c1270c2999d91949861a3e0dde88b066.ppt

- Количество слайдов: 54

Carbon Capture, Sequestration & CDM Opportunities in Power Sector Presented By:

The Major Contradictory Challenges Faced by Developing world n n s n tinued Quest for increased Generation capacity - Terawatt Challenge Climate Change - rising GHG level generation

Sustained economic growth at 8 to 9% requires that by the year 2012, we must have installed capacity at a level of over 2, 000 MW and by 2050 at the level of 10 Lakh MW i. e. a trillion or Terra Watt – This poses a Terra watt challenges for India.

Green House Gas level rise to a current level of 390 ppm and consequent climate change, floods and draughts has affected 260 million people between 2000 and 2004 through natural calamities, of these, 98% were in developing nations. Developed countries with population of 15% of world population have the share of CO 2 emissions at 50%. CO 2 level has risen to 390 ppm from 1975 level of 330 ppm. There is so much momentum in the system that we will certainly double CO 2 level by end of the century. Global temperature rise by 3 to 4 0 C will cause displacement of over 330 million people in developing world.

• China and India are projected to account for 30% of the world’s increase in energy consumption between and 2000 -2020 use. • World Green House inventory is over 29, 000 Million tones per annum (MTPA) with US over 20% (India with total emission of about 1400 MTPA is only at 4. 8 %. ) • power generation in at least next Three decades for India (99, 861 MW Coal based generation out of 1, 56, 092 MW total power installed capacity)

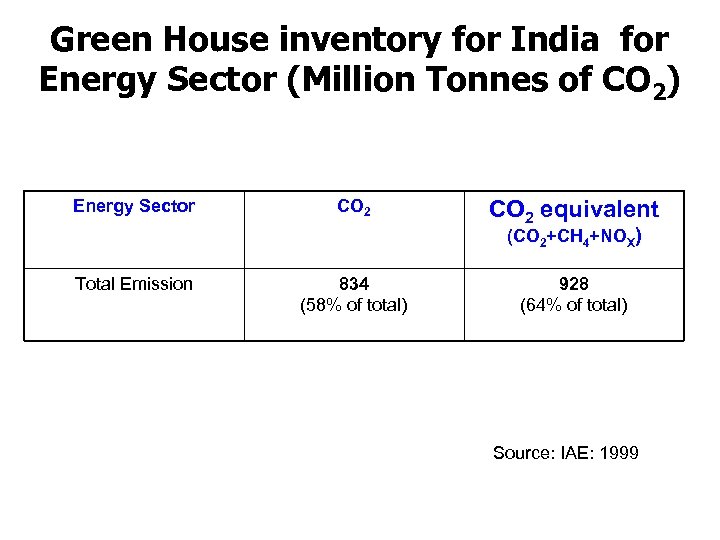

Green House inventory for India for Energy Sector (Million Tonnes of CO 2) Energy Sector CO 2 equivalent (CO 2+CH 4+NOX) Total Emission 834 (58% of total) 928 (64% of total) Source: IAE: 1999

Atmospheric Concentration of GHG increasing • Atmospheric concentrations of greenhouse gases have increased significantly since industrial revolution – Carbon dioxide +30%; Methane +100%; Nitrous oxide +15% – Greenhouse gas concentrations projected to reach double pre-industrial levels by about 2060 • Many greenhouse gases remain in atmosphere for a longtime (decades to centuries)

The Fourth Assessment Report of the Intergovernmental Panel for Climate Change (IPCC) has confirmed: n n n The temperature of the earth’s surface has increased by 0. 76˚C over the past century. It is very likely (more than 90˚ probability) that most of this global warming was due to increased GHGs(green house gases ), resulting from human activity. Eleven of the last 12 years (1995 -2006) were among the 12 warmest years on the instrumental record of global surface temperature. n Mountain glaciers are receding and snow cover has declined in both the hemispheres. n Best estimate regarding the future changes in climate by 2099 for low scenario is 1. 8” and for high scenario is 4. 0”sea level rise

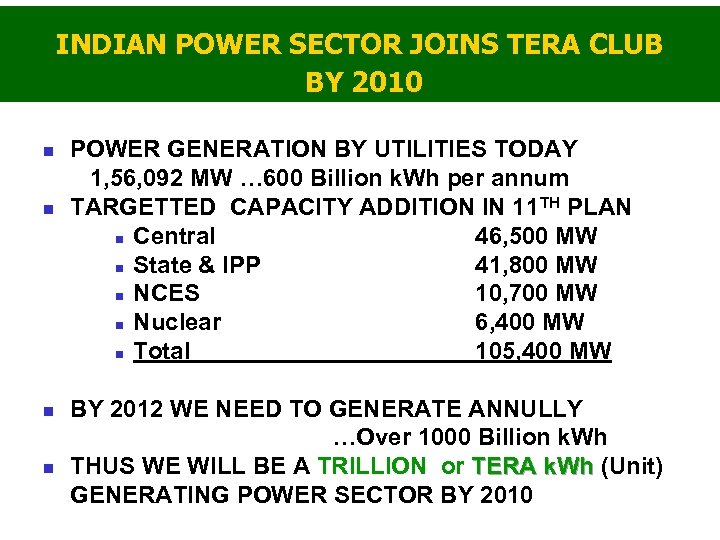

INDIAN POWER SECTOR JOINS TERA CLUB BY 2010 POWER GENERATION BY UTILITIES TODAY 1, 56, 092 MW … 600 Billion k. Wh per annum n TARGETTED CAPACITY ADDITION IN 11 TH PLAN n Central 46, 500 MW n State & IPP 41, 800 MW n NCES 10, 700 MW n Nuclear 6, 400 MW n Total 105, 400 MW n n n BY 2012 WE NEED TO GENERATE ANNULLY …Over 1000 Billion k. Wh THUS WE WILL BE A TRILLION or TERA k. Wh (Unit) TERA k. Wh GENERATING POWER SECTOR BY 2010

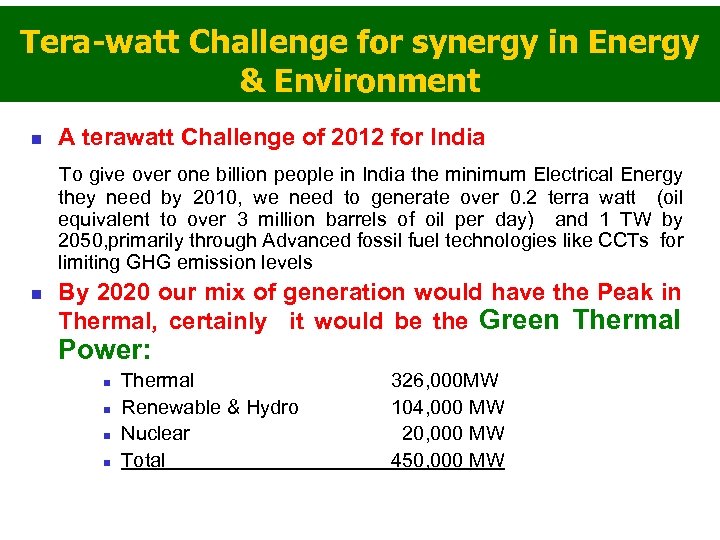

Tera-watt Challenge for synergy in Energy & Environment n A terawatt Challenge of 2012 for India To give over one billion people in India the minimum Electrical Energy they need by 2010, we need to generate over 0. 2 terra watt (oil equivalent to over 3 million barrels of oil per day) and 1 TW by 2050, primarily through Advanced fossil fuel technologies like CCTs for limiting GHG emission levels n By 2020 our mix of generation would have the Peak in Thermal, certainly it would be the Green Thermal Power: n n Thermal Renewable & Hydro Nuclear Total 326, 000 MW 104, 000 MW 20, 000 MW 450, 000 MW

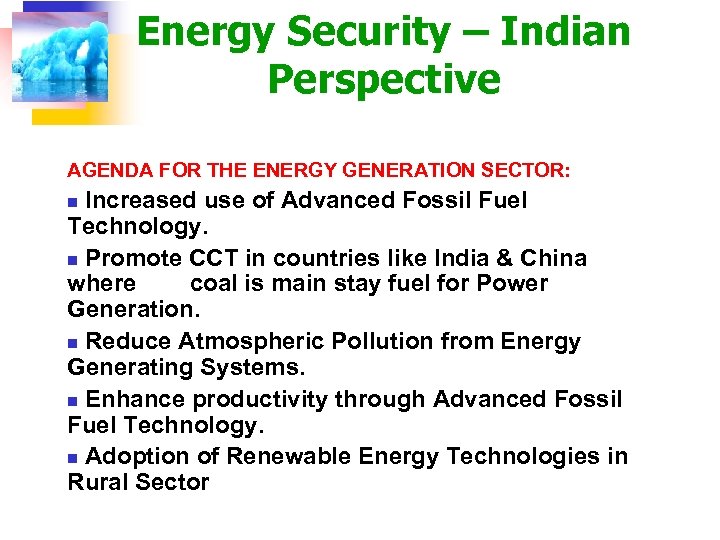

Energy Security – Indian Perspective AGENDA FOR THE ENERGY GENERATION SECTOR: Increased use of Advanced Fossil Fuel Technology. n Promote CCT in countries like India & China where coal is main stay fuel for Power Generation. n Reduce Atmospheric Pollution from Energy Generating Systems. n Enhance productivity through Advanced Fossil Fuel Technology. n Adoption of Renewable Energy Technologies in Rural Sector n

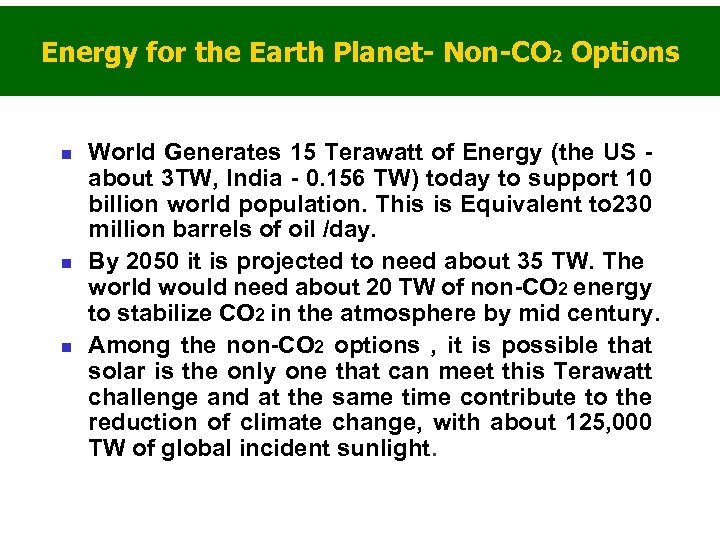

Energy for the Earth Planet- Non-CO 2 Options n n n World Generates 15 Terawatt of Energy (the US - about 3 TW, India - 0. 156 TW) today to support 10 billion world population. This is Equivalent to 230 million barrels of oil /day. By 2050 it is projected to need about 35 TW. The world would need about 20 TW of non-CO 2 energy to stabilize CO 2 in the atmosphere by mid century. Among the non-CO 2 options , it is possible that solar is the only one that can meet this Terawatt challenge and at the same time contribute to the reduction of climate change, with about 125, 000 TW of global incident sunlight.

Energy for the Earth Planet- Non-CO 2 Options…Contd. n n n Key scenario for stabilizing CO 2 in the atmosphere during 21 st century turn on the viability of CO 2 sequestration. This implies CO 2 capture, storage and then pumping to aquifers, to stay for millennia. In any case minimum 10 TW is needed within a decade from Breeder Nuclear , Clean Coal Technologies (CCTs) and Renewables. Biomass CO 2 sequestration could also meet this challenge to some extent.

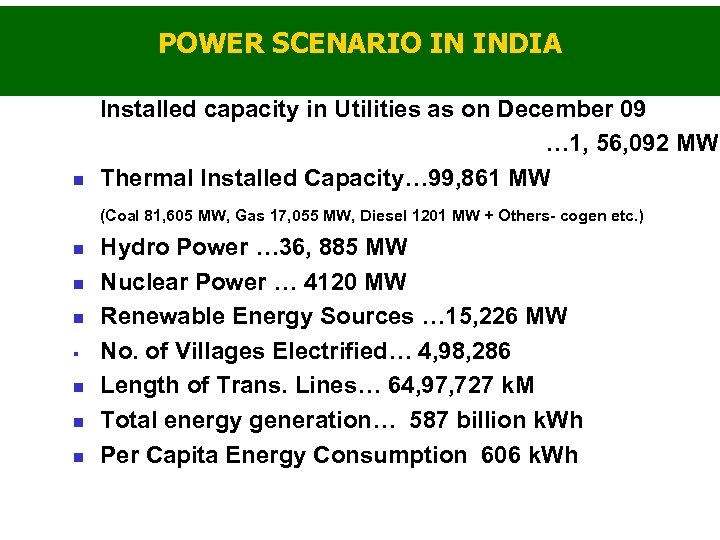

POWER SCENARIO IN INDIA Installed capacity in Utilities as on December 09 … 1, 56, 092 MW n Thermal Installed Capacity… 99, 861 MW (Coal 81, 605 MW, Gas 17, 055 MW, Diesel 1201 MW + Others- cogen etc. ) n Hydro Power … 36, 885 MW n Nuclear Power … 4120 MW n Renewable Energy Sources … 15, 226 MW § No. of Villages Electrified… 4, 98, 286 n Length of Trans. Lines… 64, 97, 727 k. M n Total energy generation… 587 billion k. Wh n Per Capita Energy Consumption 606 k. Wh

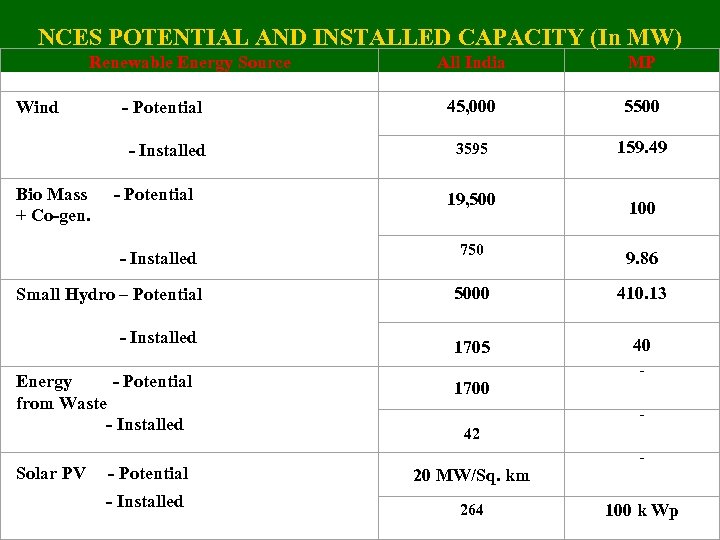

NCES POTENTIAL AND INSTALLED CAPACITY (In MW) Renewable Energy Source Wind - Potential - Installed Bio Mass + Co-gen. - Potential - Installed Small Hydro – Potential - Installed Energy - Potential from Waste - Installed Solar PV All India MP 45, 000 5500 3595 159. 49 19, 500 100 750 9. 86 5000 410. 13 1705 40 - 1700 42 - Potential 20 MW/Sq. km - Installed 264 100 k Wp

INDIAN POWER SECTOR - TOWARDS SUSTAINABLE POWER DEVELOPMENT n n Total Installed Capacity … 1, 56, 092 MW Thermal Generation … over 64 % Although no GHG reduction targets for India but taken steps through adoption of Renewable Energy Technologies, Combined cycles, Co-generation, Coal beneficiation, Plant Performance optimization Under Kyoto Protocol; Clean Development Mechanism (CDM) conceived to reduce cost of GHG mitigation, while promoting sustainable development as per Framework Convention on Climate change (FCCC)

FRONTALS IN ENERGY & ENVIRONMENT n n GREEN ENERGY TECHNOLOGIES – PRIMARILY THE CLEAN COAL TECHNOLOGIES ZERO EMISSION TECHNOLOGIES FOR TRANSPORT, POWER PLANTS & INDUSTRIAL SECTOR n AFFORDABLE RENEWABLE ENERGY TECHNOLOGIES n ENERGY EFFICIENCY n CDM OPPORTUNITIES IN ENERGY SECTOR

There are three main techniques for Capture of CO 2 in Power Generation n Post-combustion capture Pre-combustion capture Oxy-fuel combustion

Techniques for removal of CO 2 from Flue Gas Carbon dioxide can be removed from flue gas and waste gas streams produced from carbon usage by various methods. 1. Absorption with a solvent, 2. Membrane separation, 3. Cryogenic fractionation, 4. Adsorption using molecular sieves. Capture of CO 2 from absorption method is most widely used technique.

Absorption Approach Using Chemical Solvents CO 2 can be removed from flue gases using solvents that rely on chemical or physical absorption. The most common solvents used for neutralizing CO 2 in chemical absorption systems are alkanol-amines such as mono-ethanol-amine (MEA), di-ethanol-amine (DEA), and methyl-di-ethanol-amine (MDEA). Chemical absorption with MEA solvent is the most common capture technology, is readily available and can be integrated into new plants. Prior to CO 2 removal, the flue gas is typically cooled, then treated to reduce particulars and other impurities. It is then passed in to absorption tower where it comes in contact with the absorption solution.

Carbon Capture & Sequestration • • India’s position with regard to Carbon Capture & Storage (CCS) is very clear. We don’t make any commitment at this stage regarding deployment of CCS technologies. India advocates very strongly the Carbon Capture & Sequestration. Some of the demo pilot projects include. -Pilot project on Geological CO 2 sequestration in basalt rock formation. The question of adoption of CCS will depend on this technology being cost effective. -Projects under DST sponsored National Program on Carbon Sequestration (NPCS)

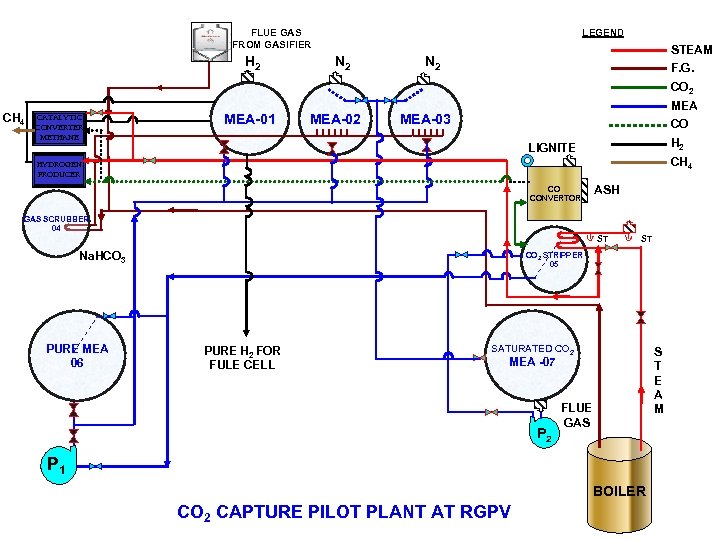

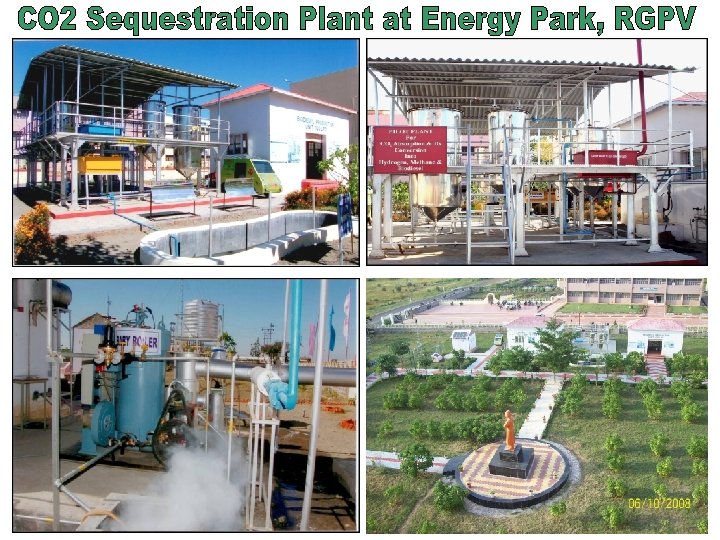

FLUE GAS FROM GASIFIER H 2 LEGEND N 2 STEAM N 2 F. G. CO 2 CH 4 CATALYTIC CONVERTER METHANE MEA-01 MEA-02 MEA-03 CO H 2 LIGNITE CH 4 HYDROGEN PRODUCER CO CONVERTOR ASH GAS SCRUBBER 04 ST Na. HCO 3 PURE MEA 06 CO 2 STRIPPER 05 PURE H 2 FOR FULE CELL SATURATED CO 2 MEA -07 P 2 FLUE GAS P 1 BOILER CO 2 CAPTURE PILOT PLANT AT RGPV S T E A M

n n n Rated Capacity of the Capture of CO 2 : 500 kg/ day Source of CO 2 - Boiler of capacity 100 kg/hr. steam & Biomass Gasifier of 10 k. W Solvent used for capture of CO 2 : Mono Ethanol Amine (MEA) SOx & NOx Removal : Na. HCO 3 Catalytic Converters / Reduction Unit - For Methane. . Input CO and H 2, Catalyst - For Hydrogen. . Input CO and Steam, Catalyst - For Carbon Monoxide. . . Fe 3 C & Lignite

CO 2 mitigation Options: Case of Electricity Sector n n n Coal: Dominates the electricity sector today Fuel switching (Coal NG) Conventional Plants + Carbon Capture & Sequestration (CCS) (Post –Combustion CO 2 Capture) Gasification/ Reforming + CCS (Pre-Combustion CO 2 Capture) Oxyfuel Combustion + CCS

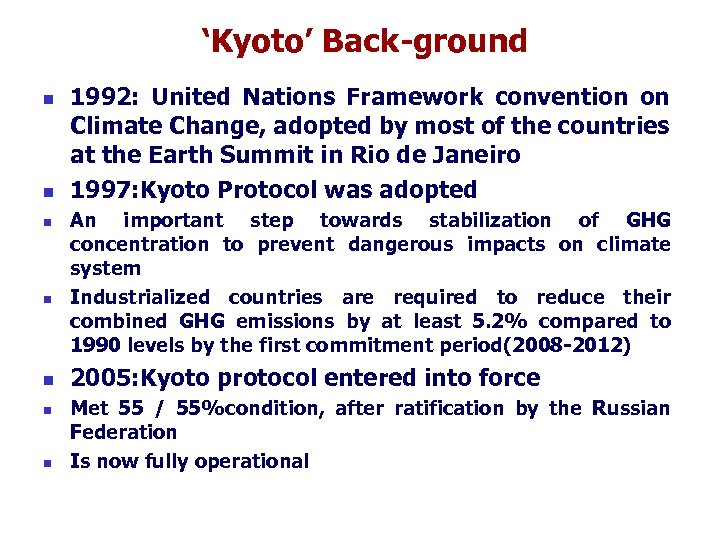

‘Kyoto’ Back-ground n n n n 1992: United Nations Framework convention on Climate Change, adopted by most of the countries at the Earth Summit in Rio de Janeiro 1997: Kyoto Protocol was adopted An important step towards stabilization of GHG concentration to prevent dangerous impacts on climate system Industrialized countries are required to reduce their combined GHG emissions by at least 5. 2% compared to 1990 levels by the first commitment period(2008 -2012) 2005: Kyoto protocol entered into force Met 55 / 55%condition, after ratification by the Russian Federation Is now fully operational

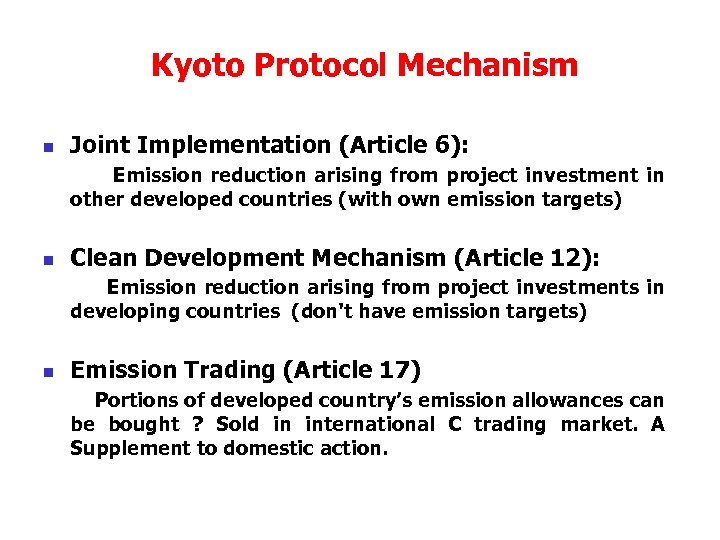

Kyoto Protocol Mechanism n Joint Implementation (Article 6): Emission reduction arising from project investment in other developed countries (with own emission targets) n Clean Development Mechanism (Article 12): Emission reduction arising from project investments in developing countries (don't have emission targets) n Emission Trading (Article 17) Portions of developed country’s emission allowances can be bought ? Sold in international C trading market. A Supplement to domestic action.

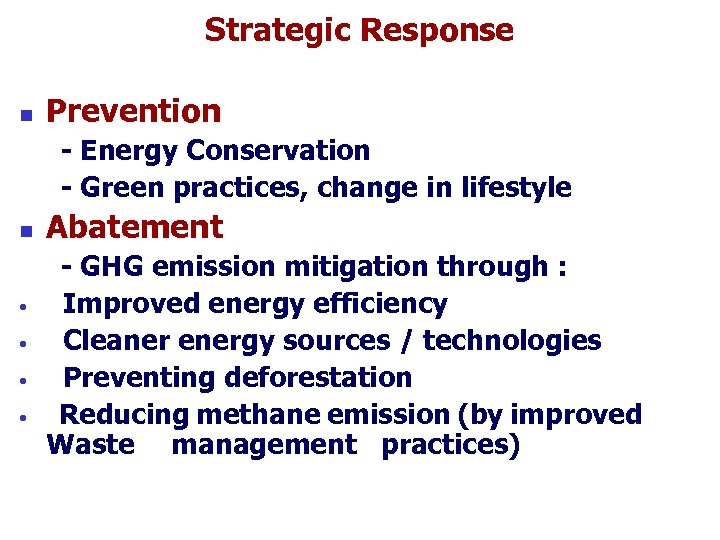

Strategic Response n Prevention - Energy Conservation - Green practices, change in lifestyle n • • Abatement - GHG emission mitigation through : Improved energy efficiency Cleaner energy sources / technologies Preventing deforestation Reducing methane emission (by improved Waste management practices)

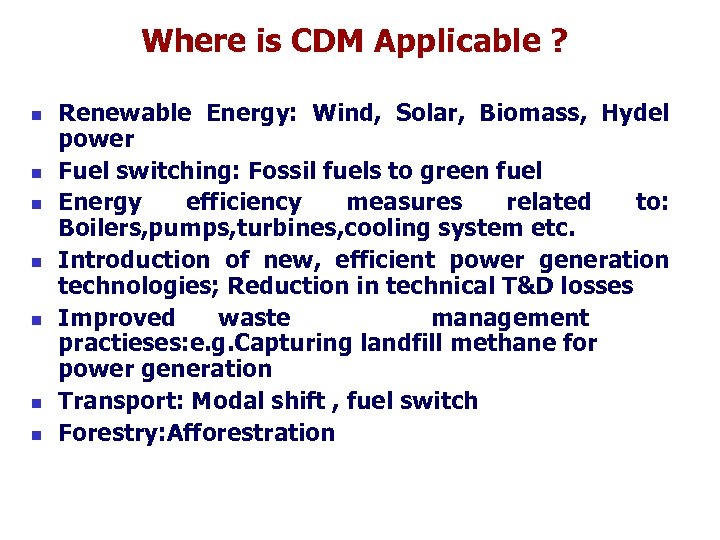

Where is CDM Applicable ? n n n n Renewable Energy: Wind, Solar, Biomass, Hydel power Fuel switching: Fossil fuels to green fuel Energy efficiency measures related to: Boilers, pumps, turbines, cooling system etc. Introduction of new, efficient power generation technologies; Reduction in technical T&D losses Improved waste management practieses: e. g. Capturing landfill methane for power generation Transport: Modal shift , fuel switch Forestry: Afforestration

CDM: Disqualifiers n n n Emission reduction from Nuclear facilities A diversion of official development assistance (ODA) from Annex – I countries Any other type of sequestration activities apart from afforestation and reforerstation!

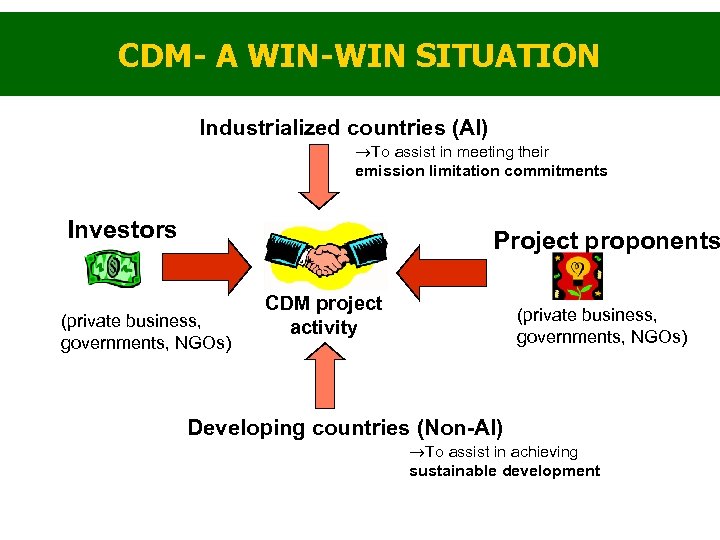

CDM- A WIN-WIN SITUATION Industrialized countries (AI) ®To assist in meeting their emission limitation commitments Investors Project proponents (private business, governments, NGOs) CDM project activity (private business, governments, NGOs) Developing countries (Non-AI) ®To assist in achieving sustainable development

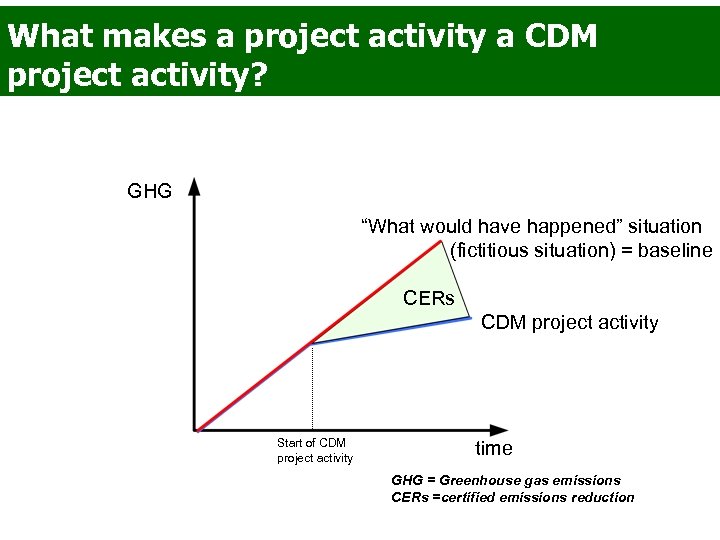

What makes a project activity a CDM project activity? GHG “What would have happened” situation (fictitious situation) = baseline CERs CDM project activity Start of CDM project activity time GHG = Greenhouse gas emissions CERs =certified emissions reduction

CDM Projects Status n n n Total projects registered by EB – 1000 Equivalent CERs – 340 Million Projects from India – 47 (~ 30%) Total Baseline Methodologies approved > 50 Majority of the projects: Biomass – energy Majority of CERs generated: HFC oxidation

Typical CDM Projects Categories in India n n n n Renewable energy (e. g. solar, wind, biomass, hydro) Fuel switching (e. g. oil to gas, coal to gas) Energy efficiency (e. g. lighting, insulation, process optimization) Waste processing (e. g. land fill gas extraction, waste incineration) Waste heat recovery projects including power generation Energy saving by elimination of reheating processes Thermal oxidation of HFC Afforestation

Towards 2012 and Beyond n n n Continue to mobilize private sector participation in the CDM, willing to respond positively to CDM criteria Encourage CDM participation of large public sector emitters (e. g. power & transport sector) possibly in sector CDM arrangements Information infrastructure to support a functioning market – e. g. baseline for major sectors like Power, Cement, Iron and Steel Explore opportunities for sector trading schemes (Sectoral & Programmatic CDM ) Integration of GHG emission reduction activities and national development programmes

Mission Energy Security and Energy independence n n n n Climate Change – Nature’s Fury Solar for irrigation High Efficiency CNT Based PV Cells Hydrogen as Fuel for future Accelerated Program on Thorium based Nuclear Reactor Clean coal Technologies like SCR, IGCC Bio-fuels for Railways and Mass Transport Energy Security by 2020, Energy Independence by 2030 …. Reference: Address by President of India 14 th Aug 2005

Prime Clean Coal Technology Options for India for 11 th & 12 th Plans n n n Supercritical Power Plants Integrated Gasification Combined Cycle (IGCC) Power Plants Circulating Fluidized Bed Combustion (CFBC) Power Plants

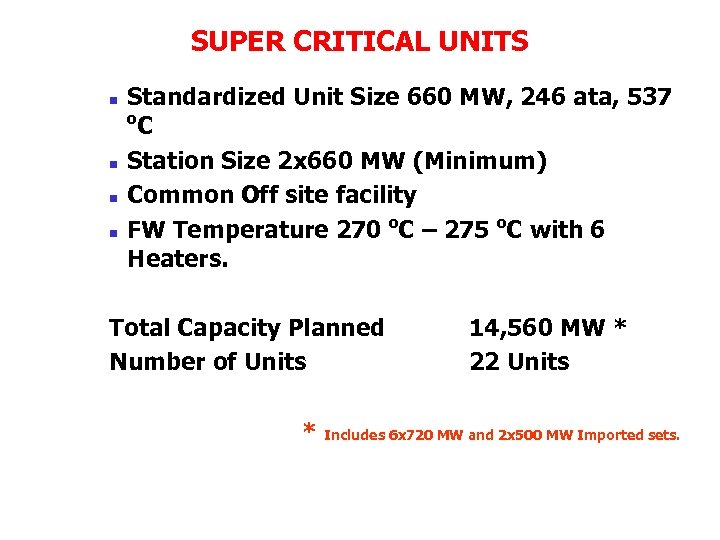

SUPER CRITICAL UNITS n n Standardized Unit Size 660 MW, 246 ata, 537 o C Station Size 2 x 660 MW (Minimum) Common Off site facility FW Temperature 270 o. C – 275 o. C with 6 Heaters. Total Capacity Planned Number of Units 14, 560 MW * 22 Units * Includes 6 x 720 MW and 2 x 500 MW Imported sets.

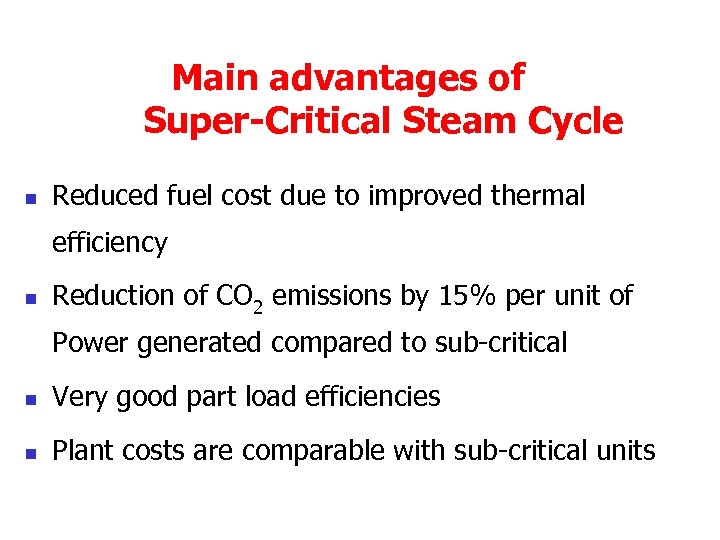

Main advantages of Super-Critical Steam Cycle n Reduced fuel cost due to improved thermal efficiency n Reduction of CO 2 emissions by 15% per unit of Power generated compared to sub-critical n Very good part load efficiencies n Plant costs are comparable with sub-critical units

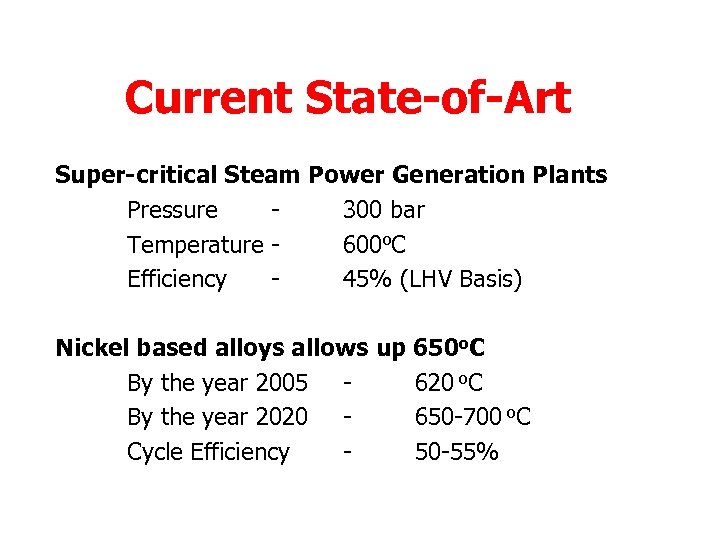

Current State-of-Art Super-critical Steam Power Generation Plants Pressure 300 bar Temperature 600 o. C Efficiency 45% (LHV Basis) Nickel based alloys allows up 650 o. C By the year 2005 620 o. C By the year 2020 650 -700 o. C Cycle Efficiency 50 -55%

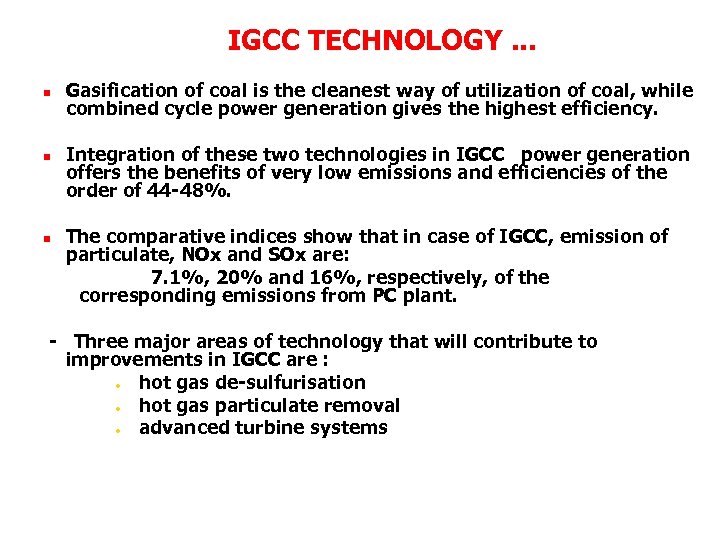

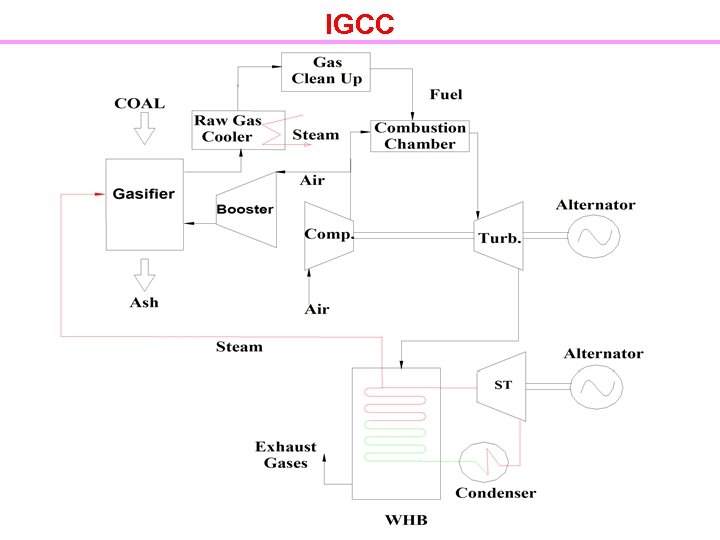

IGCC TECHNOLOGY. . . n n n Gasification of coal is the cleanest way of utilization of coal, while combined cycle power generation gives the highest efficiency. Integration of these two technologies in IGCC power generation offers the benefits of very low emissions and efficiencies of the order of 44 -48%. The comparative indices show that in case of IGCC, emission of particulate, NOx and SOx are: 7. 1%, 20% and 16%, respectively, of the corresponding emissions from PC plant. - Three major areas of technology that will contribute to improvements in IGCC are : · hot gas de-sulfurisation · hot gas particulate removal · advanced turbine systems

IGCC

Circulating fluidized Bed Combustion n Circulating Fluidized Bed Combustion (CFBC) technology has selectively been applied in India for firing high sulphur refinery residues, lignite, etc. CFBC Technology is superior to PC Power Plant Technology: n Lower NOx formation and the ability to capture SO 2 with limestone injection the furnace.

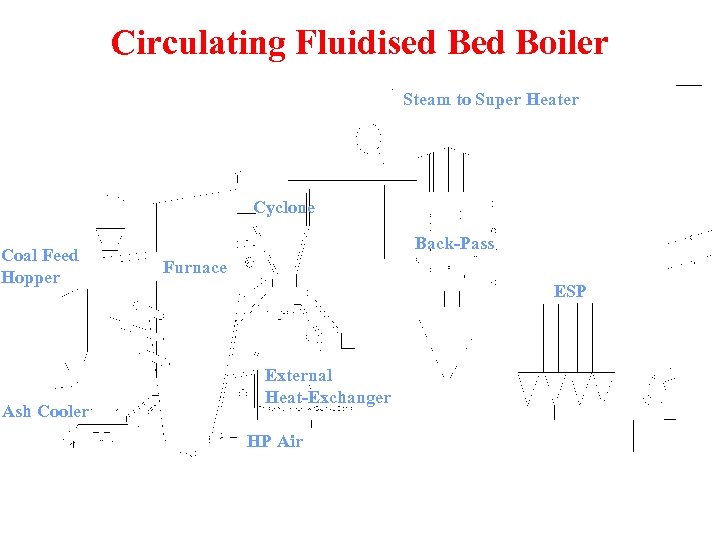

Circulating Fluidised Boiler Steam to Super Heater Cyclone Coal Feed Hopper Ash Cooler Back-Pass Furnace ESP External Heat-Exchanger HP Air

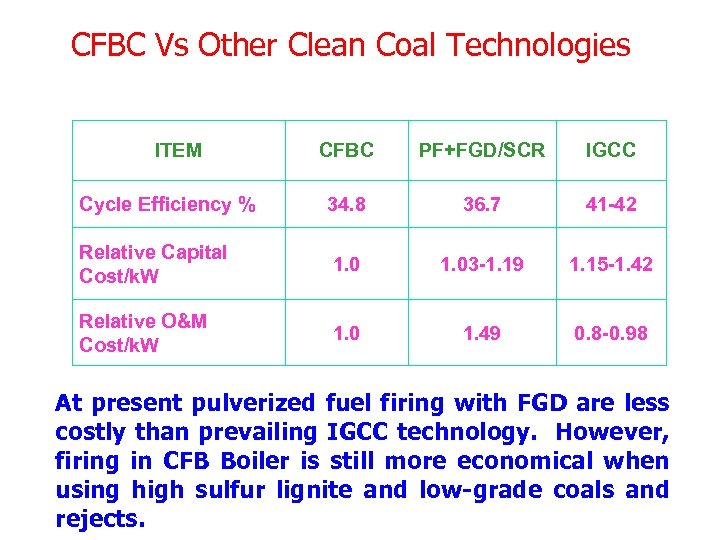

CFBC Vs Other Clean Coal Technologies ITEM CFBC PF+FGD/SCR IGCC Cycle Efficiency % 34. 8 36. 7 41 -42 Relative Capital Cost/k. W 1. 03 -1. 19 1. 15 -1. 42 Relative O&M Cost/k. W 1. 0 1. 49 0. 8 -0. 98 At present pulverized fuel firing with FGD are less costly than prevailing IGCC technology. However, firing in CFB Boiler is still more economical when using high sulfur lignite and low-grade coals and rejects.

Green Energy solutions Ø Promote CCT in countries like India & China where coal is main stay fuel for Power Generation. Ø Increased use of Advanced Fossil Fuel Technology Ø Energy Farming Ø Energy Efficiency Ø Major shift towards Green Technologies Ø Adoption of Renewable Energy Technologies in Rural Sector

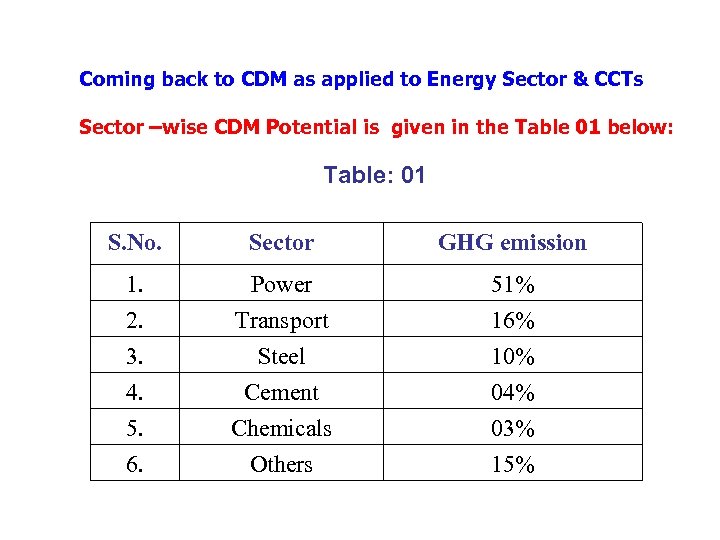

Coming back to CDM as applied to Energy Sector & CCTs Sector –wise CDM Potential is given in the Table 01 below: Table: 01 S. No. Sector GHG emission 1. 2. 3. Power Transport Steel 51% 16% 10% 4. 5. 6. Cement Chemicals Others 04% 03% 15%

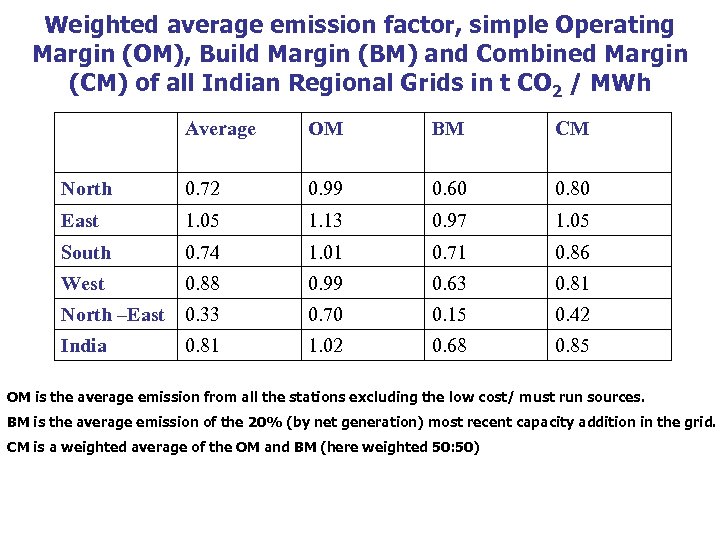

Weighted average emission factor, simple Operating Margin (OM), Build Margin (BM) and Combined Margin (CM) of all Indian Regional Grids in t CO 2 / MWh Average OM BM CM North 0. 72 0. 99 0. 60 0. 80 East 1. 05 1. 13 0. 97 1. 05 South 0. 74 1. 01 0. 71 0. 86 West 0. 88 0. 99 0. 63 0. 81 North –East 0. 33 0. 70 0. 15 0. 42 India 1. 02 0. 68 0. 85 0. 81 OM is the average emission from all the stations excluding the low cost/ must run sources. BM is the average emission of the 20% (by net generation) most recent capacity addition in the grid. CM is a weighted average of the OM and BM (here weighted 50: 50)

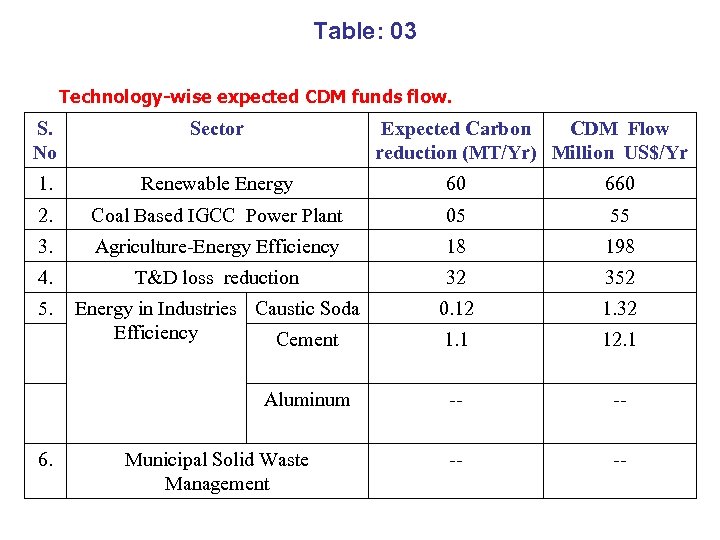

Table: 03 Technology-wise expected CDM funds flow. S. No Sector Expected Carbon CDM Flow reduction (MT/Yr) Million US$/Yr 1. Renewable Energy 60 660 2. Coal Based IGCC Power Plant 05 55 3. Agriculture-Energy Efficiency 18 198 4. T&D loss reduction 32 352 5. Energy in Industries Caustic Soda Efficiency Cement 0. 12 1. 32 1. 1 12. 1 -- -- Aluminum 6. Municipal Solid Waste Management

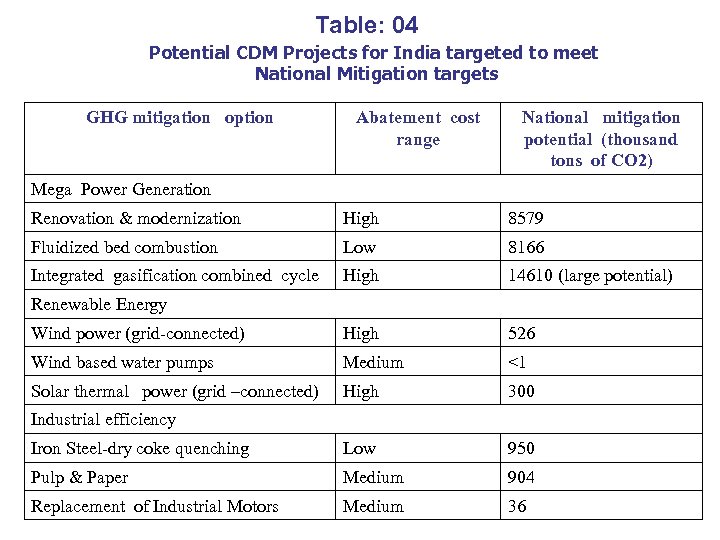

Table: 04 Potential CDM Projects for India targeted to meet National Mitigation targets GHG mitigation option Abatement cost range National mitigation potential (thousand tons of CO 2) Mega Power Generation Renovation & modernization High 8579 Fluidized bed combustion Low 8166 Integrated gasification combined cycle High 14610 (large potential) Wind power (grid-connected) High 526 Wind based water pumps Medium <1 Solar thermal power (grid –connected) High 300 Iron Steel-dry coke quenching Low 950 Pulp & Paper Medium 904 Replacement of Industrial Motors Medium 36 Renewable Energy Industrial efficiency

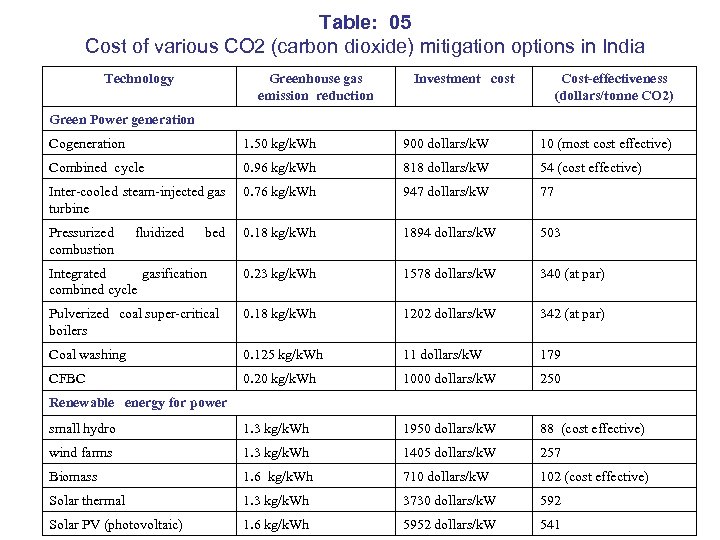

Table: 05 Cost of various CO 2 (carbon dioxide) mitigation options in India Technology Greenhouse gas emission reduction Investment cost Cost-effectiveness (dollars/tonne CO 2) Green Power generation Cogeneration 1. 50 kg/k. Wh 900 dollars/k. W 10 (most cost effective) Combined cycle 0. 96 kg/k. Wh 818 dollars/k. W 54 (cost effective) Inter-cooled steam-injected gas turbine 0. 76 kg/k. Wh 947 dollars/k. W 77 Pressurized combustion 0. 18 kg/k. Wh 1894 dollars/k. W 503 Integrated gasification combined cycle 0. 23 kg/k. Wh 1578 dollars/k. W 340 (at par) Pulverized coal super-critical boilers 0. 18 kg/k. Wh 1202 dollars/k. W 342 (at par) Coal washing 0. 125 kg/k. Wh 11 dollars/k. W 179 CFBC 0. 20 kg/k. Wh 1000 dollars/k. W 250 small hydro 1. 3 kg/k. Wh 1950 dollars/k. W 88 (cost effective) wind farms 1. 3 kg/k. Wh 1405 dollars/k. W 257 Biomass 1. 6 kg/k. Wh 710 dollars/k. W 102 (cost effective) Solar thermal 1. 3 kg/k. Wh 3730 dollars/k. W 592 Solar PV (photovoltaic) 1. 6 kg/k. Wh 5952 dollars/k. W 541 fluidized bed Renewable energy for power

Issues before the house n n n Technology break thoughts in the areas like CO 2 capture and Clean Coal Technologies Development of low cost solar photo voltaic cells Bringing Energy Efficiency & Energy Conservation on the top of the National Agenda Promotion of Carbon Trading on the strength of Energy Efficiency and Green Environment initiatives. Base line methodologies for variety of Clean and Green Technologies need to be redefined.

RGTU INITIATIVES Hybrid power plant of Wind, Solar & Biomass has been setup which will pave way for sustainable power supply for variety of biomass fuels & environment limitations. Biomass Gasifier (10 k. W) & Bio-diesel Plant (100 LPD) has been commissioned Green Energy Technology Center has been set up to focus on following areas: - Clean Coal Technology & CDM - Bio-fuels and bio-diesel Renewable Energy devices (hybrid) targeted to produce 1 MW Power for the campus - Energy Conservation & Management - CO 2 Sequestration & CO 2 capture technologies .

Impact Green Projects at RGTU n n n CO 2 Capture, Sequestration and Production of Multi-purpose fuels – Hydrogen, Methane and Biodiesel through Algae route Production of CNG from Coal–gasification route Solar, Wind & Biomass Hybrid System 60 k. W Solar-Wind Hybrid system at Hill top of RGTU High yield Jatropha plantation and Bio-diesel production using indigenously designed Bio-diesel reactors

c1270c2999d91949861a3e0dde88b066.ppt