572a57863fb0edc6a56b2621406f82e2.ppt

- Количество слайдов: 25

Chapter 10 Material & Information Flow Management in Channel

Chapter 10 Material & Information Flow Management in Channel

Ⅰ Material Flow & Logistics System

Ⅰ Material Flow & Logistics System

Thinking 1: PD or Logistics Thinking 2: content of logistics system Thinking 3: task and goal of logistics Thinking 4: programming and management of logistics

Thinking 1: PD or Logistics Thinking 2: content of logistics system Thinking 3: task and goal of logistics Thinking 4: programming and management of logistics

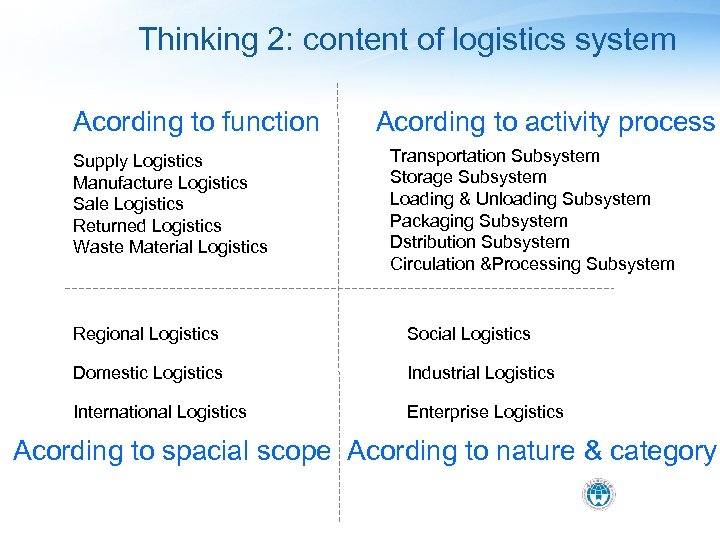

Thinking 2: content of logistics system Acording to function Supply Logistics Manufacture Logistics Sale Logistics Returned Logistics Waste Material Logistics Acording to activity process Transportation Subsystem Storage Subsystem Loading & Unloading Subsystem Packaging Subsystem Dstribution Subsystem Circulation &Processing Subsystem Regional Logistics Social Logistics Domestic Logistics Industrial Logistics International Logistics Enterprise Logistics Acording to spacial scope Acording to nature & category

Thinking 2: content of logistics system Acording to function Supply Logistics Manufacture Logistics Sale Logistics Returned Logistics Waste Material Logistics Acording to activity process Transportation Subsystem Storage Subsystem Loading & Unloading Subsystem Packaging Subsystem Dstribution Subsystem Circulation &Processing Subsystem Regional Logistics Social Logistics Domestic Logistics Industrial Logistics International Logistics Enterprise Logistics Acording to spacial scope Acording to nature & category

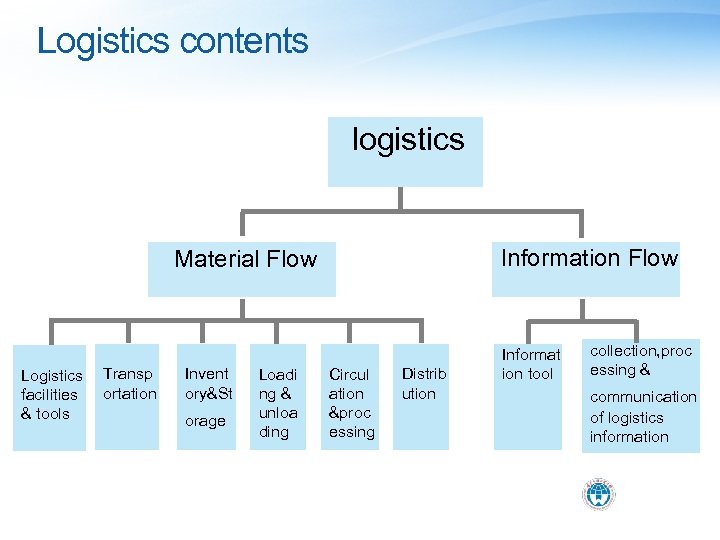

Logistics contents logistics Information Flow Material Flow Logistics facilities & tools Transp ortation Invent ory&St orage Loadi ng & unloa ding Circul ation &proc essing Distrib ution Informat ion tool collection, proc essing & communication of logistics information

Logistics contents logistics Information Flow Material Flow Logistics facilities & tools Transp ortation Invent ory&St orage Loadi ng & unloa ding Circul ation &proc essing Distrib ution Informat ion tool collection, proc essing & communication of logistics information

Thinking 3: task and goal of logistics Quick Response Maximum Transportation Amount Consolidation Minimum Inventory Relatively Balanced (Minimum Change) Total Quality Control Life Cycle Support

Thinking 3: task and goal of logistics Quick Response Maximum Transportation Amount Consolidation Minimum Inventory Relatively Balanced (Minimum Change) Total Quality Control Life Cycle Support

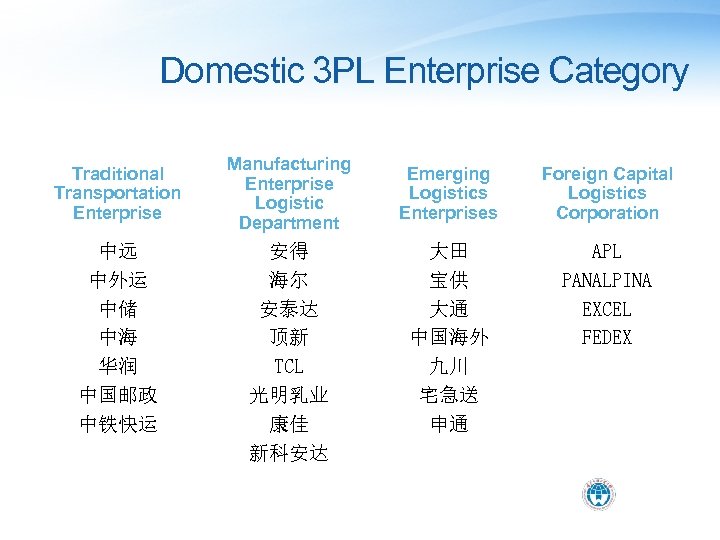

Domestic 3 PL Enterprise Category Traditional Transportation Enterprise 中远 中外运 中储 中海 华润 中国邮政 中铁快运 Manufacturing Enterprise Logistic Department 安得 海尔 安泰达 顶新 TCL 光明乳业 康佳 新科安达 Emerging Logistics Enterprises Foreign Capital Logistics Corporation 大田 宝供 大通 中国海外 九川 宅急送 申通 APL PANALPINA EXCEL FEDEX

Domestic 3 PL Enterprise Category Traditional Transportation Enterprise 中远 中外运 中储 中海 华润 中国邮政 中铁快运 Manufacturing Enterprise Logistic Department 安得 海尔 安泰达 顶新 TCL 光明乳业 康佳 新科安达 Emerging Logistics Enterprises Foreign Capital Logistics Corporation 大田 宝供 大通 中国海外 九川 宅急送 申通 APL PANALPINA EXCEL FEDEX

Thinking 4: programming and management of logistics D=T+FW+VW+S D: total cost of logistics system T: transportation cost of this system FW: fixed inventory cost of this system VW: total variable inventory cost of this system S: total opportunity cost of loss on sale caused by delayed distribution

Thinking 4: programming and management of logistics D=T+FW+VW+S D: total cost of logistics system T: transportation cost of this system FW: fixed inventory cost of this system VW: total variable inventory cost of this system S: total opportunity cost of loss on sale caused by delayed distribution

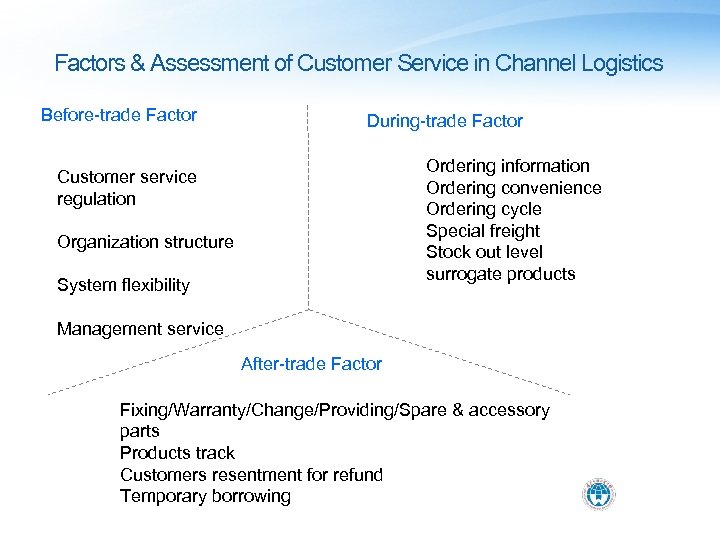

Factors & Assessment of Customer Service in Channel Logistics Before-trade Factor During-trade Factor Ordering information Ordering convenience Ordering cycle Special freight Stock out level surrogate products Customer service regulation Organization structure System flexibility Management service After-trade Factor Fixing/Warranty/Change/Providing/Spare & accessory parts Products track Customers resentment for refund Temporary borrowing

Factors & Assessment of Customer Service in Channel Logistics Before-trade Factor During-trade Factor Ordering information Ordering convenience Ordering cycle Special freight Stock out level surrogate products Customer service regulation Organization structure System flexibility Management service After-trade Factor Fixing/Warranty/Change/Providing/Spare & accessory parts Products track Customers resentment for refund Temporary borrowing

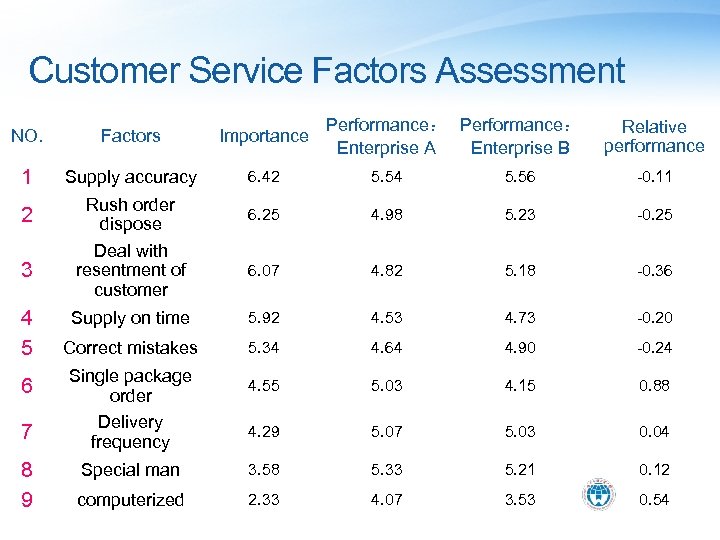

Customer Service Factors Assessment Performance: Enterprise A Enterprise B Relative performance NO. Factors Importance 1 Supply accuracy 6. 42 5. 54 5. 56 -0. 11 2 Rush order dispose Deal with resentment of customer 6. 25 4. 98 5. 23 -0. 25 6. 07 4. 82 5. 18 -0. 36 Supply on time 5. 92 4. 53 4. 73 -0. 20 Correct mistakes 5. 34 4. 64 4. 90 -0. 24 4. 55 5. 03 4. 15 0. 88 4. 29 5. 07 5. 03 0. 04 Special man 3. 58 5. 33 5. 21 0. 12 computerized 2. 33 4. 07 3. 53 0. 54 3 4 5 6 7 8 9 Single package order Delivery frequency

Customer Service Factors Assessment Performance: Enterprise A Enterprise B Relative performance NO. Factors Importance 1 Supply accuracy 6. 42 5. 54 5. 56 -0. 11 2 Rush order dispose Deal with resentment of customer 6. 25 4. 98 5. 23 -0. 25 6. 07 4. 82 5. 18 -0. 36 Supply on time 5. 92 4. 53 4. 73 -0. 20 Correct mistakes 5. 34 4. 64 4. 90 -0. 24 4. 55 5. 03 4. 15 0. 88 4. 29 5. 07 5. 03 0. 04 Special man 3. 58 5. 33 5. 21 0. 12 computerized 2. 33 4. 07 3. 53 0. 54 3 4 5 6 7 8 9 Single package order Delivery frequency

Transportation Management 2)Optimization of Transportation Line 1)Selection of Transportation Mode

Transportation Management 2)Optimization of Transportation Line 1)Selection of Transportation Mode

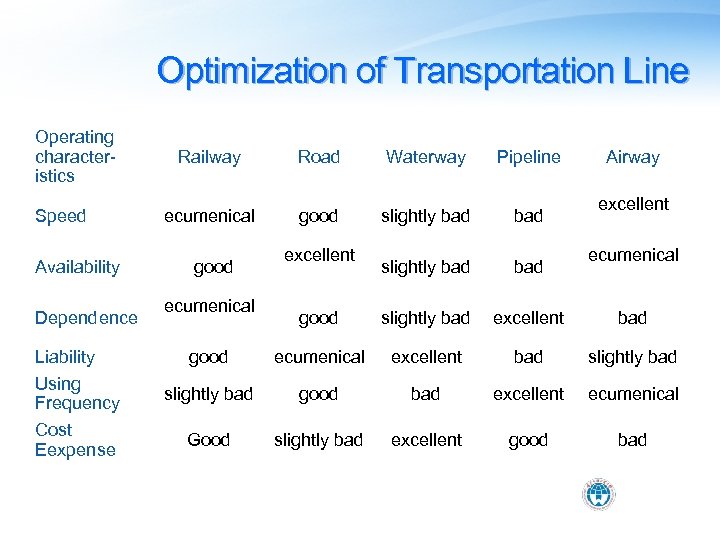

Optimization of Transportation Line Operating characteristics Speed Availability Dependence Liability Using Frequency Cost Eexpense Railway Road Waterway Pipeline ecumenical good slightly bad bad good slightly bad excellent bad good ecumenical excellent bad slightly bad good bad excellent ecumenical Good slightly bad excellent good bad good ecumenical excellent Airway excellent ecumenical

Optimization of Transportation Line Operating characteristics Speed Availability Dependence Liability Using Frequency Cost Eexpense Railway Road Waterway Pipeline ecumenical good slightly bad bad good slightly bad excellent bad good ecumenical excellent bad slightly bad good bad excellent ecumenical Good slightly bad excellent good bad good ecumenical excellent Airway excellent ecumenical

Inventory Management Products Storage Management Content Warehouse Selection Identify the warehouse category Identify the warehouse size Identify the warehouse location Inventory control Inventory Daily inventory management Management Stock anaysis

Inventory Management Products Storage Management Content Warehouse Selection Identify the warehouse category Identify the warehouse size Identify the warehouse location Inventory control Inventory Daily inventory management Management Stock anaysis

Method to Identify the Optimal Ordering Amount 1)EOQ 2) ABC Classification Method 3) Material Requirements Planning MRP II (Manufacturing Resource) 4)JIT 5)Enterprise Requirements Planning 6)QR 7)ECR

Method to Identify the Optimal Ordering Amount 1)EOQ 2) ABC Classification Method 3) Material Requirements Planning MRP II (Manufacturing Resource) 4)JIT 5)Enterprise Requirements Planning 6)QR 7)ECR

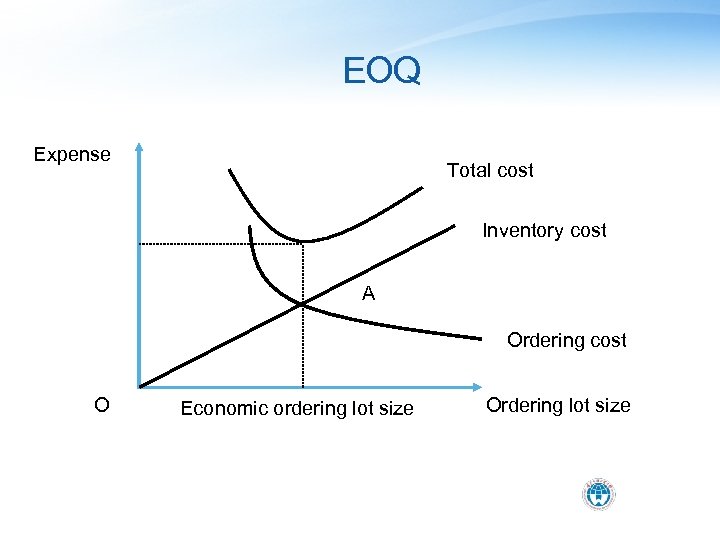

EOQ Expense Total cost Inventory cost A Ordering cost O Economic ordering lot size Ordering lot size

EOQ Expense Total cost Inventory cost A Ordering cost O Economic ordering lot size Ordering lot size

Explaination for the EOQ Model Ordering cost and inventory cost changing with amount of ordering lot size respectivrly. Ordering cost decreasing with increasing of ordering lot size; inventory cost increasing with increasing of ordering lot size. Point A stands for economic ordering lot size, or economic ordering amount.

Explaination for the EOQ Model Ordering cost and inventory cost changing with amount of ordering lot size respectivrly. Ordering cost decreasing with increasing of ordering lot size; inventory cost increasing with increasing of ordering lot size. Point A stands for economic ordering lot size, or economic ordering amount.

Ⅱ Channel Information System

Ⅱ Channel Information System

Channel Information System Defined Channel information system An integrated man-machine system, aiming at improving effect and efficiency of enterprise strategy. It is humanoriented and manage information by computer. Nature A management system & A social system

Channel Information System Defined Channel information system An integrated man-machine system, aiming at improving effect and efficiency of enterprise strategy. It is humanoriented and manage information by computer. Nature A management system & A social system

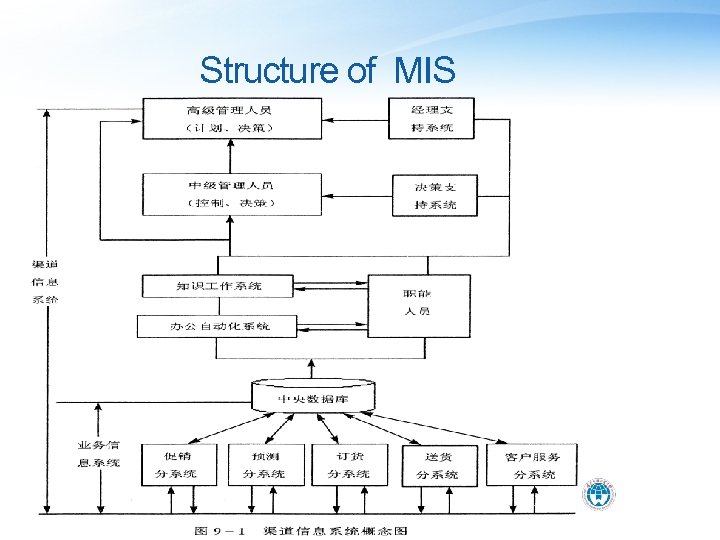

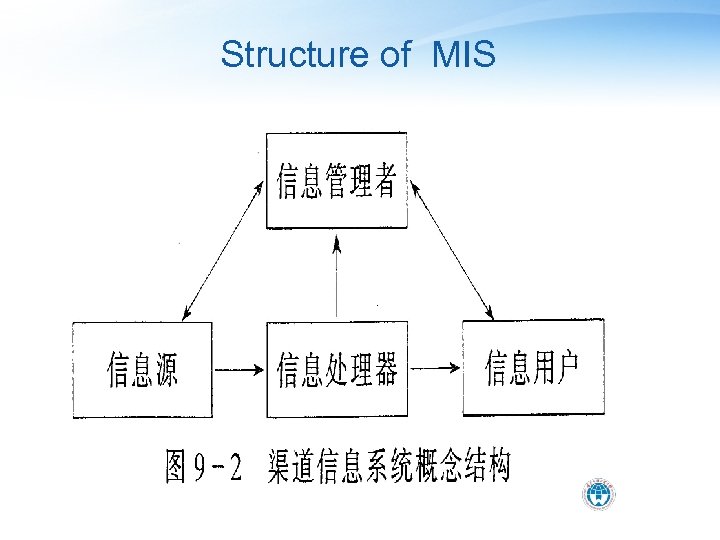

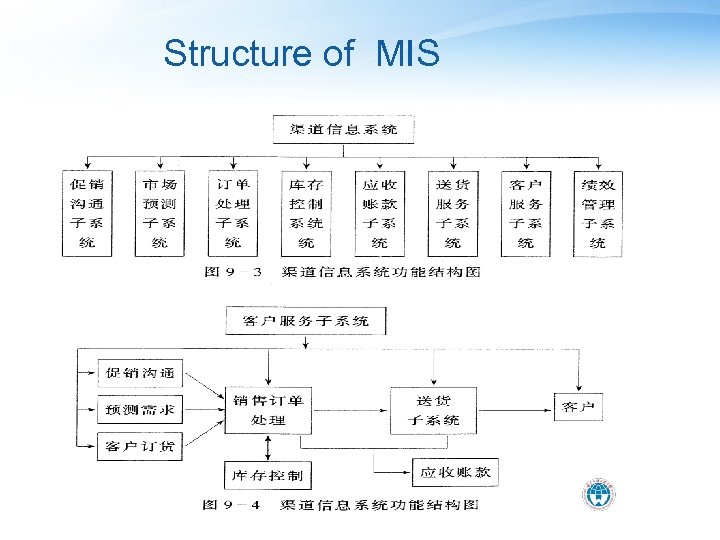

Structure of MIS

Structure of MIS

Structure of MIS

Structure of MIS

Structure of MIS

Structure of MIS

Headquarters/Franchisers/ Information Management Stores Management Technology Among System Channel Members

Headquarters/Franchisers/ Information Management Stores Management Technology Among System Channel Members

Analysis of Channel Information Process Sale Management Delivery Management Promotion Management Customer Management Inventory Management Accounts Receivable/payable Purchasing Management After-sale service

Analysis of Channel Information Process Sale Management Delivery Management Promotion Management Customer Management Inventory Management Accounts Receivable/payable Purchasing Management After-sale service

Function of Channel Information System Supporting distribution rear services strongly Assessing adjust channel members Facilitating and improving rear services data exchange Used in non-channel management

Function of Channel Information System Supporting distribution rear services strongly Assessing adjust channel members Facilitating and improving rear services data exchange Used in non-channel management

Thank you for your time!

Thank you for your time!