bb99456bf5d92fe74eae77789cf4cae1.ppt

- Количество слайдов: 22

> > > > Chapter 11 Production and Operations Management

> > > > Chapter 11 Production and Operations Management

g Goals Learnin 1 Outline the importance of production and operations management. 5 Compare alternative layouts for production facilities. 6 List the steps in the purchasing process. 2 3 4 Explain the roles of computers and related technologies in production. Identify the factors involved in a plant location decision. Explain the major tasks of production and operations managers. 7 Outline the advantages and disadvantages of maintaining large inventories. 8 Identify the steps in the production control process. 9 Explain the benefits of quality control.

g Goals Learnin 1 Outline the importance of production and operations management. 5 Compare alternative layouts for production facilities. 6 List the steps in the purchasing process. 2 3 4 Explain the roles of computers and related technologies in production. Identify the factors involved in a plant location decision. Explain the major tasks of production and operations managers. 7 Outline the advantages and disadvantages of maintaining large inventories. 8 Identify the steps in the production control process. 9 Explain the benefits of quality control.

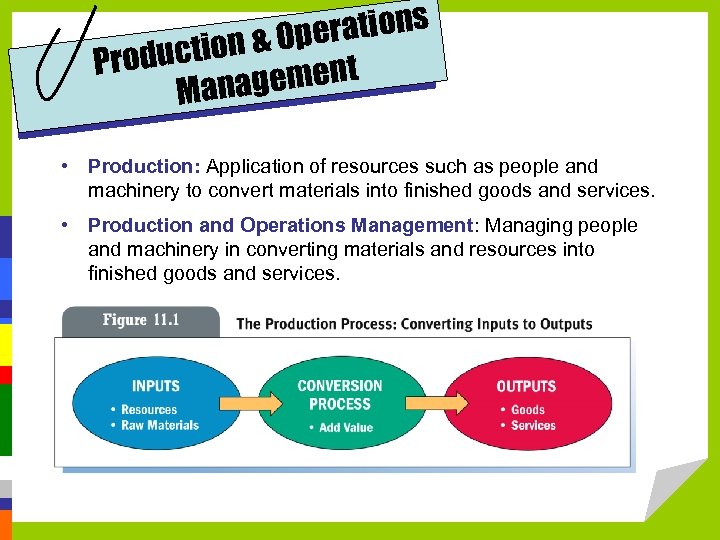

rations on & Ope Producti gement Mana • Production: Application of resources such as people and machinery to convert materials into finished goods and services. • Production and Operations Management: Managing people and machinery in converting materials and resources into finished goods and services.

rations on & Ope Producti gement Mana • Production: Application of resources such as people and machinery to convert materials into finished goods and services. • Production and Operations Management: Managing people and machinery in converting materials and resources into finished goods and services.

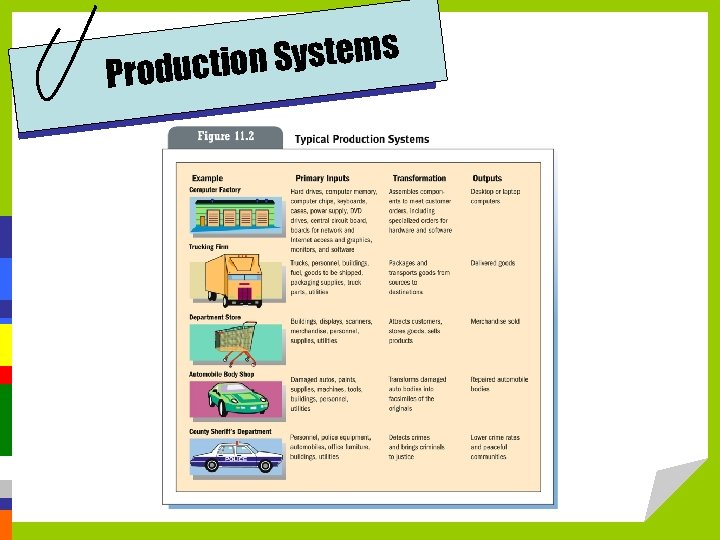

Systems roduction P

Systems roduction P

ortance of ategic Imp Str n Function e Productio th • A vital function is necessary for generating money to pay employees, lenders, and stockholders. • Effective production and operations management can: – lower a firm’s costs of production. – boost the quality of its goods and services. – allow it to respond dependably to customer demands. – enable it to renew itself by providing new products.

ortance of ategic Imp Str n Function e Productio th • A vital function is necessary for generating money to pay employees, lenders, and stockholders. • Effective production and operations management can: – lower a firm’s costs of production. – boost the quality of its goods and services. – allow it to respond dependably to customer demands. – enable it to renew itself by providing new products.

lexible and Mass, F roduction r-Driven P tome Cus • Mass Production – manufacturing products in large amounts through standardization, mechanization and specialized skills. • Flexible Production – producing smaller batches using information technology, communication and cooperation. • Customer-Driven Production – evaluating customer demands to link with manufacturer.

lexible and Mass, F roduction r-Driven P tome Cus • Mass Production – manufacturing products in large amounts through standardization, mechanization and specialized skills. • Flexible Production – producing smaller batches using information technology, communication and cooperation. • Customer-Driven Production – evaluating customer demands to link with manufacturer.

ogy and The Technol n Process Productio • Robots – reprogrammable machines capable of performing routine jobs and manipulating material • Computer-Aided Design and Manufacturing – enables engineers to design parts and buildings on computer screens faster and with fewer mistakes. • Flexible Manufacturing Systems – a production facility that workers can quickly modify to manufacture different products. • Computer-Integrated Manufacturing – integrates robots, computers and other technologies to help workers design products, control machines, handle materials, and control the production function.

ogy and The Technol n Process Productio • Robots – reprogrammable machines capable of performing routine jobs and manipulating material • Computer-Aided Design and Manufacturing – enables engineers to design parts and buildings on computer screens faster and with fewer mistakes. • Flexible Manufacturing Systems – a production facility that workers can quickly modify to manufacture different products. • Computer-Integrated Manufacturing – integrates robots, computers and other technologies to help workers design products, control machines, handle materials, and control the production function.

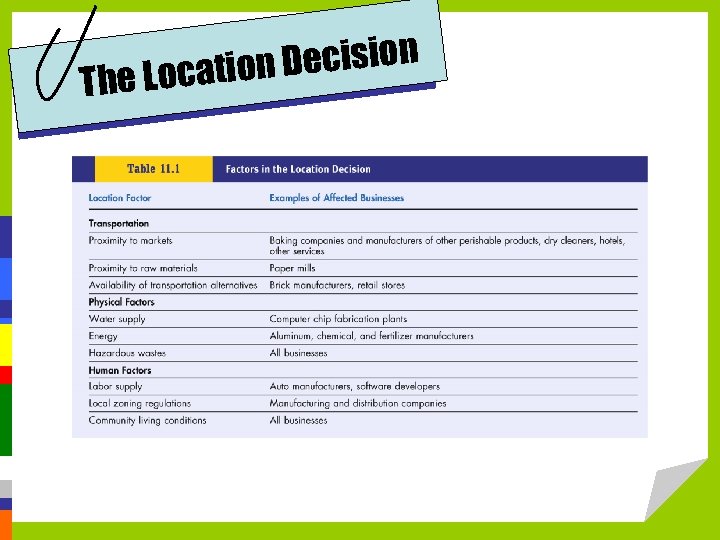

ecision Location D The

ecision Location D The

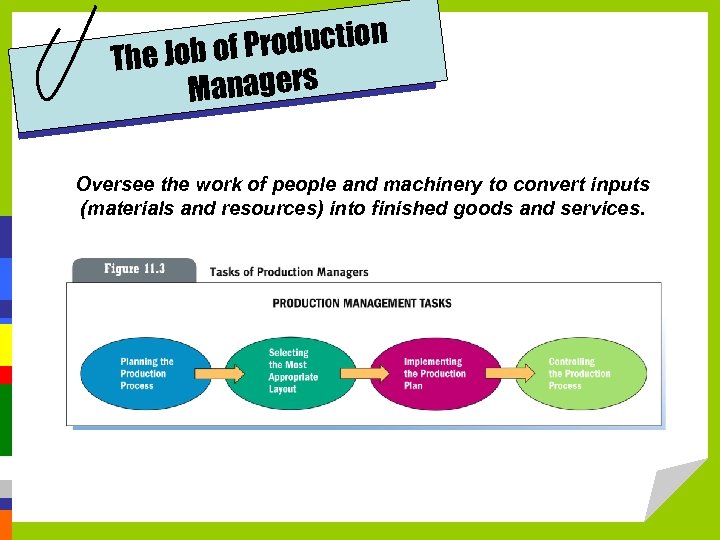

roduction The Job of P Managers Oversee the work of people and machinery to convert inputs (materials and resources) into finished goods and services.

roduction The Job of P Managers Oversee the work of people and machinery to convert inputs (materials and resources) into finished goods and services.

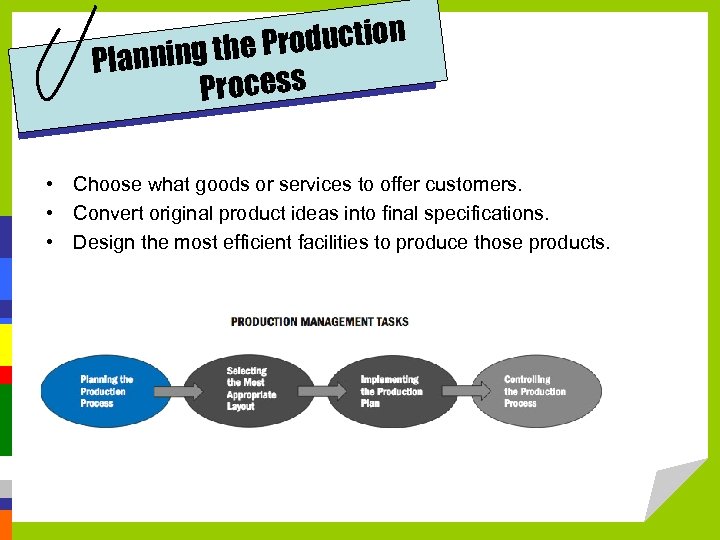

Production lanning the P Process • Choose what goods or services to offer customers. • Convert original product ideas into final specifications. • Design the most efficient facilities to produce those products.

Production lanning the P Process • Choose what goods or services to offer customers. • Convert original product ideas into final specifications. • Design the most efficient facilities to produce those products.

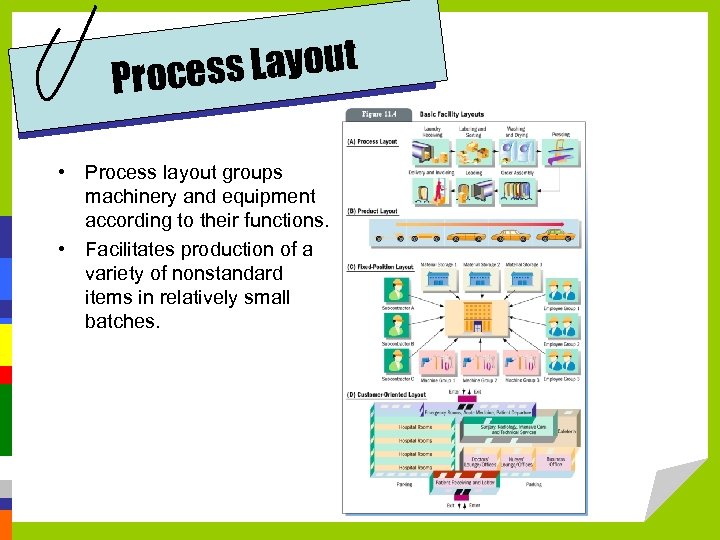

s Layout Proces • Process layout groups machinery and equipment according to their functions. • Facilitates production of a variety of nonstandard items in relatively small batches.

s Layout Proces • Process layout groups machinery and equipment according to their functions. • Facilitates production of a variety of nonstandard items in relatively small batches.

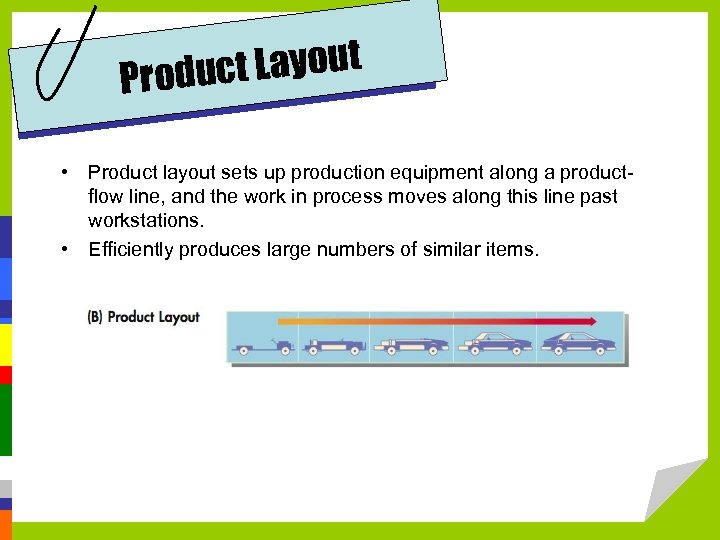

t Layout Produc • Product layout sets up production equipment along a productflow line, and the work in process moves along this line past workstations. • Efficiently produces large numbers of similar items.

t Layout Produc • Product layout sets up production equipment along a productflow line, and the work in process moves along this line past workstations. • Efficiently produces large numbers of similar items.

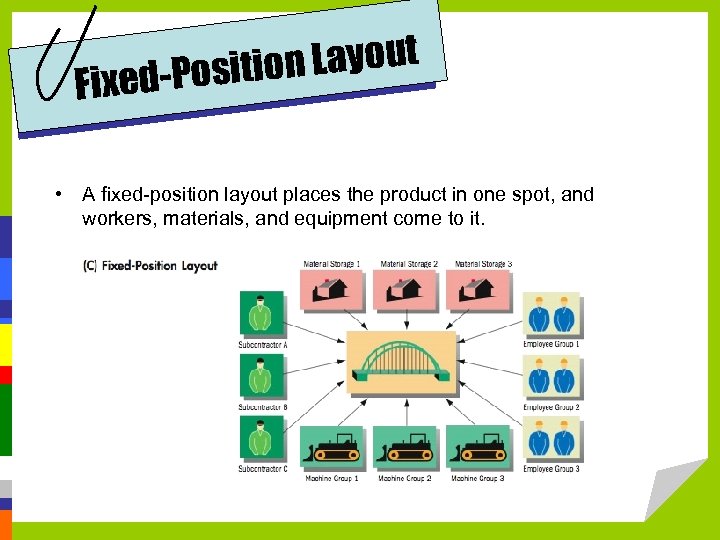

on Layout ed-Positi Fix • A fixed-position layout places the product in one spot, and workers, materials, and equipment come to it.

on Layout ed-Positi Fix • A fixed-position layout places the product in one spot, and workers, materials, and equipment come to it.

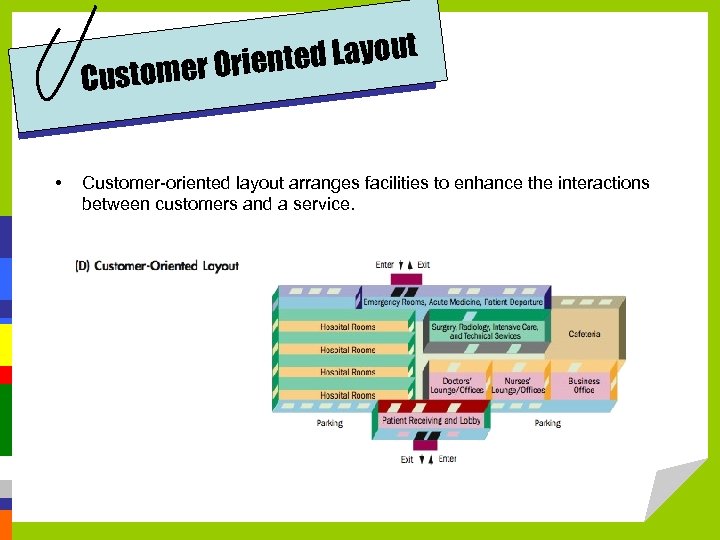

nted Layout stomer Orie Cu • Customer-oriented layout arranges facilities to enhance the interactions between customers and a service.

nted Layout stomer Orie Cu • Customer-oriented layout arranges facilities to enhance the interactions between customers and a service.

enting the Implem ction Plan Produ Make, Buy, or Lease Decision • Choosing whether to manufacture a needed product or component in-house, purchase it from an outside supplier, or lease it. • Factors in the decision include cost, availability of reliable outside suppliers, and the need for confidentiality. Selection of Suppliers • Based on comparison of quality, prices, dependability of delivery, and services offered by competing companies.

enting the Implem ction Plan Produ Make, Buy, or Lease Decision • Choosing whether to manufacture a needed product or component in-house, purchase it from an outside supplier, or lease it. • Factors in the decision include cost, availability of reliable outside suppliers, and the need for confidentiality. Selection of Suppliers • Based on comparison of quality, prices, dependability of delivery, and services offered by competing companies.

Control ventory In Inventory Control – Perpetual inventory – Vendor-managed inventory Just-in-Time Systems • Improving profits and return on investment by minimizing costs and eliminating waste through cutting inventory on hand. Materials Requirement Planning • Computer-based production planning system by which a firm can ensure that it has the correct materials for production.

Control ventory In Inventory Control – Perpetual inventory – Vendor-managed inventory Just-in-Time Systems • Improving profits and return on investment by minimizing costs and eliminating waste through cutting inventory on hand. Materials Requirement Planning • Computer-based production planning system by which a firm can ensure that it has the correct materials for production.

Production ntrolling the Co Process • Production control creates a well-defined set of procedures for coordinating people, materials, and machinery. 1) Planning 2) Routing 3) Scheduling 4) Dispatching 5) Follow-up

Production ntrolling the Co Process • Production control creates a well-defined set of procedures for coordinating people, materials, and machinery. 1) Planning 2) Routing 3) Scheduling 4) Dispatching 5) Follow-up

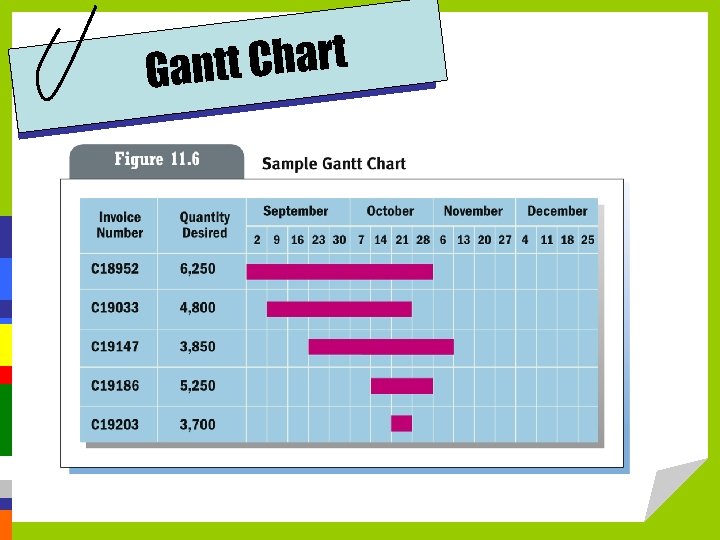

ntt Chart Ga

ntt Chart Ga

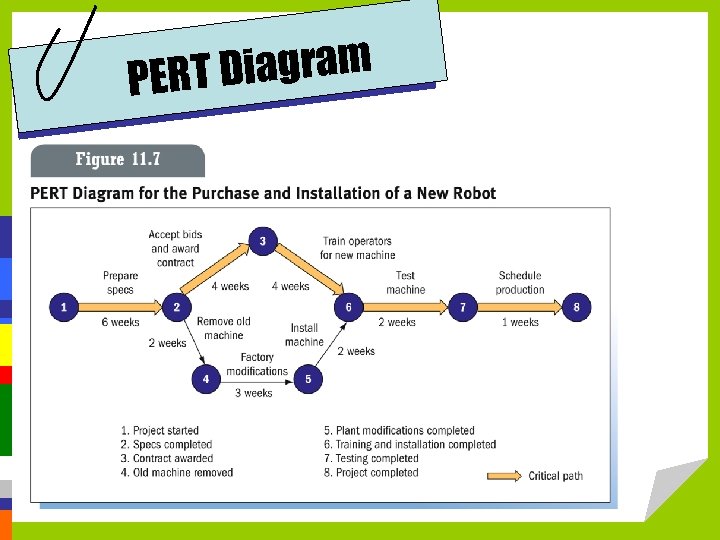

Diagram PERT

Diagram PERT

Dis Follow-up patching & Dispatching Manager instructs each department on what work to do and the time allowed for its completion. Follow-Up Employees and their supervisors spot problems in the production process and determine needed changes.

Dis Follow-up patching & Dispatching Manager instructs each department on what work to do and the time allowed for its completion. Follow-Up Employees and their supervisors spot problems in the production process and determine needed changes.

of Quality portance m I • A good or service free of deficiencies. • Poor quality can account for 20% loss in revenue. • Benchmarking is the process of analyzing other firms’ best practices. • Quality control is measuring goods and services against established quality standards. • Many companies evaluate quality using the Six Sigma concept. – A company tries to make error-free products 99. 9997% of the time, a tiny 3. 4 errors per million opportunities.

of Quality portance m I • A good or service free of deficiencies. • Poor quality can account for 20% loss in revenue. • Benchmarking is the process of analyzing other firms’ best practices. • Quality control is measuring goods and services against established quality standards. • Many companies evaluate quality using the Six Sigma concept. – A company tries to make error-free products 99. 9997% of the time, a tiny 3. 4 errors per million opportunities.

andards ISO St • International Organization for Standardization (ISO) - mission is to promote the development of standardized products to facilitate trade and cooperation across national borders. • Representatives from more than 146 nations. • ISO 9000 series of standards sets requirements for quality processes. • Nearly half a million ISO 9000 certificates have been awarded to companies around the world. • ISO 14000 series also sets standards for operations that minimize harm to the environment.

andards ISO St • International Organization for Standardization (ISO) - mission is to promote the development of standardized products to facilitate trade and cooperation across national borders. • Representatives from more than 146 nations. • ISO 9000 series of standards sets requirements for quality processes. • Nearly half a million ISO 9000 certificates have been awarded to companies around the world. • ISO 14000 series also sets standards for operations that minimize harm to the environment.