48c1344bc0690be7b93e6959951ef190.ppt

- Количество слайдов: 45

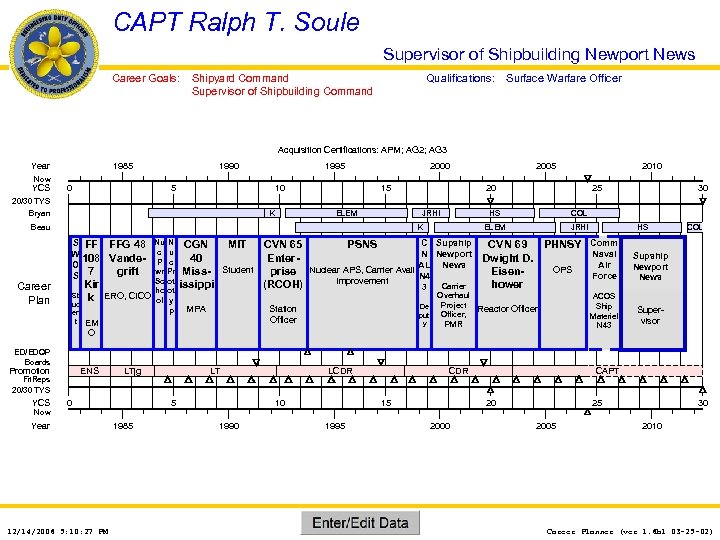

CAPT Ralph T. Soule Supervisor of Shipbuilding Newport News Career Goals: Shipyard Command Supervisor of Shipbuilding Command Qualifications: Surface Warfare Officer Acquisition Certifications: APM; AG 2; AG 3 Year Now YCS 1985 0 1990 5 1995 10 2000 15 2005 2010 20 25 30 20/30 TYS Bryan K ELEM JRHI Beau Career Plan S FF W 108 O S 7 St ud en t ED/EDQP Boards Promotion Now Kir k Nu N c u P c wr Pr Sc ot ho ot ERO, CICO ol y p FFG 48 Vandegrift 12/14/2006 5: 10: 27 PM HS MPA De put y Station Officer Overhaul Project Reactor Officer, PMR ACOS Ship Materiel N 43 COL Supship Newport News Supship Super. Newport visor News Supervisor LTjg 0 Year COL JRHI C Supship CGN MIT CVN 65 PSNS CVN 69 PHNSY Comm N Newport Dwight D. Naval 40 Enter. AL News Air OPS Miss- Student prise Nuclear APS, Carrier Avail N 4 Eisen. Force Improvement issippi (RCOH) hower Carrier 3 EM O ENS Fit. Reps 20/30 TYS YCS HS ELEM K LT 5 1985 LCDR 10 1990 CDR 15 1995 CAPT 20 2000 25 2005 30 2010 Career Planner (ver 1. 6 b 1 03 -25 -02)

UNCLAS Why You Should “Do” Carriers • The problems you encounter are really the Navy’s highest priorities. • The resource sponsors understand value maintenance. • While the problems are complex, you get great support and rapid attention. • Carriers have enough money to work ahead of most of their problems. UNCLAS 2

UNCLAS Career Planning Insight (Soule’s view) • Keep options open, 2 paths to O 6/Command as long as possible – No one path to O 6/Command • Performance will always be #1 factor • Develop the KSAs you need for future jobs, it’s not just about OJT – Always think one or two jobs ahead – Observe and get mentoring from senior officers – Personal development plan • Have fun! UNCLAS 3

CV/N Maintenance UNCLAS • Governance – Life Cycle Management Group • Management of Life Cycle material and programmatic issues – CV/N Team One • Manages the “white space” in the CV/N CNO availability process (planning and execution) UNCLAS 4

UNCLAS Current Interests and Reading UNCLAS 5

UNCLAS My Personal Development Themes • Leadership Development (of course!) • Human Performance Capabilities and Models • Systems Thinking • Safety Culture/High Reliability Organizations/Error Management • Risk (Crisis) Management/Failure Analysis • Distributed Cognition • Critical Thinking UNCLAS 6

Recent Reading UNCLAS • Recently finished – Irrationality, Sutherland – Safety at the Sharp End, Flinn et al – The Checklist Manifesto, Gwande – How the Mighty Fall, Collins UNCLAS 7

Current Reading UNCLAS • Power Rules, Gelb • 7 Deadly Scenarios, Krepinevich • Upgrade Your Life, Trapani UNCLAS 8

Suggested Reading UNCLAS • Havard Business Review – What Makes a Leader, Goleman – The Hidden Traps in Decision Making, Hammond et al – What You Don’t Know About Making Decisions – What Is Strategy? , Porter • The New Economics, Deming • Fifth Discipline, FD Fieldbook, Senge et al • Leadership and the Art of Communication, Krisco • Seven Habits, Covey • Getting Things Done, Allen • Managing the Unexpected, Weick • Intuition at Work, Klein • The New Rational Manager, Kepner-Tregoe • Becoming a Critical Thinker, Diestler • UNCLAS Boyd, Coram 9

UNCLAS JO Industrial Tour Success Strategies • Know your customers and what they value. • Read “Lean Thinking” and “The Toyota Way; ” think about where and why we fall short. • Read and understand the Shipyard Business Plan. • Get involved in Carrier or Sub Team One. • Update your career planner and always have available for "drive by career counseling" opportunities. You will get better mentoring if you frequently ask “Why do we …? ” • Complete all DAWIA quals possible during this tour. • Always be thinking about what you want to learn and get better at doing. What skill sets are you building for Navy problems? • If there is a Shipyard CO shadow program at your command, get on the schedule ASAP. UNCLAS 10

UNCLAS Decision Games/Case Studies • Running out of money in CVN RCOH • What to do when you realize your new construction ship is going to be late. UNCLAS 11

UNCLAS Recommended Reading • Managing the Unexpected • Asking the Right Questions • New Rational Manager • Intuiton at Work • The $5 B Misunderstanding • The Checklist Manifesto UNCLAS 12

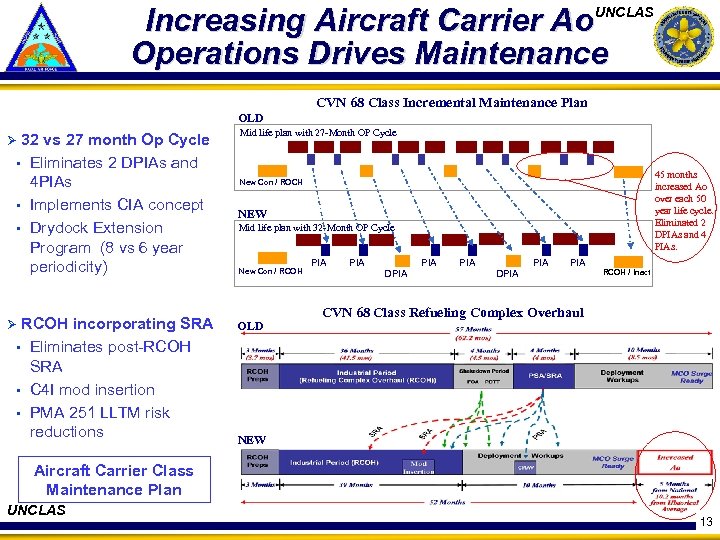

Increasing Aircraft Carrier Ao UNCLAS Operations Drives Maintenance CVN 68 Class Incremental Maintenance Plan OLD 32 vs 27 month Op Cycle • Eliminates 2 DPIAs and 4 PIAs • Implements CIA concept • Drydock Extension Program (8 vs 6 year periodicity) Ø RCOH incorporating SRA • Eliminates post-RCOH SRA • C 4 I mod insertion • PMA 251 LLTM risk reductions Ø Mid life plan with 27 -Month OP Cycle 45 months increased Ao over each 50 year life cycle. Eliminated 2 DPIAs and 4 PIAs. New Con / ROCH NEW Mid life plan with 32 -Month OP Cycle New Con / RCOH OLD PIA PIA DPIA PIA RCOH / Inact CVN 68 Class Refueling Complex Overhaul NEW Aircraft Carrier Class Maintenance Plan UNCLAS 13

UNCLAS Supervisors of Shipbuilding UNCLAS 14

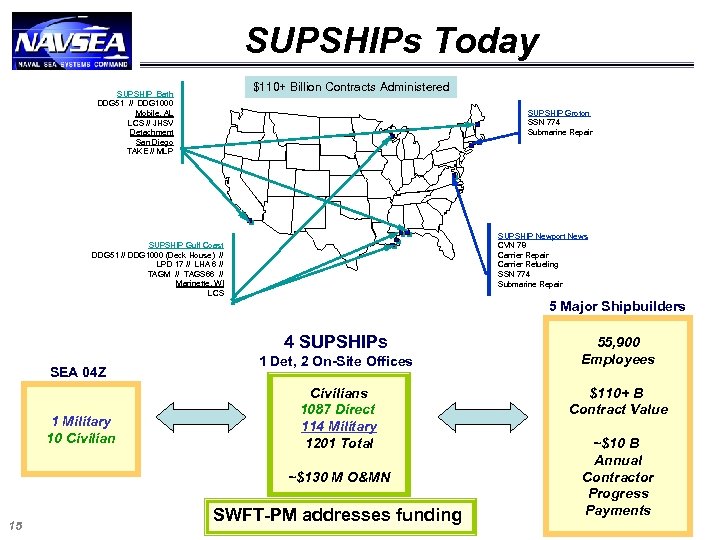

SUPSHIPs Today $110+ Billion Contracts Administered SUPSHIP Bath DDG 51 // DDG 1000 Mobile, AL LCS // JHSV Detachment San Diego TAKE // MLP SUPSHIP Groton SSN 774 Submarine Repair SUPSHIP Newport News CVN 78 Carrier Repair Carrier Refueling SSN 774 Submarine Repair SUPSHIP Gulf Coast DDG 51 // DDG 1000 (Deck House) // LPD 17 // LHA 6 // TAGM // TAGS 66 // Marinette, WI LCS 5 Major Shipbuilders 4 SUPSHIPs SEA 04 Z 1 Military 10 Civilian 1 Det, 2 On-Site Offices Civilians 1087 Direct 114 Military 1201 Total ~$130 M O&MN 15 SWFT-PM addresses funding 55, 900 Employees $110+ B Contract Value ~$10 B Annual Contractor Progress Payments

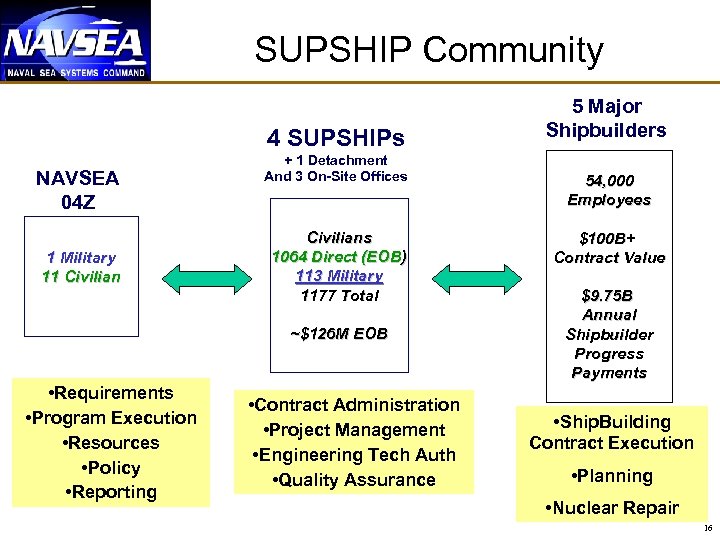

SUPSHIP Community 4 SUPSHIPs NAVSEA 04 Z 1 Military 11 Civilian + 1 Detachment And 3 On-Site Offices Civilians 1064 Direct (EOB) 113 Military 1177 Total ~$126 M EOB • Requirements • Program Execution • Resources • Policy • Reporting • Contract Administration • Project Management • Engineering Tech Auth • Quality Assurance 5 Major Shipbuilders 54, 000 Employees $100 B+ Contract Value $9. 75 B Annual Shipbuilder Progress Payments • Ship. Building Contract Execution • Planning • Nuclear Repair 16

SUPSHIP Functions · Traditional Contract Management Functions: - Administrative Contracting Officer Naval Supervisory Authority NAVSEA field engineering Program management Quality Assurance for key shipbuilder processes · Non-traditional Functions: § § § Field Pricing Support for new contracts Customer interface Solution facilitation Program management interface Program reviews Work Integration of non NGSB contractors 17

SUPSHIPNN Mission and Goals § Mission of SUPSHIP Newport News § Administer contracts for new ship construction, overhauls, and conversion § Execute NAVSEA contractual, technical, and fiduciary responsibilities § Program management and technical oversight of ship construction and repair (NSA responsibilities) § Command Goals § Inspect to get what the gov’t expects § Improve mission capability § Support lower cost of production Assure that NGSB NN adheres to Navy contracts and provide onsite technical/program support between NGSNN and Navy activities. 18

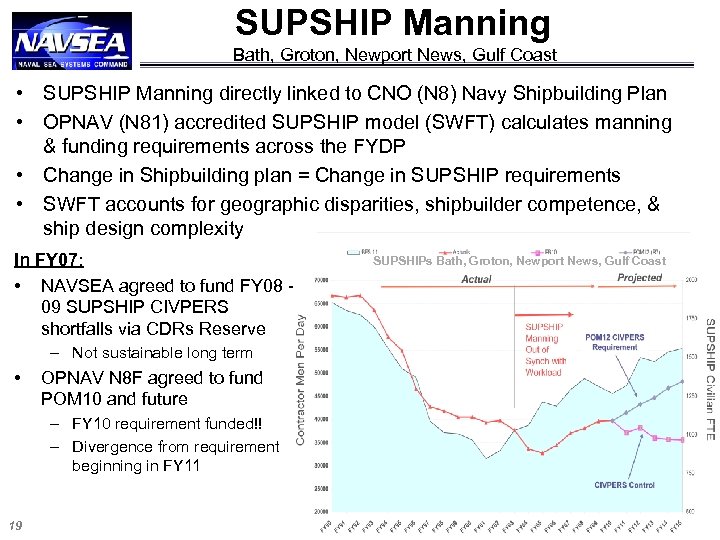

SUPSHIP Manning Bath, Groton, Newport News, Gulf Coast • SUPSHIP Manning directly linked to CNO (N 8) Navy Shipbuilding Plan • OPNAV (N 81) accredited SUPSHIP model (SWFT) calculates manning & funding requirements across the FYDP • Change in Shipbuilding plan = Change in SUPSHIP requirements • SWFT accounts for geographic disparities, shipbuilder competence, & ship design complexity In FY 07: • NAVSEA agreed to fund FY 08 09 SUPSHIP CIVPERS shortfalls via CDRs Reserve – Not sustainable long term • OPNAV N 8 F agreed to fund POM 10 and future – FY 10 requirement funded!! – Divergence from requirement beginning in FY 11 19 SUPSHIPs Bath, Groton, Newport News, Gulf Coast

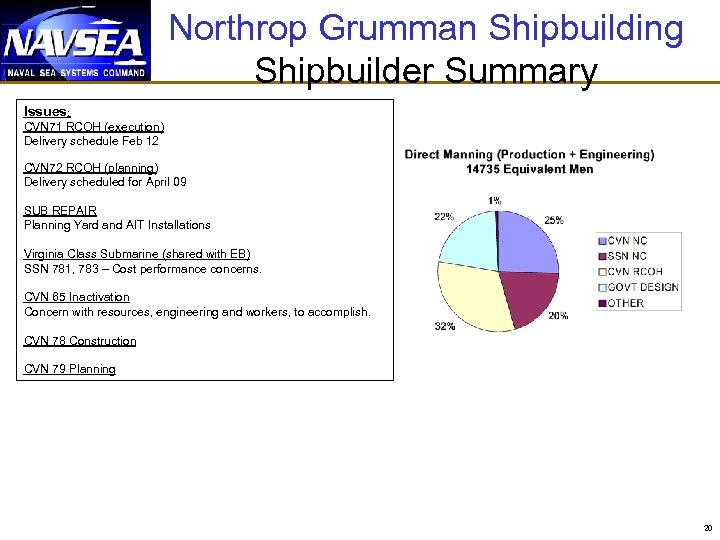

Northrop Grumman Shipbuilding Shipbuilder Summary Issues: CVN 71 RCOH (execution) Delivery schedule Feb 12 CVN 72 RCOH (planning) Delivery scheduled for April 09 SUB REPAIR Planning Yard and AIT Installations Virginia Class Submarine (shared with EB) SSN 781, 783 – Cost performance concerns. CVN 65 Inactivation Concern with resources, engineering and workers, to accomplish. CVN 78 Construction CVN 79 Planning 20

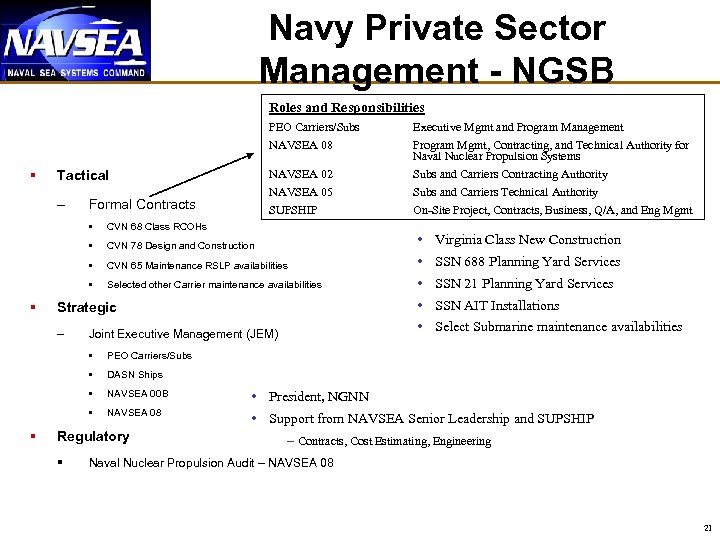

Navy Private Sector Management - NGSB Roles and Responsibilities PEO Carriers/Subs NAVSEA 08 § NAVSEA 02 – Subs and Carriers Technical Authority SUPSHIP Formal Contracts Subs and Carriers Contracting Authority NAVSEA 05 Tactical Executive Mgmt and Program Management Program Mgmt, Contracting, and Technical Authority for Naval Nuclear Propulsion Systems On-Site Project, Contracts, Business, Q/A, and Eng Mgmt • • CVN 78 Design and Construction • Virginia Class New Construction • CVN 65 Maintenance RSLP availabilities • SSN 688 Planning Yard Services • § CVN 68 Class RCOHs Selected other Carrier maintenance availabilities • SSN 21 Planning Yard Services • SSN AIT Installations Strategic – • Select Submarine maintenance availabilities Joint Executive Management (JEM) • • DASN Ships • NAVSEA 00 B • President, NGNN • § PEO Carriers/Subs NAVSEA 08 • Support from NAVSEA Senior Leadership and SUPSHIP Regulatory § – Contracts, Cost Estimating, Engineering Naval Nuclear Propulsion Audit – NAVSEA 08 21

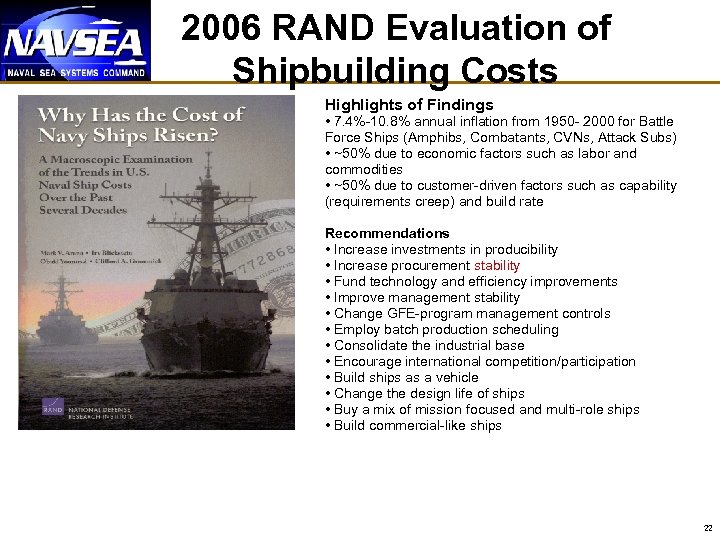

2006 RAND Evaluation of Shipbuilding Costs Highlights of Findings • 7. 4%-10. 8% annual inflation from 1950 - 2000 for Battle Force Ships (Amphibs, Combatants, CVNs, Attack Subs) • ~50% due to economic factors such as labor and commodities • ~50% due to customer-driven factors such as capability (requirements creep) and build rate Recommendations • Increase investments in producibility • Increase procurement stability • Fund technology and efficiency improvements • Improve management stability • Change GFE-program management controls • Employ batch production scheduling • Consolidate the industrial base • Encourage international competition/participation • Build ships as a vehicle • Change the design life of ships • Buy a mix of mission focused and multi-role ships • Build commercial-like ships 22

Affordability of the 313 Ship Navy § The Navy currently builds 4 -6 ships per year at a cost of $8. 9 billion § Navy needs to build 200 ships over the next 20 years at a average annual cost of $14 billion (forty percent increase above the current budget). § Navy assumes no real growth in the Navy's top line —how can we buy the ships we need? § Lower maintenance costs for in service ships § No cost growth: personnel, ship cost, operations § Increased commonality between ship classes at the component level 23

Other Navy Shipbuilding Challenges § Maintaining the industrial base § Current ship designs are too expensive for the funds available § Cost growth on lead ships of a class § Lifecycle support costs of all weapons systems and platforms are on unsustainable trend lines 24

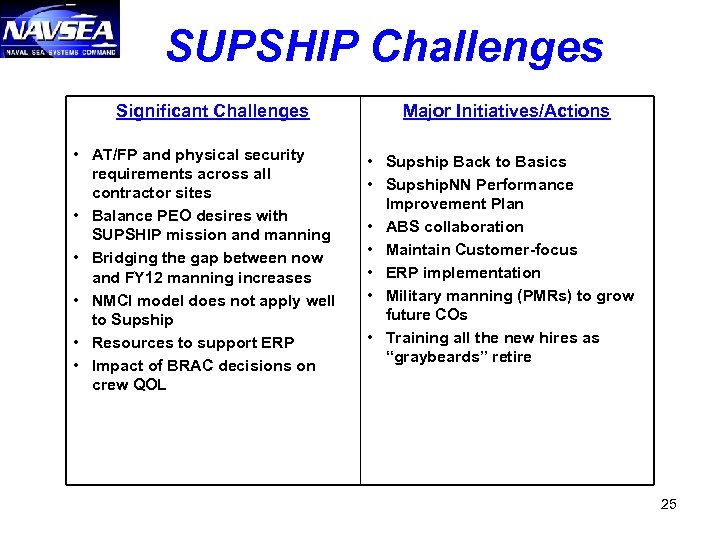

SUPSHIP Challenges Significant Challenges • AT/FP and physical security requirements across all contractor sites • Balance PEO desires with SUPSHIP mission and manning • Bridging the gap between now and FY 12 manning increases • NMCI model does not apply well to Supship • Resources to support ERP • Impact of BRAC decisions on crew QOL Major Initiatives/Actions • Supship Back to Basics • Supship. NN Performance Improvement Plan • ABS collaboration • Maintain Customer-focus • ERP implementation • Military manning (PMRs) to grow future COs • Training all the new hires as “graybeards” retire 25

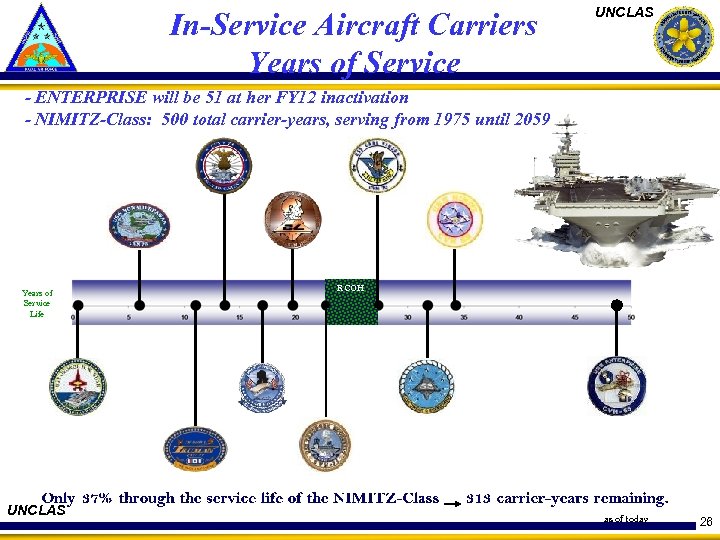

In-Service Aircraft Carriers Years of Service UNCLAS - ENTERPRISE will be 51 at her FY 12 inactivation - NIMITZ-Class: 500 total carrier-years, serving from 1975 until 2059 Years of Service Life UNCLAS RCOH as of today 26

CDRs Conference Task SUPSHIP Health: Back to Basics • Implement Actions to make SUPSHIPs a more proactive organization in driving quality performance and execution at private shipyards Lead: SEA 04/Vice Commander NAVSEA 27

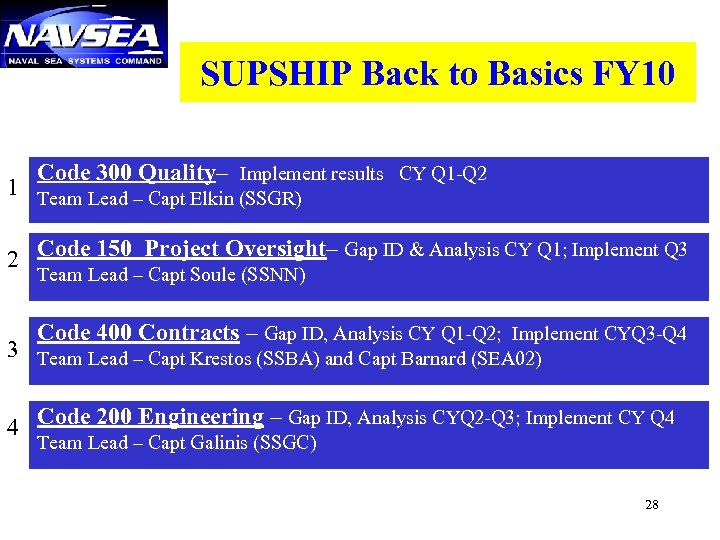

SUPSHIP Back to Basics FY 10 Code 300 Quality– Implement results CY Q 1 -Q 2 1 Team Lead – Capt Elkin (SSGR) 2 Code 150 Project Oversight– Gap ID & Analysis CY Q 1; Implement Q 3 Team Lead – Capt Soule (SSNN) Code 400 Contracts – Gap ID, Analysis CY Q 1 -Q 2; Implement CYQ 3 -Q 4 3 Team Lead – Capt Krestos (SSBA) and Capt Barnard (SEA 02) 4 Code 200 Engineering – Gap ID, Analysis CYQ 2 -Q 3; Implement CY Q 4 Team Lead – Capt Galinis (SSGC) 28

SUPSHIP Back to Basics 1. C 300 Quality Improvement - Implement CY 2010 Q 1 -2 • Chain of Accountability: • • • Changing waterfront behavior on a daily basis • • • Develop and implement a structured QA planning process Standardized CAR process Documented QA standards/requirements Ensure safe and reliable operations Clearly identify, communicate and follow up with the shipbuilders defects and corrective actions Ship Quality Metric reporting by Class, hull, CCP, sector • • Better engagement with Shipbuilder/PEO/SEA 04/SEA 00 Audits and oversight of Shipbuilder’s Quality Management Systems (QMS) • 2. SEA 04 QA Audits of SUPSHIPs (note: completed 2 SUPSHIPs and 2 Det to date) SUPSHIP Code 300 Audit of Shipbuilder QMS Major shift toward Process Evaluation (PE) vice Product Verification Inspection (PVI) C 150 Project Management Improvement - Gap ID CY 2010 Q 1 • • Better Cost/Schedule Performance Analysis (EVM) Change Management Enhance Project Analysis & Reporting Better engagement with Shipbuilder/PEO on Project Mgmt & Tech Issues • • Quality Data Schedule Analysis Tracking and resolving Open Issues Readiness for Milestones Reassert the role of the "Supervisor" of Shipbuilding • Give the PMs the “Story behind the Story” 29

SUPSHIP Back to Basics 3. C 400 Contracts Improvement - Gap ID CY 2010 Q 1 -2 • Improve Selected Shipbuilding Contract Clauses, SEA 02/PEO/SUPSHIP • • 4. Streamlined way of doing business for Shipbuilder & SUPSHIP Shipbuilder's Cost/Schedule Performance Analysis (EVM) C 200 Engineering Improvement - Gap ID CY 2010 Q 3 • Revitalize Waterfront Engineering Organization • • More time on the ships Collaboration with SUPSHIP Code 300 Quality team Focus on quicker decisions (more local decisions, faster TWH decision cycle time) Refine Tech Authority workload during design & construction phase • Clear definition of responsibilities for Code 200 30

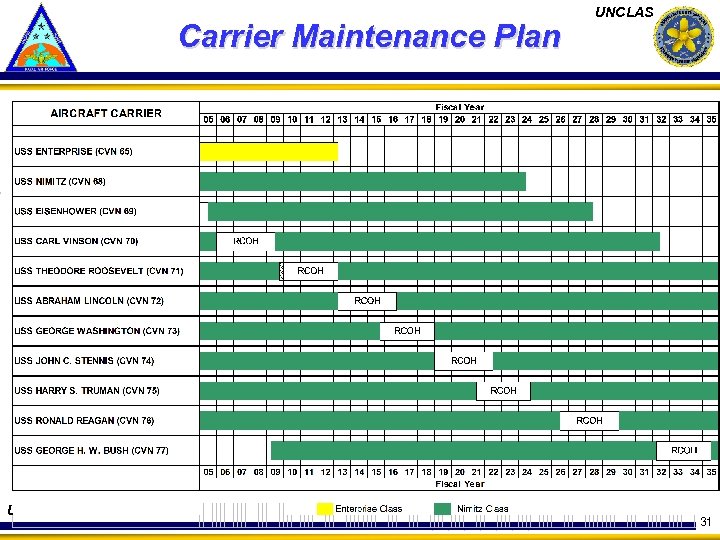

Carrier Maintenance Plan UNCLAS 31

Summary Roles of SUPSHIP ACO, NSA, Tech Authority, Quality Assurance Contract delineates requirement Unfunded Reqts – Contract Change On Site Govt Representatives Program Office, NAVSEA, Fleet, Govt Vendors SUPSHIP commands cannot easily grow/contract for workload Crew Support - Ship’s Force is often caught in the middle of repair/construction problems. SUPSHIP has to be prepared to stand up for the things they need to be successful 32

UNCLAS Questions UNCLAS 33

Backup Check out my blog at: www. rtsoule. squarespace. com 34

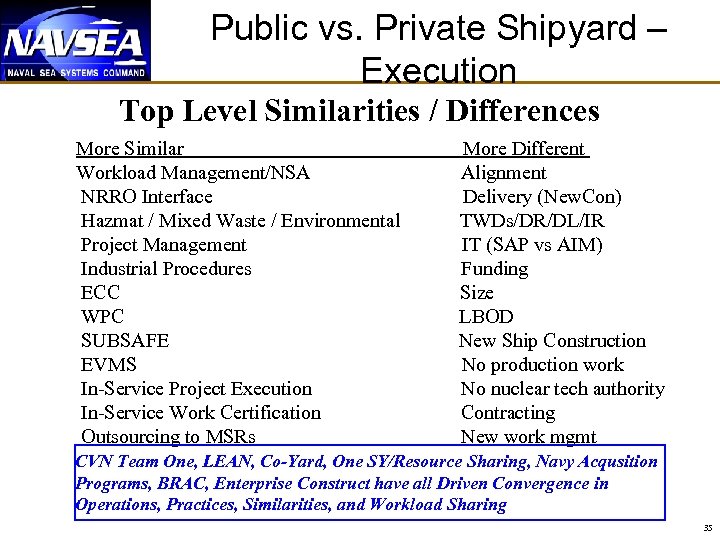

Public vs. Private Shipyard – Execution Top Level Similarities / Differences More Similar Workload Management/NSA NRRO Interface Hazmat / Mixed Waste / Environmental Project Management Industrial Procedures ECC WPC SUBSAFE EVMS In-Service Project Execution In-Service Work Certification Outsourcing to MSRs More Different Alignment Delivery (New. Con) TWDs/DR/DL/IR IT (SAP vs AIM) Funding Size LBOD New Ship Construction No production work No nuclear tech authority Contracting New work mgmt CVN Team One, LEAN, Co-Yard, One SY/Resource Sharing, Navy Acqusition Programs, BRAC, Enterprise Construct have all Driven Convergence in Operations, Practices, Similarities, and Workload Sharing 35

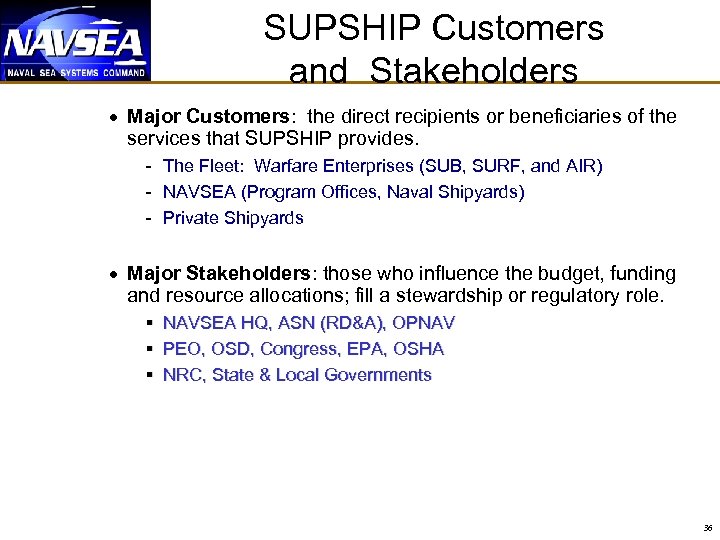

SUPSHIP Customers and Stakeholders · Major Customers: the direct recipients or beneficiaries of the services that SUPSHIP provides. - The Fleet: Warfare Enterprises (SUB, SURF, and AIR) - NAVSEA (Program Offices, Naval Shipyards) - Private Shipyards · Major Stakeholders: those who influence the budget, funding and resource allocations; fill a stewardship or regulatory role. § NAVSEA HQ, ASN (RD&A), OPNAV § PEO, OSD, Congress, EPA, OSHA § NRC, State & Local Governments 36

SUPSHIP Back to Basics Tasking #1 Affirmation of the Supervisors of Shipbuilding Role 37

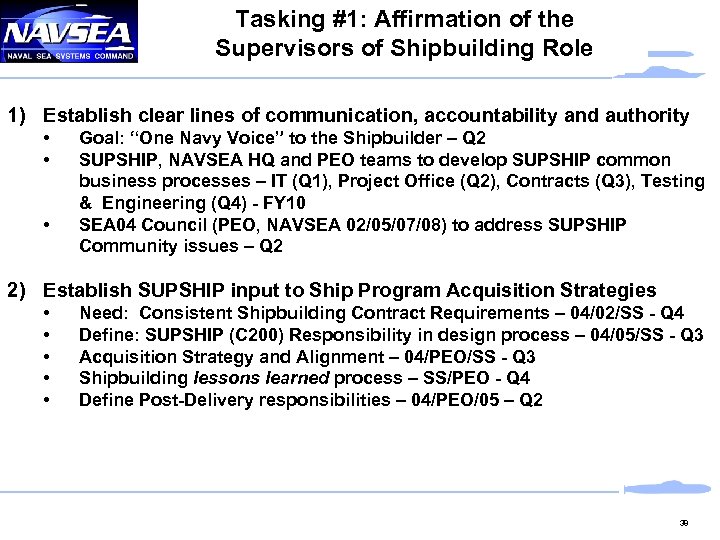

Tasking #1: Affirmation of the Supervisors of Shipbuilding Role 1) Establish clear lines of communication, accountability and authority • • • Goal: “One Navy Voice” to the Shipbuilder – Q 2 SUPSHIP, NAVSEA HQ and PEO teams to develop SUPSHIP common business processes – IT (Q 1), Project Office (Q 2), Contracts (Q 3), Testing & Engineering (Q 4) - FY 10 SEA 04 Council (PEO, NAVSEA 02/05/07/08) to address SUPSHIP Community issues – Q 2 2) Establish SUPSHIP input to Ship Program Acquisition Strategies • • • Need: Consistent Shipbuilding Contract Requirements – 04/02/SS - Q 4 Define: SUPSHIP (C 200) Responsibility in design process – 04/05/SS - Q 3 Acquisition Strategy and Alignment – 04/PEO/SS - Q 3 Shipbuilding lessons learned process – SS/PEO - Q 4 Define Post-Delivery responsibilities – 04/PEO/05 – Q 2 38

SUPSHIP Back to Basics Tasking #2 Standardize SUPSHIP Organization and Functions 39

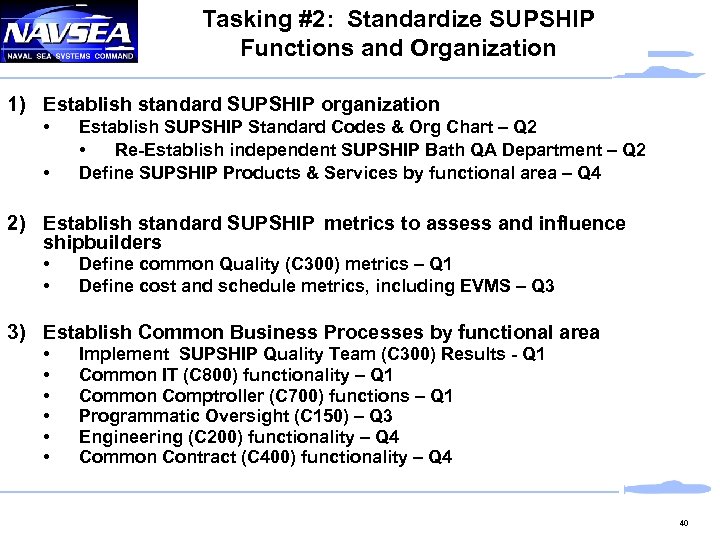

Tasking #2: Standardize SUPSHIP Functions and Organization 1) Establish standard SUPSHIP organization • • Establish SUPSHIP Standard Codes & Org Chart – Q 2 • Re-Establish independent SUPSHIP Bath QA Department – Q 2 Define SUPSHIP Products & Services by functional area – Q 4 2) Establish standard SUPSHIP metrics to assess and influence shipbuilders • • Define common Quality (C 300) metrics – Q 1 Define cost and schedule metrics, including EVMS – Q 3 3) Establish Common Business Processes by functional area • • • Implement SUPSHIP Quality Team (C 300) Results - Q 1 Common IT (C 800) functionality – Q 1 Common Comptroller (C 700) functions – Q 1 Programmatic Oversight (C 150) – Q 3 Engineering (C 200) functionality – Q 4 Common Contract (C 400) functionality – Q 4 40

SUPSHIP Back to Basics Tasking #3 Ensure SUPSHIP resources ($$ and People) are properly allocated 41

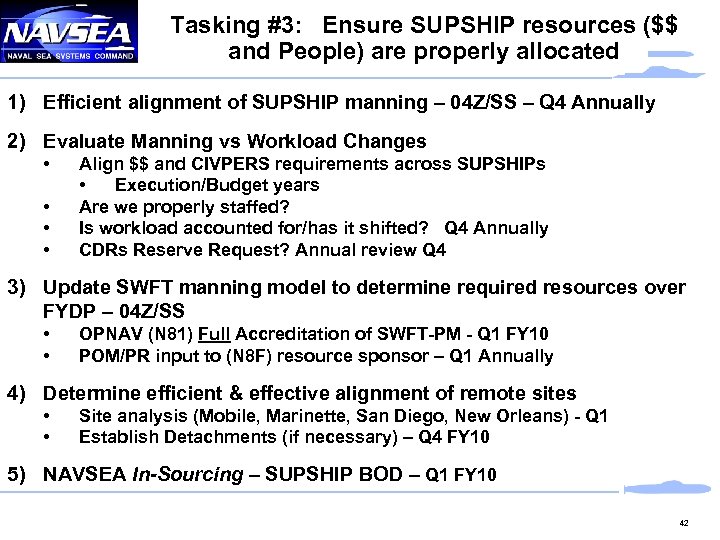

Tasking #3: Ensure SUPSHIP resources ($$ and People) are properly allocated 1) Efficient alignment of SUPSHIP manning – 04 Z/SS – Q 4 Annually 2) Evaluate Manning vs Workload Changes • • Align $$ and CIVPERS requirements across SUPSHIPs • Execution/Budget years Are we properly staffed? Is workload accounted for/has it shifted? Q 4 Annually CDRs Reserve Request? Annual review Q 4 3) Update SWFT manning model to determine required resources over FYDP – 04 Z/SS • • OPNAV (N 81) Full Accreditation of SWFT-PM - Q 1 FY 10 POM/PR input to (N 8 F) resource sponsor – Q 1 Annually 4) Determine efficient & effective alignment of remote sites • • Site analysis (Mobile, Marinette, San Diego, New Orleans) - Q 1 Establish Detachments (if necessary) – Q 4 FY 10 5) NAVSEA In-Sourcing – SUPSHIP BOD – Q 1 FY 10 42

SUPSHIP Back to Basics Tasking #4 Recruit, hire, train and retain the talent needed at the SUPSHIPs 43

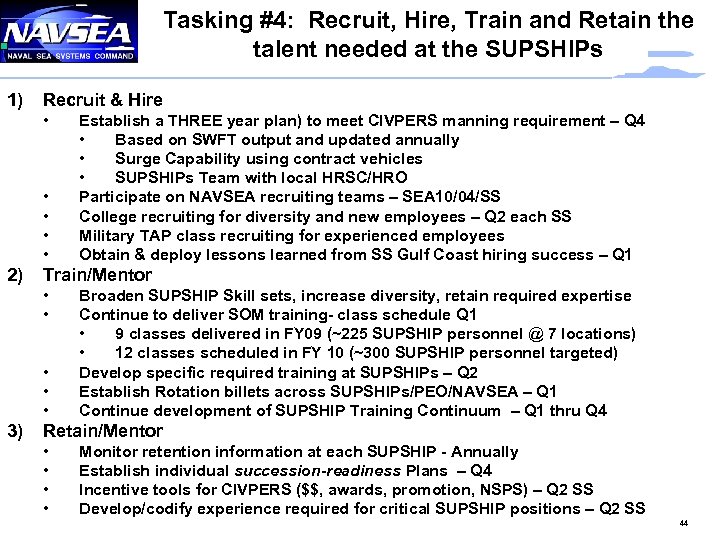

Tasking #4: Recruit, Hire, Train and Retain the talent needed at the SUPSHIPs 1) Recruit & Hire • • • 2) Train/Mentor • • • 3) Establish a THREE year plan) to meet CIVPERS manning requirement – Q 4 • Based on SWFT output and updated annually • Surge Capability using contract vehicles • SUPSHIPs Team with local HRSC/HRO Participate on NAVSEA recruiting teams – SEA 10/04/SS College recruiting for diversity and new employees – Q 2 each SS Military TAP class recruiting for experienced employees Obtain & deploy lessons learned from SS Gulf Coast hiring success – Q 1 Broaden SUPSHIP Skill sets, increase diversity, retain required expertise Continue to deliver SOM training- class schedule Q 1 • 9 classes delivered in FY 09 (~225 SUPSHIP personnel @ 7 locations) • 12 classes scheduled in FY 10 (~300 SUPSHIP personnel targeted) Develop specific required training at SUPSHIPs – Q 2 Establish Rotation billets across SUPSHIPs/PEO/NAVSEA – Q 1 Continue development of SUPSHIP Training Continuum – Q 1 thru Q 4 Retain/Mentor • • Monitor retention information at each SUPSHIP - Annually Establish individual succession-readiness Plans – Q 4 Incentive tools for CIVPERS ($$, awards, promotion, NSPS) – Q 2 SS Develop/codify experience required for critical SUPSHIP positions – Q 2 SS 44

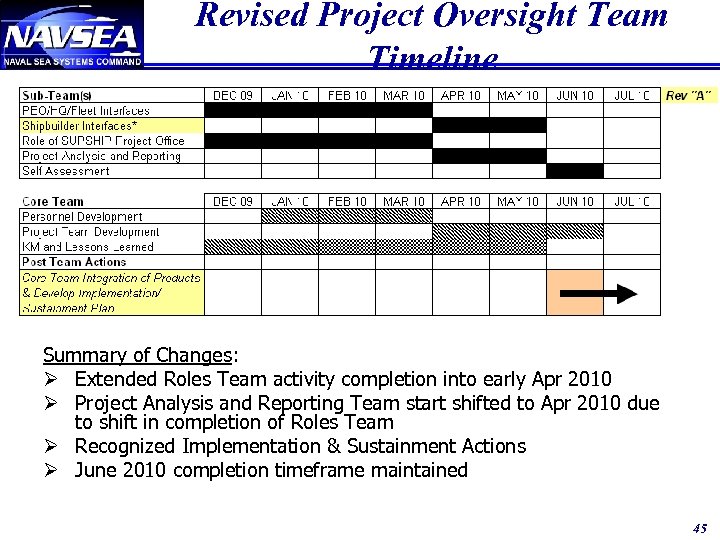

Revised Project Oversight Team Timeline Summary of Changes: Ø Extended Roles Team activity completion into early Apr 2010 Ø Project Analysis and Reporting Team start shifted to Apr 2010 due to shift in completion of Roles Team Ø Recognized Implementation & Sustainment Actions Ø June 2010 completion timeframe maintained 45

48c1344bc0690be7b93e6959951ef190.ppt