composites.pptx

- Количество слайдов: 57

Ceramic Structural Composites The Most Advanced Structural Material Lance L Snead Presented at the International School on Fusion Reactor Technology Erice, Italy July 26 - August 1, 2004

Ceramic Structural Composites The Most Advanced Structural Material Lance L Snead Presented at the International School on Fusion Reactor Technology Erice, Italy July 26 - August 1, 2004

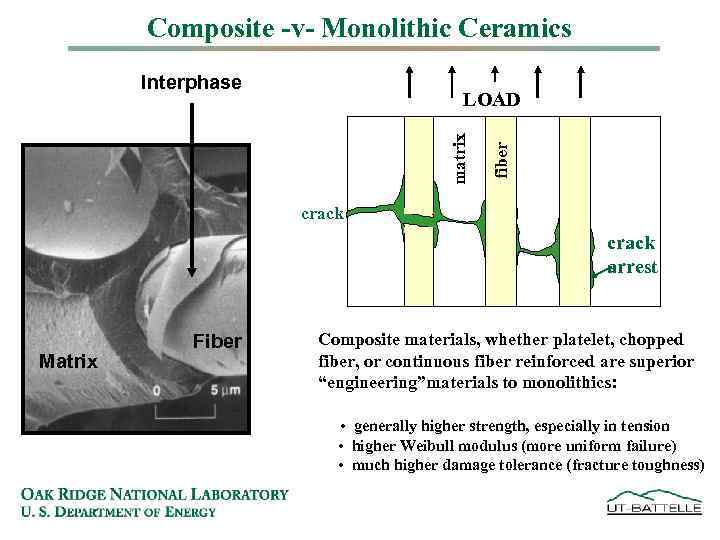

Composite -v- Monolithic Ceramics Interphase fiber matrix LOAD crack arrest Matrix Fiber Composite materials, whether platelet, chopped fiber, or continuous fiber reinforced are superior “engineering”materials to monolithics: • generally higher strength, especially in tension • higher Weibull modulus (more uniform failure) • much higher damage tolerance (fracture toughness)

Composite -v- Monolithic Ceramics Interphase fiber matrix LOAD crack arrest Matrix Fiber Composite materials, whether platelet, chopped fiber, or continuous fiber reinforced are superior “engineering”materials to monolithics: • generally higher strength, especially in tension • higher Weibull modulus (more uniform failure) • much higher damage tolerance (fracture toughness)

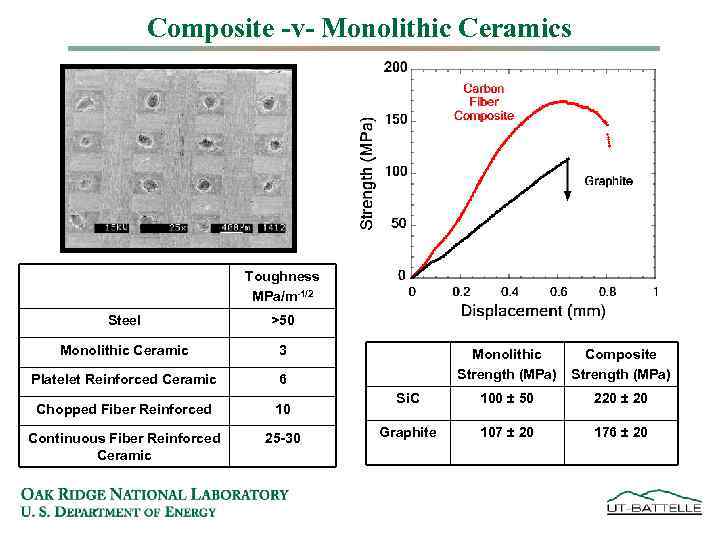

Composite -v- Monolithic Ceramics Toughness MPa/m-1/2 Steel >50 Monolithic Ceramic 3 Platelet Reinforced Ceramic 6 Chopped Fiber Reinforced 10 Continuous Fiber Reinforced Ceramic 25 -30 Monolithic Strength (MPa) Composite Strength (MPa) Si. C 100 ± 50 220 ± 20 Graphite 107 ± 20 176 ± 20

Composite -v- Monolithic Ceramics Toughness MPa/m-1/2 Steel >50 Monolithic Ceramic 3 Platelet Reinforced Ceramic 6 Chopped Fiber Reinforced 10 Continuous Fiber Reinforced Ceramic 25 -30 Monolithic Strength (MPa) Composite Strength (MPa) Si. C 100 ± 50 220 ± 20 Graphite 107 ± 20 176 ± 20

Ceramic Structural Composites The Most Advanced Structural Material Composite Examples

Ceramic Structural Composites The Most Advanced Structural Material Composite Examples

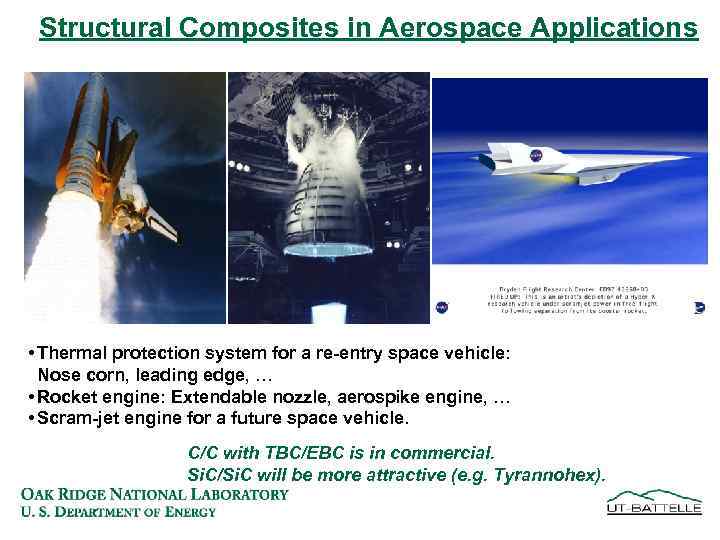

Structural Composites in Aerospace Applications • Thermal protection system for a re-entry space vehicle: Nose corn, leading edge, … • Rocket engine: Extendable nozzle, aerospike engine, … • Scram-jet engine for a future space vehicle. C/C with TBC/EBC is in commercial. Si. C/Si. C will be more attractive (e. g. Tyrannohex).

Structural Composites in Aerospace Applications • Thermal protection system for a re-entry space vehicle: Nose corn, leading edge, … • Rocket engine: Extendable nozzle, aerospike engine, … • Scram-jet engine for a future space vehicle. C/C with TBC/EBC is in commercial. Si. C/Si. C will be more attractive (e. g. Tyrannohex).

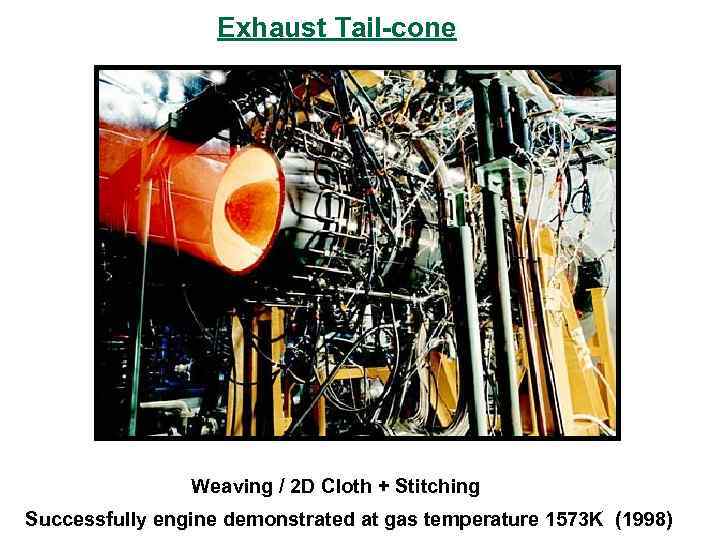

Exhaust Tail-cone Weaving / 2 D Cloth + Stitching Successfully engine demonstrated at gas temperature 1573 K (1998)

Exhaust Tail-cone Weaving / 2 D Cloth + Stitching Successfully engine demonstrated at gas temperature 1573 K (1998)

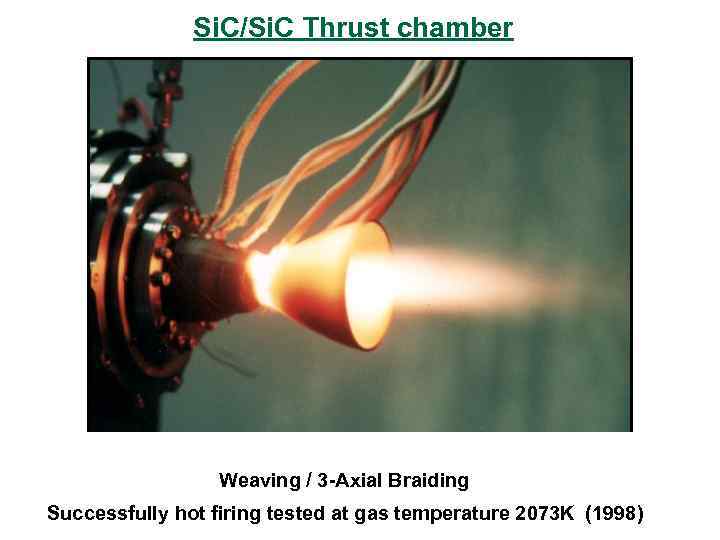

Si. C/Si. C Thrust chamber Weaving / 3 -Axial Braiding Successfully hot firing tested at gas temperature 2073 K (1998)

Si. C/Si. C Thrust chamber Weaving / 3 -Axial Braiding Successfully hot firing tested at gas temperature 2073 K (1998)

Carbon Fiber Reinforced Composites TREK Madone 5. 9 Carbon Fiber Composite

Carbon Fiber Reinforced Composites TREK Madone 5. 9 Carbon Fiber Composite

Glass Fiber Reinforced Composites Ferrari 308 GT 4 Glass Fiber Composite

Glass Fiber Reinforced Composites Ferrari 308 GT 4 Glass Fiber Composite

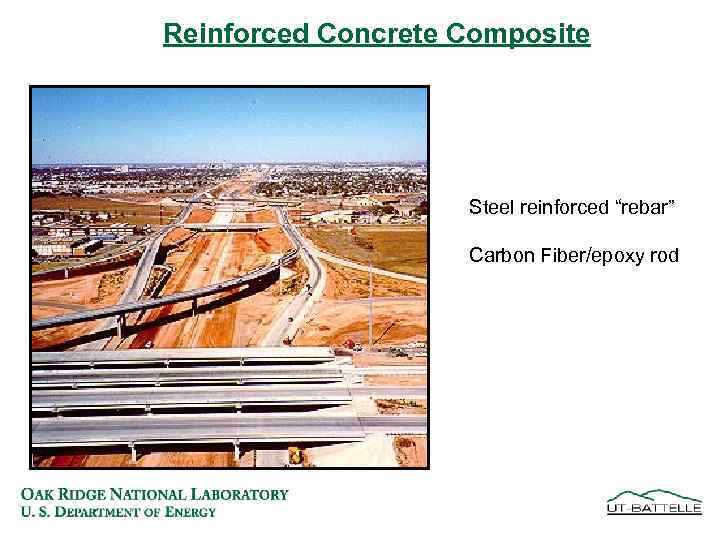

Reinforced Concrete Composite Steel reinforced “rebar” Carbon Fiber/epoxy rod

Reinforced Concrete Composite Steel reinforced “rebar” Carbon Fiber/epoxy rod

Reinforced Fired Adobe Composite

Reinforced Fired Adobe Composite

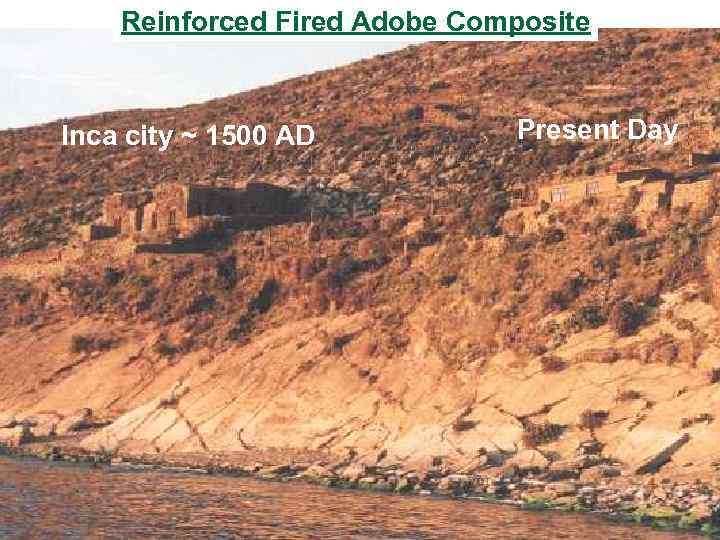

Reinforced Fired Adobe Composite Inca city ~ 1500 AD Present Day

Reinforced Fired Adobe Composite Inca city ~ 1500 AD Present Day

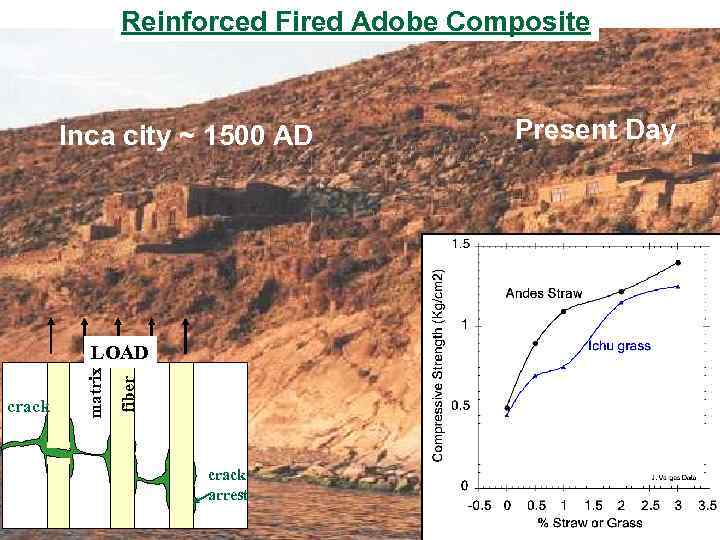

Reinforced Fired Adobe Composite Inca city ~ 1500 AD fiber crack matrix LOAD crack arrest Present Day

Reinforced Fired Adobe Composite Inca city ~ 1500 AD fiber crack matrix LOAD crack arrest Present Day

Puye Cliff Dwelling Anasaze Indians 1100 -1580 AD

Puye Cliff Dwelling Anasaze Indians 1100 -1580 AD

Fort Paramonga Chimu civilization ~1300 AD

Fort Paramonga Chimu civilization ~1300 AD

Tel-Dan Arch ~1600 BC

Tel-Dan Arch ~1600 BC

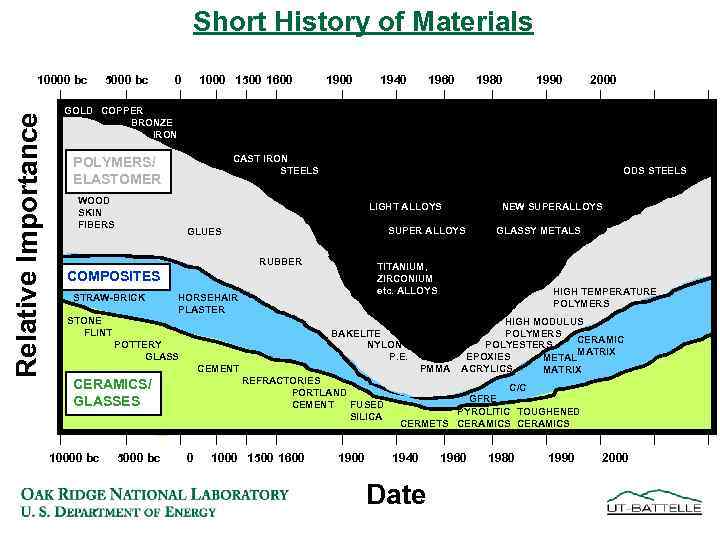

Short History of Materials Relative Importance 10000 bc 5000 bc 0 1000 1500 1600 GOLD COPPER BRONZE IRON 1900 1940 1980 ODS STEELS LIGHT ALLOYS RUBBER HORSEHAIR PLASTER CEMENT 5000 bc HIGH TEMPERATURE POLYMERS BAKELITE NYLON P. E. POTTERY GLASS PMMA REFRACTORIES PORTLAND CEMENT FUSED SILICA 0 1000 1500 1600 GLASSY METALS TITANIUM, ZIRCONIUM etc. ALLOYS COMPOSITES CERAMICS/ GLASSES NEW SUPERALLOYS SUPER ALLOYS GLUES STONE FLINT 2000 CAST IRON STEELS WOOD SKIN FIBERS STRAW-BRICK 1990 METALS POLYMERS/ ELASTOMER 10000 bc 1960 1900 HIGH MODULUS POLYMERS CERAMIC POLYESTERS MATRIX EPOXIES METAL ACRYLICS MATRIX C/C GFRE PYROLITIC TOUGHENED CERMETS CERAMICS 1940 Date 1960 1980 1990 2000

Short History of Materials Relative Importance 10000 bc 5000 bc 0 1000 1500 1600 GOLD COPPER BRONZE IRON 1900 1940 1980 ODS STEELS LIGHT ALLOYS RUBBER HORSEHAIR PLASTER CEMENT 5000 bc HIGH TEMPERATURE POLYMERS BAKELITE NYLON P. E. POTTERY GLASS PMMA REFRACTORIES PORTLAND CEMENT FUSED SILICA 0 1000 1500 1600 GLASSY METALS TITANIUM, ZIRCONIUM etc. ALLOYS COMPOSITES CERAMICS/ GLASSES NEW SUPERALLOYS SUPER ALLOYS GLUES STONE FLINT 2000 CAST IRON STEELS WOOD SKIN FIBERS STRAW-BRICK 1990 METALS POLYMERS/ ELASTOMER 10000 bc 1960 1900 HIGH MODULUS POLYMERS CERAMIC POLYESTERS MATRIX EPOXIES METAL ACRYLICS MATRIX C/C GFRE PYROLITIC TOUGHENED CERMETS CERAMICS 1940 Date 1960 1980 1990 2000

Ceramic Structural Composites The Most Advanced Structural Material Fusion Structural Composites

Ceramic Structural Composites The Most Advanced Structural Material Fusion Structural Composites

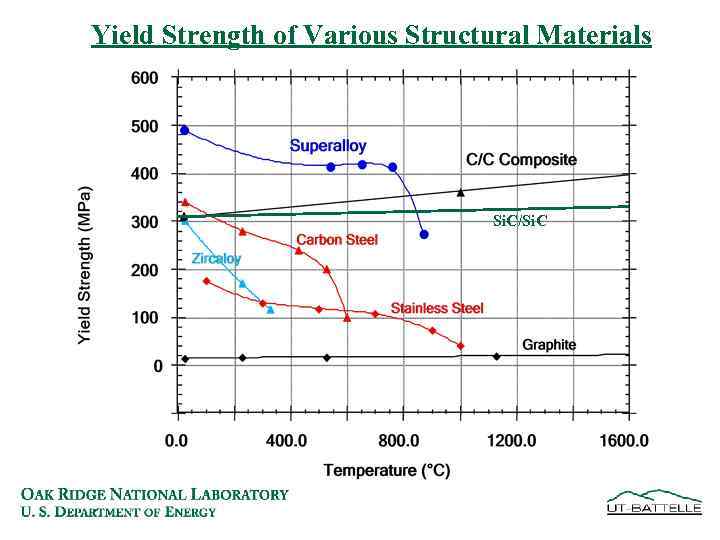

Yield Strength of Various Structural Materials Si. C/Si. C

Yield Strength of Various Structural Materials Si. C/Si. C

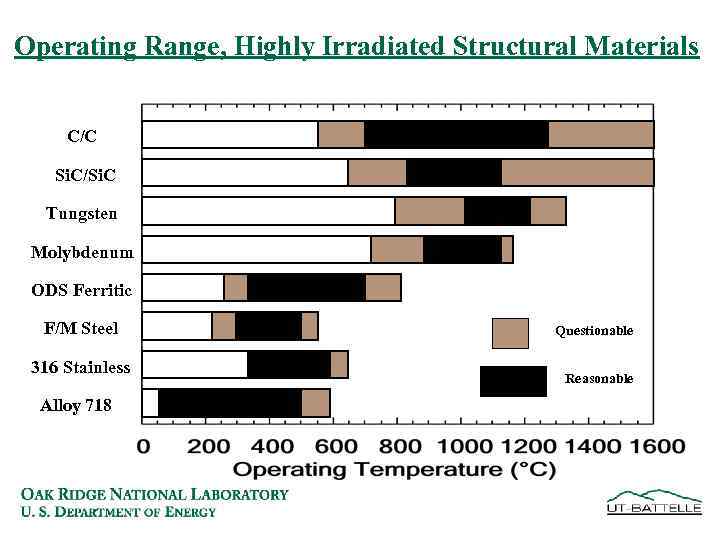

Operating Range, Highly Irradiated Structural Materials C/C Si. C/Si. C Tungsten Molybdenum ODS Ferritic F/M Steel 316 Stainless Alloy 718 Questionable Reasonable

Operating Range, Highly Irradiated Structural Materials C/C Si. C/Si. C Tungsten Molybdenum ODS Ferritic F/M Steel 316 Stainless Alloy 718 Questionable Reasonable

Ceramic Structural Composites The Most Advanced Structural Material Carbon/Carbon Composites - In widespread structural use - Manufacturing and design methods understood - Expensive…

Ceramic Structural Composites The Most Advanced Structural Material Carbon/Carbon Composites - In widespread structural use - Manufacturing and design methods understood - Expensive…

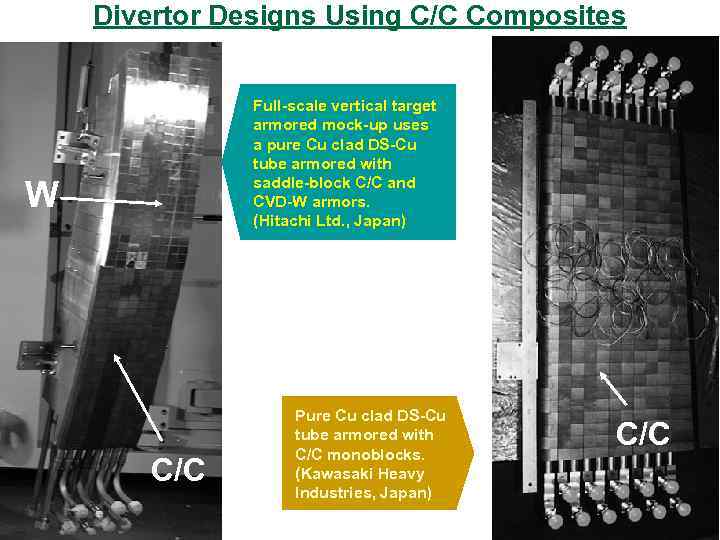

Divertor Designs Using C/C Composites Full-scale vertical target armored mock-up uses a pure Cu clad DS-Cu tube armored with saddle-block C/C and CVD-W armors. (Hitachi Ltd. , Japan) W C/C Pure Cu clad DS-Cu tube armored with C/C monoblocks. (Kawasaki Heavy Industries, Japan) C/C

Divertor Designs Using C/C Composites Full-scale vertical target armored mock-up uses a pure Cu clad DS-Cu tube armored with saddle-block C/C and CVD-W armors. (Hitachi Ltd. , Japan) W C/C Pure Cu clad DS-Cu tube armored with C/C monoblocks. (Kawasaki Heavy Industries, Japan) C/C

Ceramic Structural Composites The Most Advanced Structural Material Irradiation Performance of Carbon Fiber Composites - Lifetime is limited - Tritium Retention Unavoidable

Ceramic Structural Composites The Most Advanced Structural Material Irradiation Performance of Carbon Fiber Composites - Lifetime is limited - Tritium Retention Unavoidable

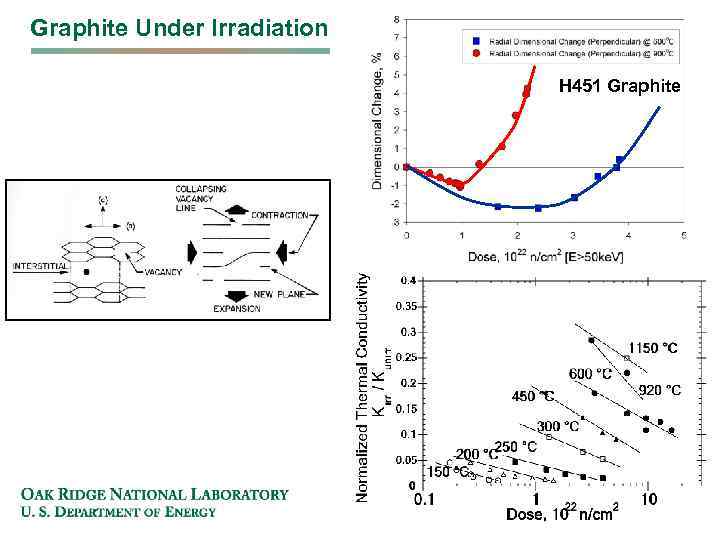

Graphite Under Irradiation H 451 Graphite

Graphite Under Irradiation H 451 Graphite

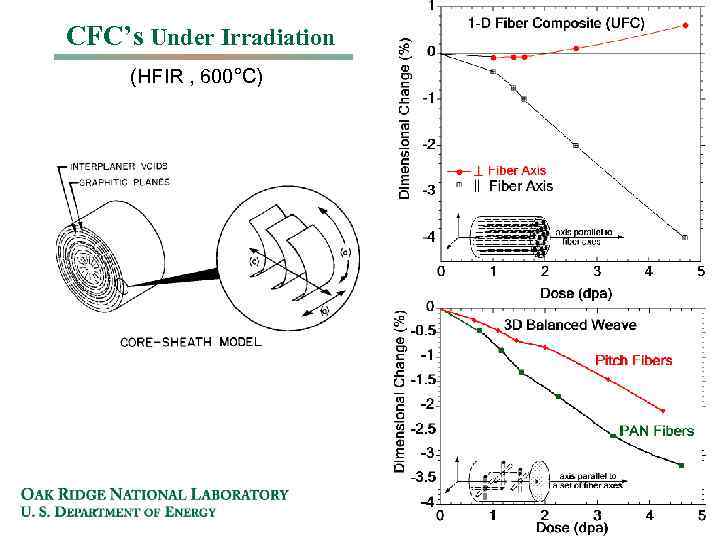

CFC’s Under Irradiation (HFIR , 600°C)

CFC’s Under Irradiation (HFIR , 600°C)

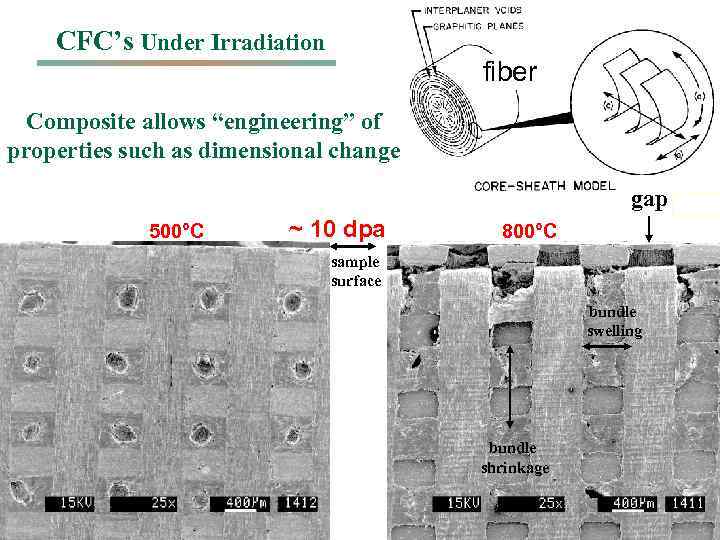

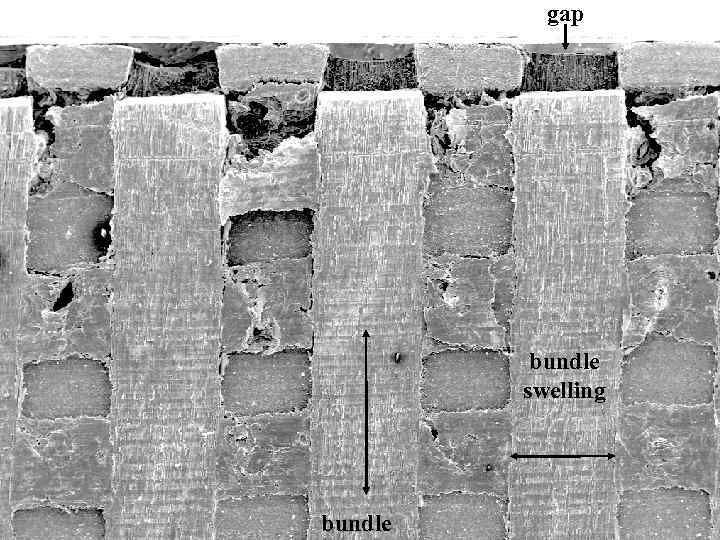

CFC’s Under Irradiation fiber Composite allows “engineering” of properties such as dimensional change gap 500°C ~ 10 dpa 800°C sample surface bundle swelling bundle shrinkage

CFC’s Under Irradiation fiber Composite allows “engineering” of properties such as dimensional change gap 500°C ~ 10 dpa 800°C sample surface bundle swelling bundle shrinkage

gap bundle swelling bundle

gap bundle swelling bundle

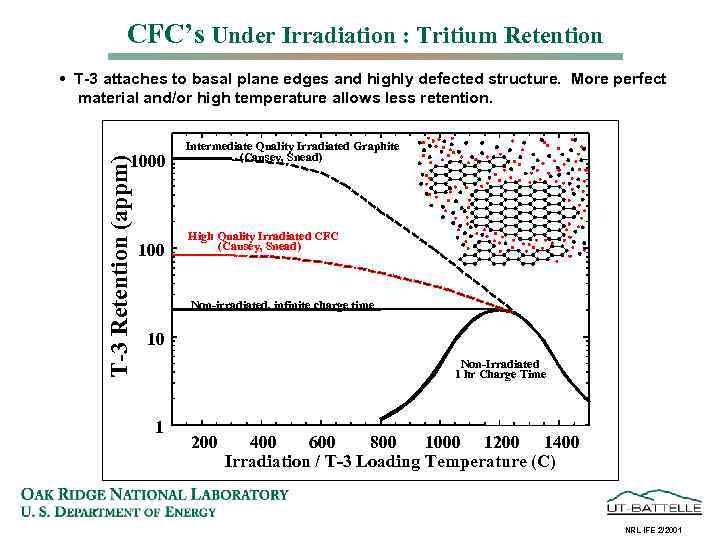

CFC’s Under Irradiation : Tritium Retention • T-3 attaches to basal plane edges and highly defected structure. More perfect material and/or high temperature allows less retention. T-3 Retention (appm) 1000 100 Intermediate Quality Irradiated Graphite (Causey, Snead) High Quality Irradiated CFC (Causey, Snead) Non-irradiated, infinite charge time 10 Non-Irradiated 1 hr Charge Time 1 200 400 600 800 1000 1200 1400 Irradiation / T-3 Loading Temperature (C) NRL IFE 2/2001

CFC’s Under Irradiation : Tritium Retention • T-3 attaches to basal plane edges and highly defected structure. More perfect material and/or high temperature allows less retention. T-3 Retention (appm) 1000 100 Intermediate Quality Irradiated Graphite (Causey, Snead) High Quality Irradiated CFC (Causey, Snead) Non-irradiated, infinite charge time 10 Non-Irradiated 1 hr Charge Time 1 200 400 600 800 1000 1200 1400 Irradiation / T-3 Loading Temperature (C) NRL IFE 2/2001

Ceramic Structural Composites The Most Advanced Structural Material Si. C/Si. C Composites - Essentially no current structural application - Manufacturing and design methods immature

Ceramic Structural Composites The Most Advanced Structural Material Si. C/Si. C Composites - Essentially no current structural application - Manufacturing and design methods immature

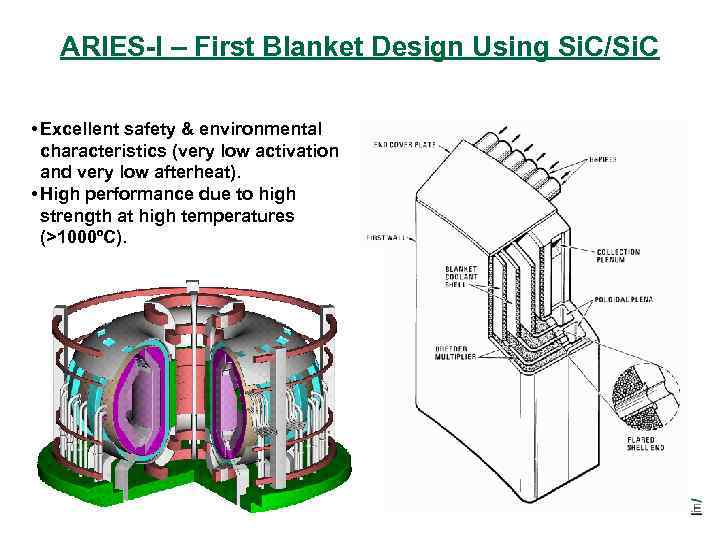

ARIES-I – First Blanket Design Using Si. C/Si. C • Excellent safety & environmental characteristics (very low activation and very low afterheat). • High performance due to high strength at high temperatures (>1000ºC).

ARIES-I – First Blanket Design Using Si. C/Si. C • Excellent safety & environmental characteristics (very low activation and very low afterheat). • High performance due to high strength at high temperatures (>1000ºC).

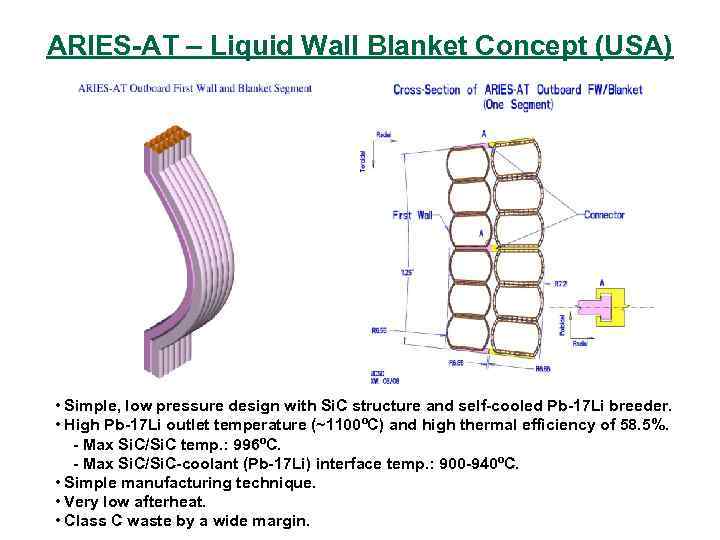

ARIES-AT – Liquid Wall Blanket Concept (USA) • Simple, low pressure design with Si. C structure and self-cooled Pb-17 Li breeder. • High Pb-17 Li outlet temperature (~1100ºC) and high thermal efficiency of 58. 5%. - Max Si. C/Si. C temp. : 996ºC. - Max Si. C/Si. C-coolant (Pb-17 Li) interface temp. : 900 -940ºC. • Simple manufacturing technique. • Very low afterheat. • Class C waste by a wide margin.

ARIES-AT – Liquid Wall Blanket Concept (USA) • Simple, low pressure design with Si. C structure and self-cooled Pb-17 Li breeder. • High Pb-17 Li outlet temperature (~1100ºC) and high thermal efficiency of 58. 5%. - Max Si. C/Si. C temp. : 996ºC. - Max Si. C/Si. C-coolant (Pb-17 Li) interface temp. : 900 -940ºC. • Simple manufacturing technique. • Very low afterheat. • Class C waste by a wide margin.

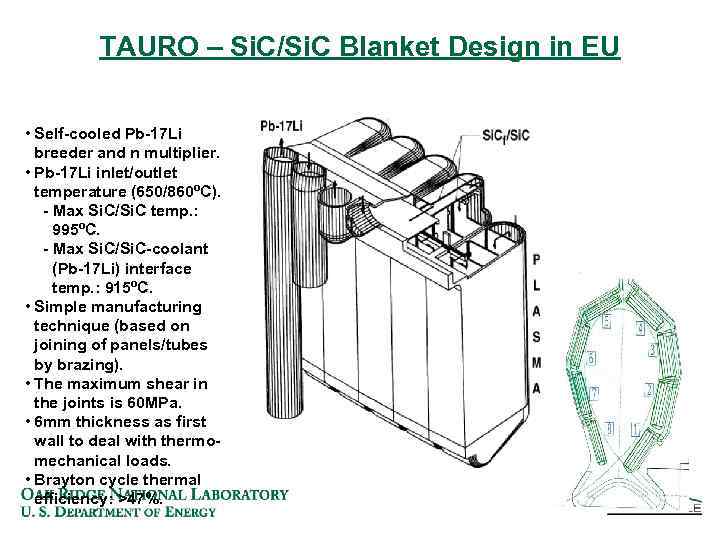

TAURO – Si. C/Si. C Blanket Design in EU • Self-cooled Pb-17 Li breeder and n multiplier. • Pb-17 Li inlet/outlet temperature (650/860ºC). - Max Si. C/Si. C temp. : 995ºC. - Max Si. C/Si. C-coolant (Pb-17 Li) interface temp. : 915ºC. • Simple manufacturing technique (based on joining of panels/tubes by brazing). • The maximum shear in the joints is 60 MPa. • 6 mm thickness as first wall to deal with thermomechanical loads. • Brayton cycle thermal efficiency: >47%.

TAURO – Si. C/Si. C Blanket Design in EU • Self-cooled Pb-17 Li breeder and n multiplier. • Pb-17 Li inlet/outlet temperature (650/860ºC). - Max Si. C/Si. C temp. : 995ºC. - Max Si. C/Si. C-coolant (Pb-17 Li) interface temp. : 915ºC. • Simple manufacturing technique (based on joining of panels/tubes by brazing). • The maximum shear in the joints is 60 MPa. • 6 mm thickness as first wall to deal with thermomechanical loads. • Brayton cycle thermal efficiency: >47%.

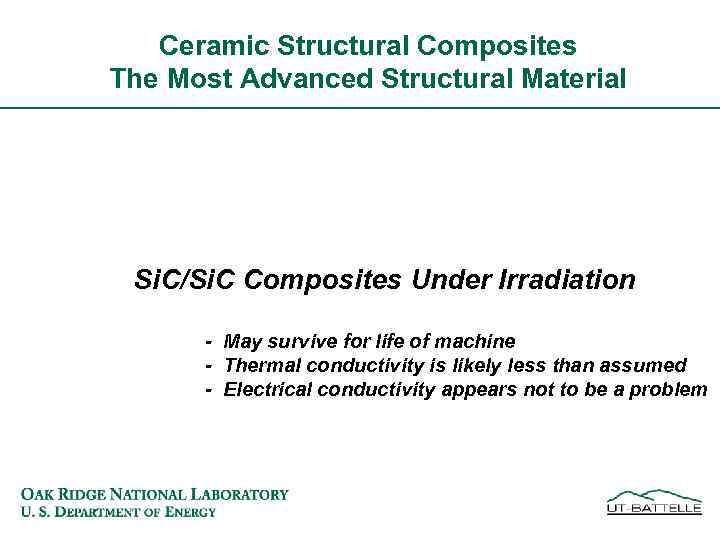

Ceramic Structural Composites The Most Advanced Structural Material Si. C/Si. C Composites Under Irradiation - May survive for life of machine - Thermal conductivity is likely less than assumed - Electrical conductivity appears not to be a problem

Ceramic Structural Composites The Most Advanced Structural Material Si. C/Si. C Composites Under Irradiation - May survive for life of machine - Thermal conductivity is likely less than assumed - Electrical conductivity appears not to be a problem

Si. C Under Irradiation • Irradiation-induced thermo-physical property changes (swelling, thermal conductivity, strength) saturate by a few dpa for T< 1000°C. Driven by simple defect clusters. • Irradiation performance for T>1000°C is not well understood.

Si. C Under Irradiation • Irradiation-induced thermo-physical property changes (swelling, thermal conductivity, strength) saturate by a few dpa for T< 1000°C. Driven by simple defect clusters. • Irradiation performance for T>1000°C is not well understood.

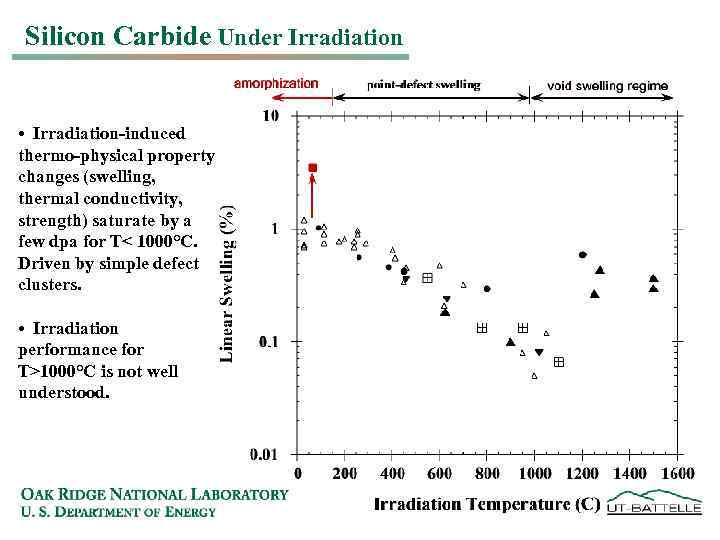

Silicon Carbide Under Irradiation • Irradiation-induced thermo-physical property changes (swelling, thermal conductivity, strength) saturate by a few dpa for T< 1000°C. Driven by simple defect clusters. • Irradiation performance for T>1000°C is not well understood.

Silicon Carbide Under Irradiation • Irradiation-induced thermo-physical property changes (swelling, thermal conductivity, strength) saturate by a few dpa for T< 1000°C. Driven by simple defect clusters. • Irradiation performance for T>1000°C is not well understood.

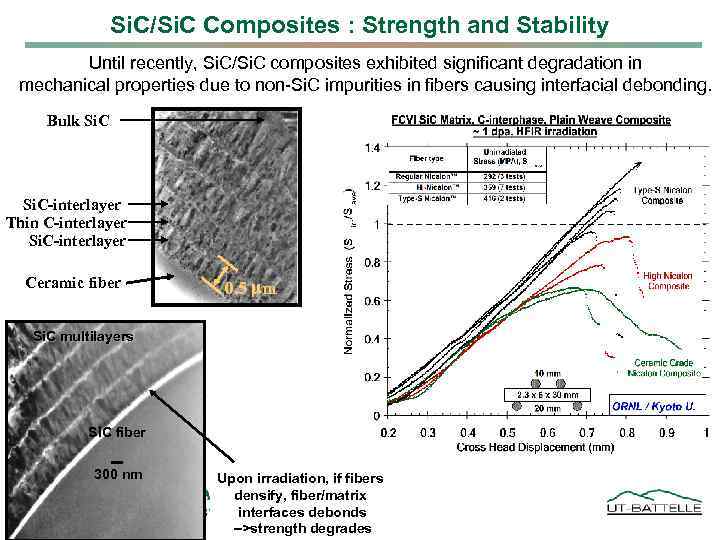

Si. C/Si. C Composites : Strength and Stability Until recently, Si. C/Si. C composites exhibited significant degradation in mechanical properties due to non-Si. C impurities in fibers causing interfacial debonding. Bulk Si. C-interlayer Thin C-interlayer Si. C-interlayer Ceramic fiber 0. 5 m Si. C multilayers Si. C fiber 300 nm Upon irradiation, if fibers densify, fiber/matrix interfaces debonds -->strength degrades

Si. C/Si. C Composites : Strength and Stability Until recently, Si. C/Si. C composites exhibited significant degradation in mechanical properties due to non-Si. C impurities in fibers causing interfacial debonding. Bulk Si. C-interlayer Thin C-interlayer Si. C-interlayer Ceramic fiber 0. 5 m Si. C multilayers Si. C fiber 300 nm Upon irradiation, if fibers densify, fiber/matrix interfaces debonds -->strength degrades

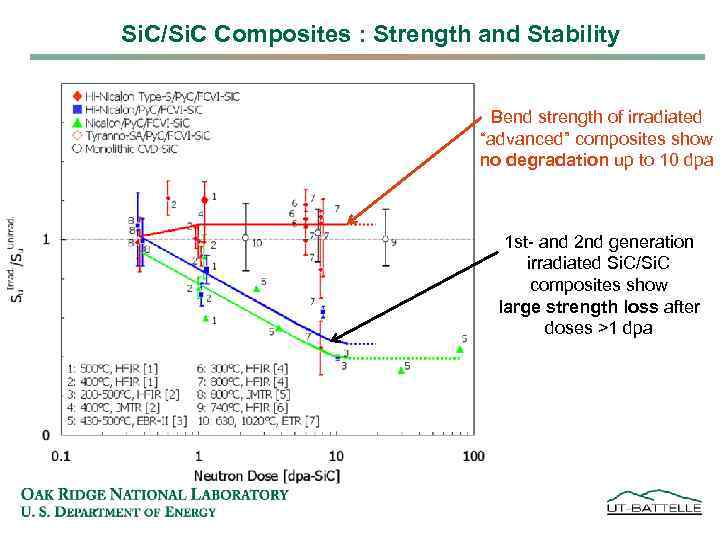

Si. C/Si. C Composites : Strength and Stability Bend strength of irradiated “advanced” composites show no degradation up to 10 dpa 1 st- and 2 nd generation irradiated Si. C/Si. C composites show large strength loss after doses >1 dpa

Si. C/Si. C Composites : Strength and Stability Bend strength of irradiated “advanced” composites show no degradation up to 10 dpa 1 st- and 2 nd generation irradiated Si. C/Si. C composites show large strength loss after doses >1 dpa

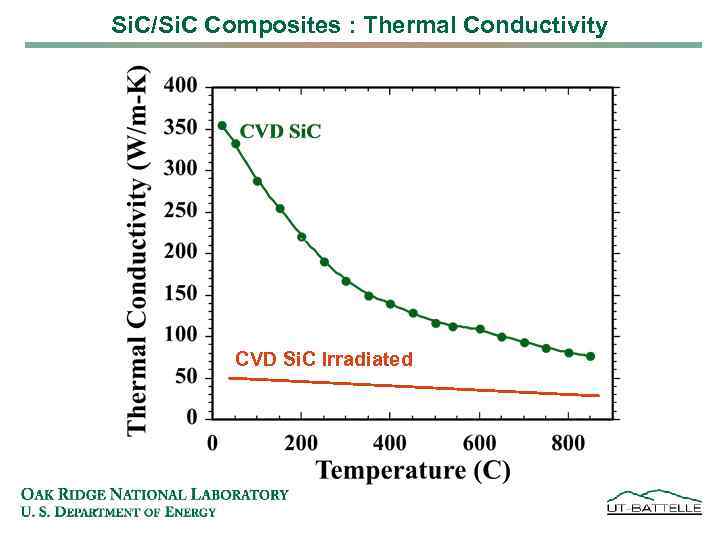

Si. C/Si. C Composites : Thermal Conductivity CVD Si. C Irradiated

Si. C/Si. C Composites : Thermal Conductivity CVD Si. C Irradiated

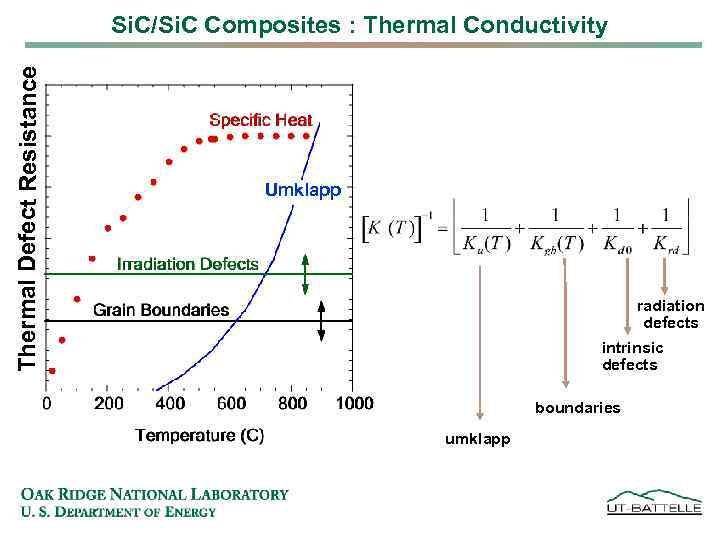

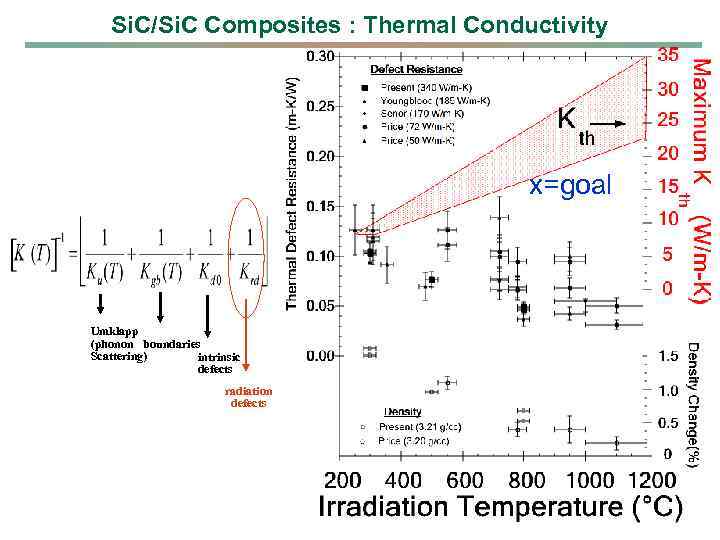

Thermal Defect Resistance Si. C/Si. C Composites : Thermal Conductivity Umklapp radiation defects intrinsic defects boundaries umklapp

Thermal Defect Resistance Si. C/Si. C Composites : Thermal Conductivity Umklapp radiation defects intrinsic defects boundaries umklapp

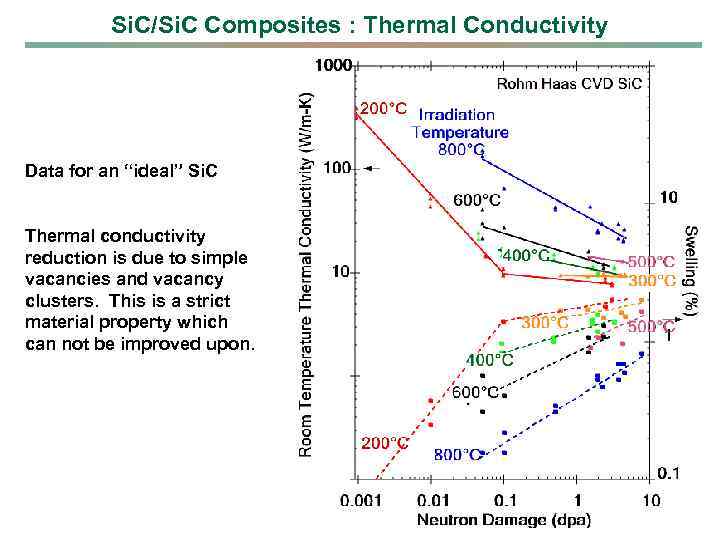

Si. C/Si. C Composites : Thermal Conductivity Data for an “ideal” Si. C Thermal conductivity reduction is due to simple vacancies and vacancy clusters. This is a strict material property which can not be improved upon.

Si. C/Si. C Composites : Thermal Conductivity Data for an “ideal” Si. C Thermal conductivity reduction is due to simple vacancies and vacancy clusters. This is a strict material property which can not be improved upon.

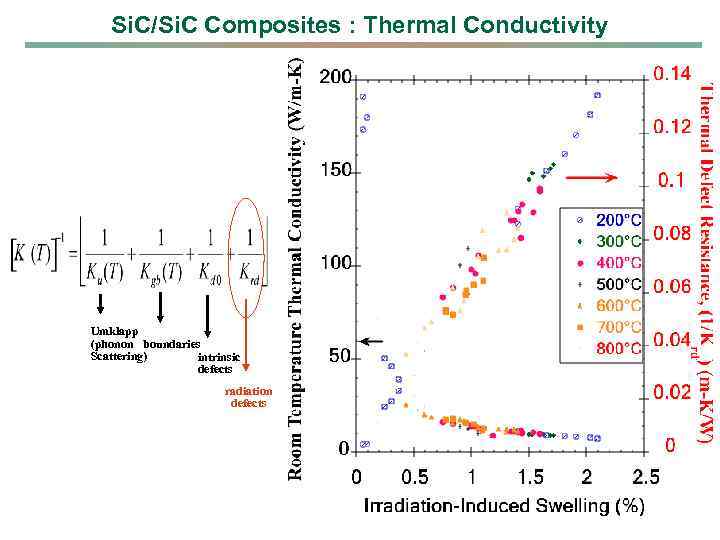

Si. C/Si. C Composites : Thermal Conductivity Umklapp (phonon boundaries Scattering) intrinsic defects radiation defects

Si. C/Si. C Composites : Thermal Conductivity Umklapp (phonon boundaries Scattering) intrinsic defects radiation defects

Si. C/Si. C Composites : Thermal Conductivity x=goal Umklapp (phonon boundaries Scattering) intrinsic defects radiation defects

Si. C/Si. C Composites : Thermal Conductivity x=goal Umklapp (phonon boundaries Scattering) intrinsic defects radiation defects

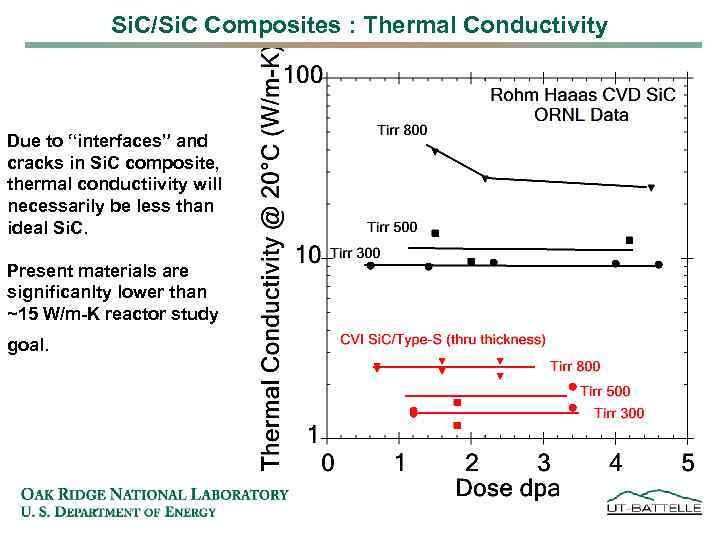

Si. C/Si. C Composites : Thermal Conductivity Due to “interfaces” and cracks in Si. C composite, thermal conductiivity will necessarily be less than ideal Si. C. Present materials are significanlty lower than ~15 W/m-K reactor study goal.

Si. C/Si. C Composites : Thermal Conductivity Due to “interfaces” and cracks in Si. C composite, thermal conductiivity will necessarily be less than ideal Si. C. Present materials are significanlty lower than ~15 W/m-K reactor study goal.

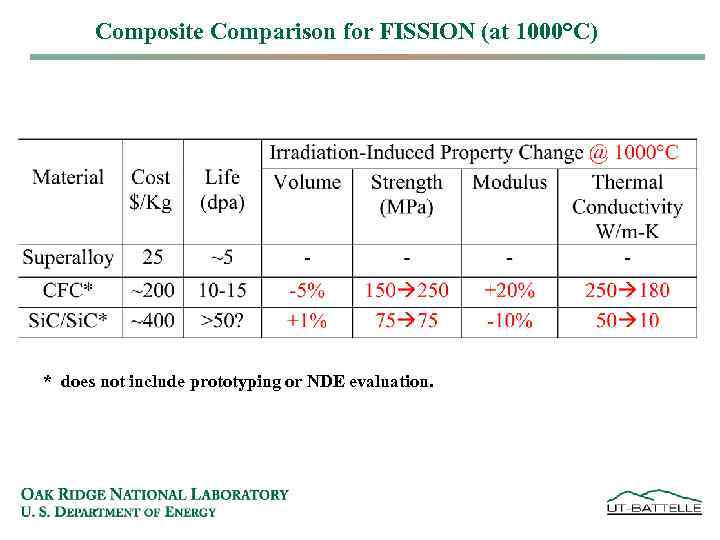

Composite Comparison for FISSION (at 1000°C) * does not include prototyping or NDE evaluation.

Composite Comparison for FISSION (at 1000°C) * does not include prototyping or NDE evaluation.

Ceramic Structural Composites The Most Advanced Structural Material Si. C Matrix / Graphite Fiber Composites - Now being used in NASA application - Manufacturing and design methods immature - May solve the dual problems of low thermal conductivity of Si. C/Si. C and high T-3 retention of C/C

Ceramic Structural Composites The Most Advanced Structural Material Si. C Matrix / Graphite Fiber Composites - Now being used in NASA application - Manufacturing and design methods immature - May solve the dual problems of low thermal conductivity of Si. C/Si. C and high T-3 retention of C/C

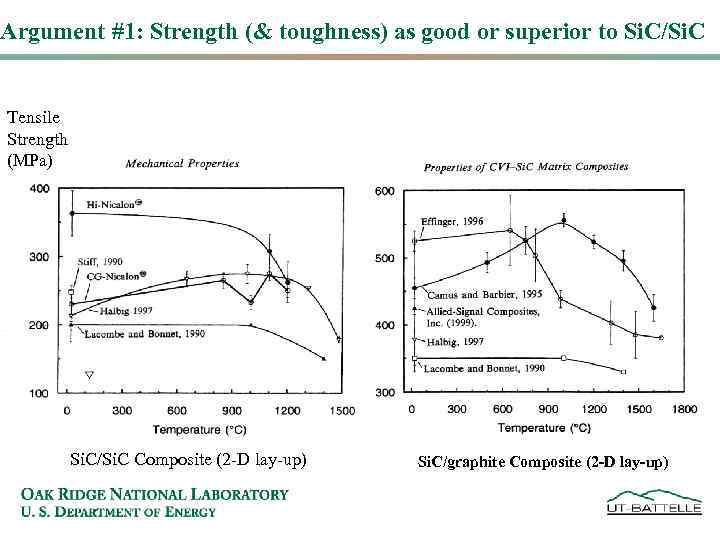

Argument #1: Strength (& toughness) as good or superior to Si. C/Si. C Tensile Strength (MPa) Si. C/Si. C Composite (2 -D lay-up) Si. C/graphite Composite (2 -D lay-up)

Argument #1: Strength (& toughness) as good or superior to Si. C/Si. C Tensile Strength (MPa) Si. C/Si. C Composite (2 -D lay-up) Si. C/graphite Composite (2 -D lay-up)

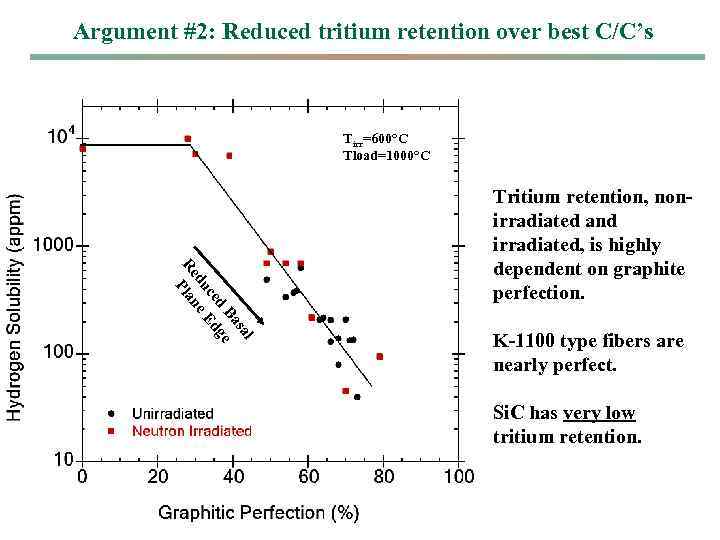

Argument #2: Reduced tritium retention over best C/C’s Tirr=600°C Tload=1000°C l sa Ba d ge ce Ed du e Re Plan Tritium retention, nonirradiated and irradiated, is highly dependent on graphite perfection. K-1100 type fibers are nearly perfect. Si. C has very low tritium retention.

Argument #2: Reduced tritium retention over best C/C’s Tirr=600°C Tload=1000°C l sa Ba d ge ce Ed du e Re Plan Tritium retention, nonirradiated and irradiated, is highly dependent on graphite perfection. K-1100 type fibers are nearly perfect. Si. C has very low tritium retention.

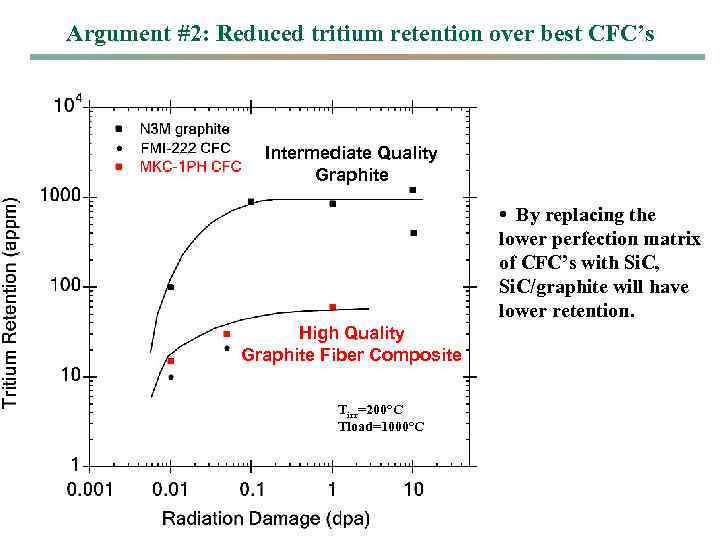

Argument #2: Reduced tritium retention over best CFC’s Intermediate Quality Graphite • By replacing the lower perfection matrix of CFC’s with Si. C, Si. C/graphite will have lower retention. High Quality Graphite Fiber Composite Tirr=200°C Tload=1000°C

Argument #2: Reduced tritium retention over best CFC’s Intermediate Quality Graphite • By replacing the lower perfection matrix of CFC’s with Si. C, Si. C/graphite will have lower retention. High Quality Graphite Fiber Composite Tirr=200°C Tload=1000°C

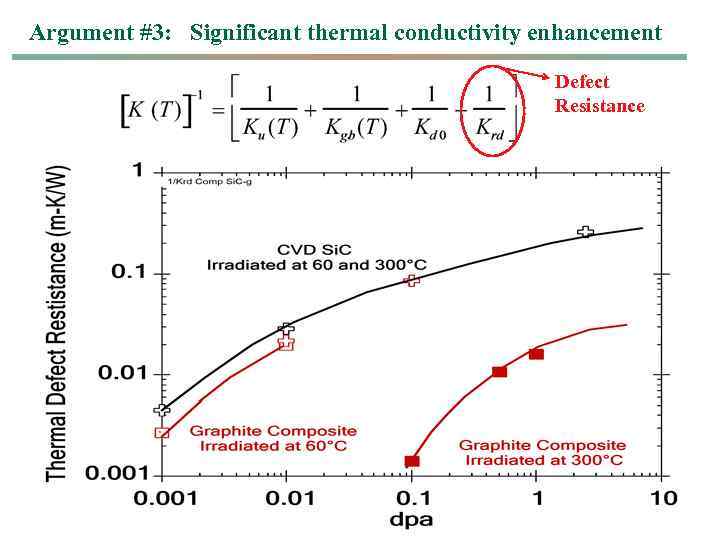

Argument #3: Significant thermal conductivity enhancement Defect Resistance

Argument #3: Significant thermal conductivity enhancement Defect Resistance

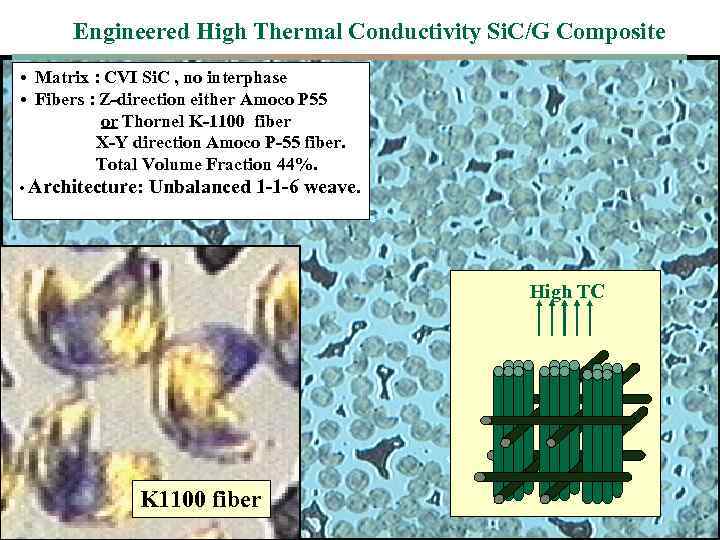

Engineered High Thermal Conductivity Si. C/G Composite • Matrix : CVI Si. C , no interphase • Fibers : Z-direction either Amoco P 55 or Thornel K-1100 fiber X-Y direction Amoco P-55 fiber. Total Volume Fraction 44%. • Architecture: Unbalanced 1 -1 -6 weave. High TC K 1100 fiber

Engineered High Thermal Conductivity Si. C/G Composite • Matrix : CVI Si. C , no interphase • Fibers : Z-direction either Amoco P 55 or Thornel K-1100 fiber X-Y direction Amoco P-55 fiber. Total Volume Fraction 44%. • Architecture: Unbalanced 1 -1 -6 weave. High TC K 1100 fiber

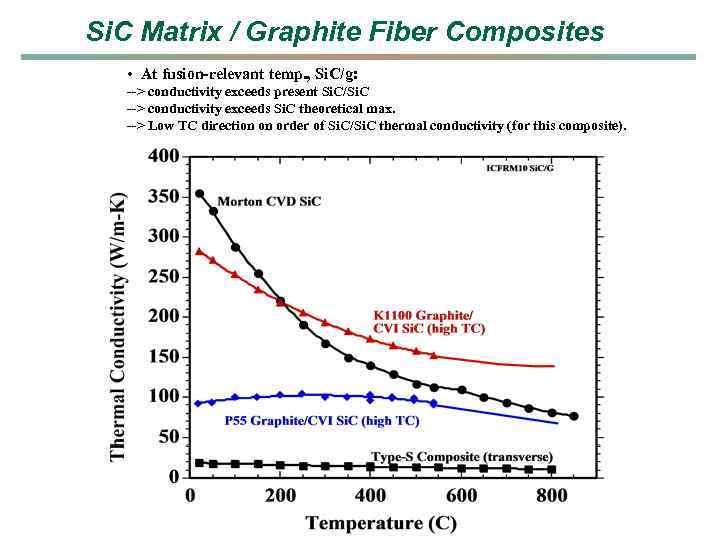

Si. C Matrix / Graphite Fiber Composites • At fusion-relevant temp. , Si. C/g: --> conductivity exceeds present Si. C/Si. C --> conductivity exceeds Si. C theoretical max. --> Low TC direction on order of Si. C/Si. C thermal conductivity (for this composite).

Si. C Matrix / Graphite Fiber Composites • At fusion-relevant temp. , Si. C/g: --> conductivity exceeds present Si. C/Si. C --> conductivity exceeds Si. C theoretical max. --> Low TC direction on order of Si. C/Si. C thermal conductivity (for this composite).

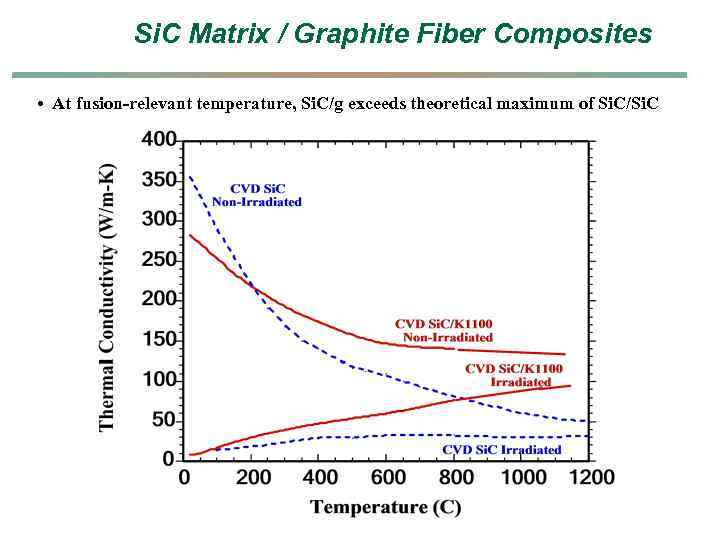

Si. C Matrix / Graphite Fiber Composites • At fusion-relevant temperature, Si. C/g exceeds theoretical maximum of Si. C/Si. C

Si. C Matrix / Graphite Fiber Composites • At fusion-relevant temperature, Si. C/g exceeds theoretical maximum of Si. C/Si. C

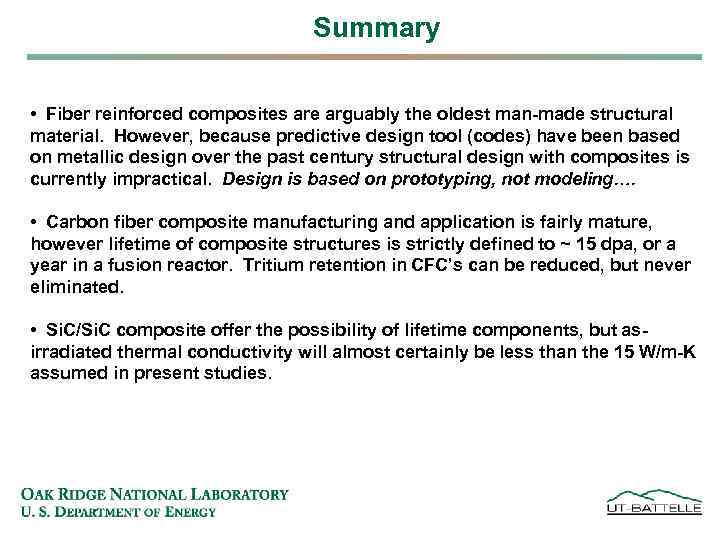

Summary • Fiber reinforced composites are arguably the oldest man-made structural material. However, because predictive design tool (codes) have been based on metallic design over the past century structural design with composites is currently impractical. Design is based on prototyping, not modeling…. • Carbon fiber composite manufacturing and application is fairly mature, however lifetime of composite structures is strictly defined to ~ 15 dpa, or a year in a fusion reactor. Tritium retention in CFC’s can be reduced, but never eliminated. • Si. C/Si. C composite offer the possibility of lifetime components, but asirradiated thermal conductivity will almost certainly be less than the 15 W/m-K assumed in present studies.

Summary • Fiber reinforced composites are arguably the oldest man-made structural material. However, because predictive design tool (codes) have been based on metallic design over the past century structural design with composites is currently impractical. Design is based on prototyping, not modeling…. • Carbon fiber composite manufacturing and application is fairly mature, however lifetime of composite structures is strictly defined to ~ 15 dpa, or a year in a fusion reactor. Tritium retention in CFC’s can be reduced, but never eliminated. • Si. C/Si. C composite offer the possibility of lifetime components, but asirradiated thermal conductivity will almost certainly be less than the 15 W/m-K assumed in present studies.

Questions ? ? ? Questions ?

Questions ? ? ? Questions ?

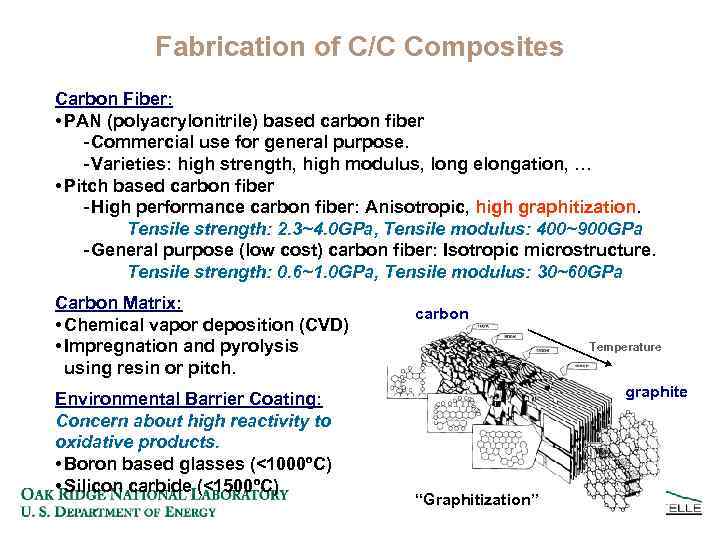

Fabrication of C/C Composites Carbon Fiber: • PAN (polyacrylonitrile) based carbon fiber - Commercial use for general purpose. - Varieties: high strength, high modulus, long elongation, … • Pitch based carbon fiber - High performance carbon fiber: Anisotropic, high graphitization. Tensile strength: 2. 3~4. 0 GPa, Tensile modulus: 400~900 GPa - General purpose (low cost) carbon fiber: Isotropic microstructure. Tensile strength: 0. 6~1. 0 GPa, Tensile modulus: 30~60 GPa Carbon Matrix: • Chemical vapor deposition (CVD) • Impregnation and pyrolysis using resin or pitch. Environmental Barrier Coating: Concern about high reactivity to oxidative products. • Boron based glasses (<1000ºC) • Silicon carbide (<1500ºC) carbon Temperature graphite “Graphitization”

Fabrication of C/C Composites Carbon Fiber: • PAN (polyacrylonitrile) based carbon fiber - Commercial use for general purpose. - Varieties: high strength, high modulus, long elongation, … • Pitch based carbon fiber - High performance carbon fiber: Anisotropic, high graphitization. Tensile strength: 2. 3~4. 0 GPa, Tensile modulus: 400~900 GPa - General purpose (low cost) carbon fiber: Isotropic microstructure. Tensile strength: 0. 6~1. 0 GPa, Tensile modulus: 30~60 GPa Carbon Matrix: • Chemical vapor deposition (CVD) • Impregnation and pyrolysis using resin or pitch. Environmental Barrier Coating: Concern about high reactivity to oxidative products. • Boron based glasses (<1000ºC) • Silicon carbide (<1500ºC) carbon Temperature graphite “Graphitization”

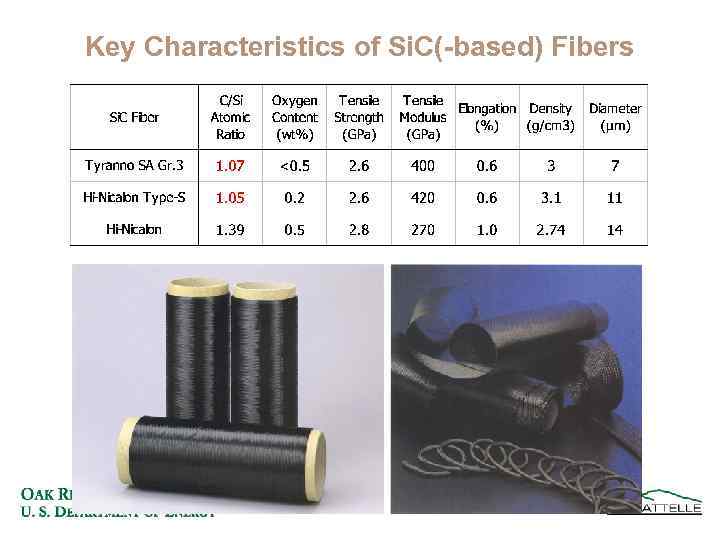

Key Characteristics of Si. C(-based) Fibers

Key Characteristics of Si. C(-based) Fibers