44b58e02f20b2d69e5837f7615d9d519.ppt

- Количество слайдов: 26

Casing Macron Technology Co. , Ltd. 2013

Casing Macron Technology Co. , Ltd. 2013

Index • • Basic Information Organization structure and Business Motto Product Lineup Business Actual Result Production Facility Why Casing? Future Plan

Index • • Basic Information Organization structure and Business Motto Product Lineup Business Actual Result Production Facility Why Casing? Future Plan

Basic Information () 1 Milestone Apr. 1995 Casing Macron Technology was found. Jul. 2001 Move to new office as Taiwan Headquarter. Aug. 2002 IPO Aug. 2005 Public-listed in Taiwan OCT Jan. 2006 Launched Battery Charger

Basic Information () 1 Milestone Apr. 1995 Casing Macron Technology was found. Jul. 2001 Move to new office as Taiwan Headquarter. Aug. 2002 IPO Aug. 2005 Public-listed in Taiwan OCT Jan. 2006 Launched Battery Charger

() 2 Taiwan Headquarter Staff: 30 Location: Sanchung, Taipei county, Taiwan

() 2 Taiwan Headquarter Staff: 30 Location: Sanchung, Taipei county, Taiwan

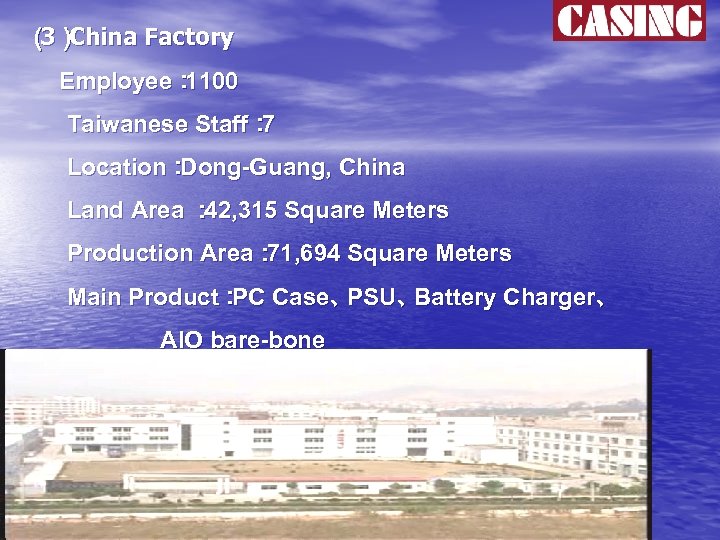

() 3 China Factory Employee: 1100 Taiwanese Staff: 7 Location: Dong-Guang, China Land Area : 42, 315 Square Meters Production Area: 71, 694 Square Meters Main Product: Case、 PC PSU、 Battery Charger、 AIO bare-bone

() 3 China Factory Employee: 1100 Taiwanese Staff: 7 Location: Dong-Guang, China Land Area : 42, 315 Square Meters Production Area: 71, 694 Square Meters Main Product: Case、 PC PSU、 Battery Charger、 AIO bare-bone

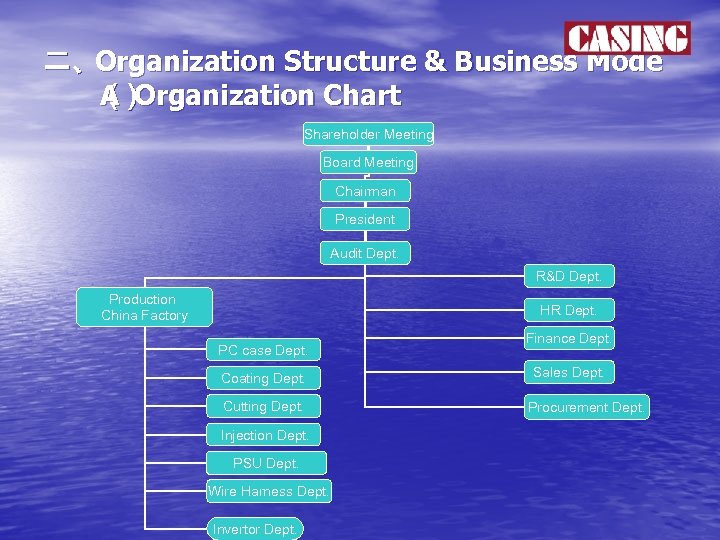

二、Organization Structure & Business Mode ( Organization Chart A) Shareholder Meeting Board Meeting Chairman President Audit Dept. R&D Dept. Production China Factory HR Dept. PC case Dept. Coating Dept. Cutting Dept. Injection Dept. PSU Dept. Wire Harness Dept. Invertor Dept. Finance Dept. Sales Dept. Procurement Dept.

二、Organization Structure & Business Mode ( Organization Chart A) Shareholder Meeting Board Meeting Chairman President Audit Dept. R&D Dept. Production China Factory HR Dept. PC case Dept. Coating Dept. Cutting Dept. Injection Dept. PSU Dept. Wire Harness Dept. Invertor Dept. Finance Dept. Sales Dept. Procurement Dept.

() B Business Motto • • 誠 信 Integrity 穩 健 Conservative 創 新 Innovation 勤 儉 Diligent

() B Business Motto • • 誠 信 Integrity 穩 健 Conservative 創 新 Innovation 勤 儉 Diligent

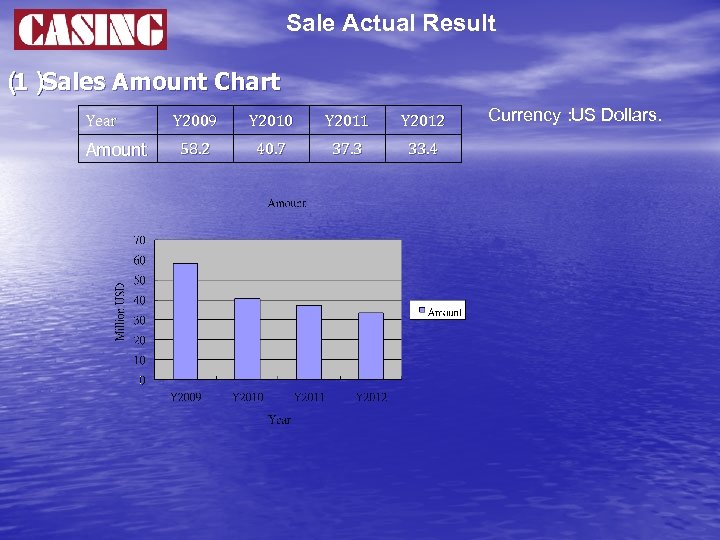

Sale Actual Result () 1 Sales Amount Chart Year Amount Y 2009 Y 2010 Y 2011 Y 2012 58. 2 40. 7 37. 3 33. 4 Currency: Dollars. US

Sale Actual Result () 1 Sales Amount Chart Year Amount Y 2009 Y 2010 Y 2011 Y 2012 58. 2 40. 7 37. 3 33. 4 Currency: Dollars. US

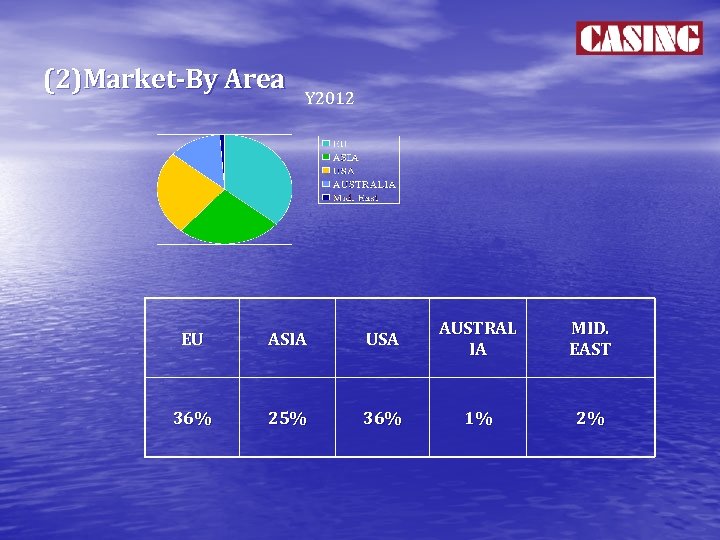

(2)Market-By Area Y 2012 EU ASIA USA AUSTRAL IA MID. EAST 36% 25% 36% 1% 2%

(2)Market-By Area Y 2012 EU ASIA USA AUSTRAL IA MID. EAST 36% 25% 36% 1% 2%

Main Partnership List

Main Partnership List

機箱 Gigazone Coolermaster

機箱 Gigazone Coolermaster

機箱 NEZT Aprevia

機箱 NEZT Aprevia

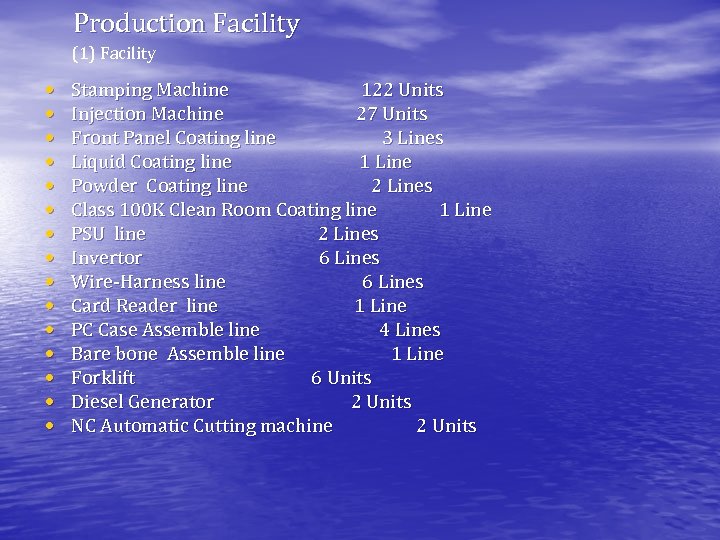

Production Facility (1) Facility • • • • Stamping Machine 122 Units Injection Machine 27 Units Front Panel Coating line 3 Lines Liquid Coating line 1 Line Powder Coating line 2 Lines Class 100 K Clean Room Coating line 1 Line PSU line 2 Lines Invertor 6 Lines Wire-Harness line 6 Lines Card Reader line 1 Line PC Case Assemble line 4 Lines Bare bone Assemble line 1 Line Forklift 6 Units Diesel Generator 2 Units NC Automatic Cutting machine 2 Units

Production Facility (1) Facility • • • • Stamping Machine 122 Units Injection Machine 27 Units Front Panel Coating line 3 Lines Liquid Coating line 1 Line Powder Coating line 2 Lines Class 100 K Clean Room Coating line 1 Line PSU line 2 Lines Invertor 6 Lines Wire-Harness line 6 Lines Card Reader line 1 Line PC Case Assemble line 4 Lines Bare bone Assemble line 1 Line Forklift 6 Units Diesel Generator 2 Units NC Automatic Cutting machine 2 Units

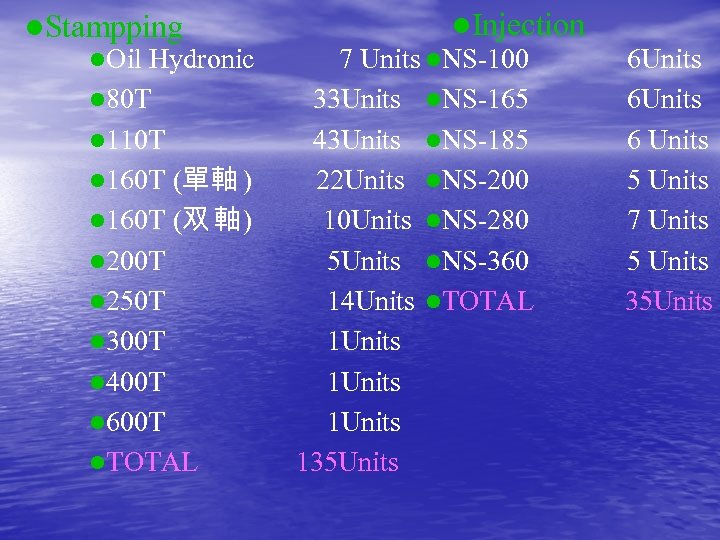

l. Stampping l. Oil Hydronic l 80 T l 110 T l 160 T (單軸 ) l 160 T (双 軸 ) l 200 T l 250 T l 300 T l 400 T l 600 T l. TOTAL l. Injection 7 Units l. NS-100 33 Units l. NS-165 43 Units l. NS-185 22 Units l. NS-200 10 Units l. NS-280 5 Units l. NS-360 14 Units l. TOTAL 1 Units 135 Units 6 Units 6 Units 5 Units 7 Units 5 Units 35 Units

l. Stampping l. Oil Hydronic l 80 T l 110 T l 160 T (單軸 ) l 160 T (双 軸 ) l 200 T l 250 T l 300 T l 400 T l 600 T l. TOTAL l. Injection 7 Units l. NS-100 33 Units l. NS-165 43 Units l. NS-185 22 Units l. NS-200 10 Units l. NS-280 5 Units l. NS-360 14 Units l. TOTAL 1 Units 135 Units 6 Units 6 Units 5 Units 7 Units 5 Units 35 Units

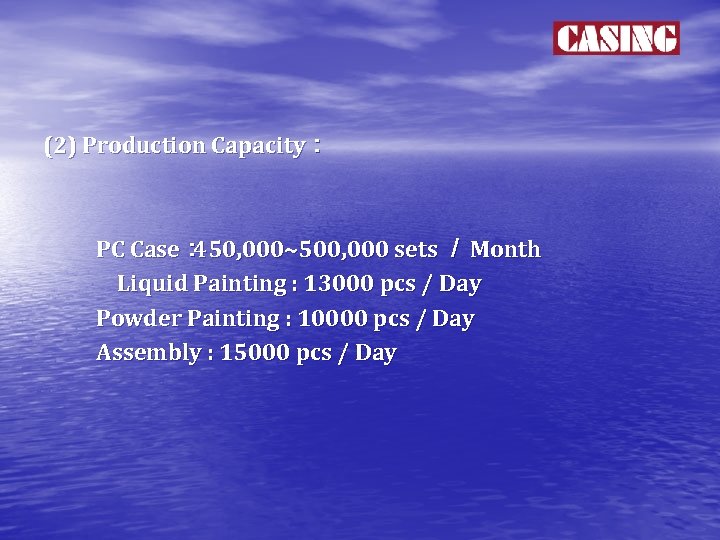

(2) Production Capacity: PC Case: 450, 000~500, 000 sets / Month Liquid Painting : 13000 pcs / Day Powder Painting : 10000 pcs / Day Assembly : 15000 pcs / Day

(2) Production Capacity: PC Case: 450, 000~500, 000 sets / Month Liquid Painting : 13000 pcs / Day Powder Painting : 10000 pcs / Day Assembly : 15000 pcs / Day

() 3 Factory Tour PC Case: Metal -Cutting

() 3 Factory Tour PC Case: Metal -Cutting

Metal Stamping

Metal Stamping

Coating . Liquid Coating

Coating . Liquid Coating

. Powder Coating Line

. Powder Coating Line

. Clean Room Coating Line

. Clean Room Coating Line

Plastic Injection

Plastic Injection

Assemble Line

Assemble Line

Finished goods warehouse

Finished goods warehouse

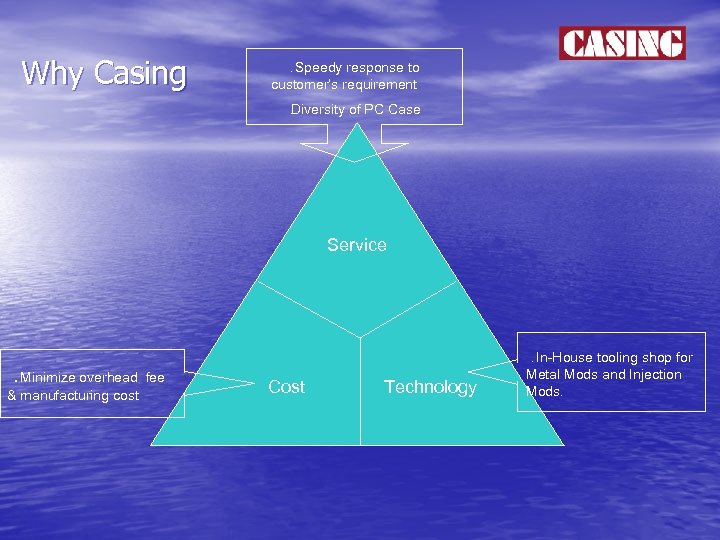

Why Casing . Speedy response to customer’s requirement . Diversity of PC Case Service . Minimize overhead & manufacturing cost fee Cost Technology . In-House tooling shop for Metal Mods and Injection Mods.

Why Casing . Speedy response to customer’s requirement . Diversity of PC Case Service . Minimize overhead & manufacturing cost fee Cost Technology . In-House tooling shop for Metal Mods and Injection Mods.

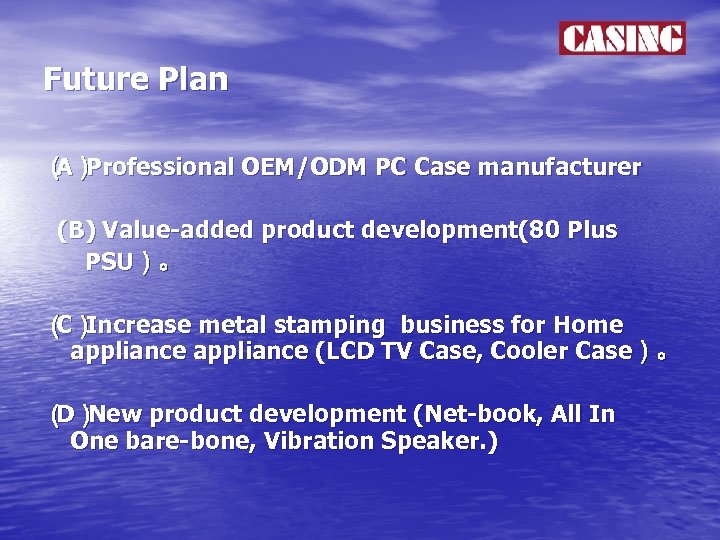

Future Plan () A Professional OEM/ODM PC Case manufacturer (B) Value-added product development(80 Plus PSU)。 () C Increase metal stamping business for Home appliance (LCD TV Case, Cooler Case)。 () D New product development (Net-book, All In One bare-bone, Vibration Speaker. )

Future Plan () A Professional OEM/ODM PC Case manufacturer (B) Value-added product development(80 Plus PSU)。 () C Increase metal stamping business for Home appliance (LCD TV Case, Cooler Case)。 () D New product development (Net-book, All In One bare-bone, Vibration Speaker. )

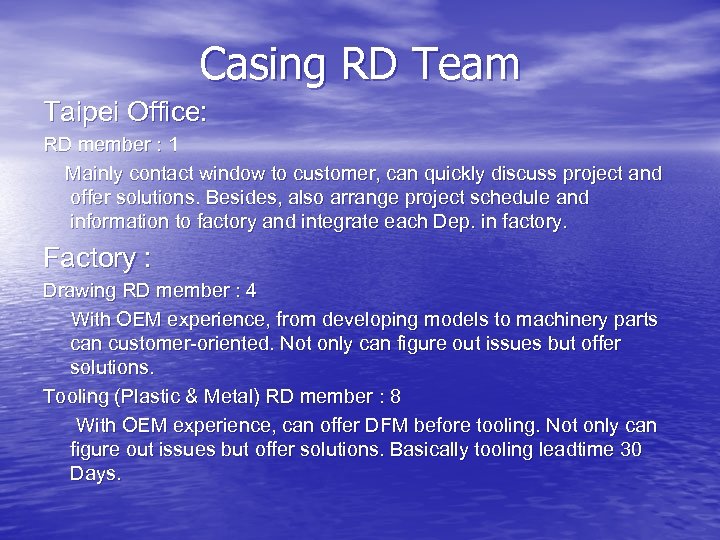

Casing RD Team Taipei Office: RD member : 1 Mainly contact window to customer, can quickly discuss project and offer solutions. Besides, also arrange project schedule and information to factory and integrate each Dep. in factory. Factory : Drawing RD member : 4 With OEM experience, from developing models to machinery parts can customer-oriented. Not only can figure out issues but offer solutions. Tooling (Plastic & Metal) RD member : 8 With OEM experience, can offer DFM before tooling. Not only can figure out issues but offer solutions. Basically tooling leadtime 30 Days.

Casing RD Team Taipei Office: RD member : 1 Mainly contact window to customer, can quickly discuss project and offer solutions. Besides, also arrange project schedule and information to factory and integrate each Dep. in factory. Factory : Drawing RD member : 4 With OEM experience, from developing models to machinery parts can customer-oriented. Not only can figure out issues but offer solutions. Tooling (Plastic & Metal) RD member : 8 With OEM experience, can offer DFM before tooling. Not only can figure out issues but offer solutions. Basically tooling leadtime 30 Days.