7f7c287462d4dcf1b44b4456155ad467.ppt

- Количество слайдов: 23

Case Study Double H Nurseries: world-class growers and packers of cut flowers. This case charts their successful lean journey from 2005 and approach to embedding a continuous improvement culture in their business. http: //www. doubleh. co. uk

The Double H Mission and Purpose Plants grown with passion, presented with pride, loved by all ……… 2

Background to the Business The business began in 1961 when Hugh Stevenson moved to New Milton to start growing tomatoes and cut chrysanthemums. Soon after that he joined forces with Helmut Gimmler to form Double H. They built a traditional nursery competing against other UK nurseries and sending plants by rail to wholesale markets for sale to florists The growth of the company has come about as a result of their response to market changes: At first all flowers were sold through florists via wholesale market The first big progression was potted plants (initially chrysanthemums) The large retailers began to show interest in selling potted plants and flowers and a contract was won with Safeway supermarkets Volumes grew and the company diversified into growing other potted plants In the 1980 s, the company simplified cropping to accommodate volume and began to supply Homebase and later Sainsbury’s Dealing with the large retailers led the company into clear specifications, quality control and bar coding. In the 1990 s, the company added Tesco to their customer portfolio At the same time the industry was consolidating. Many small players that had sprung up in the 1960 s with government funding required reinvestment 3

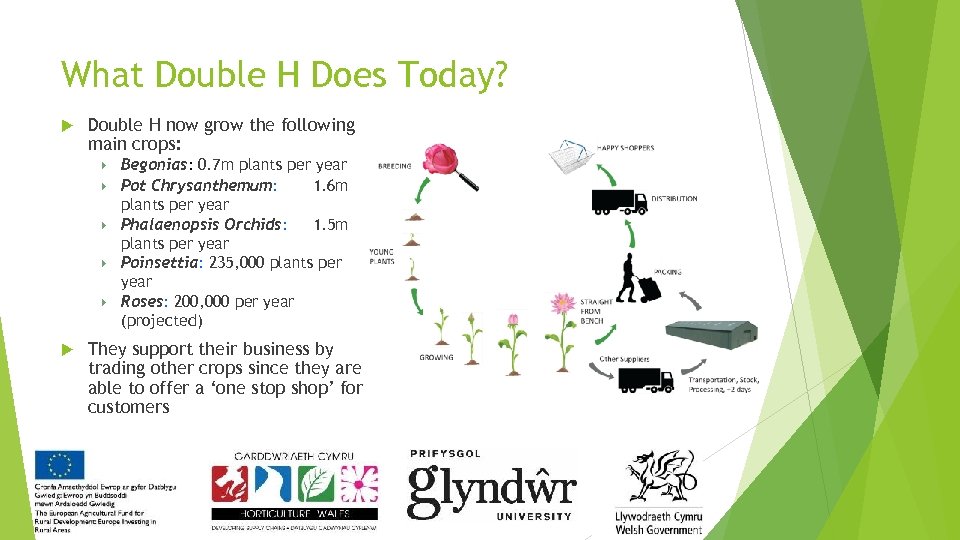

What Double H Does Today? Double H now grow the following main crops: Begonias: 0. 7 m plants per year Pot Chrysanthemum: 1. 6 m plants per year Phalaenopsis Orchids: 1. 5 m plants per year Poinsettia: 235, 000 plants per year Roses: 200, 000 per year (projected) They support their business by trading other crops since they are able to offer a ‘one stop shop’ for customers 4

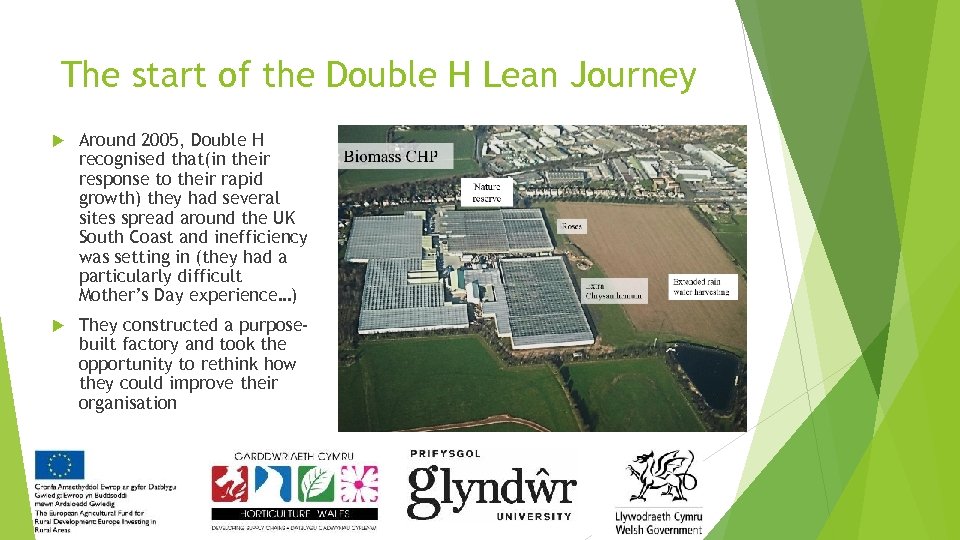

The start of the Double H Lean Journey Around 2005, Double H recognised that(in their response to their rapid growth) they had several sites spread around the UK South Coast and inefficiency was setting in (they had a particularly difficult Mother’s Day experience…) They constructed a purposebuilt factory and took the opportunity to rethink how they could improve their organisation 5

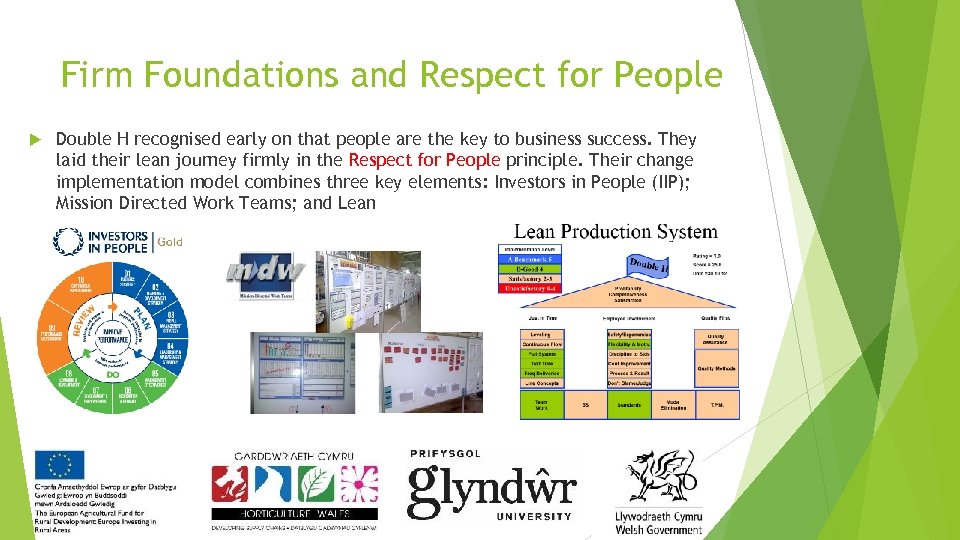

Firm Foundations and Respect for People Double H recognised early on that people are the key to business success. They laid their lean journey firmly in the Respect for People principle. Their change implementation model combines three key elements: Investors in People (IIP); Mission Directed Work Teams; and Lean 6

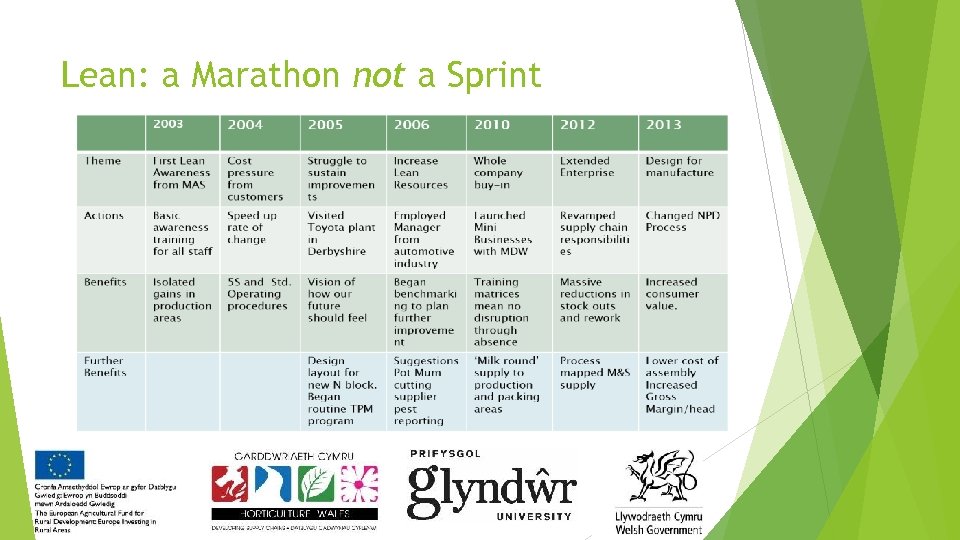

Lean: a Marathon not a Sprint 7

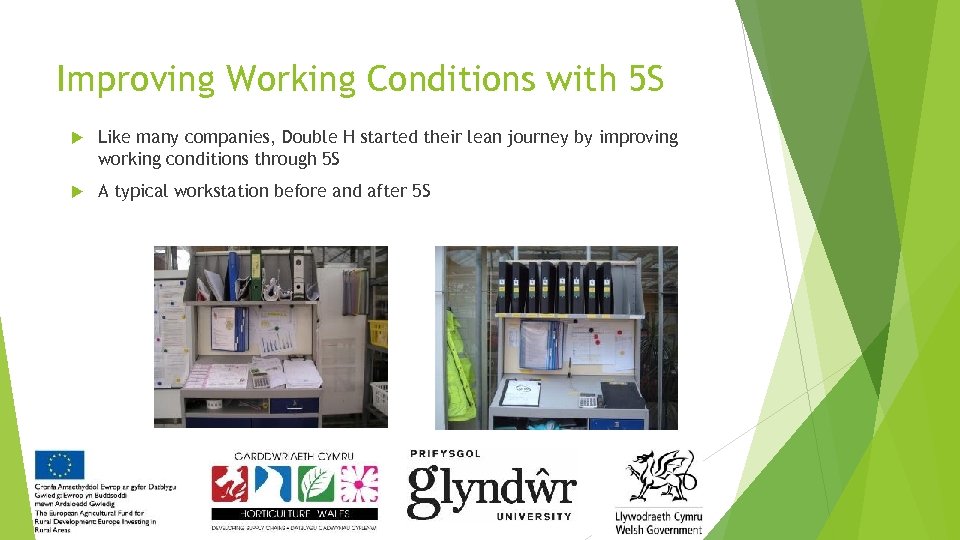

Improving Working Conditions with 5 S Like many companies, Double H started their lean journey by improving working conditions through 5 S A typical workstation before and after 5 S 8

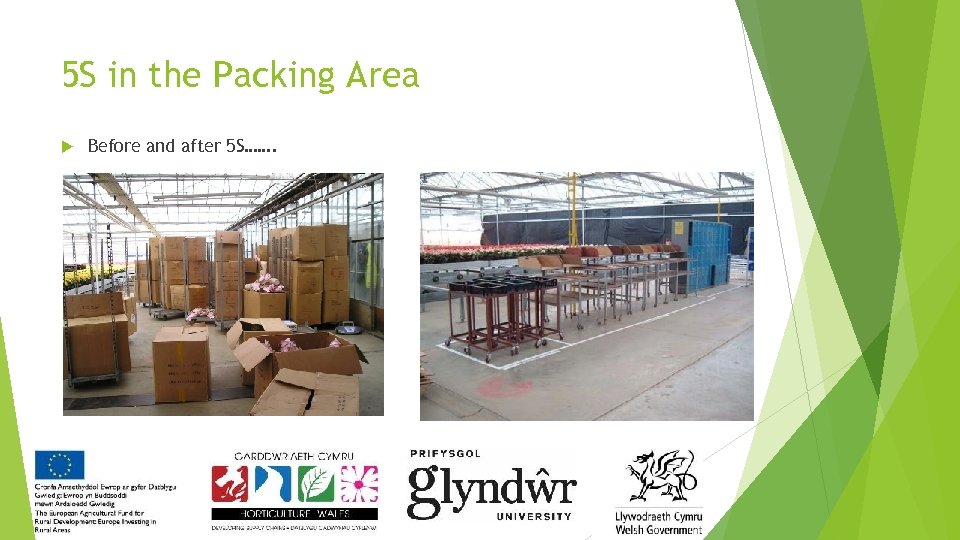

5 S in the Packing Area Before and after 5 S……. 9

5 S on the Bench Washers Before and after…… 10

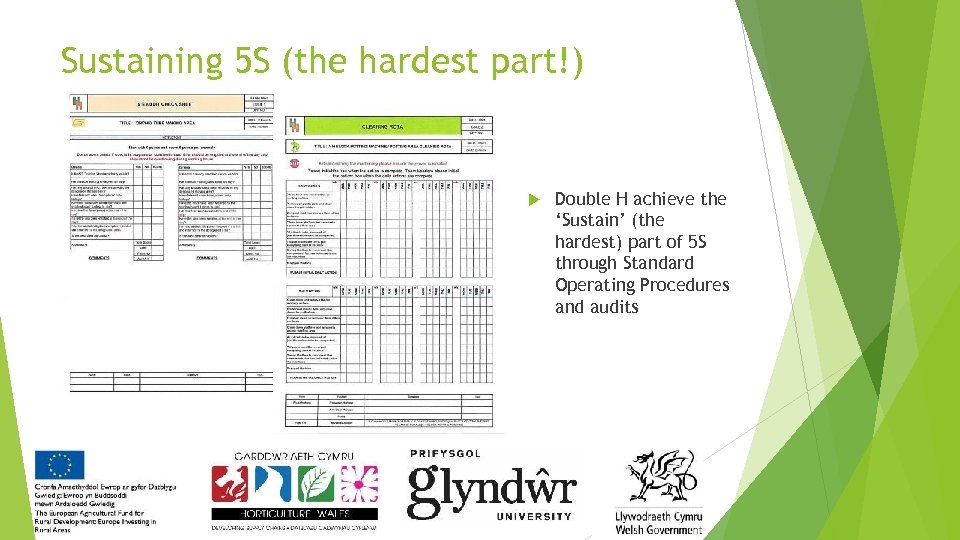

Sustaining 5 S (the hardest part!) Double H achieve the ‘Sustain’ (the hardest) part of 5 S through Standard Operating Procedures and audits 11

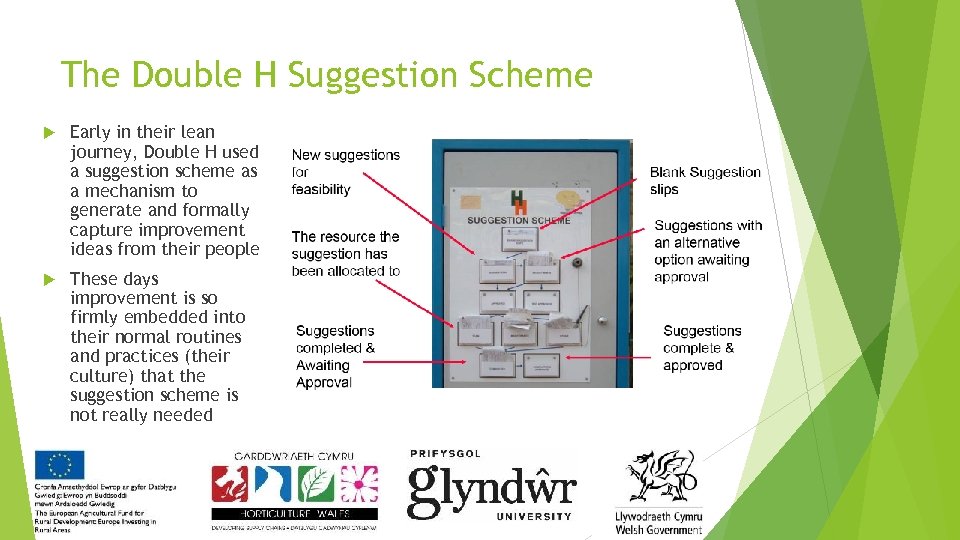

The Double H Suggestion Scheme Early in their lean journey, Double H used a suggestion scheme as a mechanism to generate and formally capture improvement ideas from their people These days improvement is so firmly embedded into their normal routines and practices (their culture) that the suggestion scheme is not really needed 12

Visual Management and SOPs Double H use visual management in the workplace to ensure everyone is clear on standards and standard operating procedures (SOPs) 13

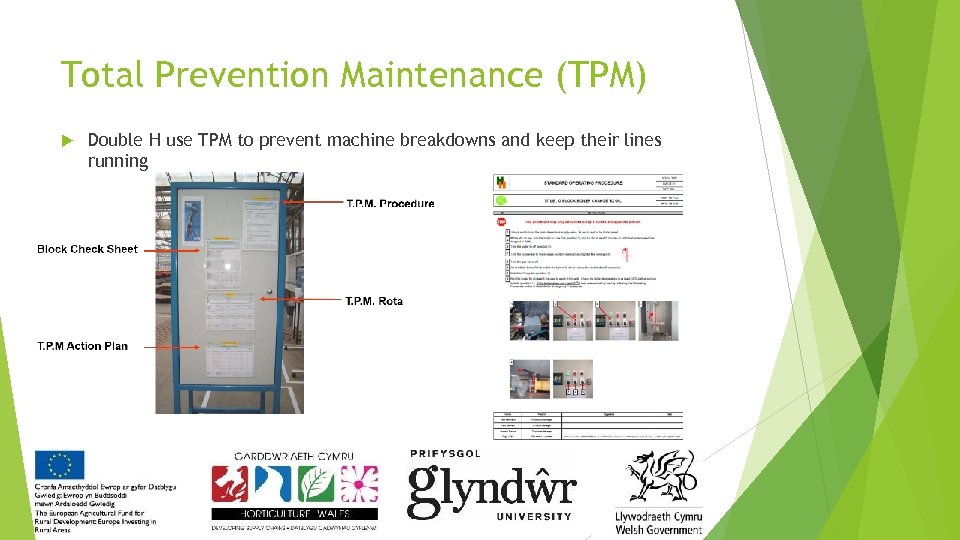

Total Prevention Maintenance (TPM) Double H use TPM to prevent machine breakdowns and keep their lines running 14

Team-working at Double H (MDTs) Having launched their lean journey on firm foundations (5 S, visual management, TPM) Double H were able to build on this by organising themselves into teams (Mission Directed Teams or MDTs) to harness the creative potential of their people MDTs have four levels: Level 1= Shop Floor (Mini Businesses); Level 2 = Team Leader; Level 3 = Department Manager; Level 4 = Senior Team Each mini-business has its own name and choose their focus from a suite of measures (that includes safety, quality, delivery, cost and management/people) Mini-businesses come together on a monthly basis and present to each other those achievements they are most proud of There are now 15 level 1 shop-floor mini-businesses Mini-businesses problem solve through daily meetings using a simple 3 Q methodology and address bigger issues using an A 3 approach All MDTs learn from each other and collaborate for the overall success of the business 15

Problem Solving and CI at Double H Problem Solving and Continuous Improvement (or Kaizen) at Double H is based on a set of guiding principles: Dissolve preconceived ideas Think “How can we do it? ” and not “Why is it impossible? ” Don’t give false excuses. Start to raise questions about general procedures Don’t immediately seek perfection. Act now even if we can only reach half of the target It’s by trial and error that we obtain wisdom Use 5 “Why” method and search for the fundamental cause Take the advice of ten people rather than the knowledge of one There’s no limit to KAIZEN ideas. 16

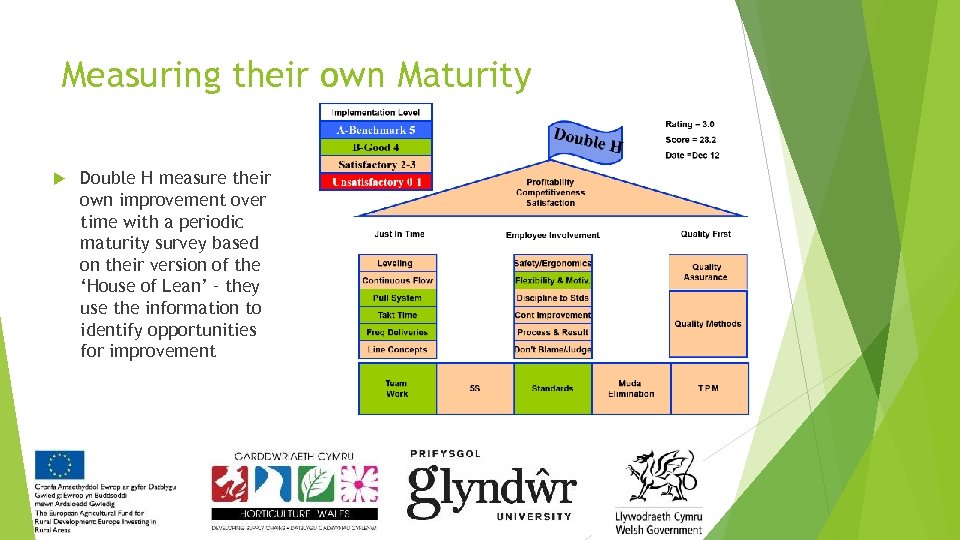

Measuring their own Maturity Double H measure their own improvement over time with a periodic maturity survey based on their version of the ‘House of Lean’ – they use the information to identify opportunities for improvement 17

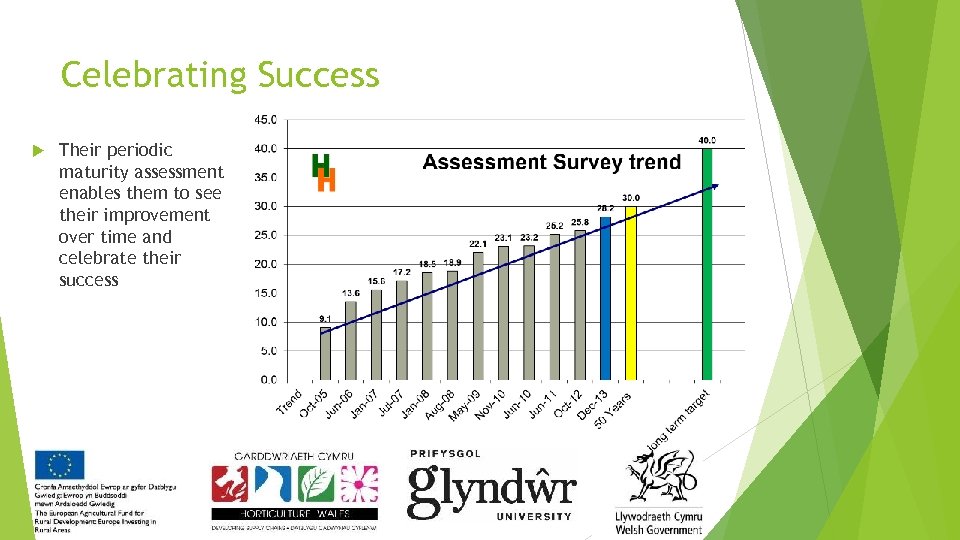

Celebrating Success Their periodic maturity assessment enables them to see their improvement over time and celebrate their success 18

Minimising People Movement A major principle underpinning the Double H approach to lean is the principle of bringing the product to the people working on it, rather than sending the people to the product This underpinning principle dictates their approach to layout and reorganisation of workflow They use ‘milk rounds’ to deliver consumables and materials to packers at the point of use. 19

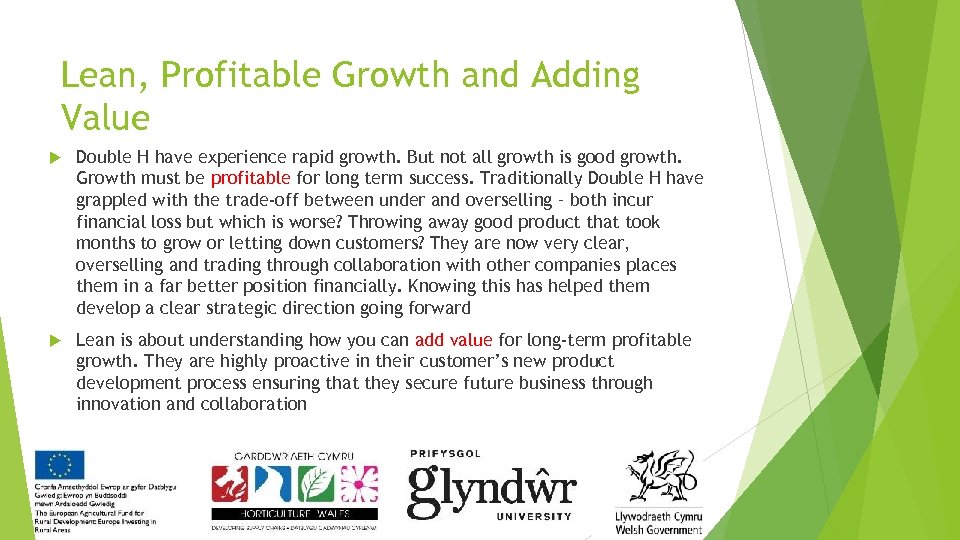

Lean, Profitable Growth and Adding Value Double H have experience rapid growth. But not all growth is good growth. Growth must be profitable for long term success. Traditionally Double H have grappled with the trade-off between under and overselling – both incur financial loss but which is worse? Throwing away good product that took months to grow or letting down customers? They are now very clear, overselling and trading through collaboration with other companies places them in a far better position financially. Knowing this has helped them develop a clear strategic direction going forward Lean is about understanding how you can add value for long-term profitable growth. They are highly proactive in their customer’s new product development process ensuring that they secure future business through innovation and collaboration 20

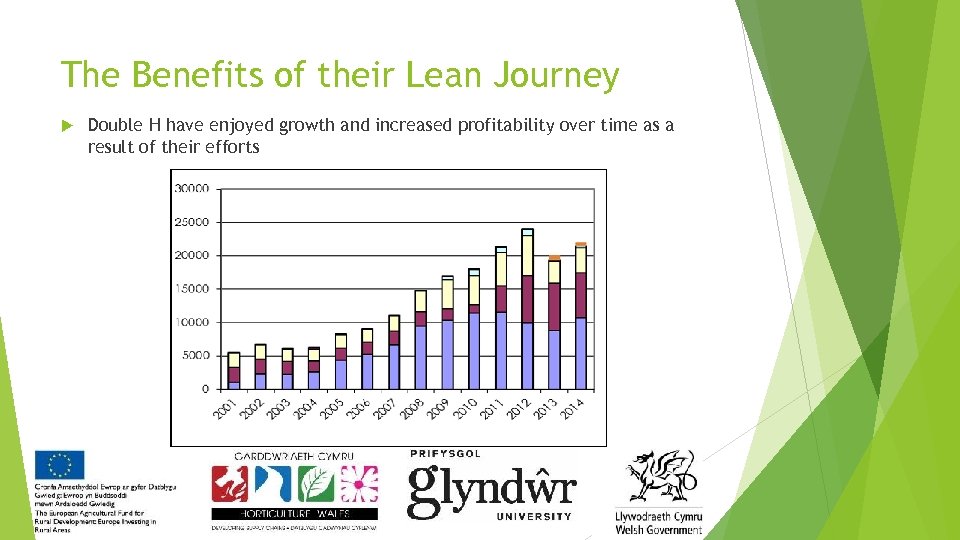

The Benefits of their Lean Journey Double H have enjoyed growth and increased profitability over time as a result of their efforts 21

Lean and Customer Satisfaction Double H have won numerous awards as a result of their lean/improvement journey over time. Here are some of them: M&S Silver Factory 2014 Tesco supplier of year 2012 M&S Plan A Lean Award 2011 New Forest Business of the Year 2010 New Forest Sustainable Business Award 2010 Hampshire and Io. W Sustainable Business Award 2008 / 2010 New Forest Award for Training 2009 Grower of the Year 2000, 2009 MAS Best Practice Award 2007 Investors in People Gold (+17 years IIP accreditation) 22

Thanks to Neil Stevenson (Managing Director) and John Miller (Operations Manager) for their time in hosting a visit to Double H Nurseries. You can learn more about Double H Nurseries at: http: //www. doubleh. co. uk Watch their video on orchid production: http: //www. doubleh. co. uk/Production_Systems_Orc hids. html Contact the team at: enquiries@doubleh. co. uk 3/18/2018 23 23

7f7c287462d4dcf1b44b4456155ad467.ppt