928af2aae2fc40f6c2b8c955ba48f4a3.ppt

- Количество слайдов: 29

Canadian Welding Bureau Presentation to ACBOA

Topics To Be Covered • • • Canadian Welding Bureau (CWB) – Who Are We? CWB – What’s New? CWB Company Certification Overview National/Provincial Building Codes – Welding Requirements Canadian and American Welding Standards Review International Welding Standards What’s Happening?

CWB – Who Are We? • CSA welding standard administrator individuals/products/companies • Independent 3 rd party body • Canadian Authorized National Body (ANB) for International Institute of Welding (IIW) qualifications • Actively involved in Standards (CSA, AWS, IIW and ISO) • Accredited by the Standards Council of Canada (SCC) • A private sector, not for profit organization • Offices and staff across Canada

CWB – What’s New? • New CSA Welding Standards W 47. 1/W 47. 2/W 55. 3/W 178. 1/W 178. 2 • Industries increasing use of CWB Certification Transportation, Oil and Gas, Wind Turbines, LNG • New Training Programs Welding Design for Engineers, Welding Inspectors (Level 1, 2, 3) • CWB Funding to Universities/Colleges/High Schools • Promoting Public Safety (Engineers and Building Officials) • International Welding Standard Development (ISO and IIW)

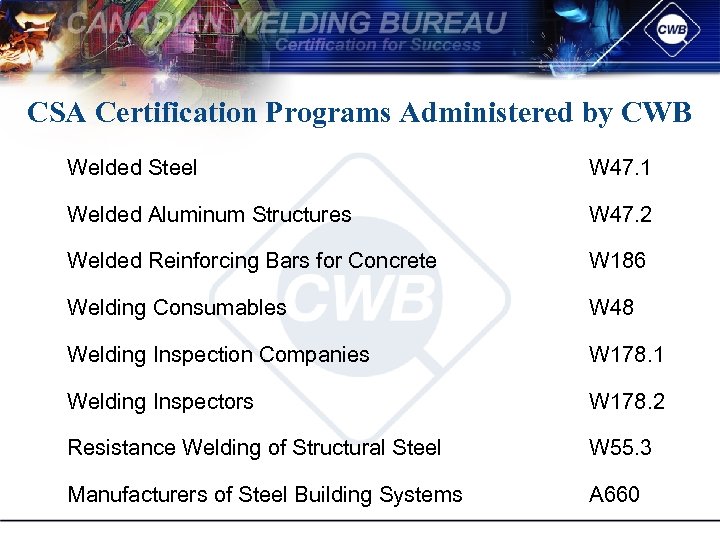

CSA Certification Programs Administered by CWB Welded Steel W 47. 1 Welded Aluminum Structures W 47. 2 Welded Reinforcing Bars for Concrete W 186 Welding Consumables W 48 Welding Inspection Companies W 178. 1 Welding Inspectors W 178. 2 Resistance Welding of Structural Steel W 55. 3 Manufacturers of Steel Building Systems A 660

CWB Company Certification – Overview CSA W 47. 1 “Certification of Companies for Fusion Welding of Steel” Four main requirements: 1. Qualified welders 2. Qualified welding supervisor(s) 3. Qualified welding engineering (Div. 1 & 2) 4. Accepted welding procedures

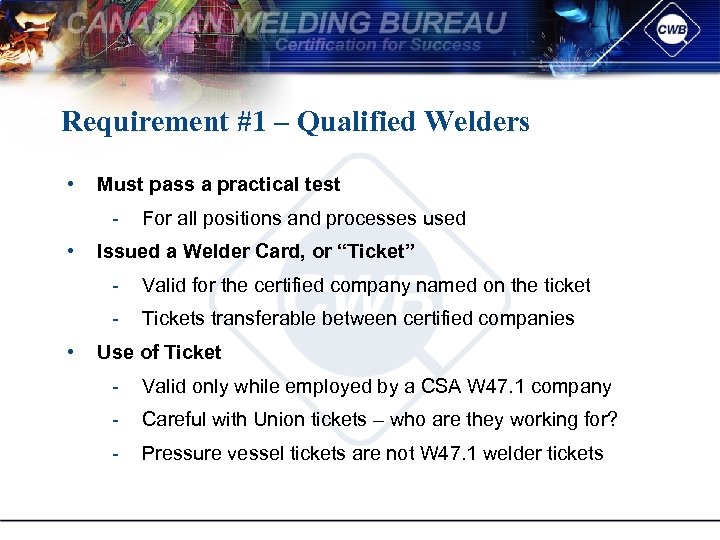

Requirement #1 – Qualified Welders • Must pass a practical test • For all positions and processes used Issued a Welder Card, or “Ticket” • Valid for the certified company named on the ticket Tickets transferable between certified companies Use of Ticket Valid only while employed by a CSA W 47. 1 company Careful with Union tickets – who are they working for? Pressure vessel tickets are not W 47. 1 welder tickets

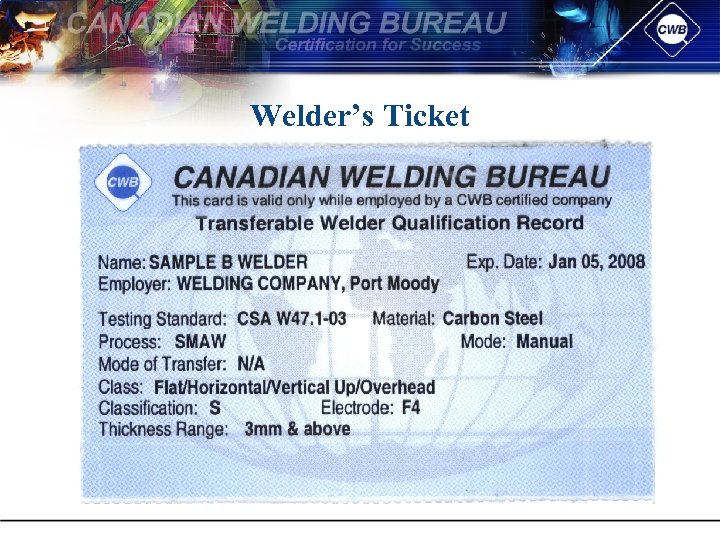

Welder’s Ticket

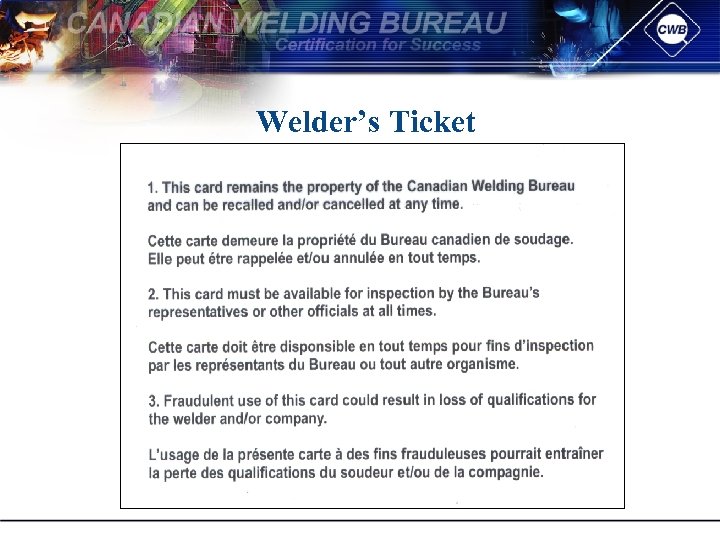

Welder’s Ticket

Requirement #2 – Qualified Welding Supervisor(s) • Employ at least one Welding Supervisor • Minimum education & experience requirements • Responsible for the welding operations and to ensure that welders are qualified & welding procedures are followed

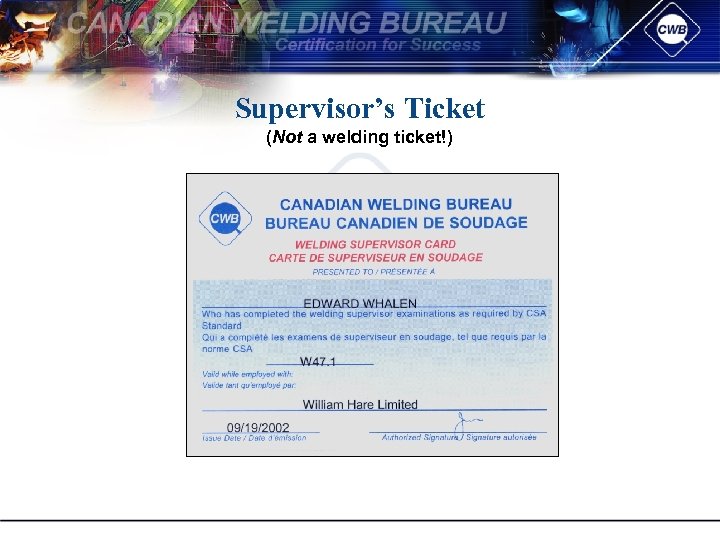

Supervisor’s Ticket (Not a welding ticket!)

Requirement #3 – Qualified Welding Engineer(s) Companies choose certification in 1 of 3 divisions: Division 1 - Welding engineer employed Division 2 - Welding engineer retained Division 3 - No welding engineer Division requirement normally specified in the design/product/safety standard

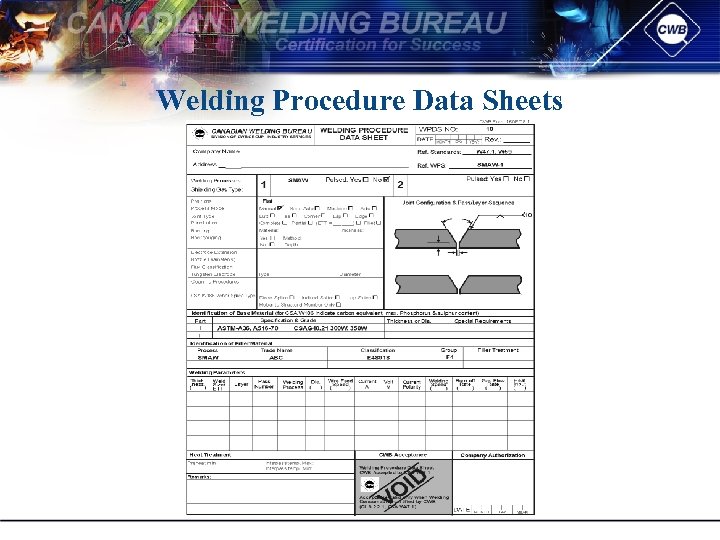

Requirement #4 – Qualified Welding Procedures • A document of welding details & parameters “A welder’s recipe book” • CWB accepted to ensure the requirements of both the certification & governing fabrication standards are met

Welding Procedure Data Sheets

Maintaining CWB Certification • Certification is an ongoing process • To maintain certification, companies must: Qualify new & check test existing welders every 2 years Submit new or revised welding procedures, as required Continually verify visual acceptance of welded product(s) Ensure any CWB “scope” work subcontracted to a CWB certified company • The CWB audits each company every 6 months

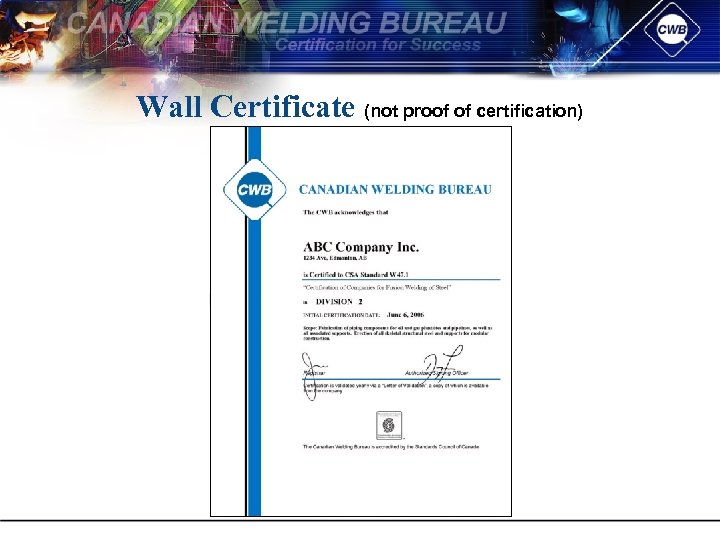

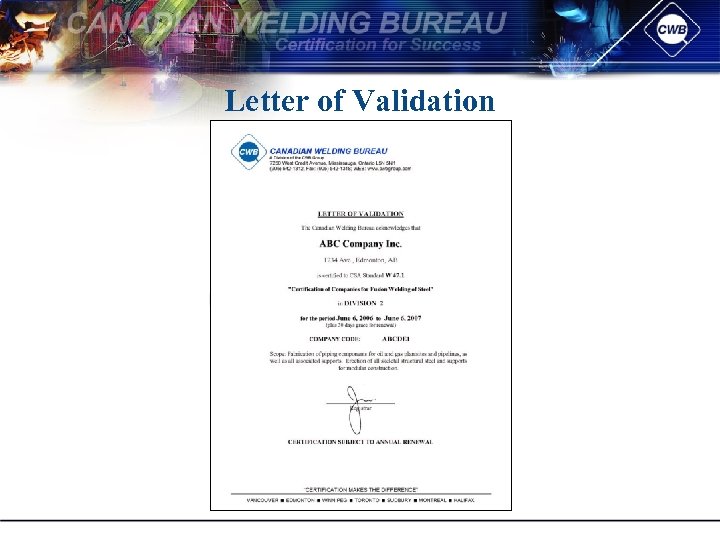

Verifying Certification • Verify company status on CWB website Company web listing updated weekly www. cwbweb. org • Ask company for current Letter of Validation Annual letter given to certified clients Verify dates • The following items are not proof of certification on their own: Welder Tickets Welding Procedures Wall Certificates Welding Supervisor Certificates • Call any local CWB Regional Office or staff

Wall Certificate (not proof of certification)

Letter of Validation

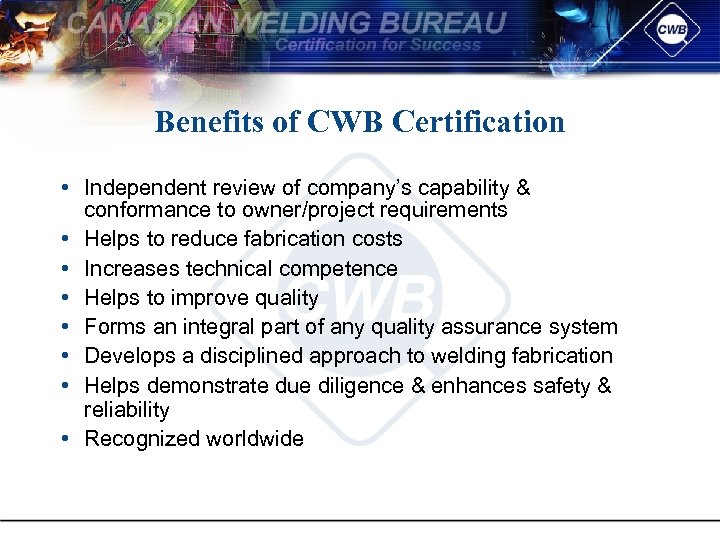

Benefits of CWB Certification • Independent review of company’s capability & conformance to owner/project requirements • Helps to reduce fabrication costs • Increases technical competence • Helps to improve quality • Forms an integral part of any quality assurance system • Develops a disciplined approach to welding fabrication • Helps demonstrate due diligence & enhances safety & reliability • Recognized worldwide

Worldwide Certification Approx. 5000 Companies Argentina Germany Slovakia Austria Holland Slovenia Brazil India South Korea Belgium Indonesia South Africa Canada Italy Spain Chile Japan Sweden China Korea Switzerland Czech Rep. Malaysia Turkey Finland Mexico United Kingdom France Singapore United States

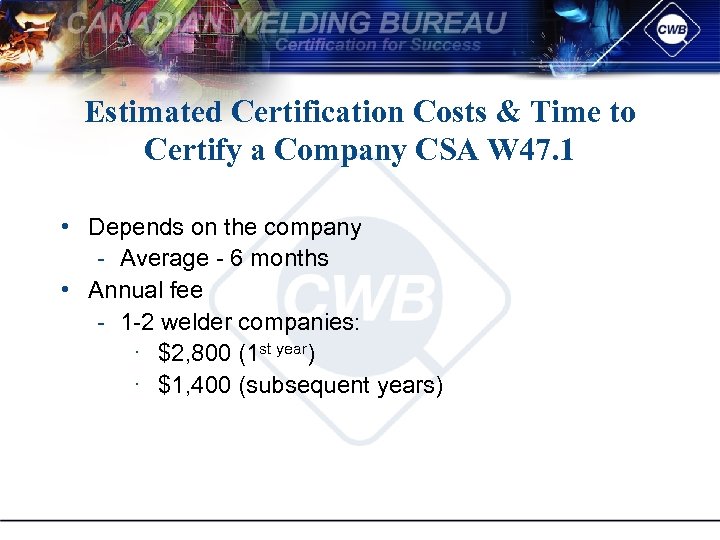

Estimated Certification Costs & Time to Certify a Company CSA W 47. 1 • Depends on the company Average 6 months • Annual fee 1 2 welder companies: · $2, 800 (1 st year) · $1, 400 (subsequent years)

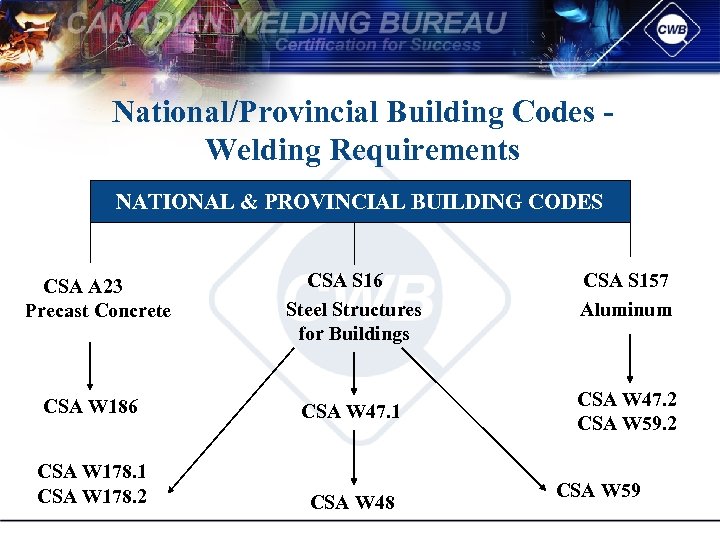

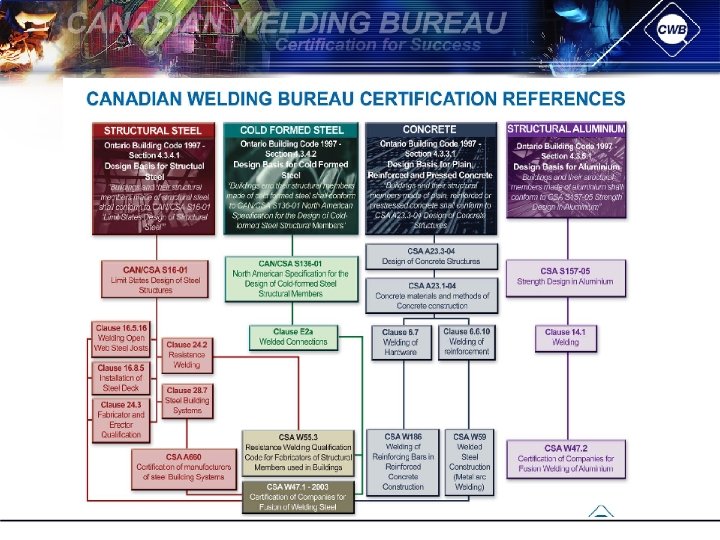

National/Provincial Building Codes Welding Requirements NATIONAL & PROVINCIAL BUILDING CODES CSA A 23 Precast Concrete CSA S 16 Steel Structures for Buildings CSA W 186 CSA W 47. 1 CSA W 178. 2 CSA W 48 CSA S 157 Aluminum CSA W 47. 2 CSA W 59

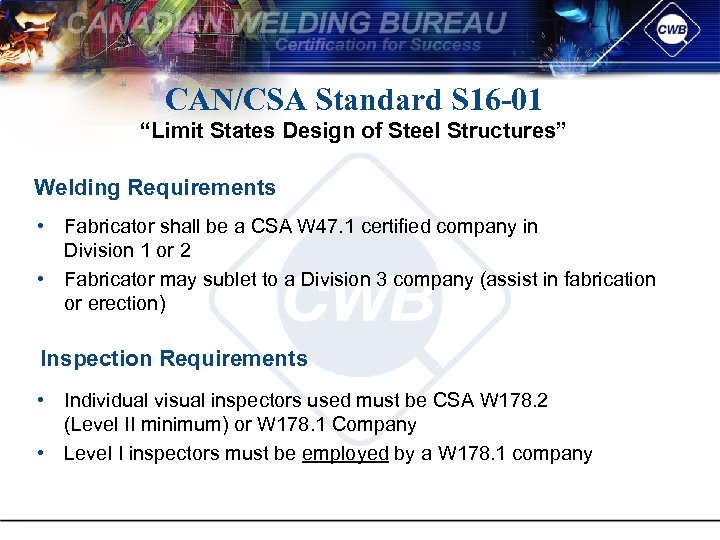

CAN/CSA Standard S 16 -01 “Limit States Design of Steel Structures” Welding Requirements • Fabricator shall be a CSA W 47. 1 certified company in Division 1 or 2 • Fabricator may sublet to a Division 3 company (assist in fabrication or erection) Inspection Requirements • Individual visual inspectors used must be CSA W 178. 2 (Level II minimum) or W 178. 1 Company • Level I inspectors must be employed by a W 178. 1 company

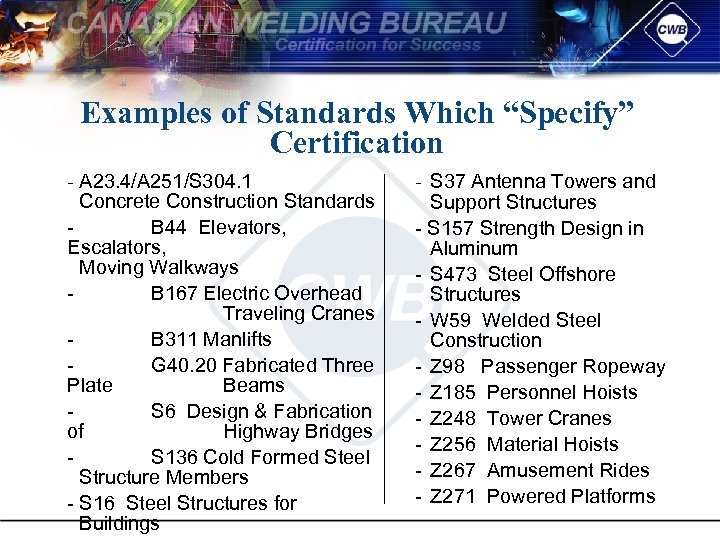

Examples of Standards Which “Specify” Certification A 23. 4/A 251/S 304. 1 Concrete Construction Standards B 44 Elevators, Escalators, Moving Walkways B 167 Electric Overhead Traveling Cranes B 311 Manlifts G 40. 20 Fabricated Three Plate Beams S 6 Design & Fabrication of Highway Bridges S 136 Cold Formed Steel Structure Members S 16 Steel Structures for Buildings S 37 Antenna Towers and Support Structures S 157 Strength Design in Aluminum S 473 Steel Offshore Structures W 59 Welded Steel Construction Z 98 Passenger Ropeway Z 185 Personnel Hoists Z 248 Tower Cranes Z 256 Material Hoists Z 267 Amusement Rides Z 271 Powered Platforms

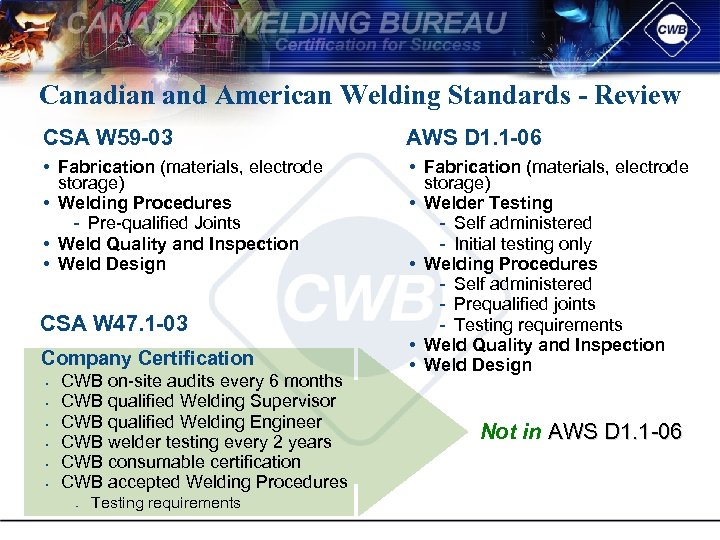

Canadian and American Welding Standards - Review CSA W 59 -03 AWS D 1. 1 -06 • Fabrication (materials, electrode storage) • Welding Procedures Pre qualified Joints • Weld Quality and Inspection • Weld Design • Fabrication (materials, electrode storage) • Welder Testing Self administered Initial testing only • Welding Procedures Self administered Prequalified joints Testing requirements • Weld Quality and Inspection • Weld Design CSA W 47. 1 -03 Company Certification • • • CWB on site audits every 6 months CWB qualified Welding Supervisor CWB qualified Welding Engineer CWB welder testing every 2 years CWB consumable certification CWB accepted Welding Procedures Testing requirements Not in AWS D 1. 1 06

International Welding Standards - What’s Happening? • ISO TC 44 • • • S/C 10 Quality Systems (ISO 3834) Welding Procedures (ISO 15614) S/C 11 Welder Testing (ISO 9606) International Institute of Welding (IIW) CWB is the ANB for Canada Welding personnel qualifications • • Welding engineers, supervisors, welders, inspectors, etc. Over 5, 000 certified worldwide and growing

CWB Services Available • Auditing Job Sites • Enquire the status of individual/company certification • • Check our website www. cwbweb. org Call any regional office or staff Inspector Qualification? Welding Information • Call any regional office or staff Inform us of non CWB certified companies on job sites Welding Design Book, Modules, On line services coming Welding Training Weld Symbols, Weld Faults, Welding Safety, Welding Inspectors

QUESTIONS? ?

928af2aae2fc40f6c2b8c955ba48f4a3.ppt