82a25aff42bb09be3b385e84f339a608.ppt

- Количество слайдов: 16

CCC Meeting Cryogenic Current Comparator in the FAIR Project Jena, 7. April 2008 Marcus Schwickert, GSI Beam Diagnostics Overview of FAIR / current status Beam diagnostics work package Tasks and installation locations for CCCs Boundary conditions / requirements Example: SIS 100 extraction beam line CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008

CCC Meeting Cryogenic Current Comparator in the FAIR Project Jena, 7. April 2008 Marcus Schwickert, GSI Beam Diagnostics Overview of FAIR / current status Beam diagnostics work package Tasks and installation locations for CCCs Boundary conditions / requirements Example: SIS 100 extraction beam line CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008

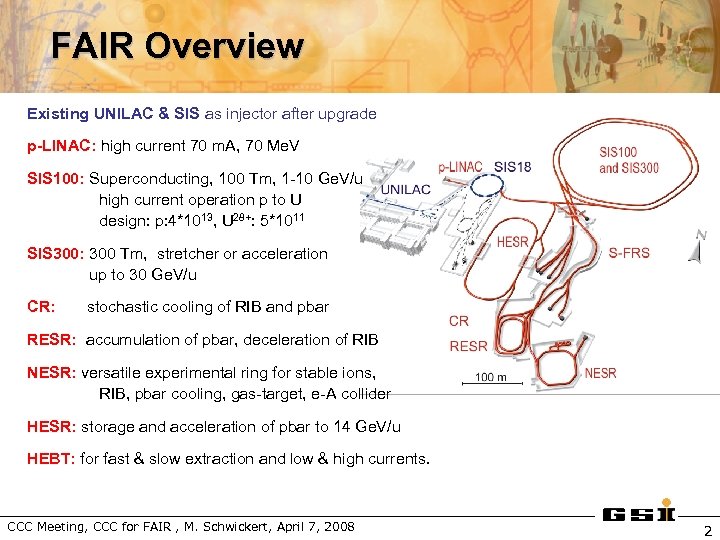

FAIR Overview Existing UNILAC & SIS as injector after upgrade p-LINAC: high current 70 m. A, 70 Me. V SIS 100: Superconducting, 100 Tm, 1 -10 Ge. V/u high current operation p to U design: p: 4*1013, U 28+: 5*1011 SIS 300: 300 Tm, stretcher or acceleration up to 30 Ge. V/u CR: stochastic cooling of RIB and pbar RESR: accumulation of pbar, deceleration of RIB NESR: versatile experimental ring for stable ions, RIB, pbar cooling, gas-target, e-A collider HESR: storage and acceleration of pbar to 14 Ge. V/u HEBT: for fast & slow extraction and low & high currents. CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 2

FAIR Overview Existing UNILAC & SIS as injector after upgrade p-LINAC: high current 70 m. A, 70 Me. V SIS 100: Superconducting, 100 Tm, 1 -10 Ge. V/u high current operation p to U design: p: 4*1013, U 28+: 5*1011 SIS 300: 300 Tm, stretcher or acceleration up to 30 Ge. V/u CR: stochastic cooling of RIB and pbar RESR: accumulation of pbar, deceleration of RIB NESR: versatile experimental ring for stable ions, RIB, pbar cooling, gas-target, e-A collider HESR: storage and acceleration of pbar to 14 Ge. V/u HEBT: for fast & slow extraction and low & high currents. CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 2

Current Status FAIR Kick-Off Event 7. November 2007 International partners signed communiqué: Austria, Germany, Spain, Finland, France, Poland, Romania, Russia, Sweden, Great Britain and State of Hesse In total 21 Expressions of Interest were submitted, i. e. international partners express their interest to take over responsibility for a FAIR work package Two possibilities for contributions: 1. In-kind, i. e. delivery of accelerator parts 2. cash At the moment: FAIR Technical Meetings on Eo. Is CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 3

Current Status FAIR Kick-Off Event 7. November 2007 International partners signed communiqué: Austria, Germany, Spain, Finland, France, Poland, Romania, Russia, Sweden, Great Britain and State of Hesse In total 21 Expressions of Interest were submitted, i. e. international partners express their interest to take over responsibility for a FAIR work package Two possibilities for contributions: 1. In-kind, i. e. delivery of accelerator parts 2. cash At the moment: FAIR Technical Meetings on Eo. Is CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 3

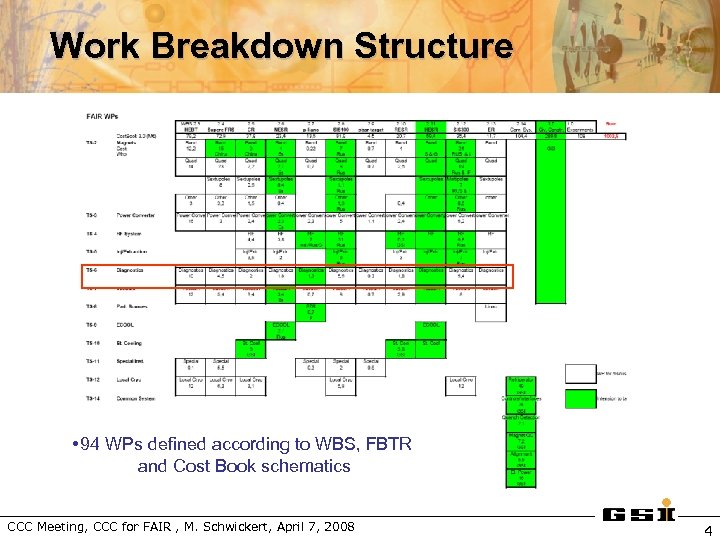

Work Breakdown Structure ∙ 94 WPs defined according to WBS, FBTR and Cost Book schematics CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 4

Work Breakdown Structure ∙ 94 WPs defined according to WBS, FBTR and Cost Book schematics CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 4

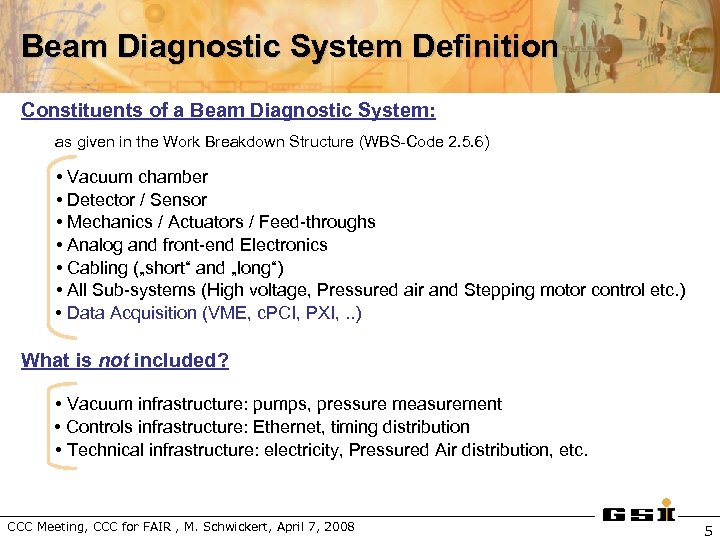

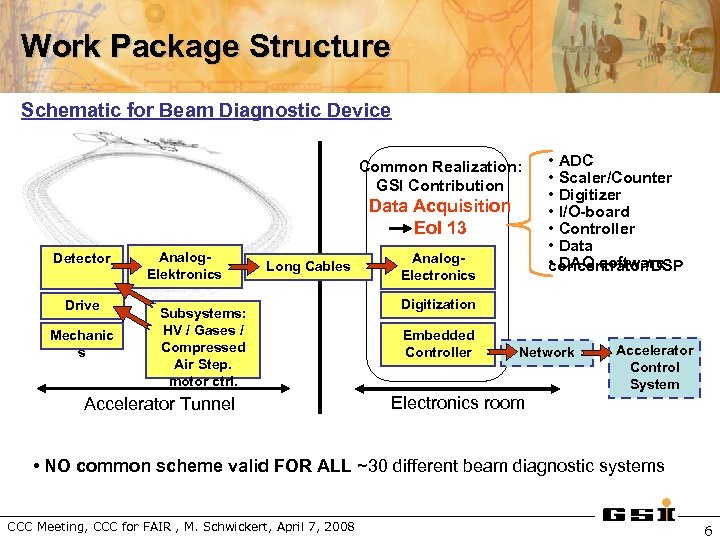

Beam Diagnostic System Definition Constituents of a Beam Diagnostic System: as given in the Work Breakdown Structure (WBS-Code 2. 5. 6) • Vacuum chamber • Detector / Sensor • Mechanics / Actuators / Feed-throughs • Analog and front-end Electronics • Cabling („short“ and „long“) • All Sub-systems (High voltage, Pressured air and Stepping motor control etc. ) • Data Acquisition (VME, c. PCI, PXI, . . ) What is not included? • Vacuum infrastructure: pumps, pressure measurement • Controls infrastructure: Ethernet, timing distribution • Technical infrastructure: electricity, Pressured Air distribution, etc. CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 5

Beam Diagnostic System Definition Constituents of a Beam Diagnostic System: as given in the Work Breakdown Structure (WBS-Code 2. 5. 6) • Vacuum chamber • Detector / Sensor • Mechanics / Actuators / Feed-throughs • Analog and front-end Electronics • Cabling („short“ and „long“) • All Sub-systems (High voltage, Pressured air and Stepping motor control etc. ) • Data Acquisition (VME, c. PCI, PXI, . . ) What is not included? • Vacuum infrastructure: pumps, pressure measurement • Controls infrastructure: Ethernet, timing distribution • Technical infrastructure: electricity, Pressured Air distribution, etc. CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 5

Work Package Structure Schematic for Beam Diagnostic Device Common Realization: GSI Contribution Data Acquisition Eo. I 13 Detector Drive Mechanic s Analog. Elektronics Long Cables Subsystems: HV / Gases / Compressed Air Step. motor ctrl. Accelerator Tunnel Analog. Electronics • ADC • Scaler/Counter • Digitizer • I/O-board • Controller • Data • DAQ software concentrator/DSP Digitization Embedded Controller Network Accelerator Control System Electronics room • NO common scheme valid FOR ALL ~30 different beam diagnostic systems CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 6

Work Package Structure Schematic for Beam Diagnostic Device Common Realization: GSI Contribution Data Acquisition Eo. I 13 Detector Drive Mechanic s Analog. Elektronics Long Cables Subsystems: HV / Gases / Compressed Air Step. motor ctrl. Accelerator Tunnel Analog. Electronics • ADC • Scaler/Counter • Digitizer • I/O-board • Controller • Data • DAQ software concentrator/DSP Digitization Embedded Controller Network Accelerator Control System Electronics room • NO common scheme valid FOR ALL ~30 different beam diagnostic systems CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 6

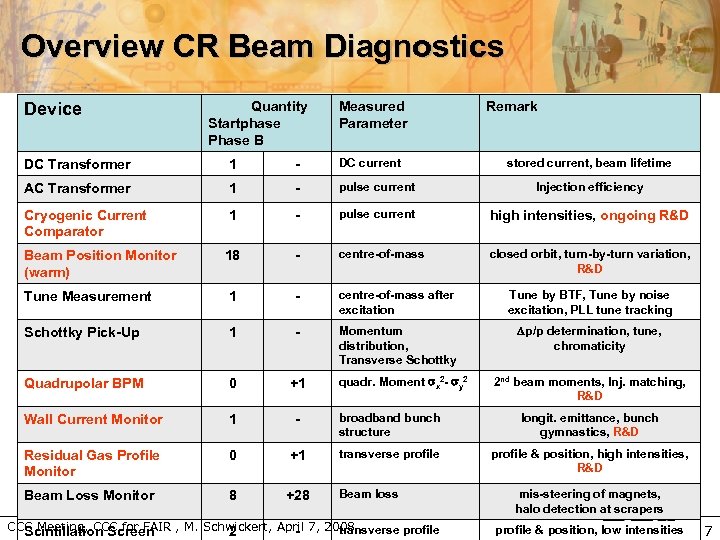

Overview CR Beam Diagnostics Device Quantity Startphase Phase B Measured Parameter Remark DC Transformer 1 - DC current AC Transformer 1 - pulse current Injection efficiency Cryogenic Current Comparator 1 - pulse current high intensities, ongoing R&D Beam Position Monitor (warm) 18 - centre-of-mass closed orbit, turn-by-turn variation, R&D Tune Measurement 1 - centre-of-mass after excitation Tune by BTF, Tune by noise excitation, PLL tune tracking Schottky Pick-Up 1 - Momentum distribution, Transverse Schottky p/p determination, tune, chromaticity Quadrupolar BPM 0 +1 Wall Current Monitor 1 - broadband bunch structure longit. emittance, bunch gymnastics, R&D Residual Gas Profile Monitor 0 +1 transverse profile & position, high intensities, R&D Beam Loss Monitor 8 +28 quadr. Moment x 2 - y 2 Beam loss CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 transverse profile Scintillation Screen 2 - stored current, beam lifetime 2 nd beam moments, Inj. matching, R&D mis-steering of magnets, halo detection at scrapers profile & position, low intensities 7

Overview CR Beam Diagnostics Device Quantity Startphase Phase B Measured Parameter Remark DC Transformer 1 - DC current AC Transformer 1 - pulse current Injection efficiency Cryogenic Current Comparator 1 - pulse current high intensities, ongoing R&D Beam Position Monitor (warm) 18 - centre-of-mass closed orbit, turn-by-turn variation, R&D Tune Measurement 1 - centre-of-mass after excitation Tune by BTF, Tune by noise excitation, PLL tune tracking Schottky Pick-Up 1 - Momentum distribution, Transverse Schottky p/p determination, tune, chromaticity Quadrupolar BPM 0 +1 Wall Current Monitor 1 - broadband bunch structure longit. emittance, bunch gymnastics, R&D Residual Gas Profile Monitor 0 +1 transverse profile & position, high intensities, R&D Beam Loss Monitor 8 +28 quadr. Moment x 2 - y 2 Beam loss CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 transverse profile Scintillation Screen 2 - stored current, beam lifetime 2 nd beam moments, Inj. matching, R&D mis-steering of magnets, halo detection at scrapers profile & position, low intensities 7

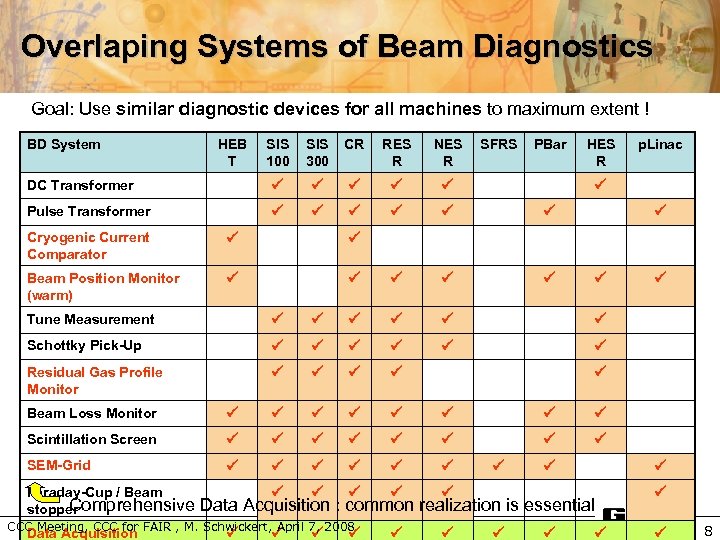

Overlaping Systems of Beam Diagnostics Goal: Use similar diagnostic devices for all machines to maximum extent ! BD System HEB T SIS 100 SIS 300 CR RES R NES R DC Transformer Pulse Transformer Cryogenic Current Comparator PBar HES R p. Linac Beam Position Monitor (warm) SFRS Tune Measurement Schottky Pick-Up Residual Gas Profile Monitor Beam Loss Monitor Scintillation Screen SEM-Grid Faraday-Cup / Beam Comprehensive stopper Data Acquisition : common realization is essential CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 Data Acquisition 8

Overlaping Systems of Beam Diagnostics Goal: Use similar diagnostic devices for all machines to maximum extent ! BD System HEB T SIS 100 SIS 300 CR RES R NES R DC Transformer Pulse Transformer Cryogenic Current Comparator PBar HES R p. Linac Beam Position Monitor (warm) SFRS Tune Measurement Schottky Pick-Up Residual Gas Profile Monitor Beam Loss Monitor Scintillation Screen SEM-Grid Faraday-Cup / Beam Comprehensive stopper Data Acquisition : common realization is essential CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 Data Acquisition 8

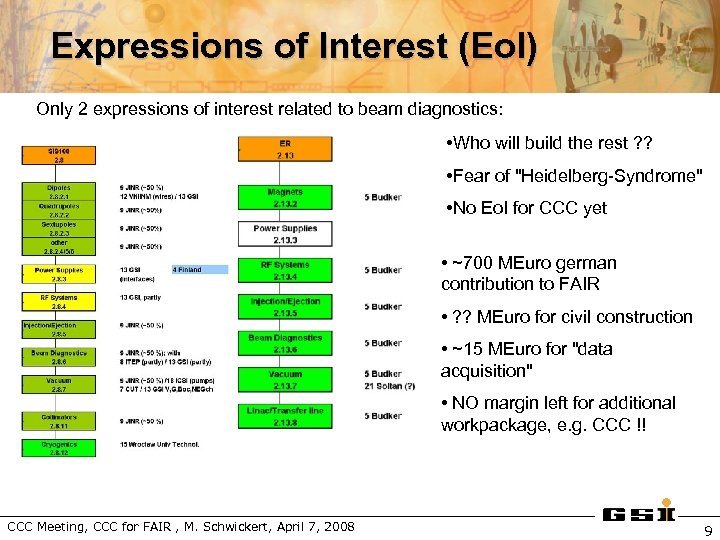

Expressions of Interest (Eo. I) Only 2 expressions of interest related to beam diagnostics: • Who will build the rest ? ? • Fear of "Heidelberg-Syndrome" • No Eo. I for CCC yet • ~700 MEuro german contribution to FAIR • ? ? MEuro for civil construction • ~15 MEuro for "data acquisition" • NO margin left for additional workpackage, e. g. CCC !! CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 9

Expressions of Interest (Eo. I) Only 2 expressions of interest related to beam diagnostics: • Who will build the rest ? ? • Fear of "Heidelberg-Syndrome" • No Eo. I for CCC yet • ~700 MEuro german contribution to FAIR • ? ? MEuro for civil construction • ~15 MEuro for "data acquisition" • NO margin left for additional workpackage, e. g. CCC !! CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 9

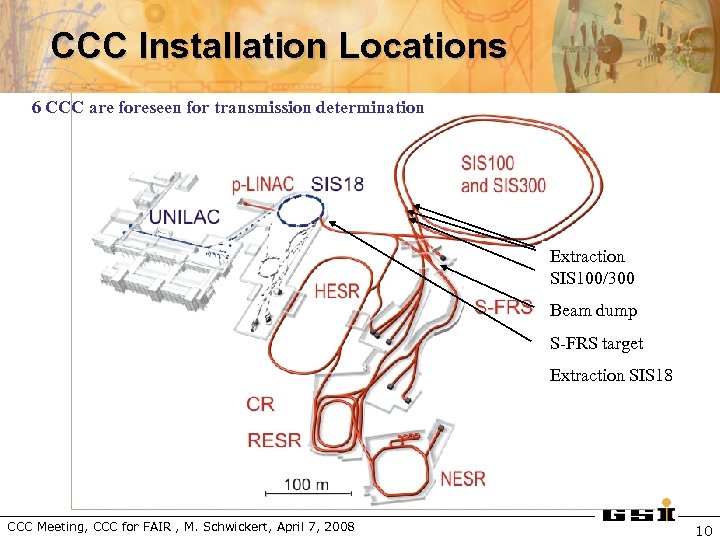

CCC Installation Locations 6 CCC are foreseen for transmission determination Extraction SIS 100/300 Beam dump S-FRS target Extraction SIS 18 CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 10

CCC Installation Locations 6 CCC are foreseen for transmission determination Extraction SIS 100/300 Beam dump S-FRS target Extraction SIS 18 CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 10

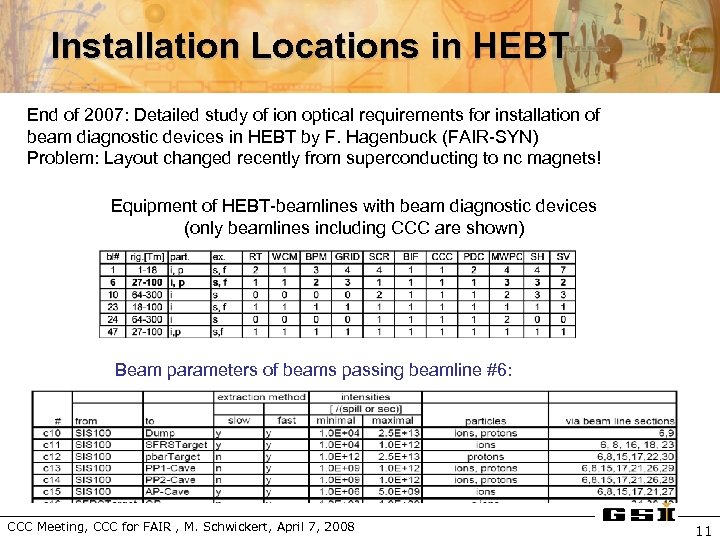

Installation Locations in HEBT End of 2007: Detailed study of ion optical requirements for installation of beam diagnostic devices in HEBT by F. Hagenbuck (FAIR-SYN) Problem: Layout changed recently from superconducting to nc magnets! Equipment of HEBT-beamlines with beam diagnostic devices (only beamlines including CCC are shown) Beam parameters of beams passing beamline #6: CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 11

Installation Locations in HEBT End of 2007: Detailed study of ion optical requirements for installation of beam diagnostic devices in HEBT by F. Hagenbuck (FAIR-SYN) Problem: Layout changed recently from superconducting to nc magnets! Equipment of HEBT-beamlines with beam diagnostic devices (only beamlines including CCC are shown) Beam parameters of beams passing beamline #6: CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 11

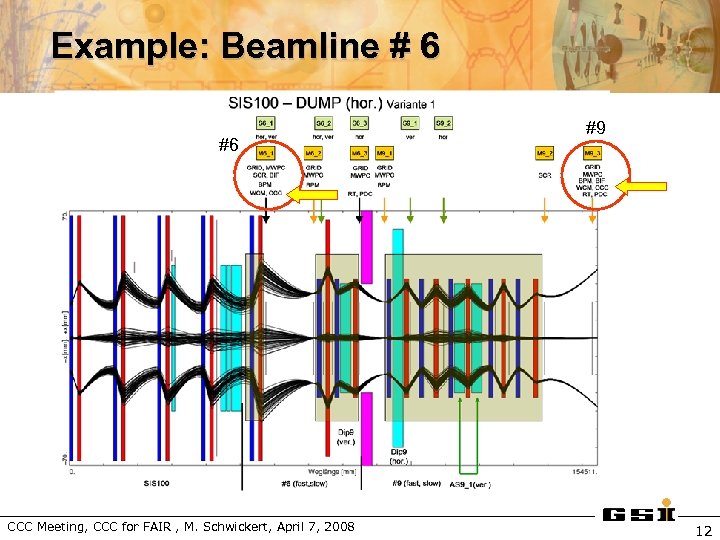

Example: Beamline # 6 #6 CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 #9 12

Example: Beamline # 6 #6 CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 #9 12

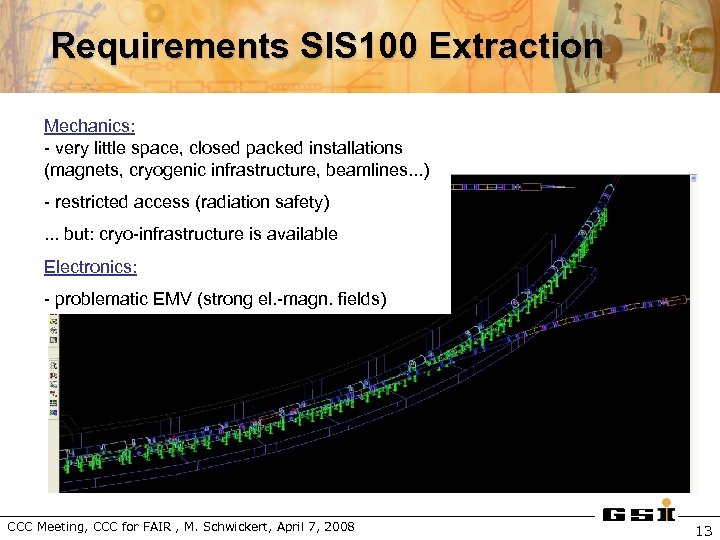

Requirements SIS 100 Extraction Mechanics: - very little space, closed packed installations (magnets, cryogenic infrastructure, beamlines. . . ) - restricted access (radiation safety). . . but: cryo-infrastructure is available Electronics: - problematic EMV (strong el. -magn. fields) CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 13

Requirements SIS 100 Extraction Mechanics: - very little space, closed packed installations (magnets, cryogenic infrastructure, beamlines. . . ) - restricted access (radiation safety). . . but: cryo-infrastructure is available Electronics: - problematic EMV (strong el. -magn. fields) CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 13

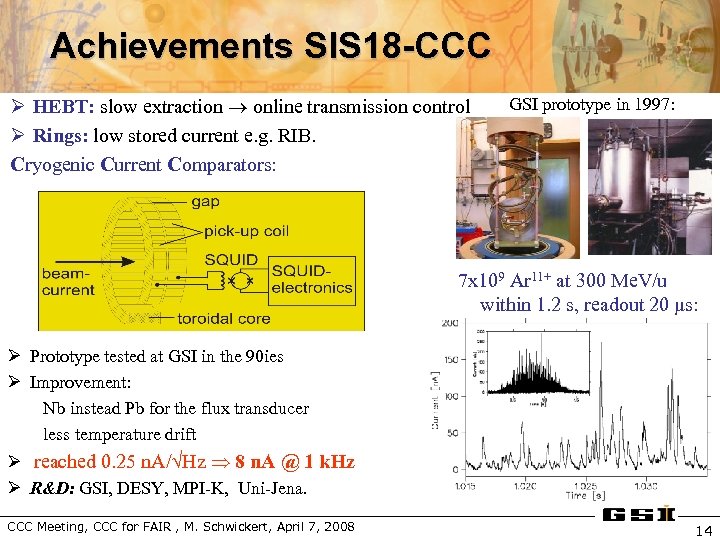

Achievements SIS 18 -CCC Ø HEBT: slow extraction online transmission control Ø Rings: low stored current e. g. RIB. Cryogenic Current Comparators: GSI prototype in 1997: 7 x 109 Ar 11+ at 300 Me. V/u within 1. 2 s, readout 20 μs: Ø Prototype tested at GSI in the 90 ies Ø Improvement: Nb instead Pb for the flux transducer less temperature drift Ø reached 0. 25 n. A/√Hz 8 n. A @ 1 k. Hz Ø R&D: GSI, DESY, MPI-K, Uni-Jena. CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 14

Achievements SIS 18 -CCC Ø HEBT: slow extraction online transmission control Ø Rings: low stored current e. g. RIB. Cryogenic Current Comparators: GSI prototype in 1997: 7 x 109 Ar 11+ at 300 Me. V/u within 1. 2 s, readout 20 μs: Ø Prototype tested at GSI in the 90 ies Ø Improvement: Nb instead Pb for the flux transducer less temperature drift Ø reached 0. 25 n. A/√Hz 8 n. A @ 1 k. Hz Ø R&D: GSI, DESY, MPI-K, Uni-Jena. CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 14

Goals for further development The new CCC should have: - low noise characteristic - resolution possibly in sub n. A-range (1 n. A 2 E 08 pps U 28+) - good magnetic shielding - installation volume as small as possible - standardized mechanical layout, matched also for SIS 100 injection line - optimized He-cryostat for long term operation between refills - standardized electronics with defined interfaces for current signal and I/O CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 15

Goals for further development The new CCC should have: - low noise characteristic - resolution possibly in sub n. A-range (1 n. A 2 E 08 pps U 28+) - good magnetic shielding - installation volume as small as possible - standardized mechanical layout, matched also for SIS 100 injection line - optimized He-cryostat for long term operation between refills - standardized electronics with defined interfaces for current signal and I/O CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 15

Summary • FAIR project started, expressions of interest are being discussed • Definition of beam diagnostic workpackage • Standardization as basic concept for overlapping systems • Beam diagnostic layout of HEBT beam lines • Special requirements for SIS 100 injection • High resolution, good noise shielding, small insertion length as goals for future CCC prototype Thank you for your attention. CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 16

Summary • FAIR project started, expressions of interest are being discussed • Definition of beam diagnostic workpackage • Standardization as basic concept for overlapping systems • Beam diagnostic layout of HEBT beam lines • Special requirements for SIS 100 injection • High resolution, good noise shielding, small insertion length as goals for future CCC prototype Thank you for your attention. CCC Meeting, CCC for FAIR , M. Schwickert, April 7, 2008 16