883c7ddce054f7b68a03a549f4e87ffa.ppt

- Количество слайдов: 34

Chapter 11 – Part I Total Quality Management COB 300 Busing

Chapter 11 – Part I Total Quality Management COB 300 Busing

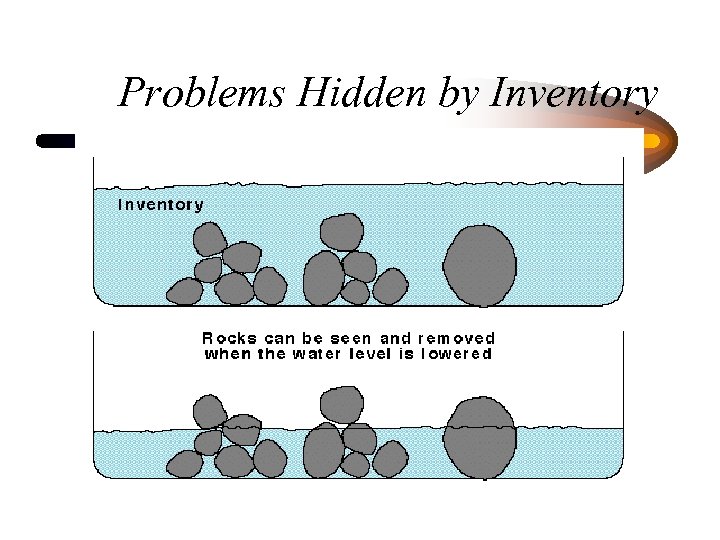

Problems Hidden by Inventory

Problems Hidden by Inventory

Simplifying the Process • • • Plant layout Group technology U-shaped layout Reducing setup time Total preventive maintenance Simplified Process

Simplifying the Process • • • Plant layout Group technology U-shaped layout Reducing setup time Total preventive maintenance Simplified Process

Strategy and JIT • Quality and reliability • Flexibility – product – volume • • Dependability Asset utilization People utilization Cost minimization

Strategy and JIT • Quality and reliability • Flexibility – product – volume • • Dependability Asset utilization People utilization Cost minimization

Internally Oriented Definitions of Quality l l Quality is the degree to which a specific product conforms to a design or specification Differences in quality amount to differences in the quantity of some desired ingredient or attribute

Internally Oriented Definitions of Quality l l Quality is the degree to which a specific product conforms to a design or specification Differences in quality amount to differences in the quantity of some desired ingredient or attribute

Externally Oriented Definitions of Quality • Quality is fitness for use • Quality consists of the capacity to satisfy wants

Externally Oriented Definitions of Quality • Quality is fitness for use • Quality consists of the capacity to satisfy wants

A Definition of Quality Used by Many Companies Quality is consistently meeting or exceeding the customer’s needs and expectations.

A Definition of Quality Used by Many Companies Quality is consistently meeting or exceeding the customer’s needs and expectations.

Dimensions of Service Quality • • • Reliability Responsiveness Assurance Empathy Tangibles

Dimensions of Service Quality • • • Reliability Responsiveness Assurance Empathy Tangibles

Dimensions of Quality for Goods • • Performance Features Reliability Conformance • • Durability Serviceability Aesthetics Perceived Quality

Dimensions of Quality for Goods • • Performance Features Reliability Conformance • • Durability Serviceability Aesthetics Perceived Quality

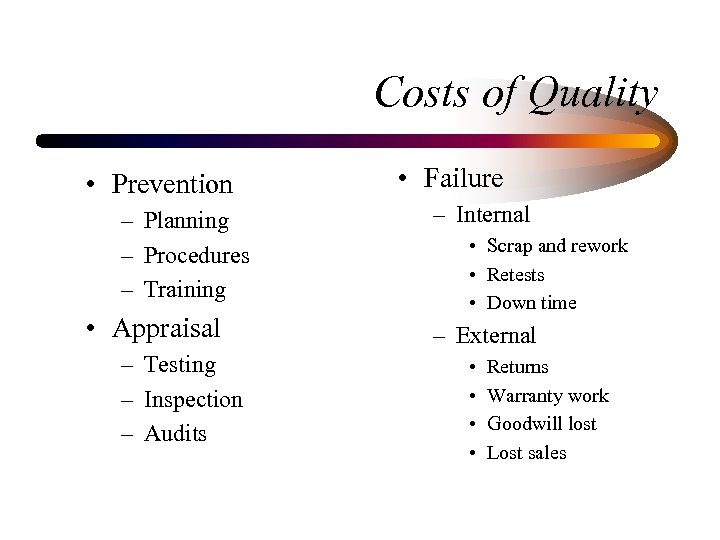

Costs of Quality • Prevention – Planning – Procedures – Training • Appraisal – Testing – Inspection – Audits • Failure – Internal • Scrap and rework • Retests • Down time – External • • Returns Warranty work Goodwill lost Lost sales

Costs of Quality • Prevention – Planning – Procedures – Training • Appraisal – Testing – Inspection – Audits • Failure – Internal • Scrap and rework • Retests • Down time – External • • Returns Warranty work Goodwill lost Lost sales

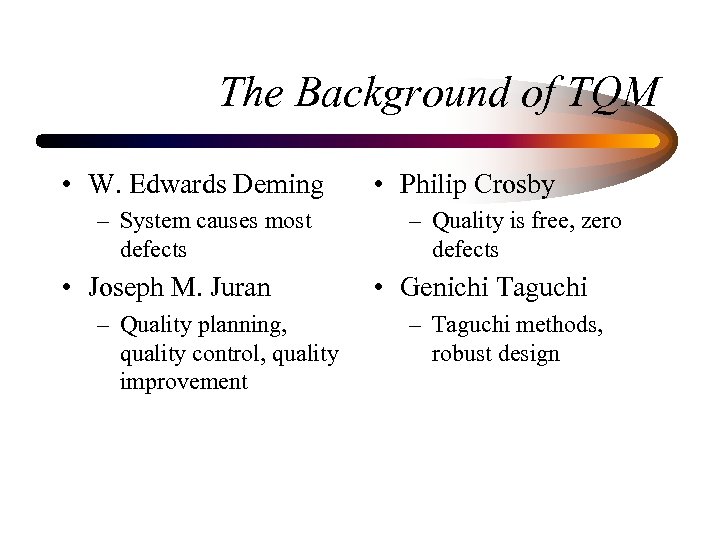

The Background of TQM • W. Edwards Deming – System causes most defects • Joseph M. Juran – Quality planning, quality control, quality improvement • Philip Crosby – Quality is free, zero defects • Genichi Taguchi – Taguchi methods, robust design

The Background of TQM • W. Edwards Deming – System causes most defects • Joseph M. Juran – Quality planning, quality control, quality improvement • Philip Crosby – Quality is free, zero defects • Genichi Taguchi – Taguchi methods, robust design

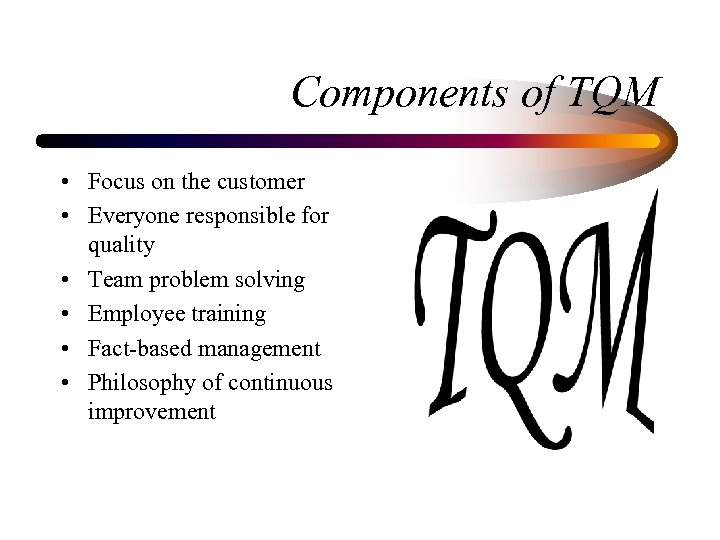

Components of TQM • Focus on the customer • Everyone responsible for quality • Team problem solving • Employee training • Fact-based management • Philosophy of continuous improvement

Components of TQM • Focus on the customer • Everyone responsible for quality • Team problem solving • Employee training • Fact-based management • Philosophy of continuous improvement

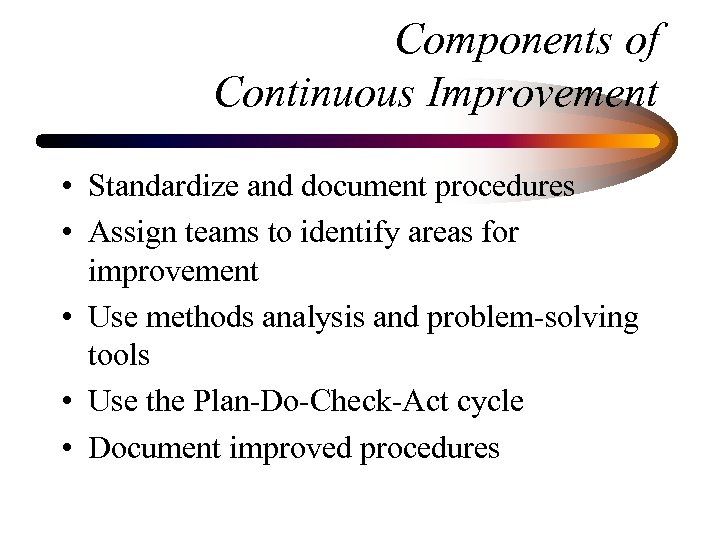

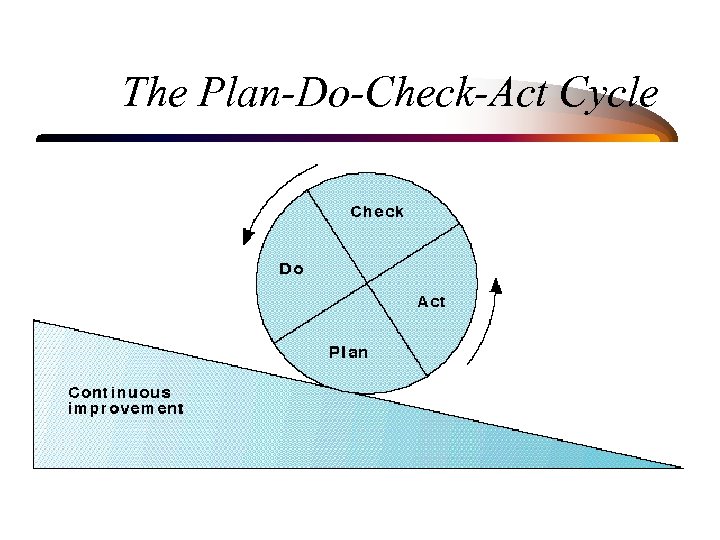

Components of Continuous Improvement • Standardize and document procedures • Assign teams to identify areas for improvement • Use methods analysis and problem-solving tools • Use the Plan-Do-Check-Act cycle • Document improved procedures

Components of Continuous Improvement • Standardize and document procedures • Assign teams to identify areas for improvement • Use methods analysis and problem-solving tools • Use the Plan-Do-Check-Act cycle • Document improved procedures

The Plan-Do-Check-Act Cycle

The Plan-Do-Check-Act Cycle

Baldridge Award • Baldridge Award Criteria for 00

Baldridge Award • Baldridge Award Criteria for 00

ISO 9000 Standards 9000 -1: Guidelines 9001: Design through installation and testing 9002: Production through installation and testing 9003: Distributors 9004 -1: Model of quality management system

ISO 9000 Standards 9000 -1: Guidelines 9001: Design through installation and testing 9002: Production through installation and testing 9003: Distributors 9004 -1: Model of quality management system

Comparing Baldrige, ISO 9000 and TQM • Baldrige – U. S. Quality Award – Focus on outcomes • ISO 9000 – International standards – Focus on documentation of processes • TQM – Organizational quality philosophy – Foundation of Baldrige criteria

Comparing Baldrige, ISO 9000 and TQM • Baldrige – U. S. Quality Award – Focus on outcomes • ISO 9000 – International standards – Focus on documentation of processes • TQM – Organizational quality philosophy – Foundation of Baldrige criteria

Chapter 11 – Part II Quality Control COB 300 C - The Operations Dimension Busing

Chapter 11 – Part II Quality Control COB 300 C - The Operations Dimension Busing

Causes of Variation • Random Causes – difficult or expensive to control – e. g. , outside humidity, line voltage • Assignable Causes – easier to correct – e. g. , employee error, new materials

Causes of Variation • Random Causes – difficult or expensive to control – e. g. , outside humidity, line voltage • Assignable Causes – easier to correct – e. g. , employee error, new materials

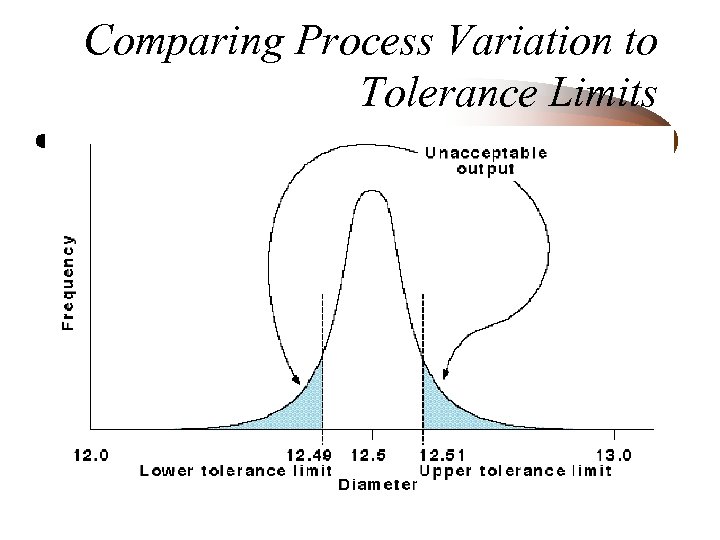

Comparing Process Variation to Tolerance Limits

Comparing Process Variation to Tolerance Limits

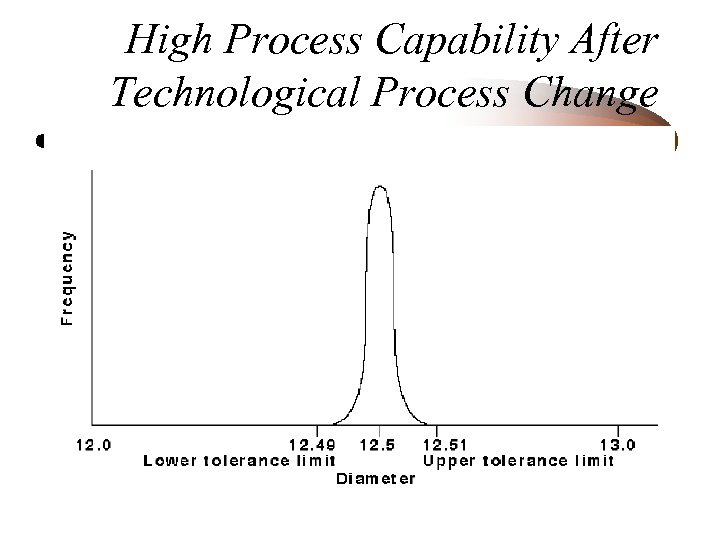

High Process Capability After Technological Process Change

High Process Capability After Technological Process Change

Control Charts • Variables - concentrates on mean for some measurable characteristic. – diameter – length • Attribute - data is based on counts or the number of times we observe a particular event. – proportion defective/non-defective – go/no go – proportion pass/fail

Control Charts • Variables - concentrates on mean for some measurable characteristic. – diameter – length • Attribute - data is based on counts or the number of times we observe a particular event. – proportion defective/non-defective – go/no go – proportion pass/fail

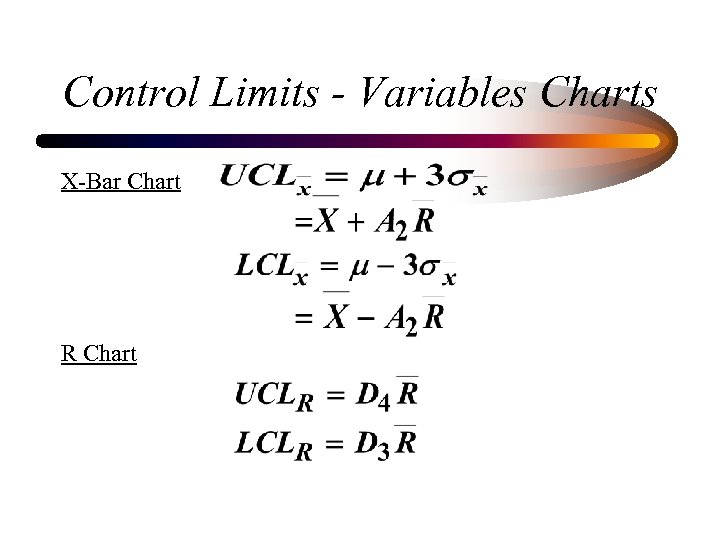

Control Limits - Variables Charts X-Bar Chart R Chart

Control Limits - Variables Charts X-Bar Chart R Chart

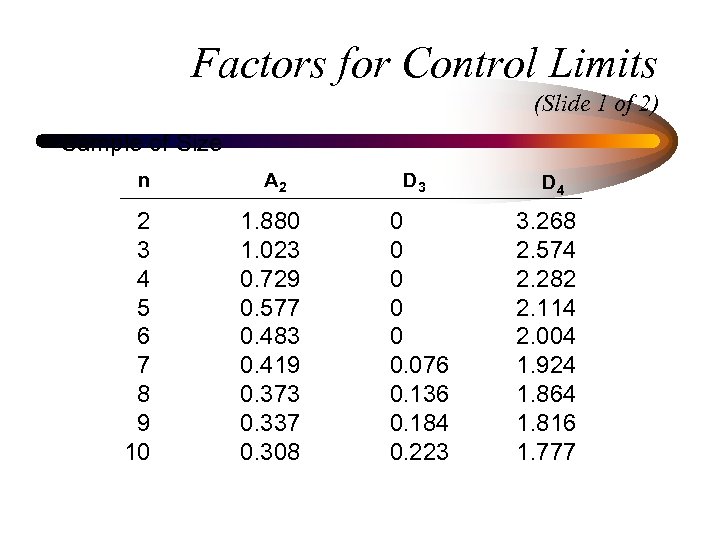

Factors for Control Limits (Slide 1 of 2) Sample of Size n 2 3 4 5 6 7 8 9 10 A 2 D 3 1. 880 1. 023 0. 729 0. 577 0. 483 0. 419 0. 373 0. 337 0. 308 0 0 0. 076 0. 136 0. 184 0. 223 D 4 3. 268 2. 574 2. 282 2. 114 2. 004 1. 924 1. 864 1. 816 1. 777

Factors for Control Limits (Slide 1 of 2) Sample of Size n 2 3 4 5 6 7 8 9 10 A 2 D 3 1. 880 1. 023 0. 729 0. 577 0. 483 0. 419 0. 373 0. 337 0. 308 0 0 0. 076 0. 136 0. 184 0. 223 D 4 3. 268 2. 574 2. 282 2. 114 2. 004 1. 924 1. 864 1. 816 1. 777

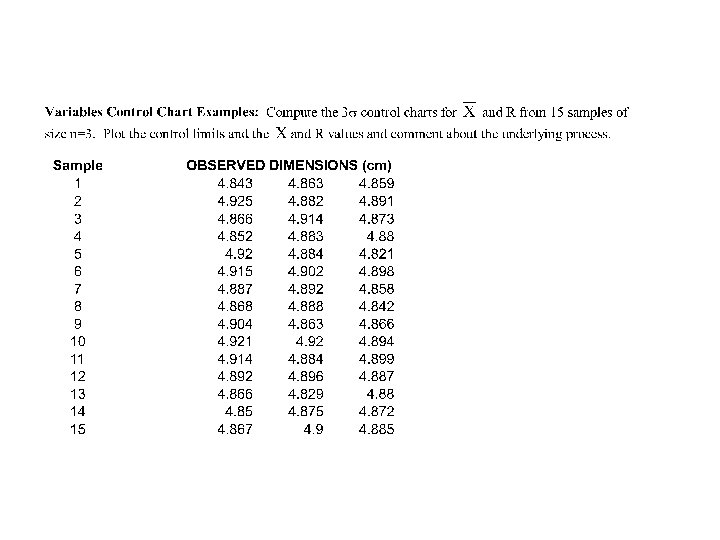

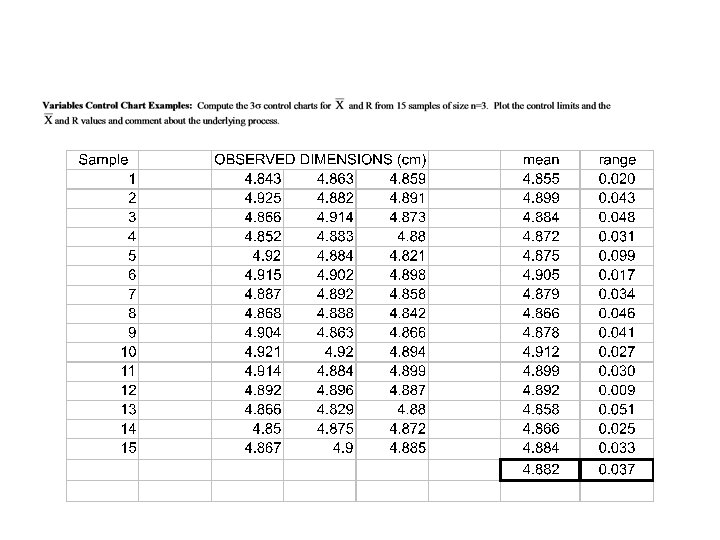

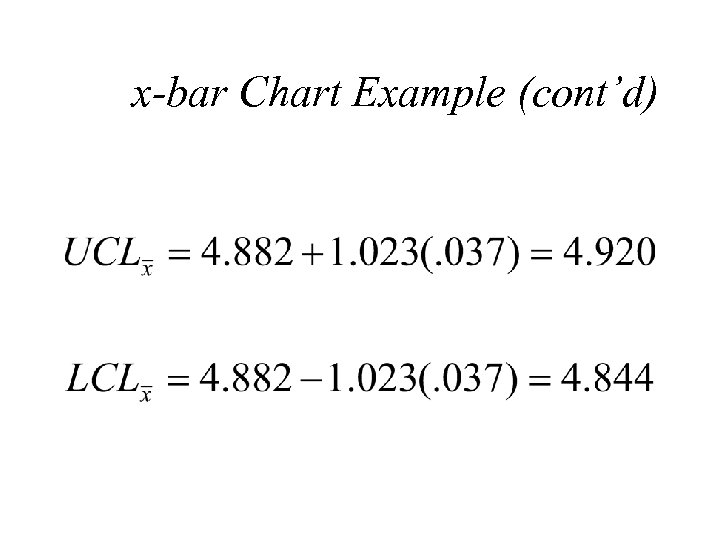

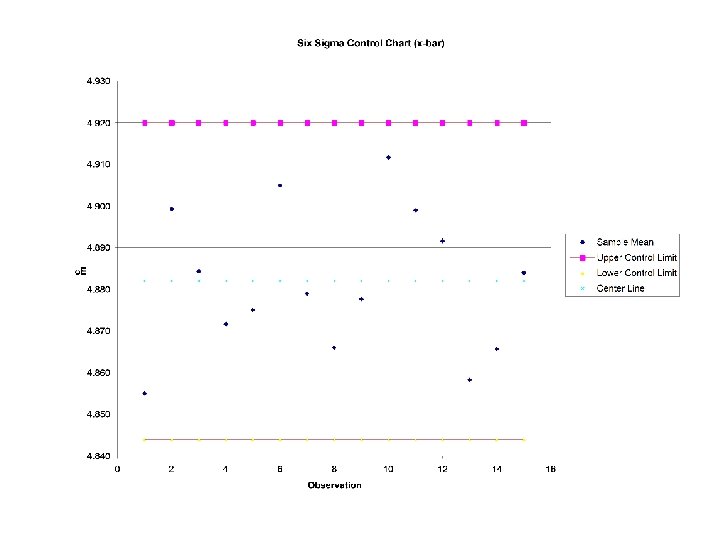

x-bar Chart Example (cont’d)

x-bar Chart Example (cont’d)

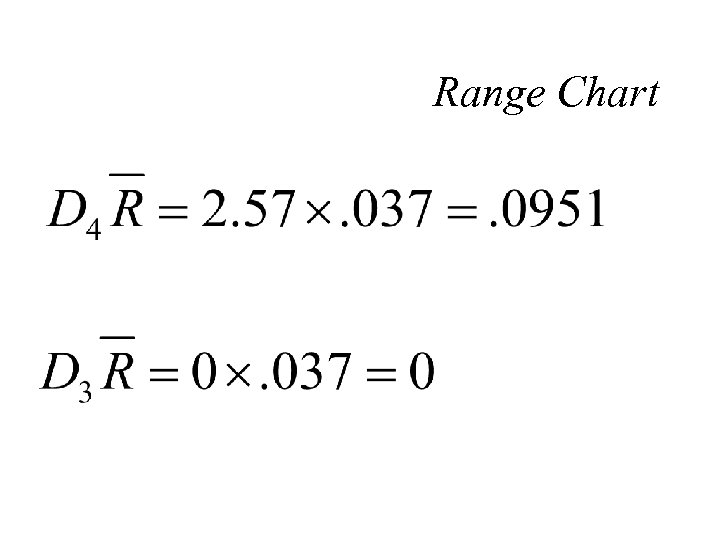

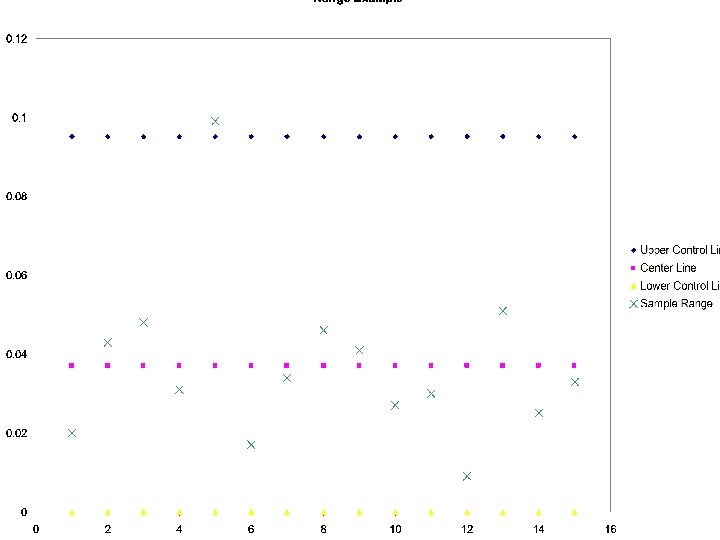

Range Chart

Range Chart

Warning Conditions • Two successive points near limit • Run of five above or below mean • Trend • Erratic behavior

Warning Conditions • Two successive points near limit • Run of five above or below mean • Trend • Erratic behavior

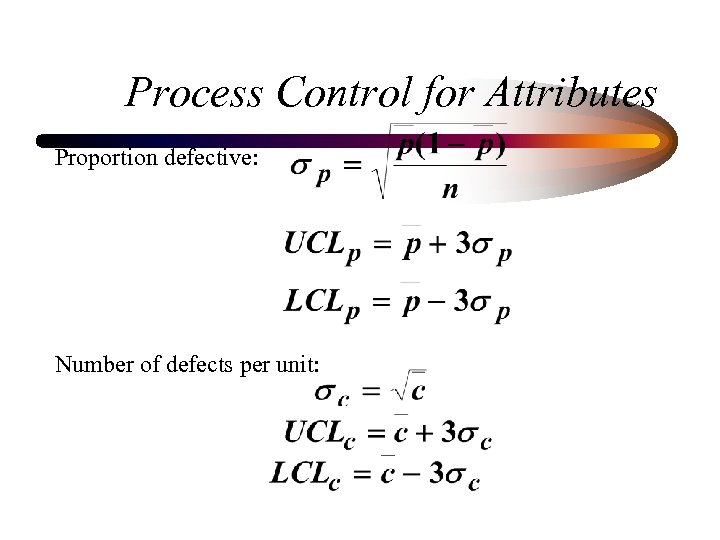

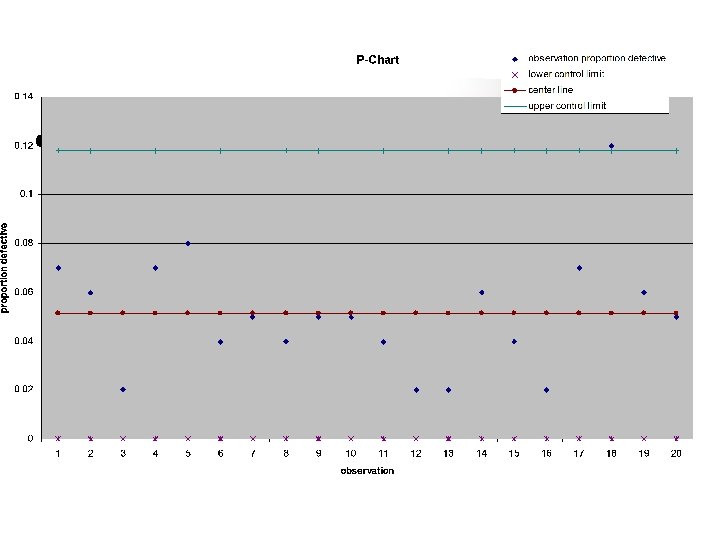

Process Control for Attributes Proportion defective: Number of defects per unit:

Process Control for Attributes Proportion defective: Number of defects per unit:

Homework • Chapter 11 – 4, 8, 9

Homework • Chapter 11 – 4, 8, 9