2e0f1aab2567497e12b8bf3d7ad8b9a1.ppt

- Количество слайдов: 31

Calorimeter Electronics Upgrade Calorimeter and Intercryostat Detectors u Objectives + Design u System Description u Current Status + Progress u Schedule u (Cost + Manpower - see Lehman reviews WBS 1. 2. 1 and 1. 2. 2) Leslie Groer Columbia University New York June 20, 2000 DØ Collaboration Workshop NIU, De. Kalb, Illinois June 19– 23, 2000 1 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calorimeter Electronics Upgrade Calorimeter and Intercryostat Detectors u Objectives + Design u System Description u Current Status + Progress u Schedule u (Cost + Manpower - see Lehman reviews WBS 1. 2. 1 and 1. 2. 2) Leslie Groer Columbia University New York June 20, 2000 DØ Collaboration Workshop NIU, De. Kalb, Illinois June 19– 23, 2000 1 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

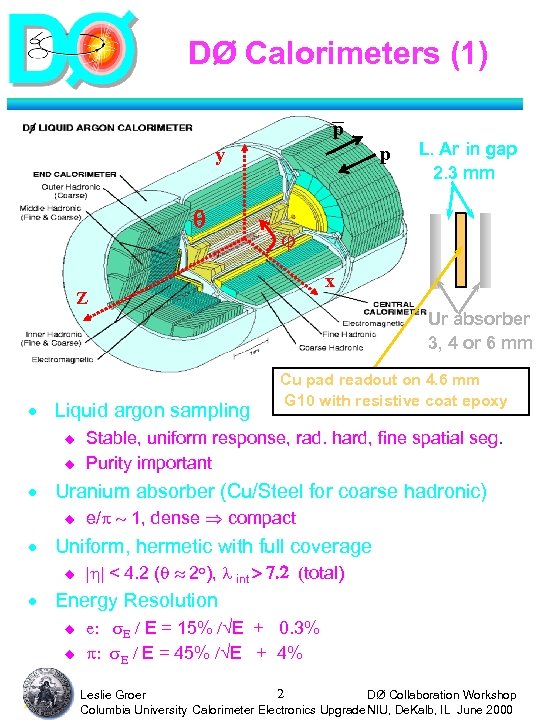

DØ Calorimeters (1) _ p p y q L. Ar in gap 2. 3 mm j x Z Ur absorber 3, 4 or 6 mm · Liquid argon sampling u u Cu pad readout on 4. 6 mm G 10 with resistive coat epoxy Stable, uniform response, rad. hard, fine spatial seg. Purity important · Uranium absorber (Cu/Steel for coarse hadronic) u e/ 1, dense compact · Uniform, hermetic with full coverage u |h| < 4. 2 ( 2 o), l int > 7. 2 (total) · Energy Resolution u u 2 e: s. E / E = 15% /ÖE + 0. 3% : s. E / E = 45% /ÖE + 4% 2 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

DØ Calorimeters (1) _ p p y q L. Ar in gap 2. 3 mm j x Z Ur absorber 3, 4 or 6 mm · Liquid argon sampling u u Cu pad readout on 4. 6 mm G 10 with resistive coat epoxy Stable, uniform response, rad. hard, fine spatial seg. Purity important · Uranium absorber (Cu/Steel for coarse hadronic) u e/ 1, dense compact · Uniform, hermetic with full coverage u |h| < 4. 2 ( 2 o), l int > 7. 2 (total) · Energy Resolution u u 2 e: s. E / E = 15% /ÖE + 0. 3% : s. E / E = 45% /ÖE + 4% 2 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

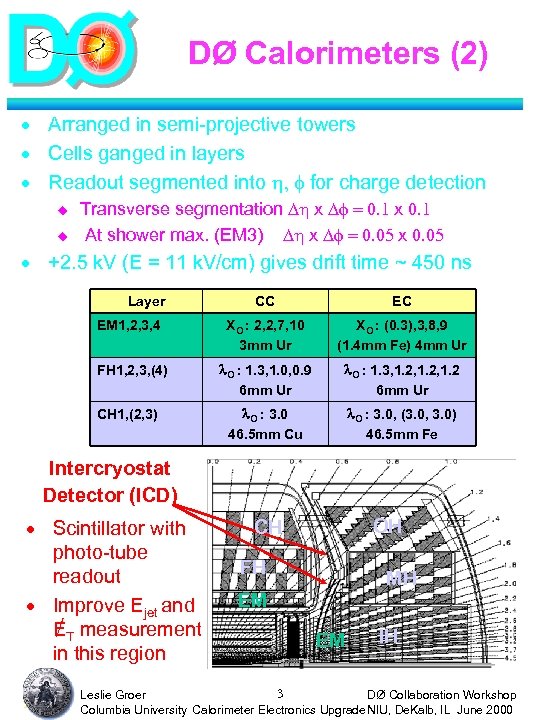

DØ Calorimeters (2) · Arranged in semi-projective towers · Cells ganged in layers · Readout segmented into h, for charge detection u u Transverse segmentation Dh x D = 0. 1 x 0. 1 At shower max. (EM 3) Dh x D = 0. 05 x 0. 05 · +2. 5 k. V (E = 11 k. V/cm) gives drift time ~ 450 ns Layer CC EC EM 1, 2, 3, 4 XO : 2, 2, 7, 10 3 mm Ur XO : (0. 3), 3, 8, 9 (1. 4 mm Fe) 4 mm Ur FH 1, 2, 3, (4) O : 1. 3, 1. 0, 0. 9 6 mm Ur O : 1. 3, 1. 2, 1. 2 6 mm Ur O : 3. 0 46. 5 mm Cu O : 3. 0, (3. 0, 3. 0) 46. 5 mm Fe CH 1, (2, 3) Intercryostat Detector (ICD) · Scintillator with photo-tube readout · Improve Ejet and ET measurement / in this region 3 OH CH FH MH EM EM IH 3 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

DØ Calorimeters (2) · Arranged in semi-projective towers · Cells ganged in layers · Readout segmented into h, for charge detection u u Transverse segmentation Dh x D = 0. 1 x 0. 1 At shower max. (EM 3) Dh x D = 0. 05 x 0. 05 · +2. 5 k. V (E = 11 k. V/cm) gives drift time ~ 450 ns Layer CC EC EM 1, 2, 3, 4 XO : 2, 2, 7, 10 3 mm Ur XO : (0. 3), 3, 8, 9 (1. 4 mm Fe) 4 mm Ur FH 1, 2, 3, (4) O : 1. 3, 1. 0, 0. 9 6 mm Ur O : 1. 3, 1. 2, 1. 2 6 mm Ur O : 3. 0 46. 5 mm Cu O : 3. 0, (3. 0, 3. 0) 46. 5 mm Fe CH 1, (2, 3) Intercryostat Detector (ICD) · Scintillator with photo-tube readout · Improve Ejet and ET measurement / in this region 3 OH CH FH MH EM EM IH 3 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calorimeter Electronics · Objectives u u Accommodate reduced minimum bunch spacing from 3. 5 s to 396 ns or 132 ns and L~ 2 x 1032 cm-2 s-1 Storage of analog signal for 4 s for L 1 trigger formation Generate trigger signals for calorimeter L 1 trigger Maintain present level of noise performance and pile-up performance · Methods u u u 4 Replace preamplifiers Replace shapers Add analog storage Replace calibration system Replace timing and control system Keep Run I ADCs, crates and cabling 4 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calorimeter Electronics · Objectives u u Accommodate reduced minimum bunch spacing from 3. 5 s to 396 ns or 132 ns and L~ 2 x 1032 cm-2 s-1 Storage of analog signal for 4 s for L 1 trigger formation Generate trigger signals for calorimeter L 1 trigger Maintain present level of noise performance and pile-up performance · Methods u u u 4 Replace preamplifiers Replace shapers Add analog storage Replace calibration system Replace timing and control system Keep Run I ADCs, crates and cabling 4 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

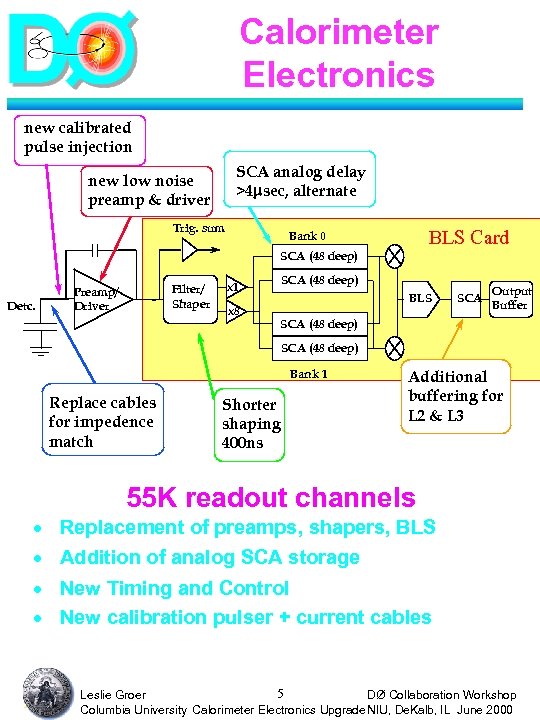

Calorimeter Electronics new calibrated pulse injection SCA analog delay >4 sec, alternate new low noise preamp & driver Trig. sum BLS Card Bank 0 SCA (48 deep) Detc. Filter/ Shaper Preamp/ Driver SCA (48 deep) x 1 x 8 BLS SCA Output Buffer SCA (48 deep) Bank 1 Replace cables for impedence match Shorter shaping 400 ns Additional buffering for L 2 & L 3 55 K readout channels · Replacement of preamps, shapers, BLS · Addition of analog SCA storage · New Timing and Control · New calibration pulser + current cables 5 5 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calorimeter Electronics new calibrated pulse injection SCA analog delay >4 sec, alternate new low noise preamp & driver Trig. sum BLS Card Bank 0 SCA (48 deep) Detc. Filter/ Shaper Preamp/ Driver SCA (48 deep) x 1 x 8 BLS SCA Output Buffer SCA (48 deep) Bank 1 Replace cables for impedence match Shorter shaping 400 ns Additional buffering for L 2 & L 3 55 K readout channels · Replacement of preamps, shapers, BLS · Addition of analog SCA storage · New Timing and Control · New calibration pulser + current cables 5 5 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

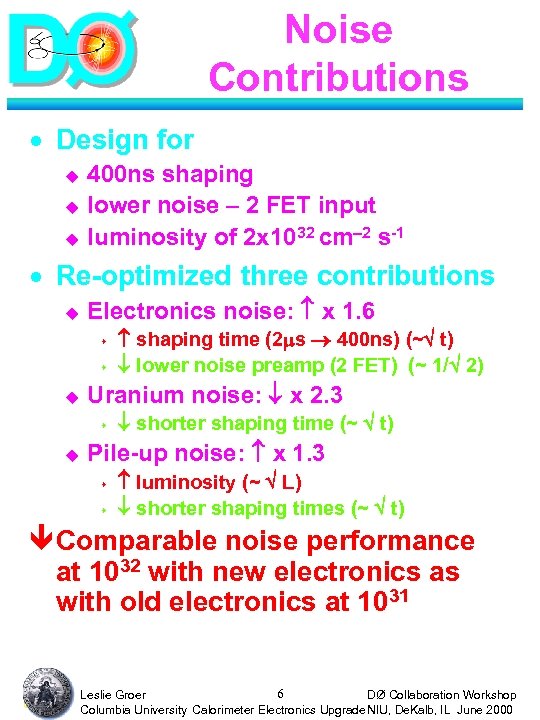

Noise Contributions · Design for u u u 400 ns shaping lower noise – 2 FET input luminosity of 2 x 1032 cm– 2 s-1 · Re-optimized three contributions u Electronics noise: x 1. 6 s s u Uranium noise: x 2. 3 s u shaping time (2 s 400 ns) (~ t) lower noise preamp (2 FET) (~ 1/ 2) shorter shaping time (~ t) Pile-up noise: x 1. 3 s s luminosity (~ L) shorter shaping times (~ t) ê Comparable noise performance at 1032 with new electronics as with old electronics at 1031 6 6 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Noise Contributions · Design for u u u 400 ns shaping lower noise – 2 FET input luminosity of 2 x 1032 cm– 2 s-1 · Re-optimized three contributions u Electronics noise: x 1. 6 s s u Uranium noise: x 2. 3 s u shaping time (2 s 400 ns) (~ t) lower noise preamp (2 FET) (~ 1/ 2) shorter shaping time (~ t) Pile-up noise: x 1. 3 s s luminosity (~ L) shorter shaping times (~ t) ê Comparable noise performance at 1032 with new electronics as with old electronics at 1031 6 6 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

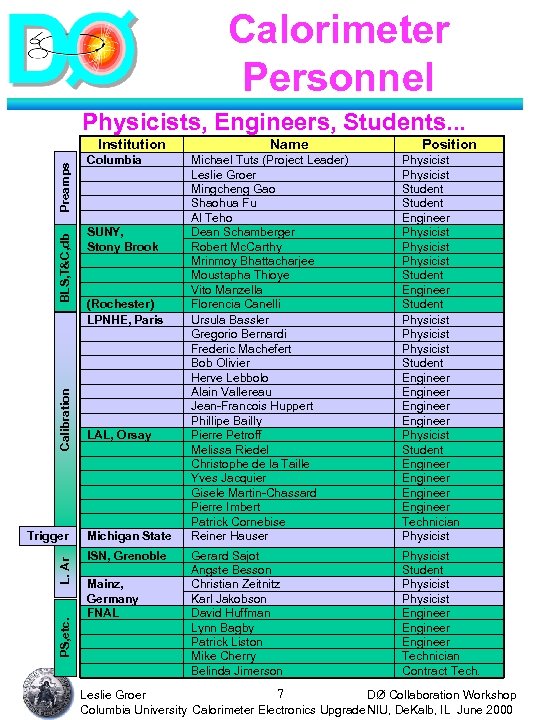

Calorimeter Personnel Physicists, Engineers, Students. . . Calibration BLS, T&C, db Preamps Institution PS, etc. L. Ar Trigger 7 Columbia SUNY, Stony Brook (Rochester) LPNHE, Paris LAL, Orsay Michigan State ISN, Grenoble Mainz, Germany FNAL Name Position Michael Tuts (Project Leader) Leslie Groer Mingcheng Gao Shaohua Fu Al Teho Dean Schamberger Robert Mc. Carthy Mrinmoy Bhattacharjee Moustapha Thioye Vito Manzella Florencia Canelli Ursula Bassler Gregorio Bernardi Frederic Machefert Bob Olivier Herve Lebbolo Alain Vallereau Jean-Francois Huppert Phillipe Bailly Pierre Petroff Melissa Riedel Christophe de la Taille Yves Jacquier Gisele Martin-Chassard Pierre Imbert Patrick Cornebise Reiner Hauser Physicist Student Engineer Physicist Student Engineer Student Physicist Student Engineer Engineer Technician Physicist Gerard Sajot Angste Besson Christian Zeitnitz Karl Jakobson David Huffman Lynn Bagby Patrick Liston Mike Cherry Belinda Jimerson Physicist Student Physicist Engineer Technician Contract Tech. 7 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calorimeter Personnel Physicists, Engineers, Students. . . Calibration BLS, T&C, db Preamps Institution PS, etc. L. Ar Trigger 7 Columbia SUNY, Stony Brook (Rochester) LPNHE, Paris LAL, Orsay Michigan State ISN, Grenoble Mainz, Germany FNAL Name Position Michael Tuts (Project Leader) Leslie Groer Mingcheng Gao Shaohua Fu Al Teho Dean Schamberger Robert Mc. Carthy Mrinmoy Bhattacharjee Moustapha Thioye Vito Manzella Florencia Canelli Ursula Bassler Gregorio Bernardi Frederic Machefert Bob Olivier Herve Lebbolo Alain Vallereau Jean-Francois Huppert Phillipe Bailly Pierre Petroff Melissa Riedel Christophe de la Taille Yves Jacquier Gisele Martin-Chassard Pierre Imbert Patrick Cornebise Reiner Hauser Physicist Student Engineer Physicist Student Engineer Student Physicist Student Engineer Engineer Technician Physicist Gerard Sajot Angste Besson Christian Zeitnitz Karl Jakobson David Huffman Lynn Bagby Patrick Liston Mike Cherry Belinda Jimerson Physicist Student Physicist Engineer Technician Contract Tech. 7 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

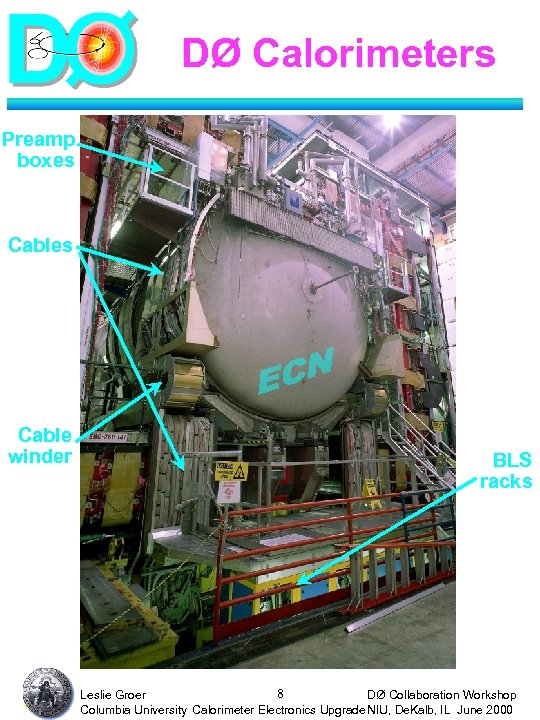

DØ Calorimeters Preamp boxes Cable winder 8 BLS racks 8 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

DØ Calorimeters Preamp boxes Cable winder 8 BLS racks 8 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

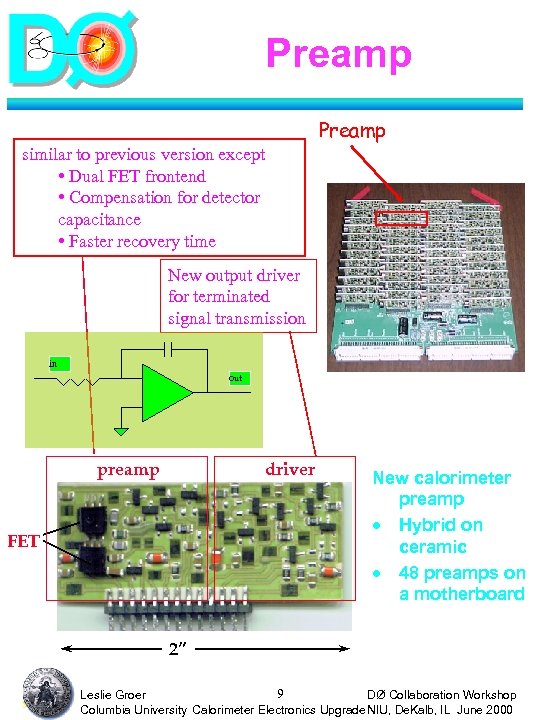

Preamp similar to previous version except • Dual FET frontend • Compensation for detector capacitance • Faster recovery time New output driver for terminated signal transmission in out preamp driver FET New calorimeter preamp · Hybrid on ceramic · 48 preamps on a motherboard 2” 9 9 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Preamp similar to previous version except • Dual FET frontend • Compensation for detector capacitance • Faster recovery time New output driver for terminated signal transmission in out preamp driver FET New calorimeter preamp · Hybrid on ceramic · 48 preamps on a motherboard 2” 9 9 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

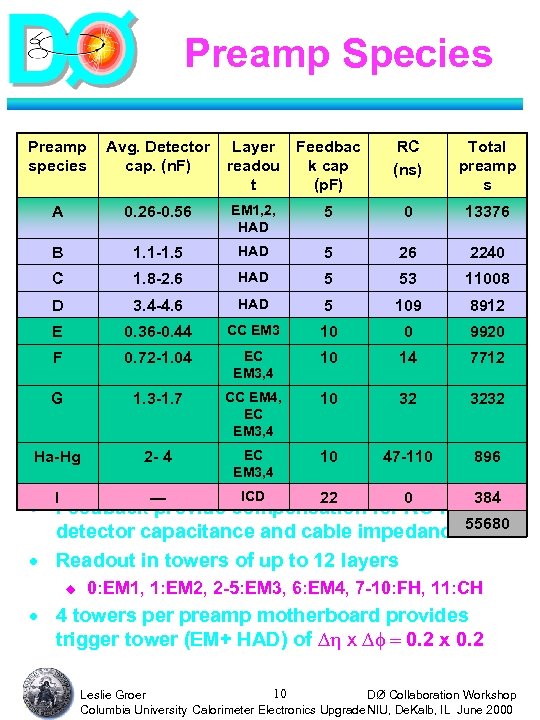

Preamp Species Preamp species Avg. Detector cap. (n. F) Layer readou t Feedbac k cap (p. F) RC (ns) Total preamp s A 0. 26 -0. 56 EM 1, 2, HAD 5 0 13376 B 1. 1 -1. 5 HAD 5 26 2240 C 1. 8 -2. 6 HAD 5 53 11008 D 3. 4 -4. 6 HAD 5 109 8912 E 0. 36 -0. 44 CC EM 3 10 0 9920 F 0. 72 -1. 04 EC EM 3, 4 10 14 7712 G 1. 3 -1. 7 CC EM 4, EC EM 3, 4 10 32 3232 Ha-Hg 2 - 4 EC EM 3, 4 10 47 -110 896 · 14+1 (ICD) species of preamp ICD I — 22 0 384 · Feedback provide compensation for RC from detector capacitance and cable impedance 55680 · Readout in towers of up to 12 layers u 0: EM 1, 1: EM 2, 2 -5: EM 3, 6: EM 4, 7 -10: FH, 11: CH · 4 towers per preamp motherboard provides trigger tower (EM+ HAD) of Dh x D = 0. 2 x 0. 2 10 10 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Preamp Species Preamp species Avg. Detector cap. (n. F) Layer readou t Feedbac k cap (p. F) RC (ns) Total preamp s A 0. 26 -0. 56 EM 1, 2, HAD 5 0 13376 B 1. 1 -1. 5 HAD 5 26 2240 C 1. 8 -2. 6 HAD 5 53 11008 D 3. 4 -4. 6 HAD 5 109 8912 E 0. 36 -0. 44 CC EM 3 10 0 9920 F 0. 72 -1. 04 EC EM 3, 4 10 14 7712 G 1. 3 -1. 7 CC EM 4, EC EM 3, 4 10 32 3232 Ha-Hg 2 - 4 EC EM 3, 4 10 47 -110 896 · 14+1 (ICD) species of preamp ICD I — 22 0 384 · Feedback provide compensation for RC from detector capacitance and cable impedance 55680 · Readout in towers of up to 12 layers u 0: EM 1, 1: EM 2, 2 -5: EM 3, 6: EM 4, 7 -10: FH, 11: CH · 4 towers per preamp motherboard provides trigger tower (EM+ HAD) of Dh x D = 0. 2 x 0. 2 10 10 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

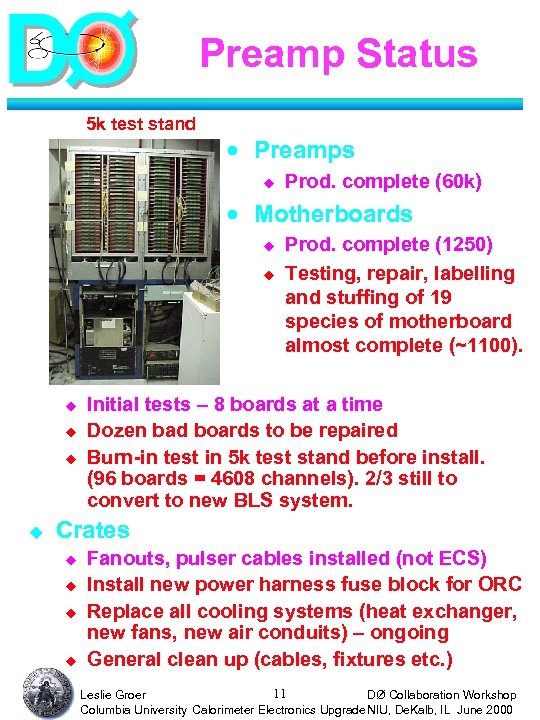

Preamp Status 5 k test stand · Preamps u Prod. complete (60 k) · Motherboards u u u Initial tests – 8 boards at a time Dozen bad boards to be repaired Burn-in test in 5 k test stand before install. (96 boards = 4608 channels). 2/3 still to convert to new BLS system. Crates u u 11 Prod. complete (1250) Testing, repair, labelling and stuffing of 19 species of motherboard almost complete (~1100). Fanouts, pulser cables installed (not ECS) Install new power harness fuse block for ORC Replace all cooling systems (heat exchanger, new fans, new air conduits) – ongoing General clean up (cables, fixtures etc. ) 11 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Preamp Status 5 k test stand · Preamps u Prod. complete (60 k) · Motherboards u u u Initial tests – 8 boards at a time Dozen bad boards to be repaired Burn-in test in 5 k test stand before install. (96 boards = 4608 channels). 2/3 still to convert to new BLS system. Crates u u 11 Prod. complete (1250) Testing, repair, labelling and stuffing of 19 species of motherboard almost complete (~1100). Fanouts, pulser cables installed (not ECS) Install new power harness fuse block for ORC Replace all cooling systems (heat exchanger, new fans, new air conduits) – ongoing General clean up (cables, fixtures etc. ) 11 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

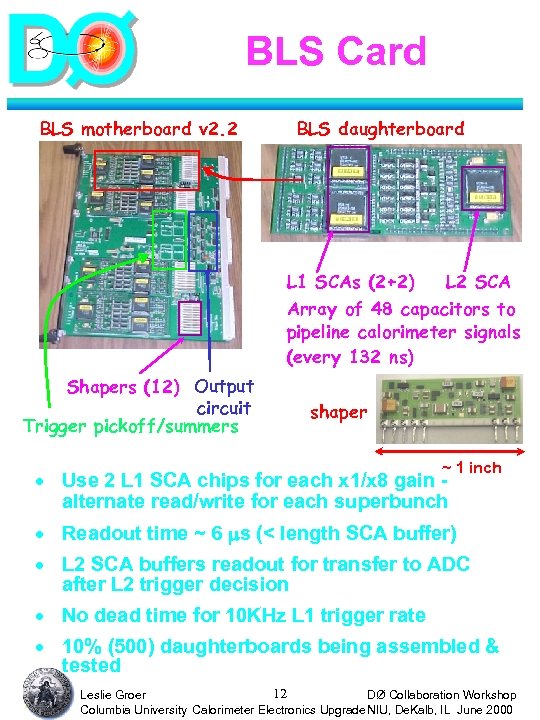

BLS Card BLS motherboard v 2. 2 BLS daughterboard L 1 SCAs (2+2) L 2 SCA Array of 48 capacitors to pipeline calorimeter signals (every 132 ns) Shapers (12) Output circuit Trigger pickoff/summers shaper ~ 1 inch · Use 2 L 1 SCA chips for each x 1/x 8 gain alternate read/write for each superbunch · Readout time ~ 6 s (< length SCA buffer) · L 2 SCA buffers readout for transfer to ADC after L 2 trigger decision · No dead time for 10 KHz L 1 trigger rate · 10% (500) daughterboards being assembled & tested 12 12 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

BLS Card BLS motherboard v 2. 2 BLS daughterboard L 1 SCAs (2+2) L 2 SCA Array of 48 capacitors to pipeline calorimeter signals (every 132 ns) Shapers (12) Output circuit Trigger pickoff/summers shaper ~ 1 inch · Use 2 L 1 SCA chips for each x 1/x 8 gain alternate read/write for each superbunch · Readout time ~ 6 s (< length SCA buffer) · L 2 SCA buffers readout for transfer to ADC after L 2 trigger decision · No dead time for 10 KHz L 1 trigger rate · 10% (500) daughterboards being assembled & tested 12 12 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

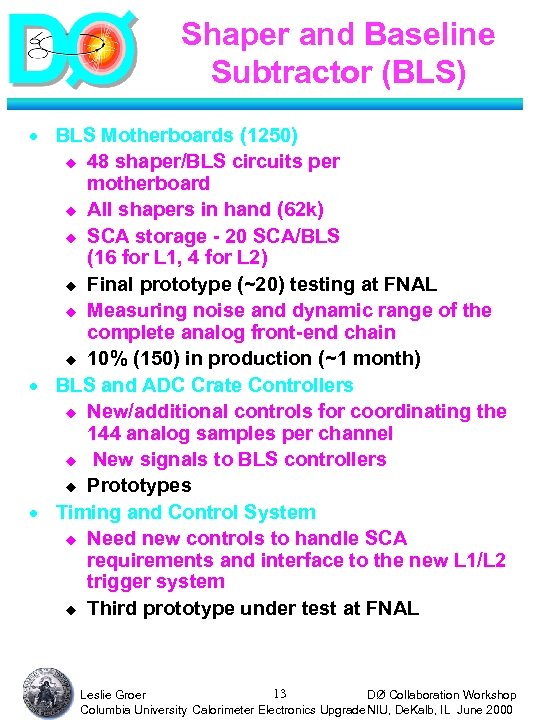

Shaper and Baseline Subtractor (BLS) · BLS Motherboards (1250) u 48 shaper/BLS circuits per motherboard u All shapers in hand (62 k) u SCA storage - 20 SCA/BLS (16 for L 1, 4 for L 2) u Final prototype (~20) testing at FNAL u Measuring noise and dynamic range of the complete analog front-end chain u 10% (150) in production (~1 month) · BLS and ADC Crate Controllers u New/additional controls for coordinating the 144 analog samples per channel u New signals to BLS controllers u Prototypes · Timing and Control System u Need new controls to handle SCA requirements and interface to the new L 1/L 2 trigger system u Third prototype under test at FNAL 13 13 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Shaper and Baseline Subtractor (BLS) · BLS Motherboards (1250) u 48 shaper/BLS circuits per motherboard u All shapers in hand (62 k) u SCA storage - 20 SCA/BLS (16 for L 1, 4 for L 2) u Final prototype (~20) testing at FNAL u Measuring noise and dynamic range of the complete analog front-end chain u 10% (150) in production (~1 month) · BLS and ADC Crate Controllers u New/additional controls for coordinating the 144 analog samples per channel u New signals to BLS controllers u Prototypes · Timing and Control System u Need new controls to handle SCA requirements and interface to the new L 1/L 2 trigger system u Third prototype under test at FNAL 13 13 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

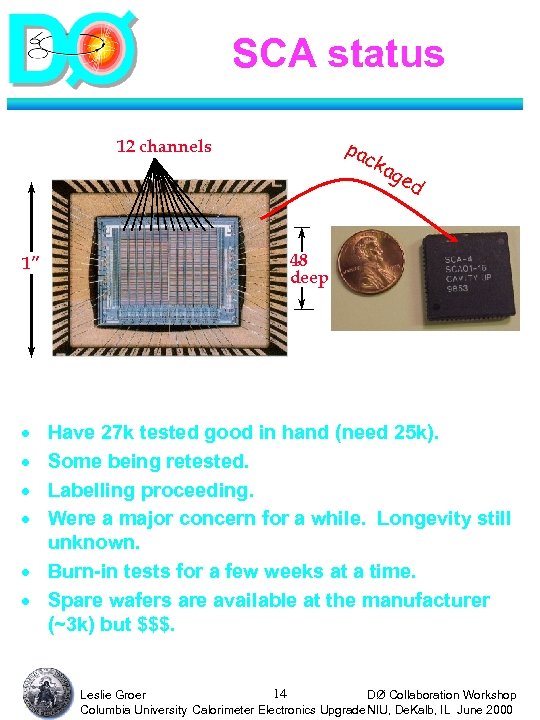

SCA status pa 12 channels 1” ck ag ed 48 deep · · Have 27 k tested good in hand (need 25 k). Some being retested. Labelling proceeding. Were a major concern for a while. Longevity still unknown. · Burn-in tests for a few weeks at a time. · Spare wafers are available at the manufacturer (~3 k) but $$$. 14 14 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

SCA status pa 12 channels 1” ck ag ed 48 deep · · Have 27 k tested good in hand (need 25 k). Some being retested. Labelling proceeding. Were a major concern for a while. Longevity still unknown. · Burn-in tests for a few weeks at a time. · Spare wafers are available at the manufacturer (~3 k) but $$$. 14 14 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

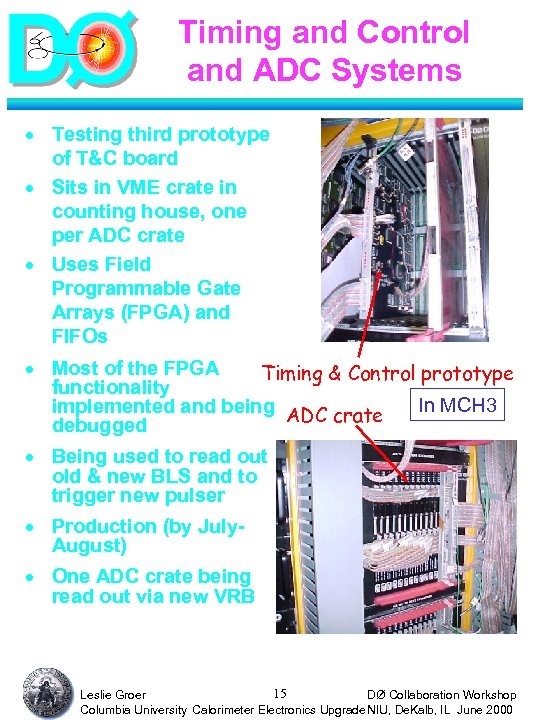

Timing and Control and ADC Systems · Testing third prototype of T&C board · Sits in VME crate in counting house, one per ADC crate · Uses Field Programmable Gate Arrays (FPGA) and FIFOs · Most of the FPGA Timing & Control prototype functionality In MCH 3 implemented and being ADC crate debugged · Being used to read out old & new BLS and to trigger new pulser · Production (by July. August) · One ADC crate being read out via new VRB 15 15 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Timing and Control and ADC Systems · Testing third prototype of T&C board · Sits in VME crate in counting house, one per ADC crate · Uses Field Programmable Gate Arrays (FPGA) and FIFOs · Most of the FPGA Timing & Control prototype functionality In MCH 3 implemented and being ADC crate debugged · Being used to read out old & new BLS and to trigger new pulser · Production (by July. August) · One ADC crate being read out via new VRB 15 15 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

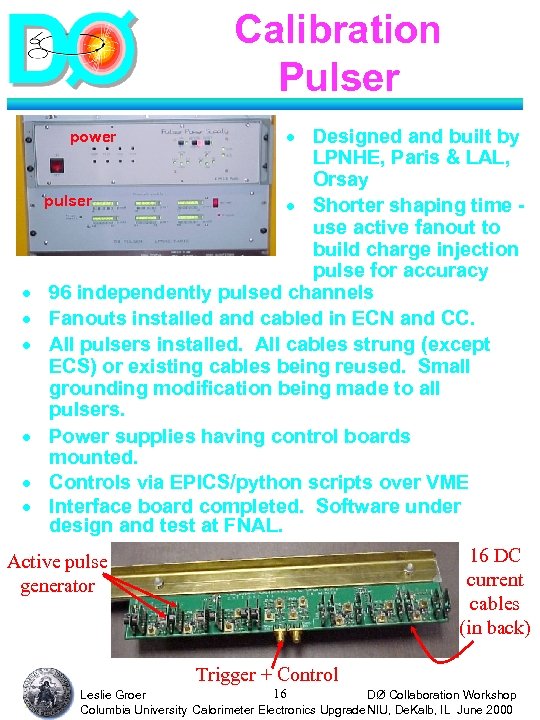

Calibration Pulser · Designed and built by LPNHE, Paris & LAL, Orsay pulser · Shorter shaping time use active fanout to build charge injection pulse for accuracy · 96 independently pulsed channels · Fanouts installed and cabled in ECN and CC. · All pulsers installed. All cables strung (except ECS) or existing cables being reused. Small grounding modification being made to all pulsers. · Power supplies having control boards mounted. · Controls via EPICS/python scripts over VME · Interface board completed. Software under design and test at FNAL. 16 DC Active pulse current generator cables (in back) power Trigger + Control 16 16 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calibration Pulser · Designed and built by LPNHE, Paris & LAL, Orsay pulser · Shorter shaping time use active fanout to build charge injection pulse for accuracy · 96 independently pulsed channels · Fanouts installed and cabled in ECN and CC. · All pulsers installed. All cables strung (except ECS) or existing cables being reused. Small grounding modification being made to all pulsers. · Power supplies having control boards mounted. · Controls via EPICS/python scripts over VME · Interface board completed. Software under design and test at FNAL. 16 DC Active pulse current generator cables (in back) power Trigger + Control 16 16 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Cables and Crates · 110 W cable 30 W from cryostat feedthrough to preamp box. Minimize reflections due to impedance mismatch. ~$0. 5 M cables. Completed 1998. Not been able to check all connections however due to lack of readout and DAQ. · Pulser cables laid. ECS still needs connectors. Control cables being laid this week. · Reusing some of the old pulser 75 W coax cables for timing pulse - 2 per preamp crate (24 + 4 total). · CC BLS cable trays modified to accomodate tracking crates and muon chambers. · Damaged ECS cables need to be repaired (~ 1 week FTE) · Recable ECS preamp backplane · BLS timing cables need to be refound and rerouted for new T&C system · 1/3 of BLS backplane needs to be replaced to accommodate new timing and control (72 crates). CC+ECS done (48). ECN to do (24) 17 17 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Cables and Crates · 110 W cable 30 W from cryostat feedthrough to preamp box. Minimize reflections due to impedance mismatch. ~$0. 5 M cables. Completed 1998. Not been able to check all connections however due to lack of readout and DAQ. · Pulser cables laid. ECS still needs connectors. Control cables being laid this week. · Reusing some of the old pulser 75 W coax cables for timing pulse - 2 per preamp crate (24 + 4 total). · CC BLS cable trays modified to accomodate tracking crates and muon chambers. · Damaged ECS cables need to be repaired (~ 1 week FTE) · Recable ECS preamp backplane · BLS timing cables need to be refound and rerouted for new T&C system · 1/3 of BLS backplane needs to be replaced to accommodate new timing and control (72 crates). CC+ECS done (48). ECN to do (24) 17 17 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Power Supplies ü Preamp PS (25 complete) ü ü Ø Low-noise commercial switching supplies for increased preamp power assembled at FNAL “Personality” card (preamps, pulser, muon etc) Steel magnetic shielding boxes ORC granted in April Install in detector June Ø BLS PS (2 proto. , 44 to rework) ü ü ü Ø Ø Ø ü Pulser PS (15) ü ü Ø ü 18 New transformer Modified output modules Modified control/monitor board Fusing for safety Similar power but run hotter Safety review soon for ORC (incl. ADC) Ø Install in detector Aug Commercial modules, assembled in Paris Supplies built Control/Monitor boards being added ORC granted in April 18 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Power Supplies ü Preamp PS (25 complete) ü ü Ø Low-noise commercial switching supplies for increased preamp power assembled at FNAL “Personality” card (preamps, pulser, muon etc) Steel magnetic shielding boxes ORC granted in April Install in detector June Ø BLS PS (2 proto. , 44 to rework) ü ü ü Ø Ø Ø ü Pulser PS (15) ü ü Ø ü 18 New transformer Modified output modules Modified control/monitor board Fusing for safety Similar power but run hotter Safety review soon for ORC (incl. ADC) Ø Install in detector Aug Commercial modules, assembled in Paris Supplies built Control/Monitor boards being added ORC granted in April 18 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

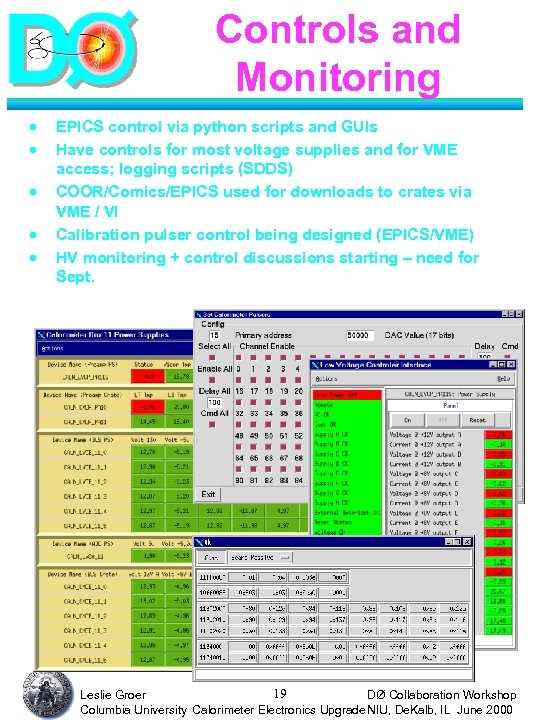

Controls and Monitoring · · · 19 EPICS control via python scripts and GUIs Have controls for most voltage supplies and for VME access; logging scripts (SDDS) COOR/Comics/EPICS used for downloads to crates via VME / VI Calibration pulser control being designed (EPICS/VME) HV monitoring + control discussions starting – need for Sept. 19 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Controls and Monitoring · · · 19 EPICS control via python scripts and GUIs Have controls for most voltage supplies and for VME access; logging scripts (SDDS) COOR/Comics/EPICS used for downloads to crates via VME / VI Calibration pulser control being designed (EPICS/VME) HV monitoring + control discussions starting – need for Sept. 19 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

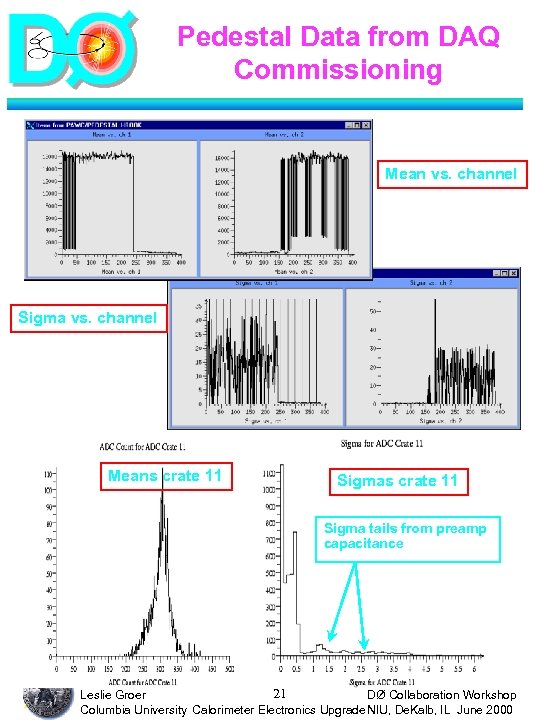

Online Calorimeter Calibration · Database design/implement by SUNYSB & Paris · Accumulate zero-bias data for each calorimeter cell u u Pedestals – electronic & Ur noise Pulsed – gains · Goals u u u Measure electronics to < 1% Study channel-to-channel response; linearity Monitoring tool · Calibration software runs in L 3 node · Accumulates ADC counts/channel · Calculate mean, sigma for both gains (x 1/x 8) · Send results to calibration server database · Version of cal_elec runs on the online host (since Feb – commissioning milestone) u u Grabs data from data distributor Calculates and reports running means/sigmas Print status reports Being used to debug ECN East crates · Still needed for Examines u u u 20 Single event dump (hex) Pulser control interface Communication with taker, COOR, comics 20 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Online Calorimeter Calibration · Database design/implement by SUNYSB & Paris · Accumulate zero-bias data for each calorimeter cell u u Pedestals – electronic & Ur noise Pulsed – gains · Goals u u u Measure electronics to < 1% Study channel-to-channel response; linearity Monitoring tool · Calibration software runs in L 3 node · Accumulates ADC counts/channel · Calculate mean, sigma for both gains (x 1/x 8) · Send results to calibration server database · Version of cal_elec runs on the online host (since Feb – commissioning milestone) u u Grabs data from data distributor Calculates and reports running means/sigmas Print status reports Being used to debug ECN East crates · Still needed for Examines u u u 20 Single event dump (hex) Pulser control interface Communication with taker, COOR, comics 20 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Pedestal Data from DAQ Commissioning Mean vs. channel Sigma vs. channel Means crate 11 Sigma tails from preamp capacitance 21 21 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Pedestal Data from DAQ Commissioning Mean vs. channel Sigma vs. channel Means crate 11 Sigma tails from preamp capacitance 21 21 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

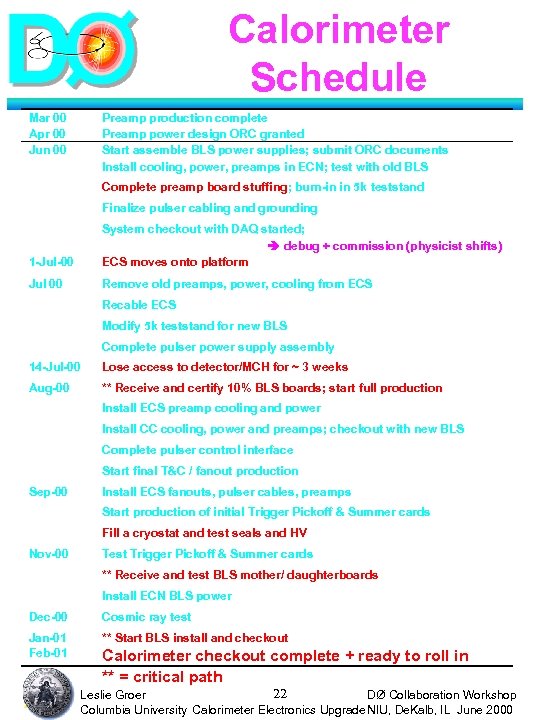

Calorimeter Schedule Mar 00 Apr 00 Jun 00 Preamp production complete Preamp power design ORC granted Start assemble BLS power supplies; submit ORC documents Install cooling, power, preamps in ECN; test with old BLS Complete preamp board stuffing; burn-in in 5 k teststand Finalize pulser cabling and grounding 1 -Jul-00 System checkout with DAQ started; debug + commission (physicist shifts) ECS moves onto platform Jul 00 Remove old preamps, power, cooling from ECS Recable ECS Modify 5 k teststand for new BLS Complete pulser power supply assembly 14 -Jul-00 Lose access to detector/MCH for ~ 3 weeks Aug-00 ** Receive and certify 10% BLS boards; start full production Install ECS preamp cooling and power Install CC cooling, power and preamps; checkout with new BLS Complete pulser control interface Start final T&C / fanout production Sep-00 Install ECS fanouts, pulser cables, preamps Start production of initial Trigger Pickoff & Summer cards Fill a cryostat and test seals and HV Nov-00 Test Trigger Pickoff & Summer cards ** Receive and test BLS mother/ daughterboards Install ECN BLS power Dec-00 Cosmic ray test Jan-01 Feb-01 ** Start BLS install and checkout 22 Calorimeter checkout complete + ready to roll in ** = critical path 22 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calorimeter Schedule Mar 00 Apr 00 Jun 00 Preamp production complete Preamp power design ORC granted Start assemble BLS power supplies; submit ORC documents Install cooling, power, preamps in ECN; test with old BLS Complete preamp board stuffing; burn-in in 5 k teststand Finalize pulser cabling and grounding 1 -Jul-00 System checkout with DAQ started; debug + commission (physicist shifts) ECS moves onto platform Jul 00 Remove old preamps, power, cooling from ECS Recable ECS Modify 5 k teststand for new BLS Complete pulser power supply assembly 14 -Jul-00 Lose access to detector/MCH for ~ 3 weeks Aug-00 ** Receive and certify 10% BLS boards; start full production Install ECS preamp cooling and power Install CC cooling, power and preamps; checkout with new BLS Complete pulser control interface Start final T&C / fanout production Sep-00 Install ECS fanouts, pulser cables, preamps Start production of initial Trigger Pickoff & Summer cards Fill a cryostat and test seals and HV Nov-00 Test Trigger Pickoff & Summer cards ** Receive and test BLS mother/ daughterboards Install ECN BLS power Dec-00 Cosmic ray test Jan-01 Feb-01 ** Start BLS install and checkout 22 Calorimeter checkout complete + ready to roll in ** = critical path 22 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

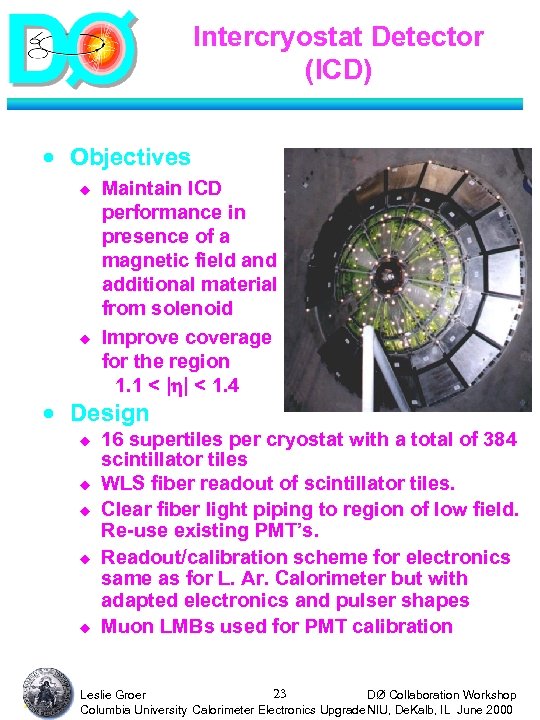

Intercryostat Detector (ICD) · Objectives u u Maintain ICD performance in presence of a magnetic field and additional material from solenoid Improve coverage for the region 1. 1 < | | < 1. 4 · Design u u u 23 16 supertiles per cryostat with a total of 384 scintillator tiles WLS fiber readout of scintillator tiles. Clear fiber light piping to region of low field. Re-use existing PMT’s. Readout/calibration scheme for electronics same as for L. Ar. Calorimeter but with adapted electronics and pulser shapes Muon LMBs used for PMT calibration 23 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Intercryostat Detector (ICD) · Objectives u u Maintain ICD performance in presence of a magnetic field and additional material from solenoid Improve coverage for the region 1. 1 < | | < 1. 4 · Design u u u 23 16 supertiles per cryostat with a total of 384 scintillator tiles WLS fiber readout of scintillator tiles. Clear fiber light piping to region of low field. Re-use existing PMT’s. Readout/calibration scheme for electronics same as for L. Ar. Calorimeter but with adapted electronics and pulser shapes Muon LMBs used for PMT calibration 23 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

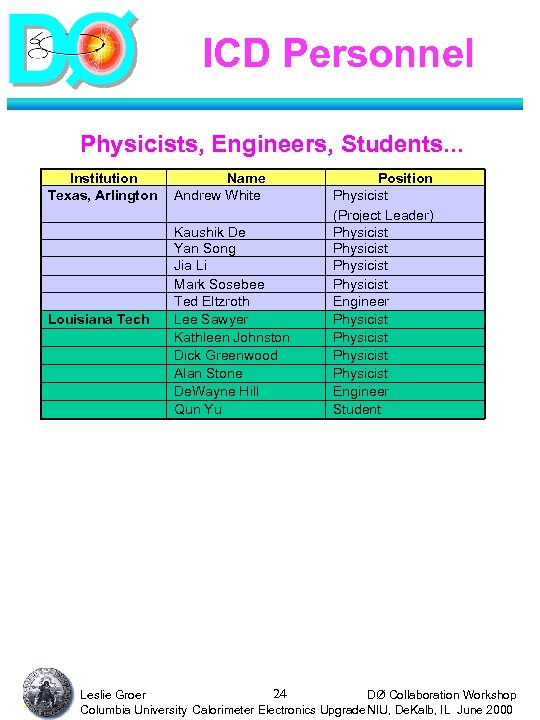

ICD Personnel Physicists, Engineers, Students. . . Institution Texas, Arlington Louisiana Tech 24 Name Andrew White Kaushik De Yan Song Jia Li Mark Sosebee Ted Eltzroth Lee Sawyer Kathleen Johnston Dick Greenwood Alan Stone De. Wayne Hill Qun Yu Position Physicist (Project Leader) Physicist Physicist Engineer Student 24 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

ICD Personnel Physicists, Engineers, Students. . . Institution Texas, Arlington Louisiana Tech 24 Name Andrew White Kaushik De Yan Song Jia Li Mark Sosebee Ted Eltzroth Lee Sawyer Kathleen Johnston Dick Greenwood Alan Stone De. Wayne Hill Qun Yu Position Physicist (Project Leader) Physicist Physicist Engineer Student 24 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

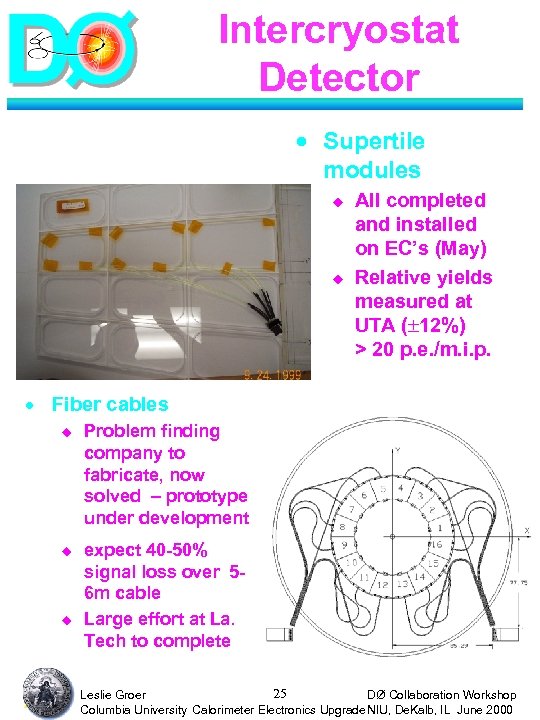

Intercryostat Detector · Supertile modules u u All completed and installed on EC’s (May) Relative yields measured at UTA ( 12%) > 20 p. e. /m. i. p. · Fiber cables u u u 25 Problem finding company to fabricate, now solved – prototype under development expect 40 -50% signal loss over 56 m cable Large effort at La. Tech to complete 25 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Intercryostat Detector · Supertile modules u u All completed and installed on EC’s (May) Relative yields measured at UTA ( 12%) > 20 p. e. /m. i. p. · Fiber cables u u u 25 Problem finding company to fabricate, now solved – prototype under development expect 40 -50% signal loss over 56 m cable Large effort at La. Tech to complete 25 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

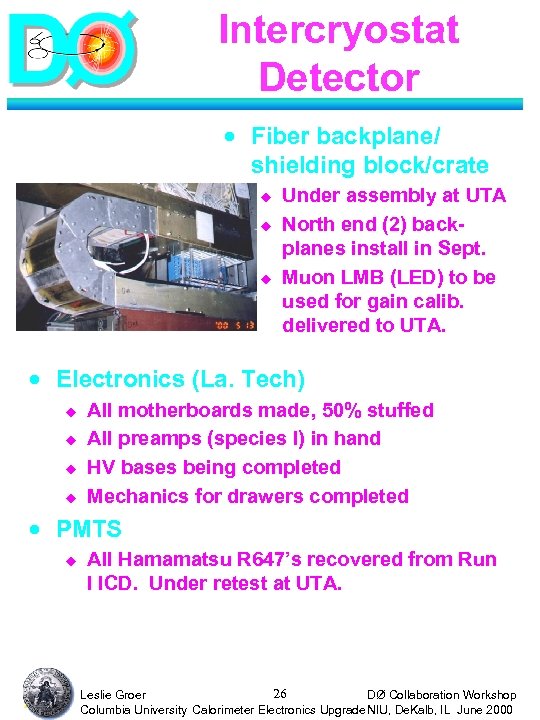

Intercryostat Detector · Fiber backplane/ shielding block/crate u u u Under assembly at UTA North end (2) backplanes install in Sept. Muon LMB (LED) to be used for gain calib. delivered to UTA. · Electronics (La. Tech) u u All motherboards made, 50% stuffed All preamps (species I) in hand HV bases being completed Mechanics for drawers completed · PMTS u 26 All Hamamatsu R 647’s recovered from Run I ICD. Under retest at UTA. 26 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Intercryostat Detector · Fiber backplane/ shielding block/crate u u u Under assembly at UTA North end (2) backplanes install in Sept. Muon LMB (LED) to be used for gain calib. delivered to UTA. · Electronics (La. Tech) u u All motherboards made, 50% stuffed All preamps (species I) in hand HV bases being completed Mechanics for drawers completed · PMTS u 26 All Hamamatsu R 647’s recovered from Run I ICD. Under retest at UTA. 26 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

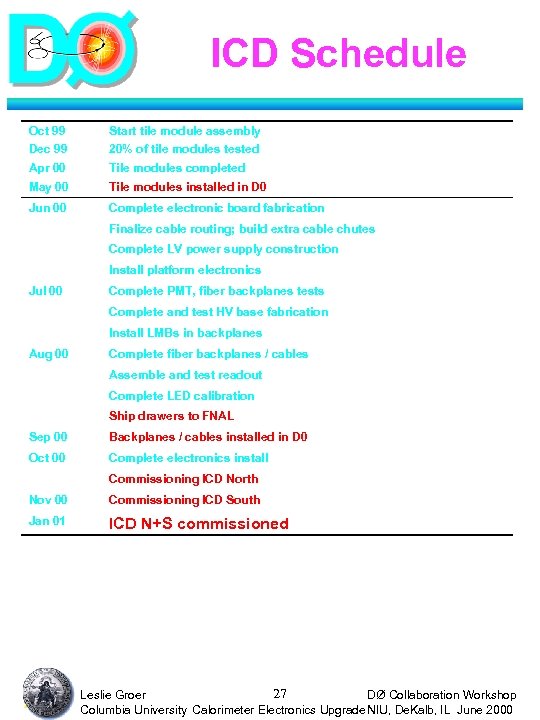

ICD Schedule Oct 99 Start tile module assembly Dec 99 20% of tile modules tested Apr 00 Tile modules completed May 00 Tile modules installed in D 0 Jun 00 Complete electronic board fabrication Finalize cable routing; build extra cable chutes Complete LV power supply construction Install platform electronics Jul 00 Complete PMT, fiber backplanes tests Complete and test HV base fabrication Install LMBs in backplanes Aug 00 Complete fiber backplanes / cables Assemble and test readout Complete LED calibration Ship drawers to FNAL Sep 00 Backplanes / cables installed in D 0 Oct 00 Complete electronics install Commissioning ICD North Nov 00 Commissioning ICD South Jan 01 ICD N+S commissioned 27 27 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

ICD Schedule Oct 99 Start tile module assembly Dec 99 20% of tile modules tested Apr 00 Tile modules completed May 00 Tile modules installed in D 0 Jun 00 Complete electronic board fabrication Finalize cable routing; build extra cable chutes Complete LV power supply construction Install platform electronics Jul 00 Complete PMT, fiber backplanes tests Complete and test HV base fabrication Install LMBs in backplanes Aug 00 Complete fiber backplanes / cables Assemble and test readout Complete LED calibration Ship drawers to FNAL Sep 00 Backplanes / cables installed in D 0 Oct 00 Complete electronics install Commissioning ICD North Nov 00 Commissioning ICD South Jan 01 ICD N+S commissioned 27 27 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

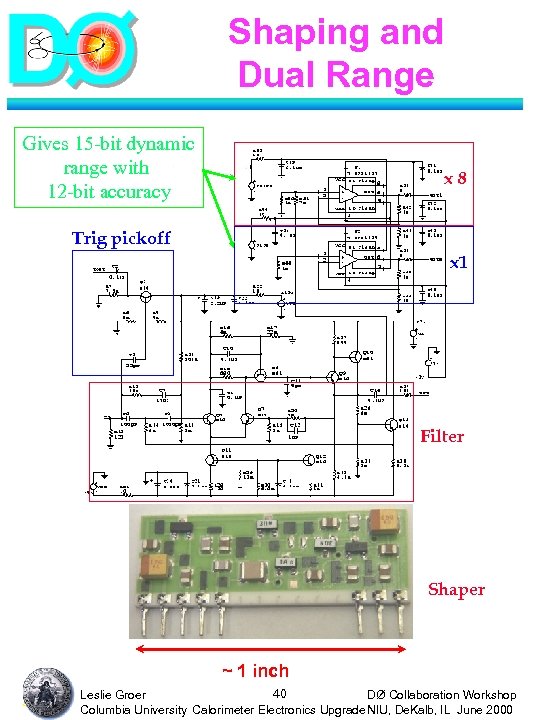

Shaping and Dual Range Gives 15 -bit dynamic range with 12 -bit accuracy x 8 Trig pickoff x 1 Filter Shaper ~ 1 inch 40 40 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Shaping and Dual Range Gives 15 -bit dynamic range with 12 -bit accuracy x 8 Trig pickoff x 1 Filter Shaper ~ 1 inch 40 40 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

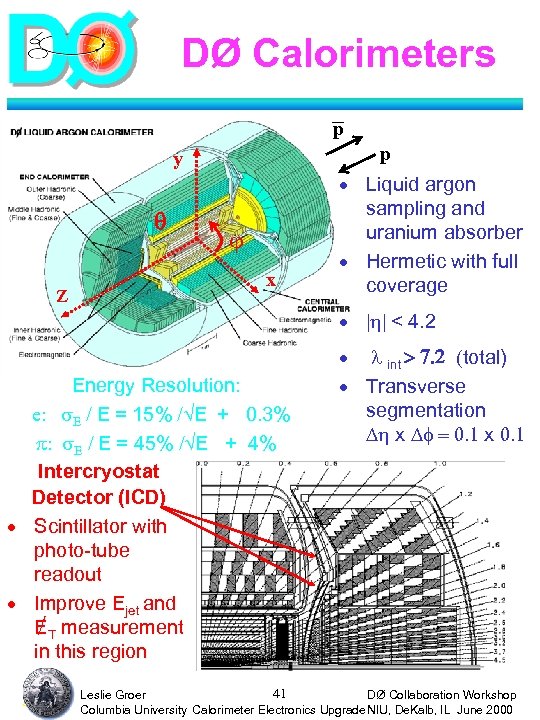

DØ Calorimeters _ p p y q Z j x · Liquid argon sampling and uranium absorber · Hermetic with full coverage · |h| < 4. 2 Energy Resolution: e: s. E / E = 15% /ÖE + 0. 3% : s. E / E = 45% /ÖE + 4% Intercryostat Detector (ICD) · Scintillator with photo-tube readout · Improve Ejet and ET measurement / in this region 41 · l int > 7. 2 (total) · Transverse segmentation Dh x D = 0. 1 x 0. 1 41 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

DØ Calorimeters _ p p y q Z j x · Liquid argon sampling and uranium absorber · Hermetic with full coverage · |h| < 4. 2 Energy Resolution: e: s. E / E = 15% /ÖE + 0. 3% : s. E / E = 45% /ÖE + 4% Intercryostat Detector (ICD) · Scintillator with photo-tube readout · Improve Ejet and ET measurement / in this region 41 · l int > 7. 2 (total) · Transverse segmentation Dh x D = 0. 1 x 0. 1 41 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calorimeter Electronics Upgrade Leslie Groer Columbia University New York June 20, 2000 DØ Collaboration Workshop NIU, De. Kalb, Illinois June 19– 23, 2000 42 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Calorimeter Electronics Upgrade Leslie Groer Columbia University New York June 20, 2000 DØ Collaboration Workshop NIU, De. Kalb, Illinois June 19– 23, 2000 42 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

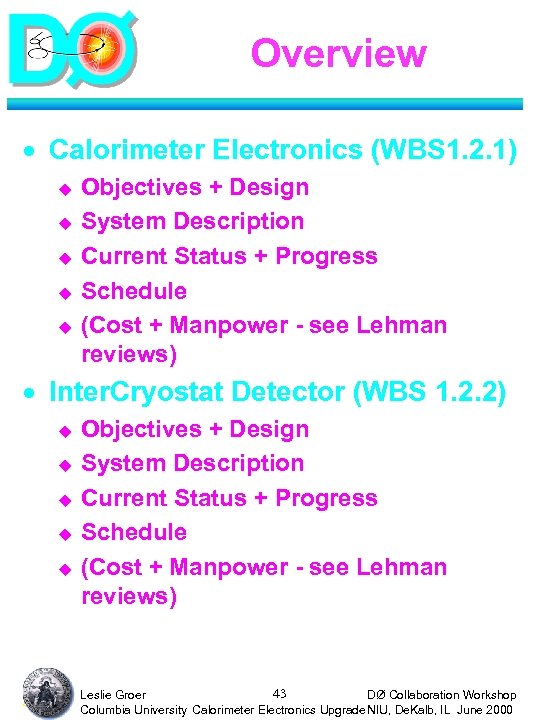

Overview · Calorimeter Electronics (WBS 1. 2. 1) u u u Objectives + Design System Description Current Status + Progress Schedule (Cost + Manpower - see Lehman reviews) · Inter. Cryostat Detector (WBS 1. 2. 2) u u u 43 Objectives + Design System Description Current Status + Progress Schedule (Cost + Manpower - see Lehman reviews) 43 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000

Overview · Calorimeter Electronics (WBS 1. 2. 1) u u u Objectives + Design System Description Current Status + Progress Schedule (Cost + Manpower - see Lehman reviews) · Inter. Cryostat Detector (WBS 1. 2. 2) u u u 43 Objectives + Design System Description Current Status + Progress Schedule (Cost + Manpower - see Lehman reviews) 43 Leslie Groer DØ Collaboration Workshop Columbia University Calorimeter Electronics Upgrade NIU, De. Kalb, IL June 2000