3979abc29f3489dddeb63180a309ad98.ppt

- Количество слайдов: 110

CF 3000 Addressable Fire Detection System

Introduction History • JSB and Menvier • Acquired by Cooper Industries ~1999 / 2000 • Analogue Addressable CF 3000 range • Started development approx 2004 • Rationalisation of the legacy technology into one new platform • To develop an entire single-manufacturer range • Includes CF 3000, DF 6000, FX 6000 • Fire Detection • Voice Evacuation, • Emergency Voice Communication Systems

Introduction Agenda • Introduction • Concept of Operation • Control Panels • Addressable Devices • Networking • Operation, Commissioning and Fault Finding

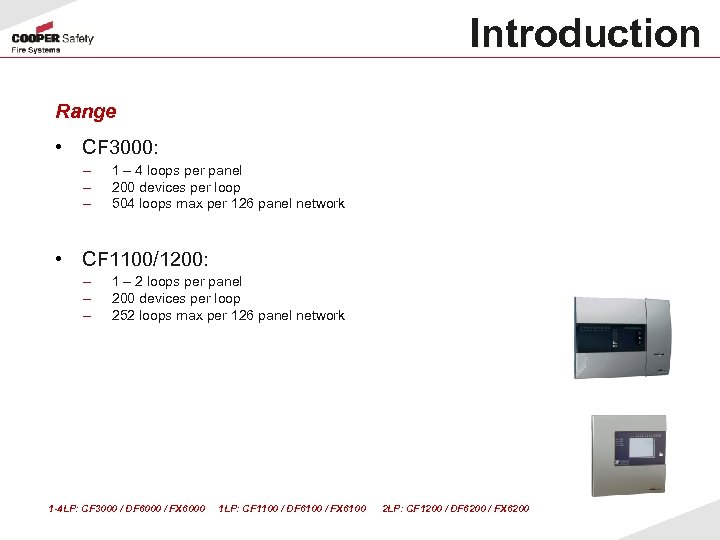

Introduction Range • CF 3000: – – – 1 – 4 loops per panel 200 devices per loop 504 loops max per 126 panel network • CF 1100/1200: – – – 1 – 2 loops per panel 200 devices per loop 252 loops max per 126 panel network 1 -4 LP: CF 3000 / DF 6000 / FX 6000 1 LP: CF 1100 / DF 6100 / FX 6100 2 LP: CF 1200 / DF 6200 / FX 6200

Introduction Key Features • UL and EN 54 Certification • 1, 2 or 4 loops per panel • 200 addresses per loop – – Max 512 detection devices per panel for EN 54 Recommended 150 devices per loop for practical application • Software Allocated Addressing – Optional hard addressing via CF 800 PROG • Network up to 126 panels – (504 or 252 max) • 96 Zone LED indication – 250 Zones per panel in configuration software

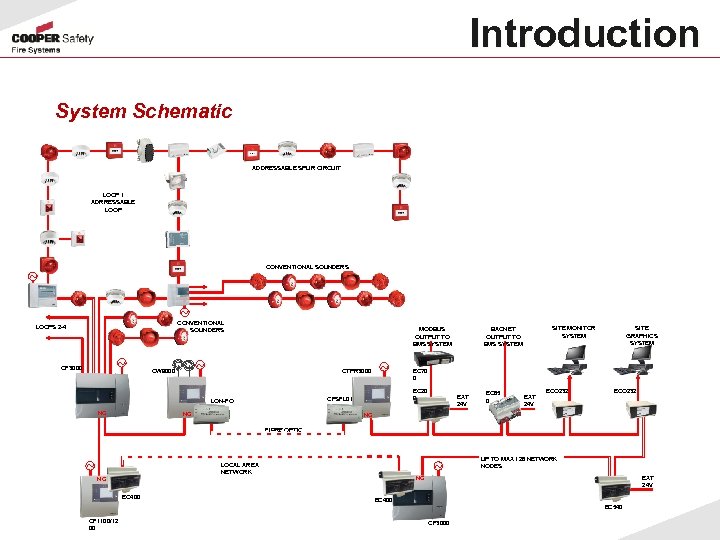

Introduction System Schematic ADDRESSABLE SPUR CIRCUIT LOOP 1 ADRRESSABLE LOOP CONVENTIONAL SOUNDERS ~ ~ CONVENTIONAL SOUNDERS LOOPS 2 -4 ~ CF 3000 MODBUS OUTPUT TO BMS SYSTEM ~ CW 9000 CTPR 3000 NC SITE GRAPHICS SYSTEM EC 70 0 EC 20 0 CFSFL 01 LON-FO NC ~ SITE MONITOR SYSTEM BACNET OUTPUT TO BMS SYSTEM EXT 24 V EC 65 0 EXT 24 V ECO 232 NC FIBRE OPTIC ~ LOCAL AREA NETWORK NC NC EC 400 ~ UP TO MAX 126 NETWORK NODES EXT 24 V EC 400 EC 540 CF 1100/12 00 CF 3000

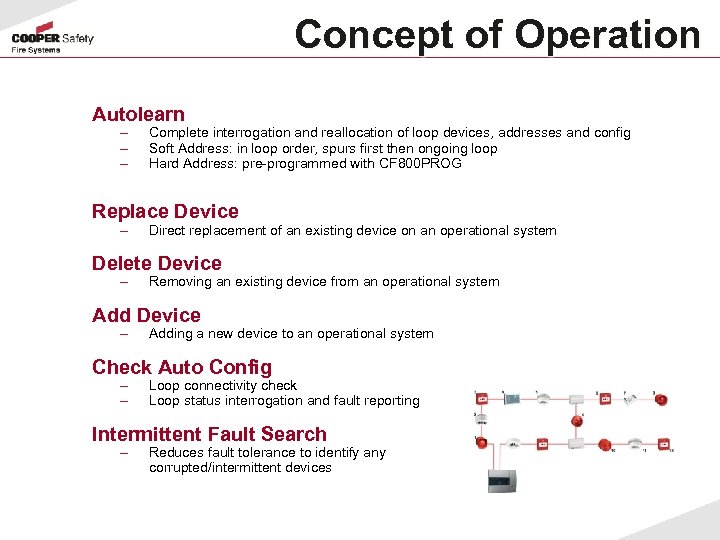

Concept of Operation Autolearn – – – Complete interrogation and reallocation of loop devices, addresses and config Soft Address: in loop order, spurs first then ongoing loop Hard Address: pre-programmed with CF 800 PROG Replace Device – Direct replacement of an existing device on an operational system Delete Device – Removing an existing device from an operational system Add Device – Adding a new device to an operational system Check Auto Config – – Loop connectivity check Loop status interrogation and fault reporting Intermittent Fault Search – Reduces fault tolerance to identify any corrupted/intermittent devices

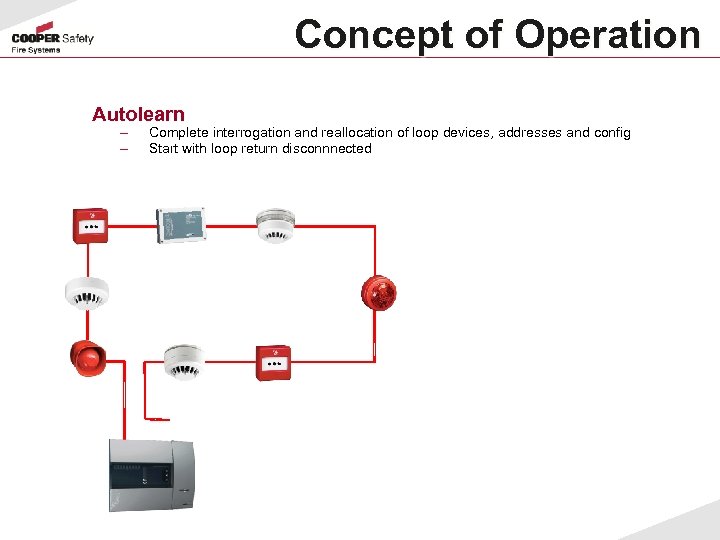

Concept of Operation Autolearn – – Complete interrogation and reallocation of loop devices, addresses and config Start with loop return disconnnected

Concept of Operation 001 Panel>>>> All isolators O/C

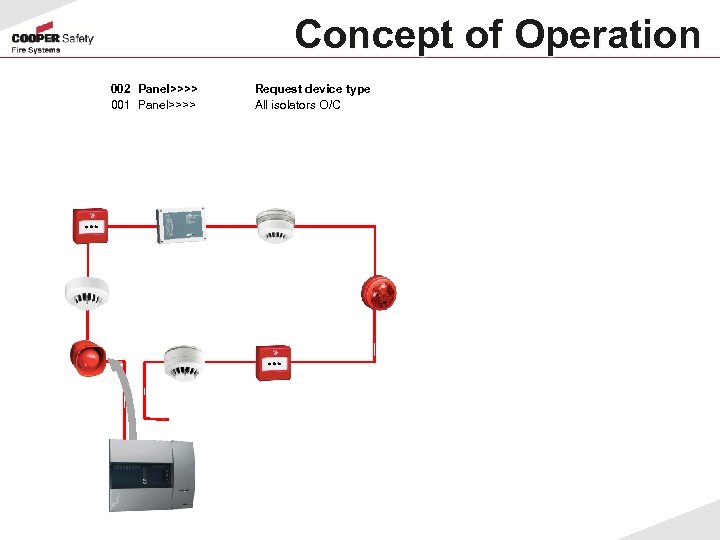

Concept of Operation 002 Panel>>>> 001 Panel>>>> Request device type All isolators O/C

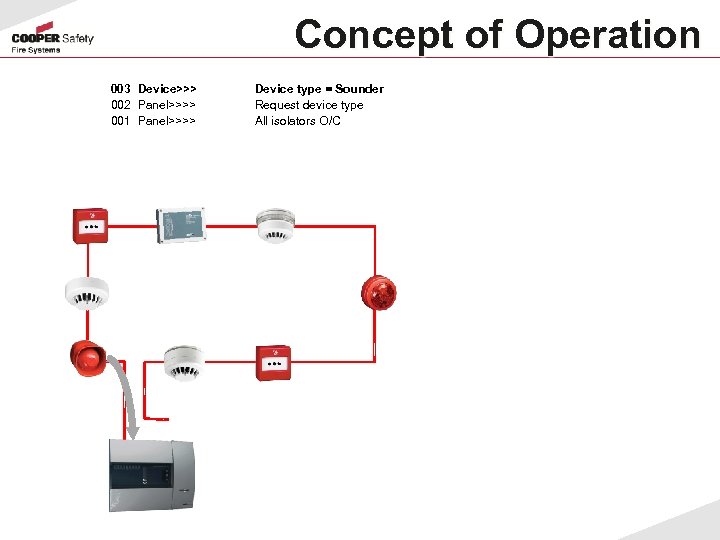

Concept of Operation 003 Device>>> 002 Panel>>>> 001 Panel>>>> Device type = Sounder Request device type All isolators O/C

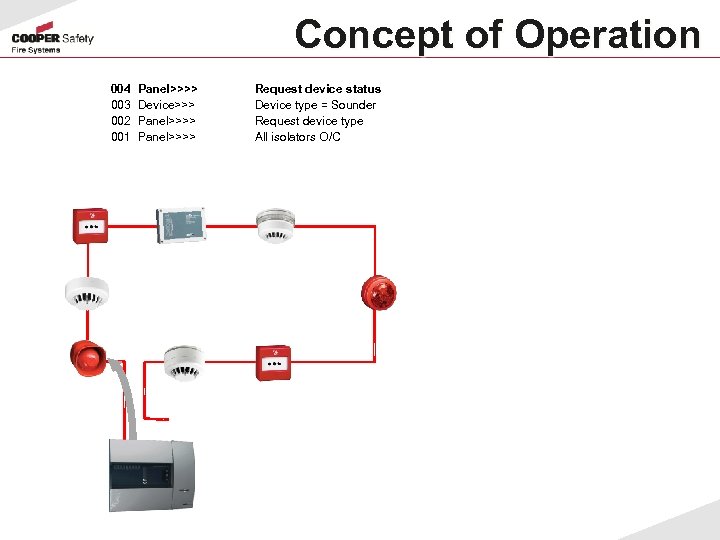

Concept of Operation 004 003 002 001 Panel>>>> Device>>> Panel>>>> Request device status Device type = Sounder Request device type All isolators O/C

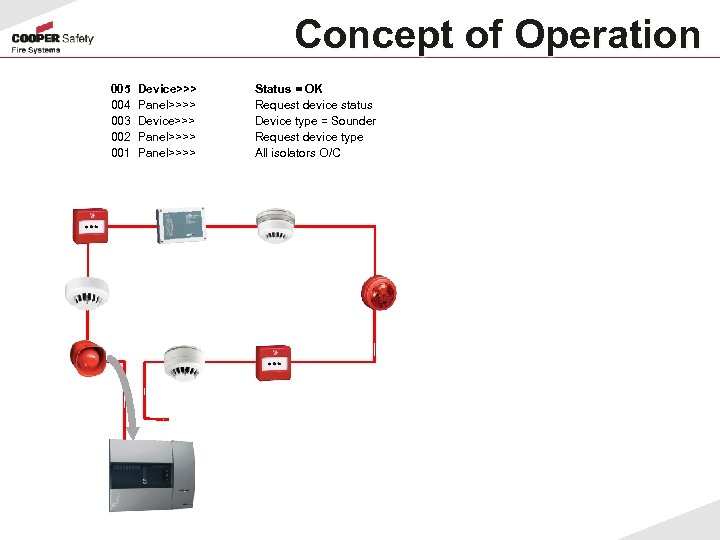

Concept of Operation 005 004 003 002 001 Device>>> Panel>>>> Status = OK Request device status Device type = Sounder Request device type All isolators O/C

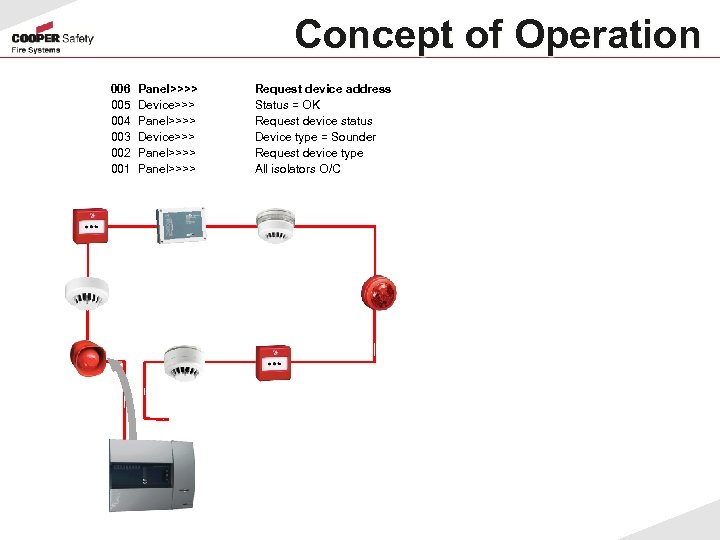

Concept of Operation 006 005 004 003 002 001 Panel>>>> Device>>> Panel>>>> Request device address Status = OK Request device status Device type = Sounder Request device type All isolators O/C

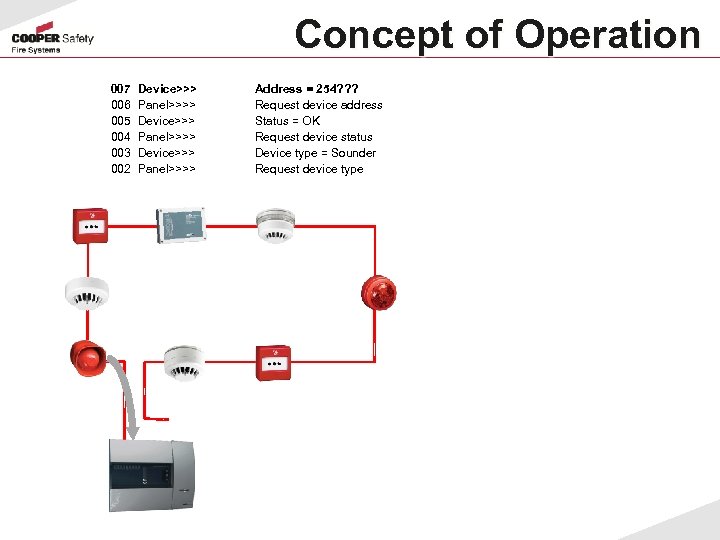

Concept of Operation 007 006 005 004 003 002 Device>>> Panel>>>> Address = 254? ? ? Request device address Status = OK Request device status Device type = Sounder Request device type

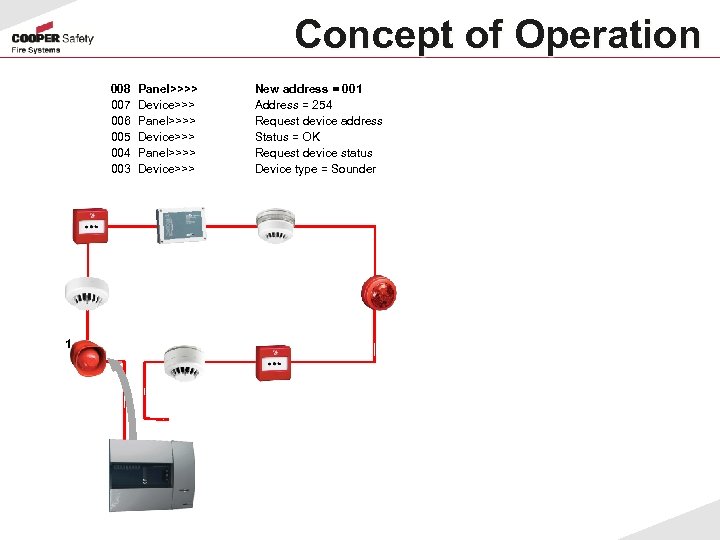

Concept of Operation 008 007 006 005 004 003 1 Panel>>>> Device>>> New address = 001 Address = 254 Request device address Status = OK Request device status Device type = Sounder

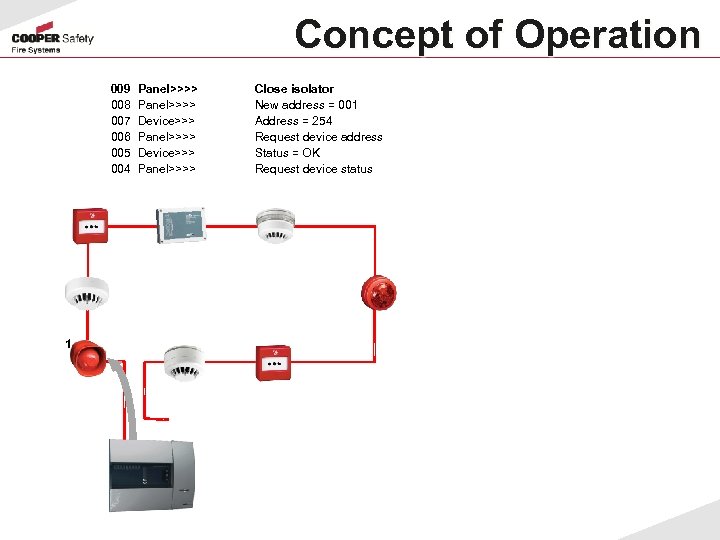

Concept of Operation 009 008 007 006 005 004 1 Panel>>>> Device>>> Panel>>>> Close isolator New address = 001 Address = 254 Request device address Status = OK Request device status

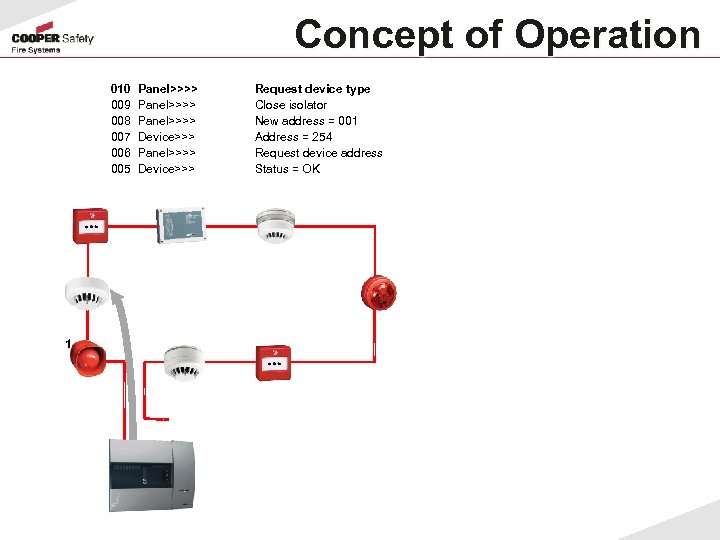

Concept of Operation 010 009 008 007 006 005 1 Panel>>>> Device>>> Request device type Close isolator New address = 001 Address = 254 Request device address Status = OK

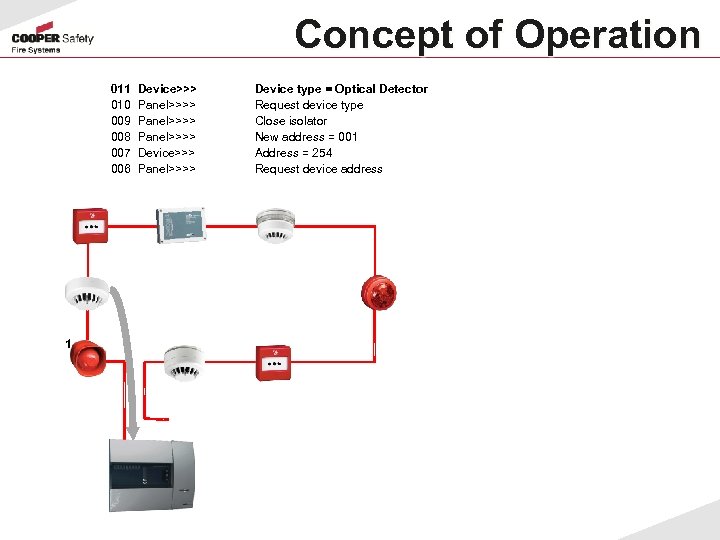

Concept of Operation 011 010 009 008 007 006 1 Device>>> Panel>>>> Device type = Optical Detector Request device type Close isolator New address = 001 Address = 254 Request device address

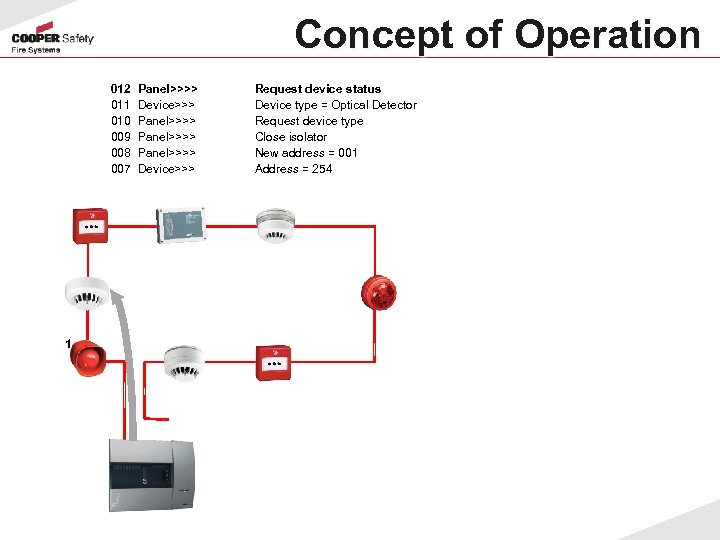

Concept of Operation 012 011 010 009 008 007 1 Panel>>>> Device>>> Panel>>>> Device>>> Request device status Device type = Optical Detector Request device type Close isolator New address = 001 Address = 254

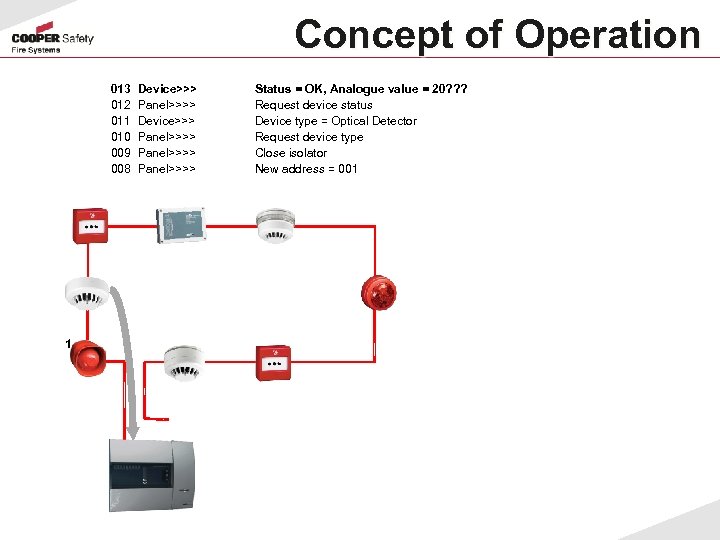

Concept of Operation 013 012 011 010 009 008 1 Device>>> Panel>>>> Status = OK, Analogue value = 20? ? ? Request device status Device type = Optical Detector Request device type Close isolator New address = 001

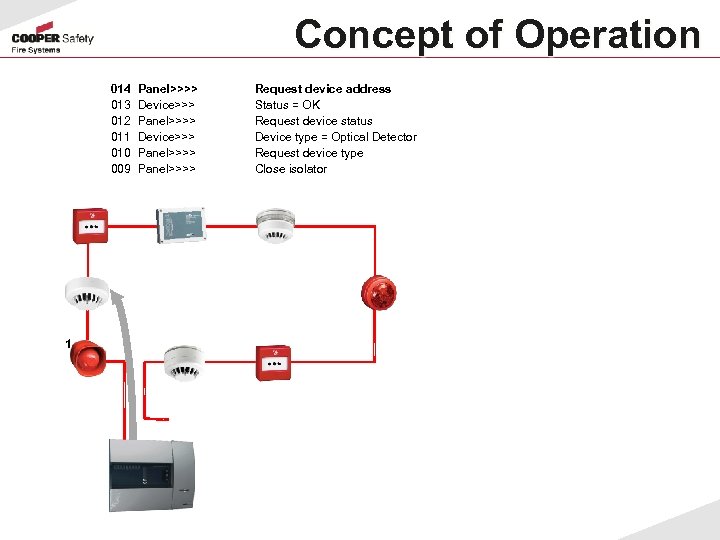

Concept of Operation 014 013 012 011 010 009 1 Panel>>>> Device>>> Panel>>>> Request device address Status = OK Request device status Device type = Optical Detector Request device type Close isolator

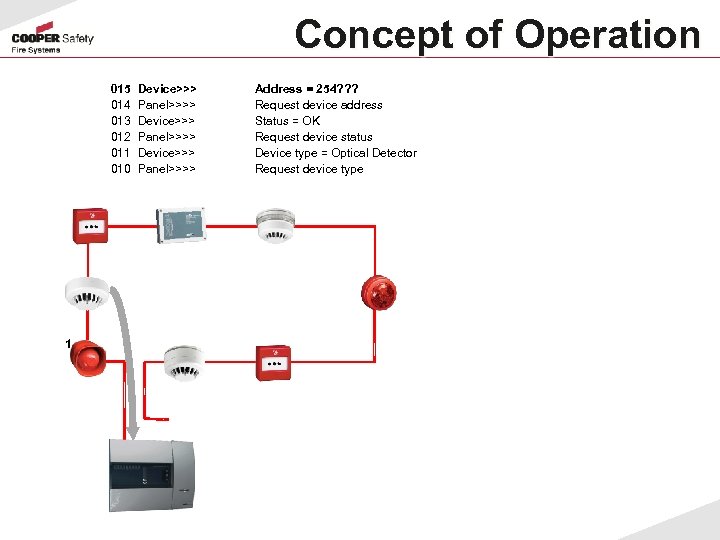

Concept of Operation 015 014 013 012 011 010 1 Device>>> Panel>>>> Address = 254? ? ? Request device address Status = OK Request device status Device type = Optical Detector Request device type

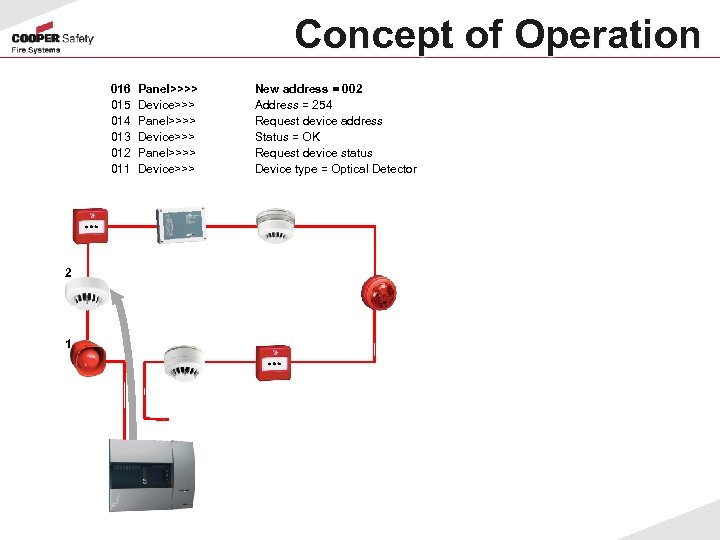

Concept of Operation 016 015 014 013 012 011 2 1 Panel>>>> Device>>> New address = 002 Address = 254 Request device address Status = OK Request device status Device type = Optical Detector

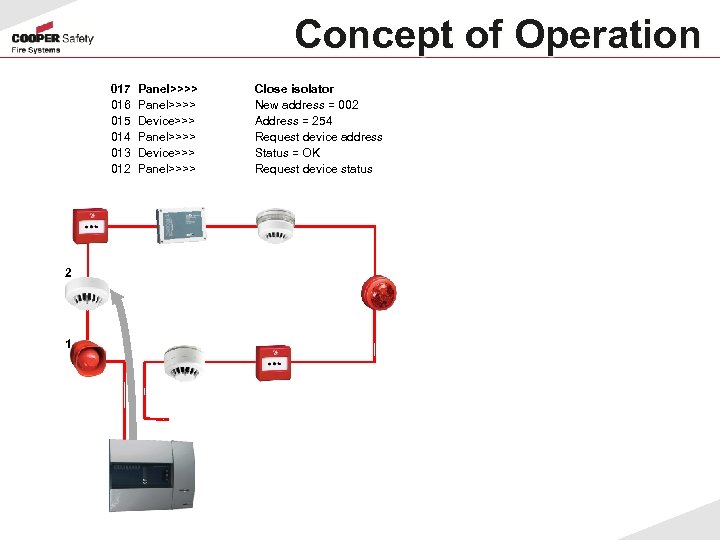

Concept of Operation 017 016 015 014 013 012 2 1 Panel>>>> Device>>> Panel>>>> Close isolator New address = 002 Address = 254 Request device address Status = OK Request device status

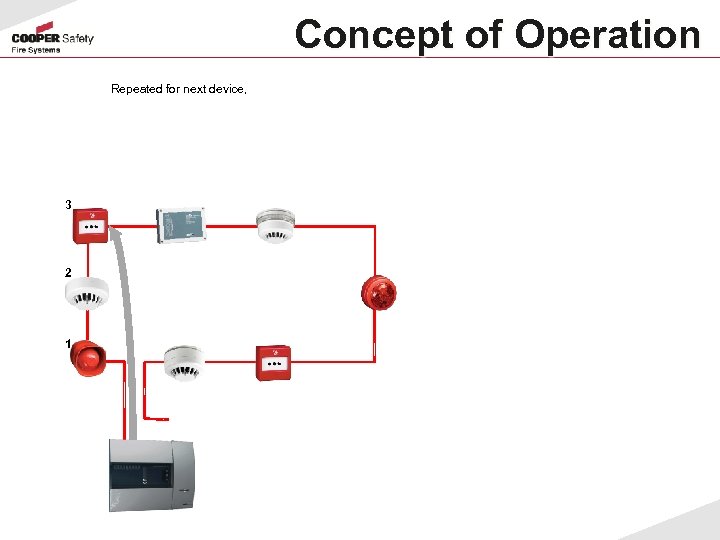

Concept of Operation Repeated for next device, 3 2 1

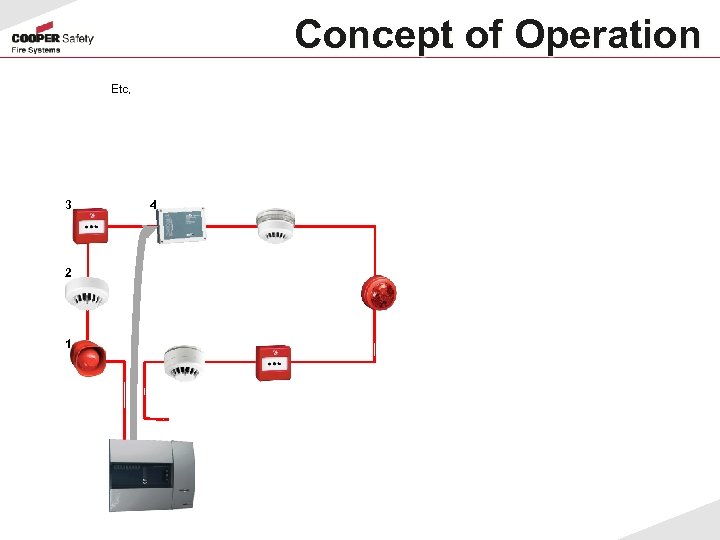

Concept of Operation Etc, 3 2 1 4

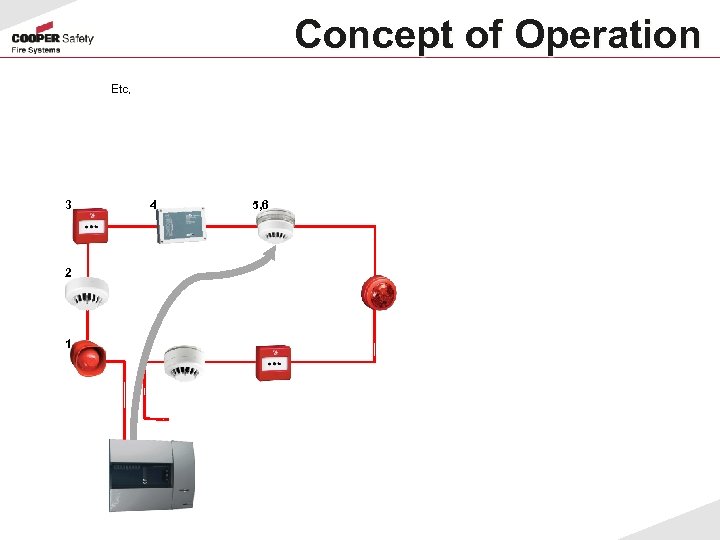

Concept of Operation Etc, 3 2 1 4 5, 6

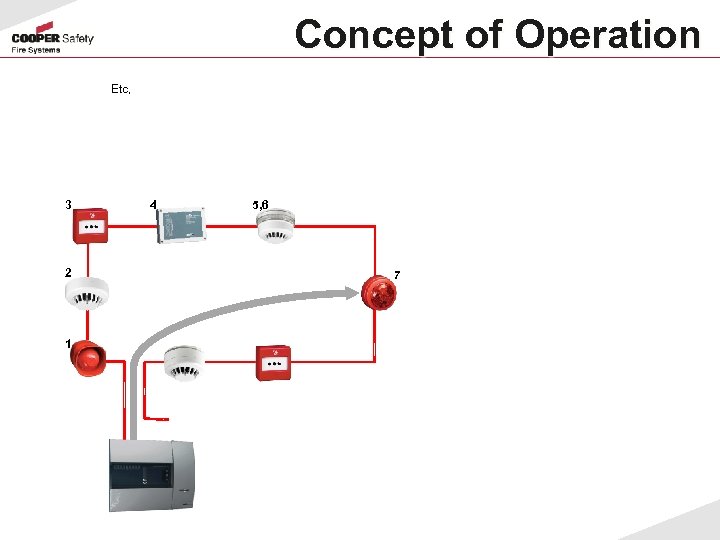

Concept of Operation Etc, 3 2 1 4 5, 6 7

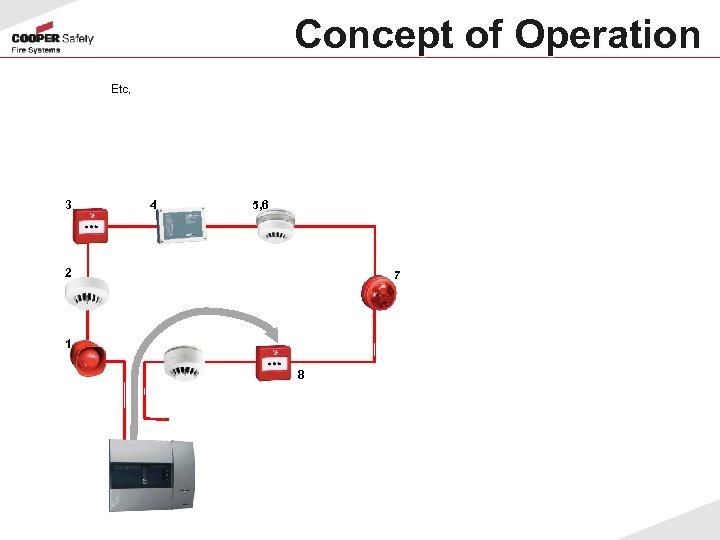

Concept of Operation Etc, 3 4 5, 6 2 7 1 8

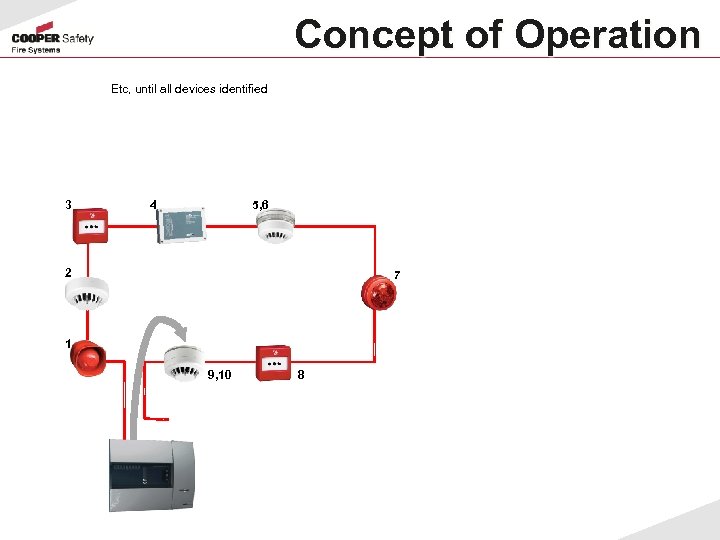

Concept of Operation Etc, until all devices identified 3 4 5, 6 2 7 1 9, 10 8

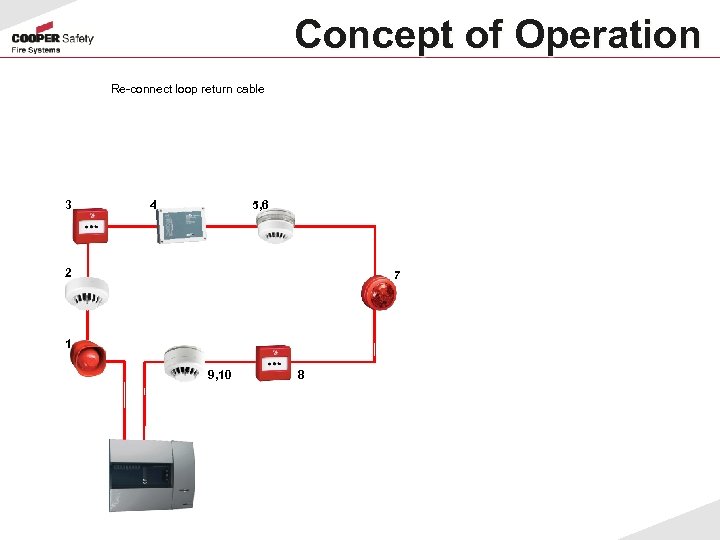

Concept of Operation Re-connect loop return cable 3 4 5, 6 2 7 1 9, 10 8

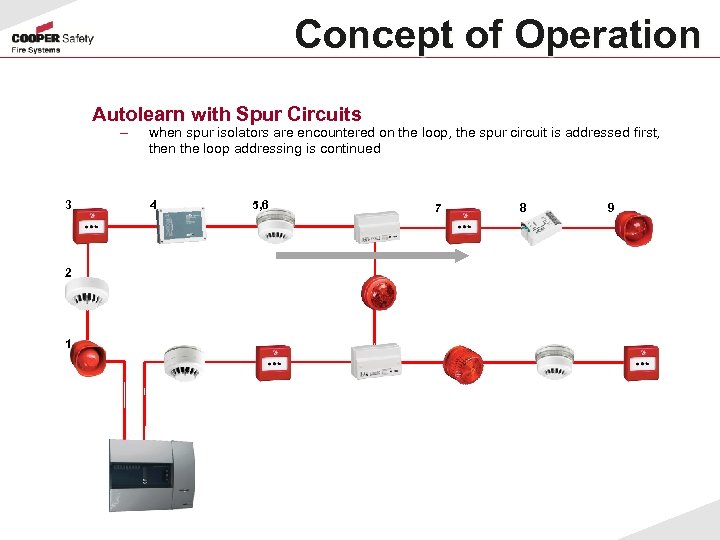

Concept of Operation Autolearn with Spur Circuits – 3 2 1 when spur isolators are encountered on the loop, the spur circuit is addressed first, then the loop addressing is continued 4 5, 6 5 7 8 9

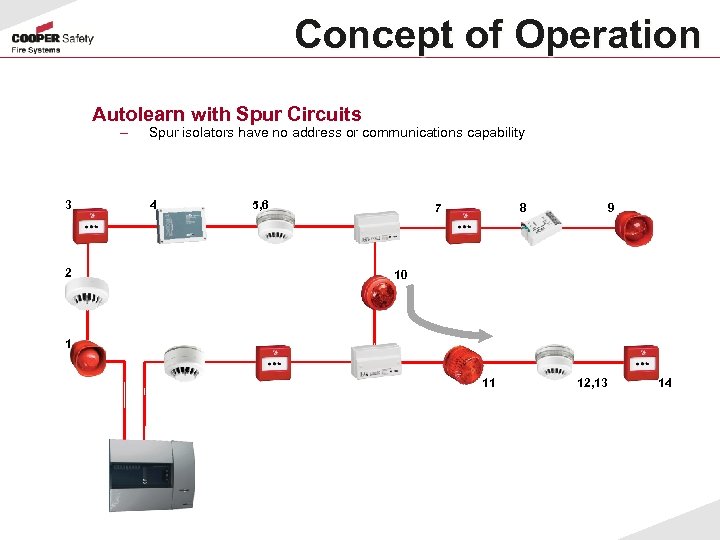

Concept of Operation Autolearn with Spur Circuits – 3 2 Spur isolators have no address or communications capability 4 5, 6 7 9 8 10 1 11 12, 13 14

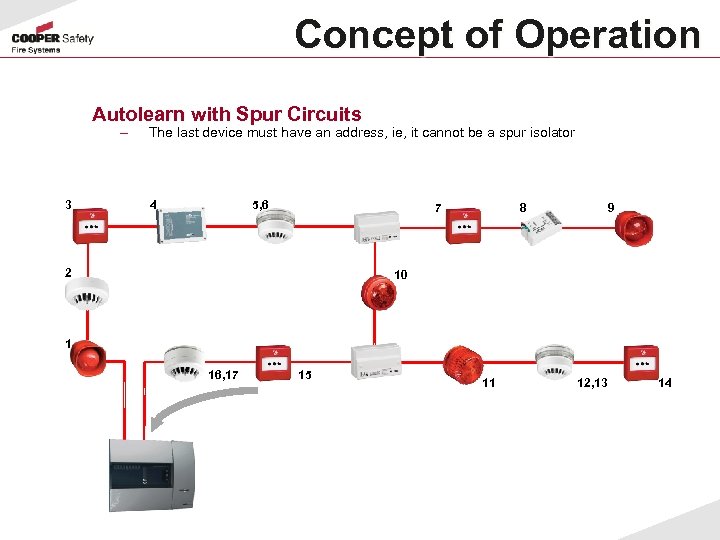

Concept of Operation Autolearn with Spur Circuits – 3 The last device must have an address, ie, it cannot be a spur isolator 4 5, 6 7 2 9 8 10 1 16, 17 15 11 12, 13 14

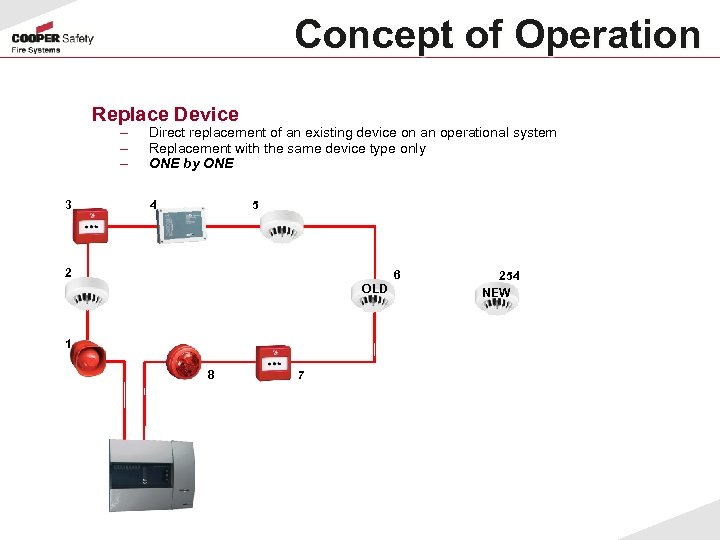

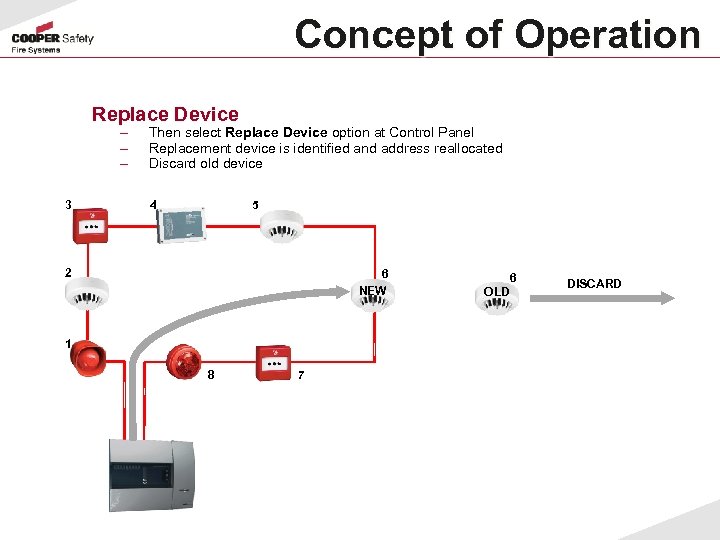

Concept of Operation Replace Device – – – 3 Direct replacement of an existing device on an operational system Replacement with the same device type only ONE by ONE 4 5 2 6 OLD 1 8 7 254 NEW

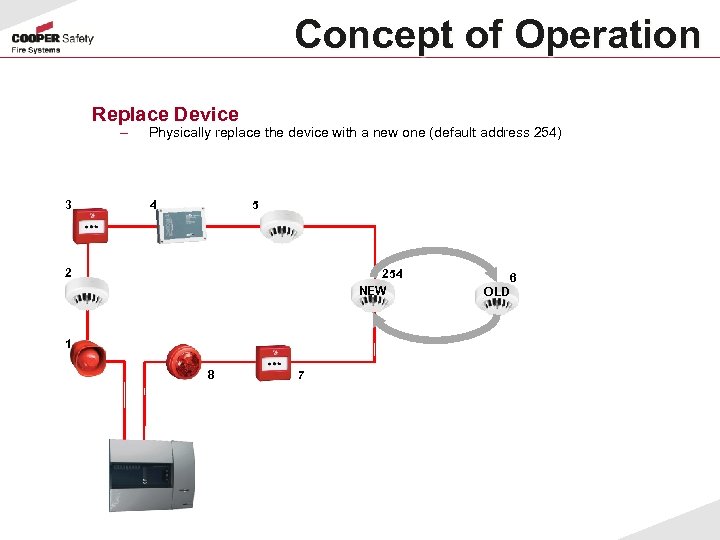

Concept of Operation Replace Device – 3 Physically replace the device with a new one (default address 254) 4 5 2 254 NEW 1 8 7 6 OLD

Concept of Operation Replace Device – – – 3 Then select Replace Device option at Control Panel Replacement device is identified and address reallocated Discard old device 4 5 2 6 NEW 1 8 7 6 OLD DISCARD

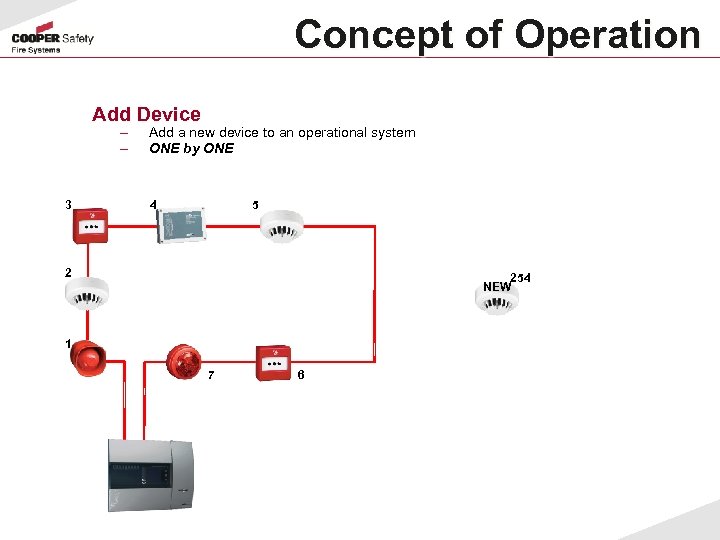

Concept of Operation Add Device – – 3 Add a new device to an operational system ONE by ONE 4 5 2 254 NEW 1 7 6

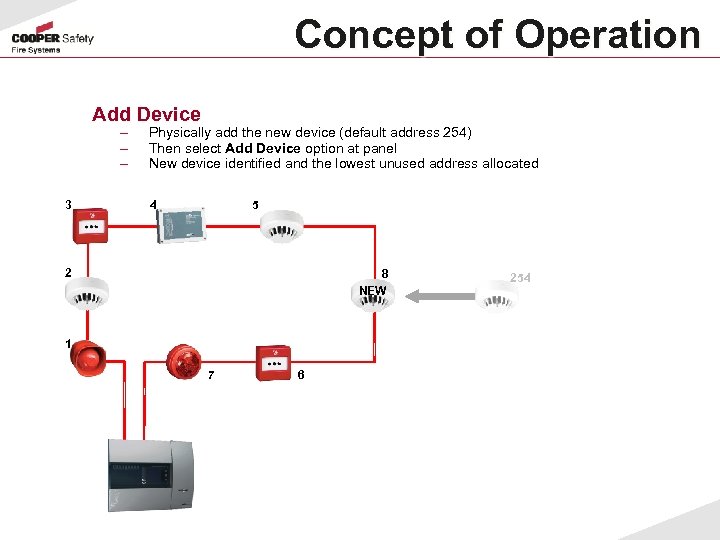

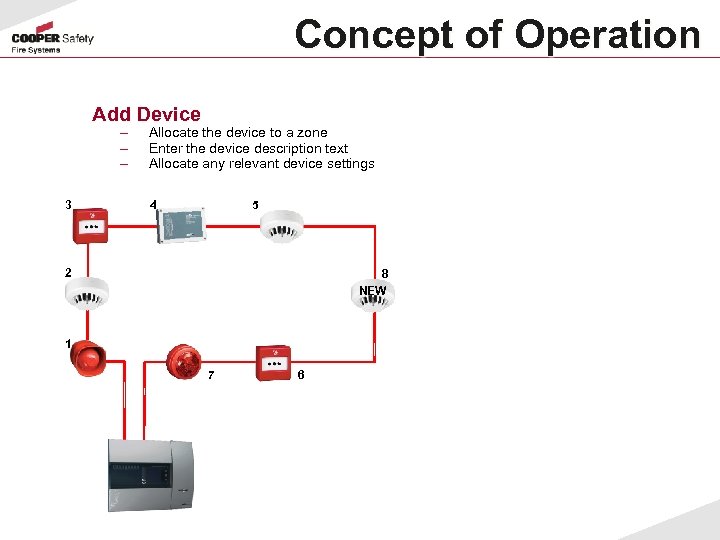

Concept of Operation Add Device – – – 3 Physically add the new device (default address 254) Then select Add Device option at panel New device identified and the lowest unused address allocated 4 5 2 8 NEW 1 7 6 254

Concept of Operation Add Device – – – 3 Allocate the device to a zone Enter the device description text Allocate any relevant device settings 4 5 2 8 NEW 1 7 6

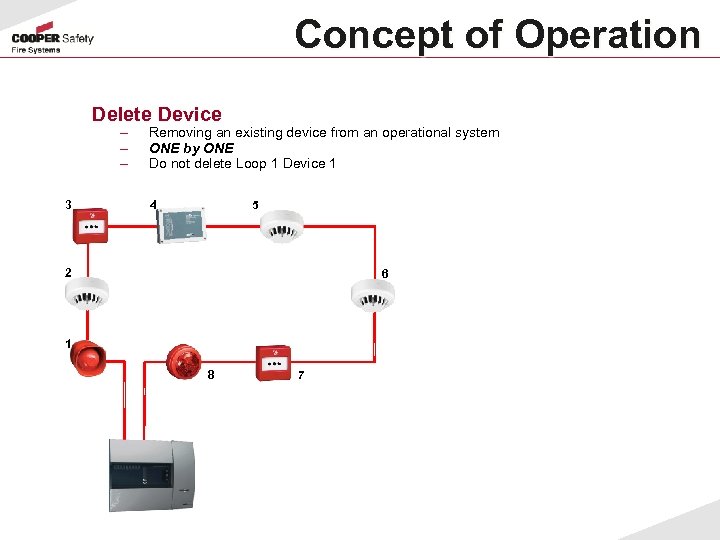

Concept of Operation Delete Device – – – 3 Removing an existing device from an operational system ONE by ONE Do not delete Loop 1 Device 1 4 5 2 6 1 8 7

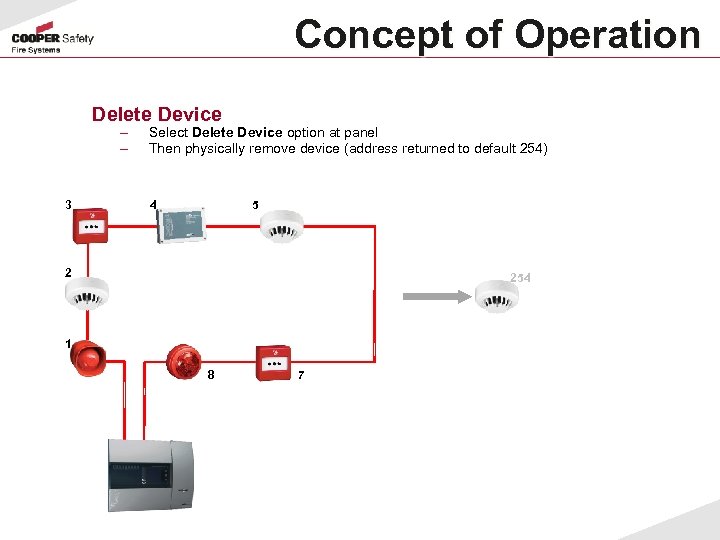

Concept of Operation Delete Device – – 3 Select Delete Device option at panel Then physically remove device (address returned to default 254) 4 5 2 254 1 8 7

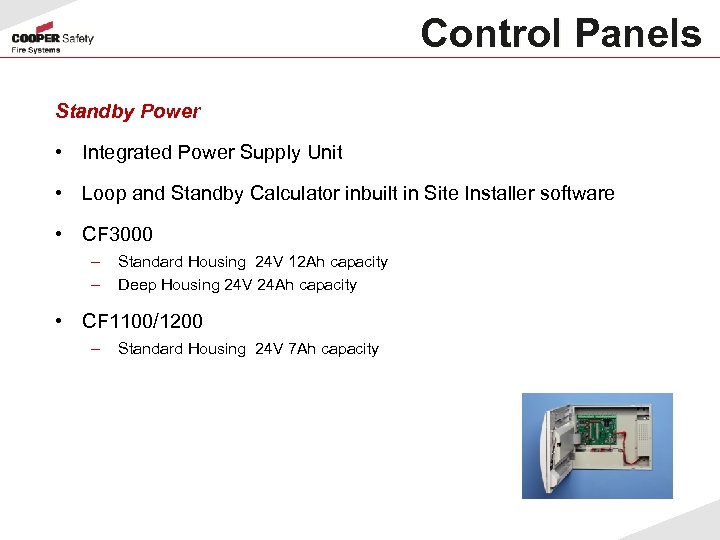

Control Panels Standby Power • Integrated Power Supply Unit • Loop and Standby Calculator inbuilt in Site Installer software • CF 3000 – – Standard Housing 24 V 12 Ah capacity Deep Housing 24 V 24 Ah capacity • CF 1100/1200 – Standard Housing 24 V 7 Ah capacity

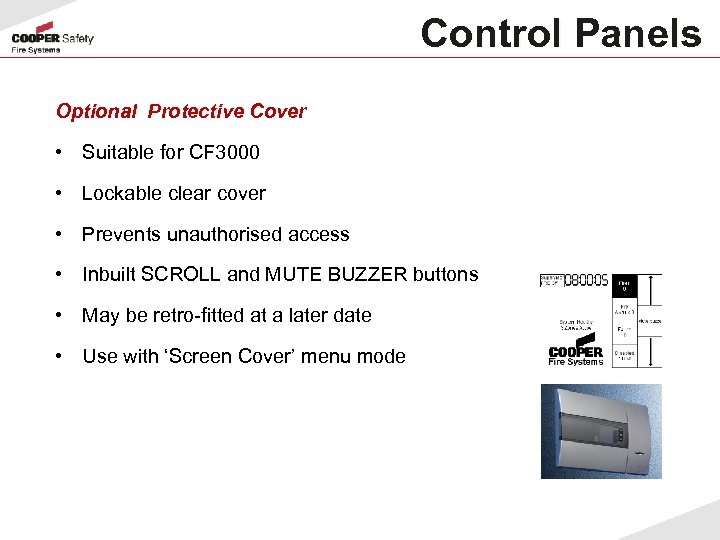

Control Panels Optional Protective Cover • Suitable for CF 3000 • Lockable clear cover • Prevents unauthorised access • Inbuilt SCROLL and MUTE BUZZER buttons • May be retro-fitted at a later date • Use with ‘Screen Cover’ menu mode

Control Panels Optional Integral Printer • Suitable for CF 3000 • Lockable printer door • Self loading ‘Drop-In’ paper cradle • Removable blanking plug for retro-fit

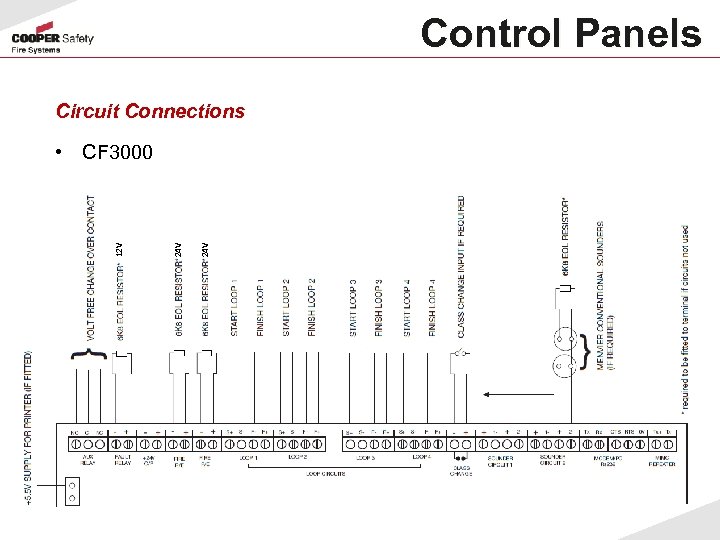

Control Panels Circuit Connections 24 V 12 V • CF 3000

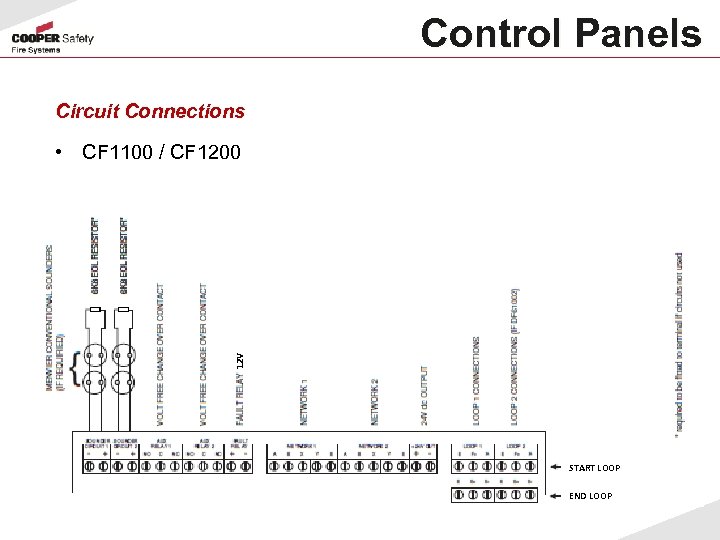

Control Panels Circuit Connections 12 V • CF 1100 / CF 1200 START LOOP END LOOP

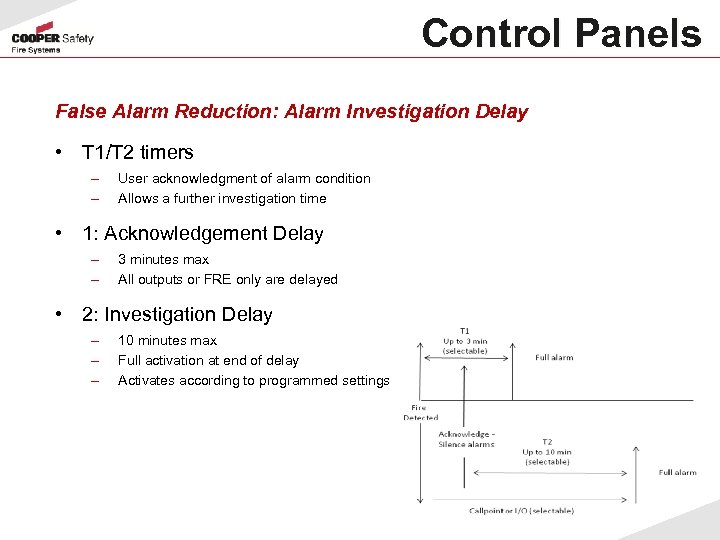

Control Panels False Alarm Reduction: Alarm Investigation Delay • T 1/T 2 timers – – User acknowledgment of alarm condition Allows a further investigation time • 1: Acknowledgement Delay – – 3 minutes max All outputs or FRE only are delayed • 2: Investigation Delay – – – 10 minutes max Full activation at end of delay Activates according to programmed settings

Control Panels False Alarm Reduction: Alarm Verification Delay • Filter out transient alarms – – Reduces disruption from nuisance alarms Select zones as required • 1: Verification Stage – – EN: 15 or 30 seconds verification delay UL: 60 seconds verification delay • 2: Full Alarm – – Full activation if smoke remains at end of delay Activates according to programmed settings

Control Panels False Alarm Reduction: HMO Mode • Housing in Multiple Occupation – – Reduces disruption from nuisance alarms Compliant with BS 5839 Pt 6 • 1: Verification Stage – – – Indication at Control Panel and Zonal sounders 1 – 5 minutes time delay Auto Reset if smoke clears within delay • 2: Full Alarm – – Full activation if smoke remains at end of delay Activates according to programmed settings

Control Panels False Alarm Reduction: Day Night Mode • Reduced Sensitivity in DAY period – – – Optical Smoke: No change Opto-Thermal: Smoke off, heat only Heat: Rof. R > Hi Fixed, Hi Fixed > Rof. R, Med Fixed > no change • Configuration – – – Select device DAY/NIGHT setting with PC Trigger from Input Module set to DAY/NIGHT Operates over loop pairs 1 -2, 3 -4

Repeater Panels Range • CF 3000 PRG: – LCD Loop repeater • CF 3000 PRGNC: – LCD Network repeater • CTPR 3000: – Touch Screen Network repeater

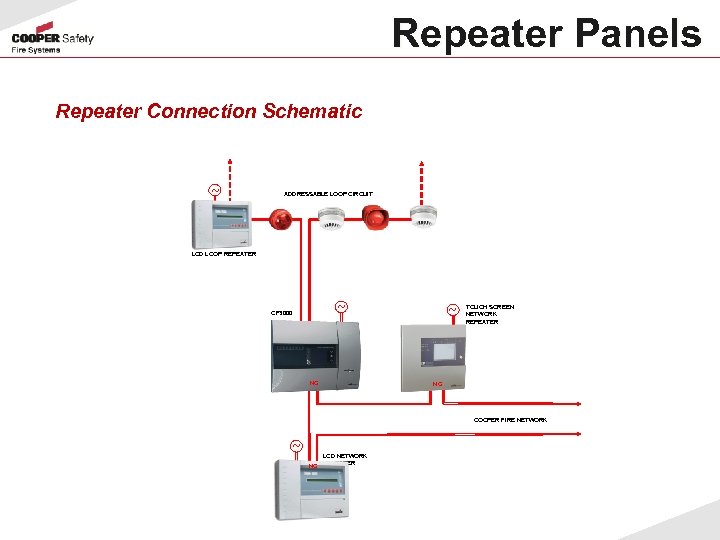

Repeater Panels Repeater Connection Schematic ~ ADDRESSABLE LOOP CIRCUIT LCD LOOP REPEATER ~ CF 3000 NC ~ TOUCH SCREEN NETWORK REPEATER NC COOPER FIRE NETWORK ~ NC LCD NETWORK REPEATER

Repeater Panels Standard Repeater Panel • Loop: stores and displays text only for its own panel • Network: automatically receives text for entire system (/NC) • LCD display • Passive or Active: – Silence, Evacuate and Reset controls LOOP: CF 3000 PRG / DF 6000 PR / FX 6000 PR NETWORK: CF 3000 PRGNC / DF 6000 PRNC / FX 6000 PRNC

Repeater Panels Touch Screen Repeater Panel • Network: automatically receives text for entire system • Touch screen display • Passive or Active: – Silence, Evacuate and Reset controls • Programmable Input: – Fire, pre-alarm, fault, silence, reset, evacuate – Custom Text CTPR 3000

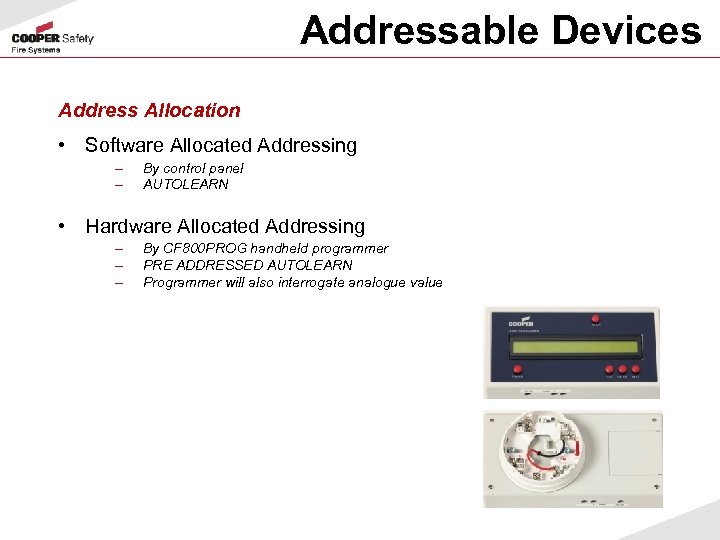

Addressable Devices Address Allocation • Software Allocated Addressing – – By control panel AUTOLEARN • Hardware Allocated Addressing – – – By CF 800 PROG handheld programmer PRE ADDRESSED AUTOLEARN Programmer will also interrogate analogue value

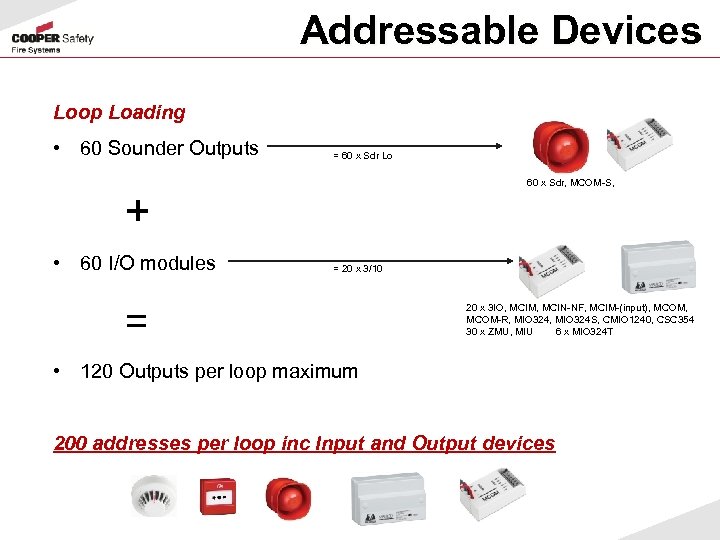

Addressable Devices Loop Loading • 60 Sounder Outputs = 60 x Sdr Lo 60 x Sdr, MCOM-S, + • 60 I/O modules = 20 x 3/10 = 20 x 3 IO, MCIM, MCIN-NF, MCIM-(input), MCOM-R, MIO 324 S, CMIO 1240, CSC 354 30 x ZMU, MIU 6 x MIO 324 T • 120 Outputs per loop maximum 200 addresses per loop inc Input and Output devices

Addressable Devices Automatic Detection • CAP 320: Optical Smoke Detector – Optical scatter • CAPT 340: Multi Criteria Opto-Thermal Smoke Detector – – Thermally enhanced optical scatter Rate of rise - (A 1 S characteristic 60 o. C) • CAH 330: Multi-mode Heat Detector – – – Rate of rise - (A 1 R characteristic 60 o. C) Med Fixed temp - (BS medium characteristic 77 o. C) Low Fixed temp - (CS high temperature characteristic 92 o. C) • All Devices – – Inbuilt S/C isolator Software or hardware allocated addressing LED 360 o viewing angle Optical chamber monitoring and drift compensation OPT SM: CAP 320 / MAP 820 / FXN 723 CAB 300 / MAB 800 / FXN 720 OPT TH SM: CAPT 340 / MAOH 850 / FXN 722 HT: CAH 330 / MAH 830 / FXN 725 BASE:

Addressable Devices Optical Smoke Detector • Optical scatter smoke detection – – – Analogue threshold compensation Pre Alarm warning Analogue value available for analysis • Inbuilt S/C Isolator – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG • Remote LED capability • Loop Loading – – 200 max Subject to Loop Calculation CAP 320 / MAP 820 / FXN 723

Addressable Devices Multi Criteria Opto-Thermal Smoke Detector • Thermally enhanced optical scatter smoke detection – – Analogue threshold compensation Pre Alarm warning Analogue value available for analysis Also independently Rate of rise - (A 1 S characteristic 60 o. C) • Inbuilt S/C Isolator – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG • Remote LED capability • Day/Night mode • Loop Loading – – 200 max Subject to Loop Calculation CAPT 340 / MAOH 850 / FXN 722

Addressable Devices Multi Function Heat Detector • Thermistor based heat Detection – – – Rate of Rise 60 o. C : A 1 R Med Fixed 77 o. C: BS High Fixed 92 o. C: CS • Panel control of sensitivity • Inbuilt S/C Isolator – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG • Remote LED capability • Day/Night mode • Loop Loading – – 200 max Subject to Loop Calculation CAH 330 / MAH 830 / FXN 725

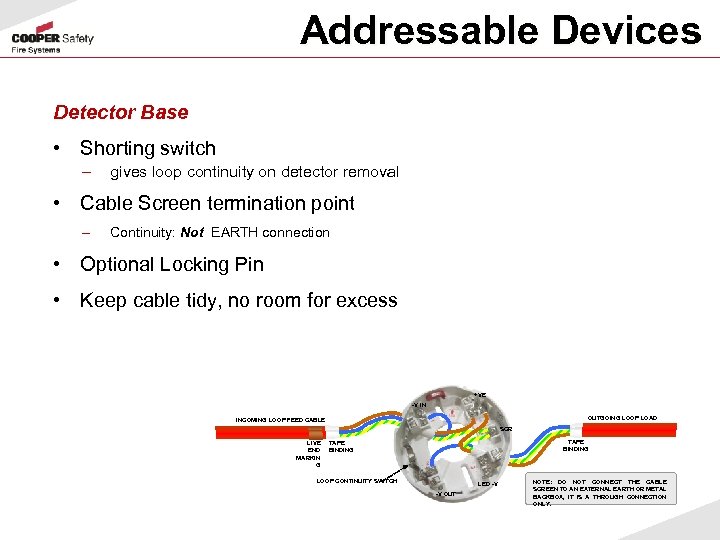

Addressable Devices Detector Base • Shorting switch – gives loop continuity on detector removal • Cable Screen termination point – Continuity: Not EARTH connection • Optional Locking Pin • Keep cable tidy, no room for excess +VE -V IN INCOMING LOOP FEED CABLE SCR LIVE END MARKIN G OUTGOING LOOP LOAD CABLE TAPE BINDING LOOP CONTINUITY SWITCH LED -V -V OUT NOTE: DO NOT CONNECT THE CABLE SCREEN TO AN EXTERNAL EARTH OR METAL BACKBOX, IT IS A THROUGH CONNECTION ONLY.

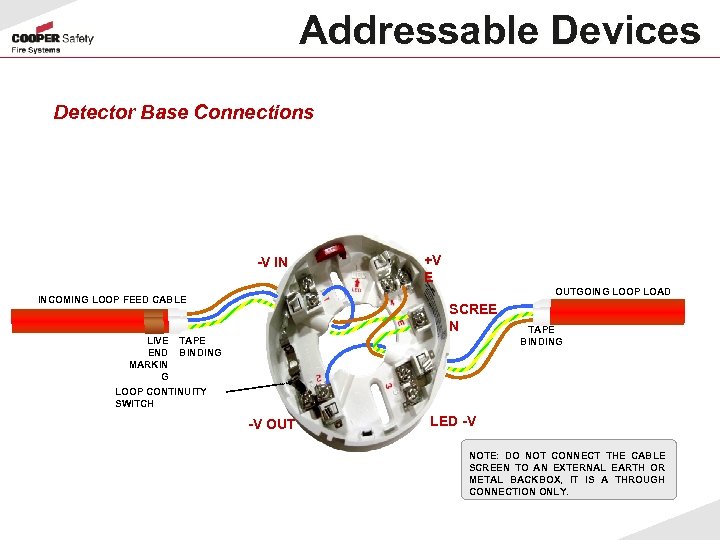

Addressable Devices Detector Base Connections -V IN INCOMING LOOP FEED CABLE +V E SCREE N LIVE TAPE END BINDING MARKIN G LOOP CONTINUITY SWITCH -V OUTGOING LOOP LOAD CABLE TAPE BINDING LED -V NOTE: DO NOT CONNECT THE CABLE SCREEN TO AN EXTERNAL EARTH OR METAL BACKBOX, IT IS A THROUGH CONNECTION ONLY.

Addressable Devices Manual Call Point • Inbuilt S/C Isolator – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG • Key operated testing • Options – – Surface / flush Weatherproof IP 66 • Accessories – – – Replacement glass or Resettable Element Hinged protective cover Bezel • Loop Loading – – 200 max Subject to Loop Calculation MCP: CBG 370 S / MBG 813 / FXN 501 MCP WP: CBG 370 WP / MBG 817 / FXN 503

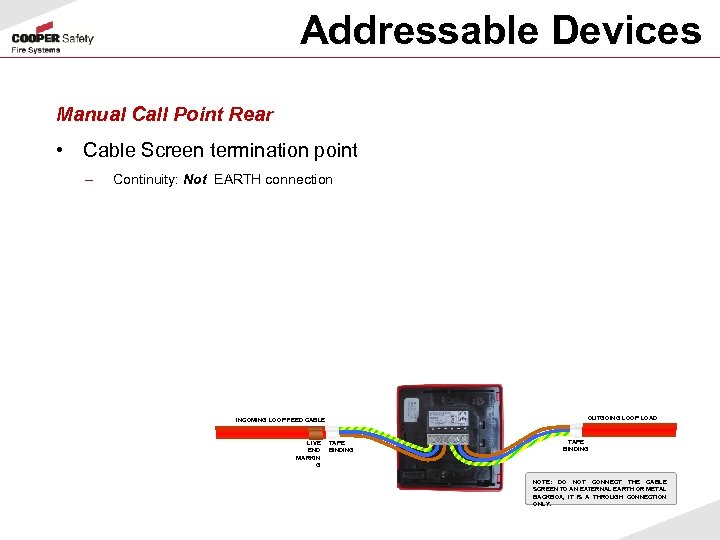

Addressable Devices Manual Call Point Rear • Cable Screen termination point – Continuity: Not EARTH connection OUTGOING LOOP LOAD CABLE INCOMING LOOP FEED CABLE LIVE END MARKIN G TAPE BINDING NOTE: DO NOT CONNECT THE CABLE SCREEN TO AN EXTERNAL EARTH OR METAL BACKBOX, IT IS A THROUGH CONNECTION ONLY.

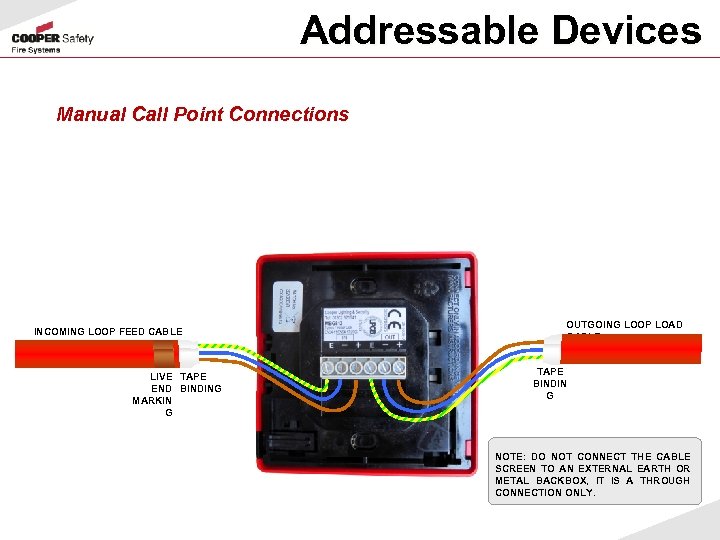

Addressable Devices Manual Call Point Connections INCOMING LOOP FEED CABLE LIVE TAPE END BINDING MARKIN G OUTGOING LOOP LOAD CABLE TAPE BINDIN G NOTE: DO NOT CONNECT THE CABLE SCREEN TO AN EXTERNAL EARTH OR METAL BACKBOX, IT IS A THROUGH CONNECTION ONLY.

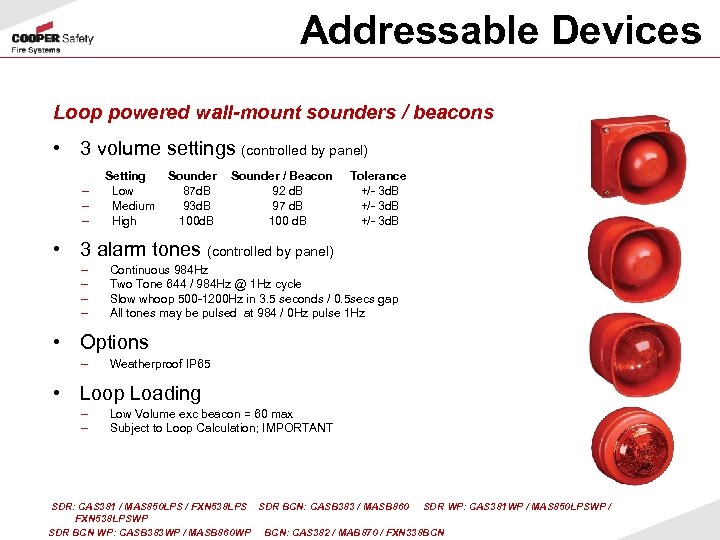

Addressable Devices Loop powered wall-mount sounders / beacons • 3 volume settings (controlled by panel) – – – Setting Low Medium High Sounder 87 d. B 93 d. B 100 d. B Sounder / Beacon 92 d. B 97 d. B 100 d. B Tolerance +/- 3 d. B • 3 alarm tones (controlled by panel) – – Continuous 984 Hz Two Tone 644 / 984 Hz @ 1 Hz cycle Slow whoop 500 -1200 Hz in 3. 5 seconds / 0. 5 secs gap All tones may be pulsed at 984 / 0 Hz pulse 1 Hz • Options – Weatherproof IP 65 • Loop Loading – – Low Volume exc beacon = 60 max Subject to Loop Calculation; IMPORTANT SDR: CAS 381 / MAS 850 LPS / FXN 538 LPS SDR BCN: CASB 383 / MASB 860 SDR WP: CAS 381 WP / MAS 850 LPSWP / FXN 538 LPSWP SDR BCN WP: CASB 383 WP / MASB 860 WP BCN: CAS 382 / MAB 870 / FXN 338 BCN

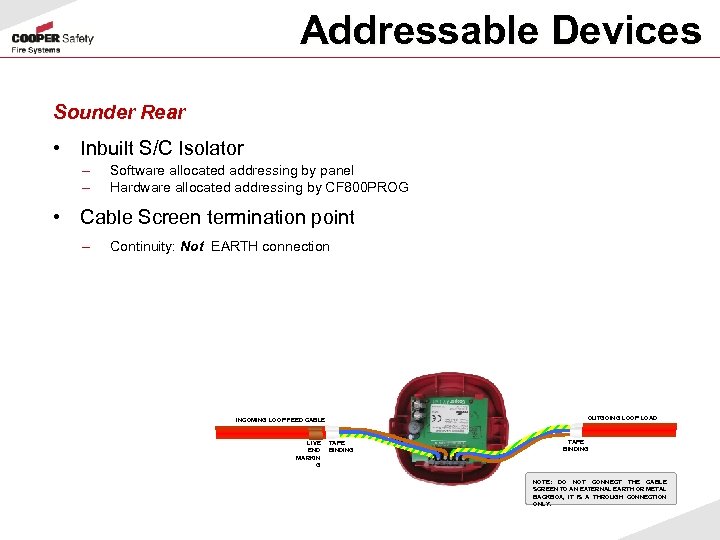

Addressable Devices Sounder Rear • Inbuilt S/C Isolator – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG • Cable Screen termination point – Continuity: Not EARTH connection OUTGOING LOOP LOAD CABLE INCOMING LOOP FEED CABLE LIVE END MARKIN G TAPE BINDING NOTE: DO NOT CONNECT THE CABLE SCREEN TO AN EXTERNAL EARTH OR METAL BACKBOX, IT IS A THROUGH CONNECTION ONLY.

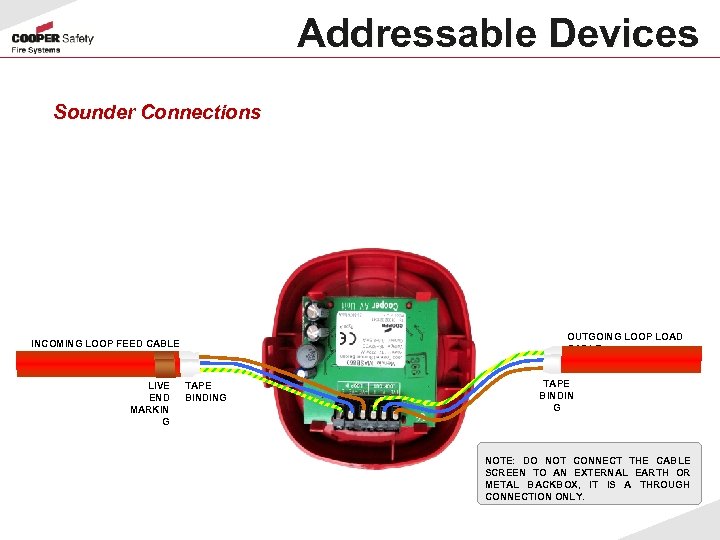

Addressable Devices Sounder Connections OUTGOING LOOP LOAD CABLE INCOMING LOOP FEED CABLE LIVE END MARKIN G TAPE BINDIN G NOTE: DO NOT CONNECT THE CABLE SCREEN TO AN EXTERNAL EARTH OR METAL BACKBOX, IT IS A THROUGH CONNECTION ONLY.

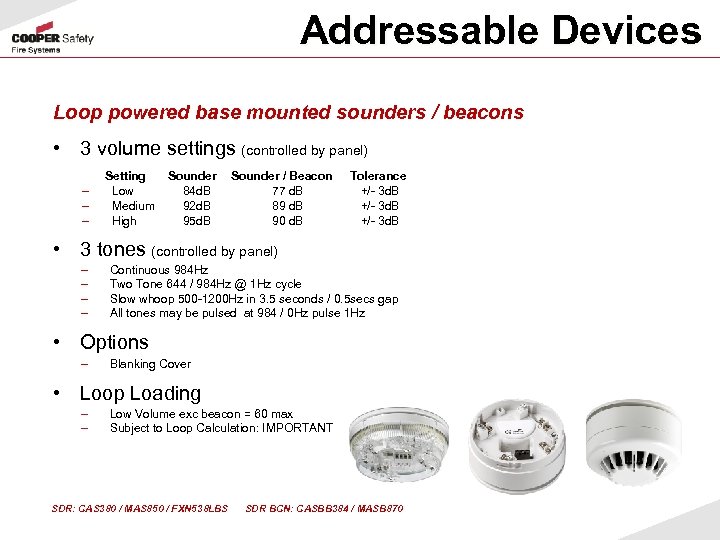

Addressable Devices Loop powered base mounted sounders / beacons • 3 volume settings (controlled by panel) – – – Setting Low Medium High Sounder 84 d. B 92 d. B 95 d. B Sounder / Beacon 77 d. B 89 d. B 90 d. B Tolerance +/- 3 d. B • 3 tones (controlled by panel) – – Continuous 984 Hz Two Tone 644 / 984 Hz @ 1 Hz cycle Slow whoop 500 -1200 Hz in 3. 5 seconds / 0. 5 secs gap All tones may be pulsed at 984 / 0 Hz pulse 1 Hz • Options – Blanking Cover • Loop Loading – – Low Volume exc beacon = 60 max Subject to Loop Calculation: IMPORTANT SDR: CAS 380 / MAS 850 / FXN 538 LBS SDR BCN: CASBB 384 / MASB 870

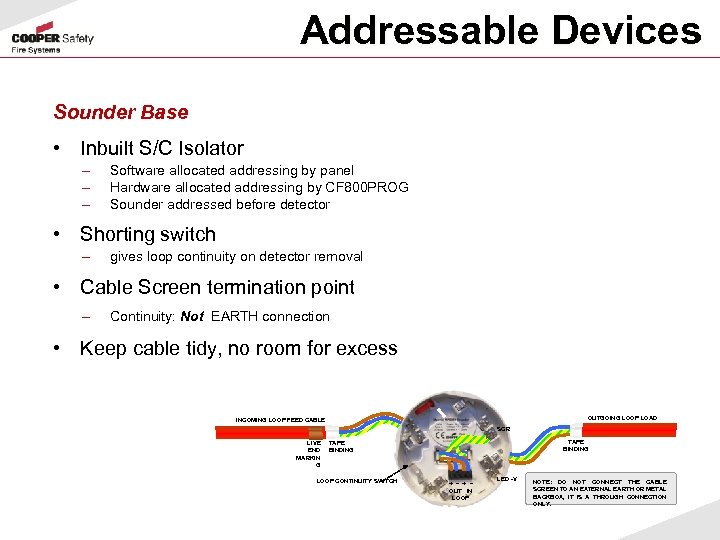

Addressable Devices Sounder Base • Inbuilt S/C Isolator – – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG Sounder addressed before detector • Shorting switch – gives loop continuity on detector removal • Cable Screen termination point – Continuity: Not EARTH connection • Keep cable tidy, no room for excess INCOMING LOOP FEED CABLE SCR LIVE END MARKIN G TAPE BINDING LOOP CONTINUITY SWITCH OUTGOING LOOP LOAD CABLE + - + OUT IN LOOP LED -V NOTE: DO NOT CONNECT THE CABLE SCREEN TO AN EXTERNAL EARTH OR METAL BACKBOX, IT IS A THROUGH CONNECTION ONLY.

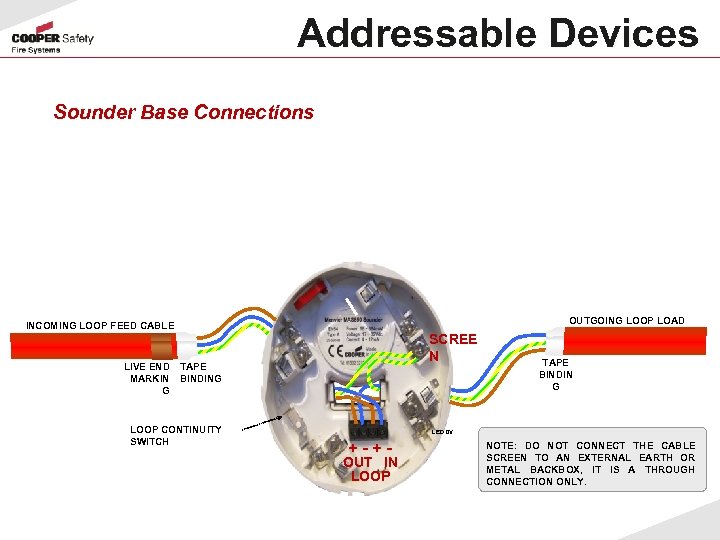

Addressable Devices Sounder Base Connections INCOMING LOOP FEED CABLE SCREE N LIVE END TAPE MARKIN BINDING G LOOP CONTINUITY SWITCH OUTGOING LOOP LOAD CABLE TAPE BINDIN G LED 0 V +-+- OUT IN LOOP NOTE: DO NOT CONNECT THE CABLE SCREEN TO AN EXTERNAL EARTH OR METAL BACKBOX, IT IS A THROUGH CONNECTION ONLY.

Addressable Devices Miniature Interface Module Range • Miniature Input Module – – MCIM standard 3 CH I/O MCIM-C mcp MCIM-NF non-fire MCIM-INPUT I/P • Miniature Output Module – – – MCOM-S MCOM-R standard sounder type pulse on reset • Miniature Zone Monitor Module – MIU 872 standard • Inbuilt S/C Isolator – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG

Addressable Devices Miniature Input Module • 1 x monitored input • Options – – MCIM = Identified as 3 CH I/0 MCIM-C = Identified as MCP MCIM-NF = Non-fire I/P MCIM-(input) = Identified as I/P • Loop Loading – – – MCIM = 20 max MCIM-C = 200 max MCIM-NF = 20 max MCIM-(input) = 200 max Subject to Loop Calculation

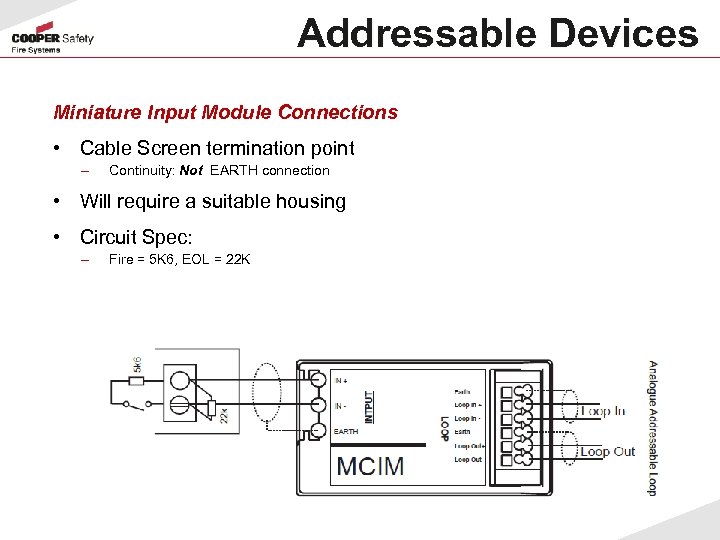

Addressable Devices Miniature Input Module Connections • Cable Screen termination point – Continuity: Not EARTH connection • Will require a suitable housing • Circuit Spec: – Fire = 5 K 6, EOL = 22 K

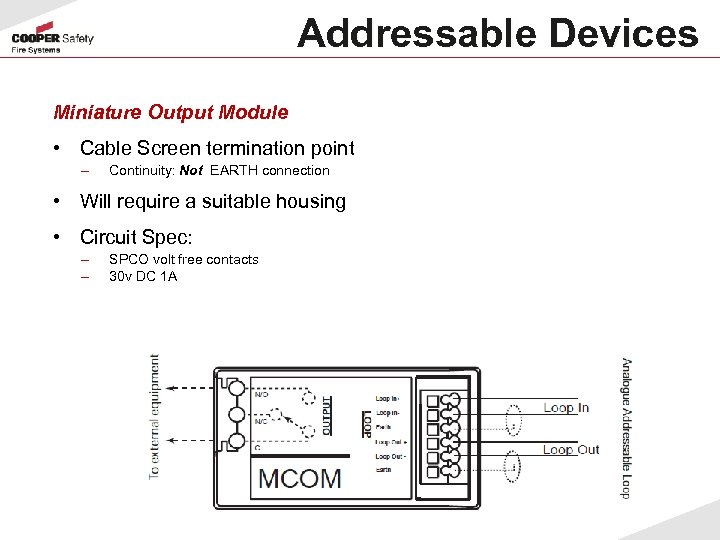

Addressable Devices Miniature Output Module • 1 x output – – SPCO volt free contacts 30 v DC 1 A • Options – – – MCOM = Standard Mini O/P Module MCOM-S = Identified as Sounder device type, relay returns on RESET MCOM-R = 5 s pulse on RESET • Max 20 O/P Modules per loop – – MCOM = 20 max MCOM-S = 60 max MCOM-R = 20 max Subject to Loop Calculation

Addressable Devices Miniature Output Module • Cable Screen termination point – Continuity: Not EARTH connection • Will require a suitable housing • Circuit Spec: – – SPCO volt free contacts 30 v DC 1 A

Addressable Devices Miniature Zone Monitor Module • 1 x zone of conventional detectors / Manual Call Points – FXN 520 conventional base with schottky diode – Max 20 detectors, suggested 10 per unit to spread load – Standard response time • Monitored Circuit • Loop Loading – – MIU 872 30 max Subject to Loop Calculation

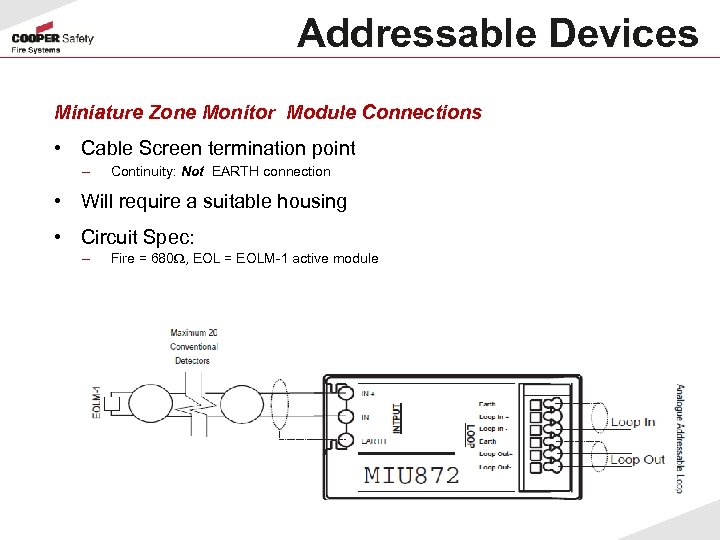

Addressable Devices Miniature Zone Monitor Module Connections • Cable Screen termination point – Continuity: Not EARTH connection • Will require a suitable housing • Circuit Spec: – Fire = 680 , EOL = EOLM-1 active module

Addressable Devices Double Gang Interface Module Range • Spur Isolator Module – MSI 850 standard • Shop Unit Monitor Module – MSU 840 standard • Zone Monitor Module – MIU 871 standard • Inbuilt S/C Isolator – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG

Addressable Devices Spur Isolator Module • Interface a spur of addressable devices to the Loop – 1 zone of devices max • Inbuilt S/C isolator • Allows connection of a radial circuit to the loop • Does not take an address • Good engineering practice to limit quantity CSI 350 / MSI 850 / FXN 513

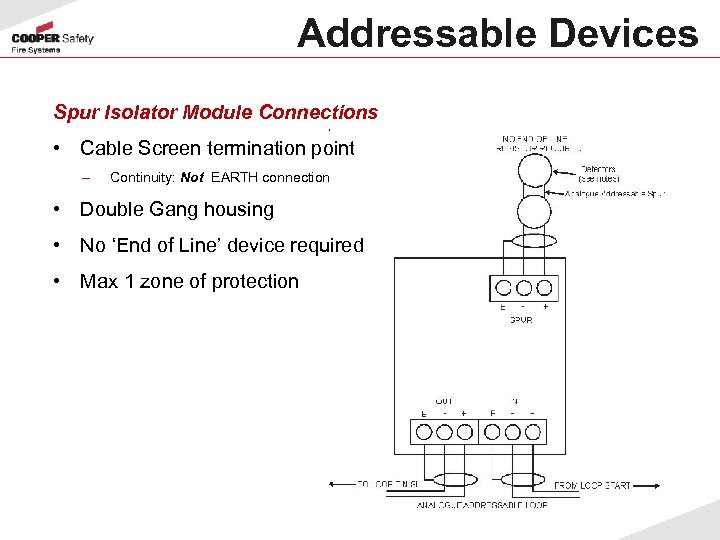

Addressable Devices Spur Isolator Module Connections • Cable Screen termination point – Continuity: Not EARTH connection • Double Gang housing • No ‘End of Line’ device required • Max 1 zone of protection

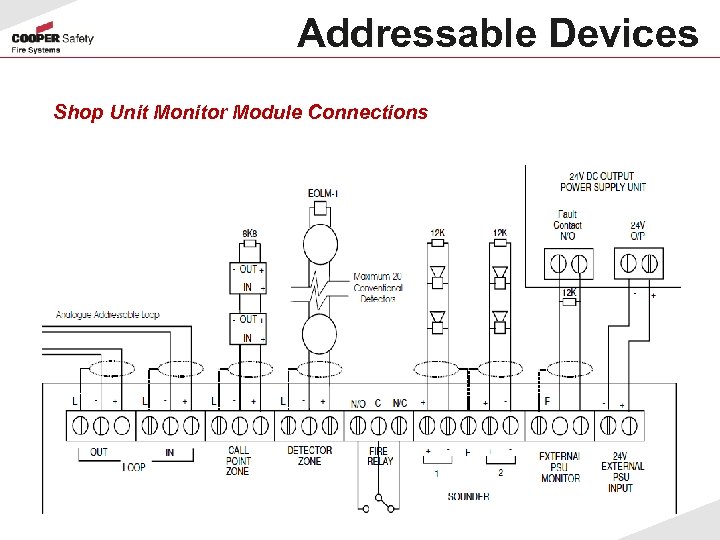

Addressable Devices Shop Unit Monitor Module • 1 x zone of conventional detectors / Manual call points – – – FXN 520 conventional base with schottky diode Max 20 detectors, suggested 10 per unit to spread load Standard response time • 1 x zone of conventional Manual Call Points – Fast response <3 seconds • Monitored Circuits • 2 x Conventional sounder circuits • Loop Loading – – – 20 max Subject to Loop Calculation Remotely 24 V DC powered to reduce loop load CSUM 355 / MSU 840 / FXN 516

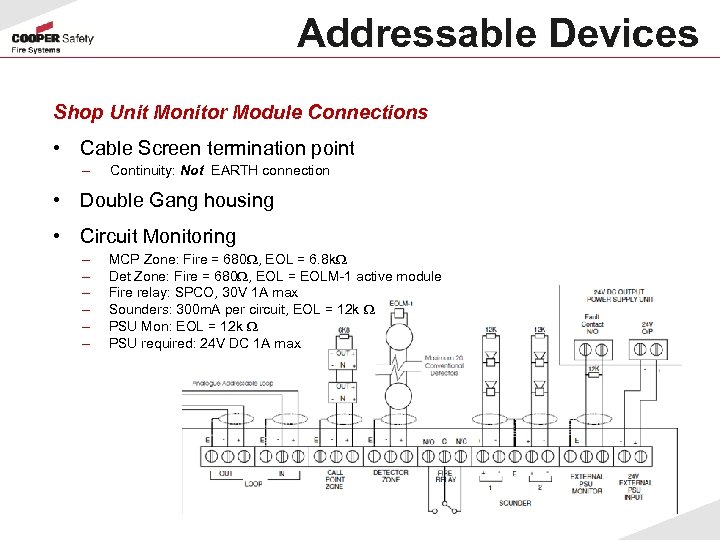

Addressable Devices Shop Unit Monitor Module Connections • Cable Screen termination point – Continuity: Not EARTH connection • Double Gang housing • Circuit Monitoring – – – MCP Zone: Fire = 680 , EOL = 6. 8 k Det Zone: Fire = 680 , EOL = EOLM-1 active module Fire relay: SPCO, 30 V 1 A max Sounders: 300 m. A per circuit, EOL = 12 k PSU Mon: EOL = 12 k PSU required: 24 V DC 1 A max

Addressable Devices Shop Unit Monitor Module Connections

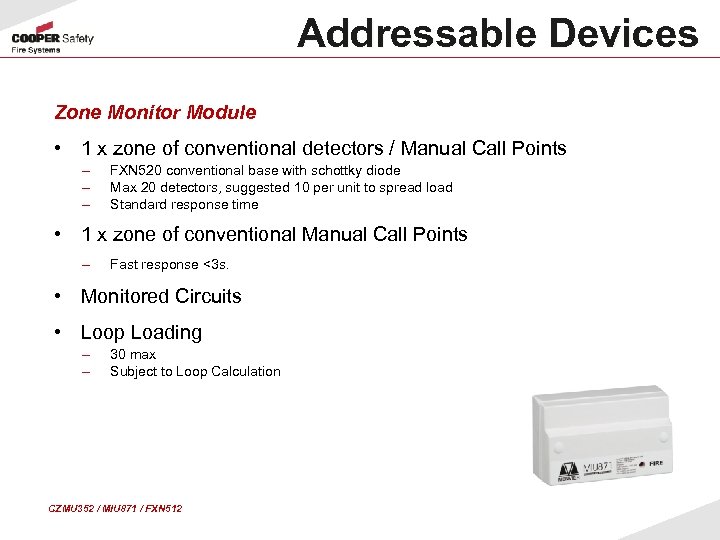

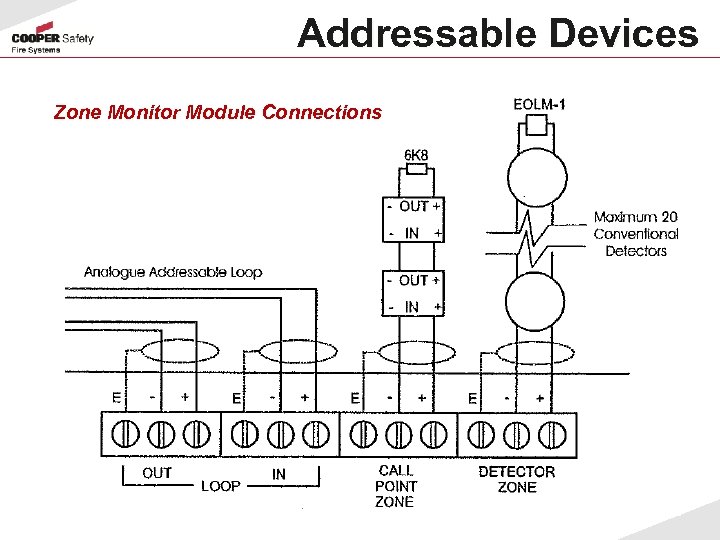

Addressable Devices Zone Monitor Module • 1 x zone of conventional detectors / Manual Call Points – – – FXN 520 conventional base with schottky diode Max 20 detectors, suggested 10 per unit to spread load Standard response time • 1 x zone of conventional Manual Call Points – Fast response <3 s. • Monitored Circuits • Loop Loading – – 30 max Subject to Loop Calculation CZMU 352 / MIU 871 / FXN 512

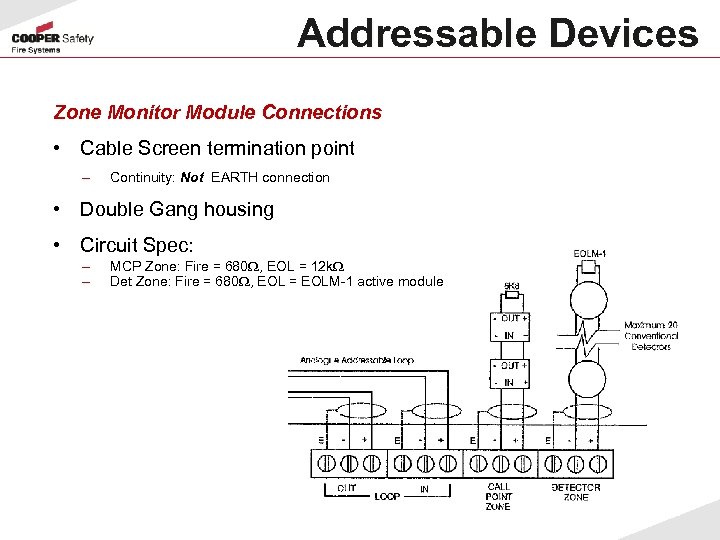

Addressable Devices Zone Monitor Module Connections • Cable Screen termination point – Continuity: Not EARTH connection • Double Gang housing • Circuit Spec: – – MCP Zone: Fire = 680 , EOL = 12 k Det Zone: Fire = 680 , EOL = EOLM-1 active module

Addressable Devices Zone Monitor Module Connections

Addressable Devices Large Interface Module Range • 3 Channel Input / Output Module – – – MIO 324 S MIO 324 T standard relay returns on silence Indepent Input & Output operation, 3 addresses • Mains Rated Input / Output Module – MIO 1240 standard • 4 Channel Sounder Controller Module – MPU 424 standard • Inbuilt S/C Isolator – – Software allocated addressing by panel Hardware allocated addressing by CF 800 PROG

Addressable Devices Large 3 Channel I/O Module • 3 x output relay – – Volt free contacts 30 v DC 1 A • 3 x monitored input – – Fire = 5 K 6 EOL = 22 K • Options – – – MIO 324 = Standard 3 Channel I/O MIO 324 S = Relay returns on SILENCE command MIO 324 T = Independent I/Ps & O/Ps, requires 3 addresses • Loop Loading – – MIO 324 = 20 max MIO 324 S = 20 max MIO 324 T = 6 max (ie 20 x I/O) Subject to Loop Calculation CIO 351 / MIO 324 / FXN 510

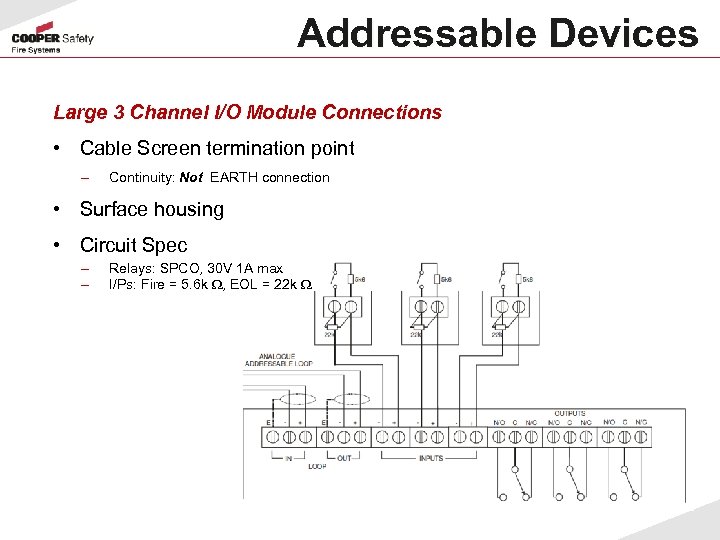

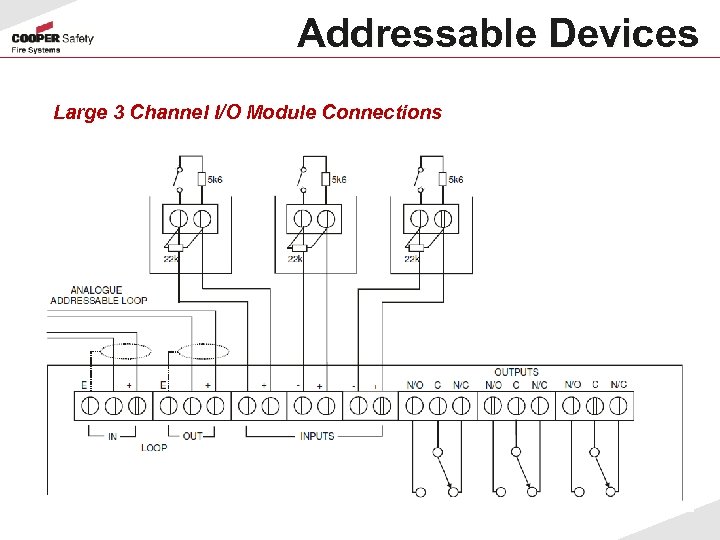

Addressable Devices Large 3 Channel I/O Module Connections • Cable Screen termination point – Continuity: Not EARTH connection • Surface housing • Circuit Spec – – Relays: SPCO, 30 V 1 A max I/Ps: Fire = 5. 6 k , EOL = 22 k

Addressable Devices Large 3 Channel I/O Module Connections

Addressable Devices Large Mains Rated I/O Module • 1 x output relay – – SPCO volt free contacts 230 V AC 30 V DC 8 A • Monitored input circuit • Loop Loading – – 20 max Subject to Loop Calculation CMIO 353 / MIO 1240 / FXN 511

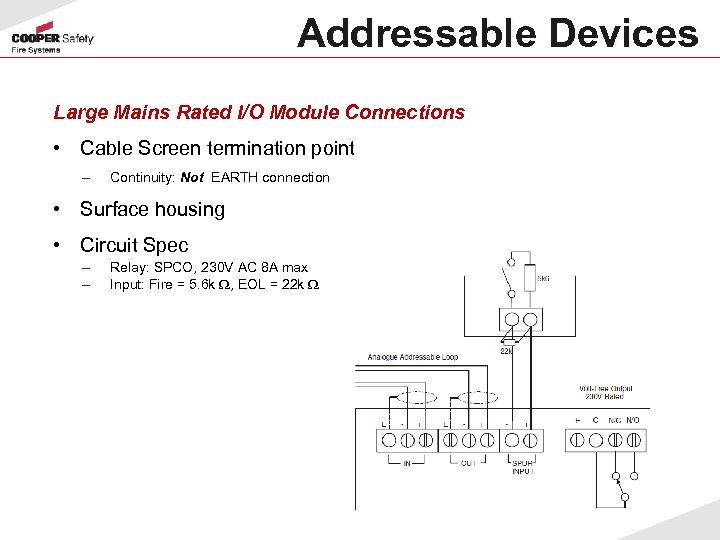

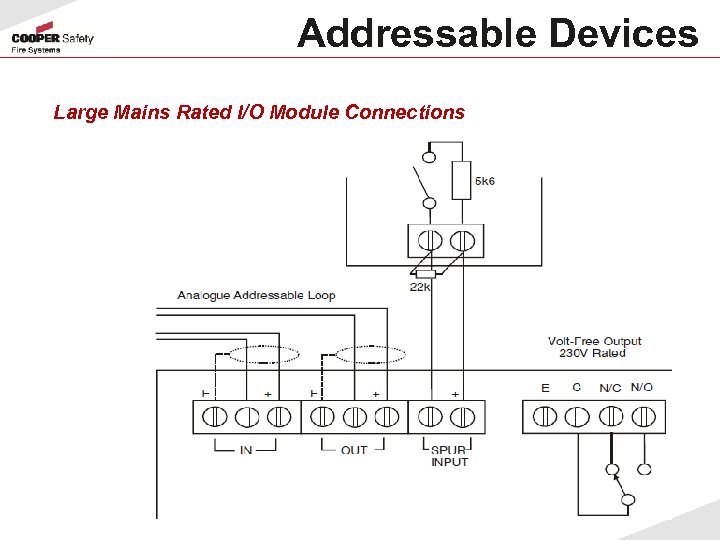

Addressable Devices Large Mains Rated I/O Module Connections • Cable Screen termination point – Continuity: Not EARTH connection • Surface housing • Circuit Spec – – Relay: SPCO, 230 V AC 8 A max Input: Fire = 5. 6 k , EOL = 22 k

Addressable Devices Large Mains Rated I/O Module Connections

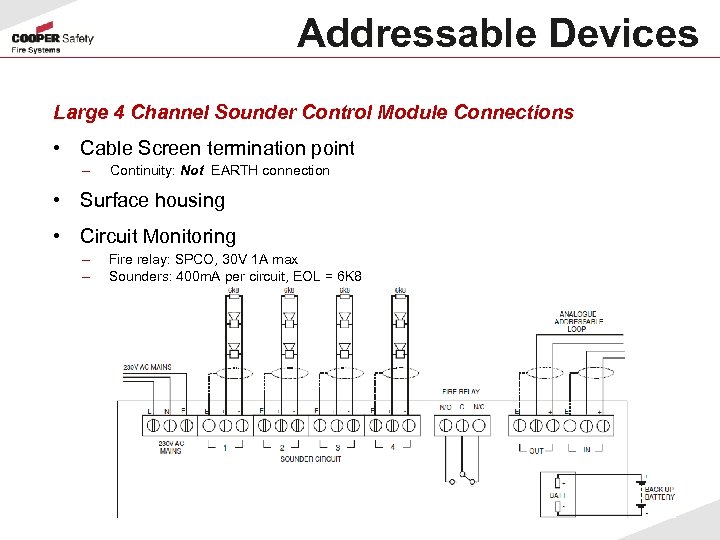

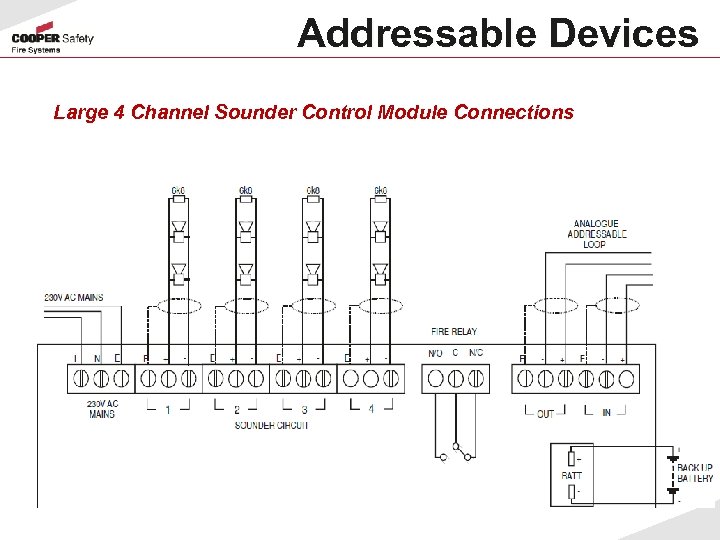

Addressable Devices Large 4 Channel Sounder Controller Module • 4 x Conventional sounder circuits • Programmable – – Optional delay on circuit 1 Separately programmable with Cause & Effect • Inbuilt 24 V DC PSU – 2 x 12 V 4 Ah batteries • Loop Loading – – – 20 max Subject to Loop Calculation Remotely 230 V AC powered to reduce loop load CSC 354 / MPU 424 / FXN 515

Addressable Devices Large 4 Channel Sounder Control Module Connections • Cable Screen termination point – Continuity: Not EARTH connection • Surface housing • Circuit Monitoring – – Fire relay: SPCO, 30 V 1 A max Sounders: 400 m. A per circuit, EOL = 6 K 8

Addressable Devices Large 4 Channel Sounder Control Module Connections

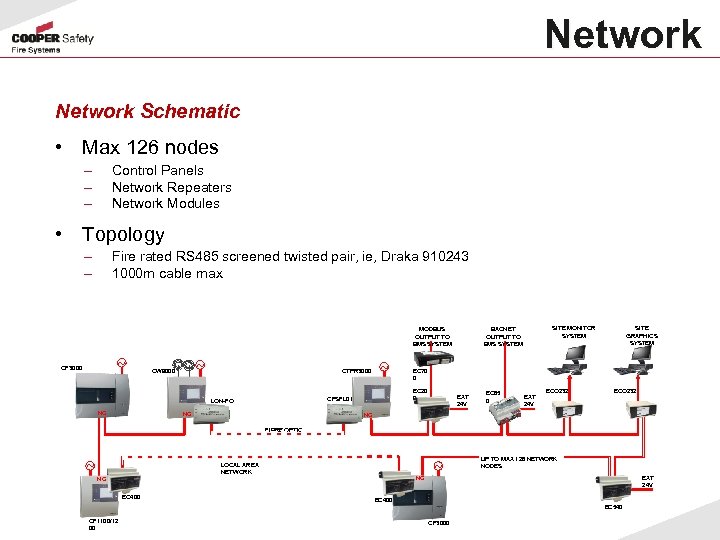

Network Schematic • Max 126 nodes – – – Control Panels Network Repeaters Network Modules • Topology – – Fire rated RS 485 screened twisted pair, ie, Draka 910243 1000 m cable max MODBUS OUTPUT TO BMS SYSTEM ~ CF 3000 ~ CW 9000 CTPR 3000 NC SITE GRAPHICS SYSTEM EC 70 0 EC 20 0 CFSFL 01 LON-FO NC ~ SITE MONITOR SYSTEM BACNET OUTPUT TO BMS SYSTEM EXT 24 V EC 65 0 EXT 24 V ECO 232 NC FIBRE OPTIC ~ LOCAL AREA NETWORK NC NC EC 400 ~ UP TO MAX 126 NETWORK NODES EXT 24 V EC 400 EC 540 CF 1100/12 00 CF 3000

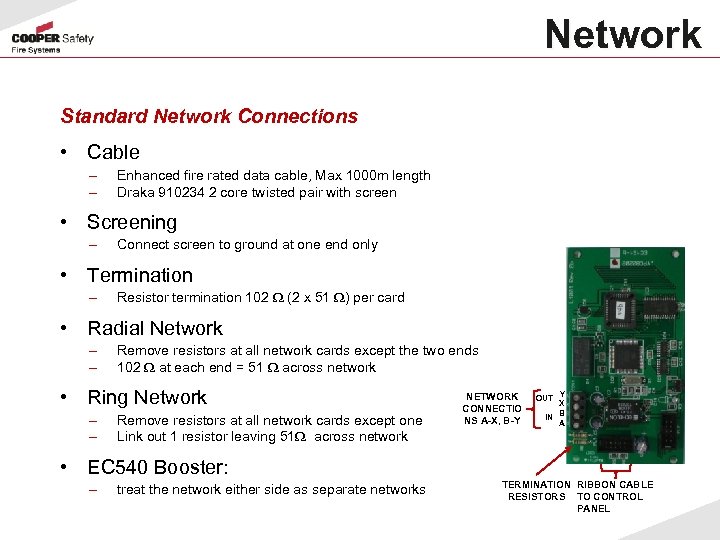

Network Standard Network Connections • Cable – – Enhanced fire rated data cable, Max 1000 m length Draka 910234 2 core twisted pair with screen • Screening – Connect screen to ground at one end only • Termination – Resistor termination 102 (2 x 51 ) per card • Radial Network – – Remove resistors at all network cards except the two ends 102 at each end = 51 across network • Ring Network – – Remove resistors at all network cards except one Link out 1 resistor leaving 51 across network NETWORK CONNECTIO NS A-X, B-Y Y X B IN A OUT • EC 540 Booster: – treat the network either side as separate networks TERMINATION RIBBON CABLE RESISTORS TO CONTROL PANEL

Network Standard Network Setup • At each control panel – – – Number of panels on network Panel Address E. g. , Panel 1 of 4 • Network Response (to commands received) – – – Silence Reset Evacuate Fire Fault Pre Alarm • Network Filter – Select Panels to respond to • Programming – Each panel Config downloaded to master site file.

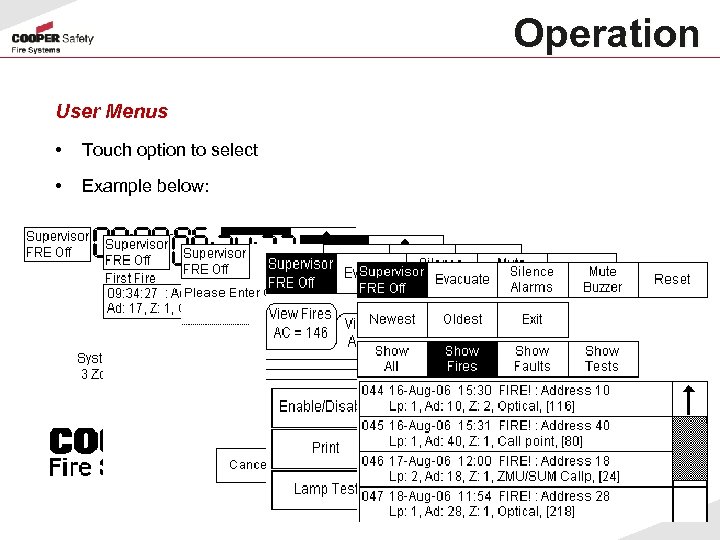

Operation User Menus • Touch option to select • Example below:

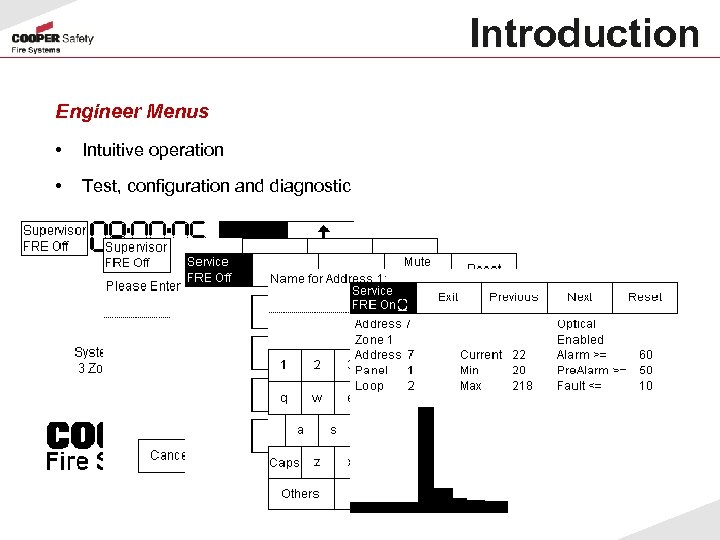

Introduction Engineer Menus • Intuitive operation • Test, configuration and diagnostic

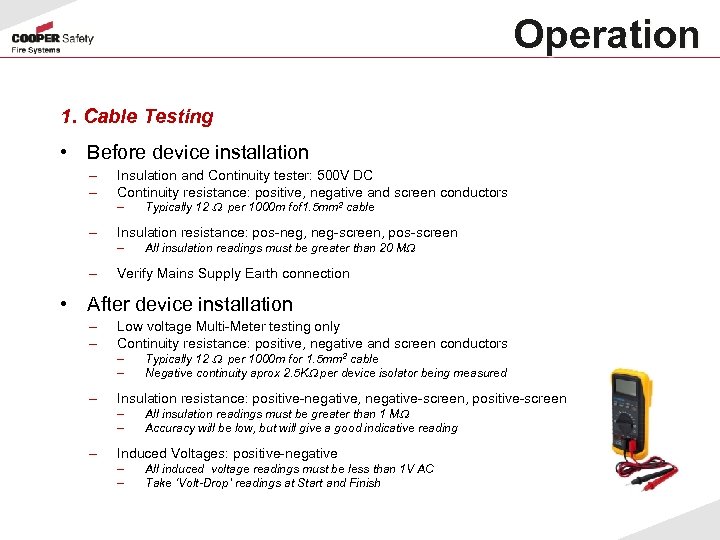

Operation 1. Cable Testing • Before device installation – – Insulation and Continuity tester: 500 V DC Continuity resistance: positive, negative and screen conductors – – Insulation resistance: pos-neg, neg-screen, pos-screen – – Typically 12 per 1000 m fof 1. 5 mm 2 cable All insulation readings must be greater than 20 M Verify Mains Supply Earth connection • After device installation – – Low voltage Multi-Meter testing only Continuity resistance: positive, negative and screen conductors – – – Insulation resistance: positive-negative, negative-screen, positive-screen – – – Typically 12 per 1000 m for 1. 5 mm 2 cable Negative continuity aprox 2. 5 K per device isolator being measured All insulation readings must be greater than 1 M Accuracy will be low, but will give a good indicative reading Induced Voltages: positive-negative – – All induced voltage readings must be less than 1 V AC Take ‘Volt-Drop’ readings at Start and Finish

Operation 2. Information required for commissioning • Cable Readings – Insulation and Continuity • ‘As-Wired’ drawings – Devices and cable routes • Device Data – – Quantity and type per loop Required settings and descriptions • Configuration – – Programming settings Cause & Effect requirements

Operation 3. Starting the Loops • Ensure panel is fault free without any devices – Sounder circuit and other EOLS must be fitted. • Auto-Learn updates the panel configuration – Save it to PC if required to avoid losing Text etc. • Auto-Learn Loops – – – Connect Loop 1 circuit cables: outgoing end only Auto-Learn and verify all devices identified correctly (ignore O/C fault) Disconnect Loop circuit cables Repeat with remaining loops temporarily in loop 1 connections When all complete, reinstate cable to correct circuits and Auto-Learn complete system • Final Checks – – – Reset System: ensure all faults are cleared Check Auto Config: investigate any issues Intermittent Fault Search: run for 30 minutes

Operation 4. Configuring the System • Verify Device Locations – Using the Test Device function verify all device locations as expected • Heat Detectors – – Default is ‘Rate of Rise’ Configure the detection settings using the panel menus PRIOR to PC upload • Site Installer – – Send CDR to PC, configure as required and return it to panel Optionally, some configuration may be carried out at the panel display • Commission System – Test all devices and all programmed operation

Operation Fault Finding during Auto-Learn • Will not identify all devices during Auto-Learn – – Faulty base/device, connections or cable At last device identified or the one immediately following • Dual Address – – – Misc connection problems Incorrect device type response Continual resetting of system • Random Fire Activations – – – Screen connected to earth / + / - in the field or with broken continuity Verify Mains supply Earth integrity Induced AC voltage Contaminated devices or activated Manual Call Points Incorrect configuration program • Miscellaneous – – – Loop circuits reversed or swapped after configuration Screen connected to earth in the field or with broken continuity Interface module connection problems Try splitting the loop and Auto-Learning one section at a time to locate unusual faults Try Auto-Learning 1 temporary device to verify panel operation Water leakage will often cause random fire activations

Thank you!

3979abc29f3489dddeb63180a309ad98.ppt