LMSLectureSlideWK9 CEMENT.ppt

- Количество слайдов: 22

CE 1205 CONSTRUCTION MATERIALS WEEK 9 Chapter 6 PORTLAND CEMENT Power. Point® Slides by Salmaliza Salleh Last Updated: 2/11/2018 © LMS SEGi education group 1

CE 1205 CONSTRUCTION MATERIALS WEEK 9 Chapter 6 PORTLAND CEMENT Power. Point® Slides by Salmaliza Salleh Last Updated: 2/11/2018 © LMS SEGi education group 1

Chapter Overview • Chapter 6 exposed you the properties of Portland Cement and its importance in concrete mixture. • You also learned different types of Portland Cement and their usage. Last Updated: 2/11/2018 © LMS SEGi education group 2

Chapter Overview • Chapter 6 exposed you the properties of Portland Cement and its importance in concrete mixture. • You also learned different types of Portland Cement and their usage. Last Updated: 2/11/2018 © LMS SEGi education group 2

Learning Objectives • In this topic, students will be highlighted with the manufacturing process of Portland Cement, its important properties and types. Last Updated: 2/11/2018 © LMS SEGi education group 3

Learning Objectives • In this topic, students will be highlighted with the manufacturing process of Portland Cement, its important properties and types. Last Updated: 2/11/2018 © LMS SEGi education group 3

Learning Outcomes • At the end of the lesson, students should be able to list the properties of Portland cement. • Students must also be able to classify different types of Portland cement. Last Updated: 2/11/2018 © LMS SEGi education group 4

Learning Outcomes • At the end of the lesson, students should be able to list the properties of Portland cement. • Students must also be able to classify different types of Portland cement. Last Updated: 2/11/2018 © LMS SEGi education group 4

Introduction • There is a variety of cements available. Each type is used under certain conditions due to its special properties. • Cement motar- mixture of cement, sand water to form a paste. • Cement concrete - composite product obtained by mixing cement, water, sand, and gravel • Commonly used cement is Portland cement. • Cement can be described as a material with adhesive and cohesive properties which make it capable of bonding mineral fragments into a compact whole. Last Updated: 2/11/2018 © LMS SEGi education group 5

Introduction • There is a variety of cements available. Each type is used under certain conditions due to its special properties. • Cement motar- mixture of cement, sand water to form a paste. • Cement concrete - composite product obtained by mixing cement, water, sand, and gravel • Commonly used cement is Portland cement. • Cement can be described as a material with adhesive and cohesive properties which make it capable of bonding mineral fragments into a compact whole. Last Updated: 2/11/2018 © LMS SEGi education group 5

The functions of cement in concrete are: • To bind the sand coarse aggregate together • __________ in between sand coarse aggregate particles to form a compact mass. Last Updated: 2/11/2018 © LMS SEGi education group 6

The functions of cement in concrete are: • To bind the sand coarse aggregate together • __________ in between sand coarse aggregate particles to form a compact mass. Last Updated: 2/11/2018 © LMS SEGi education group 6

• Cement is obtained by intimately mixing together calcareous and argillaceous materials, burning them at a very high temperature (1450°C), and ground the clinker to the required fineness. During grinding of clinker, gypsum is added. • Calcareous materials • • • containing calcium carbonate or lime e. g. limestone, chalk, marl Argillaceous materials • • containing alumina e. g. clay, shale, slate, and selected blast furnace slag Last Updated: 2/11/2018 © LMS SEGi education group 7

• Cement is obtained by intimately mixing together calcareous and argillaceous materials, burning them at a very high temperature (1450°C), and ground the clinker to the required fineness. During grinding of clinker, gypsum is added. • Calcareous materials • • • containing calcium carbonate or lime e. g. limestone, chalk, marl Argillaceous materials • • containing alumina e. g. clay, shale, slate, and selected blast furnace slag Last Updated: 2/11/2018 © LMS SEGi education group 7

Types of Cement • • • Obtain several types of cements by changing the chemical composition by varying the percentage of the four basic compounds in cement: Tricalcium silicate ( C 3 S) Dicalcium silicate ( C 2 S) Tricalcium aluminate (C 3 A) Terracalcium aluminoferrite (C 4 AF) Chemical Composition: Lime, Silica, Alumina, Iron Oxide, Magnesium, Alkalis, Sulphur trioxide. Last Updated: 2/11/2018 © LMS SEGi education group 8

Types of Cement • • • Obtain several types of cements by changing the chemical composition by varying the percentage of the four basic compounds in cement: Tricalcium silicate ( C 3 S) Dicalcium silicate ( C 2 S) Tricalcium aluminate (C 3 A) Terracalcium aluminoferrite (C 4 AF) Chemical Composition: Lime, Silica, Alumina, Iron Oxide, Magnesium, Alkalis, Sulphur trioxide. Last Updated: 2/11/2018 © LMS SEGi education group 8

Hydraulic Cement • Cement that would set and hardened under water by virtue of a chemical reaction between the constituent compounds of cement and water. • Consists mainly of silicates and aluminates of lime. • May be classified as: Natural cement 1. • • • Last Updated: 2/11/2018 Powder obtained from clayey limestone type of natural rocks. Brown colour Not used for concrete work © LMS SEGi education group 9

Hydraulic Cement • Cement that would set and hardened under water by virtue of a chemical reaction between the constituent compounds of cement and water. • Consists mainly of silicates and aluminates of lime. • May be classified as: Natural cement 1. • • • Last Updated: 2/11/2018 Powder obtained from clayey limestone type of natural rocks. Brown colour Not used for concrete work © LMS SEGi education group 9

2. Portland cement • • 3. Aluminous cement • Last Updated: 2/11/2018 Burning calcareous and argillaceous materials at a very high temperature (1450°C), ground to fine powder. Most commonly used Chief ingredients are calcareous (clay, shale) and aluminous materials (limestone or chalk and bauxite). © LMS SEGi education group 10

2. Portland cement • • 3. Aluminous cement • Last Updated: 2/11/2018 Burning calcareous and argillaceous materials at a very high temperature (1450°C), ground to fine powder. Most commonly used Chief ingredients are calcareous (clay, shale) and aluminous materials (limestone or chalk and bauxite). © LMS SEGi education group 10

High Alumina Cement (HAC) • Slow-setting but very rapid-hardening, thus, produces very high early strength. • Concrete must be kept continuously wet for at least 24 hours from the time it begins to harden. • About _____ of the ultimate strength is developed at the age of 24 hours. • For the same water cement ratio, alumina cement is more workable than Portland cement. • HAC concrete is more resistant than ordinary Portland cement concrete, thus suitable for under ________ applications. Raw materials: limestone or chalk and bauxite Fusion point: 1600°C Ground to fineness of 2500 – 3200 cm 2/g Colour: very dark grey powder • More expensive Last Updated: 2/11/2018 © LMS SEGi education group • 11

High Alumina Cement (HAC) • Slow-setting but very rapid-hardening, thus, produces very high early strength. • Concrete must be kept continuously wet for at least 24 hours from the time it begins to harden. • About _____ of the ultimate strength is developed at the age of 24 hours. • For the same water cement ratio, alumina cement is more workable than Portland cement. • HAC concrete is more resistant than ordinary Portland cement concrete, thus suitable for under ________ applications. Raw materials: limestone or chalk and bauxite Fusion point: 1600°C Ground to fineness of 2500 – 3200 cm 2/g Colour: very dark grey powder • More expensive Last Updated: 2/11/2018 © LMS SEGi education group • 11

Portland Cement • Raw materials used: mainly lime, silica, alumina, and iron oxide • Types of Portland cement: 1. Normal or ________ Portland Cement (BS 12 : 1971) - Last Updated: 2/11/2018 Medium rate of hardening Most commonly used for structural purposes © LMS SEGi education group 12

Portland Cement • Raw materials used: mainly lime, silica, alumina, and iron oxide • Types of Portland cement: 1. Normal or ________ Portland Cement (BS 12 : 1971) - Last Updated: 2/11/2018 Medium rate of hardening Most commonly used for structural purposes © LMS SEGi education group 12

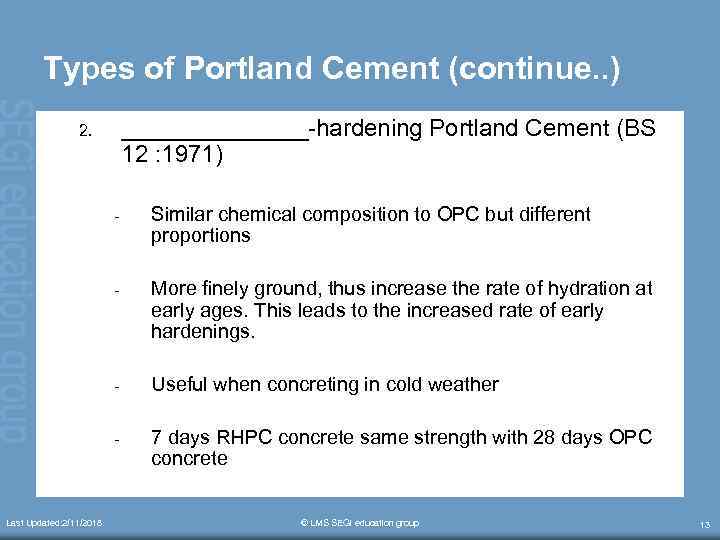

Types of Portland Cement (continue. . ) _______-hardening Portland Cement (BS 12 : 1971) 2. - - More finely ground, thus increase the rate of hydration at early ages. This leads to the increased rate of early hardenings. - Useful when concreting in cold weather - Last Updated: 2/11/2018 Similar chemical composition to OPC but different proportions 7 days RHPC concrete same strength with 28 days OPC concrete © LMS SEGi education group 13

Types of Portland Cement (continue. . ) _______-hardening Portland Cement (BS 12 : 1971) 2. - - More finely ground, thus increase the rate of hydration at early ages. This leads to the increased rate of early hardenings. - Useful when concreting in cold weather - Last Updated: 2/11/2018 Similar chemical composition to OPC but different proportions 7 days RHPC concrete same strength with 28 days OPC concrete © LMS SEGi education group 13

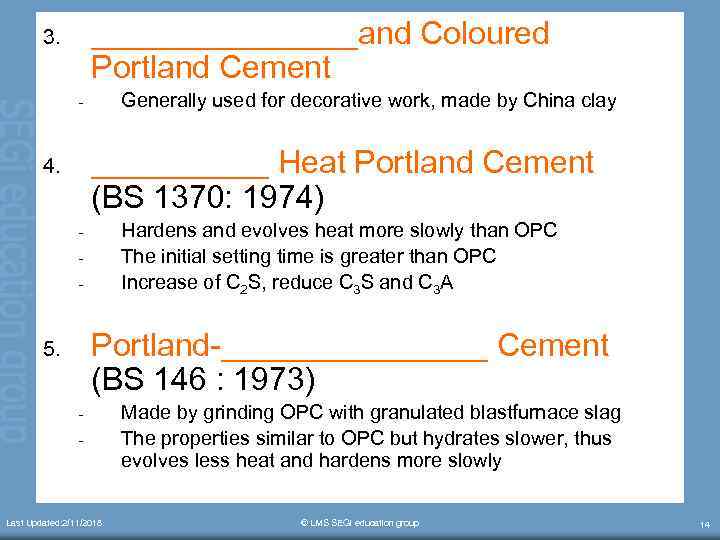

________and Coloured Portland Cement 3. Generally used for decorative work, made by China clay - _____ Heat Portland Cement (BS 1370: 1974) 4. Hardens and evolves heat more slowly than OPC The initial setting time is greater than OPC Increase of C 2 S, reduce C 3 S and C 3 A - Portland-________ Cement (BS 146 : 1973) 5. - Last Updated: 2/11/2018 Made by grinding OPC with granulated blastfurnace slag The properties similar to OPC but hydrates slower, thus evolves less heat and hardens more slowly © LMS SEGi education group 14

________and Coloured Portland Cement 3. Generally used for decorative work, made by China clay - _____ Heat Portland Cement (BS 1370: 1974) 4. Hardens and evolves heat more slowly than OPC The initial setting time is greater than OPC Increase of C 2 S, reduce C 3 S and C 3 A - Portland-________ Cement (BS 146 : 1973) 5. - Last Updated: 2/11/2018 Made by grinding OPC with granulated blastfurnace slag The properties similar to OPC but hydrates slower, thus evolves less heat and hardens more slowly © LMS SEGi education group 14

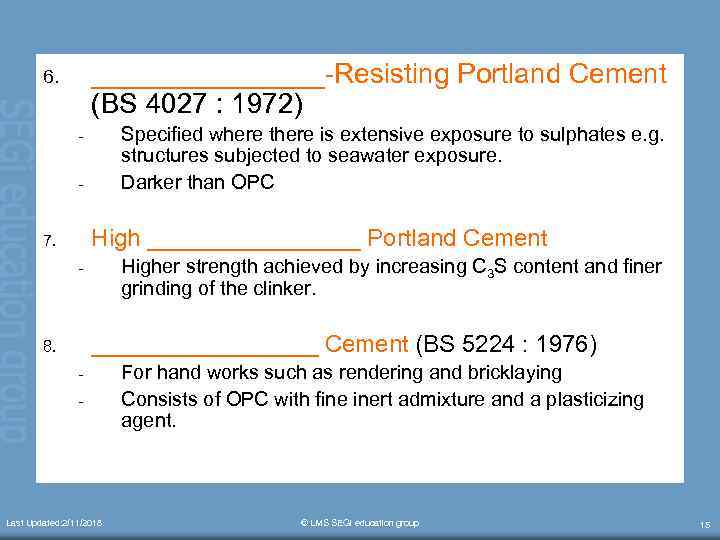

________-Resisting Portland Cement (BS 4027 : 1972) 6. Specified where there is extensive exposure to sulphates e. g. structures subjected to seawater exposure. Darker than OPC - High ________ Portland Cement 7. Higher strength achieved by increasing C 3 S content and finer grinding of the clinker. - _________ Cement (BS 5224 : 1976) 8. - Last Updated: 2/11/2018 For hand works such as rendering and bricklaying Consists of OPC with fine inert admixture and a plasticizing agent. © LMS SEGi education group 15

________-Resisting Portland Cement (BS 4027 : 1972) 6. Specified where there is extensive exposure to sulphates e. g. structures subjected to seawater exposure. Darker than OPC - High ________ Portland Cement 7. Higher strength achieved by increasing C 3 S content and finer grinding of the clinker. - _________ Cement (BS 5224 : 1976) 8. - Last Updated: 2/11/2018 For hand works such as rendering and bricklaying Consists of OPC with fine inert admixture and a plasticizing agent. © LMS SEGi education group 15

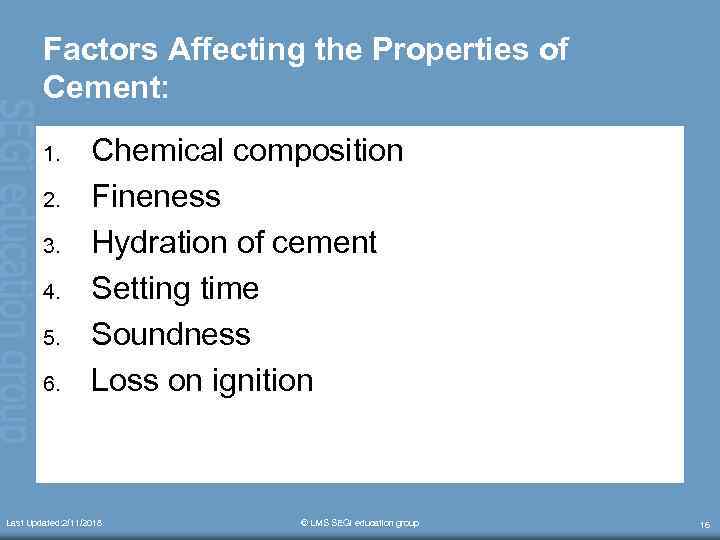

Factors Affecting the Properties of Cement: 1. 2. 3. 4. 5. 6. Chemical composition Fineness Hydration of cement Setting time Soundness Loss on ignition Last Updated: 2/11/2018 © LMS SEGi education group 16

Factors Affecting the Properties of Cement: 1. 2. 3. 4. 5. 6. Chemical composition Fineness Hydration of cement Setting time Soundness Loss on ignition Last Updated: 2/11/2018 © LMS SEGi education group 16

1. Chemical Composition Raw materials of OPC: lime, silica, alumina, and iron oxide Interact with each other in the kiln to form a series of more complex products The change percentage of chemical will produce different types of cement such as OPC, RHPC, LHPC or Sulphate-resisting cement. MAJOR constituents/ compound of cement: • • Last Updated: 2/11/2018 C 3 S – quick reaction C 2 S – slow reaction C 3 A – very quick reaction C 4 AF – not very important © LMS SEGi education group 17

1. Chemical Composition Raw materials of OPC: lime, silica, alumina, and iron oxide Interact with each other in the kiln to form a series of more complex products The change percentage of chemical will produce different types of cement such as OPC, RHPC, LHPC or Sulphate-resisting cement. MAJOR constituents/ compound of cement: • • Last Updated: 2/11/2018 C 3 S – quick reaction C 2 S – slow reaction C 3 A – very quick reaction C 4 AF – not very important © LMS SEGi education group 17

2. Fineness Is a measure of the sizes of particles of cement, expressed in terms of ‘specific surface of cement’. • The finer the cement is ground, the greater will be its specific surface. Ø Determination of fineness of cement: • Sieve analysis through a 90 micron sieve Specific surface area: • • • Air permeability method Wagners turbidimeter method Fineness of different Portland Cement: Last Updated: 2/11/2018 © LMS SEGi education group 18

2. Fineness Is a measure of the sizes of particles of cement, expressed in terms of ‘specific surface of cement’. • The finer the cement is ground, the greater will be its specific surface. Ø Determination of fineness of cement: • Sieve analysis through a 90 micron sieve Specific surface area: • • • Air permeability method Wagners turbidimeter method Fineness of different Portland Cement: Last Updated: 2/11/2018 © LMS SEGi education group 18

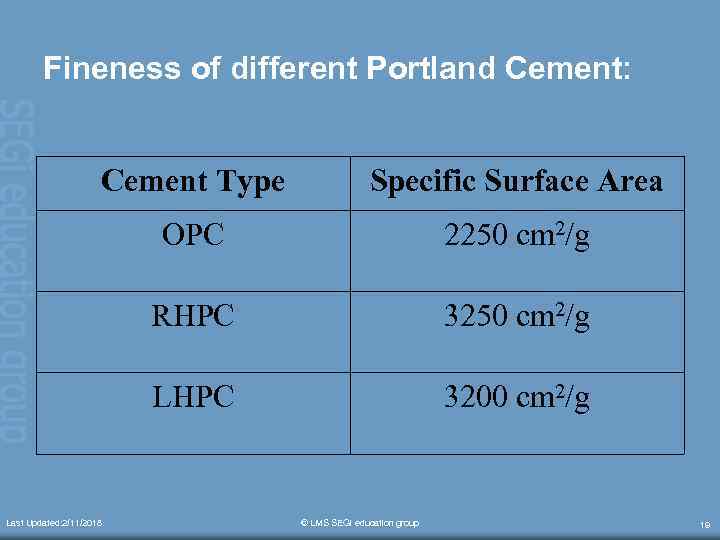

Fineness of different Portland Cement: Cement Type Specific Surface Area OPC 2250 cm 2/g RHPC 3250 cm 2/g LHPC 3200 cm 2/g Last Updated: 2/11/2018 © LMS SEGi education group 19

Fineness of different Portland Cement: Cement Type Specific Surface Area OPC 2250 cm 2/g RHPC 3250 cm 2/g LHPC 3200 cm 2/g Last Updated: 2/11/2018 © LMS SEGi education group 19

Fineness is the most important factor which will determines the properties of cement: i. The rate of hydration depends on the fineness of cement particles • ii. iv. v. vi. Last Updated: 2/11/2018 Rapid development of strength Leads to a faster reaction but does not alter the constituents’ properties Important in relation to the workability of concrete mixes _______ the cohesiveness of a concrete mix Exhibit a _______ shrinkage cracking Bleeds ______ than a coarse aggregate © LMS SEGi education group 20

Fineness is the most important factor which will determines the properties of cement: i. The rate of hydration depends on the fineness of cement particles • ii. iv. v. vi. Last Updated: 2/11/2018 Rapid development of strength Leads to a faster reaction but does not alter the constituents’ properties Important in relation to the workability of concrete mixes _______ the cohesiveness of a concrete mix Exhibit a _______ shrinkage cracking Bleeds ______ than a coarse aggregate © LMS SEGi education group 20

ANY QUESTIONS? Picture retrieved from http: //www. cartoonstock. com/directory/C/Cement. asp Last Updated: 2/11/2018 © LMS SEGi education group 21

ANY QUESTIONS? Picture retrieved from http: //www. cartoonstock. com/directory/C/Cement. asp Last Updated: 2/11/2018 © LMS SEGi education group 21

References • Smith W. F. (1993). Foundations of Materials Science and Engineering, 2 nd edition, Mc. Graw-Hill International Edition • Neville, A. M. (1995). Properties of Concrete, 4 th edition. , Addison Wesley Longman Limited, England • John, V. B. (1992) Introduction to Engineering Materials, 3 rd edition, Mc. Millan Press Ltd. • Everett, A. (1996). Materials, 3 rd edition Addison Wesley Longman Limited, England Last Updated: 2/11/2018 © LMS SEGi education group 22

References • Smith W. F. (1993). Foundations of Materials Science and Engineering, 2 nd edition, Mc. Graw-Hill International Edition • Neville, A. M. (1995). Properties of Concrete, 4 th edition. , Addison Wesley Longman Limited, England • John, V. B. (1992) Introduction to Engineering Materials, 3 rd edition, Mc. Millan Press Ltd. • Everett, A. (1996). Materials, 3 rd edition Addison Wesley Longman Limited, England Last Updated: 2/11/2018 © LMS SEGi education group 22