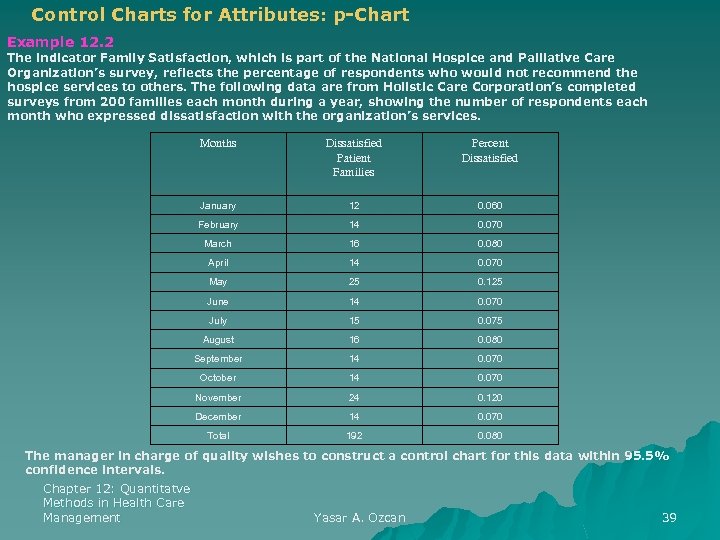

Control Charts for Attributes: p-Chart Example 12. 2 The indicator Family Satisfaction, which is part of the National Hospice and Palliative Care Organization’s survey, reflects the percentage of respondents who would not recommend the hospice services to others. The following data are from Holistic Care Corporation’s completed surveys from 200 families each month during a year, showing the number of respondents each month who expressed dissatisfaction with the organization’s services. Months Dissatisfied Patient Families Percent Dissatisfied January 12 0. 060 February 14 0. 070 March 16 0. 080 April 14 0. 070 May 25 0. 125 June 14 0. 070 July 15 0. 075 August 16 0. 080 September 14 0. 070 October 14 0. 070 November 24 0. 120 December 14 0. 070 Total 192 0. 080 The manager in charge of quality wishes to construct a control chart for this data within 95. 5% confidence intervals. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 39

Control Charts for Attributes: p-Chart Example 12. 2 The indicator Family Satisfaction, which is part of the National Hospice and Palliative Care Organization’s survey, reflects the percentage of respondents who would not recommend the hospice services to others. The following data are from Holistic Care Corporation’s completed surveys from 200 families each month during a year, showing the number of respondents each month who expressed dissatisfaction with the organization’s services. Months Dissatisfied Patient Families Percent Dissatisfied January 12 0. 060 February 14 0. 070 March 16 0. 080 April 14 0. 070 May 25 0. 125 June 14 0. 070 July 15 0. 075 August 16 0. 080 September 14 0. 070 October 14 0. 070 November 24 0. 120 December 14 0. 070 Total 192 0. 080 The manager in charge of quality wishes to construct a control chart for this data within 95. 5% confidence intervals. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 39

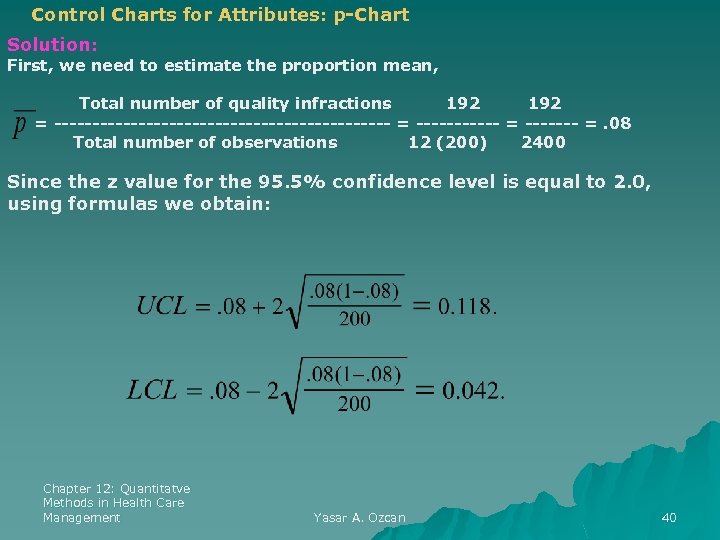

Control Charts for Attributes: p-Chart Solution: First, we need to estimate the proportion mean, Total number of quality infractions 192 = ---------------------- = ------- =. 08 Total number of observations 12 (200) 2400 Since the z value for the 95. 5% confidence level is equal to 2. 0, using formulas we obtain: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 40

Control Charts for Attributes: p-Chart Solution: First, we need to estimate the proportion mean, Total number of quality infractions 192 = ---------------------- = ------- =. 08 Total number of observations 12 (200) 2400 Since the z value for the 95. 5% confidence level is equal to 2. 0, using formulas we obtain: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 40

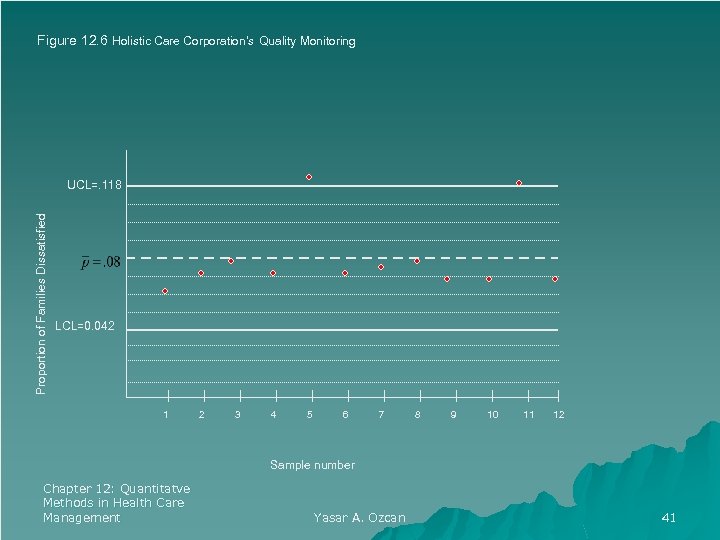

Figure 12. 6 Holistic Care Corporation’s Quality Monitoring Proportion of Families Dissatisfied UCL=. 118 LCL=0. 042 1 2 3 4 5 6 7 8 9 10 11 12 Sample number Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 41

Figure 12. 6 Holistic Care Corporation’s Quality Monitoring Proportion of Families Dissatisfied UCL=. 118 LCL=0. 042 1 2 3 4 5 6 7 8 9 10 11 12 Sample number Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 41

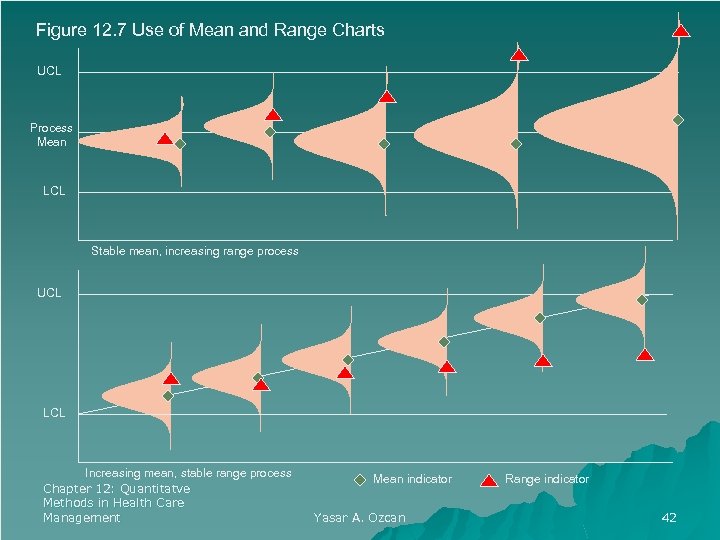

Figure 12. 7 Use of Mean and Range Charts UCL Process Mean LCL Stable mean, increasing range process UCL LCL Increasing mean, stable range process Chapter 12: Quantitatve Methods in Health Care Management Mean indicator Yasar A. Ozcan Range indicator 42

Figure 12. 7 Use of Mean and Range Charts UCL Process Mean LCL Stable mean, increasing range process UCL LCL Increasing mean, stable range process Chapter 12: Quantitatve Methods in Health Care Management Mean indicator Yasar A. Ozcan Range indicator 42

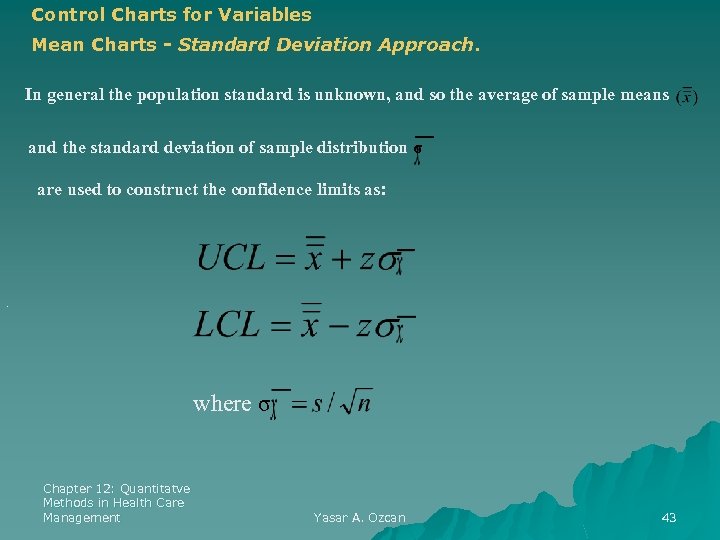

Control Charts for Variables Mean Charts - Standard Deviation Approach. In general the population standard is unknown, and so the average of sample means and the standard deviation of sample distribution σ are used to construct the confidence limits as: . where σ Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 43

Control Charts for Variables Mean Charts - Standard Deviation Approach. In general the population standard is unknown, and so the average of sample means and the standard deviation of sample distribution σ are used to construct the confidence limits as: . where σ Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 43

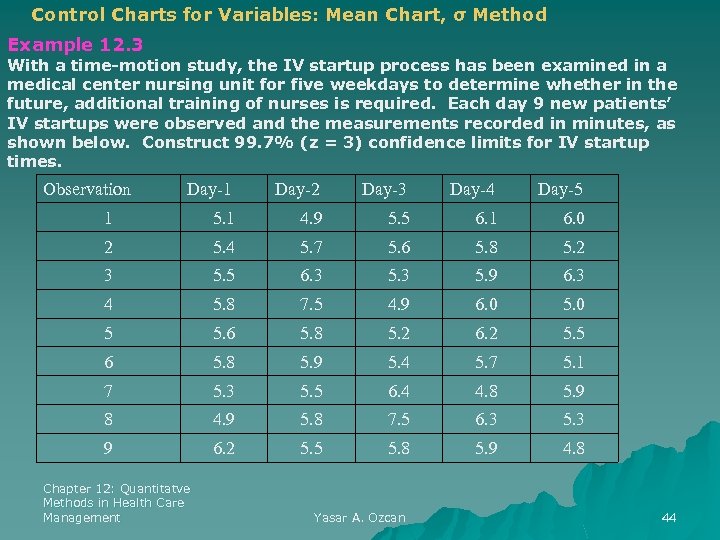

Control Charts for Variables: Mean Chart, σ Method Example 12. 3 With a time-motion study, the IV startup process has been examined in a medical center nursing unit for five weekdays to determine whether in the future, additional training of nurses is required. Each day 9 new patients’ IV startups were observed and the measurements recorded in minutes, as shown below. Construct 99. 7% (z = 3) confidence limits for IV startup times. Observation Day-1 Day-2 Day-3 Day-4 Day-5 1 5. 1 4. 9 5. 5 6. 1 6. 0 2 5. 4 5. 7 5. 6 5. 8 5. 2 3 5. 5 6. 3 5. 9 6. 3 4 5. 8 7. 5 4. 9 6. 0 5 5. 6 5. 8 5. 2 6. 2 5. 5 6 5. 8 5. 9 5. 4 5. 7 5. 1 7 5. 3 5. 5 6. 4 4. 8 5. 9 8 4. 9 5. 8 7. 5 6. 3 5. 3 9 6. 2 5. 5 5. 8 5. 9 4. 8 Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 44

Control Charts for Variables: Mean Chart, σ Method Example 12. 3 With a time-motion study, the IV startup process has been examined in a medical center nursing unit for five weekdays to determine whether in the future, additional training of nurses is required. Each day 9 new patients’ IV startups were observed and the measurements recorded in minutes, as shown below. Construct 99. 7% (z = 3) confidence limits for IV startup times. Observation Day-1 Day-2 Day-3 Day-4 Day-5 1 5. 1 4. 9 5. 5 6. 1 6. 0 2 5. 4 5. 7 5. 6 5. 8 5. 2 3 5. 5 6. 3 5. 9 6. 3 4 5. 8 7. 5 4. 9 6. 0 5 5. 6 5. 8 5. 2 6. 2 5. 5 6 5. 8 5. 9 5. 4 5. 7 5. 1 7 5. 3 5. 5 6. 4 4. 8 5. 9 8 4. 9 5. 8 7. 5 6. 3 5. 3 9 6. 2 5. 5 5. 8 5. 9 4. 8 Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 44

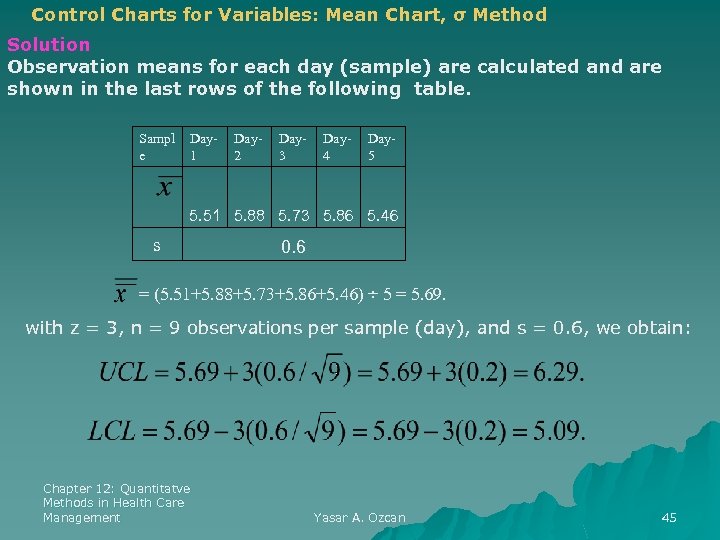

Control Charts for Variables: Mean Chart, σ Method Solution Observation means for each day (sample) are calculated and are shown in the last rows of the following table. Sampl e Day 1 Day 2 Day 3 Day 4 Day 5 5. 51 5. 88 5. 73 5. 86 5. 46 s 0. 6 = (5. 51+5. 88+5. 73+5. 86+5. 46) ÷ 5 = 5. 69. with z = 3, n = 9 observations per sample (day), and s = 0. 6, we obtain: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 45

Control Charts for Variables: Mean Chart, σ Method Solution Observation means for each day (sample) are calculated and are shown in the last rows of the following table. Sampl e Day 1 Day 2 Day 3 Day 4 Day 5 5. 51 5. 88 5. 73 5. 86 5. 46 s 0. 6 = (5. 51+5. 88+5. 73+5. 86+5. 46) ÷ 5 = 5. 69. with z = 3, n = 9 observations per sample (day), and s = 0. 6, we obtain: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 45

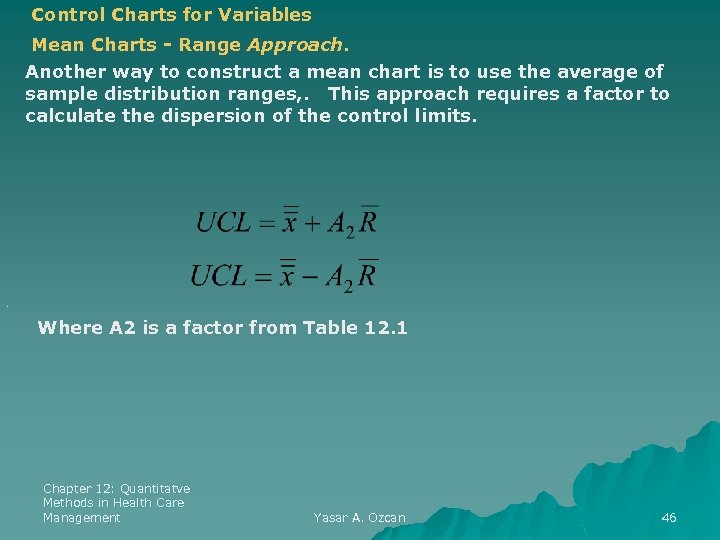

Control Charts for Variables Mean Charts - Range Approach. Another way to construct a mean chart is to use the average of sample distribution ranges, . This approach requires a factor to calculate the dispersion of the control limits. . Where A 2 is a factor from Table 12. 1 Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 46

Control Charts for Variables Mean Charts - Range Approach. Another way to construct a mean chart is to use the average of sample distribution ranges, . This approach requires a factor to calculate the dispersion of the control limits. . Where A 2 is a factor from Table 12. 1 Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 46

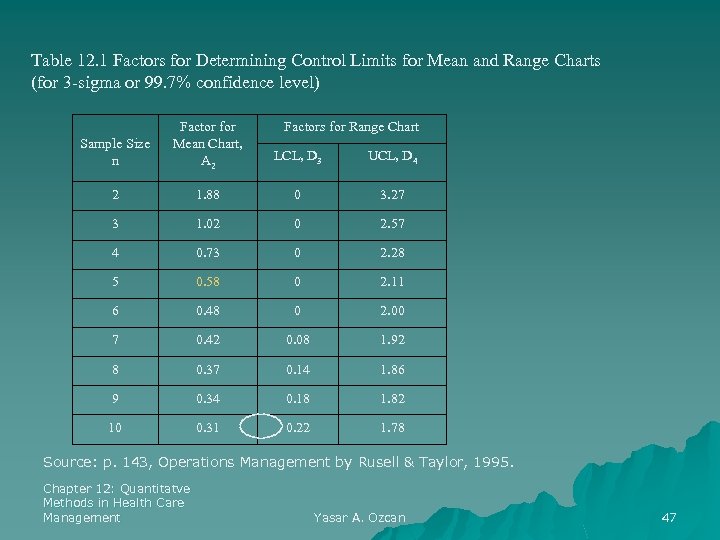

Table 12. 1 Factors for Determining Control Limits for Mean and Range Charts (for 3 -sigma or 99. 7% confidence level) Sample Size n Factor for Mean Chart, A 2 Factors for Range Chart LCL, D 3 UCL, D 4 2 1. 88 0 3. 27 3 1. 02 0 2. 57 4 0. 73 0 2. 28 5 0. 58 0 2. 11 6 0. 48 0 2. 00 7 0. 42 0. 08 1. 92 8 0. 37 0. 14 1. 86 9 0. 34 0. 18 1. 82 10 0. 31 0. 22 1. 78 Source: p. 143, Operations Management by Rusell & Taylor, 1995. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 47

Table 12. 1 Factors for Determining Control Limits for Mean and Range Charts (for 3 -sigma or 99. 7% confidence level) Sample Size n Factor for Mean Chart, A 2 Factors for Range Chart LCL, D 3 UCL, D 4 2 1. 88 0 3. 27 3 1. 02 0 2. 57 4 0. 73 0 2. 28 5 0. 58 0 2. 11 6 0. 48 0 2. 00 7 0. 42 0. 08 1. 92 8 0. 37 0. 14 1. 86 9 0. 34 0. 18 1. 82 10 0. 31 0. 22 1. 78 Source: p. 143, Operations Management by Rusell & Taylor, 1995. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 47

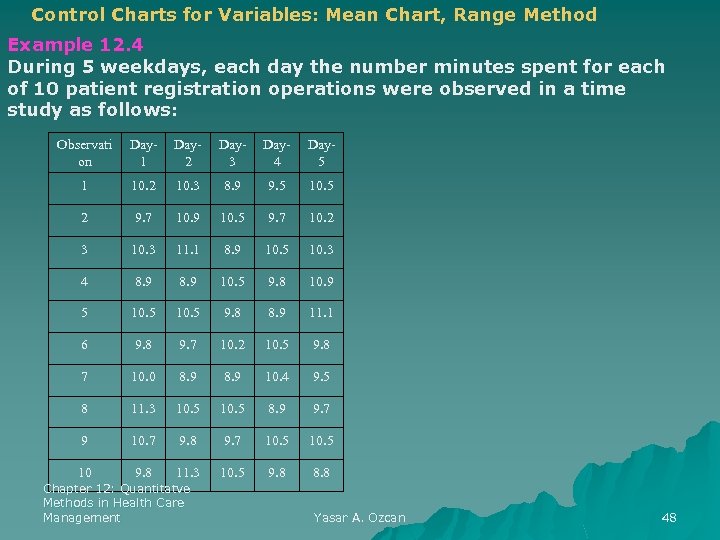

Control Charts for Variables: Mean Chart, Range Method Example 12. 4 During 5 weekdays, each day the number minutes spent for each of 10 patient registration operations were observed in a time study as follows: Observati on Day 1 Day 2 Day 3 Day 4 Day 5 1 10. 2 10. 3 8. 9 9. 5 10. 5 2 9. 7 10. 9 10. 5 9. 7 10. 2 3 10. 3 11. 1 8. 9 10. 5 10. 3 4 8. 9 10. 5 9. 8 10. 9 5 10. 5 9. 8 8. 9 11. 1 6 9. 8 9. 7 10. 2 10. 5 9. 8 7 10. 0 8. 9 10. 4 9. 5 8 11. 3 10. 5 8. 9 9. 7 9 10. 7 9. 8 9. 7 10. 5 10 9. 8 11. 3 10. 5 9. 8 8. 8 Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 48

Control Charts for Variables: Mean Chart, Range Method Example 12. 4 During 5 weekdays, each day the number minutes spent for each of 10 patient registration operations were observed in a time study as follows: Observati on Day 1 Day 2 Day 3 Day 4 Day 5 1 10. 2 10. 3 8. 9 9. 5 10. 5 2 9. 7 10. 9 10. 5 9. 7 10. 2 3 10. 3 11. 1 8. 9 10. 5 10. 3 4 8. 9 10. 5 9. 8 10. 9 5 10. 5 9. 8 8. 9 11. 1 6 9. 8 9. 7 10. 2 10. 5 9. 8 7 10. 0 8. 9 10. 4 9. 5 8 11. 3 10. 5 8. 9 9. 7 9 10. 7 9. 8 9. 7 10. 5 10 9. 8 11. 3 10. 5 9. 8 8. 8 Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 48

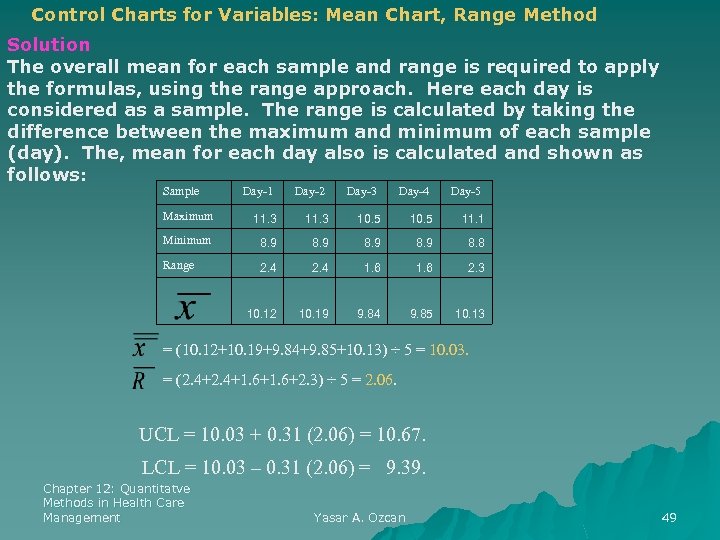

Control Charts for Variables: Mean Chart, Range Method Solution The overall mean for each sample and range is required to apply the formulas, using the range approach. Here each day is considered as a sample. The range is calculated by taking the difference between the maximum and minimum of each sample (day). The, mean for each day also is calculated and shown as follows: Sample Day-1 Day-2 Day-3 Day-4 Day-5 Maximum 11. 3 10. 5 11. 1 Minimum 8. 9 8. 8 Range 2. 4 1. 6 2. 3 10. 12 10. 19 9. 84 9. 85 10. 13 = (10. 12+10. 19+9. 84+9. 85+10. 13) ÷ 5 = 10. 03. = (2. 4+1. 6+2. 3) ÷ 5 = 2. 06. UCL = 10. 03 + 0. 31 (2. 06) = 10. 67. LCL = 10. 03 – 0. 31 (2. 06) = 9. 39. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 49

Control Charts for Variables: Mean Chart, Range Method Solution The overall mean for each sample and range is required to apply the formulas, using the range approach. Here each day is considered as a sample. The range is calculated by taking the difference between the maximum and minimum of each sample (day). The, mean for each day also is calculated and shown as follows: Sample Day-1 Day-2 Day-3 Day-4 Day-5 Maximum 11. 3 10. 5 11. 1 Minimum 8. 9 8. 8 Range 2. 4 1. 6 2. 3 10. 12 10. 19 9. 84 9. 85 10. 13 = (10. 12+10. 19+9. 84+9. 85+10. 13) ÷ 5 = 10. 03. = (2. 4+1. 6+2. 3) ÷ 5 = 2. 06. UCL = 10. 03 + 0. 31 (2. 06) = 10. 67. LCL = 10. 03 – 0. 31 (2. 06) = 9. 39. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 49

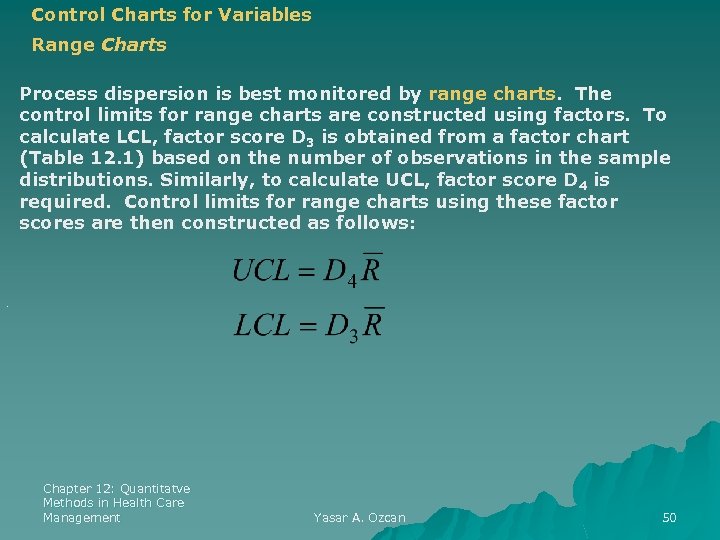

Control Charts for Variables Range Charts Process dispersion is best monitored by range charts. The control limits for range charts are constructed using factors. To calculate LCL, factor score D 3 is obtained from a factor chart (Table 12. 1) based on the number of observations in the sample distributions. Similarly, to calculate UCL, factor score D 4 is required. Control limits for range charts using these factor scores are then constructed as follows: . Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 50

Control Charts for Variables Range Charts Process dispersion is best monitored by range charts. The control limits for range charts are constructed using factors. To calculate LCL, factor score D 3 is obtained from a factor chart (Table 12. 1) based on the number of observations in the sample distributions. Similarly, to calculate UCL, factor score D 4 is required. Control limits for range charts using these factor scores are then constructed as follows: . Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 50

Control Charts for Variables: Range Chart Example 12. 5 Use the information provided in example 12. 4 to construct a range chart. Solution For n = 10, D 3 and D 4 from Table 12. 1 are 0. 22 and 1. 78, respectively. Using formulas we obtain: UCL = 1. 78 (2. 06) = 3. 67. LCL =. 22 (2. 06) = 0. 45. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 51

Control Charts for Variables: Range Chart Example 12. 5 Use the information provided in example 12. 4 to construct a range chart. Solution For n = 10, D 3 and D 4 from Table 12. 1 are 0. 22 and 1. 78, respectively. Using formulas we obtain: UCL = 1. 78 (2. 06) = 3. 67. LCL =. 22 (2. 06) = 0. 45. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 51

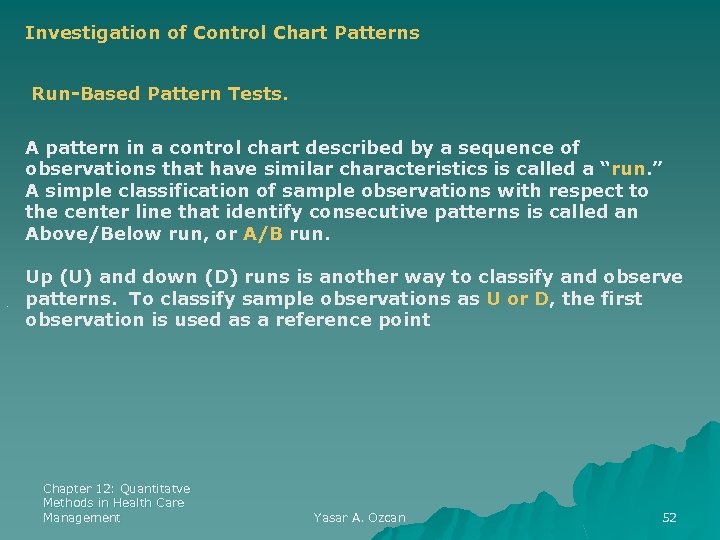

Investigation of Control Chart Patterns Run-Based Pattern Tests. A pattern in a control chart described by a sequence of observations that have similar characteristics is called a “run. ” A simple classification of sample observations with respect to the center line that identify consecutive patterns is called an Above/Below run, or A/B run. . Up (U) and down (D) runs is another way to classify and observe patterns. To classify sample observations as U or D, the first observation is used as a reference point Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 52

Investigation of Control Chart Patterns Run-Based Pattern Tests. A pattern in a control chart described by a sequence of observations that have similar characteristics is called a “run. ” A simple classification of sample observations with respect to the center line that identify consecutive patterns is called an Above/Below run, or A/B run. . Up (U) and down (D) runs is another way to classify and observe patterns. To classify sample observations as U or D, the first observation is used as a reference point Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 52

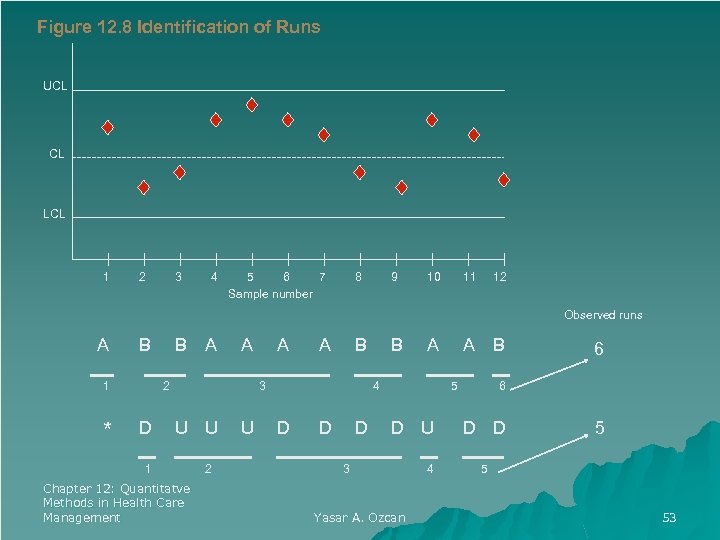

Figure 12. 8 Identification of Runs UCL CL LCL 1 2 3 4 5 6 7 Sample number 8 9 10 11 12 Observed runs A B 1 * B A A 2 D A A B 3 U U 1 Chapter 12: Quantitatve Methods in Health Care Management 2 U B A 4 D D D A B 5 D U 3 Yasar A. Ozcan 4 6 6 D D 5 5 53

Figure 12. 8 Identification of Runs UCL CL LCL 1 2 3 4 5 6 7 Sample number 8 9 10 11 12 Observed runs A B 1 * B A A 2 D A A B 3 U U 1 Chapter 12: Quantitatve Methods in Health Care Management 2 U B A 4 D D D A B 5 D U 3 Yasar A. Ozcan 4 6 6 D D 5 5 53

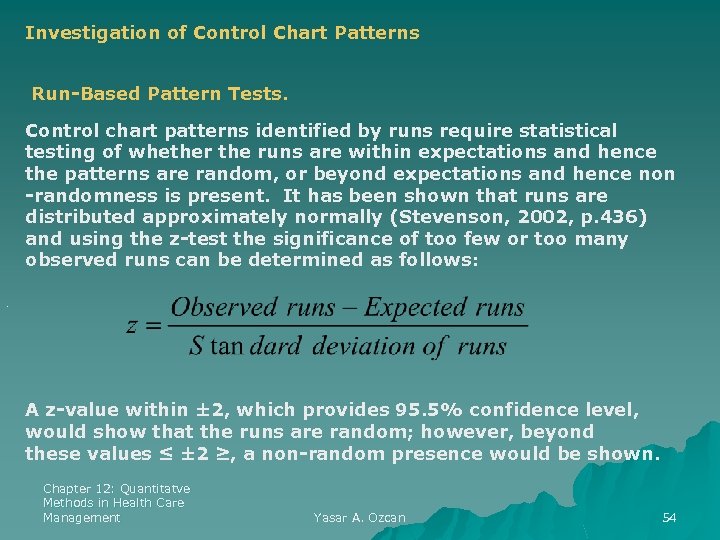

Investigation of Control Chart Patterns Run-Based Pattern Tests. Control chart patterns identified by runs require statistical testing of whether the runs are within expectations and hence the patterns are random, or beyond expectations and hence non -randomness is present. It has been shown that runs are distributed approximately normally (Stevenson, 2002, p. 436) and using the z-test the significance of too few or too many observed runs can be determined as follows: . A z-value within ± 2, which provides 95. 5% confidence level, would show that the runs are random; however, beyond these values ≤ ± 2 ≥, a non-random presence would be shown. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 54

Investigation of Control Chart Patterns Run-Based Pattern Tests. Control chart patterns identified by runs require statistical testing of whether the runs are within expectations and hence the patterns are random, or beyond expectations and hence non -randomness is present. It has been shown that runs are distributed approximately normally (Stevenson, 2002, p. 436) and using the z-test the significance of too few or too many observed runs can be determined as follows: . A z-value within ± 2, which provides 95. 5% confidence level, would show that the runs are random; however, beyond these values ≤ ± 2 ≥, a non-random presence would be shown. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 54

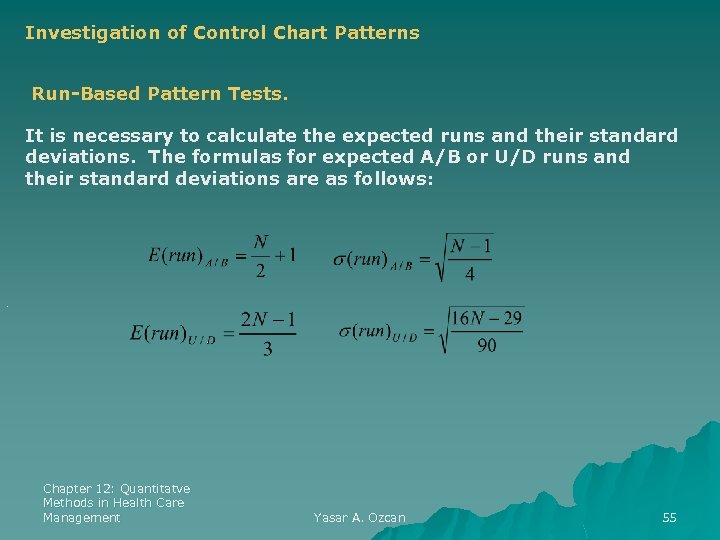

Investigation of Control Chart Patterns Run-Based Pattern Tests. It is necessary to calculate the expected runs and their standard deviations. The formulas for expected A/B or U/D runs and their standard deviations are as follows: . Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 55

Investigation of Control Chart Patterns Run-Based Pattern Tests. It is necessary to calculate the expected runs and their standard deviations. The formulas for expected A/B or U/D runs and their standard deviations are as follows: . Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 55

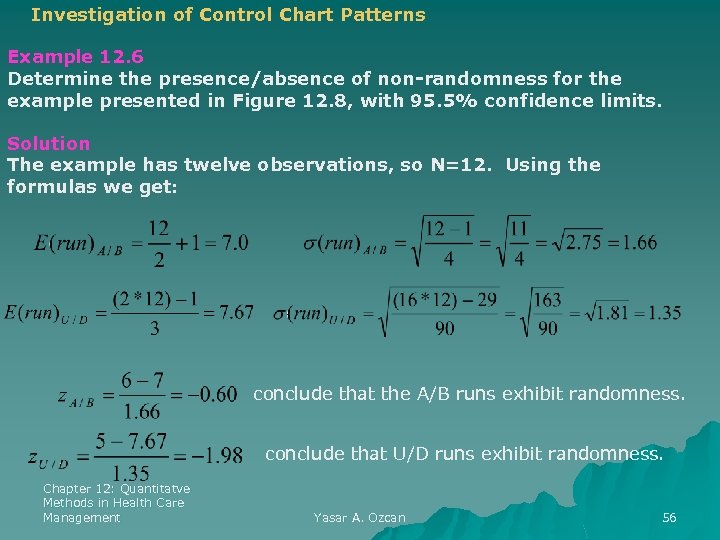

Investigation of Control Chart Patterns Example 12. 6 Determine the presence/absence of non-randomness for the example presented in Figure 12. 8, with 95. 5% confidence limits. Solution The example has twelve observations, so N=12. Using the formulas we get: conclude that the A/B runs exhibit randomness. conclude that U/D runs exhibit randomness. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 56

Investigation of Control Chart Patterns Example 12. 6 Determine the presence/absence of non-randomness for the example presented in Figure 12. 8, with 95. 5% confidence limits. Solution The example has twelve observations, so N=12. Using the formulas we get: conclude that the A/B runs exhibit randomness. conclude that U/D runs exhibit randomness. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 56

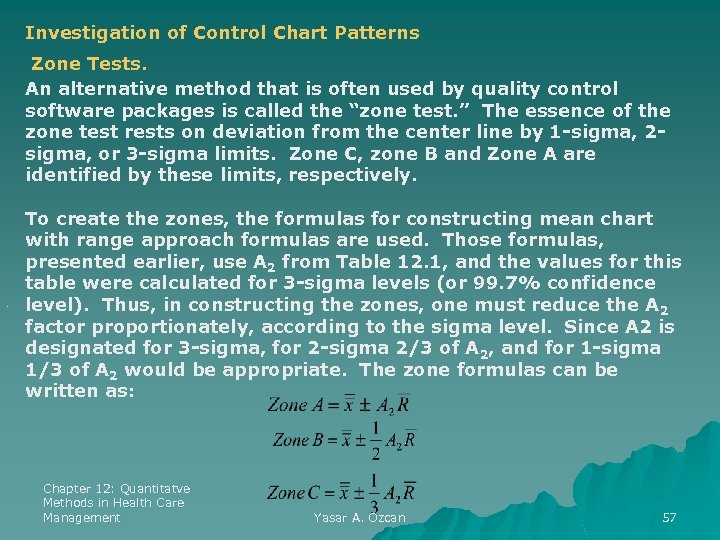

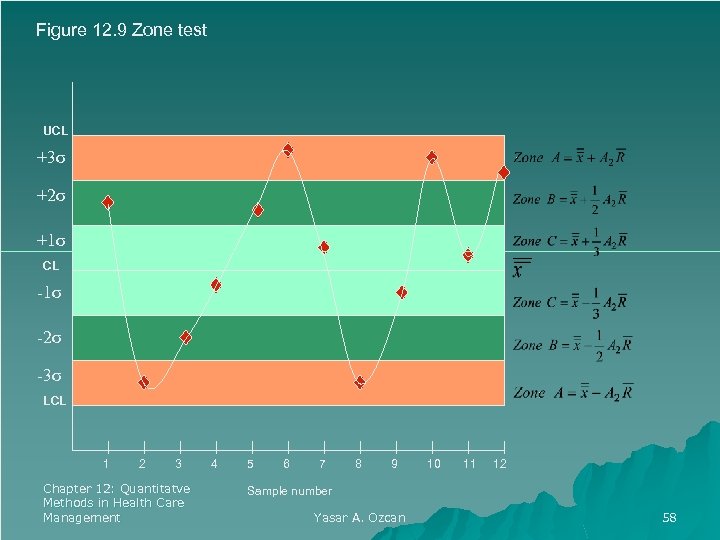

Investigation of Control Chart Patterns Zone Tests. An alternative method that is often used by quality control software packages is called the “zone test. ” The essence of the zone test rests on deviation from the center line by 1 -sigma, 2 sigma, or 3 -sigma limits. Zone C, zone B and Zone A are identified by these limits, respectively. . To create the zones, the formulas for constructing mean chart with range approach formulas are used. Those formulas, presented earlier, use A 2 from Table 12. 1, and the values for this table were calculated for 3 -sigma levels (or 99. 7% confidence level). Thus, in constructing the zones, one must reduce the A 2 factor proportionately, according to the sigma level. Since A 2 is designated for 3 -sigma, for 2 -sigma 2/3 of A 2, and for 1 -sigma 1/3 of A 2 would be appropriate. The zone formulas can be written as: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 57

Investigation of Control Chart Patterns Zone Tests. An alternative method that is often used by quality control software packages is called the “zone test. ” The essence of the zone test rests on deviation from the center line by 1 -sigma, 2 sigma, or 3 -sigma limits. Zone C, zone B and Zone A are identified by these limits, respectively. . To create the zones, the formulas for constructing mean chart with range approach formulas are used. Those formulas, presented earlier, use A 2 from Table 12. 1, and the values for this table were calculated for 3 -sigma levels (or 99. 7% confidence level). Thus, in constructing the zones, one must reduce the A 2 factor proportionately, according to the sigma level. Since A 2 is designated for 3 -sigma, for 2 -sigma 2/3 of A 2, and for 1 -sigma 1/3 of A 2 would be appropriate. The zone formulas can be written as: Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 57

Figure 12. 9 Zone test UCL +3σ +2σ +1σ CL -1σ -2σ -3σ LCL 1 2 3 Chapter 12: Quantitatve Methods in Health Care Management 4 5 6 7 8 9 10 11 12 Sample number Yasar A. Ozcan 58

Figure 12. 9 Zone test UCL +3σ +2σ +1σ CL -1σ -2σ -3σ LCL 1 2 3 Chapter 12: Quantitatve Methods in Health Care Management 4 5 6 7 8 9 10 11 12 Sample number Yasar A. Ozcan 58

Process Improvement Methods for Generating New Ideas: . The 5 W 2 H Approach Brainstorming Nominal Group Technique Interviewing Focus Groups Quality Circles “Kaizen Teams” Benchmarking. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 59

Process Improvement Methods for Generating New Ideas: . The 5 W 2 H Approach Brainstorming Nominal Group Technique Interviewing Focus Groups Quality Circles “Kaizen Teams” Benchmarking. Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 59

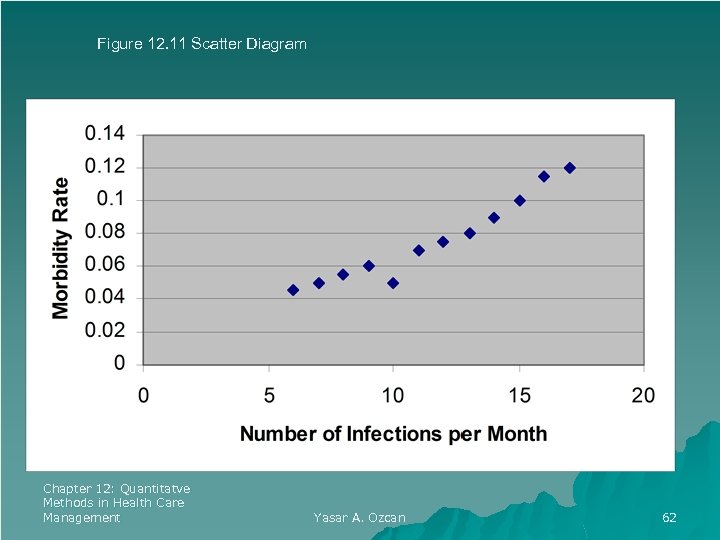

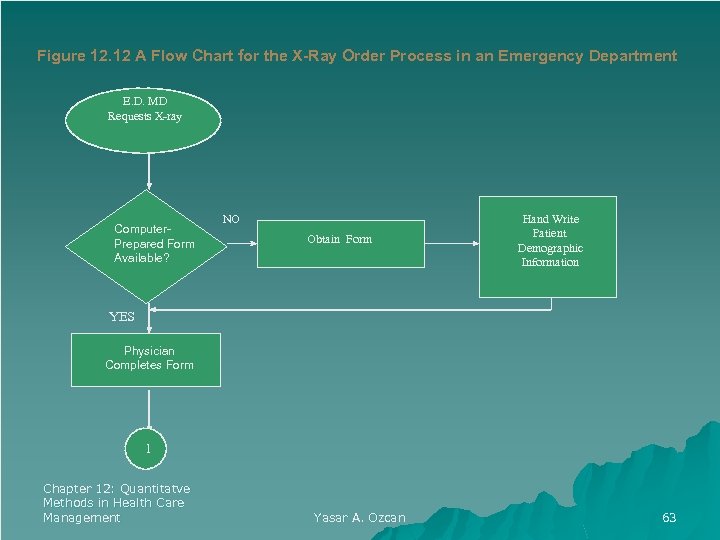

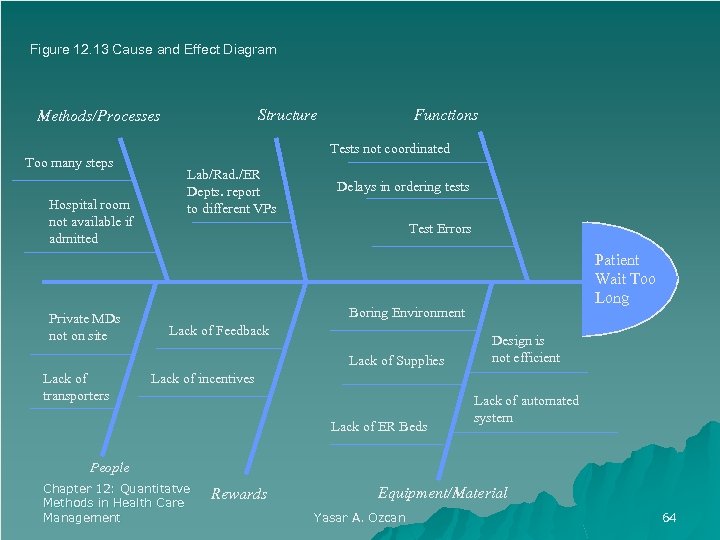

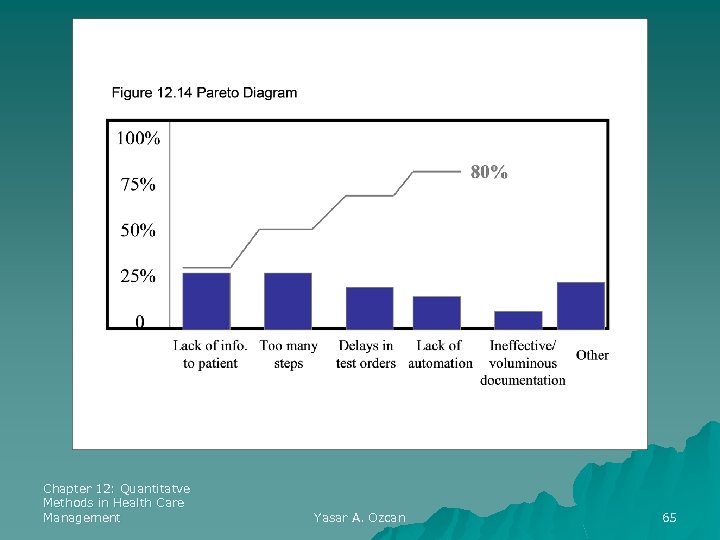

Process Improvement Tools for Investigating the Presence of Quality Problems and Their Causes . Check Sheet Histogram Scatter Diagram Flow Chart Cause-and-Effect Diagram Pareto Chart Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 60

Process Improvement Tools for Investigating the Presence of Quality Problems and Their Causes . Check Sheet Histogram Scatter Diagram Flow Chart Cause-and-Effect Diagram Pareto Chart Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 60

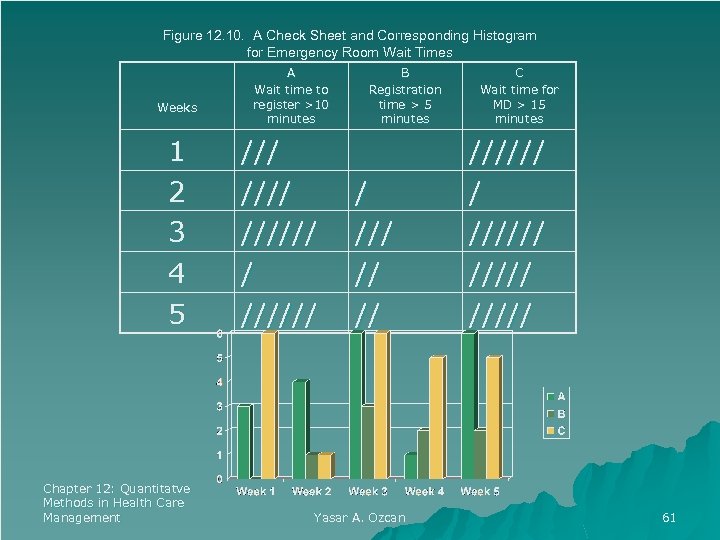

Figure 12. 10. A Check Sheet and Corresponding Histogram for Emergency Room Wait Times Weeks 1 2 3 4 5 Chapter 12: Quantitatve Methods in Health Care Management A Wait time to register >10 minutes ////// B Registration time > 5 minutes / // // Yasar A. Ozcan C Wait time for MD > 15 minutes ////// ///// 61

Figure 12. 10. A Check Sheet and Corresponding Histogram for Emergency Room Wait Times Weeks 1 2 3 4 5 Chapter 12: Quantitatve Methods in Health Care Management A Wait time to register >10 minutes ////// B Registration time > 5 minutes / // // Yasar A. Ozcan C Wait time for MD > 15 minutes ////// ///// 61

Figure 12. 11 Scatter Diagram Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 62

Figure 12. 11 Scatter Diagram Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 62

Figure 12. 12 A Flow Chart for the X-Ray Order Process in an Emergency Department E. D. MD Requests X-ray Computer. Prepared Form Available? NO Obtain Form Hand Write Patient Demographic Information YES Physician Completes Form 1 Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 63

Figure 12. 12 A Flow Chart for the X-Ray Order Process in an Emergency Department E. D. MD Requests X-ray Computer. Prepared Form Available? NO Obtain Form Hand Write Patient Demographic Information YES Physician Completes Form 1 Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 63

Figure 12. 13 Cause and Effect Diagram Structure Methods/Processes Too many steps Hospital room not available if admitted Private MDs not on site Functions Tests not coordinated Lab/Rad. /ER Depts. report to different VPs Delays in ordering tests Test Errors Boring Environment Lack of Feedback Lack of Supplies Lack of transporters Patient Wait Too Long Design is not efficient Lack of incentives Lack of ER Beds Lack of automated system People Chapter 12: Quantitatve Methods in Health Care Management Rewards Equipment/Material Yasar A. Ozcan 64

Figure 12. 13 Cause and Effect Diagram Structure Methods/Processes Too many steps Hospital room not available if admitted Private MDs not on site Functions Tests not coordinated Lab/Rad. /ER Depts. report to different VPs Delays in ordering tests Test Errors Boring Environment Lack of Feedback Lack of Supplies Lack of transporters Patient Wait Too Long Design is not efficient Lack of incentives Lack of ER Beds Lack of automated system People Chapter 12: Quantitatve Methods in Health Care Management Rewards Equipment/Material Yasar A. Ozcan 64

Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 65

Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 65

The End Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 66

The End Chapter 12: Quantitatve Methods in Health Care Management Yasar A. Ozcan 66