b4965575e1030adf4c0222416acda8a0.ppt

- Количество слайдов: 20

Calibration Management In Food & Beverage 10/07/2009 Matthias Schuetzeberg 1

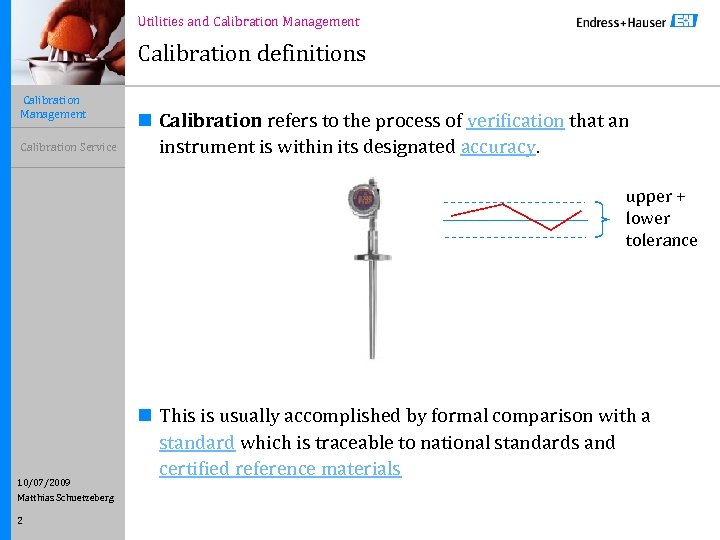

Utilities and Calibration Management Calibration definitions Calibration Management Calibration Service n Calibration refers to the process of verification that an instrument is within its designated accuracy. upper + lower tolerance 10/07/2009 Matthias Schuetzeberg 2 n This is usually accomplished by formal comparison with a standard which is traceable to national standards and certified reference materials

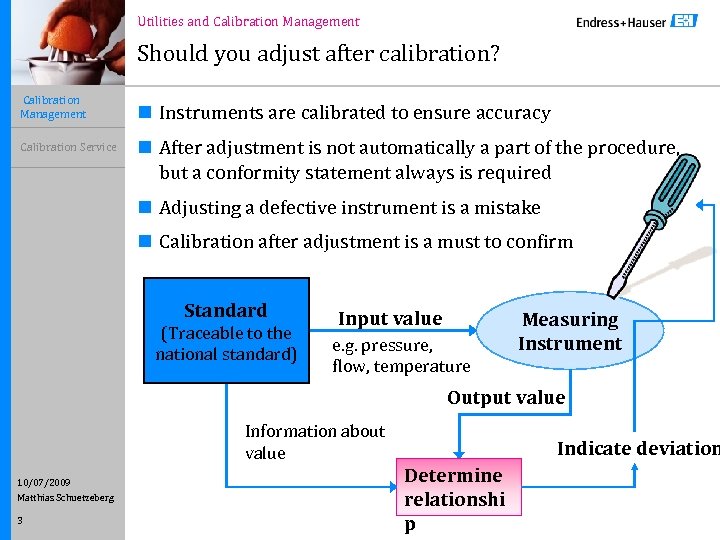

Utilities and Calibration Management Should you adjust after calibration? Calibration Management Calibration Service n Instruments are calibrated to ensure accuracy n After adjustment is not automatically a part of the procedure, but a conformity statement always is required n Adjusting a defective instrument is a mistake n Calibration after adjustment is a must to confirm Standard (Traceable to the national standard) Input value e. g. pressure, flow, temperature Measuring Instrument Output value Information about value 10/07/2009 Matthias Schuetzeberg 3 Indicate deviation Determine relationshi p

Utilities and Calibration Management Why and when do you calibrate? Calibration Management n For a new instrument Calibration Service n To ensure compliancy n At a specific frequency n when a specified usage (operating hours) has passed n when an instrument has had a shock or vibration which potentially may have put it out of calibration n whenever observations appear questionable 10/07/2009 Matthias Schuetzeberg 4

Utilities and Calibration Management Reasons for Calibration Management Calibration Service What can be a reason for calibration? - Lining is deformed - pollution/scaling on the lining - Electronics defect - Coil current is changed - Combination of factors - Legislation demands -… What could be the consequences when there is a deviation discovered? 10/07/2009 Matthias Schuetzeberg 5 - Production loss à cost loss? - Environmental impact? - Personal impact? - Lost of enegy - money lost. . .

Utilities and Calibration Management What do you do when…? Calibration Management Calibration Service …there is deviation found? Adjusting the K-factor? Replace instrument? …. - How do you record this? - Who manages this? - When is this done? - Which departments are involved? - What is the history of the instrument? - …? 10/07/2009 Matthias Schuetzeberg 7

Utilities and Calibration Management I need information about your results … Calibration Management Calibration Service 10/07/2009 Matthias Schuetzeberg 8 Tell me which assets where me. . . I need help, please tellreported with a reduce costs on Tell me, how do I find the how to deviation last year and how this is solved. calibration certificates when the maintenance and calibration auditor wants to see over the life cycle. them?

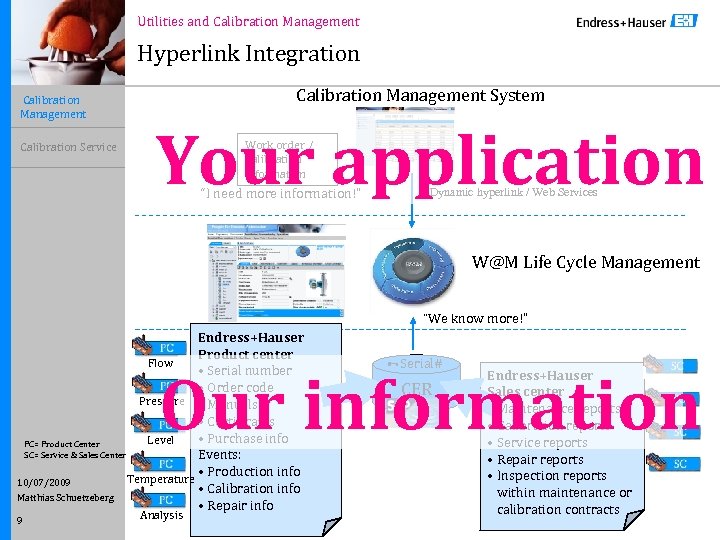

Utilities and Calibration Management Hyperlink Integration Calibration Management Calibration Service Calibration Management System Your application Work order / Calibration information “I need more information!” Dynamic hyperlink / Web Services W@M Life Cycle Management “We know more!” Endress+Hauser Product center Flow • Serial number • Order code Pressure • Manuals • Certificates • Purchase info Level PC= Product Center SC= Service & Sales Center Events: • Production info Temperature 10/07/2009 • Calibration info Matthias Schuetzeberg • Repair info Serial# Our information 9 Analysis CER Endress+Hauser Sales center • Maintenance reports • Calibration reports • Service reports • Repair reports • Inspection reports within maintenance or calibration contracts

Utilities and Calibration Management Recalibration in the factory Calibration Management Calibration Service Requirements Delivery to the factory Flowmeter must be cleaned n Accredited and traceable calibration n Diameter 1 mm up to 2000 mm n Total Accuracy 0 f 0. 05% 10/07/2009 Matthias Schuetzeberg 10 n Economical for single devices

Utilities and Calibration Management Advantage for a recalibration in field Calibration Management Calibration Service n Short shut down time only during the calibration n No mounting or demounting of the sensor n Recalibration on traceable international standards 10/07/2009 Matthias Schuetzeberg 11

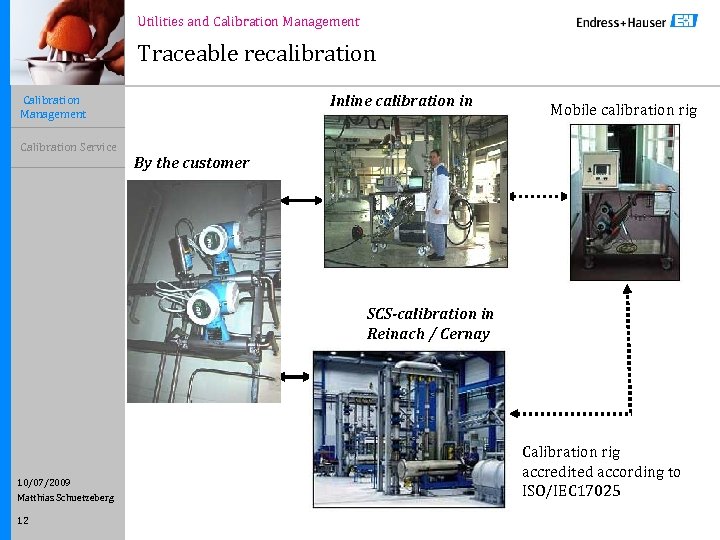

Utilities and Calibration Management Traceable recalibration Inline calibration in field Calibration Management Calibration Service Mobile calibration rig By the customer SCS-calibration in Reinach / Cernay 10/07/2009 Matthias Schuetzeberg 12 Calibration rig accredited according to ISO/IEC 17025

Utilities and Calibration Management Calibration in field Movable calibration riggs Calibration Management Calibration Service n Temperature n Pressure 10/07/2009 Matthias Schuetzeberg 13 n p. H Instruments

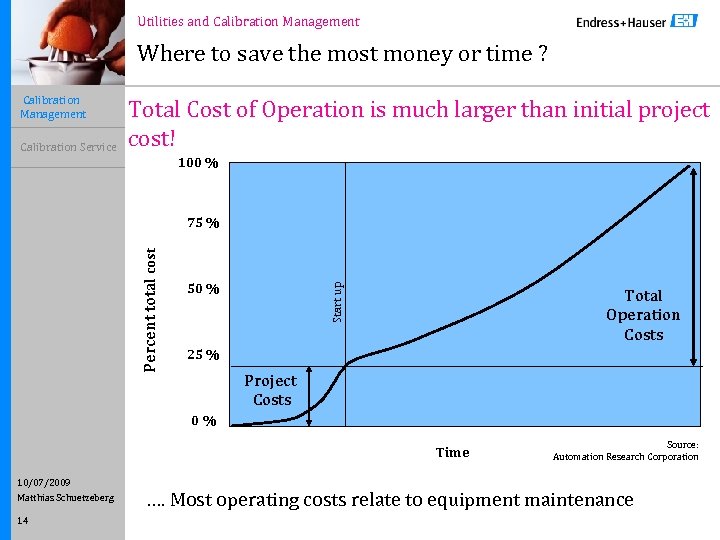

Utilities and Calibration Management Where to save the most money or time ? Calibration Management Calibration Service Total Cost of Operation is much larger than initial project cost! 100 % 50 % Start up Percent total cost 75 % Total Operation Costs 25 % Project Costs 0% Time 10/07/2009 Matthias Schuetzeberg 14 Source: Automation Research Corporation …. Most operating costs relate to equipment maintenance

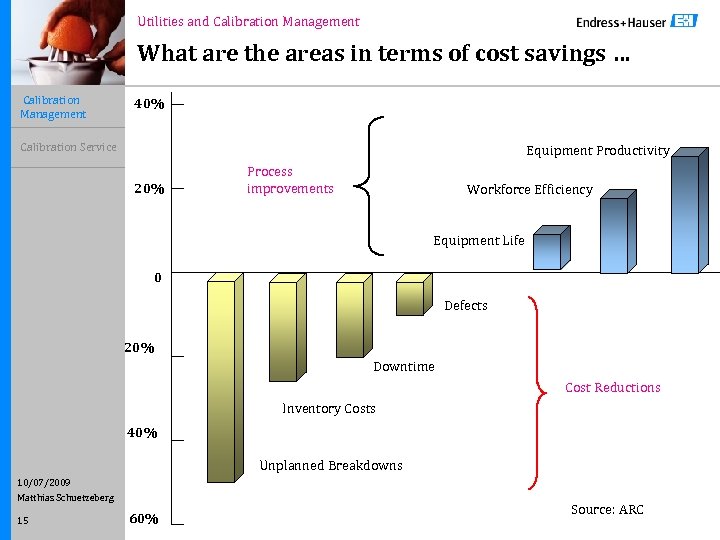

Utilities and Calibration Management What are the areas in terms of cost savings … Calibration Management 40% Calibration Service Equipment Productivity 20% Process improvements Workforce Efficiency Equipment Life 0 Defects 20% Downtime Cost Reductions Inventory Costs 40% Unplanned Breakdowns 10/07/2009 Matthias Schuetzeberg 15 60% Source: ARC

Calibration in Food Industry But there is still more to safe your money Calibration Management Calibration Service Calibration of instruments 10/07/2009 Matthias Schützeberg 18 TPPC/MEG, No. 18

Calibration in Food Industry Consider the total cost Calibration Management Calibration Service Direct cost Indirect cost 10/07/2009 Matthias Schützeberg 20

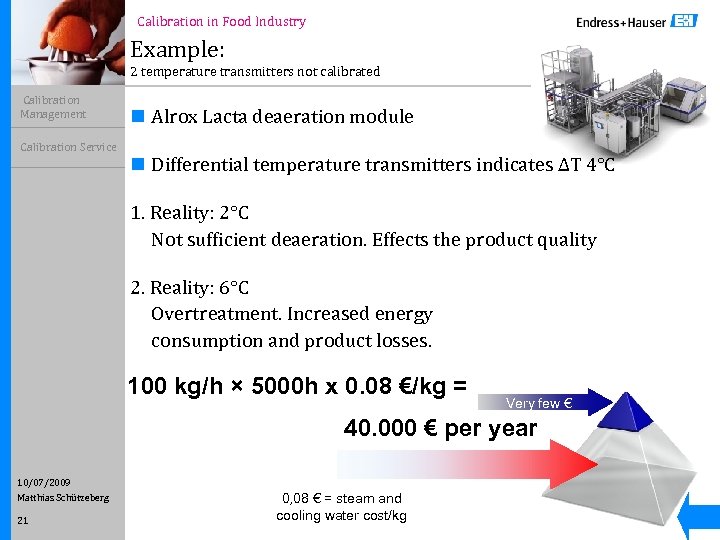

Calibration in Food Industry Example: 2 temperature transmitters not calibrated Calibration Management Calibration Service n Alrox Lacta deaeration module n Differential temperature transmitters indicates ΔT 4°C 1. Reality: 2°C Not sufficient deaeration. Effects the product quality 2. Reality: 6°C Overtreatment. Increased energy consumption and product losses. 100 kg/h × 5000 h x 0. 08 €/kg = Very few € 40. 000 € per year 10/07/2009 Matthias Schützeberg 21 0, 08 € = steam and cooling water cost/kg

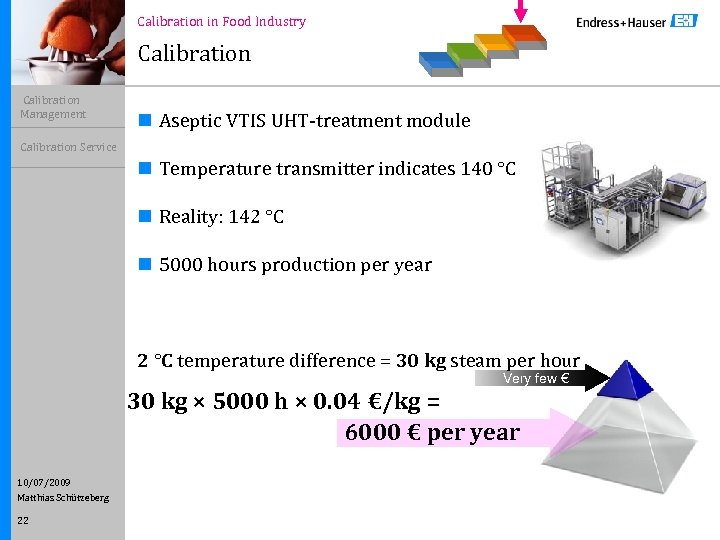

Calibration in Food Industry Calibration Management n Aseptic VTIS UHT-treatment module Calibration Service n Temperature transmitter indicates 140 °C n Reality: 142 °C n 5000 hours production per year 2 °C temperature difference = 30 kg steam per hour Very few € 30 kg × 5000 h × 0. 04 €/kg = 6000 € per year 10/07/2009 Matthias Schützeberg 22

Calibration in Food Industry Just some Questions - general Calibration Management Did you ever ask yourself… Calibration Service n…how can I ensure the quality of my product? n…how can I fulfill my calibration and maintenance obligations of my critical instruments? n…are my calibration cycles set correctly? n…are there more efficient calibration procedures than my current ones? n…how can I optimize my maintenance cost. 10/07/2009 Matthias Schützeberg 23 n…is it possible to work with one supplier for all my calibration needs?

Thank you very much for your attention! 10/07/2009 Matthias Schützeberg 24

b4965575e1030adf4c0222416acda8a0.ppt