033147fc5d2cdfaf24c6dfff78e6e136.ppt

- Количество слайдов: 42

Centre for Technology Management Cambridge Institute for Manufacturing Centre for Technology Management David Probert UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management Topics • Institute for Manufacturing • Centre for Technology Management - Aims - Activities - Research portfolio UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

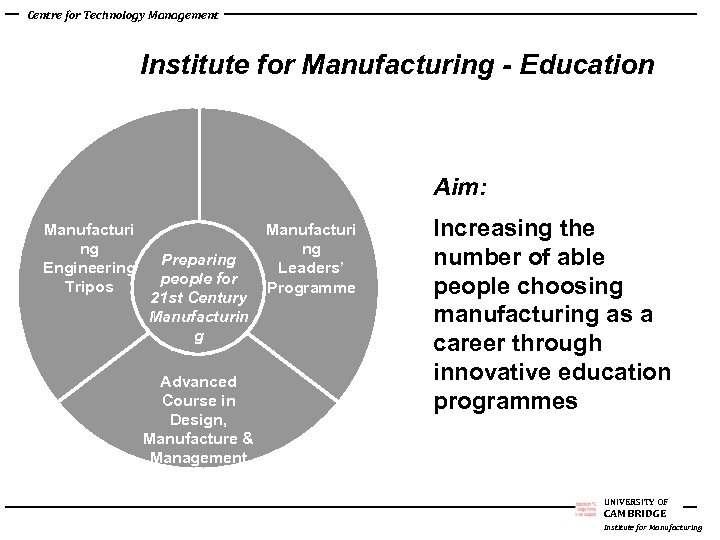

Centre for Technology Management Institute for Manufacturing - Education Aim: Manufacturi ng Engineering Tripos Preparing people for 21 st Century Manufacturin g Advanced Course in Design, Manufacture & Management Manufacturi ng Leaders’ Programme Increasing the number of able people choosing manufacturing as a career through innovative education programmes UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

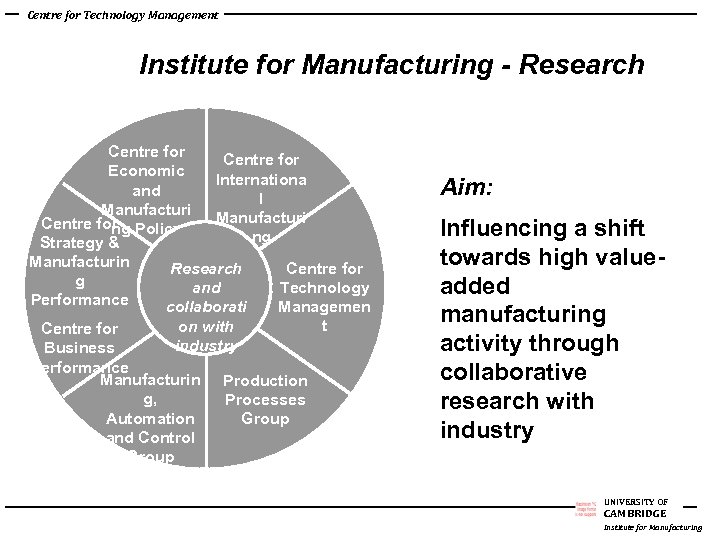

Centre for Technology Management Institute for Manufacturing - Research Centre for Economic Internationa and l Manufacturi Centre for Policy ng ng Strategy & Manufacturin Centre for Research g Technology and Performance Managemen collaborati t on with Centre for industry Business Performance Manufacturin Production g, Processes Automation Group and Control Group Aim: Influencing a shift towards high valueadded manufacturing activity through collaborative research with industry UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

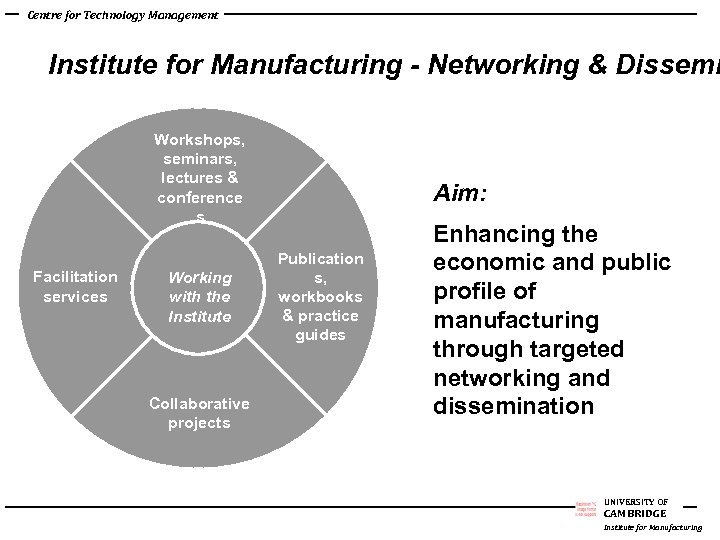

Centre for Technology Management Institute for Manufacturing - Networking & Dissemi Workshops, seminars, lectures & conference s Facilitation services Working with the Institute Collaborative projects Aim: Publication s, workbooks & practice guides Enhancing the economic and public profile of manufacturing through targeted networking and dissemination UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

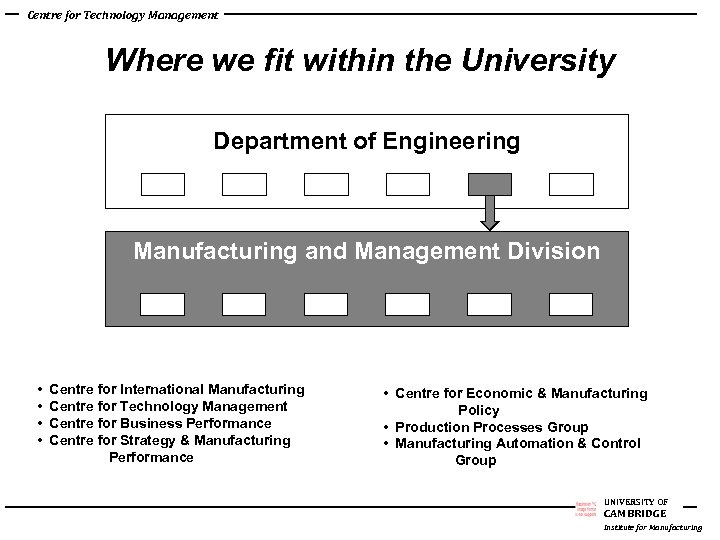

Centre for Technology Management Where we fit within the University Department of Engineering Manufacturing and Management Division • • Centre for International Manufacturing Centre for Technology Management Centre for Business Performance Centre for Strategy & Manufacturing Performance • Centre for Economic & Manufacturing Policy • Production Processes Group • Manufacturing Automation & Control Group UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

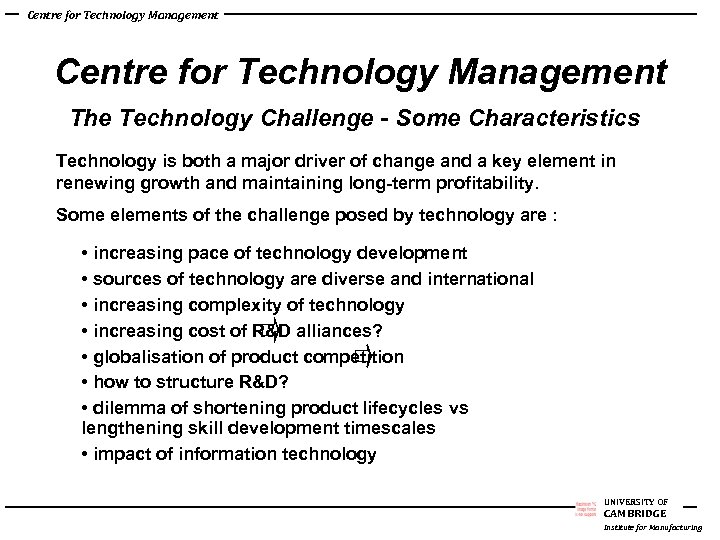

Centre for Technology Management The Technology Challenge - Some Characteristics Technology is both a major driver of change and a key element in renewing growth and maintaining long-term profitability. Some elements of the challenge posed by technology are : • increasing pace of technology development • sources of technology are diverse and international • increasing complexity of technology • increasing cost of R&D alliances? • globalisation of product competition • how to structure R&D? • dilemma of shortening product lifecycles vs lengthening skill development timescales • impact of information technology UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

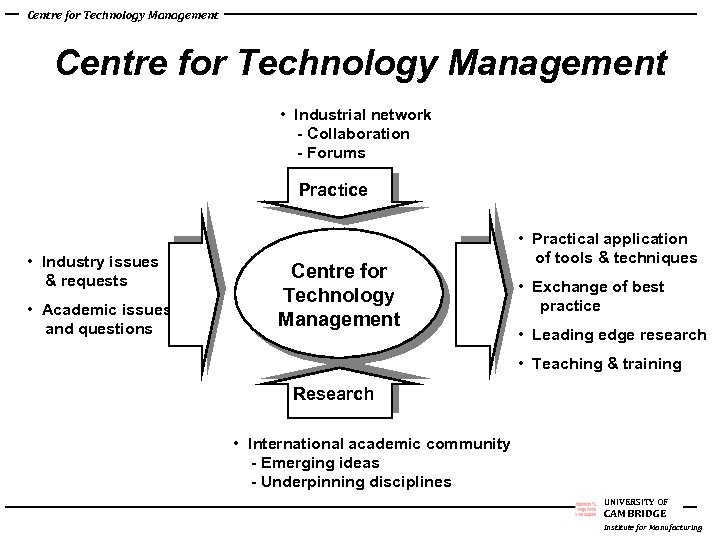

Centre for Technology Management • Industrial network - Collaboration - Forums Practice • Industry issues & requests • Academic issues and questions Centre for Technology Management • Practical application of tools & techniques • Exchange of best practice • Leading edge research • Teaching & training Research • International academic community - Emerging ideas - Underpinning disciplines UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management Centre Events • Forums • Workshops • Training & education • Annual symposium th - 13 -14 July 2000, Cambridge: Technology Planning - Technology roadmapping workshop UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

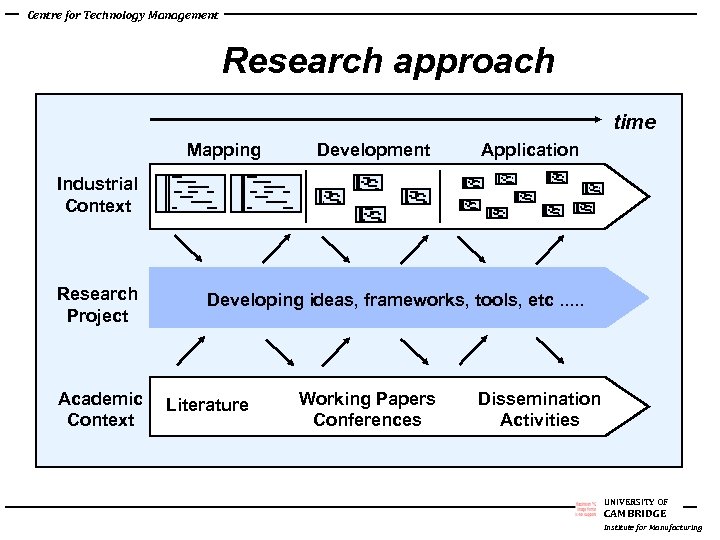

Centre for Technology Management Research approach time Mapping Development Application Industrial Context Research Project Academic Context Developing ideas, frameworks, tools, etc. . . Literature Working Papers Conferences Dissemination Activities UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

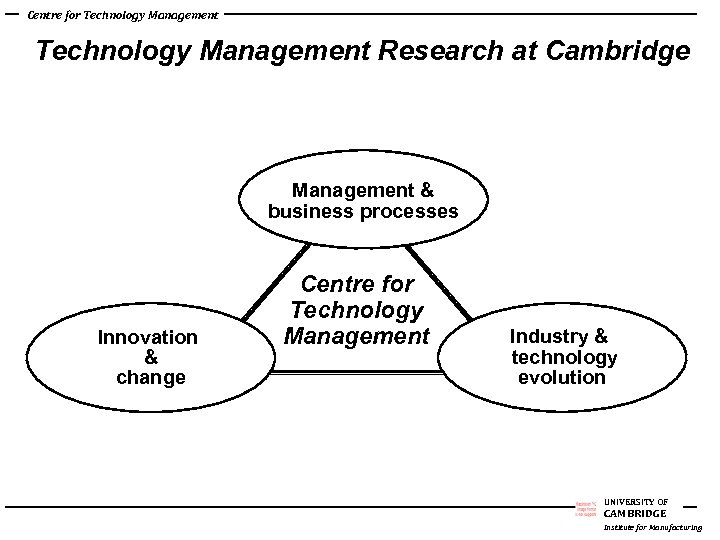

Centre for Technology Management Research at Cambridge Management & business processes Innovation & change Centre for Technology Management Industry & technology evolution UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

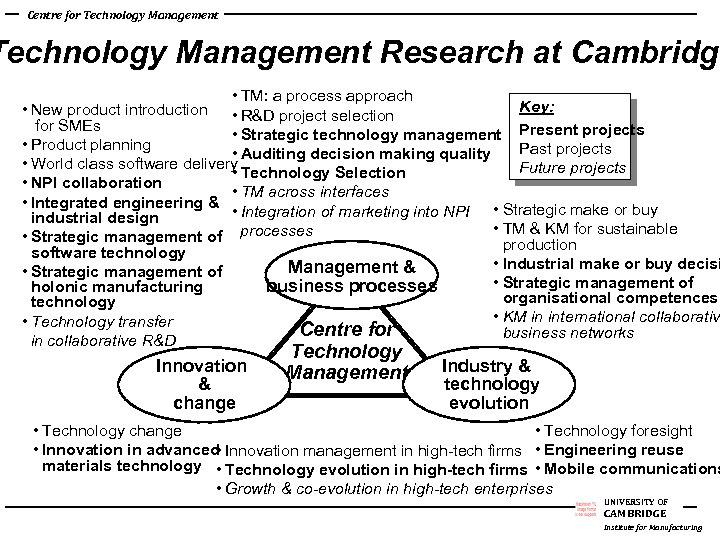

Centre for Technology Management Research at Cambridge • TM: a process approach Key: • New product introduction • R&D project selection for SMEs • Strategic technology management Present projects • Product planning Past projects • Auditing decision making quality • World class software delivery Future projects • Technology Selection • NPI collaboration • TM across interfaces • Integrated engineering & • Integration of marketing into NPI • Strategic make or buy industrial design • TM & KM for sustainable • Strategic management of processes production software technology • Industrial make or buy decisi Management & • Strategic management of business processes holonic manufacturing organisational competences technology • KM in international collaborativ • Technology transfer Centre for business networks in collaborative R&D Innovation & change Technology Management Industry & technology evolution • Technology change • Technology foresight • Innovation in advanced Innovation management in high-tech firms • Engineering reuse • materials technology • Technology evolution in high-tech firms • Mobile communications • Growth & co-evolution in high-tech enterprises UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

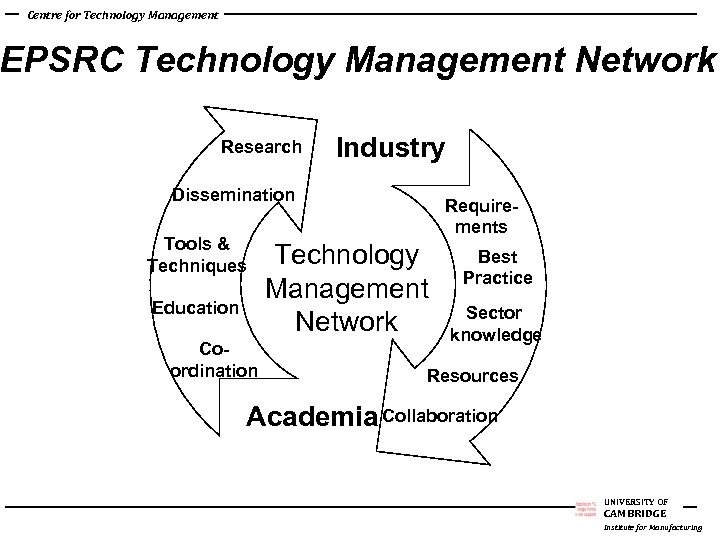

Centre for Technology Management EPSRC Technology Management Network Research Industry Dissemination Tools & Techniques Education Coordination Requirements Technology Management Network Best Practice Sector knowledge Resources Academia Collaboration UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

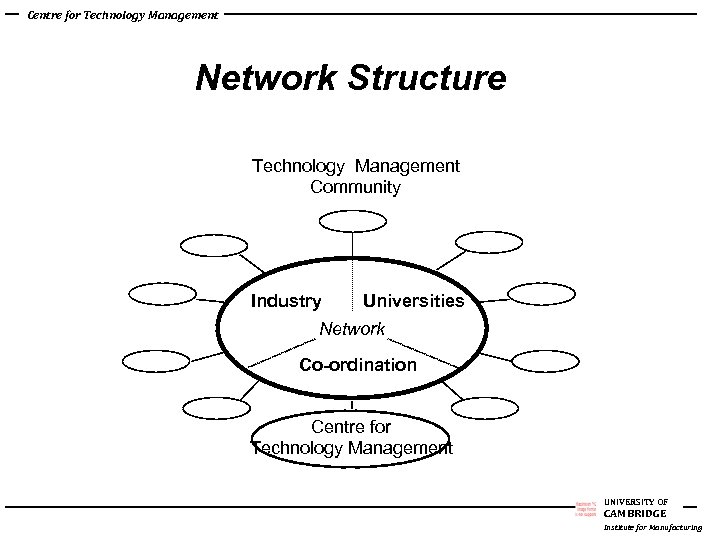

Centre for Technology Management Network Structure Technology Management Community Industry Universities Network Co-ordination Centre for Technology Management UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

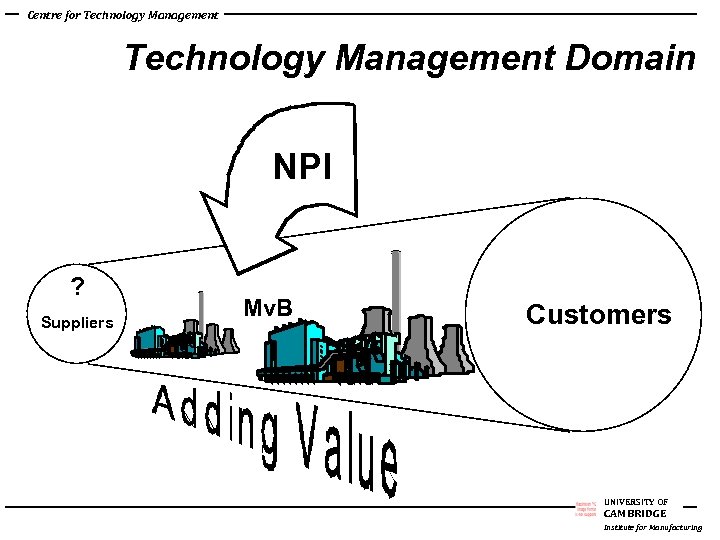

Centre for Technology Management Domain NPI ? Suppliers Mv. B Customers UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

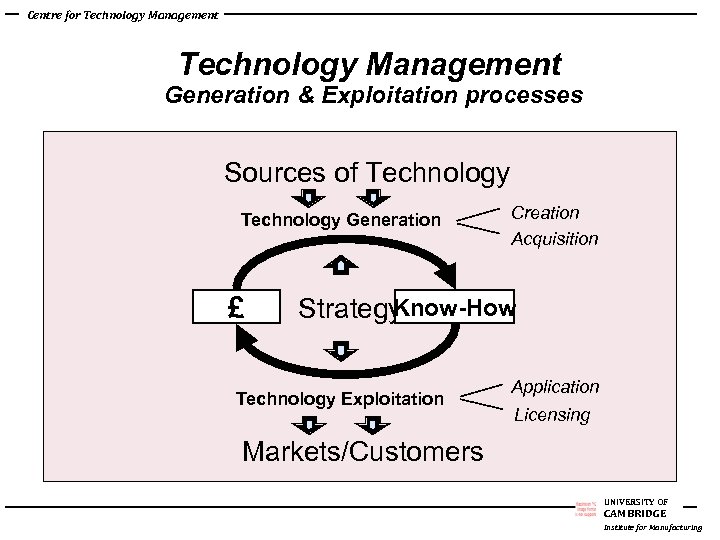

Centre for Technology Management Generation & Exploitation processes Sources of Technology Generation £ Creation Acquisition Know-How Strategy Technology Exploitation Application Licensing Markets/Customers UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management of Technology Key Questions • What are our technological assets? • How to manage them for business benefit? • What new technologies are relevant to our business? • How best to acquire and exploit new technologies? • How to protect technological assets? UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

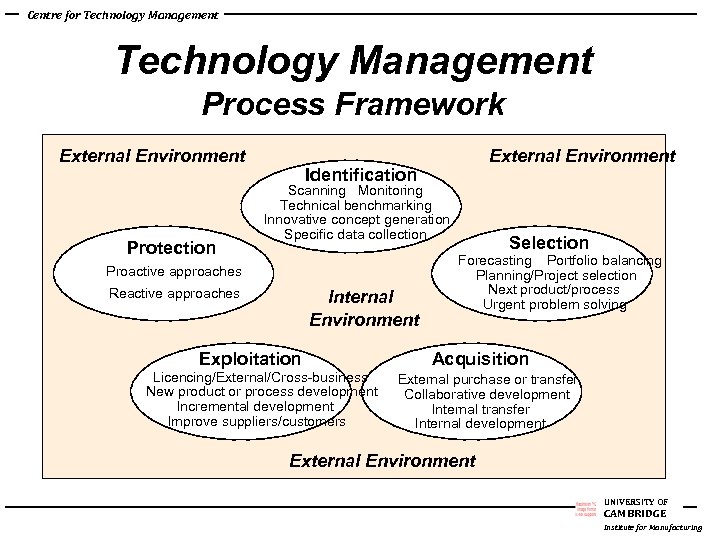

Centre for Technology Management Process Framework External Environment Protection External Environment Identification Scanning Monitoring Technical benchmarking Innovative concept generation Specific data collection Proactive approaches Reactive approaches Internal Environment Exploitation Licencing/External/Cross-business New product or process development Incremental development Improve suppliers/customers Selection Forecasting Portfolio balancing Planning/Project selection Next product/process Urgent problem solving Acquisition External purchase or transfer Collaborative development Internal transfer Internal development External Environment UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

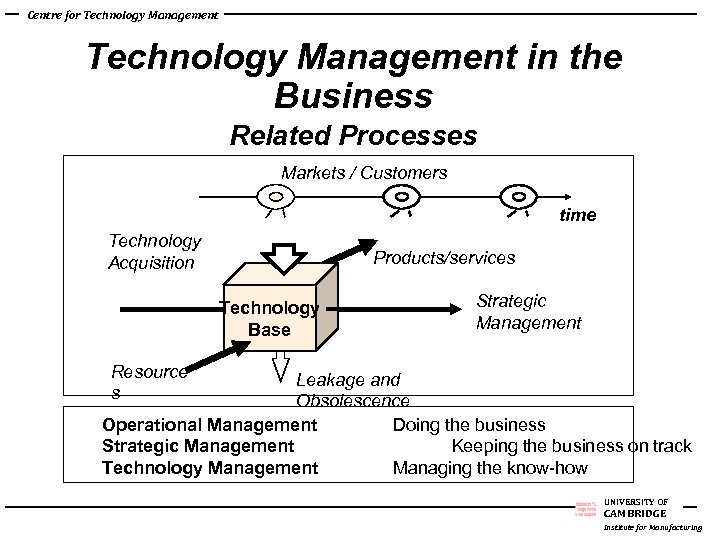

Centre for Technology Management in the Business Related Processes Markets / Customers time Technology Acquisition Products/services Technology Base Strategic Management Resource s Leakage and Obsolescence Operational Management Doing the business Strategic Management Keeping the business on track Technology Management Managing the know-how UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

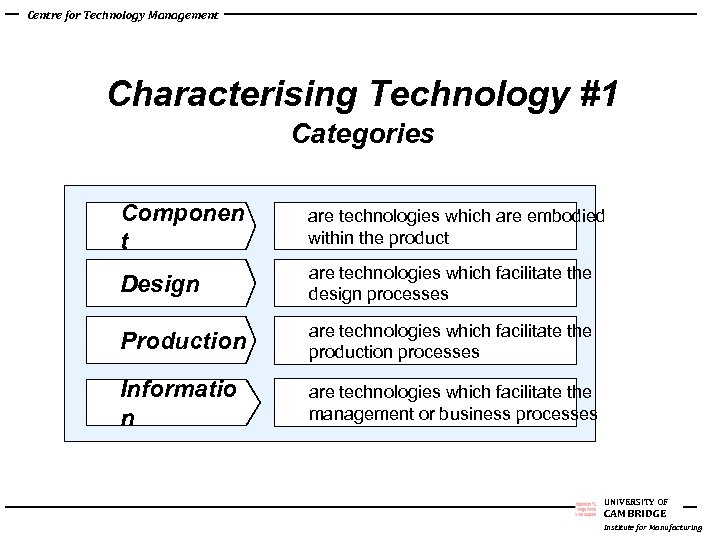

Centre for Technology Management Characterising Technology #1 Categories Componen t are technologies which are embodied within the product Design are technologies which facilitate the design processes Production are technologies which facilitate the production processes Informatio n are technologies which facilitate the management or business processes UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

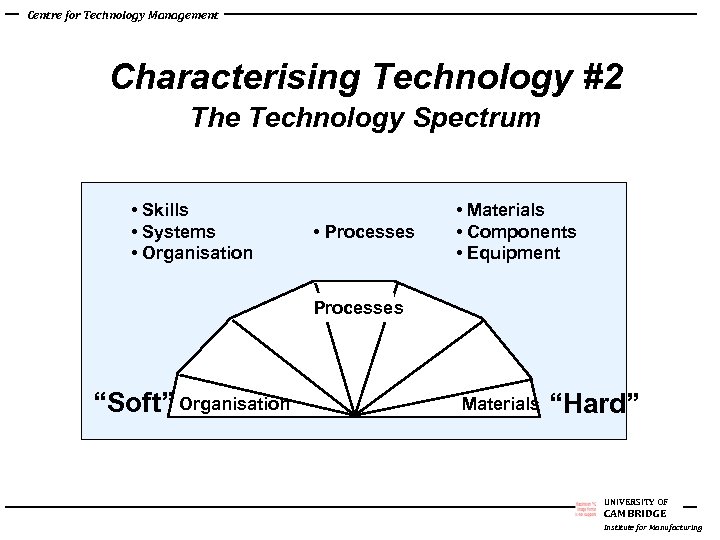

Centre for Technology Management Characterising Technology #2 The Technology Spectrum • Skills • Systems • Organisation • Processes • Materials • Components • Equipment Processes “Soft” Organisation Materials “Hard” UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

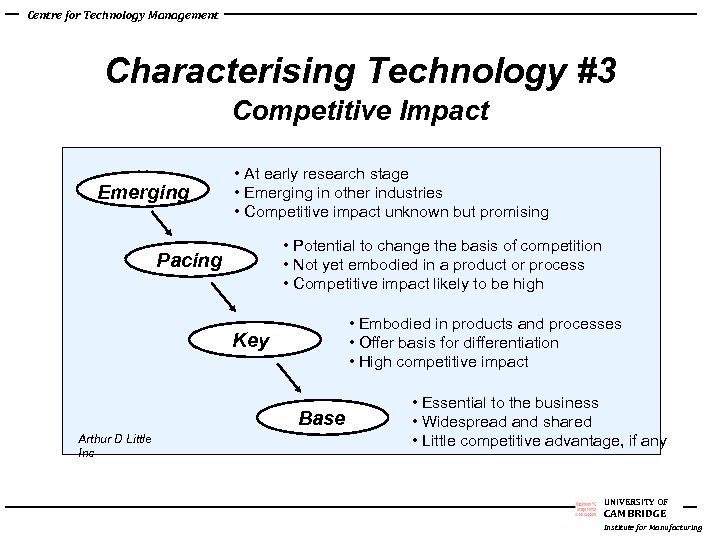

Centre for Technology Management Characterising Technology #3 Competitive Impact Emerging • At early research stage • Emerging in other industries • Competitive impact unknown but promising • Potential to change the basis of competition • Not yet embodied in a product or process • Competitive impact likely to be high Pacing • Embodied in products and processes • Offer basis for differentiation • High competitive impact Key Base Arthur D Little Inc • Essential to the business • Widespread and shared • Little competitive advantage, if any UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

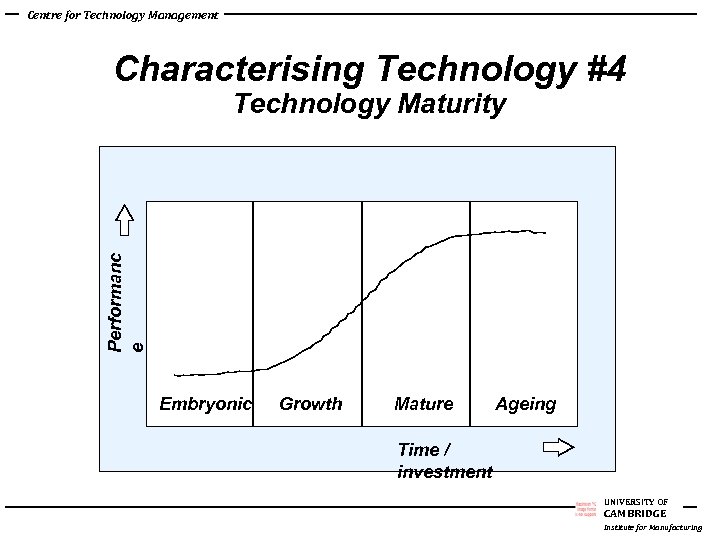

Centre for Technology Management Characterising Technology #4 Performanc e Technology Maturity Embryonic Growth Mature Ageing Time / investment UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

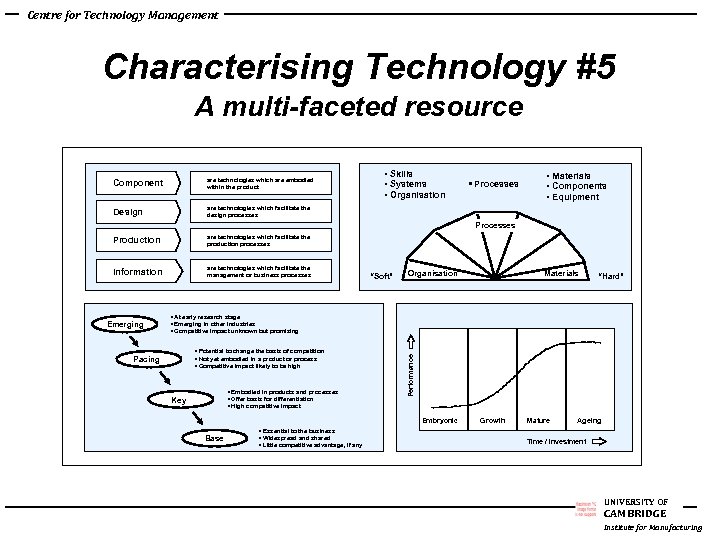

Centre for Technology Management Characterising Technology #5 A multi-faceted resource Component are technologies which are embodied within the product Design are technologies which facilitate the production processes Information are technologies which facilitate the management or business processes • Materials • Components • Equipment are technologies which facilitate the design processes Production • Skills • Systems • Organisation • Processes Organisation Materials “Hard” • At early research stage • Emerging in other industries • Competitive impact unknown but promising • Potential to change the basis of competition • Not yet embodied in a product or process • Competitive impact likely to be high Pacing • Embodied in products and processes • Offer basis for differentiation • High competitive impact Key Performance Emerging “Soft” Embryonic Base • Essential to the business • Widespread and shared • Little competitive advantage, if any Growth Mature Ageing Time / investment UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management Managing the Know-How Technology Management. . is concerned with ensuring that all necessary technology is available within the business in a timely manner. . addresses the processes of understanding and applying technology within the business for profit UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management Technology and Technology Managem A central issue is communication: • Between technologists & technologists • Between technologists & business managers • Between different businesses UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

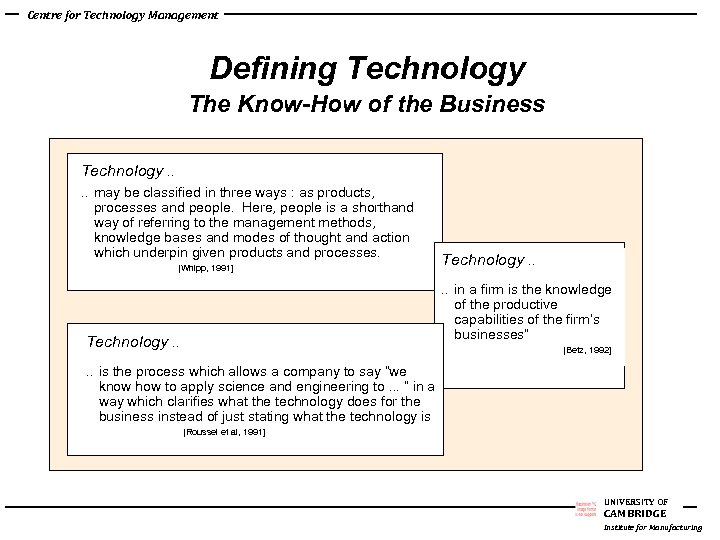

Centre for Technology Management Defining Technology The Know-How of the Business Technology. . may be classified in three ways : as products, processes and people. Here, people is a shorthand way of referring to the management methods, knowledge bases and modes of thought and action which underpin given products and processes. [Whipp, 1991] Technology. . in a firm is the knowledge of the productive capabilities of the firm’s businesses” Technology. . [Betz, 1992] . . is the process which allows a company to say “we know how to apply science and engineering to. . . ” in a way which clarifies what the technology does for the business instead of just stating what the technology is [Roussel et al, 1991] UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

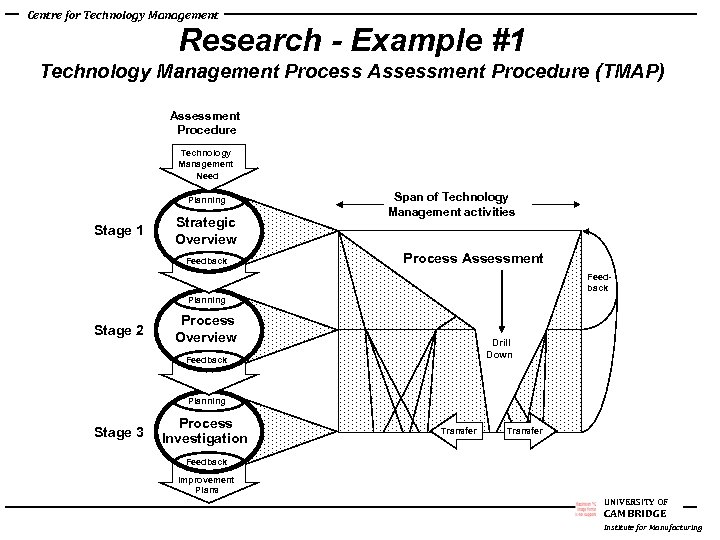

Centre for Technology Management Research - Example #1 Technology Management Process Assessment Procedure (TMAP) Assessment Procedure Technology Management Need Planning Stage 1 Strategic Overview Feedback Span of Technology Management activities Process Assessment Feedback Planning Stage 2 Process Overview Drill Down Feedback Planning Stage 3 Process Investigation Transfer Feedback Improvement Plans UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

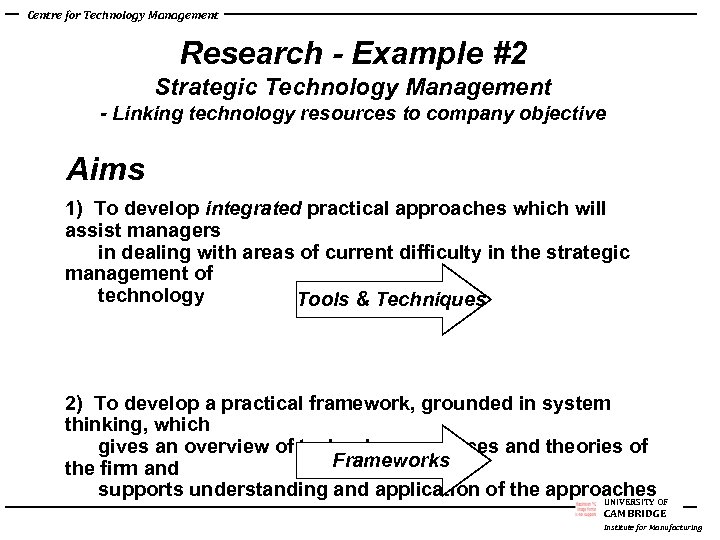

Centre for Technology Management Research - Example #2 Strategic Technology Management - Linking technology resources to company objective Aims 1) To develop integrated practical approaches which will assist managers in dealing with areas of current difficulty in the strategic management of technology Tools & Techniques 2) To develop a practical framework, grounded in system thinking, which gives an overview of technology practices and theories of Frameworks the firm and supports understanding and application of the approaches. OF UNIVERSITY CAMBRIDGE Institute for Manufacturing

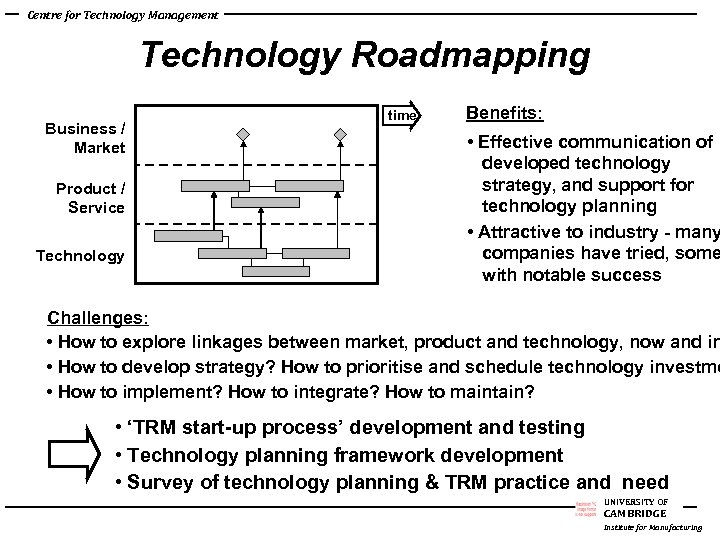

Centre for Technology Management Technology Roadmapping Business / Market Product / Service Technology time Benefits: • Effective communication of developed technology strategy, and support for technology planning • Attractive to industry - many companies have tried, some with notable success Challenges: • How to explore linkages between market, product and technology, now and in • How to develop strategy? How to prioritise and schedule technology investme • How to implement? How to integrate? How to maintain? • ‘TRM start-up process’ development and testing • Technology planning framework development • Survey of technology planning & TRM practice and need UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

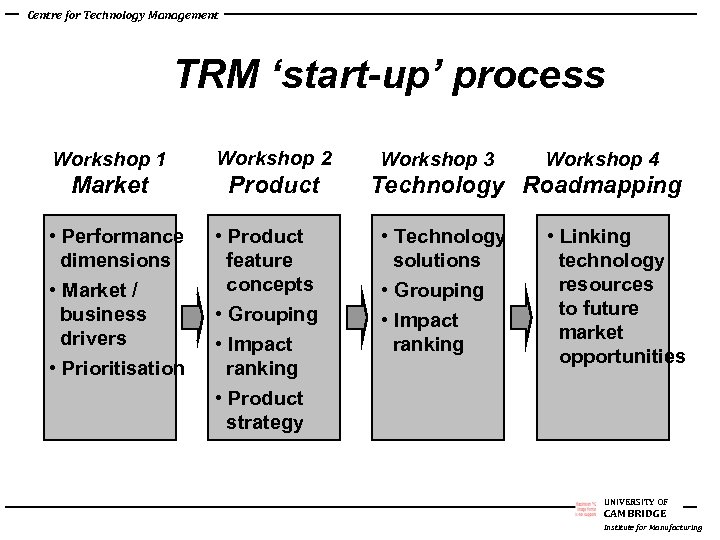

Centre for Technology Management TRM ‘start-up’ process Workshop 1 Workshop 2 Market Product • Performance dimensions • Market / business drivers • Prioritisation • Product feature concepts • Grouping • Impact ranking • Product strategy Workshop 3 Workshop 4 Technology Roadmapping • Technology solutions • Grouping • Impact ranking • Linking technology resources to future market opportunities UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

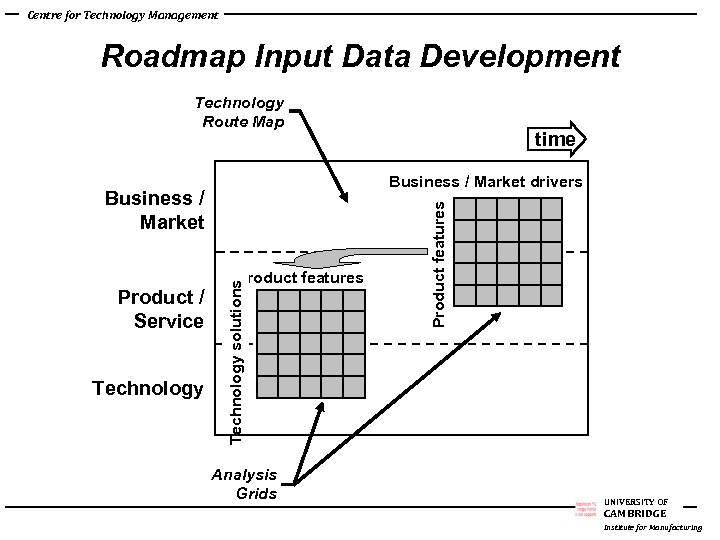

Centre for Technology Management Roadmap Input Data Development Technology Route Map Technology solutions Technology Product features Analysis Grids Product features Business / Market drivers Business / Market Product / Service time UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

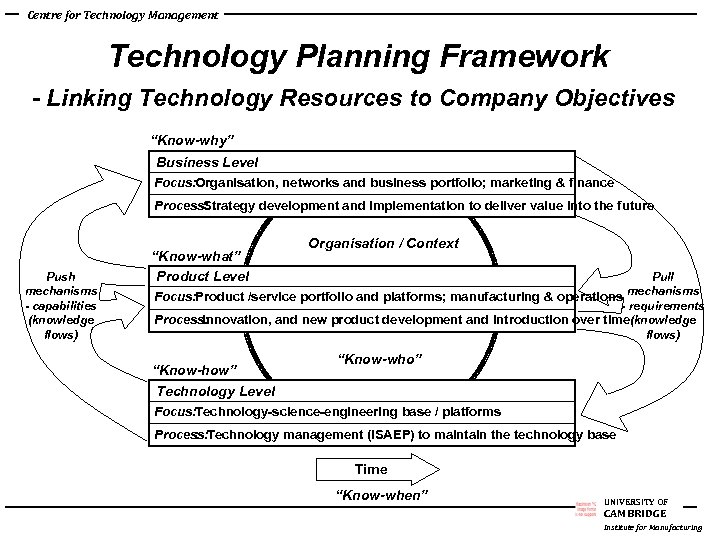

Centre for Technology Management Technology Planning Framework - Linking Technology Resources to Company Objectives “Know-why” Business Level Focus: Organisation, networks and business portfolio; marketing & finance Process: Strategy development and implementation to deliver value into the future Push mechanisms - capabilities (knowledge flows) “Know-what” Product Level Organisation / Context Pull mechanisms Focus: Product /service portfolio and platforms; manufacturing & operations - requirements Process: Innovation, and new product development and introduction over time(knowledge flows) “Know-how” “Know-who” Technology Level Focus: Technology-science-engineering base / platforms Process: Technology management (ISAEP) to maintain the technology base : Time “Know-when” UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

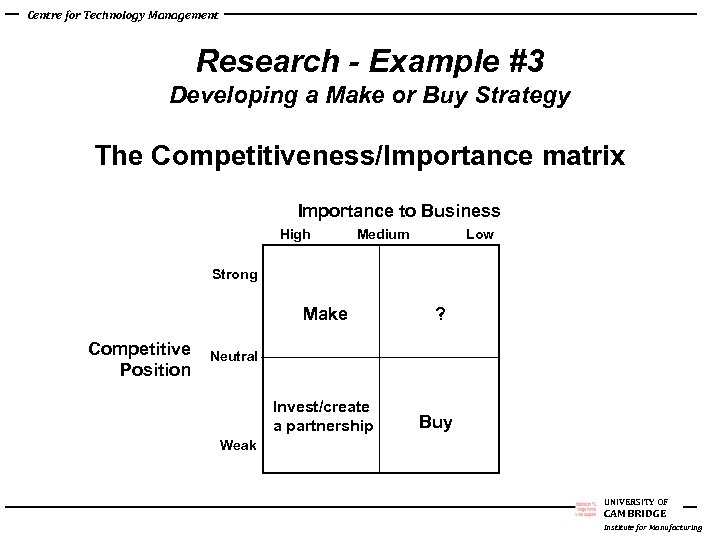

Centre for Technology Management Research - Example #3 Developing a Make or Buy Strategy The Competitiveness/Importance matrix Importance to Business High Medium Low Strong Make Competitive Position ? Invest/create a partnership Buy Neutral Weak UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

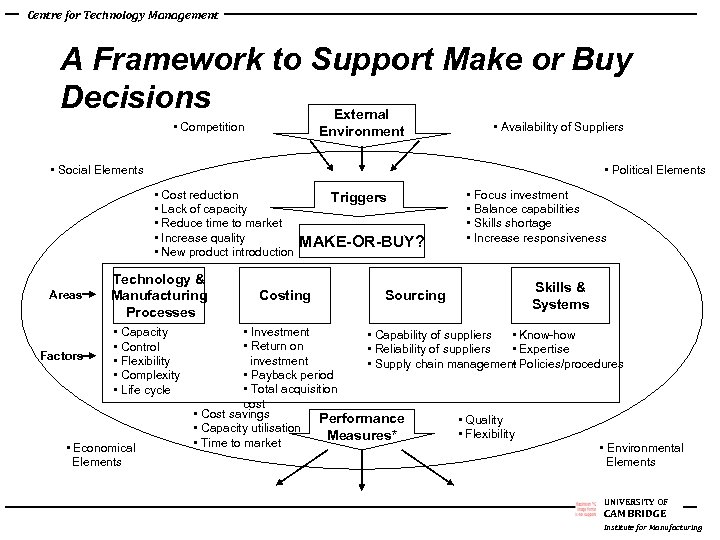

Centre for Technology Management A Framework to Support Make or Buy Decisions External • Competition Environment • Availability of Suppliers • Social Elements • Political Elements • Cost reduction • Lack of capacity • Reduce time to market • Increase quality • New product introduction Areas Factors Technology & Manufacturing Processes • Capacity • Control • Flexibility • Complexity • Life cycle • Economical Elements Triggers MAKE-OR-BUY? Costing Sourcing • Focus investment • Balance capabilities • Skills shortage • Increase responsiveness Skills & Systems • Investment • Capability of suppliers • Know-how • Return on • Reliability of suppliers • Expertise investment • Supply chain management Policies/procedures • • Payback period • Total acquisition cost • Cost savings Performance • Quality • Capacity utilisation • Flexibility Measures* • Time to market • Environmental Elements UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management Research - Example #4 New Product Introduction • Scope – NPI research addresses any activity associated with the management of the product life-cycle • Recent and current projects – New Product Introduction in SMEs – NPI Collaborations – Good Design Practice Program (with RCA) UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management NPI Collaborations project Aims & Objectives • Improve the understanding of the processes of introducing new products to market when significant development work is provided by new supplier / customer combinations • Develop and test self-help workbooks for both supplier and customer that will assist them in managing the processes of starting, operating and withdrawing from product development collaborations. UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management Good Design Practice Program Aims & Objectives • Specify the elements of current good design practice, defining success factors for the process outcome • Create and validate a generic process for the creation of new products using business, product planning, industrial design and product design inputs • Identify any major issues affecting the adoption of good design practice by small and medium sized companies UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management Elements of Good Design Practice UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

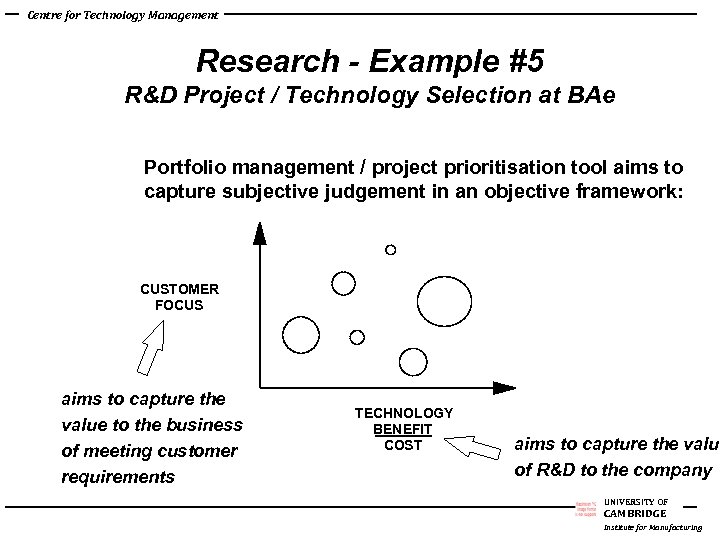

Centre for Technology Management Research - Example #5 R&D Project / Technology Selection at BAe Portfolio management / project prioritisation tool aims to capture subjective judgement in an objective framework: CUSTOMER FOCUS aims to capture the value to the business of meeting customer requirements TECHNOLOGY BENEFIT COST aims to capture the value of R&D to the company UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

Centre for Technology Management Future activities • Medium term themes – software technology management – cross boundary aspects / technology transfer – valuation • Long term themes – technology strategy, new product introduction, sustainability/reuse, foresight, cultural & behavioural aspects • Long term emphasis – metrics, tools, processes, decision support UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

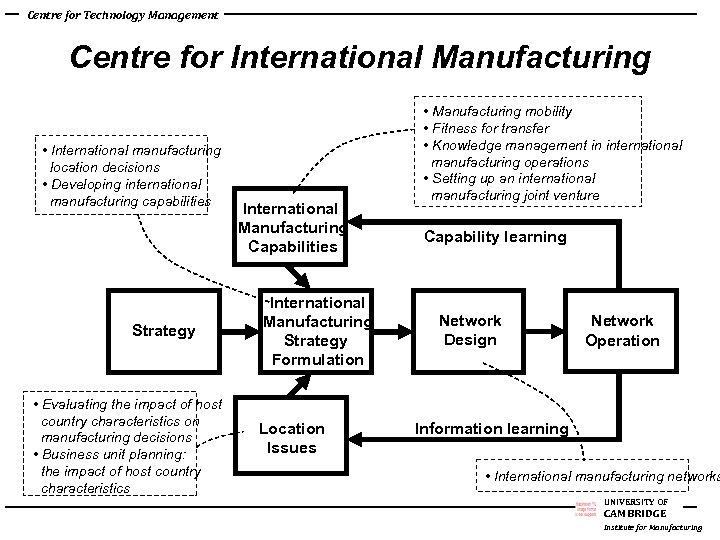

Centre for Technology Management Centre for International Manufacturing • International manufacturing location decisions • Developing international manufacturing capabilities Strategy • Evaluating the impact of host country characteristics on manufacturing decisions • Business unit planning: the impact of host country characteristics International Manufacturing Capabilities International Manufacturing Strategy Formulation Location Issues • Manufacturing mobility • Fitness for transfer • Knowledge management in international manufacturing operations • Setting up an international manufacturing joint venture Capability learning Network Design Network Operation Information learning • International manufacturing networks UNIVERSITY OF CAMBRIDGE Institute for Manufacturing

033147fc5d2cdfaf24c6dfff78e6e136.ppt