LMSLectureSlideWK8 AGGREGATES.ppt

- Количество слайдов: 33

CE 1205 CONSTRUCTION MATERIALS WEEK 8 Chapter 5 PROPERTIES OF AGGREGATE Power. Point® Slides by Salmaliza Salleh Last Updated: 2/11/2018 © LMS SEGi education group 1

CE 1205 CONSTRUCTION MATERIALS WEEK 8 Chapter 5 PROPERTIES OF AGGREGATE Power. Point® Slides by Salmaliza Salleh Last Updated: 2/11/2018 © LMS SEGi education group 1

Physical Properties of Aggregate • Can be classified into: • • • Strength Hardness Toughness Durability Porosity Water Absorption Last Updated: 2/11/2018 © LMS SEGi education group 2

Physical Properties of Aggregate • Can be classified into: • • • Strength Hardness Toughness Durability Porosity Water Absorption Last Updated: 2/11/2018 © LMS SEGi education group 2

Physical Properties of Aggregate Strength of concrete cannot exceed the bulk of aggregate contained therein Majority of normal weight aggregates are stronger than concrete 1) • • Concrete strength 20 N/mm 2 to 50 N/mm 2 Aggregate strength 70 to 350 N/mm 2 • • Test conducted to determine aggregate strength: • • Last Updated: 2/11/2018 Aggregate crushing value, (popular) Aggregate impact value, and 10% fines value (more reliable) © LMS SEGi education group 3

Physical Properties of Aggregate Strength of concrete cannot exceed the bulk of aggregate contained therein Majority of normal weight aggregates are stronger than concrete 1) • • Concrete strength 20 N/mm 2 to 50 N/mm 2 Aggregate strength 70 to 350 N/mm 2 • • Test conducted to determine aggregate strength: • • Last Updated: 2/11/2018 Aggregate crushing value, (popular) Aggregate impact value, and 10% fines value (more reliable) © LMS SEGi education group 3

Physical Properties of Aggregate Hardness The ability to withstand wear or load or applied pressure Use abrasion test (BS 812) to obtain hardness: 2) • • Abrasion value < 30% for wearing surfaces Abrasion value < 50% for non-wearing surface • • Toughness Resistance to failure by impact Determined by Aggregate Impact Test (MS 30: Part 10: 1995): 3) • • Last Updated: 2/11/2018 Impact value < 30% for wearing surfaces Impact value < 45% for non-wearing surface © LMS SEGi education group 4

Physical Properties of Aggregate Hardness The ability to withstand wear or load or applied pressure Use abrasion test (BS 812) to obtain hardness: 2) • • Abrasion value < 30% for wearing surfaces Abrasion value < 50% for non-wearing surface • • Toughness Resistance to failure by impact Determined by Aggregate Impact Test (MS 30: Part 10: 1995): 3) • • Last Updated: 2/11/2018 Impact value < 30% for wearing surfaces Impact value < 45% for non-wearing surface © LMS SEGi education group 4

Physical Properties of Aggregate 4) • • • Durability Ability to withstand external or internal damaging attack or soundness • creep and shrinkage • crack Soundness Test (BS 812: Part 121: 1989) High modulus of elasticity aggregate are better Last Updated: 2/11/2018 © LMS SEGi education group 5

Physical Properties of Aggregate 4) • • • Durability Ability to withstand external or internal damaging attack or soundness • creep and shrinkage • crack Soundness Test (BS 812: Part 121: 1989) High modulus of elasticity aggregate are better Last Updated: 2/11/2018 © LMS SEGi education group 5

Physical Properties of Aggregate 5) • • Porosity of aggregate contribute to overall porosity of concrete Can be estimated from the relationship below: Porosity = 100 WGs / (W +100)% W = water absorption (%) Gs = specific gravity on a saturated surface -dry basis Last Updated: 2/11/2018 © LMS SEGi education group 6

Physical Properties of Aggregate 5) • • Porosity of aggregate contribute to overall porosity of concrete Can be estimated from the relationship below: Porosity = 100 WGs / (W +100)% W = water absorption (%) Gs = specific gravity on a saturated surface -dry basis Last Updated: 2/11/2018 © LMS SEGi education group 6

Physical Properties of Aggregate 6) • • • Water Absorption Aggregates absorb water when dry, release water when wet Water absorption is express as ‘percentage of the weight of the dry aggregate’. Determined by measuring the increase in weight of an oven dry sample immersed in water for 24 hours and weighted at a saturated and surface dry condition Last Updated: 2/11/2018 © LMS SEGi education group 7

Physical Properties of Aggregate 6) • • • Water Absorption Aggregates absorb water when dry, release water when wet Water absorption is express as ‘percentage of the weight of the dry aggregate’. Determined by measuring the increase in weight of an oven dry sample immersed in water for 24 hours and weighted at a saturated and surface dry condition Last Updated: 2/11/2018 © LMS SEGi education group 7

Physical Properties of Aggregate 6. 1) Moisture Content in Aggregate • Expressed as ‘percentage of the weight of the saturated surface dry aggregate’ • A high moisture content will increase the effective water-cement ratio and make the concrete weak Last Updated: 2/11/2018 © LMS SEGi education group 8

Physical Properties of Aggregate 6. 1) Moisture Content in Aggregate • Expressed as ‘percentage of the weight of the saturated surface dry aggregate’ • A high moisture content will increase the effective water-cement ratio and make the concrete weak Last Updated: 2/11/2018 © LMS SEGi education group 8

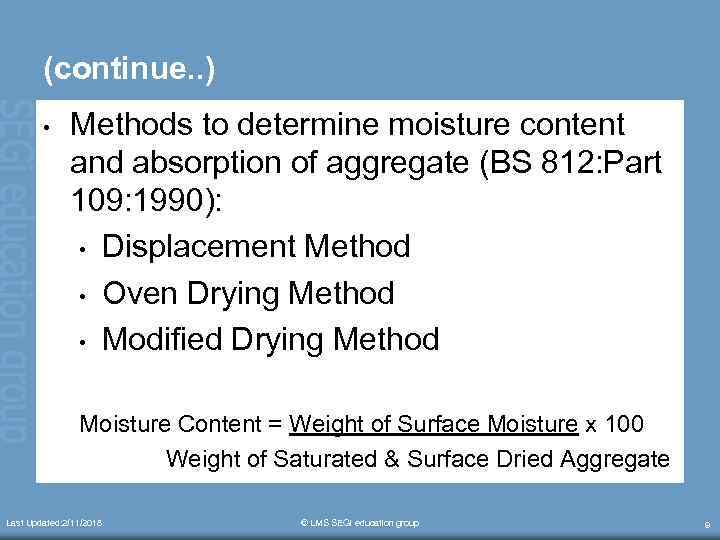

(continue. . ) • Methods to determine moisture content and absorption of aggregate (BS 812: Part 109: 1990): • Displacement Method • Oven Drying Method • Modified Drying Method Moisture Content = Weight of Surface Moisture x 100 Weight of Saturated & Surface Dried Aggregate Last Updated: 2/11/2018 © LMS SEGi education group 9

(continue. . ) • Methods to determine moisture content and absorption of aggregate (BS 812: Part 109: 1990): • Displacement Method • Oven Drying Method • Modified Drying Method Moisture Content = Weight of Surface Moisture x 100 Weight of Saturated & Surface Dried Aggregate Last Updated: 2/11/2018 © LMS SEGi education group 9

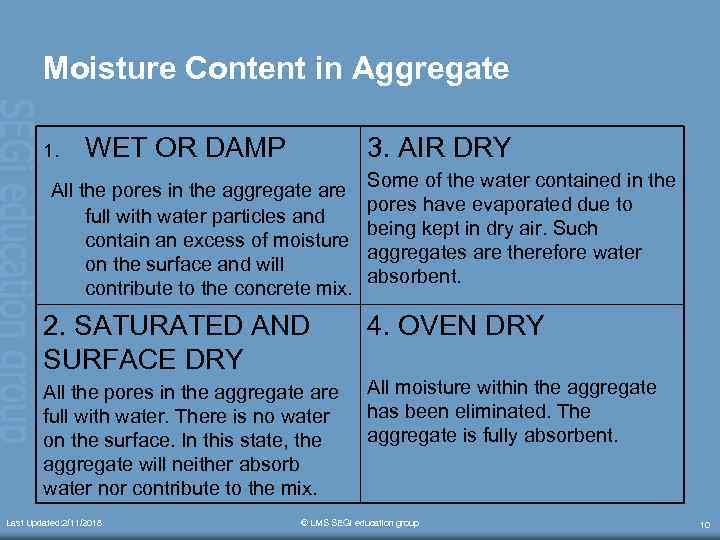

Moisture Content in Aggregate 1. WET OR DAMP 3. AIR DRY All the pores in the aggregate are full with water particles and contain an excess of moisture on the surface and will contribute to the concrete mix. Some of the water contained in the pores have evaporated due to being kept in dry air. Such aggregates are therefore water absorbent. 2. SATURATED AND SURFACE DRY 4. OVEN DRY All the pores in the aggregate are full with water. There is no water on the surface. In this state, the aggregate will neither absorb water nor contribute to the mix. All moisture within the aggregate has been eliminated. The aggregate is fully absorbent. Last Updated: 2/11/2018 © LMS SEGi education group 10

Moisture Content in Aggregate 1. WET OR DAMP 3. AIR DRY All the pores in the aggregate are full with water particles and contain an excess of moisture on the surface and will contribute to the concrete mix. Some of the water contained in the pores have evaporated due to being kept in dry air. Such aggregates are therefore water absorbent. 2. SATURATED AND SURFACE DRY 4. OVEN DRY All the pores in the aggregate are full with water. There is no water on the surface. In this state, the aggregate will neither absorb water nor contribute to the mix. All moisture within the aggregate has been eliminated. The aggregate is fully absorbent. Last Updated: 2/11/2018 © LMS SEGi education group 10

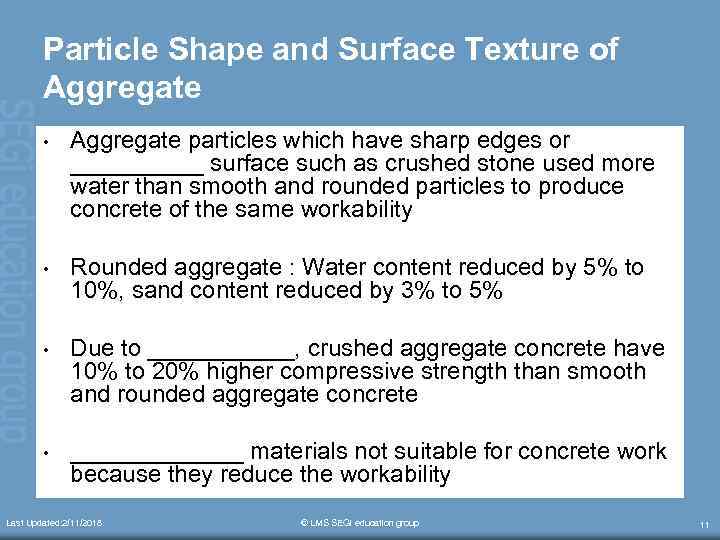

Particle Shape and Surface Texture of Aggregate • Aggregate particles which have sharp edges or _____ surface such as crushed stone used more water than smooth and rounded particles to produce concrete of the same workability • Rounded aggregate : Water content reduced by 5% to 10%, sand content reduced by 3% to 5% • Due to ______, crushed aggregate concrete have 10% to 20% higher compressive strength than smooth and rounded aggregate concrete • _______ materials not suitable for concrete work because they reduce the workability Last Updated: 2/11/2018 © LMS SEGi education group 11

Particle Shape and Surface Texture of Aggregate • Aggregate particles which have sharp edges or _____ surface such as crushed stone used more water than smooth and rounded particles to produce concrete of the same workability • Rounded aggregate : Water content reduced by 5% to 10%, sand content reduced by 3% to 5% • Due to ______, crushed aggregate concrete have 10% to 20% higher compressive strength than smooth and rounded aggregate concrete • _______ materials not suitable for concrete work because they reduce the workability Last Updated: 2/11/2018 © LMS SEGi education group 11

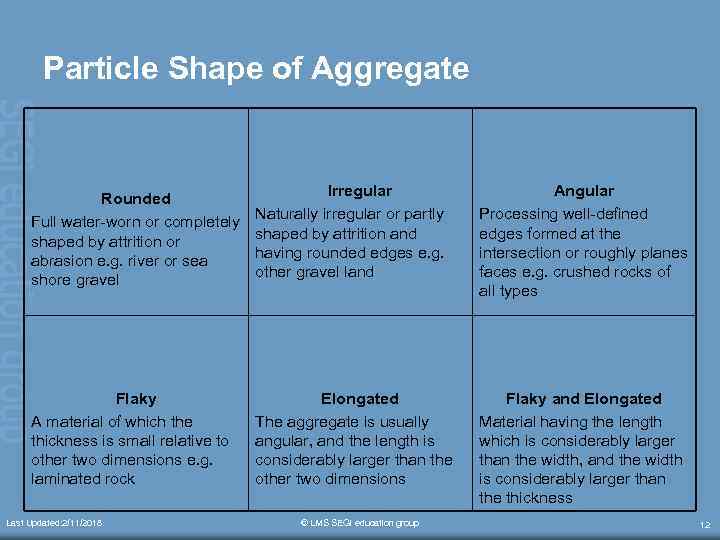

Particle Shape of Aggregate Rounded Full water-worn or completely shaped by attrition or abrasion e. g. river or sea shore gravel Flaky A material of which the thickness is small relative to other two dimensions e. g. laminated rock Last Updated: 2/11/2018 Irregular Naturally irregular or partly shaped by attrition and having rounded edges e. g. other gravel land Angular Processing well-defined edges formed at the intersection or roughly planes faces e. g. crushed rocks of all types Elongated The aggregate is usually angular, and the length is considerably larger than the other two dimensions Flaky and Elongated Material having the length which is considerably larger than the width, and the width is considerably larger than the thickness © LMS SEGi education group 12

Particle Shape of Aggregate Rounded Full water-worn or completely shaped by attrition or abrasion e. g. river or sea shore gravel Flaky A material of which the thickness is small relative to other two dimensions e. g. laminated rock Last Updated: 2/11/2018 Irregular Naturally irregular or partly shaped by attrition and having rounded edges e. g. other gravel land Angular Processing well-defined edges formed at the intersection or roughly planes faces e. g. crushed rocks of all types Elongated The aggregate is usually angular, and the length is considerably larger than the other two dimensions Flaky and Elongated Material having the length which is considerably larger than the width, and the width is considerably larger than the thickness © LMS SEGi education group 12

Surface Texture of Aggregate • It is the measure of _______ or roughness of the aggregate. • Strength of the bond between aggregate and cement paste depends upon the surface texture: roughness and porosity • The more angular the aggregate, the more surface it will produce, thus, result in greater _______ Last Updated: 2/11/2018 © LMS SEGi education group 13

Surface Texture of Aggregate • It is the measure of _______ or roughness of the aggregate. • Strength of the bond between aggregate and cement paste depends upon the surface texture: roughness and porosity • The more angular the aggregate, the more surface it will produce, thus, result in greater _______ Last Updated: 2/11/2018 © LMS SEGi education group 13

Classification of surface texture based on: • • • The degree to which the particles surface are polished, dull, smooth, or rough Hardness Grain size Pore characteristic of the parent material Degree to which forces acting on the surface have smoothed or roughened. Last Updated: 2/11/2018 © LMS SEGi education group 14

Classification of surface texture based on: • • • The degree to which the particles surface are polished, dull, smooth, or rough Hardness Grain size Pore characteristic of the parent material Degree to which forces acting on the surface have smoothed or roughened. Last Updated: 2/11/2018 © LMS SEGi education group 14

BS 812: Part 1: 1975 characterized the surface texture of aggregate as: i. iii. iv. v. vi. Glassy : Conchoidal fracture. Smooth : Water-worn, or smooth due to fracture of laminated or fine grained rock. Granular : Fracture showing more or less uniform rounded grains. Rough: Rough fracture of fine or medium grained rock. Crystalline: Containing easily visible crystalline constituents. Honeycomb: With visible pores and cavities. Last Updated: 2/11/2018 © LMS SEGi education group 15

BS 812: Part 1: 1975 characterized the surface texture of aggregate as: i. iii. iv. v. vi. Glassy : Conchoidal fracture. Smooth : Water-worn, or smooth due to fracture of laminated or fine grained rock. Granular : Fracture showing more or less uniform rounded grains. Rough: Rough fracture of fine or medium grained rock. Crystalline: Containing easily visible crystalline constituents. Honeycomb: With visible pores and cavities. Last Updated: 2/11/2018 © LMS SEGi education group 15

GRADING OF AGGREGATE • Quantity of material to be presented as bulk sample carried out by: • • • Quartering by hand Riffle box Sample splitter Grading obtained by ________ test Grading curves drawn based on the analysis Detailed procedure: MS 30: Part 3 : 1995 Last Updated: 2/11/2018 © LMS SEGi education group 16

GRADING OF AGGREGATE • Quantity of material to be presented as bulk sample carried out by: • • • Quartering by hand Riffle box Sample splitter Grading obtained by ________ test Grading curves drawn based on the analysis Detailed procedure: MS 30: Part 3 : 1995 Last Updated: 2/11/2018 © LMS SEGi education group 16

GRADING OF AGGREGATE • Expressed in terms of ‘percentages by weight retained or passing through a series of sieves taken in order’. • The grading curve indicates whether the grading of a given sample conforms to the specified size. • The grading of aggregates affects the _______, which in turn controls the water and cement requirements, segregation, and influences the placing and finishing of concrete. Last Updated: 2/11/2018 © LMS SEGi education group 17

GRADING OF AGGREGATE • Expressed in terms of ‘percentages by weight retained or passing through a series of sieves taken in order’. • The grading curve indicates whether the grading of a given sample conforms to the specified size. • The grading of aggregates affects the _______, which in turn controls the water and cement requirements, segregation, and influences the placing and finishing of concrete. Last Updated: 2/11/2018 © LMS SEGi education group 17

The reading of the grading curve will indicates the followings: • If the actual grading curve is lower than the specified grading curve, the aggregate is coarser and segregation of mix might take place. • If the actual grading curve lies well above the specified curve, the aggregate is finer and more water will be required, thus increasing the quantity of cement – uneconomical. Last Updated: 2/11/2018 © LMS SEGi education group 18

The reading of the grading curve will indicates the followings: • If the actual grading curve is lower than the specified grading curve, the aggregate is coarser and segregation of mix might take place. • If the actual grading curve lies well above the specified curve, the aggregate is finer and more water will be required, thus increasing the quantity of cement – uneconomical. Last Updated: 2/11/2018 © LMS SEGi education group 18

(continue. . ) • If the actual grading curve is steeper than the specified curve, it indicates an excess of middle-size particles and leads to harsh mix. • If the actual grading curve is flatter than the specified curve, the aggregate will be deficient in middle size particles. Last Updated: 2/11/2018 © LMS SEGi education group 19

(continue. . ) • If the actual grading curve is steeper than the specified curve, it indicates an excess of middle-size particles and leads to harsh mix. • If the actual grading curve is flatter than the specified curve, the aggregate will be deficient in middle size particles. Last Updated: 2/11/2018 © LMS SEGi education group 19

Main factors governing the desired aggregate grading are: • The ________ area of aggregate • The relative volume occupied by the aggregate • The ________ of the mix • The tendency to ________ Last Updated: 2/11/2018 © LMS SEGi education group 20

Main factors governing the desired aggregate grading are: • The ________ area of aggregate • The relative volume occupied by the aggregate • The ________ of the mix • The tendency to ________ Last Updated: 2/11/2018 © LMS SEGi education group 20

Surface Area of Aggregate • The smaller the size of aggregate, the greater is the surface area per unit mass or unit volume. • The aim is to have a large a maximum aggregate as possible & to grade it down in such a way that the voids in the coarse aggregate are filled with minimum amount of fine aggregate. • Too coarse a fine aggregate results in harshness, _____, and ______ • Too fine an aggregate requires too _____ a water-cement ratio for adequate workability Last Updated: 2/11/2018 © LMS SEGi education group 21

Surface Area of Aggregate • The smaller the size of aggregate, the greater is the surface area per unit mass or unit volume. • The aim is to have a large a maximum aggregate as possible & to grade it down in such a way that the voids in the coarse aggregate are filled with minimum amount of fine aggregate. • Too coarse a fine aggregate results in harshness, _____, and ______ • Too fine an aggregate requires too _____ a water-cement ratio for adequate workability Last Updated: 2/11/2018 © LMS SEGi education group 21

Maximum Size of Aggregate • • The larger the maximum size of aggregate, the smaller is the cement requirement for a particular water-cement ratio. Workability of concrete increase with the increase in the maximum size of aggregate. Reduce the heat of hydration Influence the compressive strength of concrete: • Compressive strength of concrete increase with the decrease in size of the coarse aggregate Last Updated: 2/11/2018 © LMS SEGi education group 22

Maximum Size of Aggregate • • The larger the maximum size of aggregate, the smaller is the cement requirement for a particular water-cement ratio. Workability of concrete increase with the increase in the maximum size of aggregate. Reduce the heat of hydration Influence the compressive strength of concrete: • Compressive strength of concrete increase with the decrease in size of the coarse aggregate Last Updated: 2/11/2018 © LMS SEGi education group 22

BULK DENSITY • • • Is defined as the mass of the material in a given volume and is expressed in kg/litre. Depends on how densely the aggregate is packed in the measure. Other factors affecting the bulk density are: • • The particle shape Size The grading of aggregate The moisture content Last Updated: 2/11/2018 © LMS SEGi education group 23

BULK DENSITY • • • Is defined as the mass of the material in a given volume and is expressed in kg/litre. Depends on how densely the aggregate is packed in the measure. Other factors affecting the bulk density are: • • The particle shape Size The grading of aggregate The moisture content Last Updated: 2/11/2018 © LMS SEGi education group 23

BULK DENSITY • • • For a coarse aggregate of a given specific gravity, a higher bulk density indicates that there are fewer voids to be filled by sand cement. Can be used for judging the quality of aggregate by comparison with normal density for that type of aggregate. Also required for converting proportion by weight into the proportions by volume. Void ratio = 1 – bulk density specific gravity Last Updated: 2/11/2018 © LMS SEGi education group 24

BULK DENSITY • • • For a coarse aggregate of a given specific gravity, a higher bulk density indicates that there are fewer voids to be filled by sand cement. Can be used for judging the quality of aggregate by comparison with normal density for that type of aggregate. Also required for converting proportion by weight into the proportions by volume. Void ratio = 1 – bulk density specific gravity Last Updated: 2/11/2018 © LMS SEGi education group 24

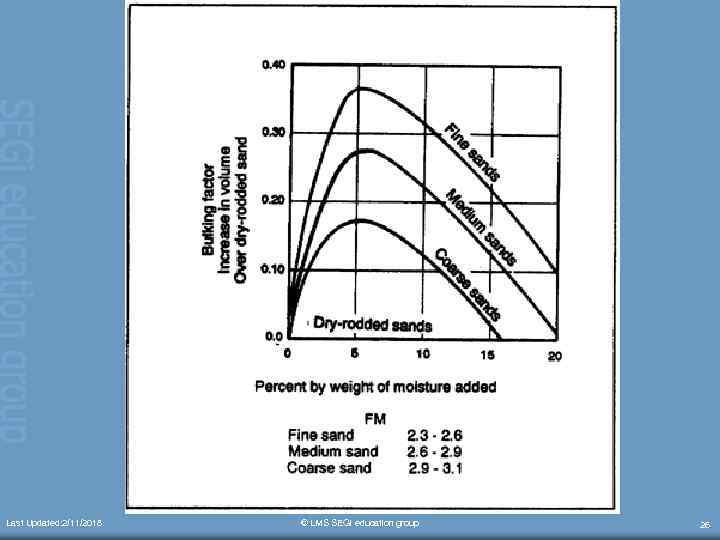

Bulking of Fine Aggregate (Sand) • Defined as ‘the increase in volume of a given weight of fine aggregate (sand) caused by the films of water pushing the sand particles apart. ’ • The extent of bulking depends on % of moisture present in the sand on its fineness. • Bulking increases gradually with moisture content up to certain point & then begins to decrease with further addition of water due to merging of films • If no allowance is made for the bulking of sand, a nominal concrete mix 1: 2: 4 will correspond to 1: 1. 74: 4 for a bulking of 15%, increasing the chances of the segregation and honeycombing of concrete Last Updated: 2/11/2018 © LMS SEGi education group 25

Bulking of Fine Aggregate (Sand) • Defined as ‘the increase in volume of a given weight of fine aggregate (sand) caused by the films of water pushing the sand particles apart. ’ • The extent of bulking depends on % of moisture present in the sand on its fineness. • Bulking increases gradually with moisture content up to certain point & then begins to decrease with further addition of water due to merging of films • If no allowance is made for the bulking of sand, a nominal concrete mix 1: 2: 4 will correspond to 1: 1. 74: 4 for a bulking of 15%, increasing the chances of the segregation and honeycombing of concrete Last Updated: 2/11/2018 © LMS SEGi education group 25

Last Updated: 2/11/2018 © LMS SEGi education group 26

Last Updated: 2/11/2018 © LMS SEGi education group 26

DURABILITY OF AGGREGATE • Ability of the aggregate to withstand external or internal damaging attack of aggregate. i. Soundness of Aggregate - Last Updated: 2/11/2018 Indicates the ability of aggregate to resist excessive changes in volume due to changes in environmental condition e. g. thermal, freezing, thawing which leads to crack, disintegration © LMS SEGi education group 27

DURABILITY OF AGGREGATE • Ability of the aggregate to withstand external or internal damaging attack of aggregate. i. Soundness of Aggregate - Last Updated: 2/11/2018 Indicates the ability of aggregate to resist excessive changes in volume due to changes in environmental condition e. g. thermal, freezing, thawing which leads to crack, disintegration © LMS SEGi education group 27

DURABILITY OF AGGREGATE ii. Alkali-Aggregate Reaction - - iii. Is the reaction between the active silica constituents of the aggregate and the alkalies in cement Expansion leading to crack & disruption of cement paste Thermal Properties of Aggregate i. iii. Last Updated: 2/11/2018 Coefficient of thermal expansion Specific heat: measure of its heat capacity Thermal conductivity: ability to conduct heat © LMS SEGi education group 28

DURABILITY OF AGGREGATE ii. Alkali-Aggregate Reaction - - iii. Is the reaction between the active silica constituents of the aggregate and the alkalies in cement Expansion leading to crack & disruption of cement paste Thermal Properties of Aggregate i. iii. Last Updated: 2/11/2018 Coefficient of thermal expansion Specific heat: measure of its heat capacity Thermal conductivity: ability to conduct heat © LMS SEGi education group 28

DELETERIOUS SUBSTANCES IN AGGREGATE • • • Are the materials whose presence may adversely affect the strength, workability & long-term performance of concrete Should not exceed 5%. Categories of deleterious substances found in aggregate are: i. iii. Impurities Coating Unsound Particles i. Last Updated: 2/11/2018 Salt Contamination © LMS SEGi education group 29

DELETERIOUS SUBSTANCES IN AGGREGATE • • • Are the materials whose presence may adversely affect the strength, workability & long-term performance of concrete Should not exceed 5%. Categories of deleterious substances found in aggregate are: i. iii. Impurities Coating Unsound Particles i. Last Updated: 2/11/2018 Salt Contamination © LMS SEGi education group 29

Impurities • • • In the form of ________ matter Interfere with the process of _____ of cement. Generally consisting of decayed ______ matter. Appear in the form of humus or organic loam More likely to be present in ____ aggregate Use Colorimeter Test of ASTM standard to test organic impurities of the aggregate Last Updated: 2/11/2018 © LMS SEGi education group 30

Impurities • • • In the form of ________ matter Interfere with the process of _____ of cement. Generally consisting of decayed ______ matter. Appear in the form of humus or organic loam More likely to be present in ____ aggregate Use Colorimeter Test of ASTM standard to test organic impurities of the aggregate Last Updated: 2/11/2018 © LMS SEGi education group 30

Coating • • • Preventing the development of _______ between aggregate and cement paste. Example: clay, silt, fine dust Can be removed by ______ Salt Contamination • • • Sand taken from ______ or river estuary If not removed, it will absorb moisture from air & cause efflorescence (white deposits) Also may result _______ of reinforcement Last Updated: 2/11/2018 © LMS SEGi education group 31

Coating • • • Preventing the development of _______ between aggregate and cement paste. Example: clay, silt, fine dust Can be removed by ______ Salt Contamination • • • Sand taken from ______ or river estuary If not removed, it will absorb moisture from air & cause efflorescence (white deposits) Also may result _______ of reinforcement Last Updated: 2/11/2018 © LMS SEGi education group 31

Unsound Particles • Particles which are _______ & unsound in themselves or bring about chemical _____ between the aggregate and cement paste. • Types of unsound particles: i. ii. Those that fail to maintain their integrity Those that lead to disruptive expansion on freezing or even on exposure to water • ______ particles e. g. shale, soft inclusion e. g. clay lumps, wood & coal, expansive inclusions e. g. iron pyrities & marcasite. • BS 812: Part 122 describes the methods for determination of the content of deleterious materials in fine aggregates Last Updated: 2/11/2018 © LMS SEGi education group 32

Unsound Particles • Particles which are _______ & unsound in themselves or bring about chemical _____ between the aggregate and cement paste. • Types of unsound particles: i. ii. Those that fail to maintain their integrity Those that lead to disruptive expansion on freezing or even on exposure to water • ______ particles e. g. shale, soft inclusion e. g. clay lumps, wood & coal, expansive inclusions e. g. iron pyrities & marcasite. • BS 812: Part 122 describes the methods for determination of the content of deleterious materials in fine aggregates Last Updated: 2/11/2018 © LMS SEGi education group 32

References • John, V. B. (1992) Introduction to Engineering Materials, 3 rd edition, Mc. Millan Press Ltd. • Everett, A. (1996). Materials, 3 rd edition Addison Wesley Longman Limited, England Last Updated: 2/11/2018 © LMS SEGi education group 33

References • John, V. B. (1992) Introduction to Engineering Materials, 3 rd edition, Mc. Millan Press Ltd. • Everett, A. (1996). Materials, 3 rd edition Addison Wesley Longman Limited, England Last Updated: 2/11/2018 © LMS SEGi education group 33