074cf5959f89e709430fcd1d1ca282cb.ppt

- Количество слайдов: 34

Central tracker for 12 Ge. V upgrade in Hall. B P. Konczykowski CEA Saclay 06/28/08 n. Micromégas : a new detector for CLAS 12 ü Detector’s principle ü GARFIELD simulation ü Spatial resolution measurement n Long Micromégas prototype tests n Integration to the CLAS magnet Saclay team: S. Aune, J. Ball, M. Combet, M. El Yakoubi, P. Konczykowski, C. Lacombe-Hamdoun, S. Procureur, F. Sabatié

Central tracker for 12 Ge. V upgrade in Hall. B P. Konczykowski CEA Saclay 06/28/08 n. Micromégas : a new detector for CLAS 12 ü Detector’s principle ü GARFIELD simulation ü Spatial resolution measurement n Long Micromégas prototype tests n Integration to the CLAS magnet Saclay team: S. Aune, J. Ball, M. Combet, M. El Yakoubi, P. Konczykowski, C. Lacombe-Hamdoun, S. Procureur, F. Sabatié

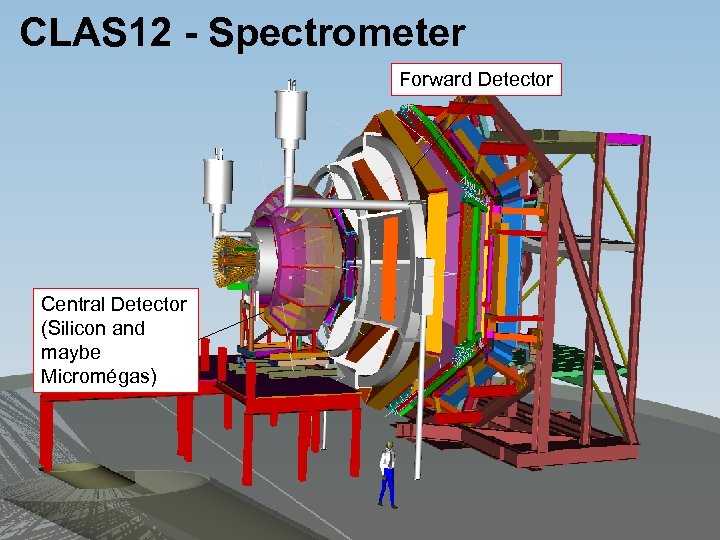

CLAS 12 - Spectrometer Forward Detector Central Detector (Silicon and maybe Micromégas)

CLAS 12 - Spectrometer Forward Detector Central Detector (Silicon and maybe Micromégas)

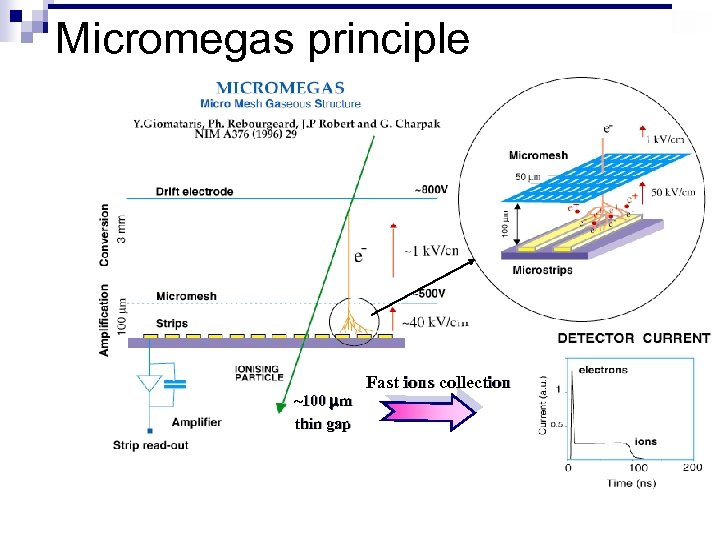

Micromegas principle ~100 mm thin gap Fast ions collection

Micromegas principle ~100 mm thin gap Fast ions collection

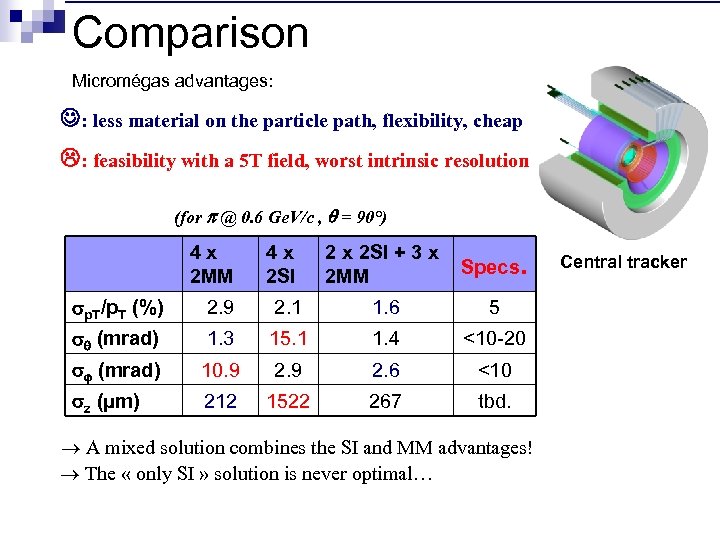

Comparison Micromégas advantages: : less material on the particle path, flexibility, cheap : feasibility with a 5 T field, worst intrinsic resolution (for @ 0. 6 Ge. V/c , = 90°) 4 x 2 MM 4 x 2 SI 2 x 2 SI + 3 x 2 MM Specs. p. T/p. T (%) 2. 9 2. 1 1. 6 5 (mrad) 1. 3 15. 1 1. 4 <10 -20 (mrad) 10. 9 2. 6 <10 z (μm) 212 1522 267 tbd. A mixed solution combines the SI and MM advantages! The « only SI » solution is never optimal… Central tracker

Comparison Micromégas advantages: : less material on the particle path, flexibility, cheap : feasibility with a 5 T field, worst intrinsic resolution (for @ 0. 6 Ge. V/c , = 90°) 4 x 2 MM 4 x 2 SI 2 x 2 SI + 3 x 2 MM Specs. p. T/p. T (%) 2. 9 2. 1 1. 6 5 (mrad) 1. 3 15. 1 1. 4 <10 -20 (mrad) 10. 9 2. 6 <10 z (μm) 212 1522 267 tbd. A mixed solution combines the SI and MM advantages! The « only SI » solution is never optimal… Central tracker

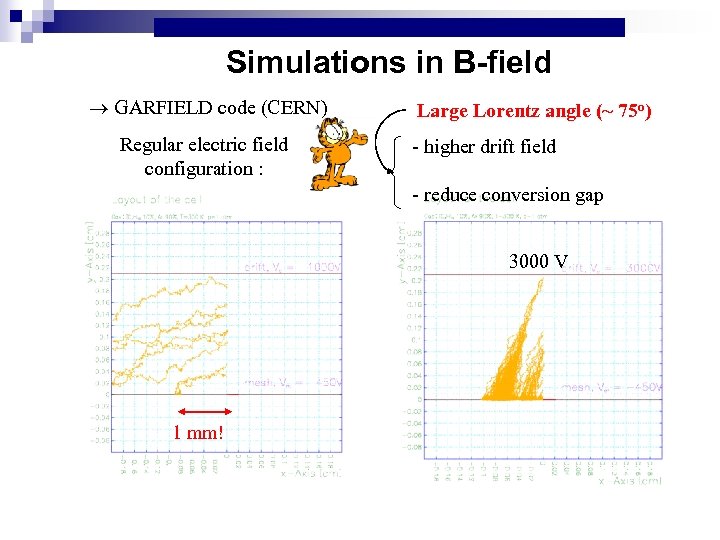

Simulations in B-field GARFIELD code (CERN) Regular electric field configuration : Large Lorentz angle (~ 75 o) - higher drift field - reduce conversion gap 2500 V 2000 V 3000 V 1500 V 1000 V 1 mm!

Simulations in B-field GARFIELD code (CERN) Regular electric field configuration : Large Lorentz angle (~ 75 o) - higher drift field - reduce conversion gap 2500 V 2000 V 3000 V 1500 V 1000 V 1 mm!

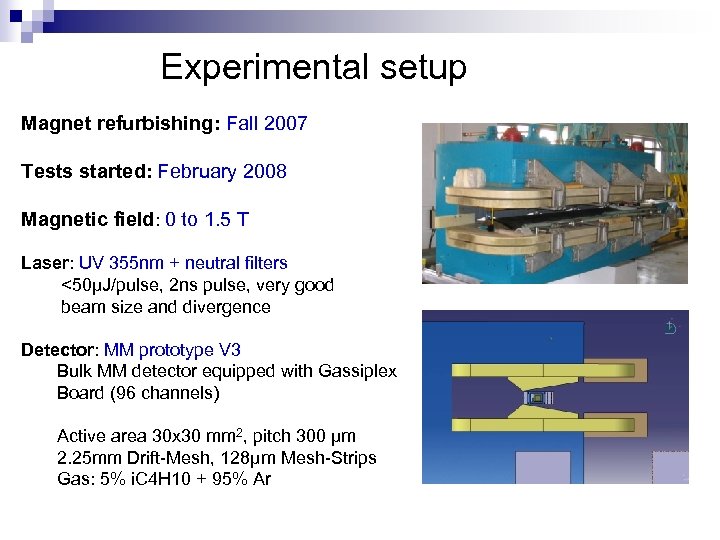

Experimental setup Magnet refurbishing: Fall 2007 Tests started: February 2008 Magnetic field: 0 to 1. 5 T Laser: UV 355 nm + neutral filters <50µJ/pulse, 2 ns pulse, very good beam size and divergence Detector: MM prototype V 3 Bulk MM detector equipped with Gassiplex Board (96 channels) Active area 30 x 30 mm 2, pitch 300 μm 2. 25 mm Drift-Mesh, 128µm Mesh-Strips Gas: 5% i. C 4 H 10 + 95% Ar

Experimental setup Magnet refurbishing: Fall 2007 Tests started: February 2008 Magnetic field: 0 to 1. 5 T Laser: UV 355 nm + neutral filters <50µJ/pulse, 2 ns pulse, very good beam size and divergence Detector: MM prototype V 3 Bulk MM detector equipped with Gassiplex Board (96 channels) Active area 30 x 30 mm 2, pitch 300 μm 2. 25 mm Drift-Mesh, 128µm Mesh-Strips Gas: 5% i. C 4 H 10 + 95% Ar

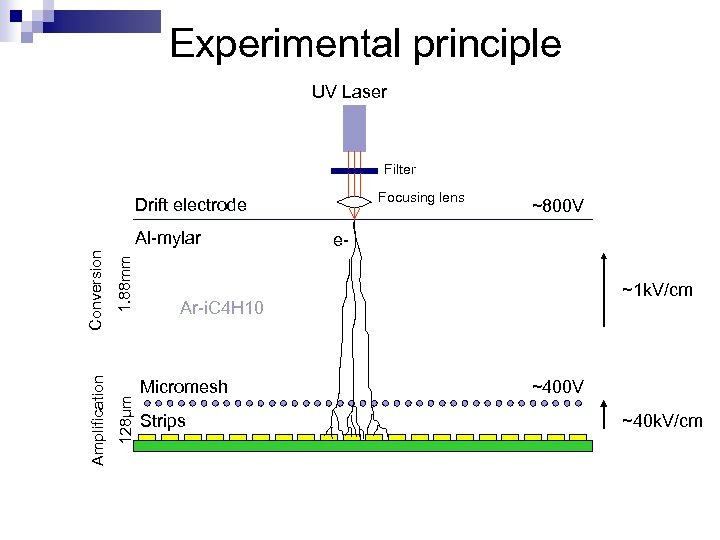

Experimental principle UV Laser Filter Focusing lens Drift electrode 1. 88 mm 128μm Amplification Conversion Al-mylar ~800 V e~1 k. V/cm Ar-i. C 4 H 10 Micromesh Strips ~400 V ~40 k. V/cm

Experimental principle UV Laser Filter Focusing lens Drift electrode 1. 88 mm 128μm Amplification Conversion Al-mylar ~800 V e~1 k. V/cm Ar-i. C 4 H 10 Micromesh Strips ~400 V ~40 k. V/cm

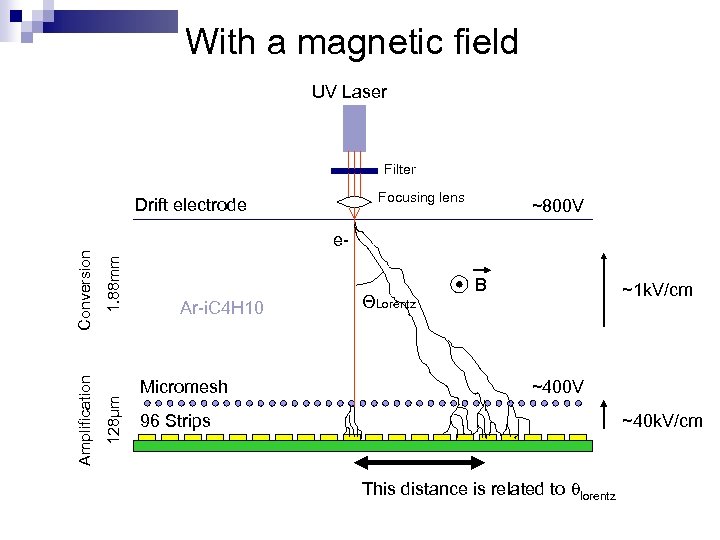

With a magnetic field UV Laser Filter Focusing lens Drift electrode ~800 V 1. 88 mm 128μm Amplification Conversion e- Ar-i. C 4 H 10 Micromesh ΘLorentz B ~1 k. V/cm ~400 V ~40 k. V/cm 96 Strips This distance is related to qlorentz

With a magnetic field UV Laser Filter Focusing lens Drift electrode ~800 V 1. 88 mm 128μm Amplification Conversion e- Ar-i. C 4 H 10 Micromesh ΘLorentz B ~1 k. V/cm ~400 V ~40 k. V/cm 96 Strips This distance is related to qlorentz

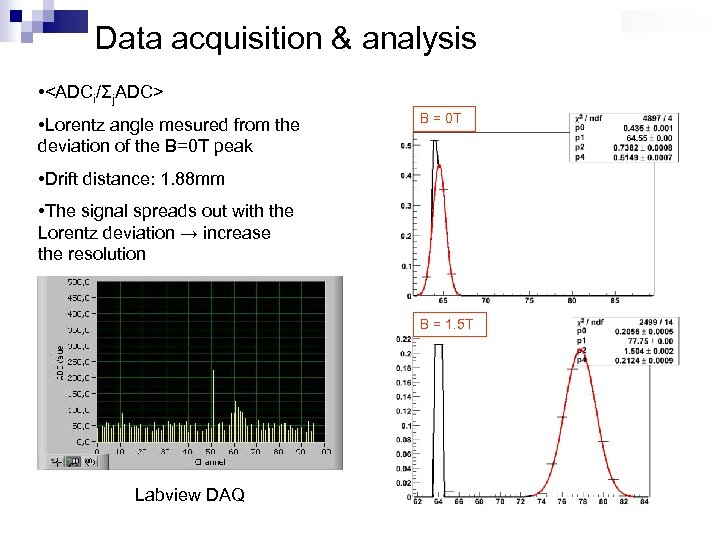

Data acquisition & analysis •

Data acquisition & analysis •

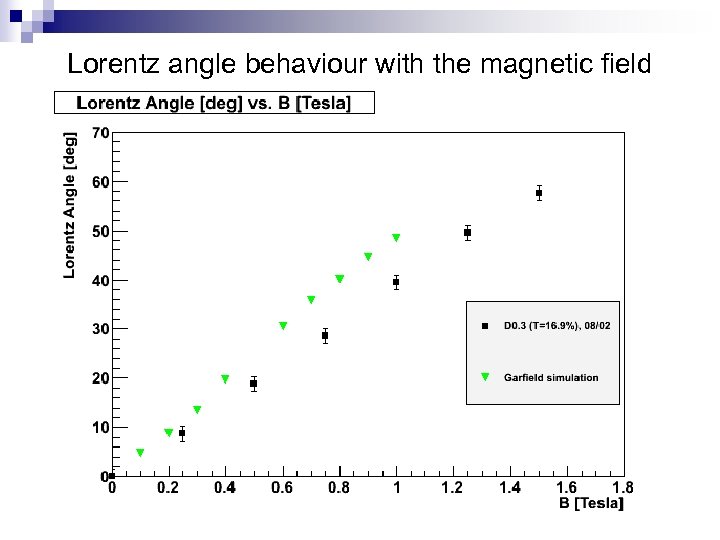

Lorentz angle behaviour with the magnetic field

Lorentz angle behaviour with the magnetic field

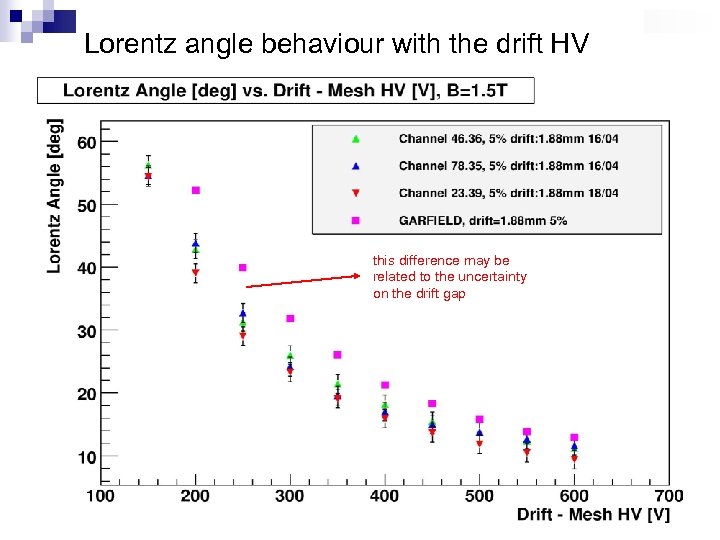

Lorentz angle behaviour with the drift HV this difference may be related to the uncertainty on the drift gap

Lorentz angle behaviour with the drift HV this difference may be related to the uncertainty on the drift gap

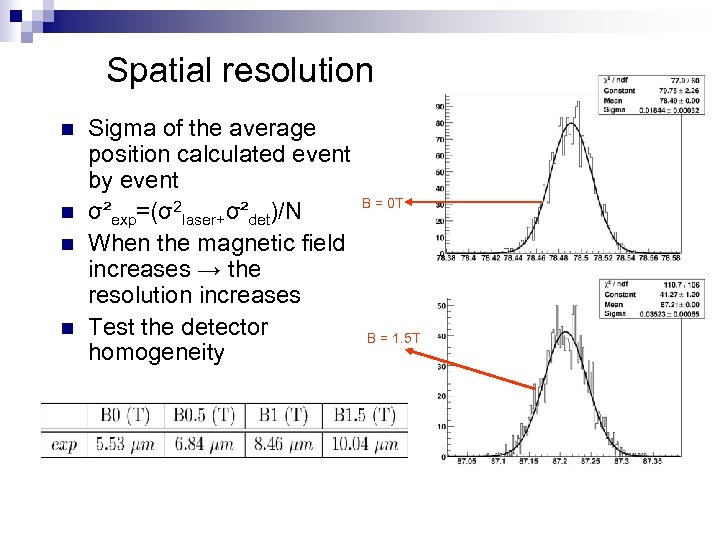

Spatial resolution n n Sigma of the average position calculated event by event B = 0 T σ²exp=(σ2 laser+σ²det)/N When the magnetic field increases → the resolution increases Test the detector B = 1. 5 T homogeneity

Spatial resolution n n Sigma of the average position calculated event by event B = 0 T σ²exp=(σ2 laser+σ²det)/N When the magnetic field increases → the resolution increases Test the detector B = 1. 5 T homogeneity

Micromégas prototype for the central tracker

Micromégas prototype for the central tracker

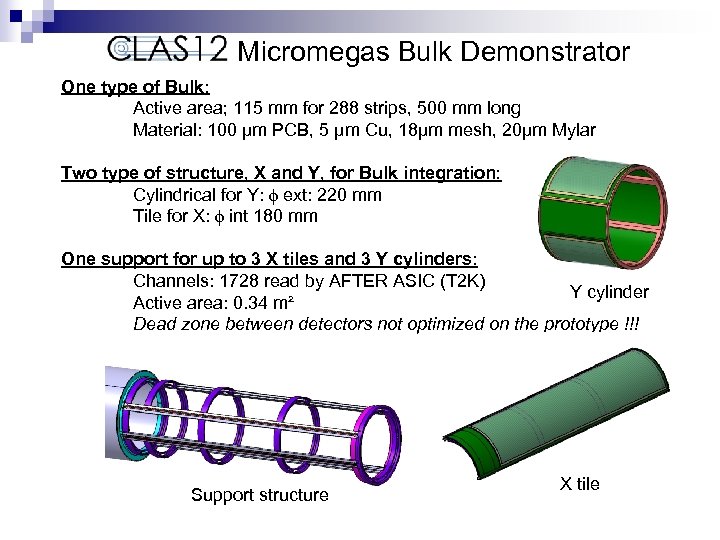

Micromegas Bulk Demonstrator One type of Bulk: Active area; 115 mm for 288 strips, 500 mm long Material: 100 µm PCB, 5 µm Cu, 18µm mesh, 20µm Mylar Two type of structure, X and Y, for Bulk integration: Cylindrical for Y: f ext: 220 mm Tile for X: f int 180 mm One support for up to 3 X tiles and 3 Y cylinders: Channels: 1728 read by AFTER ASIC (T 2 K) Y cylinder Active area: 0. 34 m² Dead zone between detectors not optimized on the prototype !!! Support structure X tile

Micromegas Bulk Demonstrator One type of Bulk: Active area; 115 mm for 288 strips, 500 mm long Material: 100 µm PCB, 5 µm Cu, 18µm mesh, 20µm Mylar Two type of structure, X and Y, for Bulk integration: Cylindrical for Y: f ext: 220 mm Tile for X: f int 180 mm One support for up to 3 X tiles and 3 Y cylinders: Channels: 1728 read by AFTER ASIC (T 2 K) Y cylinder Active area: 0. 34 m² Dead zone between detectors not optimized on the prototype !!! Support structure X tile

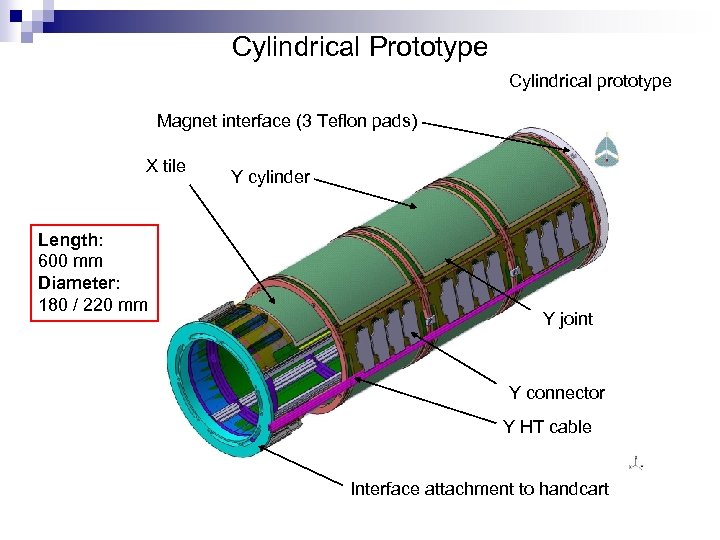

Cylindrical Prototype Cylindrical prototype Magnet interface (3 Teflon pads) X tile Length: 600 mm Diameter: 180 / 220 mm Y cylinder Y joint Y connector Y HT cable Interface attachment to handcart

Cylindrical Prototype Cylindrical prototype Magnet interface (3 Teflon pads) X tile Length: 600 mm Diameter: 180 / 220 mm Y cylinder Y joint Y connector Y HT cable Interface attachment to handcart

Received friday May 23 rd

Received friday May 23 rd

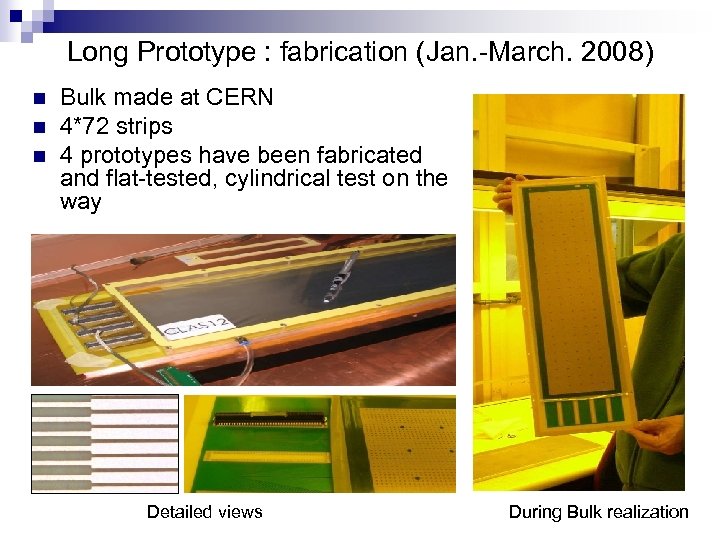

Long Prototype : fabrication (Jan. -March. 2008) n n n Bulk made at CERN 4*72 strips 4 prototypes have been fabricated and flat-tested, cylindrical test on the way Detailed views During Bulk realization

Long Prototype : fabrication (Jan. -March. 2008) n n n Bulk made at CERN 4*72 strips 4 prototypes have been fabricated and flat-tested, cylindrical test on the way Detailed views During Bulk realization

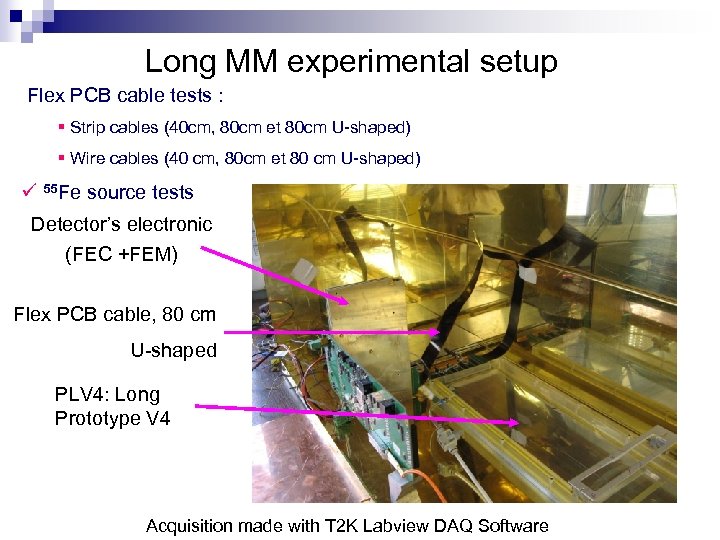

Long MM experimental setup Flex PCB cable tests : § Strip cables (40 cm, 80 cm et 80 cm U-shaped) § Wire cables (40 cm, 80 cm et 80 cm U-shaped) ü 55 Fe source tests Detector’s electronic (FEC +FEM) Flex PCB cable, 80 cm U-shaped PLV 4: Long Prototype V 4 Acquisition made with T 2 K Labview DAQ Software

Long MM experimental setup Flex PCB cable tests : § Strip cables (40 cm, 80 cm et 80 cm U-shaped) § Wire cables (40 cm, 80 cm et 80 cm U-shaped) ü 55 Fe source tests Detector’s electronic (FEC +FEM) Flex PCB cable, 80 cm U-shaped PLV 4: Long Prototype V 4 Acquisition made with T 2 K Labview DAQ Software

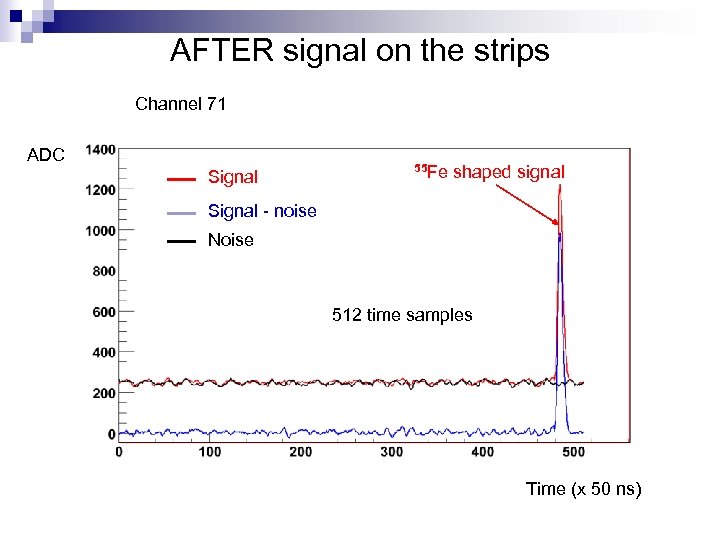

AFTER signal on the strips Channel 71 ADC Signal 55 Fe shaped signal Signal - noise Noise 512 time samples Time (x 50 ns)

AFTER signal on the strips Channel 71 ADC Signal 55 Fe shaped signal Signal - noise Noise 512 time samples Time (x 50 ns)

Integration to the CLAS magnet

Integration to the CLAS magnet

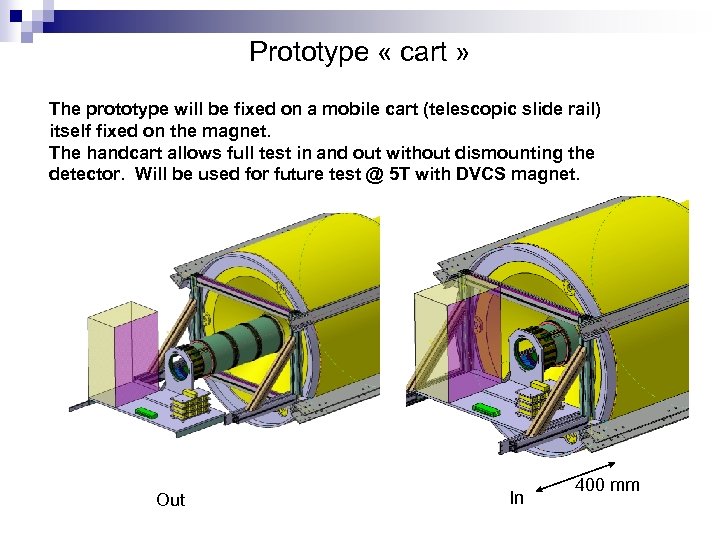

Prototype « cart » The prototype will be fixed on a mobile cart (telescopic slide rail) itself fixed on the magnet. The handcart allows full test in and out without dismounting the detector. Will be used for future test @ 5 T with DVCS magnet. Out In 400 mm

Prototype « cart » The prototype will be fixed on a mobile cart (telescopic slide rail) itself fixed on the magnet. The handcart allows full test in and out without dismounting the detector. Will be used for future test @ 5 T with DVCS magnet. Out In 400 mm

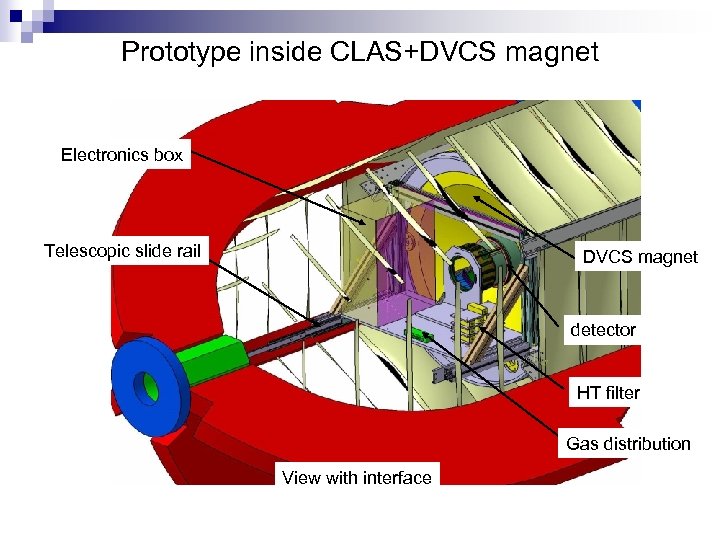

Prototype inside CLAS+DVCS magnet Electronics box Telescopic slide rail DVCS magnet detector HT filter Gas distribution View with interface

Prototype inside CLAS+DVCS magnet Electronics box Telescopic slide rail DVCS magnet detector HT filter Gas distribution View with interface

2000 -channel tests #1 and 2 1. During fall 2008, 5 T test inside DVCS solenoid: Goals: • Dry test for test beam end 2008: full prototype on handcart • Lorentz angle @ 5 T: one X tile with UV laser • Cosmic test @ 5 T: Three X tiles. 2. During change-out between e 1 -dvcs and eg 1 -dvcs(? ), beam test: Goals: • Beam test: full cylindrical prototype on cart • Beam test: Forward prototype if possible

2000 -channel tests #1 and 2 1. During fall 2008, 5 T test inside DVCS solenoid: Goals: • Dry test for test beam end 2008: full prototype on handcart • Lorentz angle @ 5 T: one X tile with UV laser • Cosmic test @ 5 T: Three X tiles. 2. During change-out between e 1 -dvcs and eg 1 -dvcs(? ), beam test: Goals: • Beam test: full cylindrical prototype on cart • Beam test: Forward prototype if possible

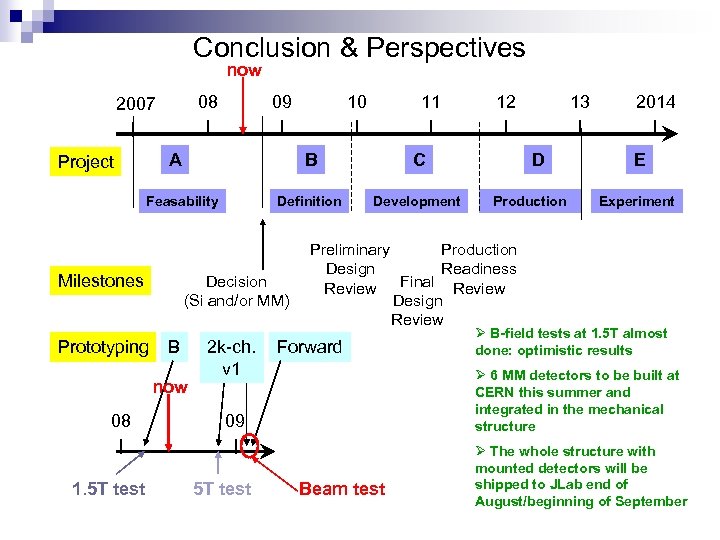

Conclusion & Perspectives now 08 2007 09 A Project Prototyping Definition 1. 5 T test Development B 2 k-ch. v 1 13 D Production 2014 E Experiment Preliminary Production Design Readiness Final Review Design Review Forward Ø B-field tests at 1. 5 T almost done: optimistic results Ø 6 MM detectors to be built at CERN this summer and integrated in the mechanical structure 09 5 T test 12 C Decision (Si and/or MM) now 08 11 B Feasability Milestones 10 Beam test Ø The whole structure with mounted detectors will be shipped to JLab end of August/beginning of September

Conclusion & Perspectives now 08 2007 09 A Project Prototyping Definition 1. 5 T test Development B 2 k-ch. v 1 13 D Production 2014 E Experiment Preliminary Production Design Readiness Final Review Design Review Forward Ø B-field tests at 1. 5 T almost done: optimistic results Ø 6 MM detectors to be built at CERN this summer and integrated in the mechanical structure 09 5 T test 12 C Decision (Si and/or MM) now 08 11 B Feasability Milestones 10 Beam test Ø The whole structure with mounted detectors will be shipped to JLab end of August/beginning of September

ANNEXES

ANNEXES

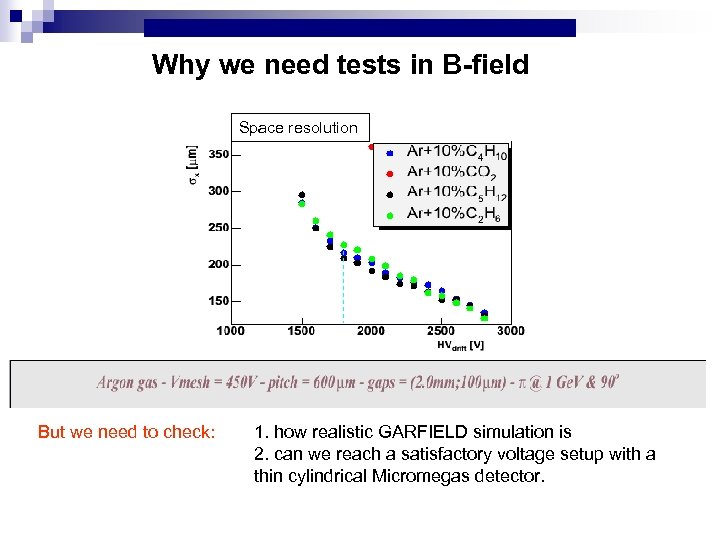

Why we need tests in B-field Space resolution But we need to check: 1. how realistic GARFIELD simulation is 2. can we reach a satisfactory voltage setup with a thin cylindrical Micromegas detector.

Why we need tests in B-field Space resolution But we need to check: 1. how realistic GARFIELD simulation is 2. can we reach a satisfactory voltage setup with a thin cylindrical Micromegas detector.

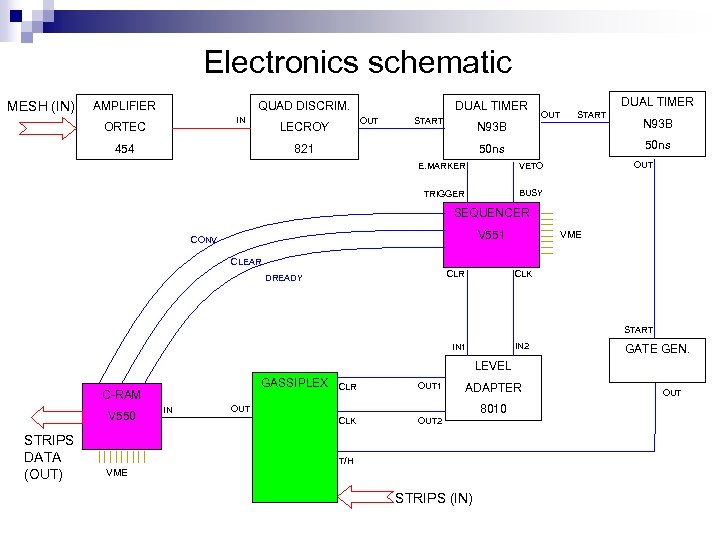

Electronics schematic MESH (IN) AMPLIFIER QUAD DISCRIM. IN ORTEC 454 DUAL TIMER OUT START N 93 B 821 N 93 B 50 ns LECROY 50 ns E. MARKER TRIGGER OUT VETO BUSY SEQUENCER V 551 CONV VME CLEAR CLR DREADY CLK START IN 2 IN 1 GATE GEN. LEVEL GASSIPLEX C-RAM V 550 STRIPS DATA (OUT) IN CLR OUT 1 CLK OUT 2 ADAPTER OUT T/H VME STRIPS (IN) 8010 OUT

Electronics schematic MESH (IN) AMPLIFIER QUAD DISCRIM. IN ORTEC 454 DUAL TIMER OUT START N 93 B 821 N 93 B 50 ns LECROY 50 ns E. MARKER TRIGGER OUT VETO BUSY SEQUENCER V 551 CONV VME CLEAR CLR DREADY CLK START IN 2 IN 1 GATE GEN. LEVEL GASSIPLEX C-RAM V 550 STRIPS DATA (OUT) IN CLR OUT 1 CLK OUT 2 ADAPTER OUT T/H VME STRIPS (IN) 8010 OUT

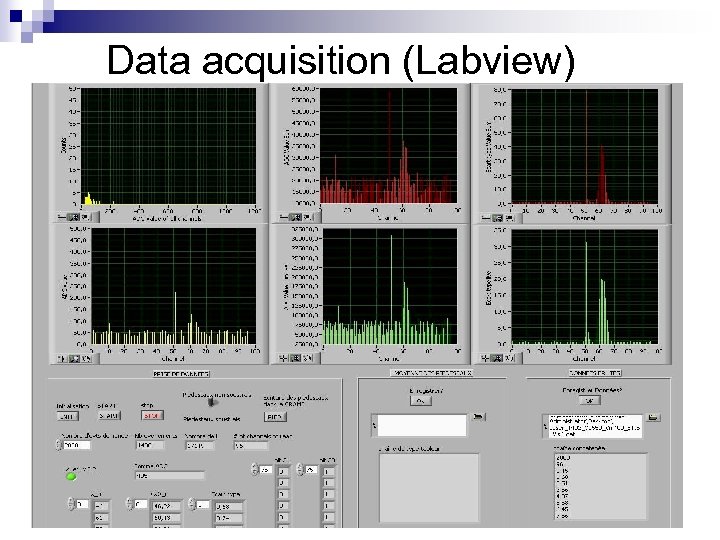

Data acquisition (Labview)

Data acquisition (Labview)

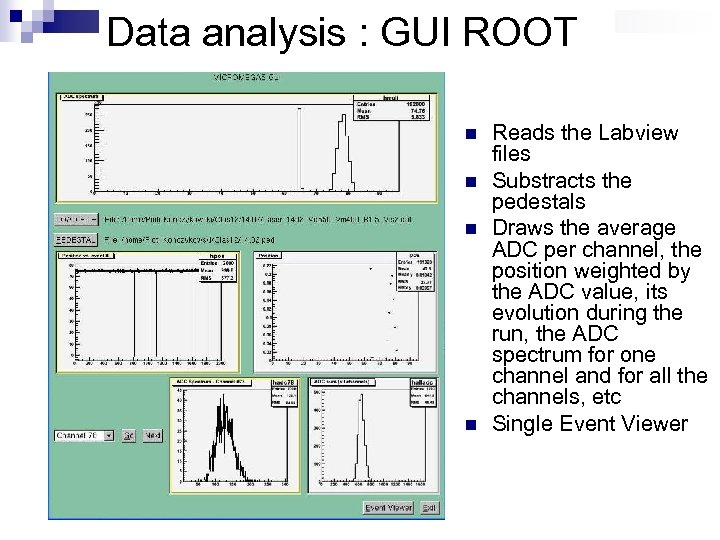

Data analysis : GUI ROOT n n Reads the Labview files Substracts the pedestals Draws the average ADC per channel, the position weighted by the ADC value, its evolution during the run, the ADC spectrum for one channel and for all the channels, etc Single Event Viewer

Data analysis : GUI ROOT n n Reads the Labview files Substracts the pedestals Draws the average ADC per channel, the position weighted by the ADC value, its evolution during the run, the ADC spectrum for one channel and for all the channels, etc Single Event Viewer

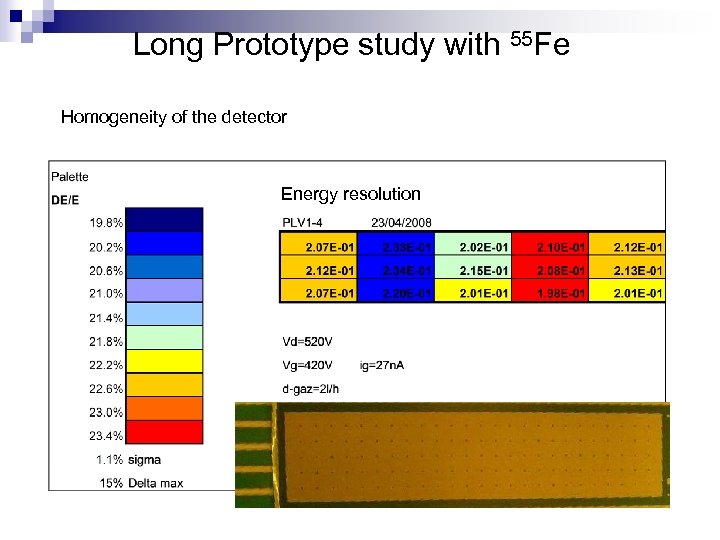

Long Prototype study with 55 Fe Homogeneity of the detector Energy resolution

Long Prototype study with 55 Fe Homogeneity of the detector Energy resolution

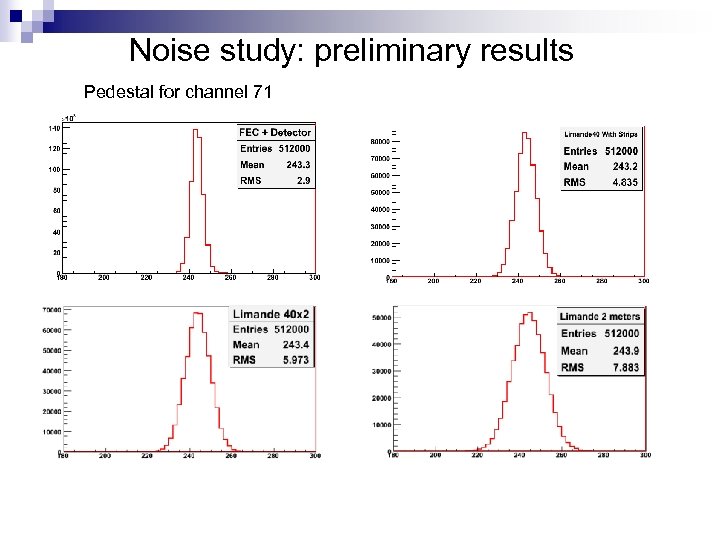

Noise study: preliminary results Pedestal for channel 71

Noise study: preliminary results Pedestal for channel 71

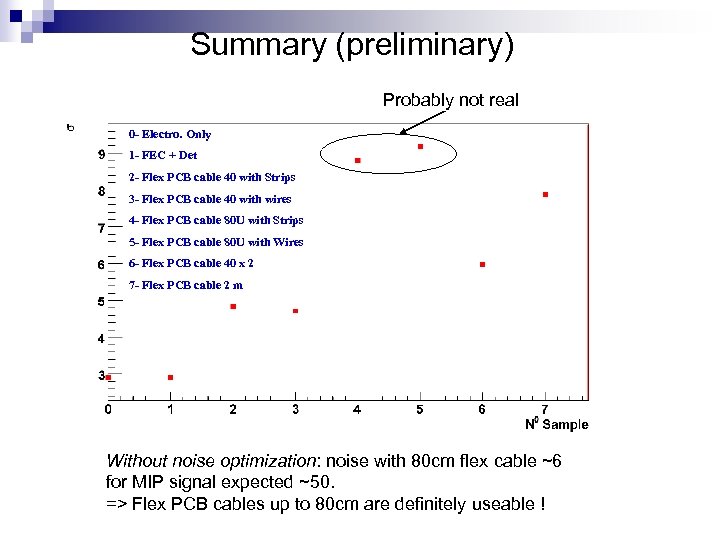

Summary (preliminary) Probably not real 0 - Electro. Only 1 - FEC + Det 2 - Flex PCB cable 40 with Strips 3 - Flex PCB cable 40 with wires 4 - Flex PCB cable 80 U with Strips 5 - Flex PCB cable 80 U with Wires 6 - Flex PCB cable 40 x 2 7 - Flex PCB cable 2 m Without noise optimization: noise with 80 cm flex cable ~6 for MIP signal expected ~50. => Flex PCB cables up to 80 cm are definitely useable !

Summary (preliminary) Probably not real 0 - Electro. Only 1 - FEC + Det 2 - Flex PCB cable 40 with Strips 3 - Flex PCB cable 40 with wires 4 - Flex PCB cable 80 U with Strips 5 - Flex PCB cable 80 U with Wires 6 - Flex PCB cable 40 x 2 7 - Flex PCB cable 2 m Without noise optimization: noise with 80 cm flex cable ~6 for MIP signal expected ~50. => Flex PCB cables up to 80 cm are definitely useable !

Future plans with B-field tests (June. July + fall ’ 08) -Improved precision tests thanks to a larger drift gap -Direct measurement of gap with the laser setup -Precise variation of the laser intensity with neutral filter wheel -Tests planned in the fall ’ 08 with e 1 -dvcs magnet at 5 T and large-area detectors

Future plans with B-field tests (June. July + fall ’ 08) -Improved precision tests thanks to a larger drift gap -Direct measurement of gap with the laser setup -Precise variation of the laser intensity with neutral filter wheel -Tests planned in the fall ’ 08 with e 1 -dvcs magnet at 5 T and large-area detectors

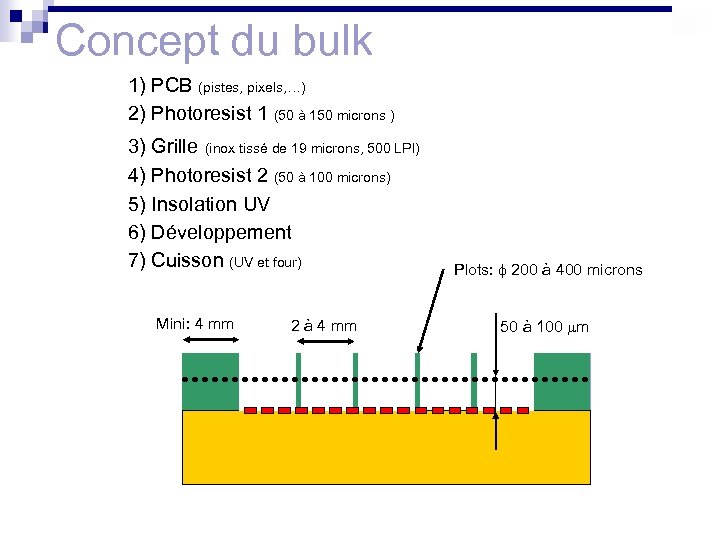

Concept du bulk 1) PCB (pistes, pixels, …) 2) Photoresist 1 (50 à 150 microns ) 3) Grille (inox tissé de 19 microns, 500 LPI) 4) Photoresist 2 (50 à 100 microns) 5) Insolation UV 6) Développement UV 7) Cuisson (UV et four) Mask Photoresist 2 Photoresist 1 Mini: 4 mm 2 à 4 mm Plots: f 200 à 400 microns 50 à 100 mm Mesh PCB

Concept du bulk 1) PCB (pistes, pixels, …) 2) Photoresist 1 (50 à 150 microns ) 3) Grille (inox tissé de 19 microns, 500 LPI) 4) Photoresist 2 (50 à 100 microns) 5) Insolation UV 6) Développement UV 7) Cuisson (UV et four) Mask Photoresist 2 Photoresist 1 Mini: 4 mm 2 à 4 mm Plots: f 200 à 400 microns 50 à 100 mm Mesh PCB