CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH

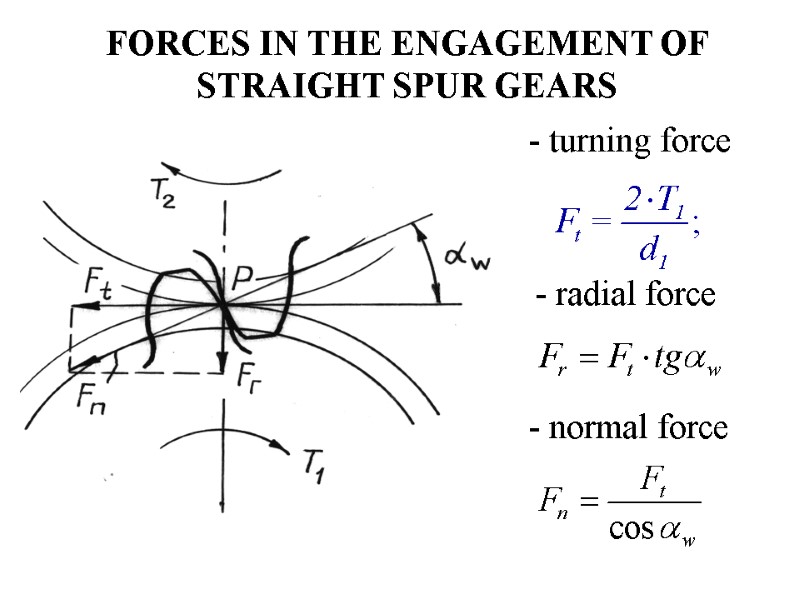

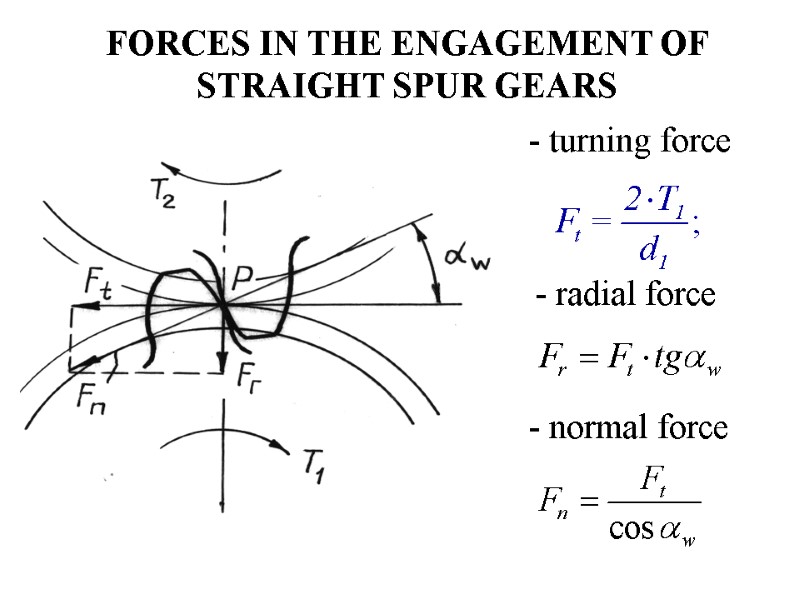

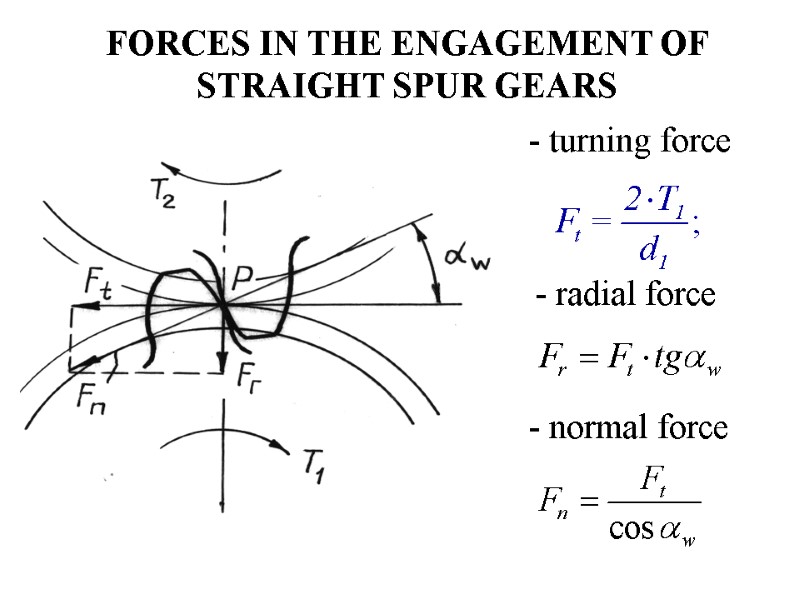

FORCES IN THE ENGAGEMENT OF STRAIGHT SPUR GEARS - turning force - radial force - normal force

FORCES IN THE ENGAGEMENT OF STRAIGHT SPUR GEARS - turning force - radial force - normal force

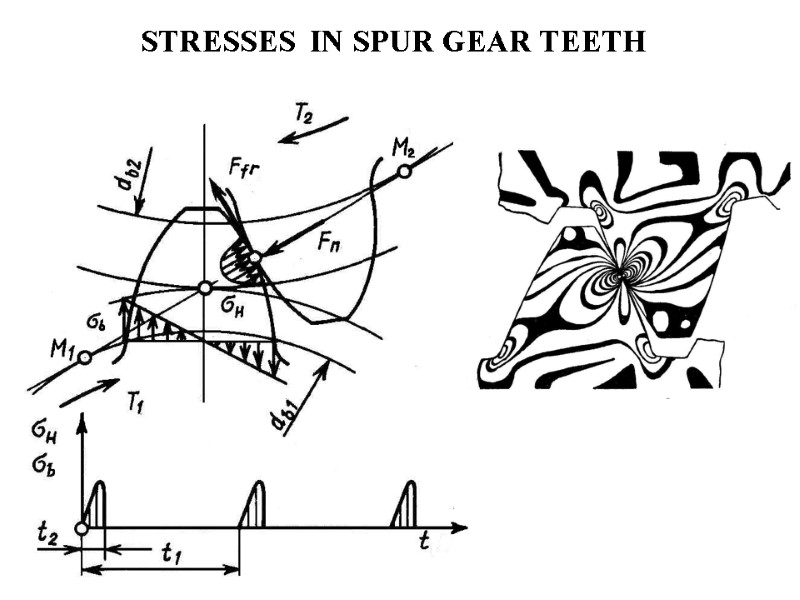

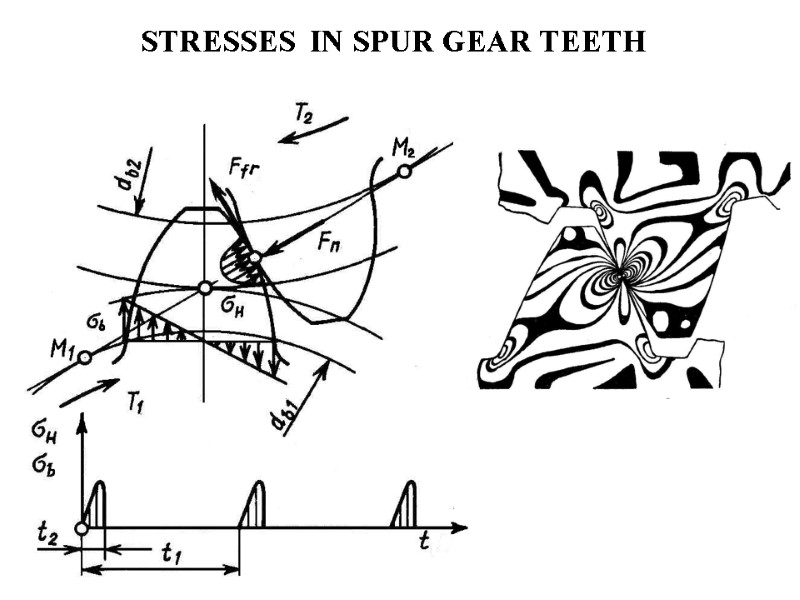

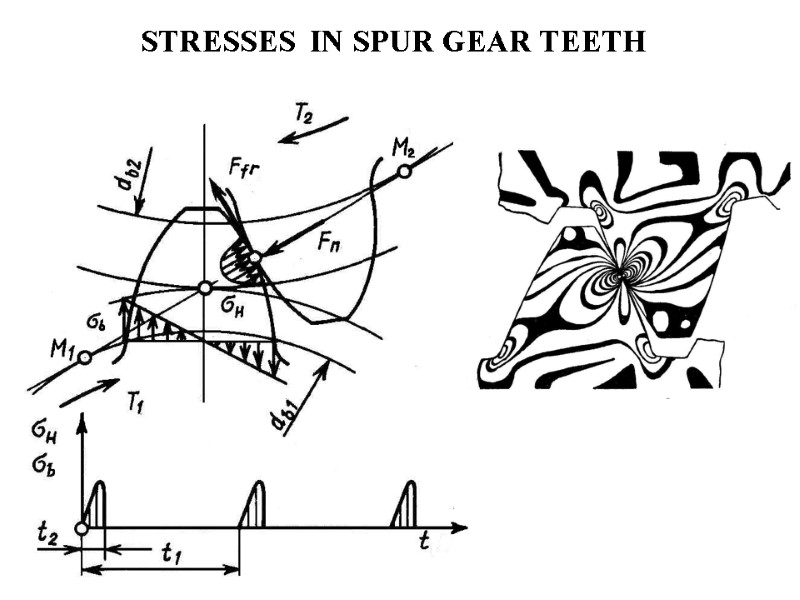

STRESSES IN SPUR GEAR TEETH

STRESSES IN SPUR GEAR TEETH

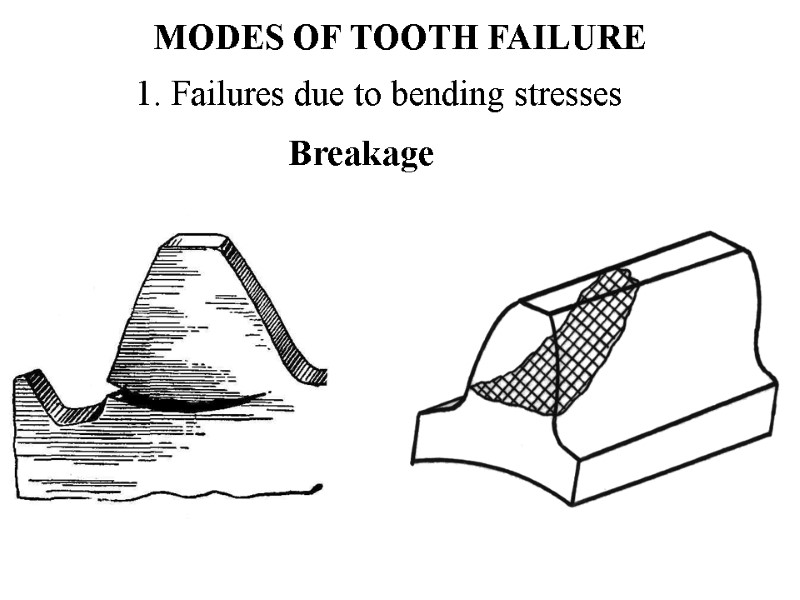

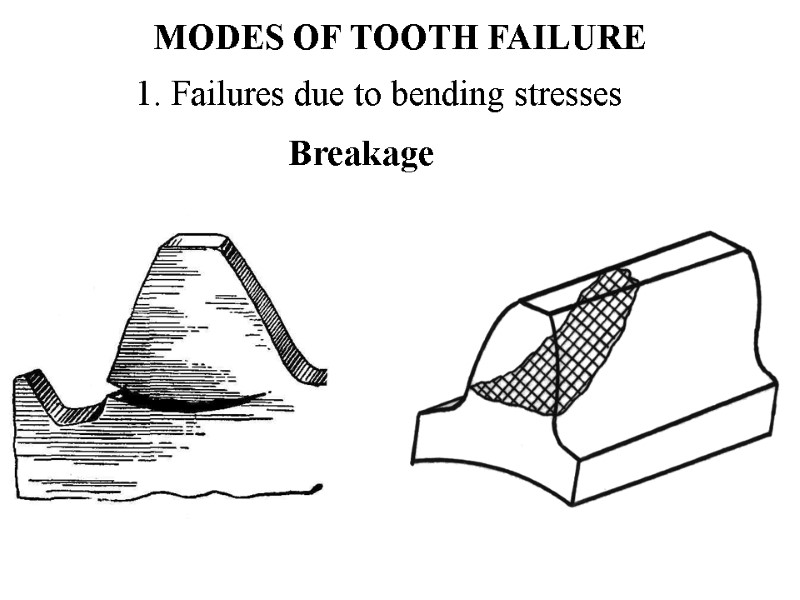

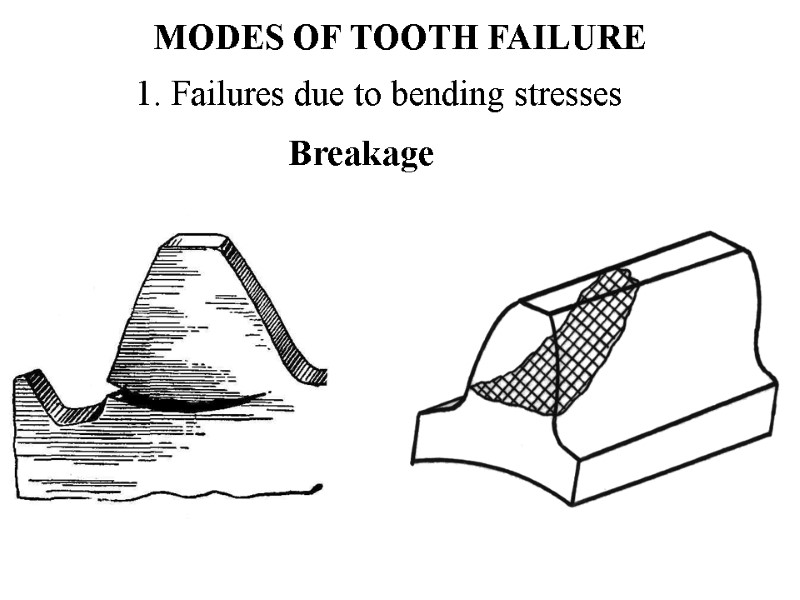

MODES OF TOOTH FAILURE 1. Failures due to bending stresses Breakage

MODES OF TOOTH FAILURE 1. Failures due to bending stresses Breakage

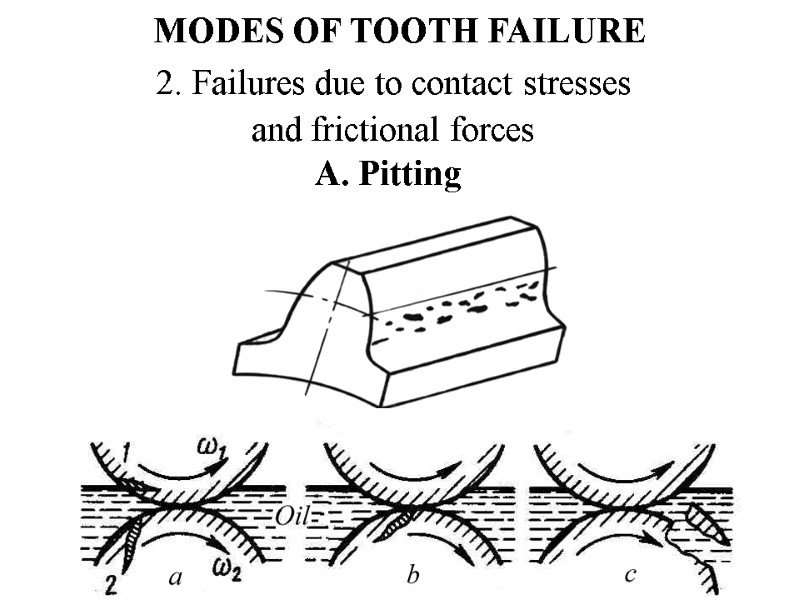

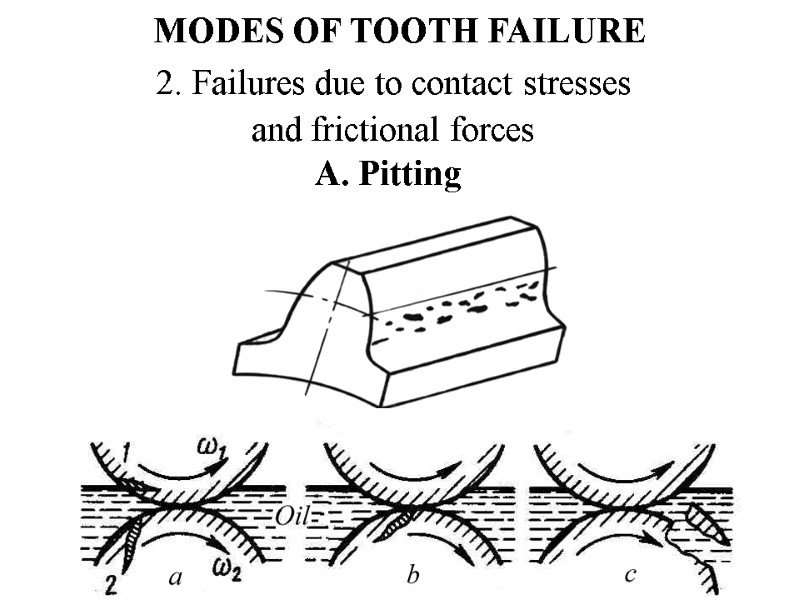

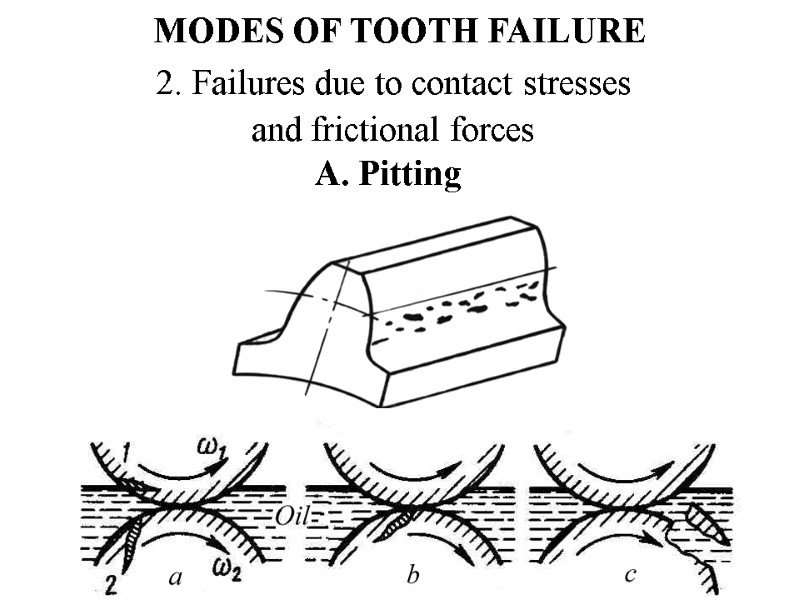

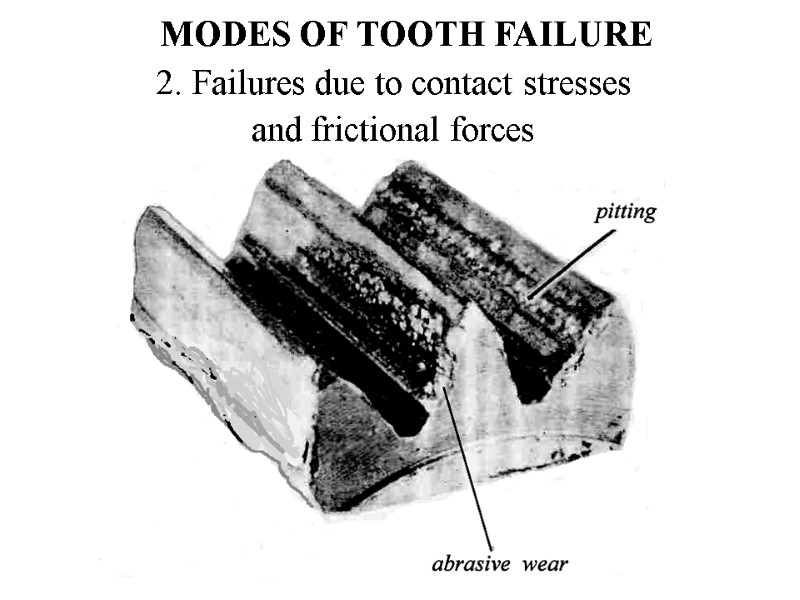

MODES OF TOOTH FAILURE 2. Failures due to contact stresses and frictional forces A. Pitting

MODES OF TOOTH FAILURE 2. Failures due to contact stresses and frictional forces A. Pitting

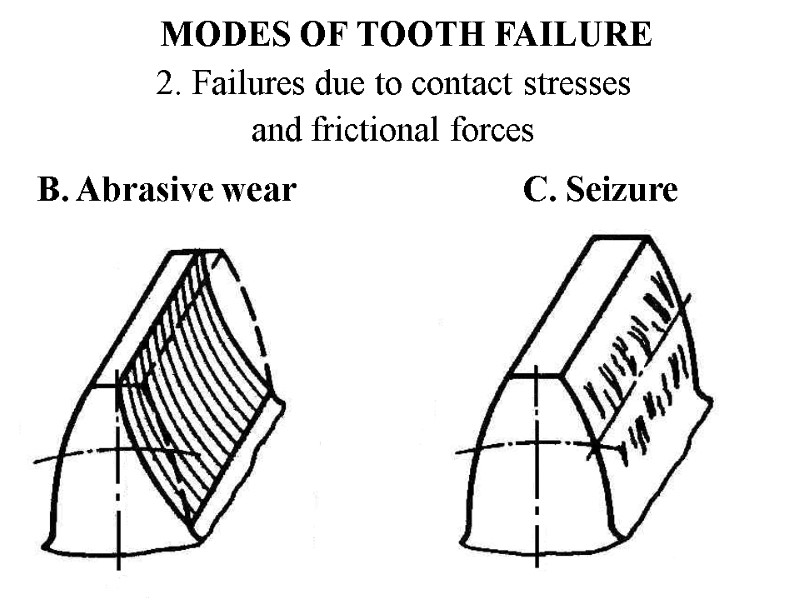

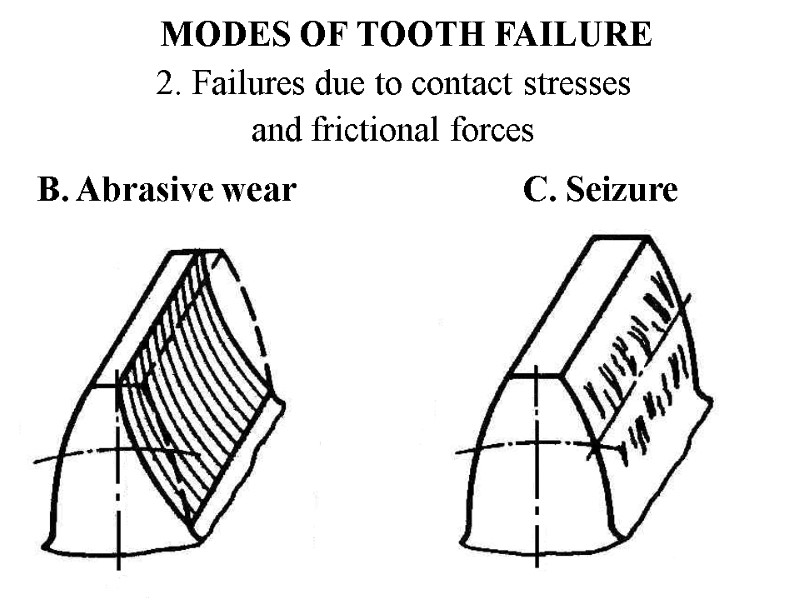

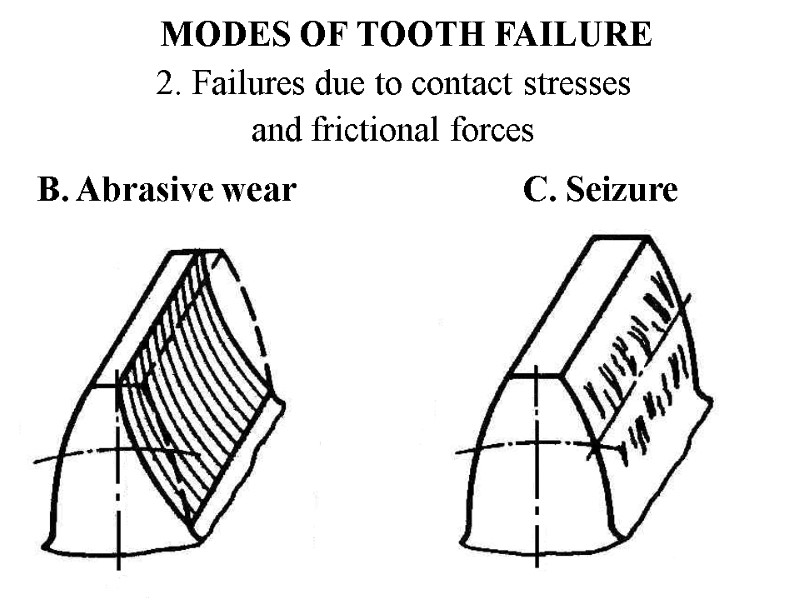

MODES OF TOOTH FAILURE 2. Failures due to contact stresses and frictional forces B. Abrasive wear C. Seizure

MODES OF TOOTH FAILURE 2. Failures due to contact stresses and frictional forces B. Abrasive wear C. Seizure

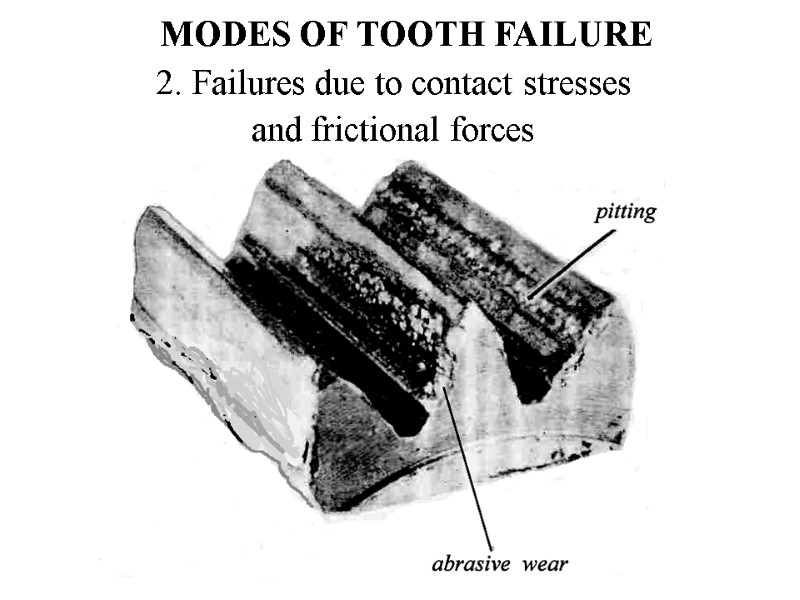

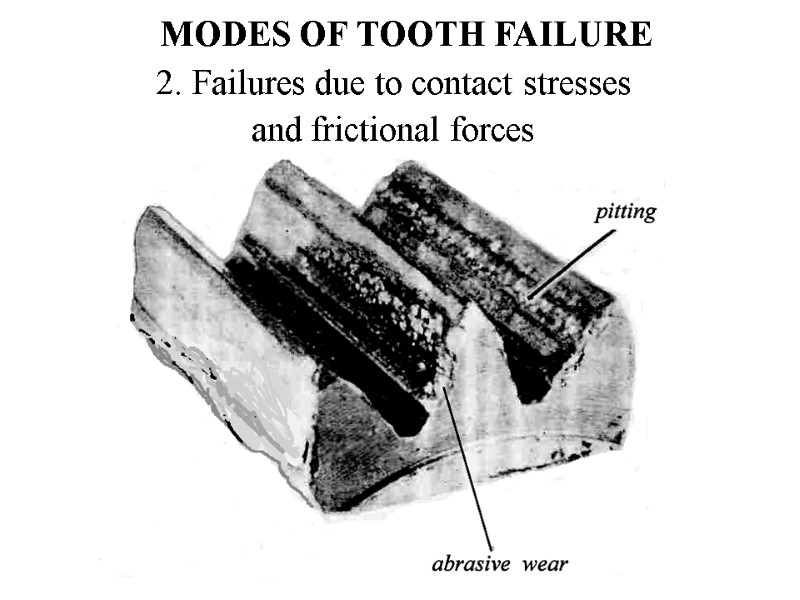

MODES OF TOOTH FAILURE 2. Failures due to contact stresses and frictional forces

MODES OF TOOTH FAILURE 2. Failures due to contact stresses and frictional forces

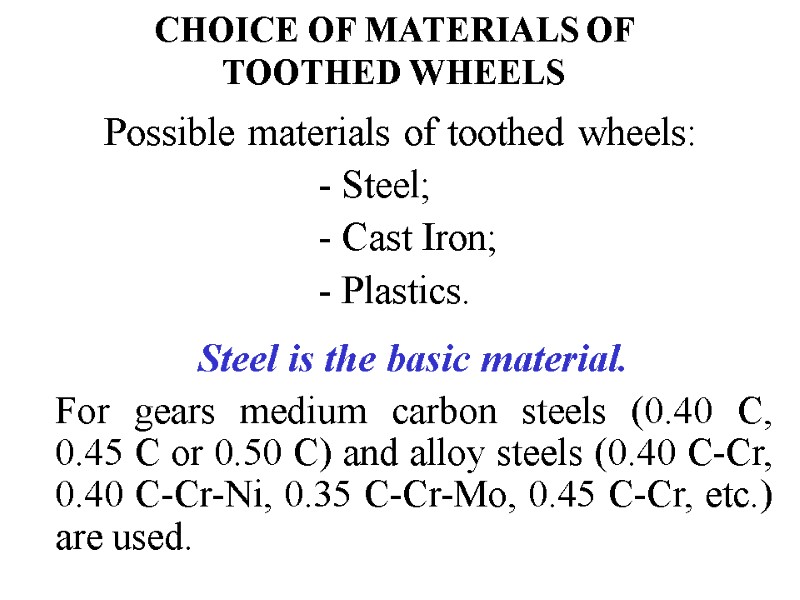

CHOICE OF MATERIALS OF TOOTHED WHEELS Possible materials of toothed wheels: - Steel; - Cast Iron; - Plastics. Steel is the basic material. For gears medium carbon steels (0.40 C, 0.45 C or 0.50 C) and alloy steels (0.40 C-Cr, 0.40 C-Cr-Ni, 0.35 C-Cr-Mo, 0.45 C-Cr, etc.) are used.

CHOICE OF MATERIALS OF TOOTHED WHEELS Possible materials of toothed wheels: - Steel; - Cast Iron; - Plastics. Steel is the basic material. For gears medium carbon steels (0.40 C, 0.45 C or 0.50 C) and alloy steels (0.40 C-Cr, 0.40 C-Cr-Ni, 0.35 C-Cr-Mo, 0.45 C-Cr, etc.) are used.

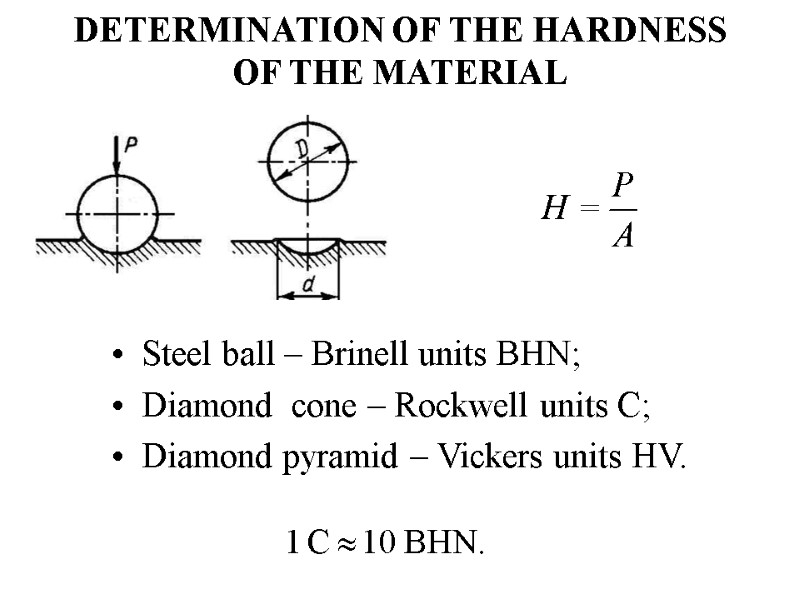

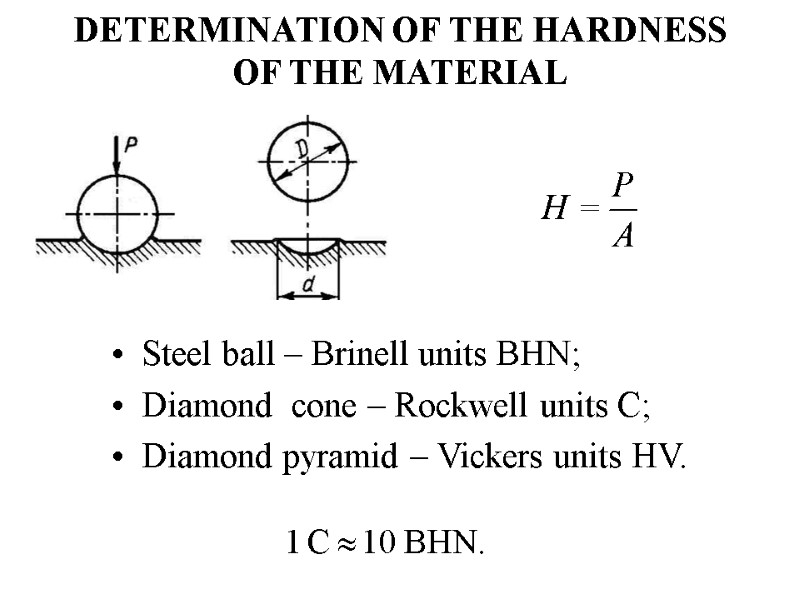

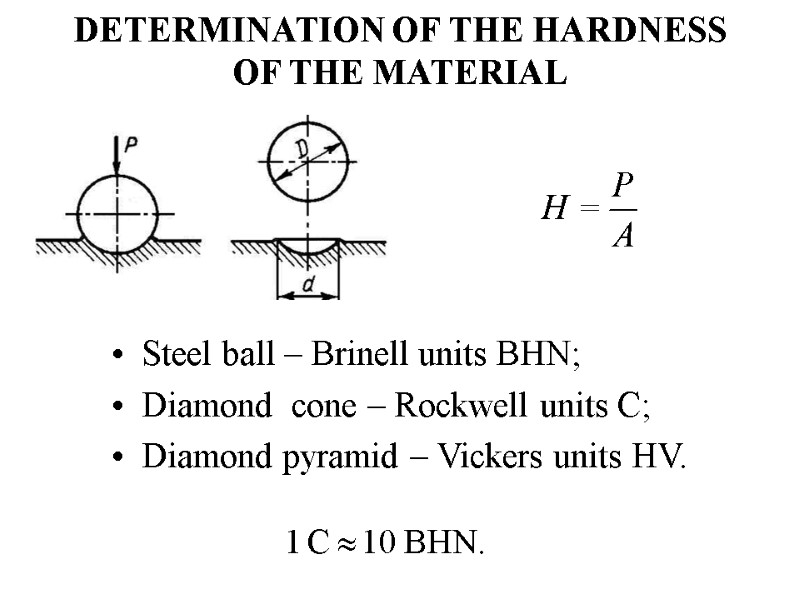

DETERMINATION OF THE HARDNESS OF THE MATERIAL Steel ball – Brinell units BHN; Diamond cone – Rockwell units C; Diamond pyramid – Vickers units HV.

DETERMINATION OF THE HARDNESS OF THE MATERIAL Steel ball – Brinell units BHN; Diamond cone – Rockwell units C; Diamond pyramid – Vickers units HV.

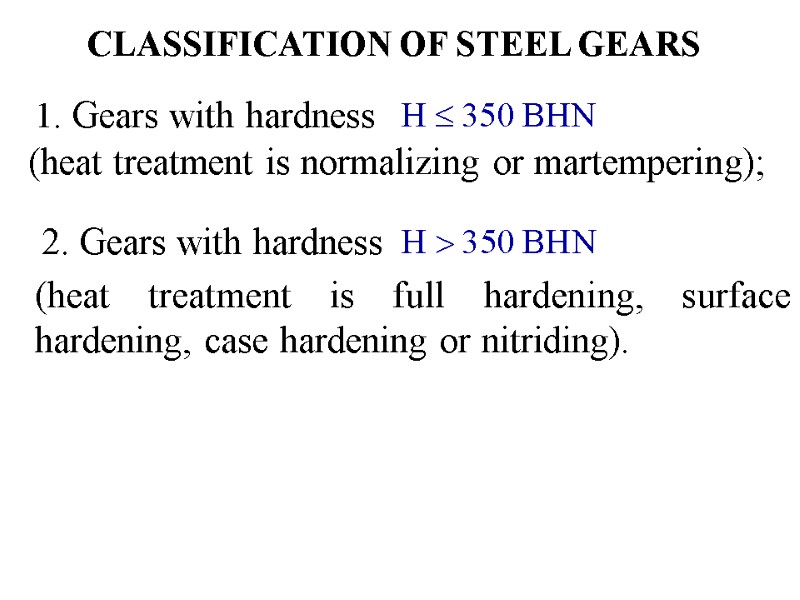

CLASSIFICATION OF STEEL GEARS 1. Gears with hardness (heat treatment is normalizing or martempering); 2. Gears with hardness (heat treatment is full hardening, surface hardening, case hardening or nitriding).

CLASSIFICATION OF STEEL GEARS 1. Gears with hardness (heat treatment is normalizing or martempering); 2. Gears with hardness (heat treatment is full hardening, surface hardening, case hardening or nitriding).

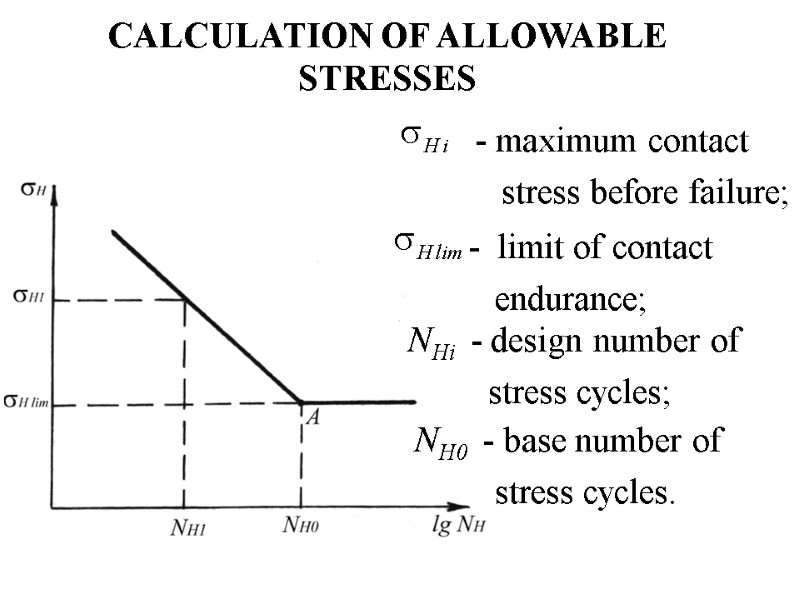

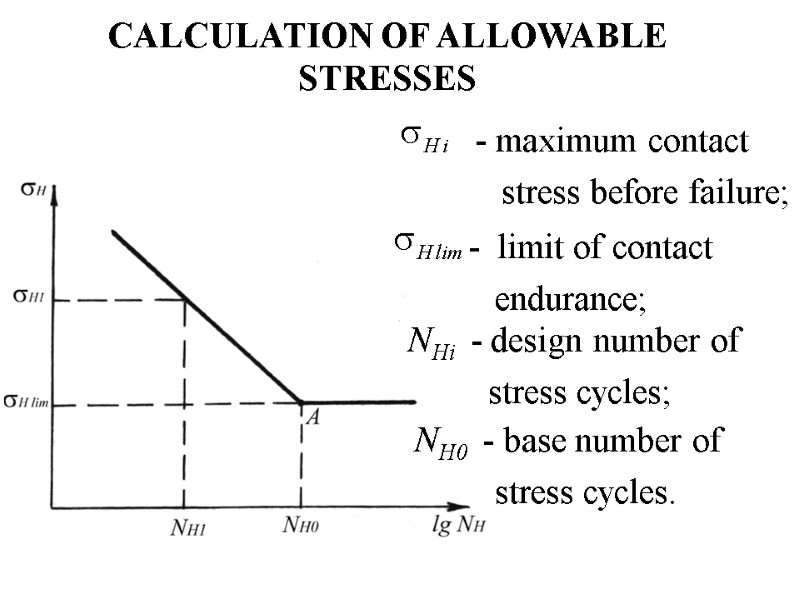

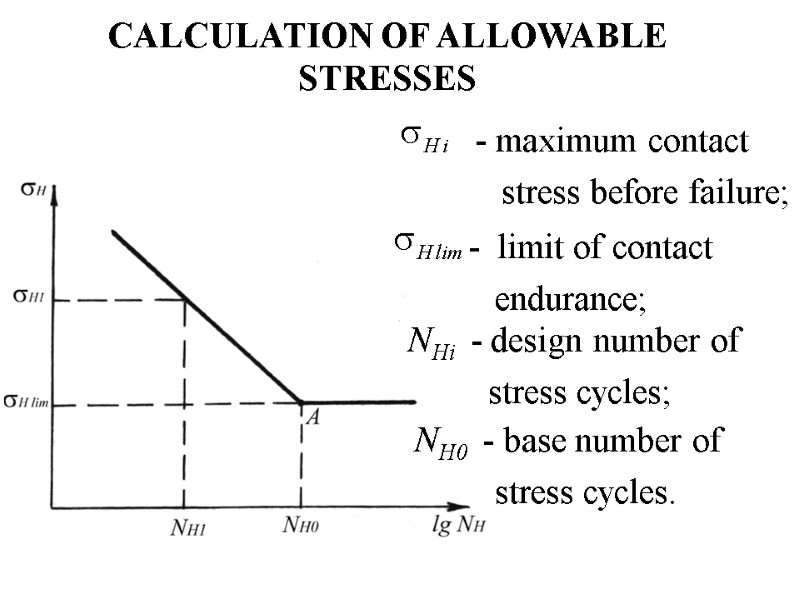

CALCULATION OF ALLOWABLE STRESSES maximum contact stress before failure; limit of contact endurance; NHi - design number of stress cycles; NH0 - base number of stress cycles.

CALCULATION OF ALLOWABLE STRESSES maximum contact stress before failure; limit of contact endurance; NHi - design number of stress cycles; NH0 - base number of stress cycles.

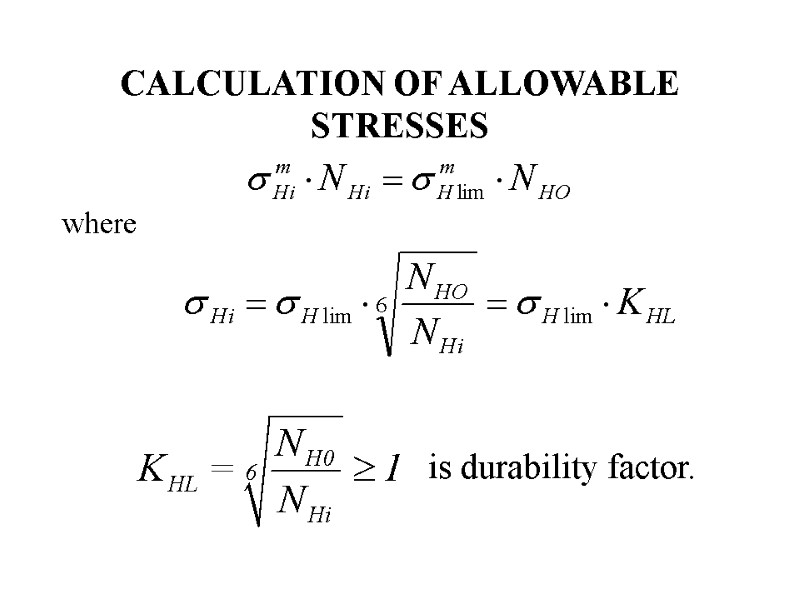

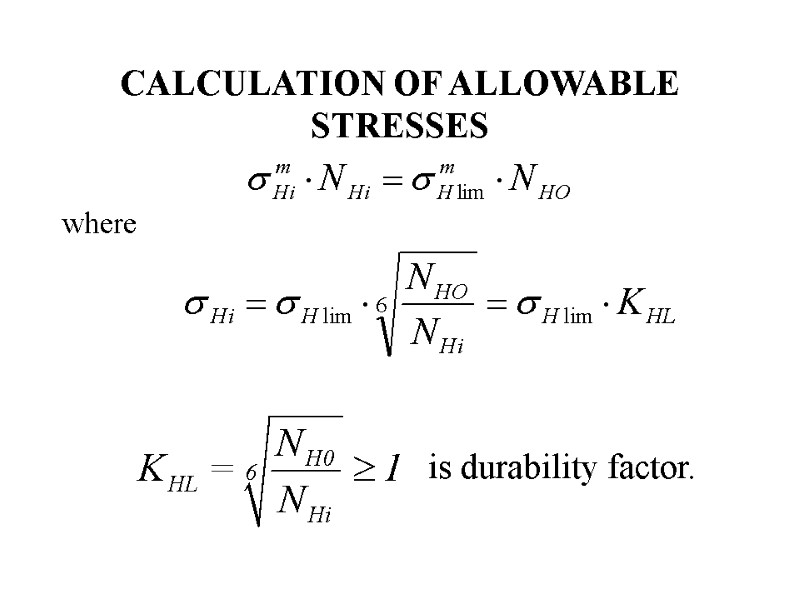

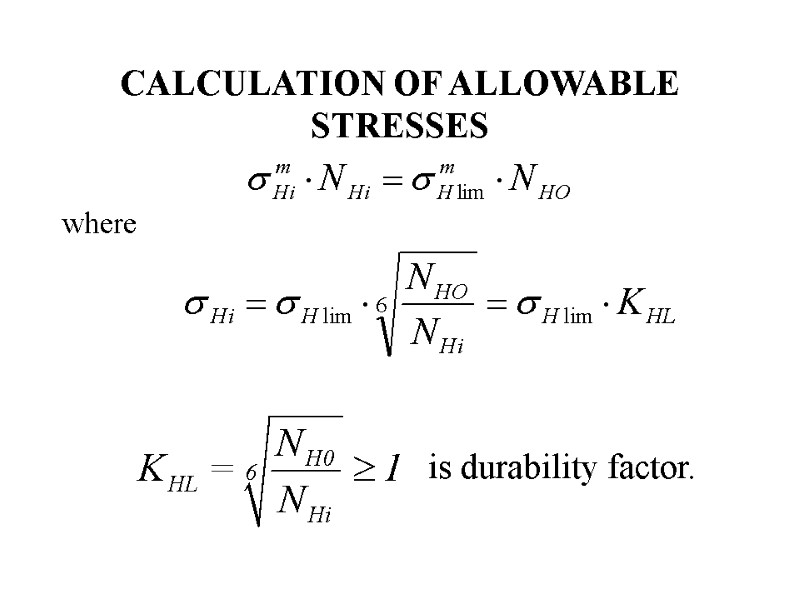

CALCULATION OF ALLOWABLE STRESSES where is durability factor.

CALCULATION OF ALLOWABLE STRESSES where is durability factor.

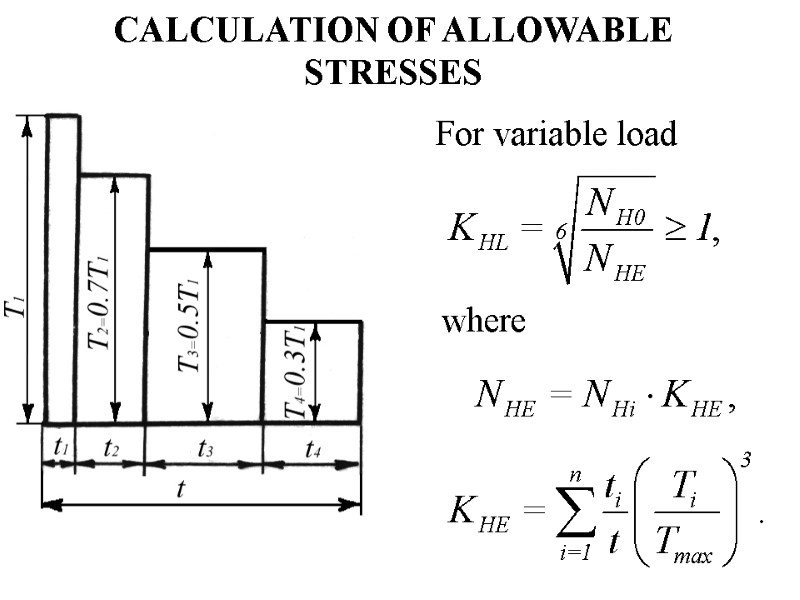

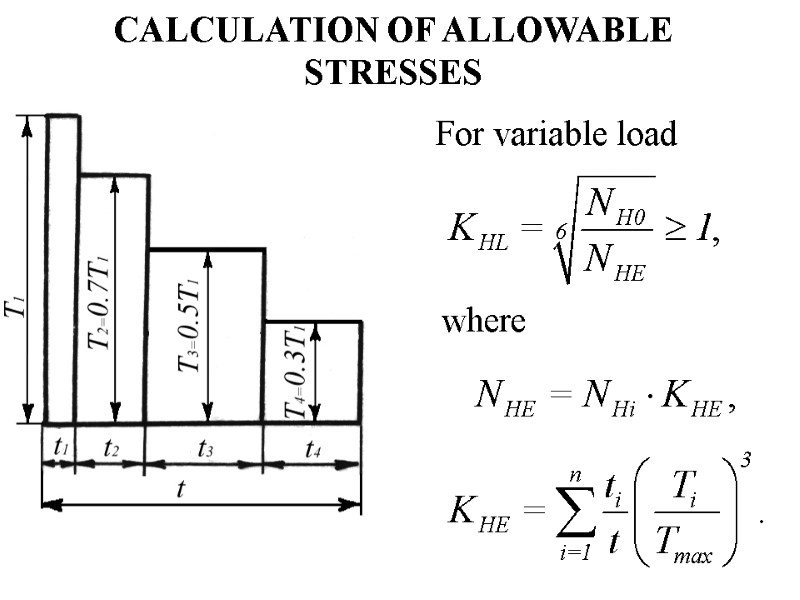

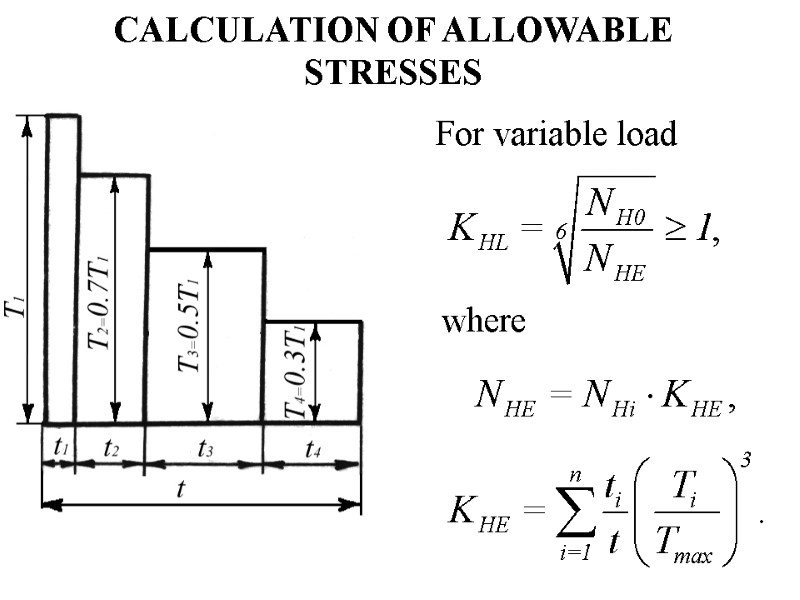

CALCULATION OF ALLOWABLE STRESSES For variable load where

CALCULATION OF ALLOWABLE STRESSES For variable load where

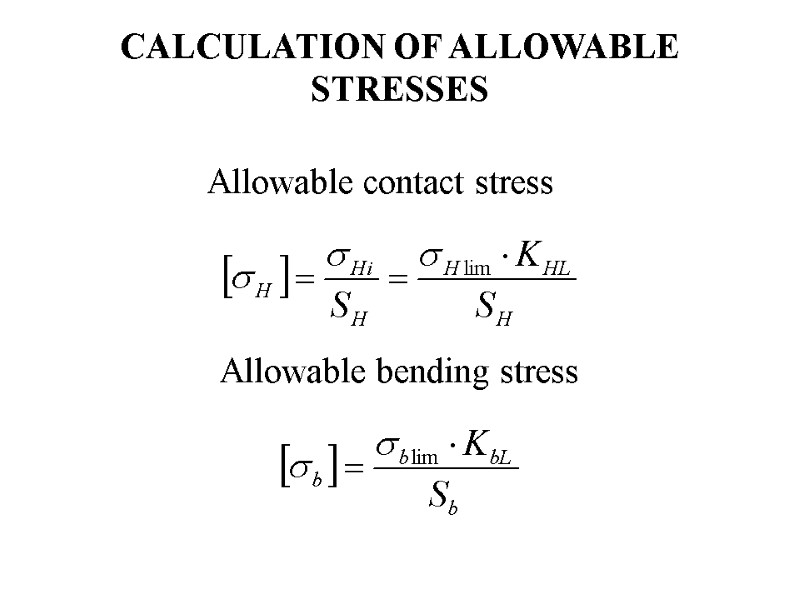

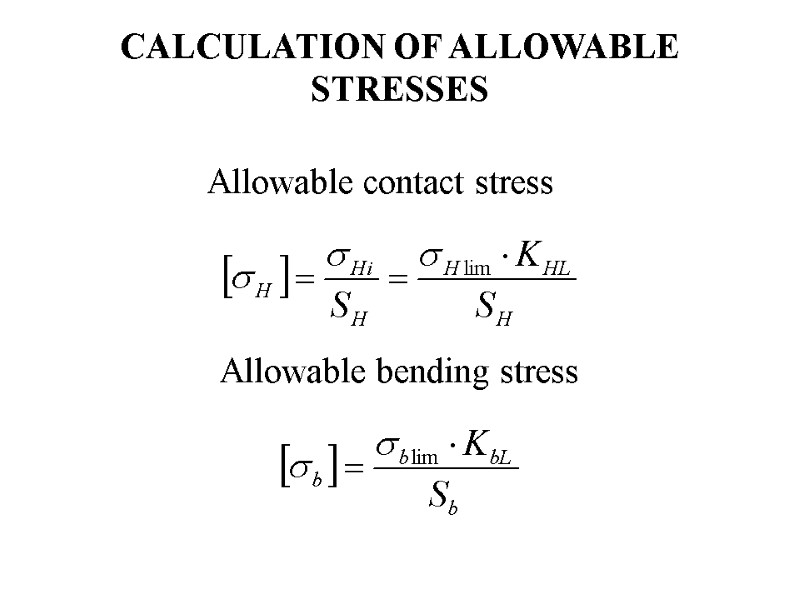

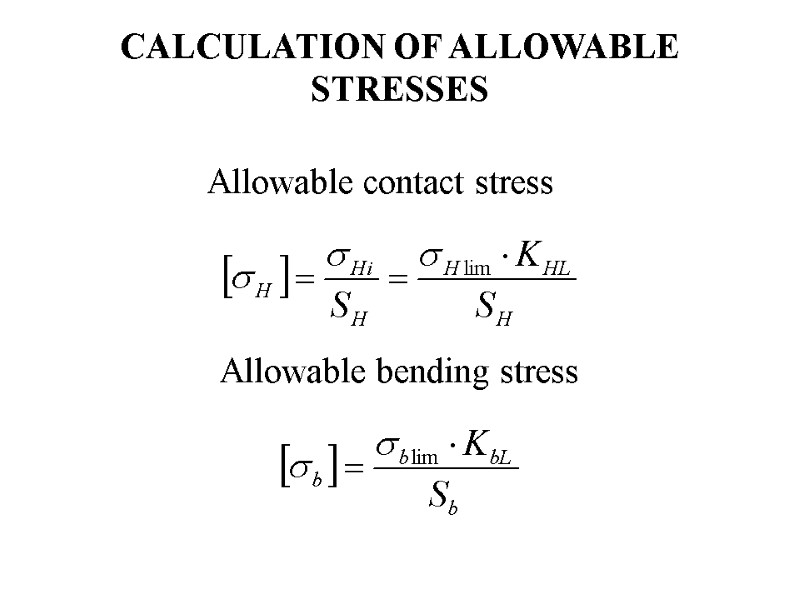

CALCULATION OF ALLOWABLE STRESSES Allowable contact stress Allowable bending stress

CALCULATION OF ALLOWABLE STRESSES Allowable contact stress Allowable bending stress

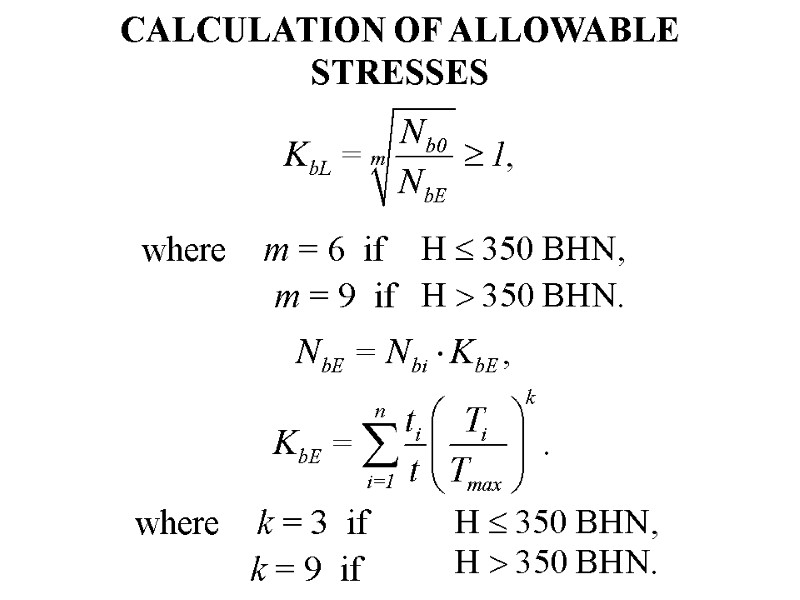

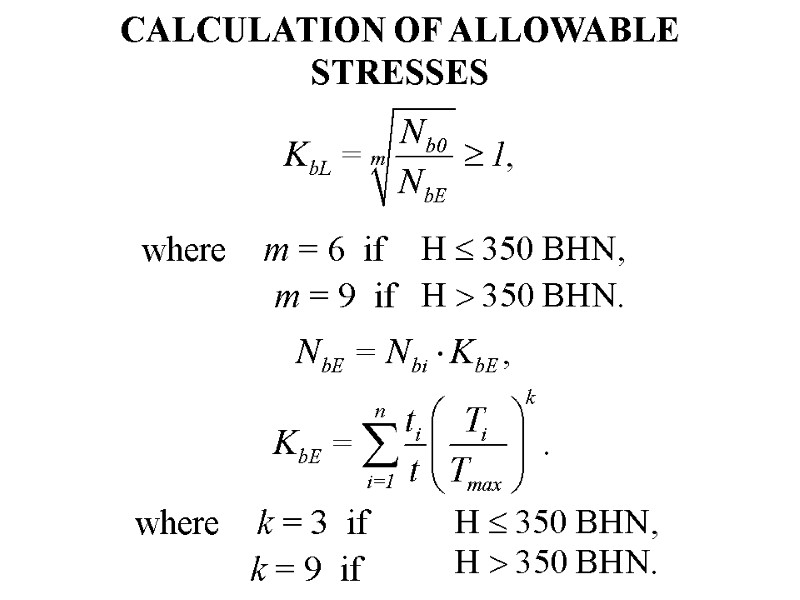

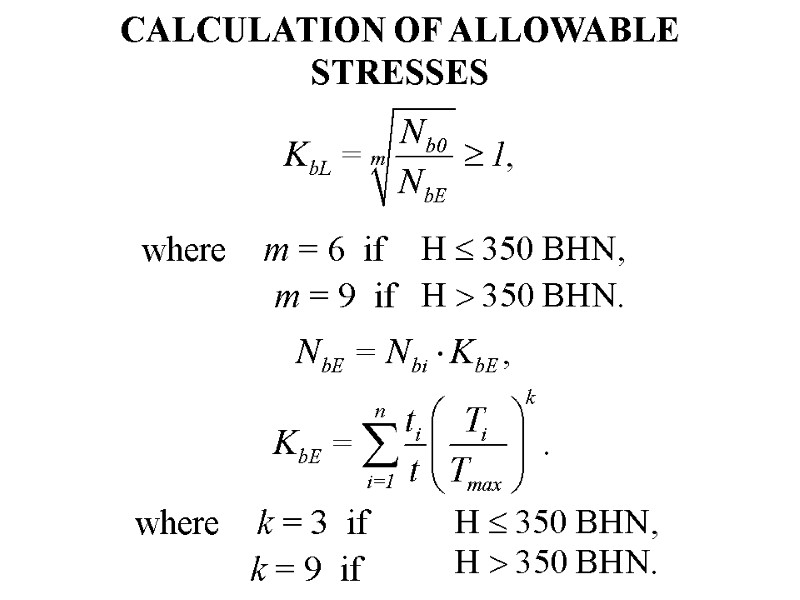

CALCULATION OF ALLOWABLE STRESSES where m = 6 if m = 9 if where k = 3 if k = 9 if

CALCULATION OF ALLOWABLE STRESSES where m = 6 if m = 9 if where k = 3 if k = 9 if

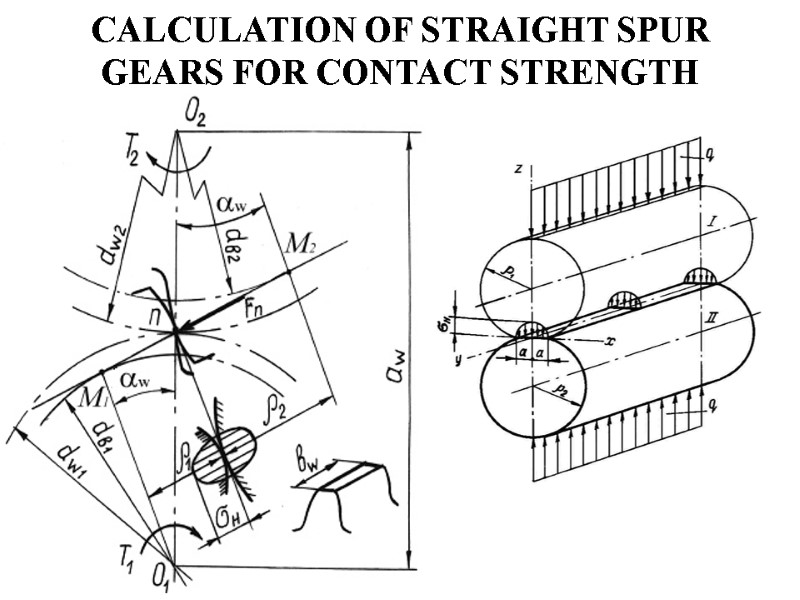

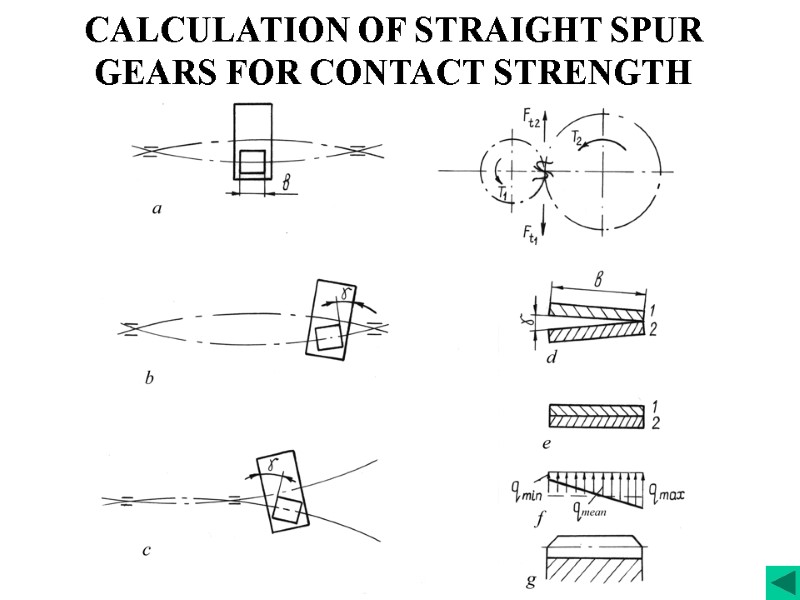

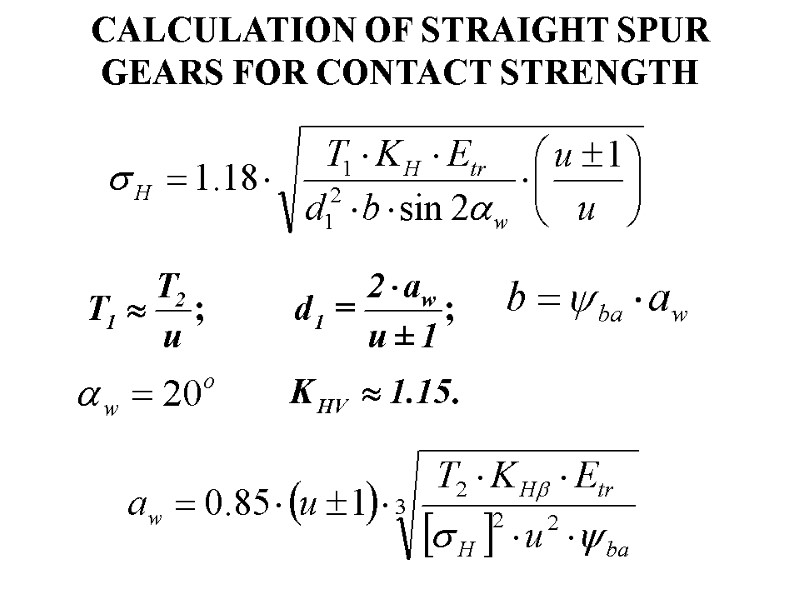

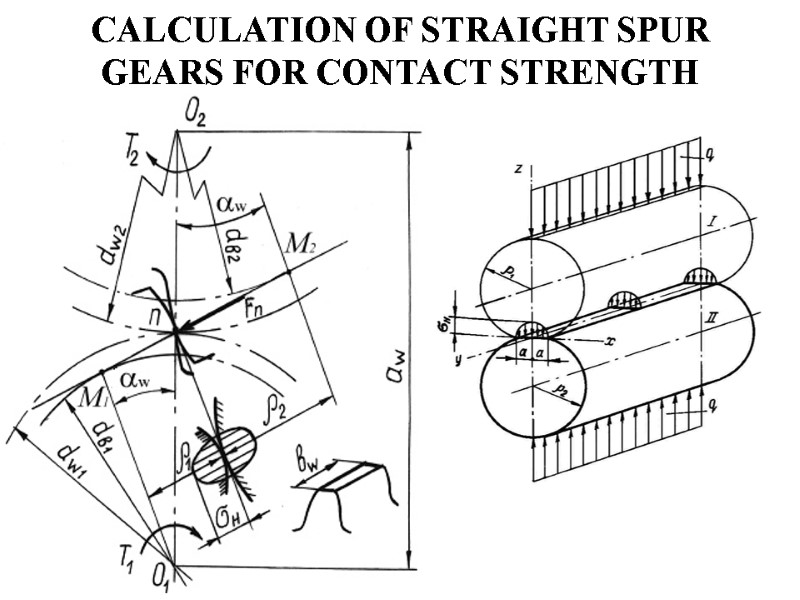

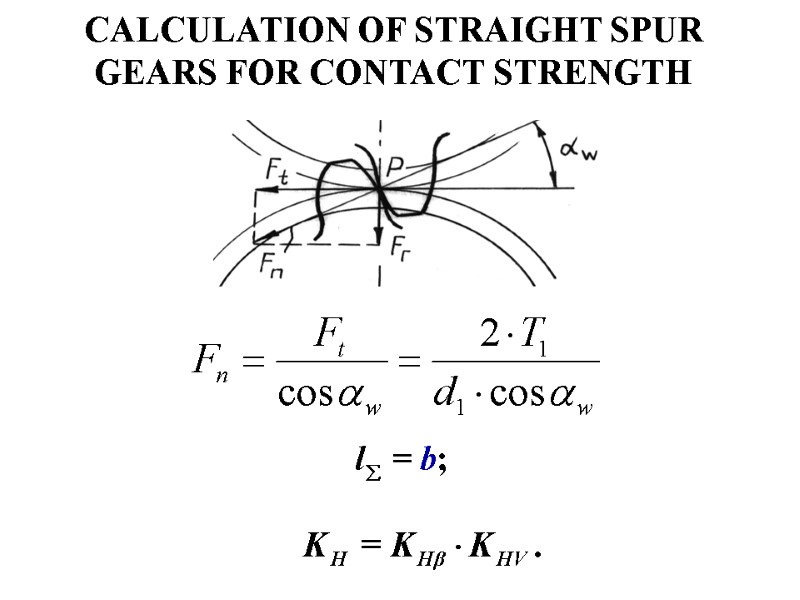

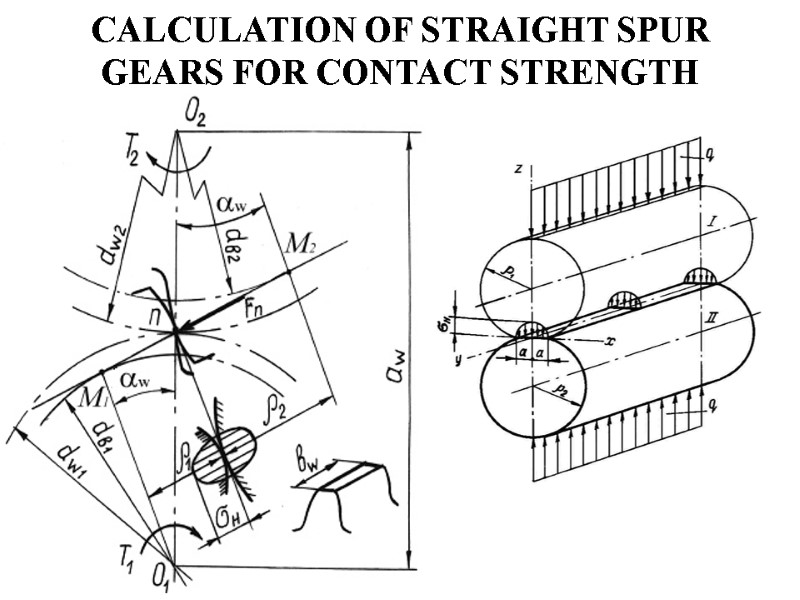

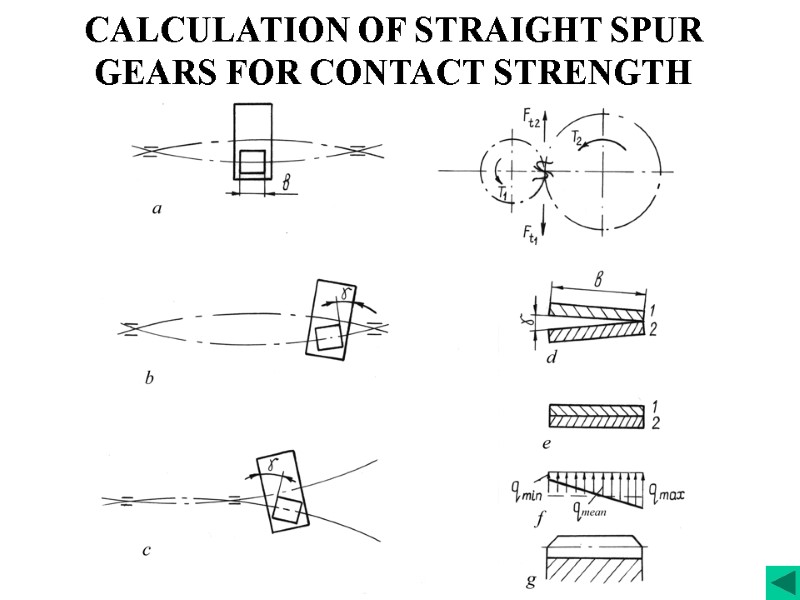

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

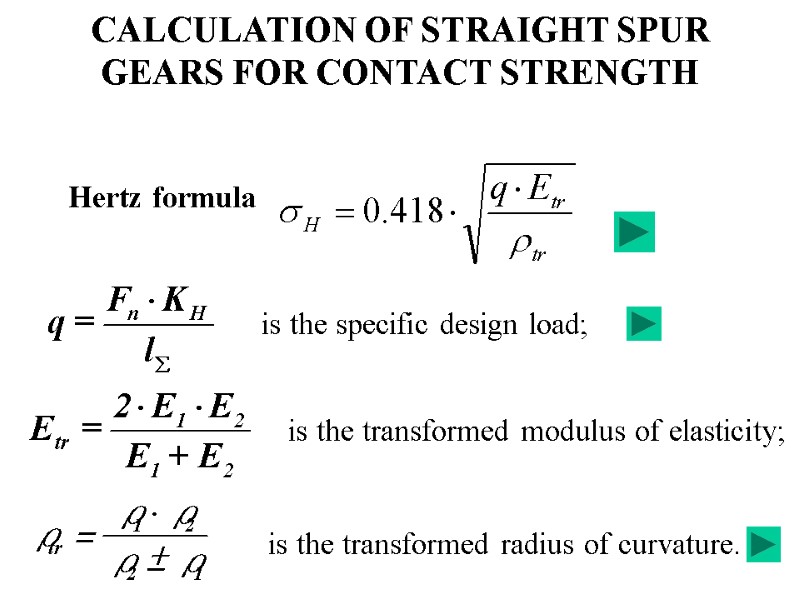

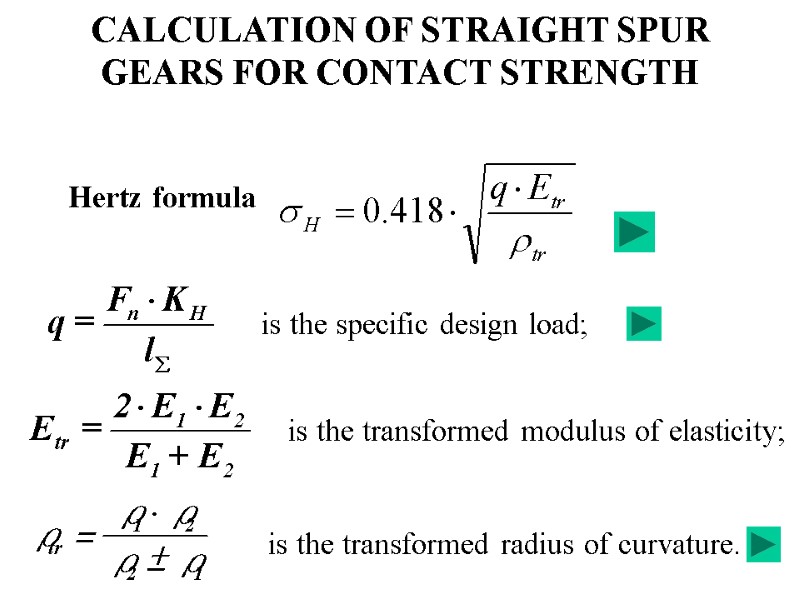

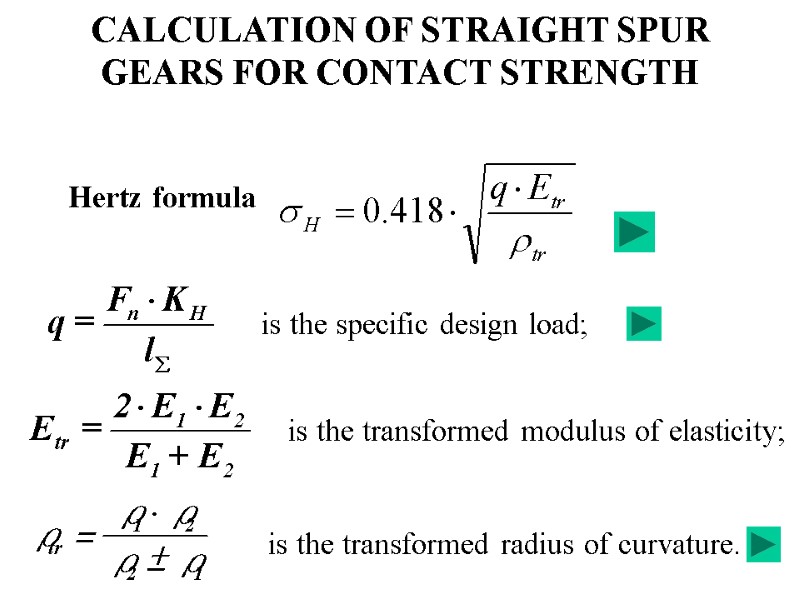

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH Hertz formula is the specific design load; is the transformed modulus of elasticity; is the transformed radius of curvature.

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH Hertz formula is the specific design load; is the transformed modulus of elasticity; is the transformed radius of curvature.

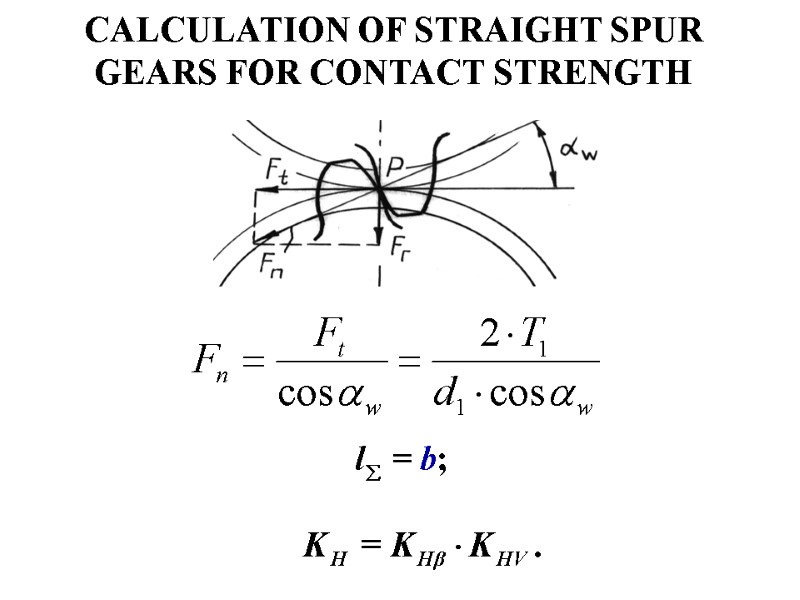

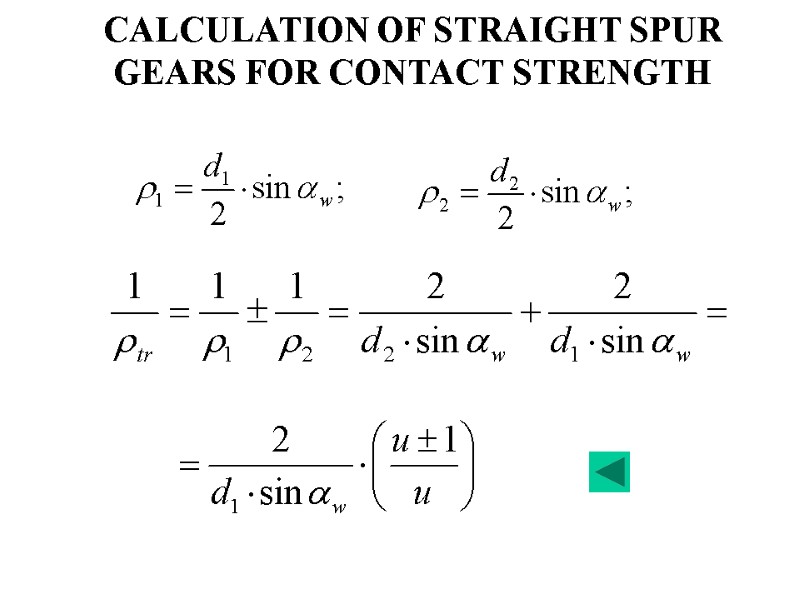

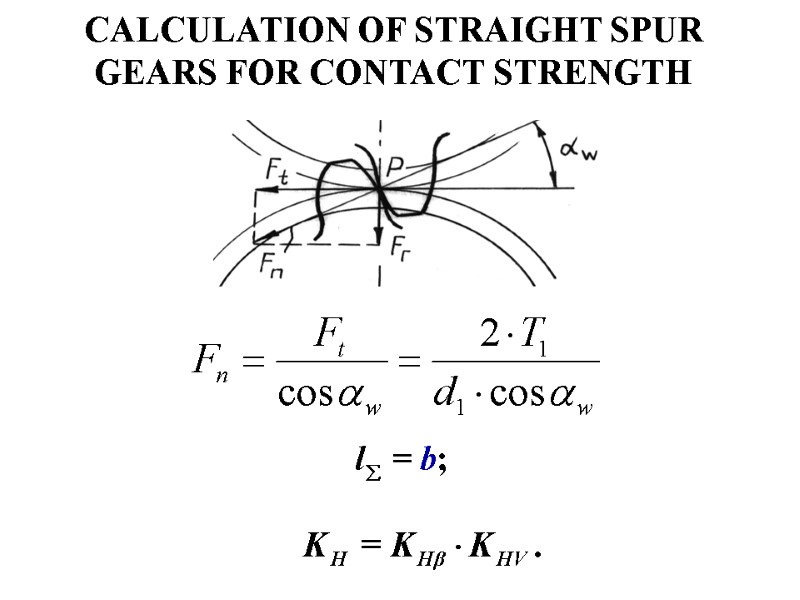

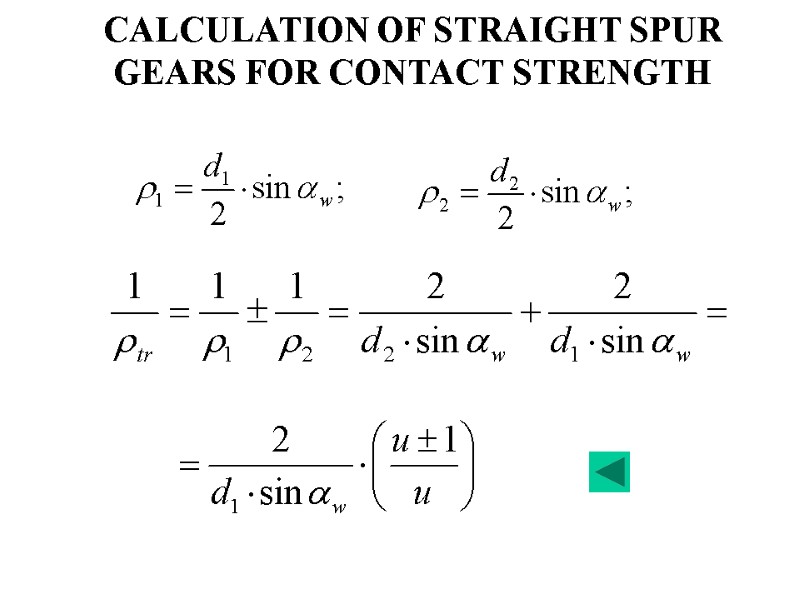

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

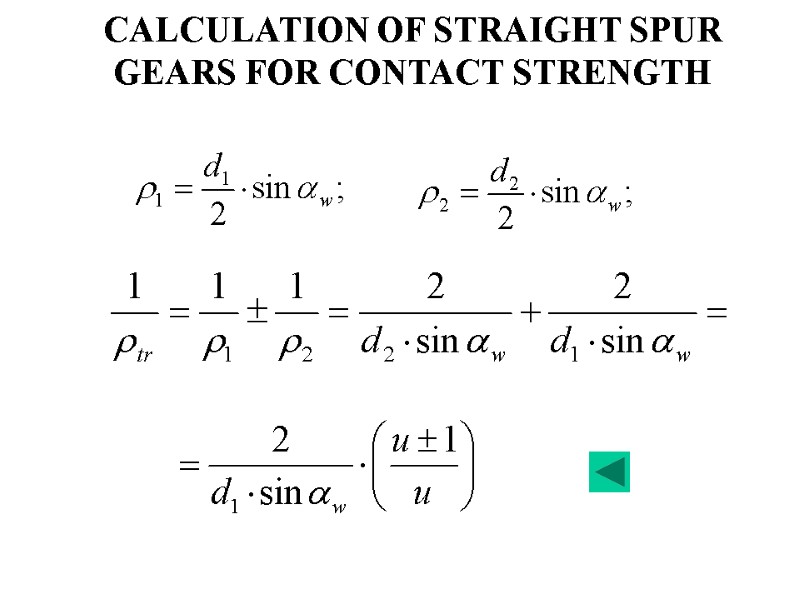

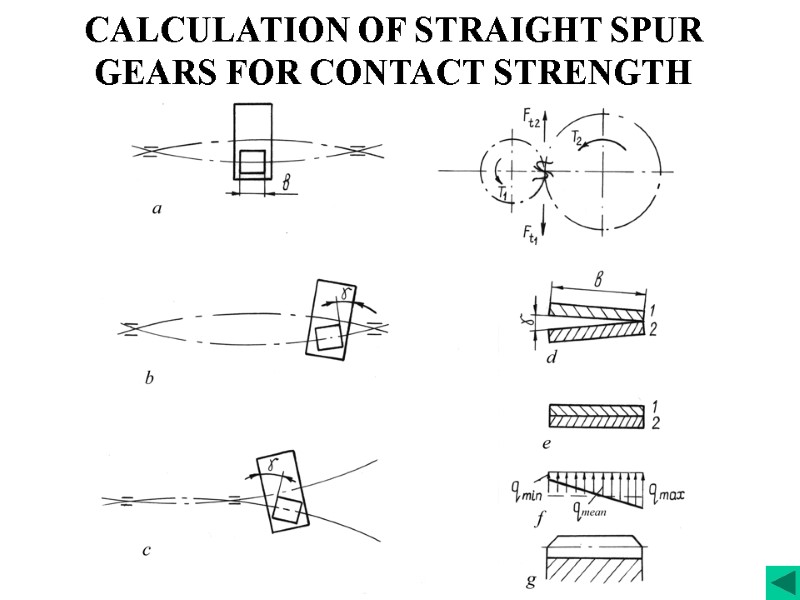

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

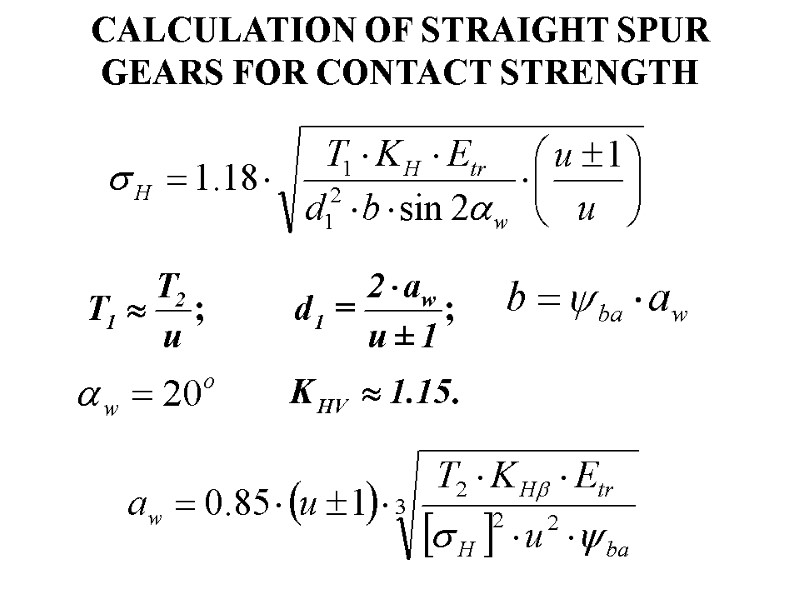

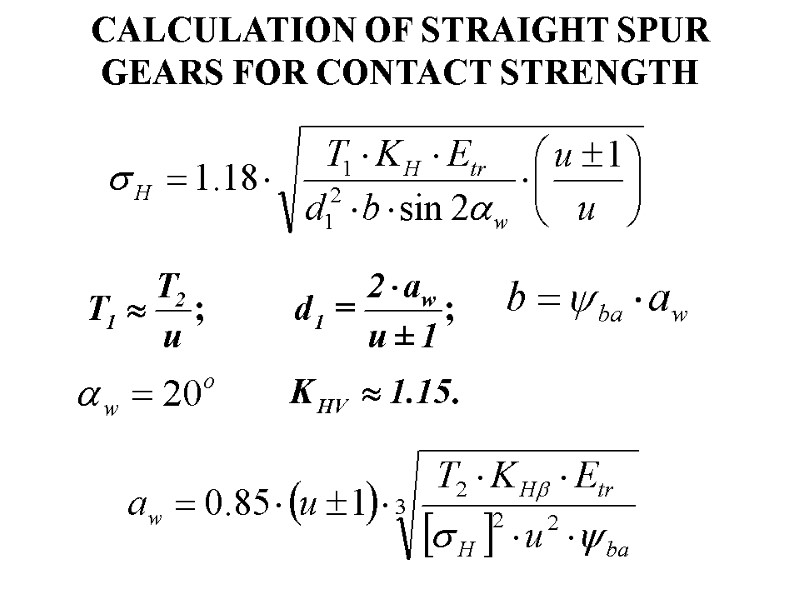

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR CONTACT STRENGTH

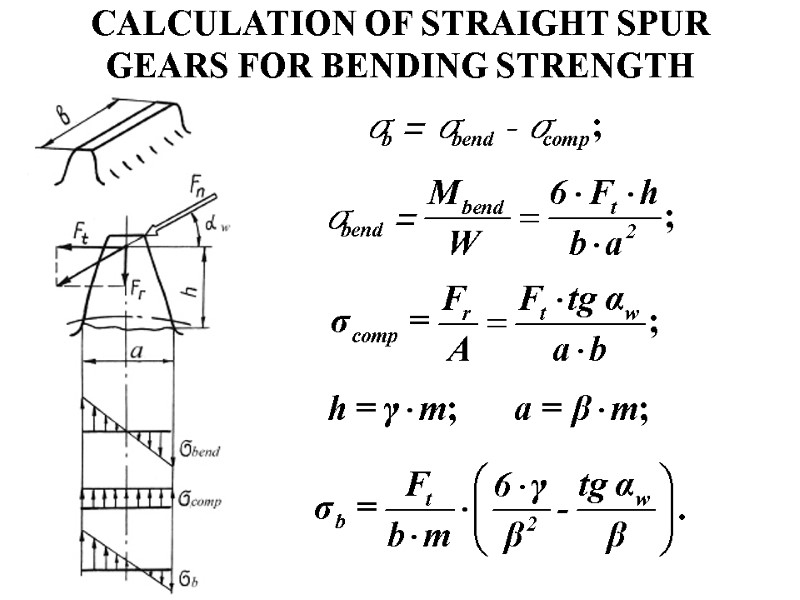

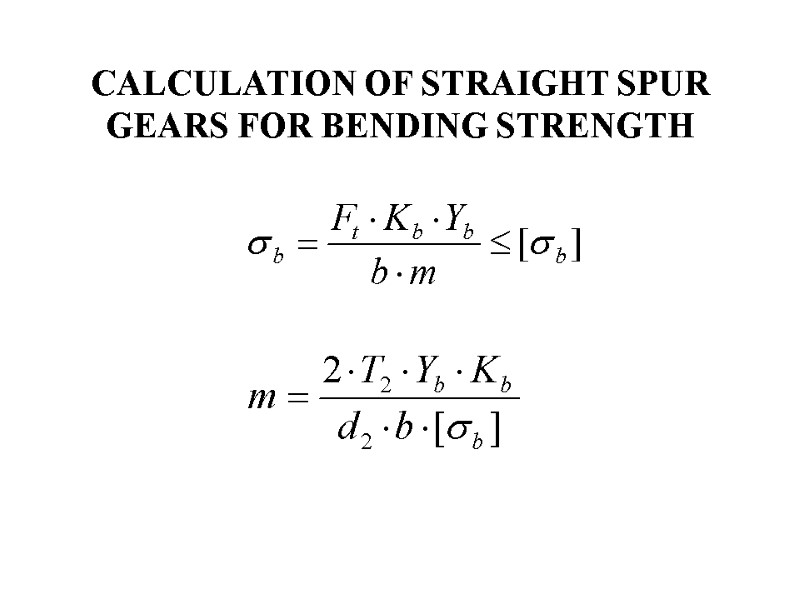

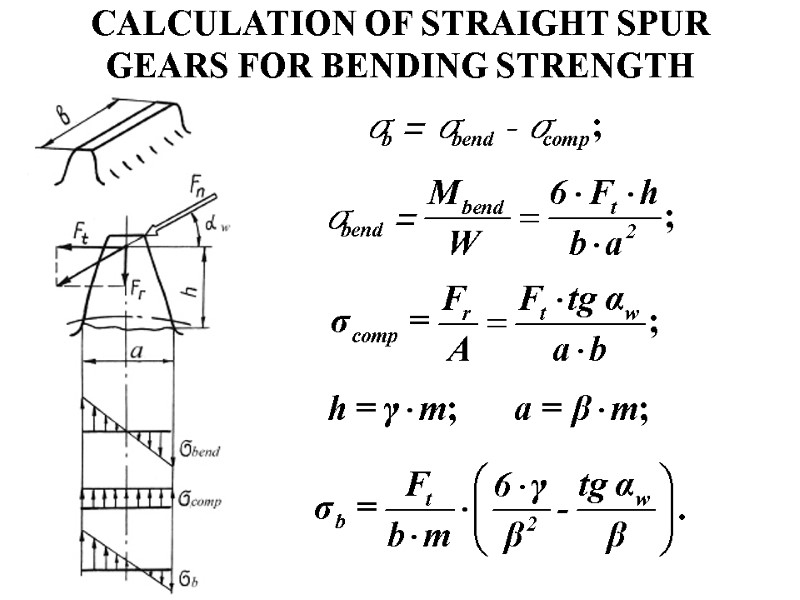

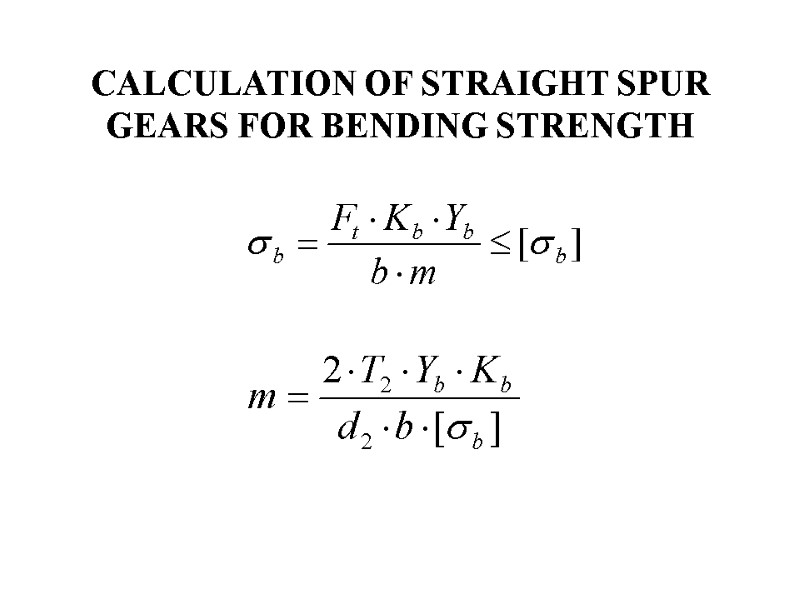

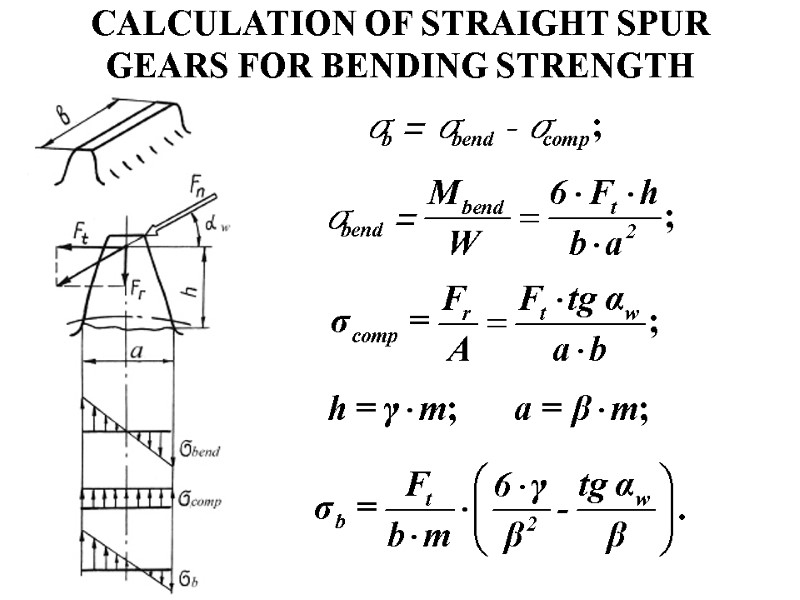

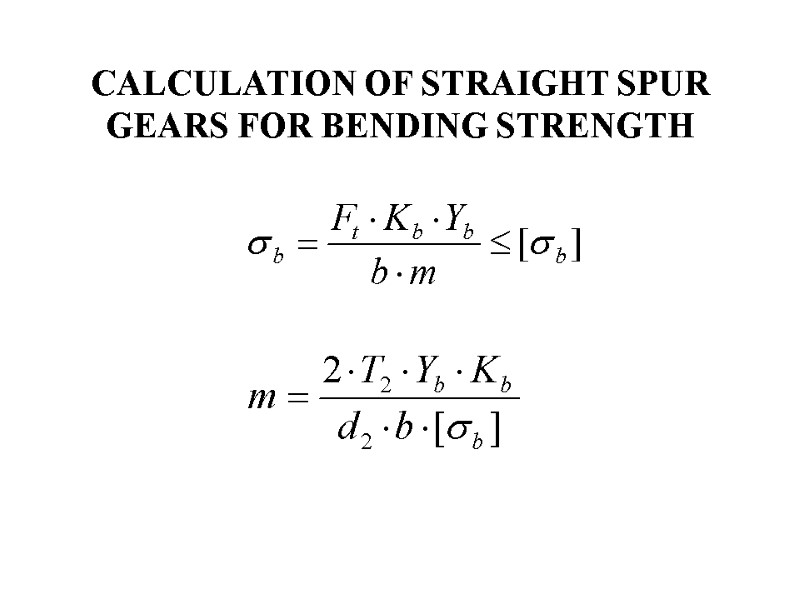

CALCULATION OF STRAIGHT SPUR GEARS FOR BENDING STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR BENDING STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR BENDING STRENGTH

CALCULATION OF STRAIGHT SPUR GEARS FOR BENDING STRENGTH