fd0ab941efbf53089296734ef1816301.ppt

- Количество слайдов: 57

Chapter 11 Supply Chain Management Slides prepared by Laurel Donaldson Douglas College Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

Learning Objectives LO 1 Explain what a supply chain is, the need to manage a supply chain including outsourcing, and identify strategic and tactical/operational supply chain activities. LO 2 Describe what logistics is, select a transportation mode, and discuss some fast delivery methods, third party logistics, reverse logistics, and global supply chains. LO 3 Discuss three technologies used in supply chain management, LO 4 Outline the key steps in creating an effective supply chain, including Collaborative Planning Forecasting Replenishment (CPFR) and performance metrics. LO 5 Explain the purchasing function in business organizations. LO 6 Explain supplier management and partnership. Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 2

Chapter Outline ®Introduction ®The Need for Supply Chain Management ®Managing the Supply Chain ®Logistics ®Some Supply Chain Technologies ®Creating an Effective Supply Chain ®Purchasing ®Supplier Management Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 3

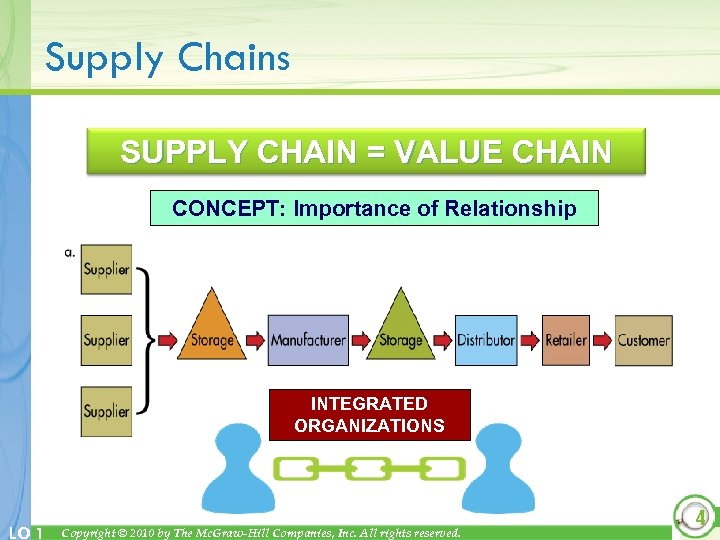

Supply Chains SUPPLY CHAIN = VALUE CHAIN CONCEPT: Importance of Relationship INTEGRATED ORGANIZATIONS LO 1 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 4

Supply Chain Management ®collaboration and coordination of all components of the supply chain so that market demand is met as efficiently and effectively as possible. Information movement (beginning of chain) LO 1 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. Physical movement of material (end of chain) 5

Functions and Activities I g t i n e f t r Q y a e Pcu a r sc I hn av sn i n no go m u S tc lih ioe n dy o d u c g i S o nr tv i i oc D l i t t e Pt r u i s n r b u r a LO 1 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 6

Need for Supply Chain Management 1. Improve operations 2. Increasing levels of outsourcing 3. Increasing globalization 4. Increasing e-commerce 5. Manage inventories (bullwhip effect) LO 1 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 7

Outsourcing ®Buying goods or services instead of producing or providing them in-house. ®Benefits: ®lower cost (due to economies of scale) ®gain expertise and knowledge, or patent ®gain flexibility (for temporary demand) ®increase capacity ®Risks: ®reduction in control and expertise. LO 1 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 8

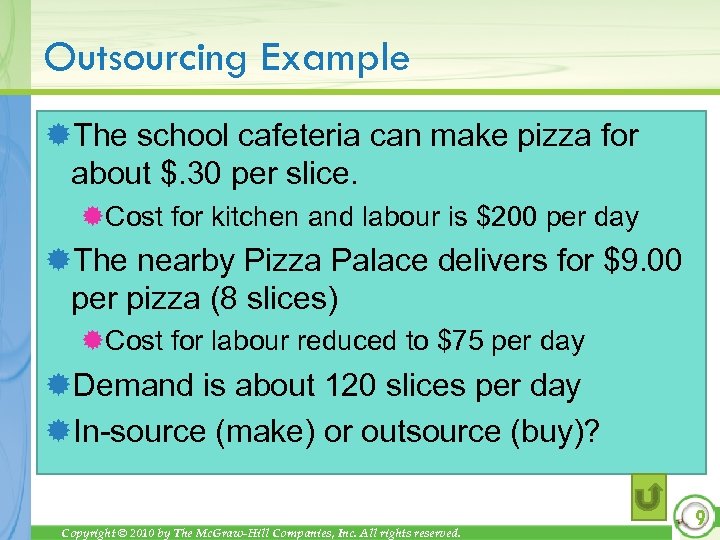

Outsourcing Example ®The school cafeteria can make pizza for about $. 30 per slice. ®Cost for kitchen and labour is $200 per day ®The nearby Pizza Palace delivers for $9. 00 per pizza (8 slices) ®Cost for labour reduced to $75 per day ®Demand is about 120 slices per day ®In-source (make) or outsource (buy)? Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 9

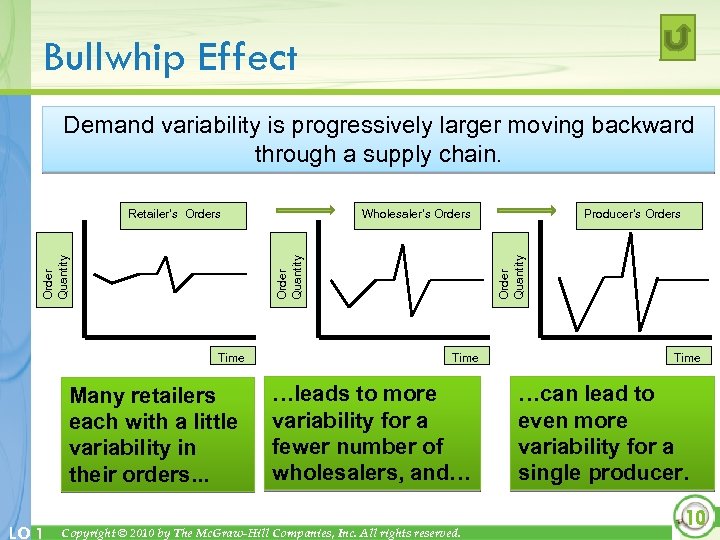

Bullwhip Effect Demand variability is progressively larger moving backward through a supply chain. Time Many retailers each with a little variability in their orders. . . LO 1 Producer’s Order Quantity Wholesaler’s Order Quantity Retailer’s Orders Time …leads to more variability for a fewer number of wholesalers, and… Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. Time …can lead to even more variability for a single producer. 10

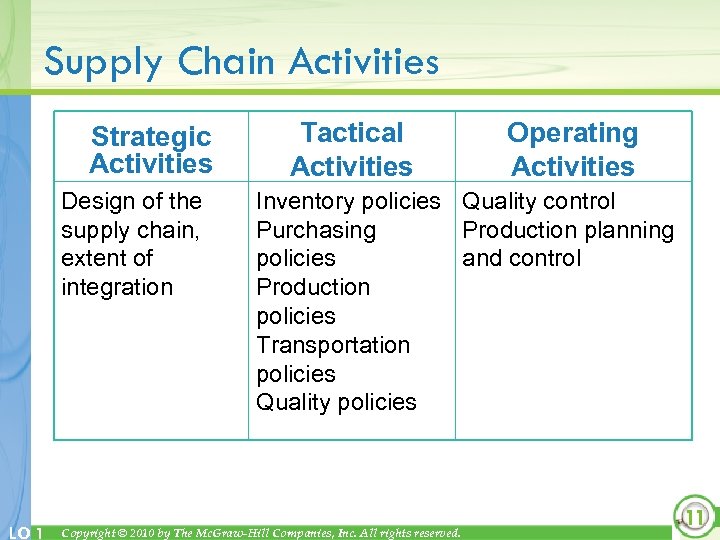

Supply Chain Activities Strategic Activities Design of the supply chain, extent of integration LO 1 Tactical Activities Operating Activities Inventory policies Quality control Purchasing Production planning policies and control Production policies Transportation policies Quality policies Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 11

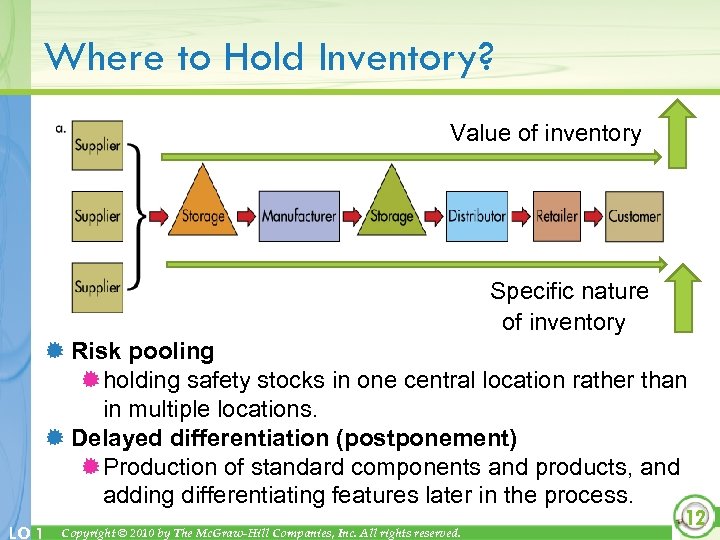

Where to Hold Inventory? Value of inventory Specific nature of inventory ® Risk pooling ®holding safety stocks in one central location rather than in multiple locations. ® Delayed differentiation (postponement) ®Production of standard components and products, and adding differentiating features later in the process. 12 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. LO 1

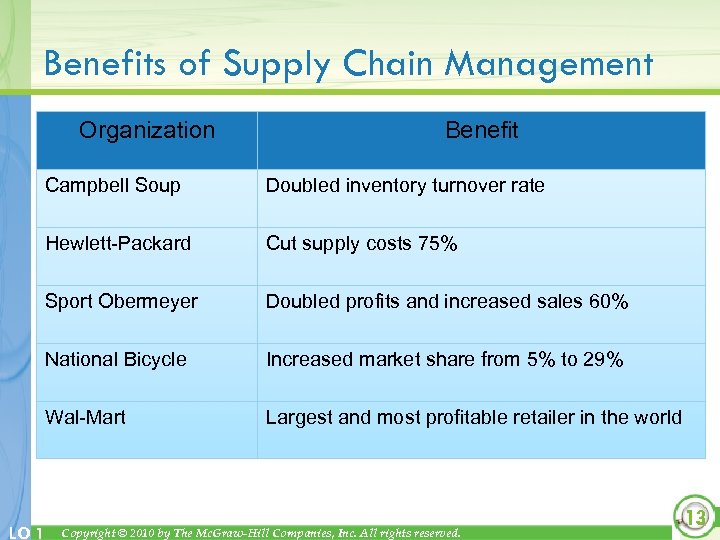

Benefits of Supply Chain Management Organization Benefit Campbell Soup Hewlett-Packard Cut supply costs 75% Sport Obermeyer Doubled profits and increased sales 60% National Bicycle Increased market share from 5% to 29% Wal-Mart LO 1 Doubled inventory turnover rate Largest and most profitable retailer in the world Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 13

Logistics ®Refers to the movement of materials and information ®Movement within the facility ®Incoming and outgoing shipments ®Traffic management ðoverseeing the delivery of incoming and outgoing goods. ®Distribution management ðpack, store, handle at receiving docks, warehouses, retail outlets LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 14

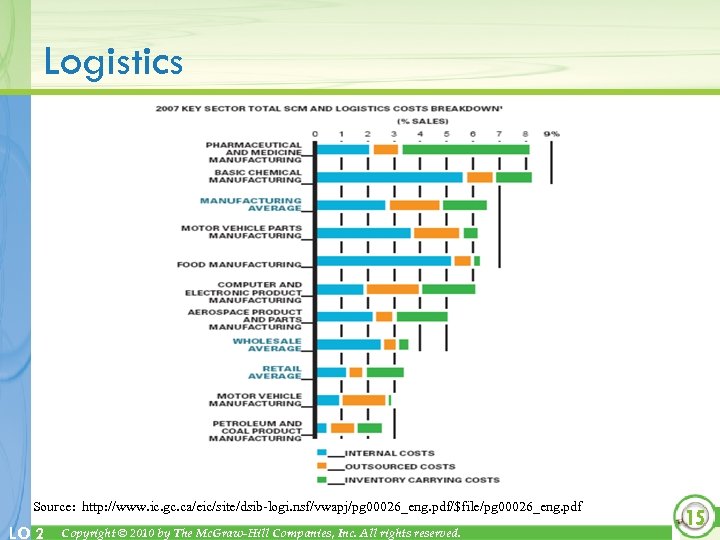

Logistics Source: http: //www. ic. gc. ca/eic/site/dsib-logi. nsf/vwapj/pg 00026_eng. pdf/$file/pg 00026_eng. pdf LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 15

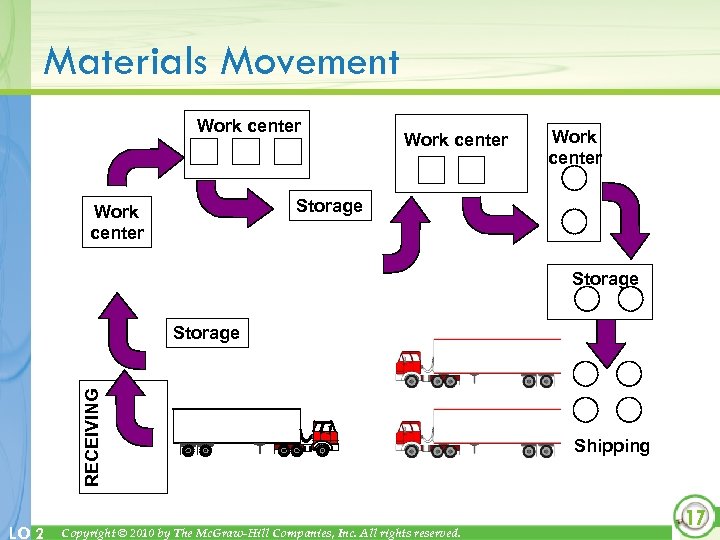

Logistics • Movement within the facility • Incoming and outgoing deliveries • Modes of transportation • Warehousing • Fast Delivery Methods • Distribution Requirements Planning • Third-Party Logistics • Reverse Logistics 0 • Global Supply Chains • EDI, RFID and E-commerce LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 214800 232087768 16

Materials Movement Work center Storage RECEIVING Storage LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. Shipping 17

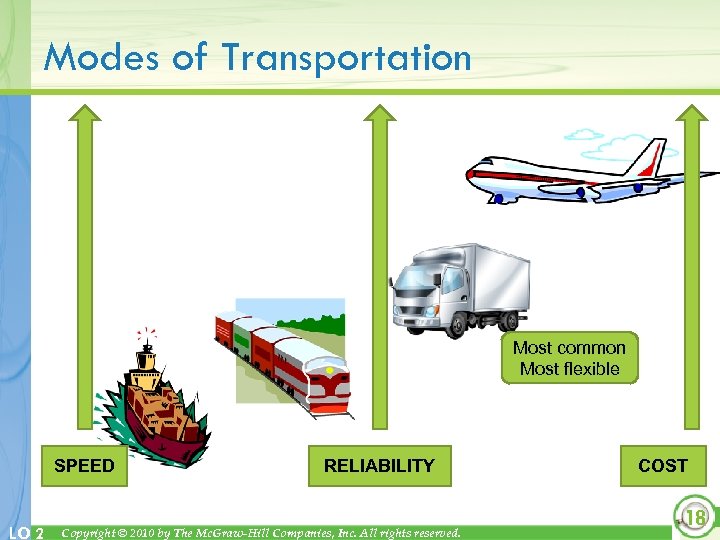

Modes of Transportation Most common Most flexible SPEED LO 2 RELIABILITY Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. COST 18

Selecting a Transportation Mode ®Speed vs. Cost? ®Balance transportation cost with inventory holding costs ®Consider differences in safety stock required Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 19

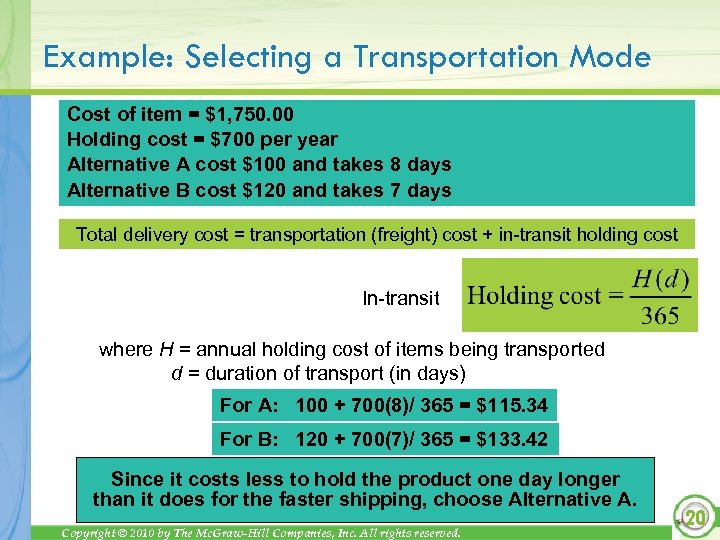

Example: Selecting a Transportation Mode Cost of item = $1, 750. 00 Holding cost = $700 per year Alternative A cost $100 and takes 8 days Alternative B cost $120 and takes 7 days Total delivery cost = transportation (freight) cost + in-transit holding cost In-transit where H = annual holding cost of items being transported d = duration of transport (in days) For A: 100 + 700(8)/ 365 = $115. 34 For B: 120 + 700(7)/ 365 = $133. 42 Since it costs less to hold the product one day longer than it does for the faster shipping, choose Alternative A. Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 20

Warehousing consolidating shipments deconsolidating shipments cross docking ®Cross-docking ®Goods arriving at a warehouse from a supplier are unloaded from the supplier’s truck and loaded onto outbound trucks ®Avoids warehouse storage Shipping and receiving docks LO 1 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 21

Fast Delivery Methods ® quick response Just-in-time inventory replenishment ® used in retailing ® orders based on actual sales, not periodic orders ® Efficient consumer response (ECR) expanded version of quick response initiative which includes some collaboration ® used in the grocery industry ® Vendor-Managed Inventory (VMI) agreement for supplier to access and maintain customer’s inventory ® used in convenience stores, etc. LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 22

Distribution Requirements Planning (DRP) ® system for synchronizing replenishment schedules across the supply chain ®starts with forecast demand at the end of the distribution network (retail stores) ®works backwards through network to obtain timephased replenishment schedules for moving goods from factory through each level of the network DRP is a push system (based on forecasts) whereas quick response is a pull system (based on actual demand). LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 23

Reverse Logistics ® Reverse logistics – the backward flow of goods returned to the supply chain ®Processing returned goods ®Sorting, examining/testing, restocking, repairing ®Reconditioning, recycling, disposing ®Gatekeeping – screening goods to prevent incorrect acceptance of goods ®Avoidance – finding ways to minimize the number of items that are returned LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 24

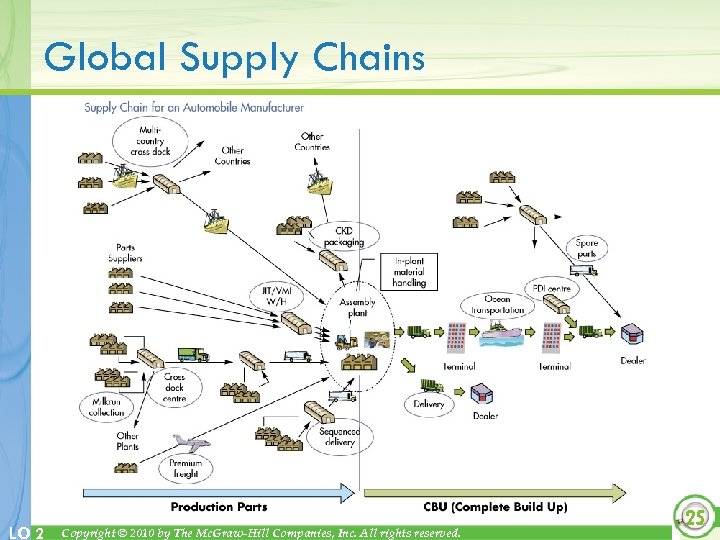

Global Supply Chains LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 25

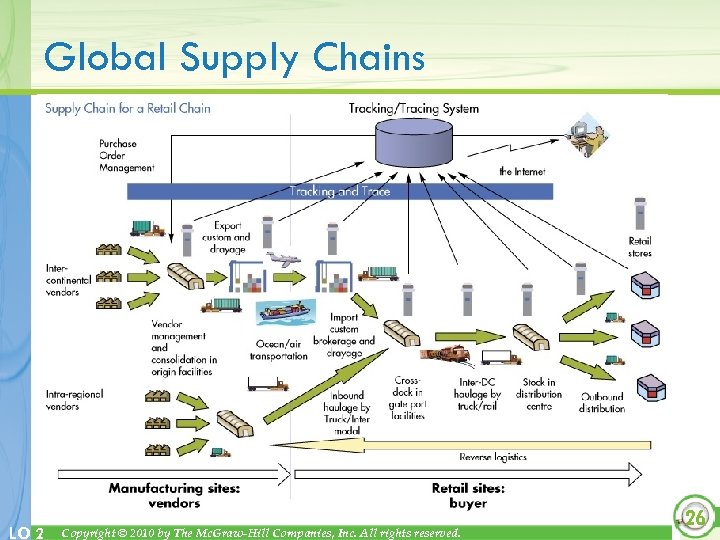

Global Supply Chains LO 2 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 26

Electronic Data Interchange ®Direct, computer-to-computer transmission of transactions between organizations ® Purchase orders, shipping notices, payments ® Can extend to sales and inventory data ® Many benefits ®Reduced paperwork, clerical labour ®Reduced lead time and inventory ®Improved control of operations ®Increased accuracy Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 27

RFID Technology ®Used to track goods in supply chain ®RFID tag attached to object ®uses radio frequency to transmit product information to receiver ®eliminates need for manual counting and bar code scanning LO 3 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 28

E-Commerce ®the use of computers and Internet to conduct buying and selling ®Business to business (B 2 B) ®Business to consumer (B 2 C) ®E-marketplaces LO 3 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 29

Advantages E-Business ®Companies can: ®Have a global presence ®Improve competitiveness and quality ®Analyze customer interests ®Collect detailed information ®Shorten supply chain response times and costs ®disintermediation ®Realize substantial cost savings ®Create virtual companies ®Level the playing field for small companies LO 3 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 30

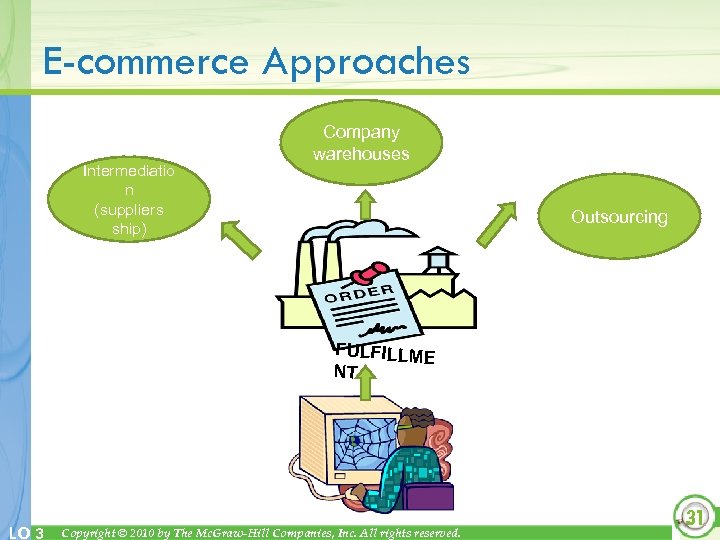

E-commerce Approaches Intermediatio n (suppliers ship) Company warehouses Outsourcing FULFILLME NT LO 3 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 31

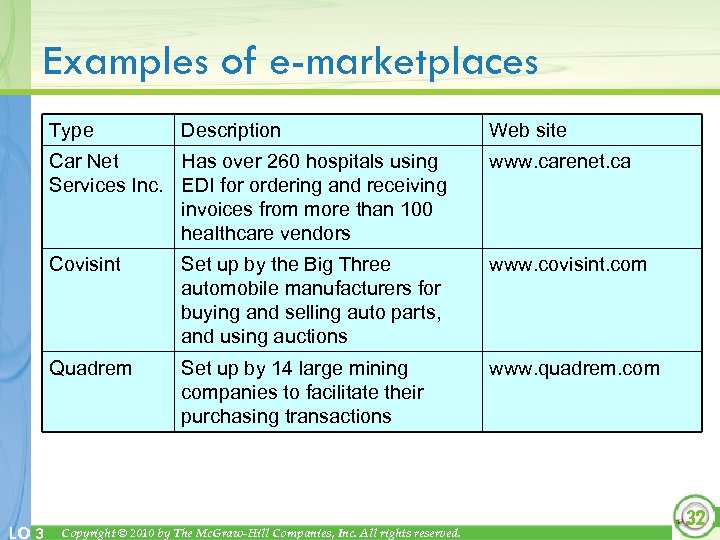

Examples of e-marketplaces Type Description Web site Car Net Has over 260 hospitals using Services Inc. EDI for ordering and receiving invoices from more than 100 healthcare vendors Covisint Set up by the Big Three automobile manufacturers for buying and selling auto parts, and using auctions www. covisint. com Quadrem LO 3 www. carenet. ca Set up by 14 large mining companies to facilitate their purchasing transactions www. quadrem. com Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 32

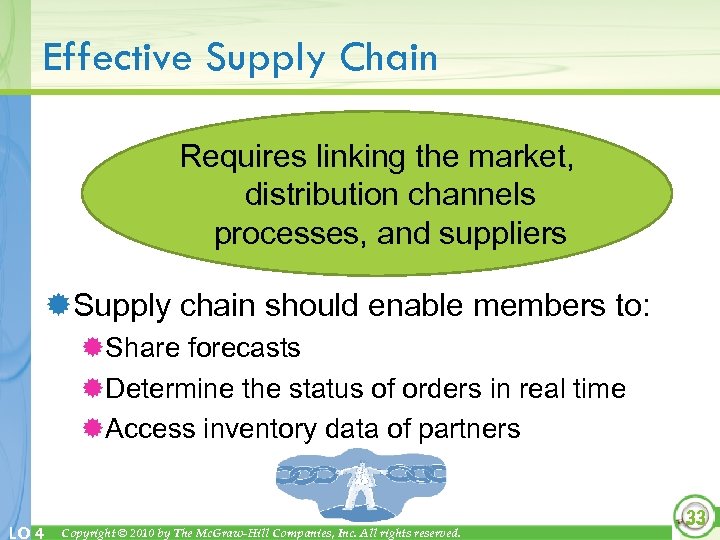

Effective Supply Chain Requires linking the market, distribution channels processes, and suppliers ®Supply chain should enable members to: ®Share forecasts ®Determine the status of orders in real time ®Access inventory data of partners LO 4 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 33

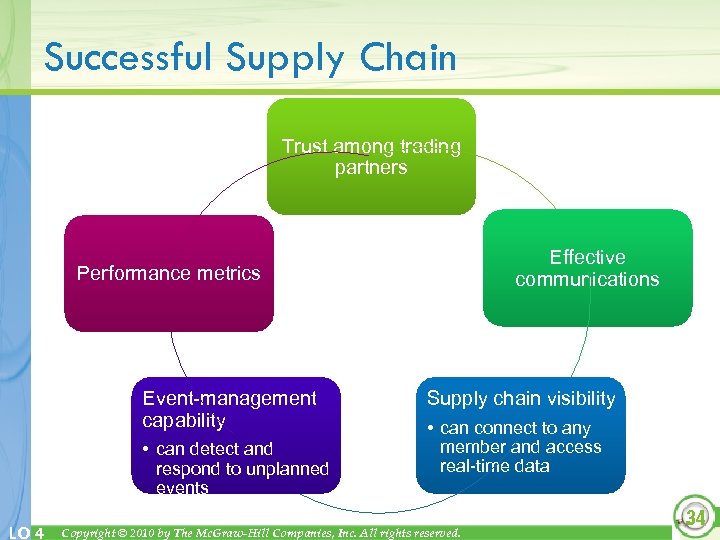

Successful Supply Chain Trust among trading partners Effective communications Performance metrics Event-management capability • can detect and respond to unplanned events LO 4 Supply chain visibility • can connect to any member and access real-time data Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 34

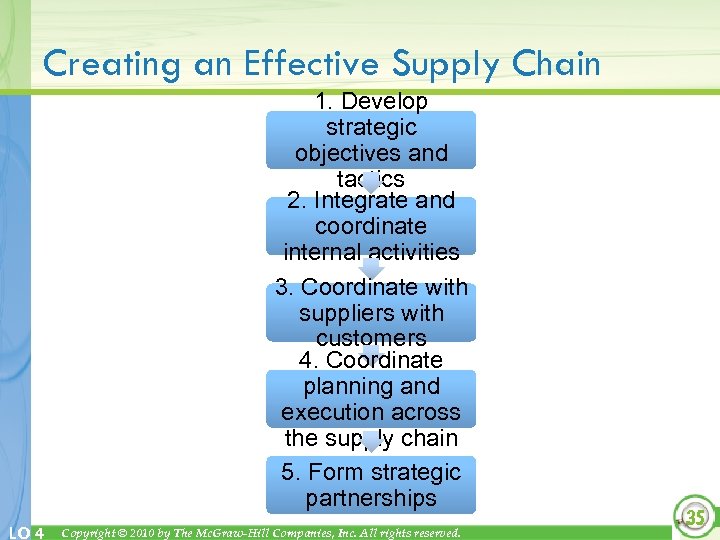

Creating an Effective Supply Chain 1. Develop strategic objectives and tactics 2. Integrate and coordinate internal activities 3. Coordinate with suppliers with customers 4. Coordinate planning and execution across the supply chain 5. Form strategic partnerships LO 4 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 35

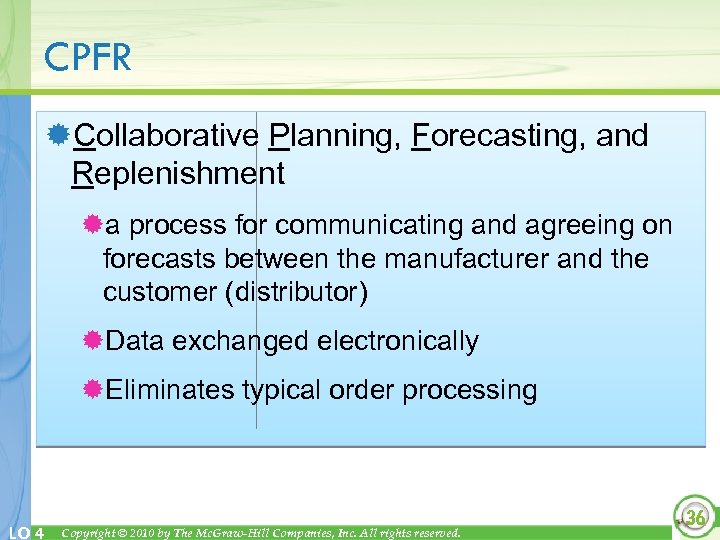

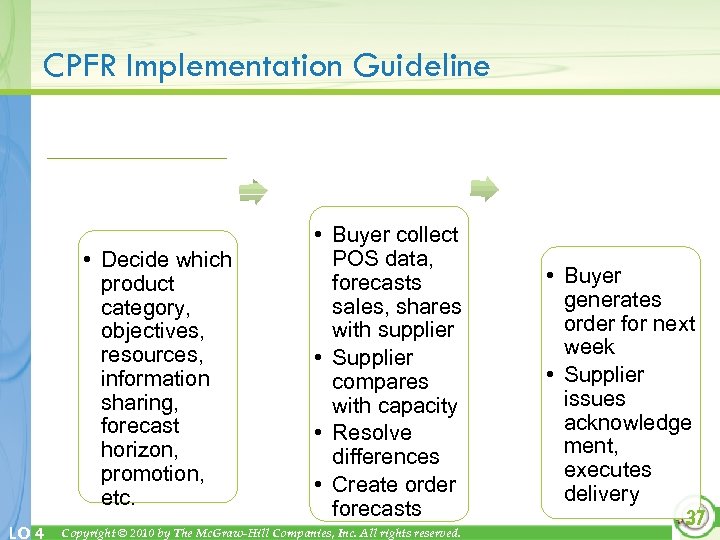

CPFR ®Collaborative Planning, Forecasting, and Replenishment ®a process for communicating and agreeing on forecasts between the manufacturer and the customer (distributor) ®Data exchanged electronically ®Eliminates typical order processing LO 4 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 36

CPFR Implementation Guideline Planni ng • Decide which product category, objectives, resources, information sharing, forecast horizon, promotion, etc. LO 4 Forec asting • Buyer collect POS data, forecasts sales, shares with supplier • Supplier compares with capacity • Resolve differences • Create order forecasts Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. Reple nishin g • Buyer generates order for next week • Supplier issues acknowledge ment, executes delivery 37

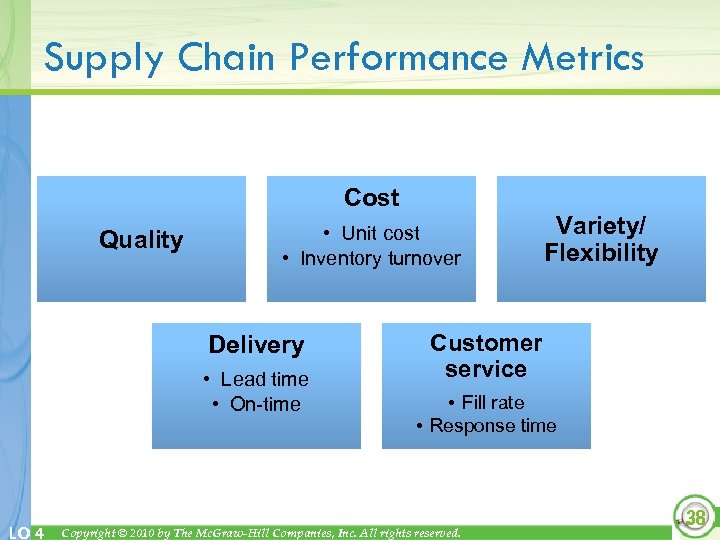

Supply Chain Performance Metrics Cost Quality • Unit cost • Inventory turnover Delivery • Lead time • On-time LO 4 Variety/ Flexibility Customer service • Fill rate • Response time Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 38

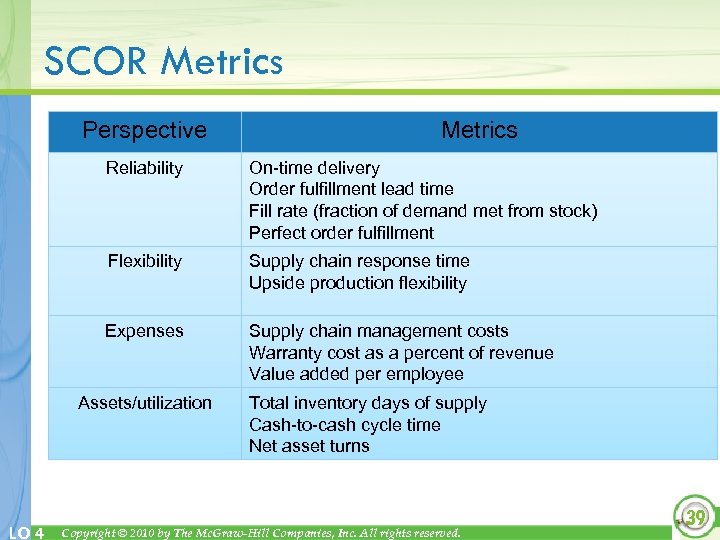

SCOR Metrics Perspective Metrics Reliability On-time delivery Order fulfillment lead time Fill rate (fraction of demand met from stock) Perfect order fulfillment Flexibility Supply chain response time Upside production flexibility Expenses Supply chain management costs Warranty cost as a percent of revenue Value added per employee Assets/utilization LO 4 Total inventory days of supply Cash-to-cash cycle time Net asset turns Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 39

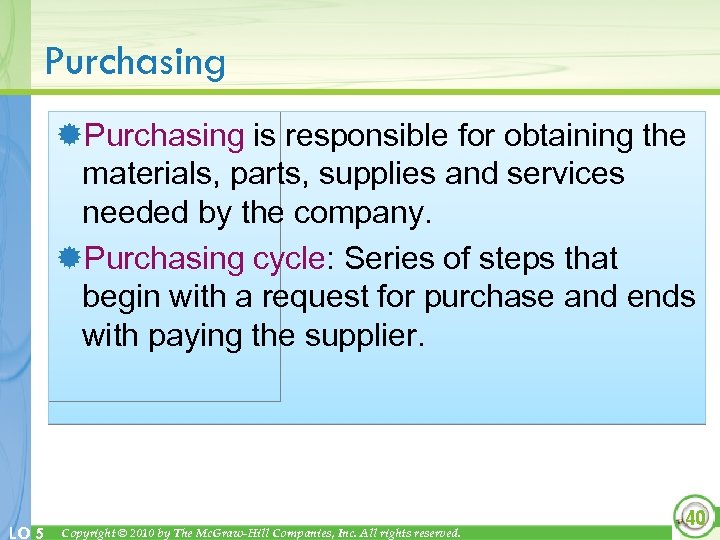

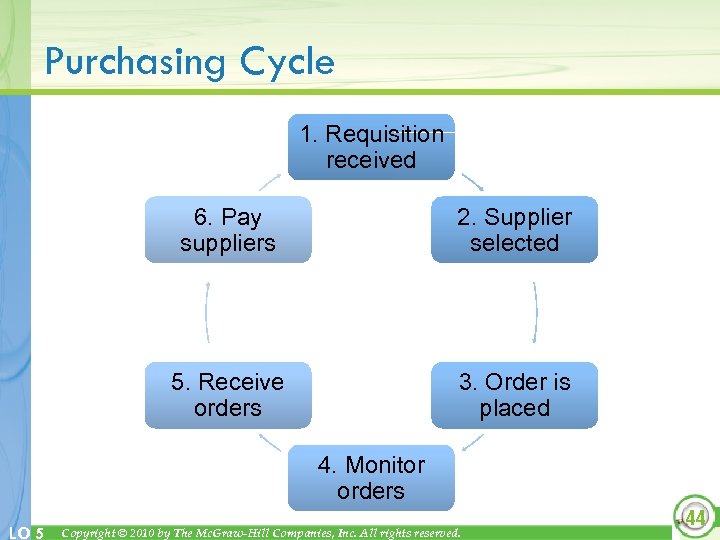

Purchasing ®Purchasing is responsible for obtaining the materials, parts, supplies and services needed by the company. ®Purchasing cycle: Series of steps that begin with a request for purchase and ends with paying the supplier. LO 5 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 40

Purchasing ® GOAL develop and implement purchasing plans for goods and services that support the business plan Cost of purchases Forming partnerships LO 5 Responsible for Timing of deliveries Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. Quality of purchases 41

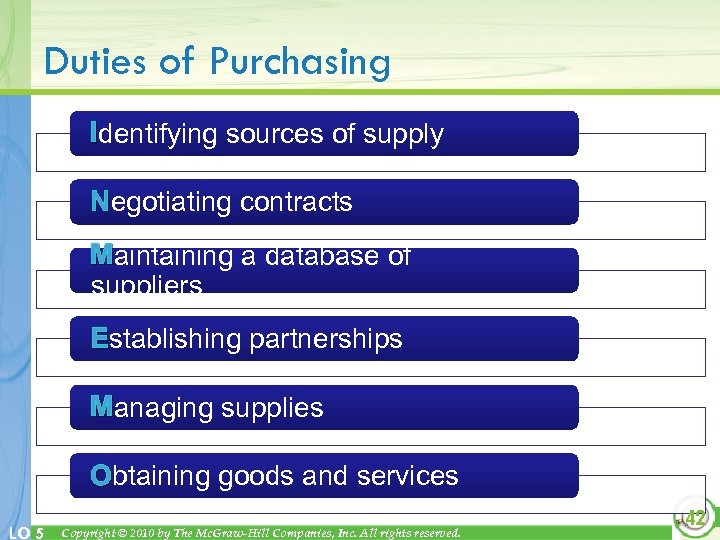

Duties of Purchasing Identifying sources of supply Negotiating contracts Maintaining a database of suppliers Establishing partnerships Managing supplies Obtaining goods and services LO 5 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 42

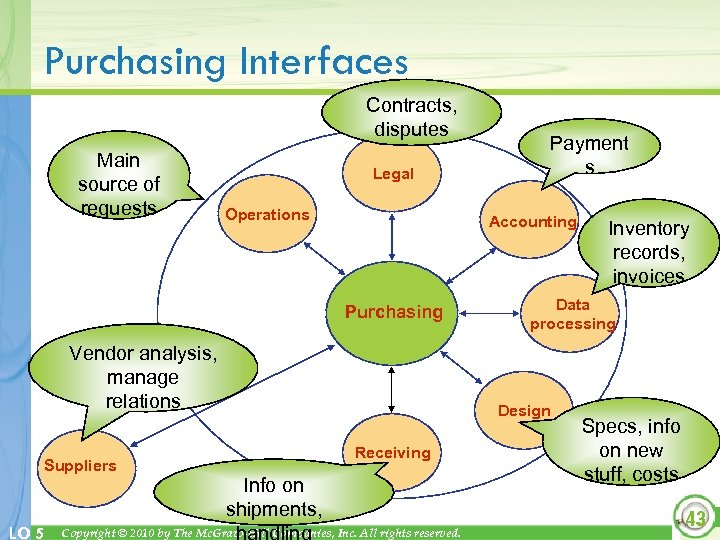

Purchasing Interfaces Contracts, disputes Main source of requests Legal Operations Accounting Purchasing Vendor analysis, manage relations Suppliers Payment s Data processing Design Receiving Info on shipments, LO 5 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. handling Inventory records, invoices Specs, info on new stuff, costs 43

Purchasing Cycle 1. Requisition received 6. Pay suppliers 2. Supplier selected 5. Receive orders 3. Order is placed 4. Monitor orders LO 5 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 44

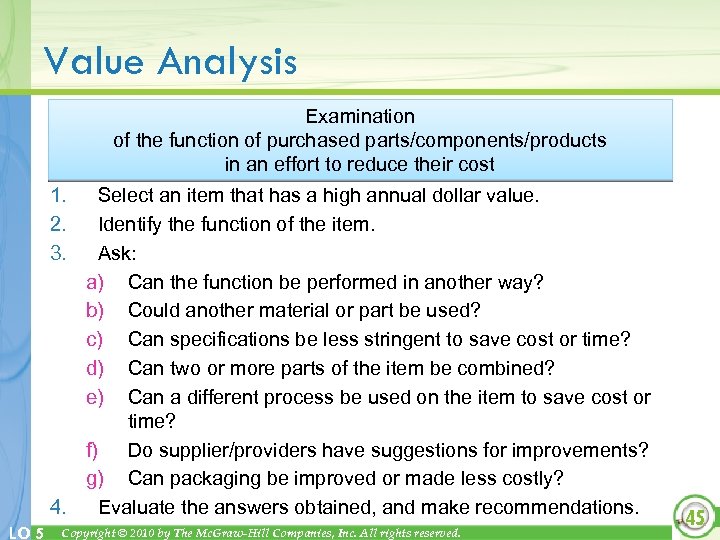

Value Analysis Examination of the function of purchased parts/components/products in an effort to reduce their cost 1. 2. 3. Select an item that has a high annual dollar value. Identify the function of the item. Ask: a) Can the function be performed in another way? b) Could another material or part be used? c) Can specifications be less stringent to save cost or time? d) Can two or more parts of the item be combined? e) Can a different process be used on the item to save cost or time? f) Do supplier/providers have suggestions for improvements? g) Can packaging be improved or made less costly? 4. Evaluate the answers obtained, and make recommendations. LO 5 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 45

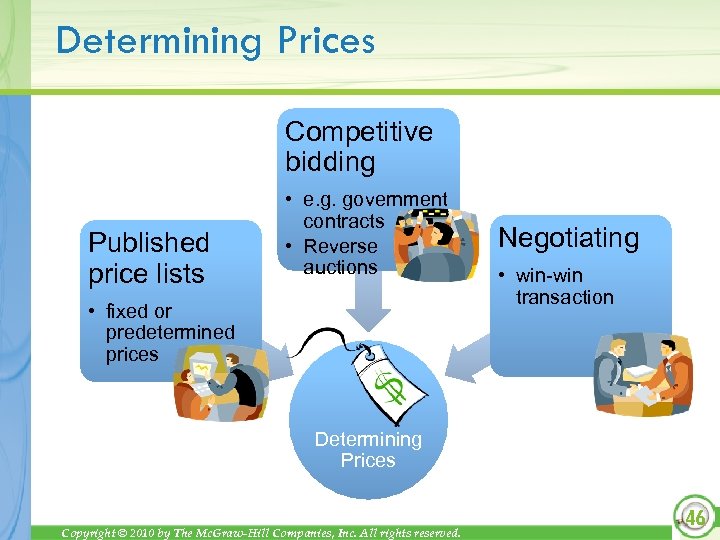

Determining Prices Competitive bidding Published price lists • e. g. government contracts • Reverse auctions • fixed or predetermined prices Negotiating • win-win transaction Determining Prices Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 46

Negotiations Myths 1. Negotiation is a win-lose confrontation 2. The main goal is to obtain the lowest possible price 3. Each negotiation is an isolated transaction LO 5 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 47

Centralized vs. Decentralized Purchasing ®Centralized purchasing ® Purchasing is handled by one special department ®Decentralized purchasing ®Individual departments or separate locations handle their own purchasing requirements LO 5 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 48

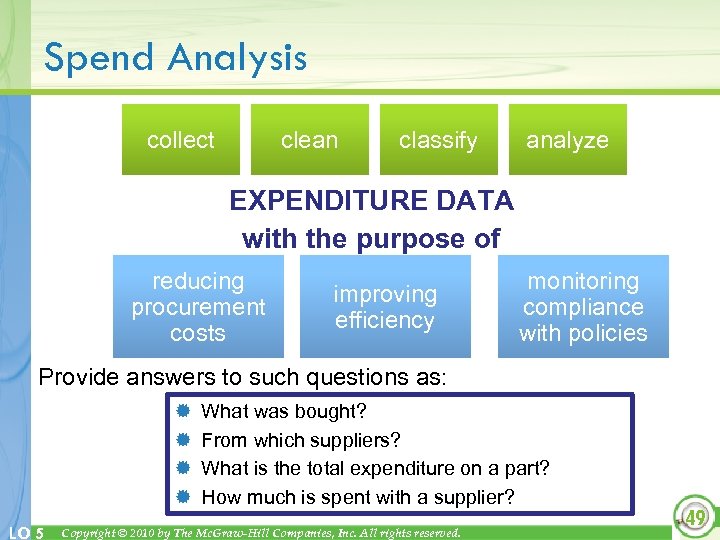

Spend Analysis collect clean classify analyze EXPENDITURE DATA with the purpose of reducing procurement costs improving efficiency monitoring compliance with policies Provide answers to such questions as: ® ® LO 5 What was bought? From which suppliers? What is the total expenditure on a part? How much is spent with a supplier? Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 49

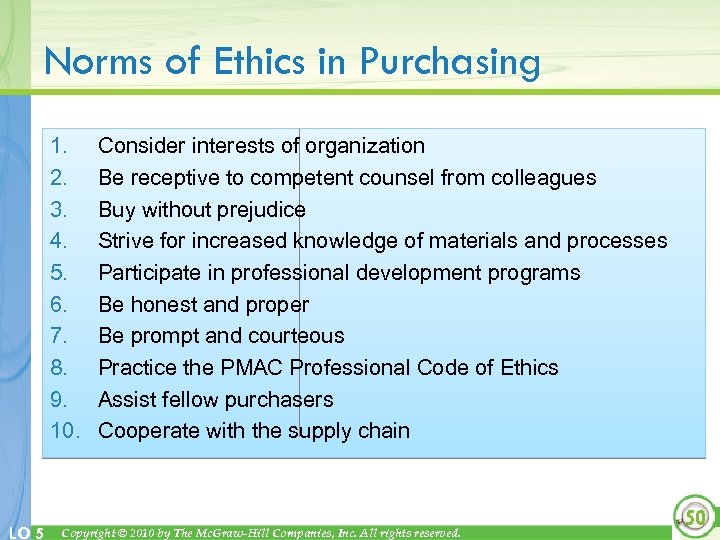

Norms of Ethics in Purchasing 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. LO 5 Consider interests of organization Be receptive to competent counsel from colleagues Buy without prejudice Strive for increased knowledge of materials and processes Participate in professional development programs Be honest and proper Be prompt and courteous Practice the PMAC Professional Code of Ethics Assist fellow purchasers Cooperate with the supply chain Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 50

Supplier Management and Partnerships Choosing suppliers Supplier certification Supplier relationships Supplier partnerships LO 6 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 51

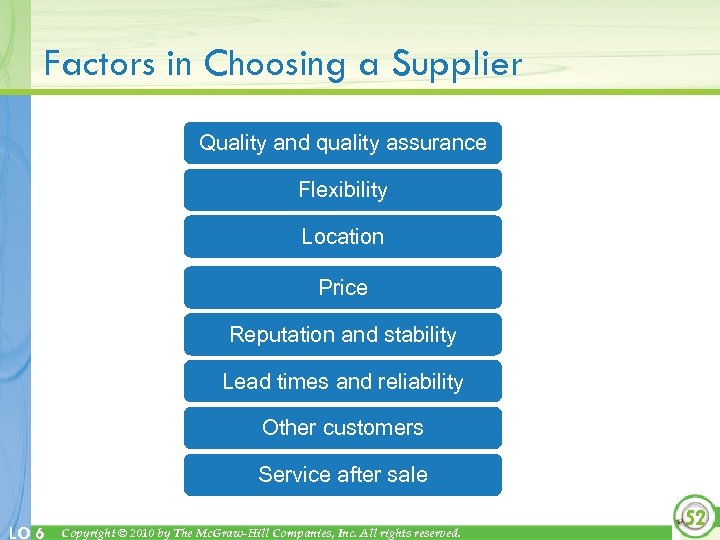

Factors in Choosing a Supplier Quality and quality assurance Flexibility Location Price Reputation and stability Lead times and reliability Other customers Service after sale LO 6 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 52

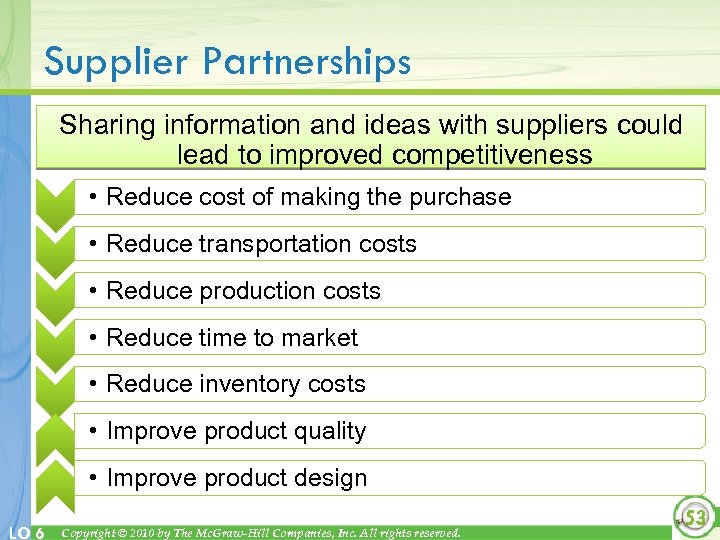

Supplier Partnerships Sharing information and ideas with suppliers could lead to improved competitiveness • Reduce cost of making the purchase • Reduce transportation costs • Reduce production costs • Reduce time to market • Reduce inventory costs • Improve product quality • Improve product design LO 6 Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 53

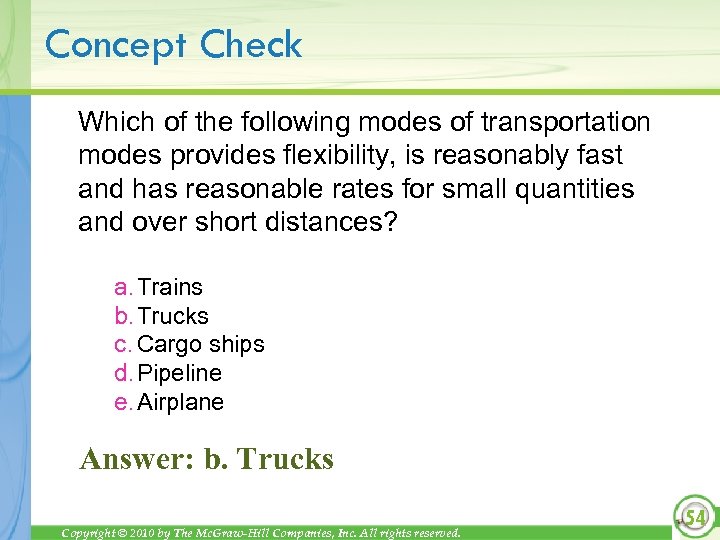

Concept Check Which of the following modes of transportation modes provides flexibility, is reasonably fast and has reasonable rates for small quantities and over short distances? a. Trains b. Trucks c. Cargo ships d. Pipeline e. Airplane Answer: b. Trucks Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 54

Concept Check Which of the following refers to the phenomenon of increasing variability and need for inventory as we move from the customer to the producer in the supply chain? a. Continuous replenishing b. EDI c. Quick response d. DRP e. None of the above Answer: e. None of the above (The correct term is “Bullwhip effect”. ) Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 55

Learning Checklist Explain what a supply chain is. Explain the need to manage a supply chain and the potential benefits of doing so. Explain the reasons for outsourcing. Describe the bullwhip effect and the reasons why it occurs. Identify the strategic, tactical, and operations issues in supply chain management. Describe what logistics is Know how to select a transportation mode Discuss some fast delivery methods, reverse logistics, and global supply chains. Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 56

Learning Checklist Discuss the three technologies used in supply chain management: EDI, RFID, and E-commerce. Outline the requirements of and key steps in creating an effective supply chain. Explain CPFR and the value of strategic partnering. Describe the responsibilities and issues of purchasing. Explain the term value analysis. Identify several guidelines for ethical behaviour in purchasing. Discuss supplier management and partnership. Copyright © 2010 by The Mc. Graw-Hill Companies, Inc. All rights reserved. 57

fd0ab941efbf53089296734ef1816301.ppt