d5a272e987414b6dcf9a667441ff2bb2.ppt

- Количество слайдов: 16

Capitalizing on Self-Desiccation for Autogenous Distribution of Chemical Admixtures Dale P. Bentz 4 th International Seminar on Self. Desiccation in Concrete June 20, 2005

Background • Self-desiccation due to chemical shrinkage results in: – Reduction in internal RH – Creation of capillary stresses in the pore solution – Reduction in achieved degree of hydration relative to saturated curing – Measurable autogenous deformation – Possible (micro)cracking at early (and later) ages

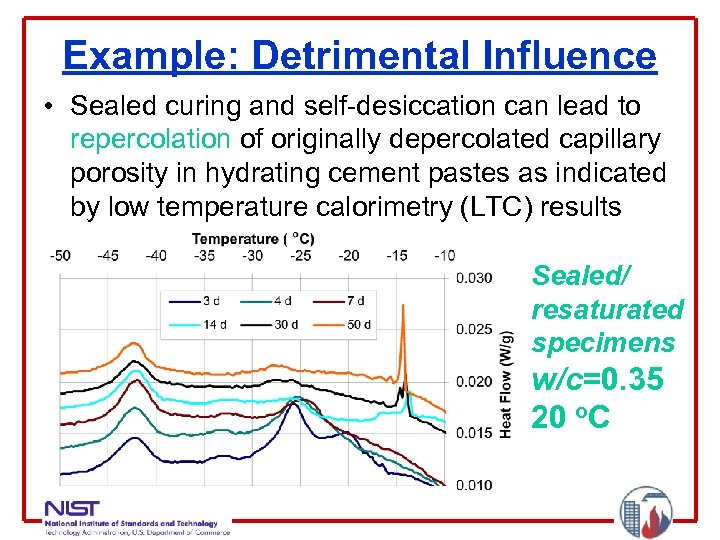

Example: Detrimental Influence • Sealed curing and self-desiccation can lead to repercolation of originally depercolated capillary porosity in hydrating cement pastes as indicated by low temperature calorimetry (LTC) results Sealed/ resaturated specimens w/c=0. 35 20 o. C

Some Possible Benefits of Self. Desiccation • Earlier application of flooring materials (Persson, 2002) • Increased frost resistance (Powers, 1947) • Offsetting thermal expansion at early ages (Swayze, 1942) • Earlier depercolation of capillary porosity for intermediate w/c ratios (0. 40 to 0. 45) • Autogenous distribution of chemical admixtures

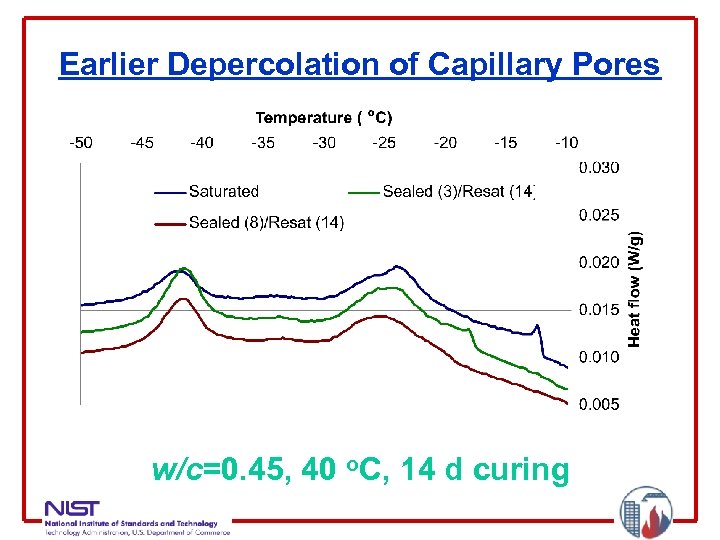

Earlier Depercolation of Capillary Pores w/c=0. 45, 40 o. C, 14 d curing

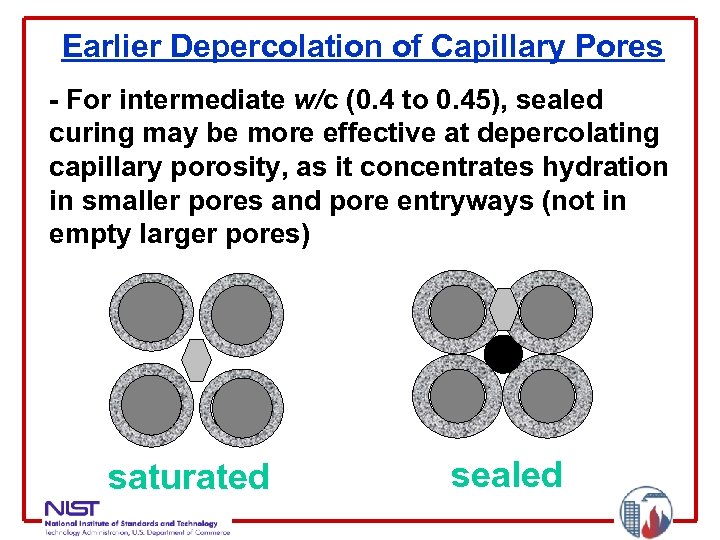

Earlier Depercolation of Capillary Pores - For intermediate w/c (0. 4 to 0. 45), sealed curing may be more effective at depercolating capillary porosity, as it concentrates hydration in smaller pores and pore entryways (not in empty larger pores) saturated sealed

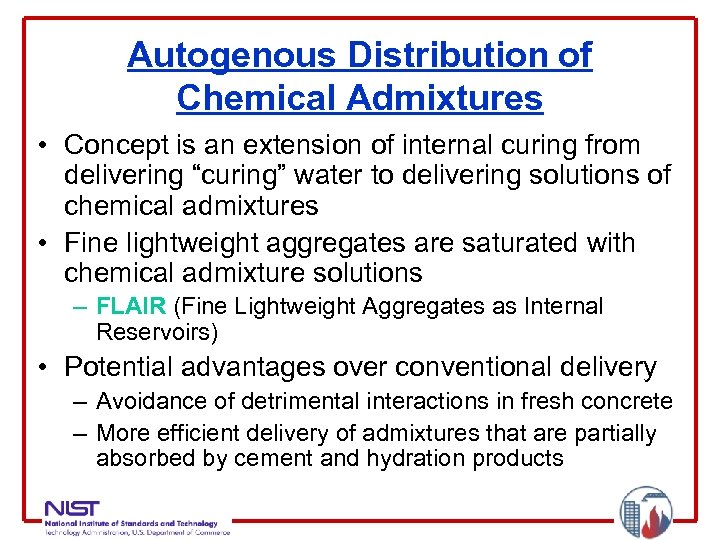

Autogenous Distribution of Chemical Admixtures • Concept is an extension of internal curing from delivering “curing” water to delivering solutions of chemical admixtures • Fine lightweight aggregates are saturated with chemical admixture solutions – FLAIR (Fine Lightweight Aggregates as Internal Reservoirs) • Potential advantages over conventional delivery – Avoidance of detrimental interactions in fresh concrete – More efficient delivery of admixtures that are partially absorbed by cement and hydration products

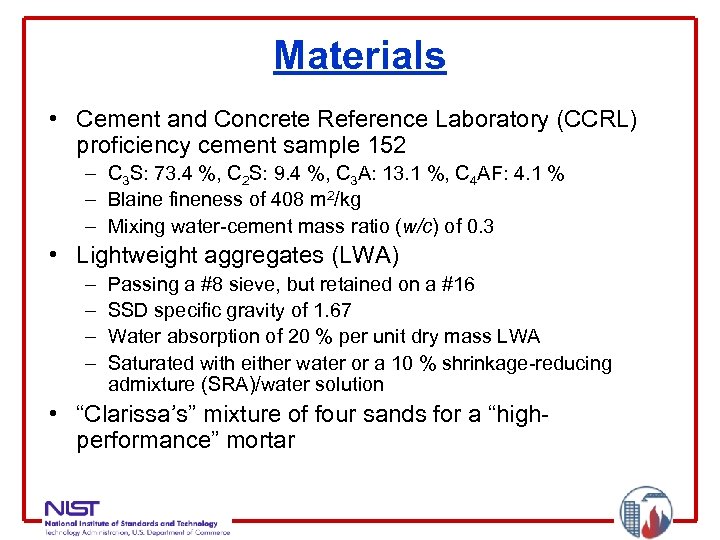

Materials • Cement and Concrete Reference Laboratory (CCRL) proficiency cement sample 152 – C 3 S: 73. 4 %, C 2 S: 9. 4 %, C 3 A: 13. 1 %, C 4 AF: 4. 1 % – Blaine fineness of 408 m 2/kg – Mixing water-cement mass ratio (w/c) of 0. 3 • Lightweight aggregates (LWA) – – Passing a #8 sieve, but retained on a #16 SSD specific gravity of 1. 67 Water absorption of 20 % per unit dry mass LWA Saturated with either water or a 10 % shrinkage-reducing admixture (SRA)/water solution • “Clarissa’s” mixture of four sands for a “highperformance” mortar

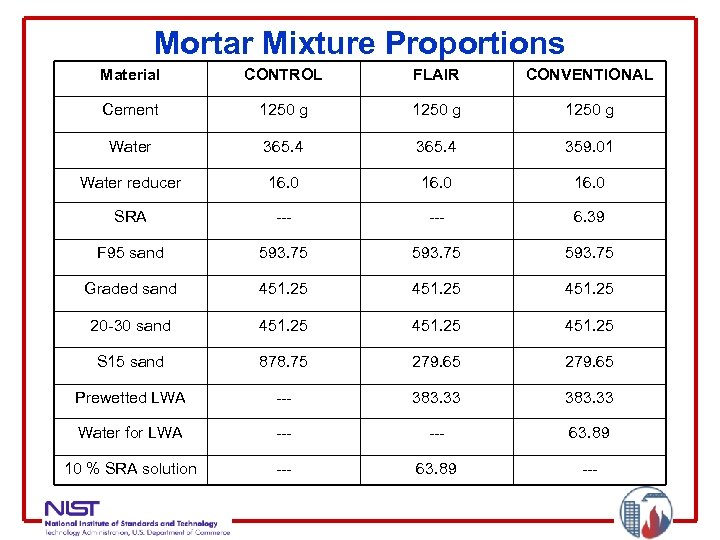

Mortar Mixture Proportions Material CONTROL FLAIR CONVENTIONAL Cement 1250 g Water 365. 4 359. 01 Water reducer 16. 0 SRA --- 6. 39 F 95 sand 593. 75 Graded sand 451. 25 20 -30 sand 451. 25 S 15 sand 878. 75 279. 65 Prewetted LWA --- 383. 33 Water for LWA --- 63. 89 10 % SRA solution --- 63. 89 ---

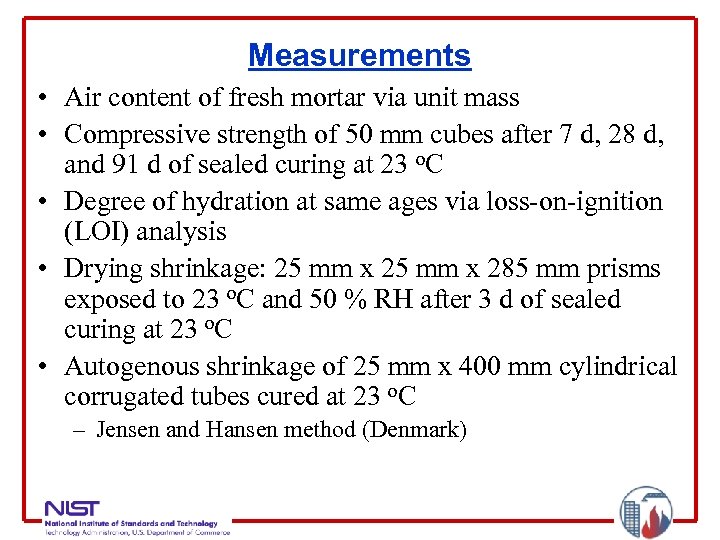

Measurements • Air content of fresh mortar via unit mass • Compressive strength of 50 mm cubes after 7 d, 28 d, and 91 d of sealed curing at 23 o. C • Degree of hydration at same ages via loss-on-ignition (LOI) analysis • Drying shrinkage: 25 mm x 285 mm prisms exposed to 23 o. C and 50 % RH after 3 d of sealed curing at 23 o. C • Autogenous shrinkage of 25 mm x 400 mm cylindrical corrugated tubes cured at 23 o. C – Jensen and Hansen method (Denmark)

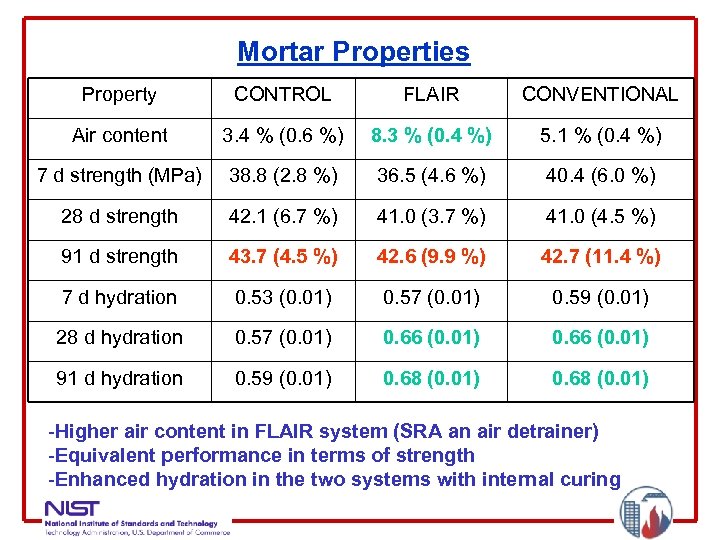

Mortar Properties Property CONTROL FLAIR CONVENTIONAL Air content 3. 4 % (0. 6 %) 8. 3 % (0. 4 %) 5. 1 % (0. 4 %) 7 d strength (MPa) 38. 8 (2. 8 %) 36. 5 (4. 6 %) 40. 4 (6. 0 %) 28 d strength 42. 1 (6. 7 %) 41. 0 (3. 7 %) 41. 0 (4. 5 %) 91 d strength 43. 7 (4. 5 %) 42. 6 (9. 9 %) 42. 7 (11. 4 %) 7 d hydration 0. 53 (0. 01) 0. 57 (0. 01) 0. 59 (0. 01) 28 d hydration 0. 57 (0. 01) 0. 66 (0. 01) 91 d hydration 0. 59 (0. 01) 0. 68 (0. 01) -Higher air content in FLAIR system (SRA an air detrainer) -Equivalent performance in terms of strength -Enhanced hydration in the two systems with internal curing

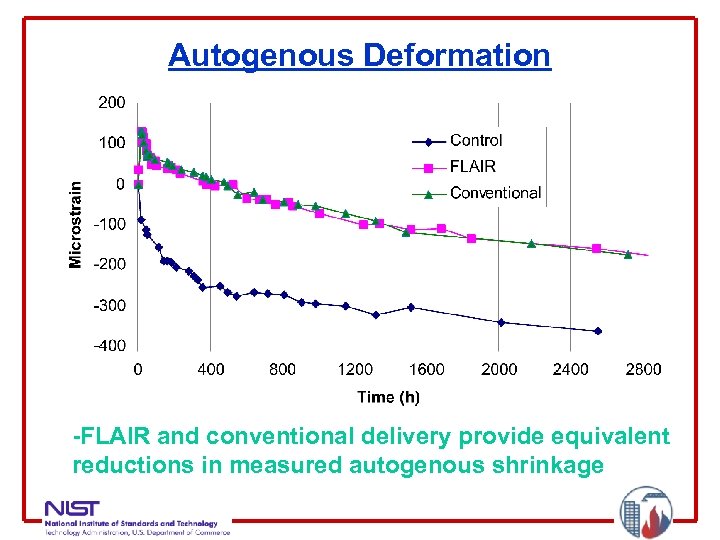

Autogenous Deformation -FLAIR and conventional delivery provide equivalent reductions in measured autogenous shrinkage

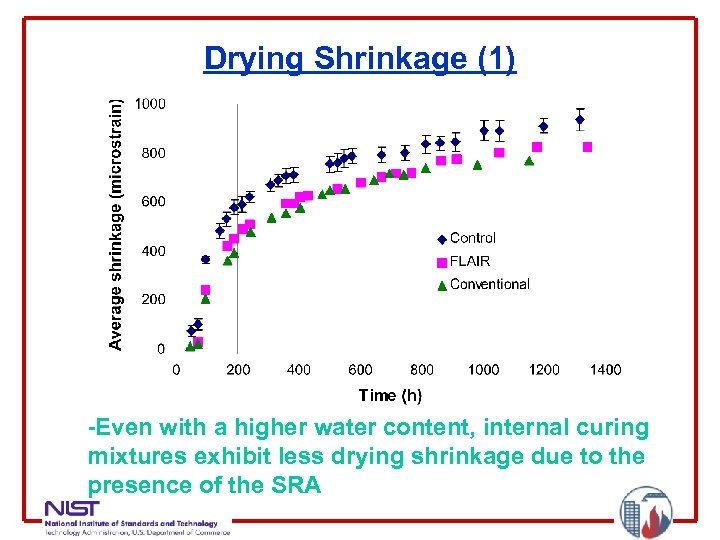

Drying Shrinkage (1) -Even with a higher water content, internal curing mixtures exhibit less drying shrinkage due to the presence of the SRA

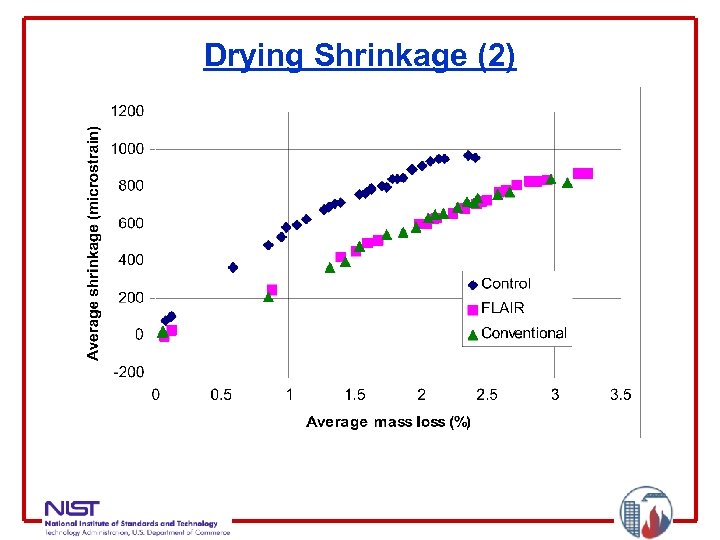

Drying Shrinkage (2)

Summary • In this preliminary study contrasting FLAIR vs. conventional delivery of chemical admixtures: – FLAIR system exhibited a significantly higher fresh air content (avoidance of SRA air detraining action) – FLAIR and conventional delivery of the SRA, along with internal curing, provided basically equivalent improvements in both autogenous and drying shrinkage • Further studies are underway for a variety of chemical admixtures and two LWA sources: – Shrinkage-reducing admixtures – Corrosion inhibitors – Admixtures for mitigating alkali-silica reaction (ASR)

Acknowledgements • FLAIR collaborators – Mr. Max Peltz (NIST) – Mr. John W. Roberts (Northeast Solite) – Mr. Thomas A. Holm (ESCSI) – Dr. Neal Berke (W. R. Grace) – Dr. Aiping Lu (Sika) – Dr. Daniel Constantiner (Degussa) – Ms. Caroline Talbot (Euclid Chemical)

d5a272e987414b6dcf9a667441ff2bb2.ppt