LMSLectureSlideWK12 CONCRETE.ppt

- Количество слайдов: 41

CE 1205 CONSTRUCTION MATERIALS WEEK 12 Chapter 7 FRESH CONCRETE Power. Point® Slides by Salmaliza Salleh Last Updated: © LMS SEGi education group 1

CE 1205 CONSTRUCTION MATERIALS WEEK 12 Chapter 7 FRESH CONCRETE Power. Point® Slides by Salmaliza Salleh Last Updated: © LMS SEGi education group 1

HARDENED CONCRETE Last Updated: © LMS SEGi education group 2

HARDENED CONCRETE Last Updated: © LMS SEGi education group 2

HARDENED CONCRETE • Setting and Hardening • • At a certain stage, however, the paste begins to stiffen to such a degree that, although still soft, it becomes unworkable which known as ‘initial set’. • The time required for the paste to reach this stage is called ‘initial setting time’. • Last Updated: Mixing cement with water produces a plastic workable paste for a certain period of time known as ‘dormant period’. Initial setting time determines the length of time concrete remain plastic and workable i. e. minimum 45 minutes for OPC © LMS SEGi education group 3

HARDENED CONCRETE • Setting and Hardening • • At a certain stage, however, the paste begins to stiffen to such a degree that, although still soft, it becomes unworkable which known as ‘initial set’. • The time required for the paste to reach this stage is called ‘initial setting time’. • Last Updated: Mixing cement with water produces a plastic workable paste for a certain period of time known as ‘dormant period’. Initial setting time determines the length of time concrete remain plastic and workable i. e. minimum 45 minutes for OPC © LMS SEGi education group 3

• ‘Final set’ is which the paste continues to stiffen until a stage is reached when it may be regarded as a rigid solid. • The time required for the paste to reach this stage is known as ‘ final setting time’. • Final setting time should not be too long in order to allow construction work to continue after casting the concrete i. e. maximum of 10 hours. • With time, the hardened paste continues to harden and gain in strength. • This process is known as ‘hardening’. Last Updated: © LMS SEGi education group 4

• ‘Final set’ is which the paste continues to stiffen until a stage is reached when it may be regarded as a rigid solid. • The time required for the paste to reach this stage is known as ‘ final setting time’. • Final setting time should not be too long in order to allow construction work to continue after casting the concrete i. e. maximum of 10 hours. • With time, the hardened paste continues to harden and gain in strength. • This process is known as ‘hardening’. Last Updated: © LMS SEGi education group 4

Last Updated: © LMS SEGi education group 5

Last Updated: © LMS SEGi education group 5

PROPERTY OF HARDENED CONCRETE 1. 2. 3. 4. 5. Last Updated: Strength Deformation under load Durability Permeability Shrinkage © LMS SEGi education group 6

PROPERTY OF HARDENED CONCRETE 1. 2. 3. 4. 5. Last Updated: Strength Deformation under load Durability Permeability Shrinkage © LMS SEGi education group 6

1. Strength of Concrete • Usually gives an overall picture of the quality of concrete. • Is defined as the maximum stress it can resist or the maximum load it can carry. • Cubes, cylinders and prisms are three types of compression test specimens used to determine the compressive strength. • To estimate the load at which the concrete members may crack, normally flexural tensile strength test will be conducted. Last Updated: © LMS SEGi education group 7

1. Strength of Concrete • Usually gives an overall picture of the quality of concrete. • Is defined as the maximum stress it can resist or the maximum load it can carry. • Cubes, cylinders and prisms are three types of compression test specimens used to determine the compressive strength. • To estimate the load at which the concrete members may crack, normally flexural tensile strength test will be conducted. Last Updated: © LMS SEGi education group 7

Factors Influencing The Strength Of Concrete • Type of cement, age of concrete, type of aggregate and admixture • Degree of compaction • Concrete mix proportions i. e. cement content, aggregatecement ratio, amount of voids and water-cement ratio • Type & temperature of curing • Nature of loading to which the specimen is subjected i. e. static, sustained, dynamic, etc. • Type of stress situation that may exist Last Updated: © LMS SEGi education group 8

Factors Influencing The Strength Of Concrete • Type of cement, age of concrete, type of aggregate and admixture • Degree of compaction • Concrete mix proportions i. e. cement content, aggregatecement ratio, amount of voids and water-cement ratio • Type & temperature of curing • Nature of loading to which the specimen is subjected i. e. static, sustained, dynamic, etc. • Type of stress situation that may exist Last Updated: © LMS SEGi education group 8

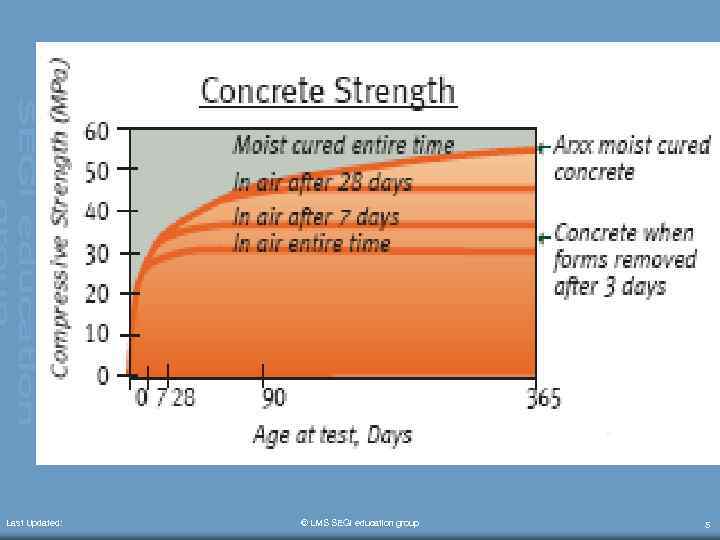

• Type of Cement • • • Age of Concrete • • • The development of concrete strength with age depends on few factors such as type of cement, water -cement ratio, and curing conditions. Owing to continuing hydration of the cement, the strength of concrete increases with age. Type of Aggregate • • Last Updated: Different types of cement will exhibit different properties or characteristics. E. g. RHPC gain strength more quickly than OPC, but after several month, their strength is almost the same. The surface characteristics of the aggregate will affect bond strength & that a rougher surface would result in higher strength. The compressive strength tends to increase with the decrease in the size of the coarse aggregate. © LMS SEGi education group 9

• Type of Cement • • • Age of Concrete • • • The development of concrete strength with age depends on few factors such as type of cement, water -cement ratio, and curing conditions. Owing to continuing hydration of the cement, the strength of concrete increases with age. Type of Aggregate • • Last Updated: Different types of cement will exhibit different properties or characteristics. E. g. RHPC gain strength more quickly than OPC, but after several month, their strength is almost the same. The surface characteristics of the aggregate will affect bond strength & that a rougher surface would result in higher strength. The compressive strength tends to increase with the decrease in the size of the coarse aggregate. © LMS SEGi education group 9

• Admixture • • Degree of Compaction • • When cement compacts, it have a very low porosity, thus, result in a very high strength. Type and Temperature of Curing • • • Adding accelerating admixture for example calcium chloride in the fresh concrete mix will speed up the initial set of the concrete, thus increase the hydration of cement and hence increase the rate of development of strength. An increase in concrete strength is to be expected with the increase in its maturity. The ‘maturity’ is defined as the product of curing period and temperature, & it represents their combined effect. Concrete mix proportion • The design of concrete mix should be based on the following factors: • • Last Updated: The grade designation: gives the characteristic compressive strength requirements of the concrete. Type of cement Maximum nominal size of aggregates, Minimum water-cement ratio, Workability, Durability, and Quality control © LMS SEGi education group 10

• Admixture • • Degree of Compaction • • When cement compacts, it have a very low porosity, thus, result in a very high strength. Type and Temperature of Curing • • • Adding accelerating admixture for example calcium chloride in the fresh concrete mix will speed up the initial set of the concrete, thus increase the hydration of cement and hence increase the rate of development of strength. An increase in concrete strength is to be expected with the increase in its maturity. The ‘maturity’ is defined as the product of curing period and temperature, & it represents their combined effect. Concrete mix proportion • The design of concrete mix should be based on the following factors: • • Last Updated: The grade designation: gives the characteristic compressive strength requirements of the concrete. Type of cement Maximum nominal size of aggregates, Minimum water-cement ratio, Workability, Durability, and Quality control © LMS SEGi education group 10

Concrete Mix Proportion: • Cement content • • Aggregate-Cement Ratio • • When the aggregate-cement ratio increase, the compressive strength reduces. Water-Cement Ratio • • Last Updated: The choice of the type of cement depends upon the requirements of performance. The lower the water-cement ratio, the greater is the compressive strength and vice versa. But, mixes with a very low water-cement ratio and extremely high cement contents (470 to 530 kg/m 3) exhibit reduction of strength, particularly when large size aggregate is used. © LMS SEGi education group 11

Concrete Mix Proportion: • Cement content • • Aggregate-Cement Ratio • • When the aggregate-cement ratio increase, the compressive strength reduces. Water-Cement Ratio • • Last Updated: The choice of the type of cement depends upon the requirements of performance. The lower the water-cement ratio, the greater is the compressive strength and vice versa. But, mixes with a very low water-cement ratio and extremely high cement contents (470 to 530 kg/m 3) exhibit reduction of strength, particularly when large size aggregate is used. © LMS SEGi education group 11

2. Deformation Under Load • • It is a stress-strain relationship under normal loading and under sustained loading. Obey Hooke’s Law under normal loading: • • Under sustained loading, prolong application of stress causes a slow deformation, commonly known as ‘creep’: • • Last Updated: Concrete is elastroplastic material, therefore as the load increases, deformation increases. The increase of deformation is not proportional, as the time passes, the deformation is lesser. If the load is later removed, the concrete undergoes an immediate elastic recovery but will not fully regain its original dimensions. © LMS SEGi education group 12

2. Deformation Under Load • • It is a stress-strain relationship under normal loading and under sustained loading. Obey Hooke’s Law under normal loading: • • Under sustained loading, prolong application of stress causes a slow deformation, commonly known as ‘creep’: • • Last Updated: Concrete is elastroplastic material, therefore as the load increases, deformation increases. The increase of deformation is not proportional, as the time passes, the deformation is lesser. If the load is later removed, the concrete undergoes an immediate elastic recovery but will not fully regain its original dimensions. © LMS SEGi education group 12

3. Durability of Concrete • Durability is defined as the ability to withstand the damaging effects of the environment over a long period of time. • The absence of durability may be caused by: External causes i. - Internal causes ii. - • The alkali-aggregate reaction, Volume changes due to differences in thermal properties of aggregate and cement paste, and The permeability of the concrete In order to have durable concrete, it is recommended to: - Last Updated: Physical, chemical or mechanical Due to weathering, extreme temperature, abrasion, eletrolytic action, and Attack by natural or industrial liquids and gases. Use low water-cement ratio, Well compacted the concrete to reduce porosity, Good workmanship, Sufficient cover reinforcement, and Use aluminious sulphate resisting cement, Portland blast-furnace or Portland pozzolana cement. © LMS SEGi education group 13

3. Durability of Concrete • Durability is defined as the ability to withstand the damaging effects of the environment over a long period of time. • The absence of durability may be caused by: External causes i. - Internal causes ii. - • The alkali-aggregate reaction, Volume changes due to differences in thermal properties of aggregate and cement paste, and The permeability of the concrete In order to have durable concrete, it is recommended to: - Last Updated: Physical, chemical or mechanical Due to weathering, extreme temperature, abrasion, eletrolytic action, and Attack by natural or industrial liquids and gases. Use low water-cement ratio, Well compacted the concrete to reduce porosity, Good workmanship, Sufficient cover reinforcement, and Use aluminious sulphate resisting cement, Portland blast-furnace or Portland pozzolana cement. © LMS SEGi education group 13

4. Permeability • Concrete has a tendency to be porous due to the presence of voids formed during or after placing. • To produce concrete of low permeability, full compaction and proper curing is essential. • Low permeability of concrete is important in increasing resistant to frost action and chemical attack, and in protecting embedded steel against corrosion. Last Updated: © LMS SEGi education group 14

4. Permeability • Concrete has a tendency to be porous due to the presence of voids formed during or after placing. • To produce concrete of low permeability, full compaction and proper curing is essential. • Low permeability of concrete is important in increasing resistant to frost action and chemical attack, and in protecting embedded steel against corrosion. Last Updated: © LMS SEGi education group 14

5. Shrinkage • Shrinkage is a contraction deformation suffered by concrete even under no load. • It is dependent on the amount of drying that can take place. • It is therefore influenced by: • • Two types of shrinkage strains are: • • Last Updated: The humidity and temperature of the surrounding air, The rate of air flow over the surface, and The proportion of the surface area to volume of concrete Plastic shrinkage, and Drying shrinkage © LMS SEGi education group 15

5. Shrinkage • Shrinkage is a contraction deformation suffered by concrete even under no load. • It is dependent on the amount of drying that can take place. • It is therefore influenced by: • • Two types of shrinkage strains are: • • Last Updated: The humidity and temperature of the surrounding air, The rate of air flow over the surface, and The proportion of the surface area to volume of concrete Plastic shrinkage, and Drying shrinkage © LMS SEGi education group 15

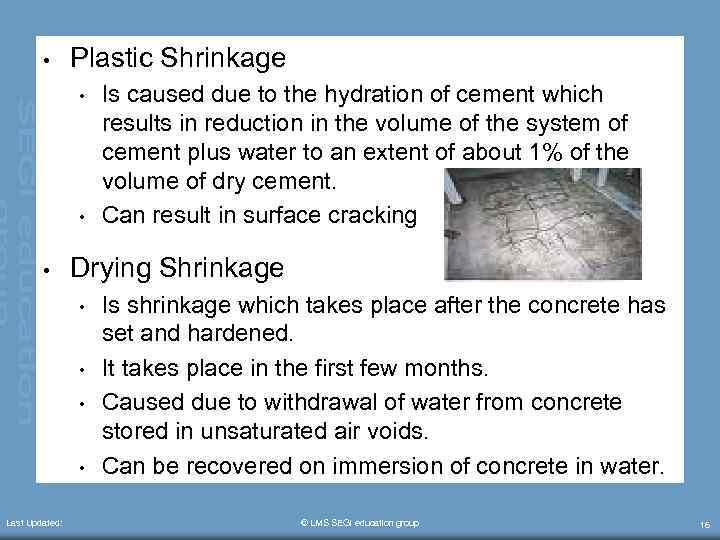

• Plastic Shrinkage • • • Drying Shrinkage • • Last Updated: Is caused due to the hydration of cement which results in reduction in the volume of the system of cement plus water to an extent of about 1% of the volume of dry cement. Can result in surface cracking Is shrinkage which takes place after the concrete has set and hardened. It takes place in the first few months. Caused due to withdrawal of water from concrete stored in unsaturated air voids. Can be recovered on immersion of concrete in water. © LMS SEGi education group 16

• Plastic Shrinkage • • • Drying Shrinkage • • Last Updated: Is caused due to the hydration of cement which results in reduction in the volume of the system of cement plus water to an extent of about 1% of the volume of dry cement. Can result in surface cracking Is shrinkage which takes place after the concrete has set and hardened. It takes place in the first few months. Caused due to withdrawal of water from concrete stored in unsaturated air voids. Can be recovered on immersion of concrete in water. © LMS SEGi education group 16

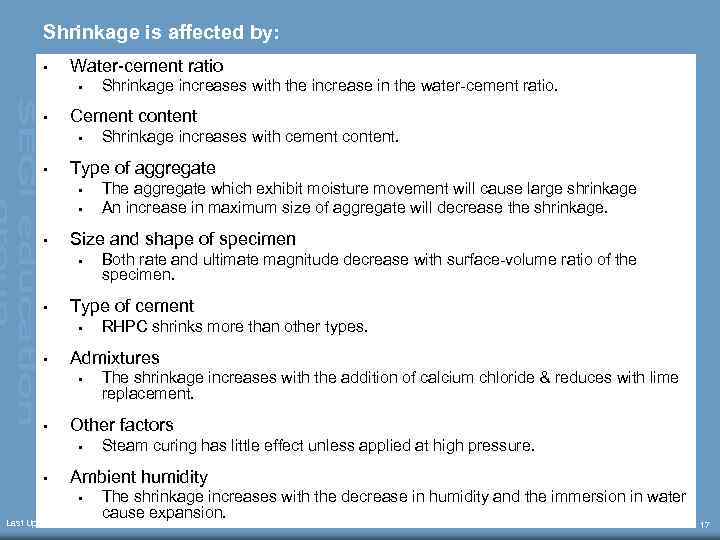

Shrinkage is affected by: • Water-cement ratio • • Cement content • • • Steam curing has little effect unless applied at high pressure. Ambient humidity • Last Updated: The shrinkage increases with the addition of calcium chloride & reduces with lime replacement. Other factors • • RHPC shrinks more than other types. Admixtures • • Both rate and ultimate magnitude decrease with surface-volume ratio of the specimen. Type of cement • • The aggregate which exhibit moisture movement will cause large shrinkage An increase in maximum size of aggregate will decrease the shrinkage. Size and shape of specimen • • Shrinkage increases with cement content. Type of aggregate • • Shrinkage increases with the increase in the water-cement ratio. The shrinkage increases with the decrease in humidity and the immersion in water cause expansion. © LMS SEGi education group 17

Shrinkage is affected by: • Water-cement ratio • • Cement content • • • Steam curing has little effect unless applied at high pressure. Ambient humidity • Last Updated: The shrinkage increases with the addition of calcium chloride & reduces with lime replacement. Other factors • • RHPC shrinks more than other types. Admixtures • • Both rate and ultimate magnitude decrease with surface-volume ratio of the specimen. Type of cement • • The aggregate which exhibit moisture movement will cause large shrinkage An increase in maximum size of aggregate will decrease the shrinkage. Size and shape of specimen • • Shrinkage increases with cement content. Type of aggregate • • Shrinkage increases with the increase in the water-cement ratio. The shrinkage increases with the decrease in humidity and the immersion in water cause expansion. © LMS SEGi education group 17

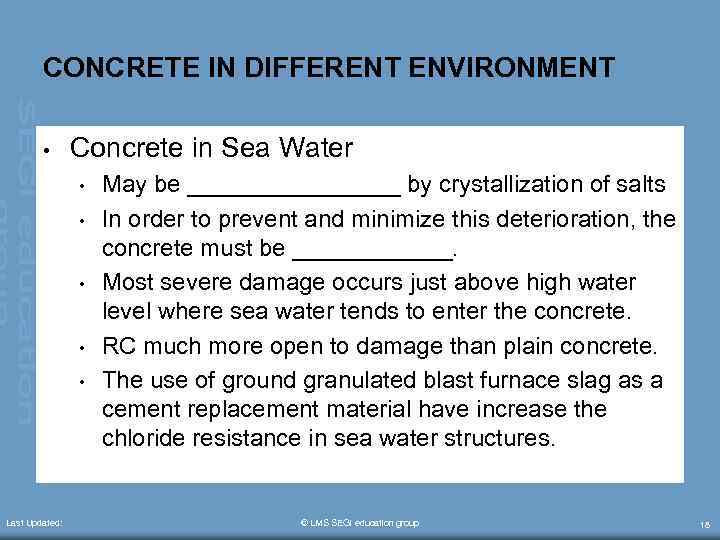

CONCRETE IN DIFFERENT ENVIRONMENT • Concrete in Sea Water • • • Last Updated: May be ________ by crystallization of salts In order to prevent and minimize this deterioration, the concrete must be ______. Most severe damage occurs just above high water level where sea water tends to enter the concrete. RC much more open to damage than plain concrete. The use of ground granulated blast furnace slag as a cement replacement material have increase the chloride resistance in sea water structures. © LMS SEGi education group 18

CONCRETE IN DIFFERENT ENVIRONMENT • Concrete in Sea Water • • • Last Updated: May be ________ by crystallization of salts In order to prevent and minimize this deterioration, the concrete must be ______. Most severe damage occurs just above high water level where sea water tends to enter the concrete. RC much more open to damage than plain concrete. The use of ground granulated blast furnace slag as a cement replacement material have increase the chloride resistance in sea water structures. © LMS SEGi education group 18

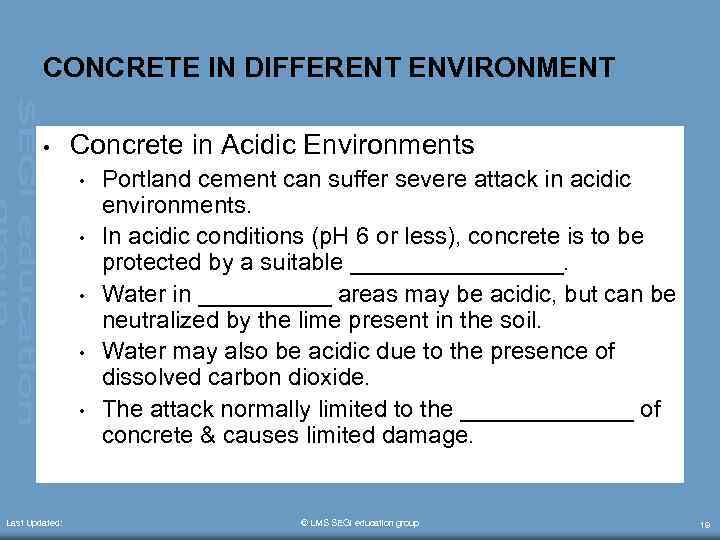

CONCRETE IN DIFFERENT ENVIRONMENT • Concrete in Acidic Environments • • • Last Updated: Portland cement can suffer severe attack in acidic environments. In acidic conditions (p. H 6 or less), concrete is to be protected by a suitable ________. Water in _____ areas may be acidic, but can be neutralized by the lime present in the soil. Water may also be acidic due to the presence of dissolved carbon dioxide. The attack normally limited to the _______ of concrete & causes limited damage. © LMS SEGi education group 19

CONCRETE IN DIFFERENT ENVIRONMENT • Concrete in Acidic Environments • • • Last Updated: Portland cement can suffer severe attack in acidic environments. In acidic conditions (p. H 6 or less), concrete is to be protected by a suitable ________. Water in _____ areas may be acidic, but can be neutralized by the lime present in the soil. Water may also be acidic due to the presence of dissolved carbon dioxide. The attack normally limited to the _______ of concrete & causes limited damage. © LMS SEGi education group 19

INFLUENCE OF TECHNICAL FACTORS ON CONCRETE PROPERTIES Last Updated: © LMS SEGi education group 20

INFLUENCE OF TECHNICAL FACTORS ON CONCRETE PROPERTIES Last Updated: © LMS SEGi education group 20

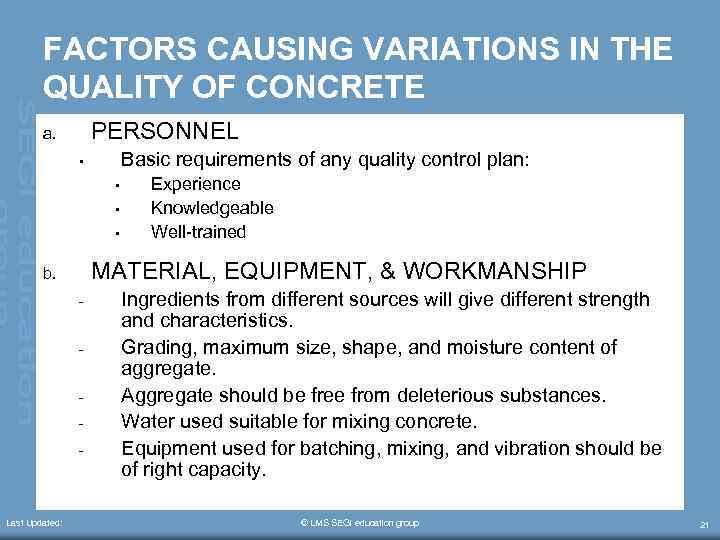

FACTORS CAUSING VARIATIONS IN THE QUALITY OF CONCRETE PERSONNEL a. Basic requirements of any quality control plan: • • MATERIAL, EQUIPMENT, & WORKMANSHIP b. - Last Updated: Experience Knowledgeable Well-trained Ingredients from different sources will give different strength and characteristics. Grading, maximum size, shape, and moisture content of aggregate. Aggregate should be free from deleterious substances. Water used suitable for mixing concrete. Equipment used for batching, mixing, and vibration should be of right capacity. © LMS SEGi education group 21

FACTORS CAUSING VARIATIONS IN THE QUALITY OF CONCRETE PERSONNEL a. Basic requirements of any quality control plan: • • MATERIAL, EQUIPMENT, & WORKMANSHIP b. - Last Updated: Experience Knowledgeable Well-trained Ingredients from different sources will give different strength and characteristics. Grading, maximum size, shape, and moisture content of aggregate. Aggregate should be free from deleterious substances. Water used suitable for mixing concrete. Equipment used for batching, mixing, and vibration should be of right capacity. © LMS SEGi education group 21

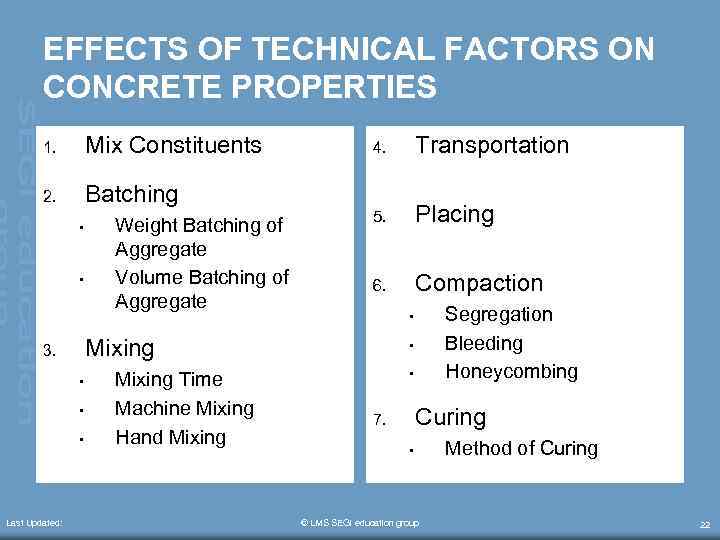

EFFECTS OF TECHNICAL FACTORS ON CONCRETE PROPERTIES 1. Mix Constituents 2. Batching • • Transportation 5. Placing 6. Compaction • • • Mixing Time Machine Mixing Hand Mixing Segregation Bleeding Honeycombing • Mixing 3. Last Updated: Weight Batching of Aggregate Volume Batching of Aggregate 4. • • Curing 7. • © LMS SEGi education group Method of Curing 22

EFFECTS OF TECHNICAL FACTORS ON CONCRETE PROPERTIES 1. Mix Constituents 2. Batching • • Transportation 5. Placing 6. Compaction • • • Mixing Time Machine Mixing Hand Mixing Segregation Bleeding Honeycombing • Mixing 3. Last Updated: Weight Batching of Aggregate Volume Batching of Aggregate 4. • • Curing 7. • © LMS SEGi education group Method of Curing 22

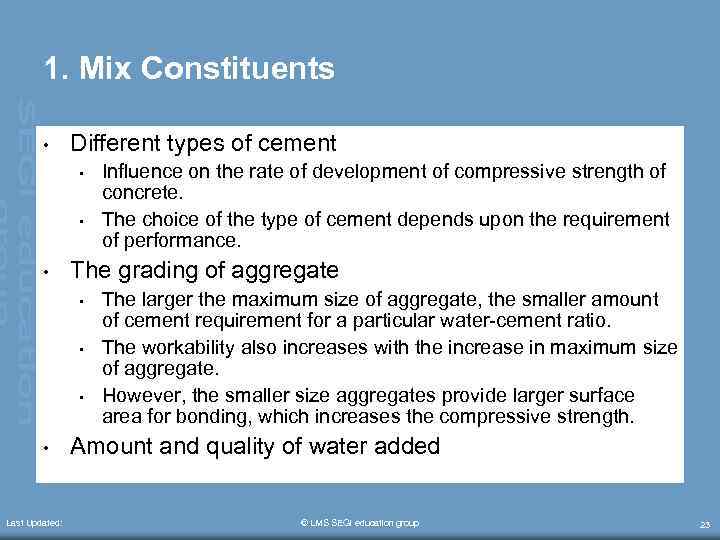

1. Mix Constituents • Different types of cement • • • The grading of aggregate • • Last Updated: Influence on the rate of development of compressive strength of concrete. The choice of the type of cement depends upon the requirement of performance. The larger the maximum size of aggregate, the smaller amount of cement requirement for a particular water-cement ratio. The workability also increases with the increase in maximum size of aggregate. However, the smaller size aggregates provide larger surface area for bonding, which increases the compressive strength. Amount and quality of water added © LMS SEGi education group 23

1. Mix Constituents • Different types of cement • • • The grading of aggregate • • Last Updated: Influence on the rate of development of compressive strength of concrete. The choice of the type of cement depends upon the requirement of performance. The larger the maximum size of aggregate, the smaller amount of cement requirement for a particular water-cement ratio. The workability also increases with the increase in maximum size of aggregate. However, the smaller size aggregates provide larger surface area for bonding, which increases the compressive strength. Amount and quality of water added © LMS SEGi education group 23

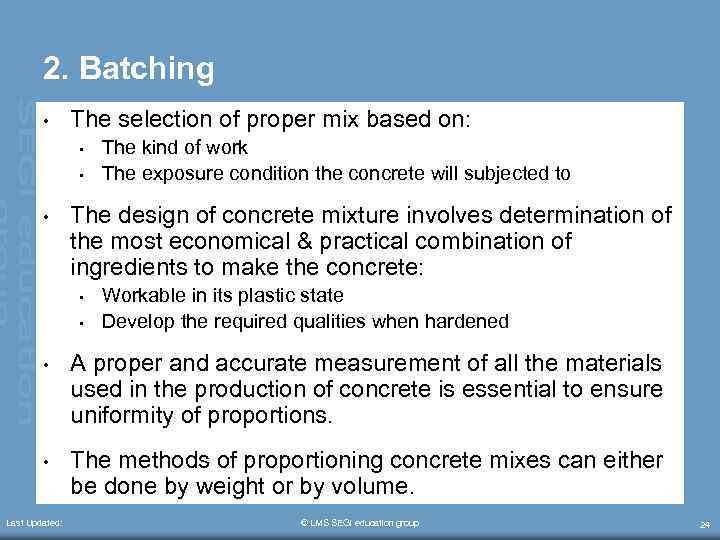

2. Batching • The selection of proper mix based on: • • • The kind of work The exposure condition the concrete will subjected to The design of concrete mixture involves determination of the most economical & practical combination of ingredients to make the concrete: • • Workable in its plastic state Develop the required qualities when hardened • A proper and accurate measurement of all the materials used in the production of concrete is essential to ensure uniformity of proportions. • The methods of proportioning concrete mixes can either be done by weight or by volume. Last Updated: © LMS SEGi education group 24

2. Batching • The selection of proper mix based on: • • • The kind of work The exposure condition the concrete will subjected to The design of concrete mixture involves determination of the most economical & practical combination of ingredients to make the concrete: • • Workable in its plastic state Develop the required qualities when hardened • A proper and accurate measurement of all the materials used in the production of concrete is essential to ensure uniformity of proportions. • The methods of proportioning concrete mixes can either be done by weight or by volume. Last Updated: © LMS SEGi education group 24

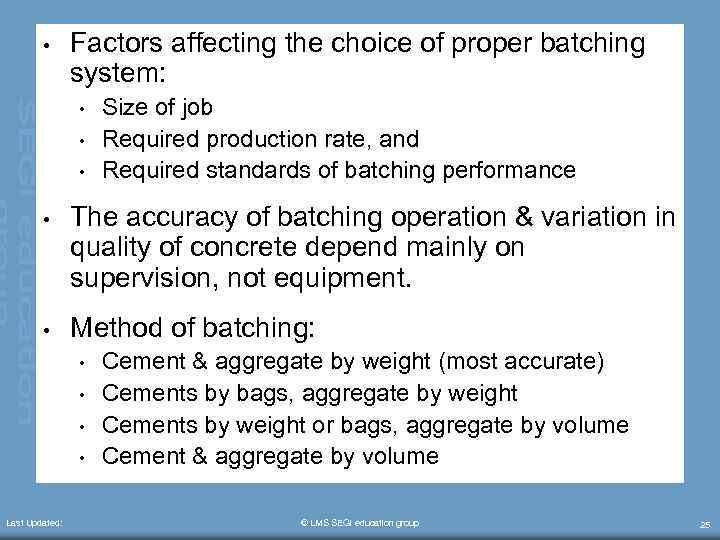

• Factors affecting the choice of proper batching system: • • • Size of job Required production rate, and Required standards of batching performance • The accuracy of batching operation & variation in quality of concrete depend mainly on supervision, not equipment. • Method of batching: • • Last Updated: Cement & aggregate by weight (most accurate) Cements by bags, aggregate by weight Cements by weight or bags, aggregate by volume Cement & aggregate by volume © LMS SEGi education group 25

• Factors affecting the choice of proper batching system: • • • Size of job Required production rate, and Required standards of batching performance • The accuracy of batching operation & variation in quality of concrete depend mainly on supervision, not equipment. • Method of batching: • • Last Updated: Cement & aggregate by weight (most accurate) Cements by bags, aggregate by weight Cements by weight or bags, aggregate by volume Cement & aggregate by volume © LMS SEGi education group 25

• Method of batching aggregate: a. Weight batching of aggregate Ø Ø Ø For large and important jobs Advantage: greater uniformity between concrete Batching equipment categories: - b. Volume batching of aggregate Ø Ø Last Updated: Manual batching Semiautomatic batching Automatic batching For small jobs Using measuring boxes, gauge box, hopper or wheel barrows. © LMS SEGi education group 26

• Method of batching aggregate: a. Weight batching of aggregate Ø Ø Ø For large and important jobs Advantage: greater uniformity between concrete Batching equipment categories: - b. Volume batching of aggregate Ø Ø Last Updated: Manual batching Semiautomatic batching Automatic batching For small jobs Using measuring boxes, gauge box, hopper or wheel barrows. © LMS SEGi education group 26

A concrete batching plant for ready-mix concrete trucks Adapted from www. builderbill-diy-help. com/concrete-basics. html Last Updated: © LMS SEGi education group 27

A concrete batching plant for ready-mix concrete trucks Adapted from www. builderbill-diy-help. com/concrete-basics. html Last Updated: © LMS SEGi education group 27

4. Transportation • Methods to move the concrete: • • • Last Updated: Small jobs: wheelbarrows Chutes Buggies operated over runways Buckets handled by cranes or cable ways Trucks Pumps to force the concrete through pipelines © LMS SEGi education group 28

4. Transportation • Methods to move the concrete: • • • Last Updated: Small jobs: wheelbarrows Chutes Buggies operated over runways Buckets handled by cranes or cable ways Trucks Pumps to force the concrete through pipelines © LMS SEGi education group 28

• The requirements to be fulfilled during transportation: • • Fresh concrete tends to segregate. In transportation, segregation can be prevented by: • • Last Updated: Economical, No segregation or separation of materials in the concrete, and Concrete delivered at the point of placing should be uniform and of proper consistency. Direction of fall must be vertical If flow at high velocity, discharge the concrete through another chute. © LMS SEGi education group 29

• The requirements to be fulfilled during transportation: • • Fresh concrete tends to segregate. In transportation, segregation can be prevented by: • • Last Updated: Economical, No segregation or separation of materials in the concrete, and Concrete delivered at the point of placing should be uniform and of proper consistency. Direction of fall must be vertical If flow at high velocity, discharge the concrete through another chute. © LMS SEGi education group 29

5. Placing • The methods used in placing concrete in its final position have important effect on its homogeneity, density and behaviour in service: a. The ______ must be examined for correct ______ and adequate rigidity to withstand the weight of concrete and impact loads during construction without undue deformation. b. ______ must be checked for _______ to avoid any loss of mortar which may result in _________. c. Inside of forms must be _____ & _____ with release agent to facilitate their removal when concrete is set. Last Updated: © LMS SEGi education group 30

5. Placing • The methods used in placing concrete in its final position have important effect on its homogeneity, density and behaviour in service: a. The ______ must be examined for correct ______ and adequate rigidity to withstand the weight of concrete and impact loads during construction without undue deformation. b. ______ must be checked for _______ to avoid any loss of mortar which may result in _________. c. Inside of forms must be _____ & _____ with release agent to facilitate their removal when concrete is set. Last Updated: © LMS SEGi education group 30

d. ______ should be moistened before the concrete is placed, otherwise they will absorb water from the concrete and swell. e. Forms should be _____ to make form removal easier. f. Reinforcing _______ should be clean and free of loose rust. g. Any _____ of hardened mortar should be _____ from the steel. h. Check for ______ with the plans for size, spacing and location. i. Concrete should be placed in its final position _____ to avoid stiffness. j. ___________ add water after concrete left the mixer. k. Drop the concrete ________ and not too high. Last Updated: © LMS SEGi education group 31

d. ______ should be moistened before the concrete is placed, otherwise they will absorb water from the concrete and swell. e. Forms should be _____ to make form removal easier. f. Reinforcing _______ should be clean and free of loose rust. g. Any _____ of hardened mortar should be _____ from the steel. h. Check for ______ with the plans for size, spacing and location. i. Concrete should be placed in its final position _____ to avoid stiffness. j. ___________ add water after concrete left the mixer. k. Drop the concrete ________ and not too high. Last Updated: © LMS SEGi education group 31

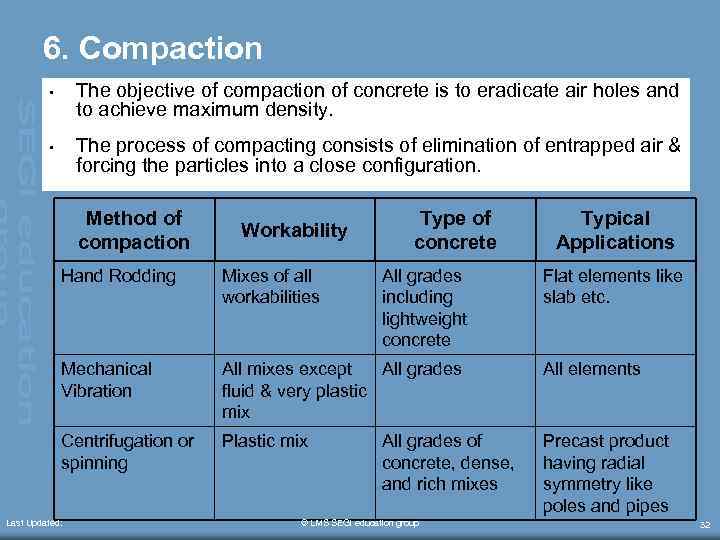

6. Compaction • The objective of compaction of concrete is to eradicate air holes and to achieve maximum density. • The process of compacting consists of elimination of entrapped air & forcing the particles into a close configuration. Method of compaction Workability Type of concrete Hand Rodding Mixes of all workabilities Mechanical Vibration All mixes except All grades fluid & very plastic mix All elements Centrifugation or spinning Plastic mix Precast product having radial symmetry like poles and pipes Last Updated: All grades including lightweight concrete Typical Applications All grades of concrete, dense, and rich mixes © LMS SEGi education group Flat elements like slab etc. 32

6. Compaction • The objective of compaction of concrete is to eradicate air holes and to achieve maximum density. • The process of compacting consists of elimination of entrapped air & forcing the particles into a close configuration. Method of compaction Workability Type of concrete Hand Rodding Mixes of all workabilities Mechanical Vibration All mixes except All grades fluid & very plastic mix All elements Centrifugation or spinning Plastic mix Precast product having radial symmetry like poles and pipes Last Updated: All grades including lightweight concrete Typical Applications All grades of concrete, dense, and rich mixes © LMS SEGi education group Flat elements like slab etc. 32

Compaction Equipment www. pattonhire. co. uk Last Updated: © LMS SEGi education group 33

Compaction Equipment www. pattonhire. co. uk Last Updated: © LMS SEGi education group 33

6 a. SEGREGATION • It is the separation of constituents so that their distribution is no longer uniform. • • Last Updated: Very dry mix: coarse aggregate tend to separate Very wet mix: cement & water tend to separate If specific gravity of coarse & fine aggregate differs, segregation increases. Over vibration is prone to segregation © LMS SEGi education group 34

6 a. SEGREGATION • It is the separation of constituents so that their distribution is no longer uniform. • • Last Updated: Very dry mix: coarse aggregate tend to separate Very wet mix: cement & water tend to separate If specific gravity of coarse & fine aggregate differs, segregation increases. Over vibration is prone to segregation © LMS SEGi education group 34

6 b. BLEEDING • It is a form of segregation where water rise to surface of freshly placed concrete. • It is natural tendency for solid particles to move downwards and displace water. • It can cause plastic shrinkage cracking. • Can be reduced by finer cement, high alkali, high C 3 A & addition of calcium chloride. Last Updated: © LMS SEGi education group 35

6 b. BLEEDING • It is a form of segregation where water rise to surface of freshly placed concrete. • It is natural tendency for solid particles to move downwards and displace water. • It can cause plastic shrinkage cracking. • Can be reduced by finer cement, high alkali, high C 3 A & addition of calcium chloride. Last Updated: © LMS SEGi education group 35

6 c. HONEYCOMBING • Refers to ______ in concrete caused by the mortar not filling the spaces between the coarse aggregate particles. • Always an aesthetic problem, and depending on the depth and extent may reduce both the durability performance and the structural strength of the member. • Caused by • • Last Updated: the _________not having been adequate to cause the mortar to fill the voids between the coarse aggregate, or by holes and _______ in the formwork allowing some of the mortar to drain out of the concrete. © LMS SEGi education group 36

6 c. HONEYCOMBING • Refers to ______ in concrete caused by the mortar not filling the spaces between the coarse aggregate particles. • Always an aesthetic problem, and depending on the depth and extent may reduce both the durability performance and the structural strength of the member. • Caused by • • Last Updated: the _________not having been adequate to cause the mortar to fill the voids between the coarse aggregate, or by holes and _______ in the formwork allowing some of the mortar to drain out of the concrete. © LMS SEGi education group 36

7. CURING • Curing is the process of maintaining the ______ and _____ conditions so that the cement hydration reaction can take place. • The purpose is to promote the hydration of cement, thus the development of strength & durability of concrete. • Water must be continually available to the cement particles for hydration to continue. This continuing hydration will cause the concrete to become _____, less porous and more ______ *. When moisture is no longer available, hydration stops. * Capable of withstanding the wear and tear Last Updated: © LMS SEGi education group 37

7. CURING • Curing is the process of maintaining the ______ and _____ conditions so that the cement hydration reaction can take place. • The purpose is to promote the hydration of cement, thus the development of strength & durability of concrete. • Water must be continually available to the cement particles for hydration to continue. This continuing hydration will cause the concrete to become _____, less porous and more ______ *. When moisture is no longer available, hydration stops. * Capable of withstanding the wear and tear Last Updated: © LMS SEGi education group 37

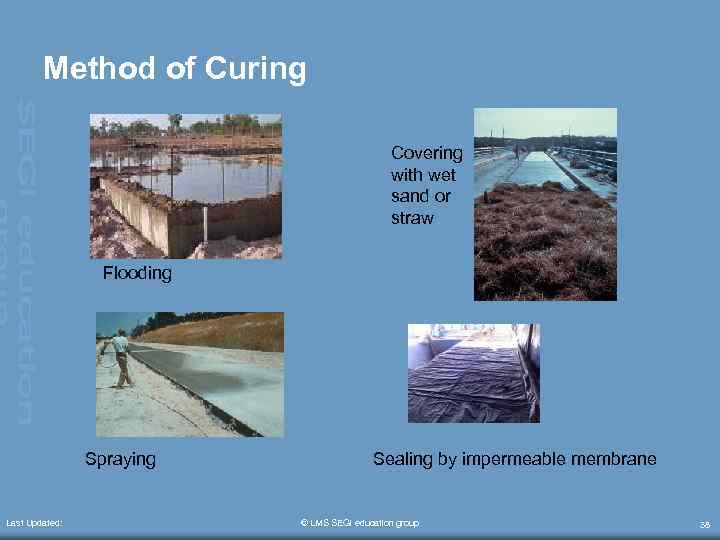

Method of Curing Covering with wet sand or straw Flooding Spraying Last Updated: Sealing by impermeable membrane © LMS SEGi education group 38

Method of Curing Covering with wet sand or straw Flooding Spraying Last Updated: Sealing by impermeable membrane © LMS SEGi education group 38

• • • Concrete should be cured for at least three days, preferably for a week after it is placed. Curing time depends on the temperature of concrete. The length of time that the concrete is to be protected against the loss of moisture depends on: • • • Last Updated: The cement content Mix proportions Required strength Size & shape of the concrete mass Weather Future exposure conditions © LMS SEGi education group 39

• • • Concrete should be cured for at least three days, preferably for a week after it is placed. Curing time depends on the temperature of concrete. The length of time that the concrete is to be protected against the loss of moisture depends on: • • • Last Updated: The cement content Mix proportions Required strength Size & shape of the concrete mass Weather Future exposure conditions © LMS SEGi education group 39

ANY QUESTIONS? Picture retrieved from http: //www. cartoonstock. com/directory/C/Cement. asp Last Updated: © LMS SEGi education group 40

ANY QUESTIONS? Picture retrieved from http: //www. cartoonstock. com/directory/C/Cement. asp Last Updated: © LMS SEGi education group 40

References • Smith W. F. (1993). Foundations of Materials Science and Engineering, 2 nd edition, Mc. Graw-Hill International Edition • Neville, A. M. (1995). Properties of Concrete, 4 th edition. , Addison Wesley Longman Limited, England • John, V. B. (1992) Introduction to Engineering Materials, 3 rd edition, Mc. Millan Press Ltd. • Everett, A. (1996). Materials, 3 rd edition Addison Wesley Longman Limited, England Last Updated: © LMS SEGi education group 41

References • Smith W. F. (1993). Foundations of Materials Science and Engineering, 2 nd edition, Mc. Graw-Hill International Edition • Neville, A. M. (1995). Properties of Concrete, 4 th edition. , Addison Wesley Longman Limited, England • John, V. B. (1992) Introduction to Engineering Materials, 3 rd edition, Mc. Millan Press Ltd. • Everett, A. (1996). Materials, 3 rd edition Addison Wesley Longman Limited, England Last Updated: © LMS SEGi education group 41