LMSLectureSlideWK7 AGGREGATES.ppt

- Количество слайдов: 25

CE 1205 CONSTRUCTION MATERIALS WEEK 7 Chapter 5 PROPERTIES OF AGGREGATE Power. Point® Slides by Salmaliza Salleh Last Updated: 2/13/2018 © LMS SEGi education group 1

CE 1205 CONSTRUCTION MATERIALS WEEK 7 Chapter 5 PROPERTIES OF AGGREGATE Power. Point® Slides by Salmaliza Salleh Last Updated: 2/13/2018 © LMS SEGi education group 1

Chapter Overview • Chapter 5 exposed you the properties of aggregates and its importance in concrete mixture • You also learned how to perform sieve analysis for aggregate. Last Updated: 2/13/2018 © LMS SEGi education group 2

Chapter Overview • Chapter 5 exposed you the properties of aggregates and its importance in concrete mixture • You also learned how to perform sieve analysis for aggregate. Last Updated: 2/13/2018 © LMS SEGi education group 2

Learning Objectives • In this topic, the properties of aggregates and its importance in concrete mixture will be focused. • To exposed the students on how to perform the sieve analysis. Last Updated: 2/13/2018 © LMS SEGi education group 3

Learning Objectives • In this topic, the properties of aggregates and its importance in concrete mixture will be focused. • To exposed the students on how to perform the sieve analysis. Last Updated: 2/13/2018 © LMS SEGi education group 3

Learning Outcomes • At the end of this unit, students must be able to classify the aggregate and to explain the specific gravity, porosity, moisture content, and density of aggregate. • Students must also be able to perform sieve analysis for aggregate. Last Updated: 2/13/2018 © LMS SEGi education group 4

Learning Outcomes • At the end of this unit, students must be able to classify the aggregate and to explain the specific gravity, porosity, moisture content, and density of aggregate. • Students must also be able to perform sieve analysis for aggregate. Last Updated: 2/13/2018 © LMS SEGi education group 4

INTRODUCTION • Concrete: Most widely used as construction materials e. g. foundations, buildings, roads, dams, bridges, waterretaining structures, etc. • Obtained by mixing cement, water, aggregates and sometimes admixtures in required proportions. • Major constituent materials: • Water Admixture Cement • AGGREGATES • • Last Updated: 2/13/2018 Fine: sand < 5 mm Coarse: many ranges of sizes © LMS SEGi education group 5

INTRODUCTION • Concrete: Most widely used as construction materials e. g. foundations, buildings, roads, dams, bridges, waterretaining structures, etc. • Obtained by mixing cement, water, aggregates and sometimes admixtures in required proportions. • Major constituent materials: • Water Admixture Cement • AGGREGATES • • Last Updated: 2/13/2018 Fine: sand < 5 mm Coarse: many ranges of sizes © LMS SEGi education group 5

AGGREGATES: Introduction To describe ‘the gravels, crushed stones and other materials’ which are mixed with cement and water to make concrete • Form the bulk of concrete volume i. e. 75% • The function is to resist: • action of applied load • abrasion and ________ of moisture, and • action of weather • Also to reduce strenght of concrete volume during setting and hardening process Last Updated: 2/13/2018 © LMS SEGi education group 6

AGGREGATES: Introduction To describe ‘the gravels, crushed stones and other materials’ which are mixed with cement and water to make concrete • Form the bulk of concrete volume i. e. 75% • The function is to resist: • action of applied load • abrasion and ________ of moisture, and • action of weather • Also to reduce strenght of concrete volume during setting and hardening process Last Updated: 2/13/2018 © LMS SEGi education group 6

Classification of Aggregate • Classified according to their unit weight: i. Light weight aggregate – Pumice, expanded shale, expanded clay i. Last Updated: 2/13/2018 Normal Aggregate – Crushed rock, sand & gravel, broken bricks Heavy weight aggregate – Magnetite, hematite, limonite © LMS SEGi education group 7

Classification of Aggregate • Classified according to their unit weight: i. Light weight aggregate – Pumice, expanded shale, expanded clay i. Last Updated: 2/13/2018 Normal Aggregate – Crushed rock, sand & gravel, broken bricks Heavy weight aggregate – Magnetite, hematite, limonite © LMS SEGi education group 7

Normal Density Aggregate Last Updated: 2/13/2018 © LMS SEGi education group 8

Normal Density Aggregate Last Updated: 2/13/2018 © LMS SEGi education group 8

Normal Density Aggregate • • Specific gravity: between 2. 5 and 3. 0 Bulk density: 1450 to 1750 kg/m 3 May be crushed or naturally reduced in size MS 29: 1995 classified according to size: • • Comire aggregate Fine aggregate (e. g. Sand) All-in aggregate BS 812: Part 103: 1985 describe the methods for determination of particle size distribution Last Updated: 2/13/2018 © LMS SEGi education group 9

Normal Density Aggregate • • Specific gravity: between 2. 5 and 3. 0 Bulk density: 1450 to 1750 kg/m 3 May be crushed or naturally reduced in size MS 29: 1995 classified according to size: • • Comire aggregate Fine aggregate (e. g. Sand) All-in aggregate BS 812: Part 103: 1985 describe the methods for determination of particle size distribution Last Updated: 2/13/2018 © LMS SEGi education group 9

Normal Density Aggregate • Coarse Aggregate • • The materials retired on 5 mm BS 410 test sieve May be described: • Uncrushed Gravel or uncrushed stone • • Crushed stone or crushed gravel • • Produced by crushing hard stone and gravel respectively Partially crushed gravel or stone • Last Updated: 2/13/2018 Natural disintegration of rock Blending of uncrushed and crushed gravel/stone © LMS SEGi education group 10

Normal Density Aggregate • Coarse Aggregate • • The materials retired on 5 mm BS 410 test sieve May be described: • Uncrushed Gravel or uncrushed stone • • Crushed stone or crushed gravel • • Produced by crushing hard stone and gravel respectively Partially crushed gravel or stone • Last Updated: 2/13/2018 Natural disintegration of rock Blending of uncrushed and crushed gravel/stone © LMS SEGi education group 10

Normal Density Aggregate • Fine Aggregate • • Materials which patted through a 5 mm (3/16 inch) BS 410 test sieve Size limit of sand about 0, 07 mm • • • Material between 0. 06 mm and 0. 002 mm is classified as silt Smaller particles are called clay Sand may be described: • Natural Sand • • Crushed stone sand or crushing gravel sand • • From natural disintegration of rocks Produced by crushing hard stone or natural gravel respectively Sand Grade Zone 2 & 3 suitable for concreting Last Updated: 2/13/2018 © LMS SEGi education group 11

Normal Density Aggregate • Fine Aggregate • • Materials which patted through a 5 mm (3/16 inch) BS 410 test sieve Size limit of sand about 0, 07 mm • • • Material between 0. 06 mm and 0. 002 mm is classified as silt Smaller particles are called clay Sand may be described: • Natural Sand • • Crushed stone sand or crushing gravel sand • • From natural disintegration of rocks Produced by crushing hard stone or natural gravel respectively Sand Grade Zone 2 & 3 suitable for concreting Last Updated: 2/13/2018 © LMS SEGi education group 11

Normal Density Aggregate • All-In Aggregate • • • Materials composed of a mixture of coarse and fine aggregate Normally not graded Used in unimportant works Taken from the pit or river bed Also referred as “ Pit run Aggregate” Last Updated: 2/13/2018 © LMS SEGi education group 12

Normal Density Aggregate • All-In Aggregate • • • Materials composed of a mixture of coarse and fine aggregate Normally not graded Used in unimportant works Taken from the pit or river bed Also referred as “ Pit run Aggregate” Last Updated: 2/13/2018 © LMS SEGi education group 12

Light Weight Aggregate PUMICE BLAST FURNACE SLAG SHALE SLATE Last Updated: 2/13/2018 © LMS SEGi education group 13

Light Weight Aggregate PUMICE BLAST FURNACE SLAG SHALE SLATE Last Updated: 2/13/2018 © LMS SEGi education group 13

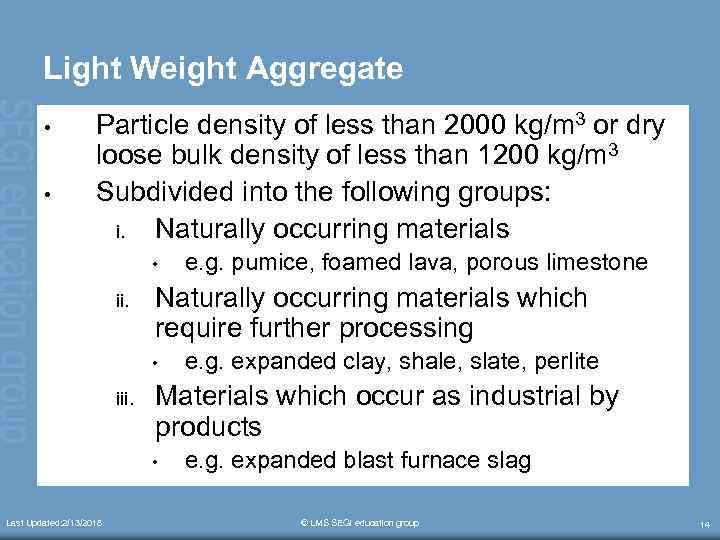

Light Weight Aggregate • • Particle density of less than 2000 kg/m 3 or dry loose bulk density of less than 1200 kg/m 3 Subdivided into the following groups: i. Naturally occurring materials • ii. Naturally occurring materials which require further processing • iii. e. g. expanded clay, shale, slate, perlite Materials which occur as industrial by products • Last Updated: 2/13/2018 e. g. pumice, foamed lava, porous limestone e. g. expanded blast furnace slag © LMS SEGi education group 14

Light Weight Aggregate • • Particle density of less than 2000 kg/m 3 or dry loose bulk density of less than 1200 kg/m 3 Subdivided into the following groups: i. Naturally occurring materials • ii. Naturally occurring materials which require further processing • iii. e. g. expanded clay, shale, slate, perlite Materials which occur as industrial by products • Last Updated: 2/13/2018 e. g. pumice, foamed lava, porous limestone e. g. expanded blast furnace slag © LMS SEGi education group 14

Light Weight Aggregate • • Main requirement is its low density Has _____ water _____, thus the workable concrete mixes become stiff within few minutes of mixing Require ______ before mixing The cover to reinforcement in concrete should be _____ Last Updated: 2/13/2018 © LMS SEGi education group 15

Light Weight Aggregate • • Main requirement is its low density Has _____ water _____, thus the workable concrete mixes become stiff within few minutes of mixing Require ______ before mixing The cover to reinforcement in concrete should be _____ Last Updated: 2/13/2018 © LMS SEGi education group 15

Light Weight Aggregate • Other characteristics: • • • Coarse surface texture caused reduced workability, ______ tensile strength, Lower modulus of elasticity (50% to 70% of normal concrete), Higher creep and shrinkage, Have tendency to segregate Last Updated: 2/13/2018 © LMS SEGi education group 16

Light Weight Aggregate • Other characteristics: • • • Coarse surface texture caused reduced workability, ______ tensile strength, Lower modulus of elasticity (50% to 70% of normal concrete), Higher creep and shrinkage, Have tendency to segregate Last Updated: 2/13/2018 © LMS SEGi education group 16

Heavy Weight Aggregate MAGNETITE BARYTES Last Updated: 2/13/2018 © LMS SEGi education group 17

Heavy Weight Aggregate MAGNETITE BARYTES Last Updated: 2/13/2018 © LMS SEGi education group 17

Heavy Weight Aggregate • • • Also referred as ‘High-Density Aggregate’ Specific gravity ranging from 2. 8 to 2. 9 Unit weight from 2800 kg/m 3 to 2900 kg/m 3 Used to make high density concrete Examples: magnetite, barytes Compressive strength of these concretes: 20 to 21 N/mm 2 Last Updated: 2/13/2018 © LMS SEGi education group 18

Heavy Weight Aggregate • • • Also referred as ‘High-Density Aggregate’ Specific gravity ranging from 2. 8 to 2. 9 Unit weight from 2800 kg/m 3 to 2900 kg/m 3 Used to make high density concrete Examples: magnetite, barytes Compressive strength of these concretes: 20 to 21 N/mm 2 Last Updated: 2/13/2018 © LMS SEGi education group 18

Heavy Weight Aggregate • • • Cement-aggregate ratio varies from 1: 5 to 1: 9 with water-cement ratio between 0. 5 to 0. 65. Produce dense and crack free concrete Difficult to have adequate workability without segregation Last Updated: 2/13/2018 © LMS SEGi education group 19

Heavy Weight Aggregate • • • Cement-aggregate ratio varies from 1: 5 to 1: 9 with water-cement ratio between 0. 5 to 0. 65. Produce dense and crack free concrete Difficult to have adequate workability without segregation Last Updated: 2/13/2018 © LMS SEGi education group 19

Characteristics of Aggregates • • Properties and the performance of concrete depends on the characteristics and properties of aggregates In general, aggregate must be: • • • Clean Hard Strong Properly shaped Well graded Last Updated: 2/13/2018 © LMS SEGi education group 20

Characteristics of Aggregates • • Properties and the performance of concrete depends on the characteristics and properties of aggregates In general, aggregate must be: • • • Clean Hard Strong Properly shaped Well graded Last Updated: 2/13/2018 © LMS SEGi education group 20

Characteristics of Aggregates • Must possess chemical stability • Resistance resistance • Resistance to freezing and thawing • Compresive strength • Good particle shape and surface texture Last Updated: 2/13/2018 © LMS SEGi education group 21

Characteristics of Aggregates • Must possess chemical stability • Resistance resistance • Resistance to freezing and thawing • Compresive strength • Good particle shape and surface texture Last Updated: 2/13/2018 © LMS SEGi education group 21

Characteristics of Aggregates • Chemical stability • • Aggregate will not react chemically with cement or chemically effected by other external influences Abrasion resistance • • Used as a general index of aggregate quality Essential when concrete subject to abrasion as in floors and pavements Last Updated: 2/13/2018 © LMS SEGi education group 22

Characteristics of Aggregates • Chemical stability • • Aggregate will not react chemically with cement or chemically effected by other external influences Abrasion resistance • • Used as a general index of aggregate quality Essential when concrete subject to abrasion as in floors and pavements Last Updated: 2/13/2018 © LMS SEGi education group 22

Characteristics of Aggregates • Resistance to freezing and thawing • • • Compressive strength • • Important when the aggregates are used in exposed concrete Related to its porosity, absorption, and pore structure Is its resistance to compressive forces Good particle shape and surface texture • Influence the properties of fresh concrete more than hardened concrete Last Updated: 2/13/2018 © LMS SEGi education group 23

Characteristics of Aggregates • Resistance to freezing and thawing • • • Compressive strength • • Important when the aggregates are used in exposed concrete Related to its porosity, absorption, and pore structure Is its resistance to compressive forces Good particle shape and surface texture • Influence the properties of fresh concrete more than hardened concrete Last Updated: 2/13/2018 © LMS SEGi education group 23

Physical Properties of Aggregate • Can be classified into: • • • Strength Hardness Toughness Durability Porosity Water Absorption Last Updated: 2/13/2018 © LMS SEGi education group 24

Physical Properties of Aggregate • Can be classified into: • • • Strength Hardness Toughness Durability Porosity Water Absorption Last Updated: 2/13/2018 © LMS SEGi education group 24

References • http: //www. materialsengineer. com/CAcorrosion. htm • http: //www. tis-gdv. de/tis_e/misc/korro. htm • http: //www. tech. plym. ac. uk/sme/mats 340/cpintro. pdf • John, V. B. (1992) Introduction to Engineering Materials, 3 rd edition, Mc. Millan Press Ltd. Last Updated: 2/13/2018 © LMS SEGi education group 25

References • http: //www. materialsengineer. com/CAcorrosion. htm • http: //www. tis-gdv. de/tis_e/misc/korro. htm • http: //www. tech. plym. ac. uk/sme/mats 340/cpintro. pdf • John, V. B. (1992) Introduction to Engineering Materials, 3 rd edition, Mc. Millan Press Ltd. Last Updated: 2/13/2018 © LMS SEGi education group 25