49f0b36146f22897f1a212442c3fb375.ppt

- Количество слайдов: 86

CAD/Graphics, Hong Kong, Dec. 7 -10, 2005 Interactive, Procedural Computer-Aided Design Carlo H. Séquin EECS Computer Science Division University of California, Berkeley

CAD/Graphics, Hong Kong, Dec. 7 -10, 2005 Interactive, Procedural Computer-Aided Design Carlo H. Séquin EECS Computer Science Division University of California, Berkeley

CAD Tools for the Early and Creative Phases of Design u Tutorial u E-CAD Examples Lessons for M-CAD, CAGD

CAD Tools for the Early and Creative Phases of Design u Tutorial u E-CAD Examples Lessons for M-CAD, CAGD

Outline I. The Power of u Parametric Procedural Design u Computer-Aided u CAD Optimization / Synthesis Tools for the Early Phases of Design u Evolution u Towards (G. A. ) versus Intelligent Design an Integrated CAD Environment

Outline I. The Power of u Parametric Procedural Design u Computer-Aided u CAD Optimization / Synthesis Tools for the Early Phases of Design u Evolution u Towards (G. A. ) versus Intelligent Design an Integrated CAD Environment

Julia Sets, Mandelbrot Set, Fractals Defined by just a few numbers. . .

Julia Sets, Mandelbrot Set, Fractals Defined by just a few numbers. . .

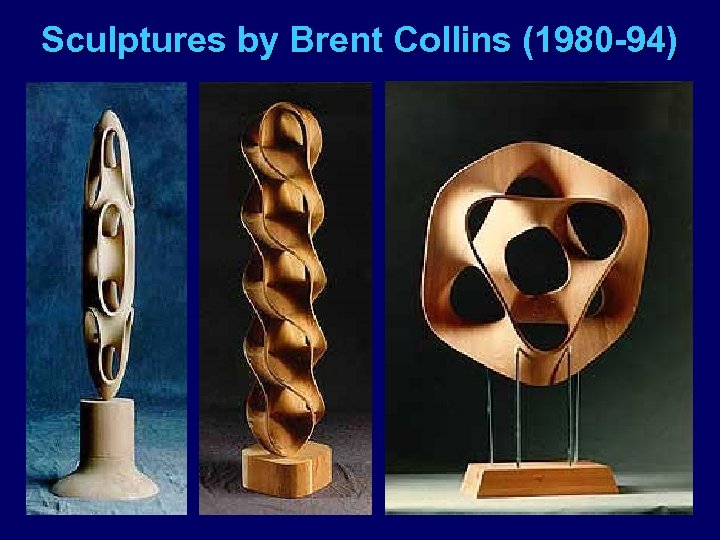

Sculptures by Brent Collins (1980 -94)

Sculptures by Brent Collins (1980 -94)

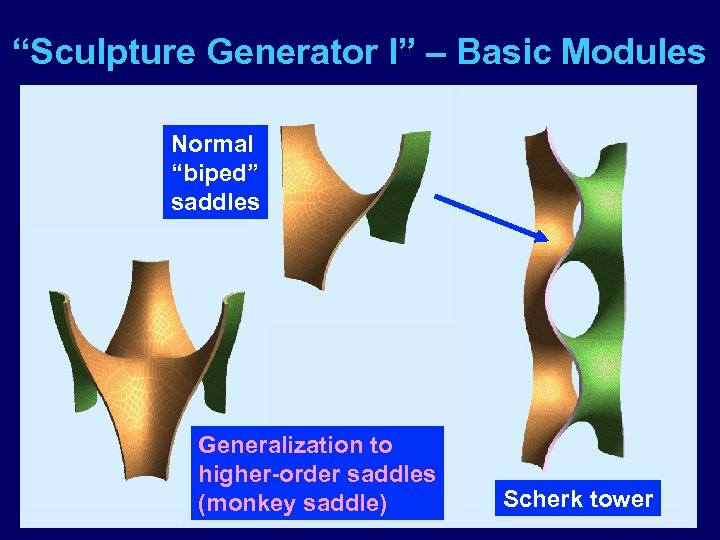

“Sculpture Generator I” – Basic Modules Normal “biped” saddles Generalization to higher-order saddles (monkey saddle) Scherk tower

“Sculpture Generator I” – Basic Modules Normal “biped” saddles Generalization to higher-order saddles (monkey saddle) Scherk tower

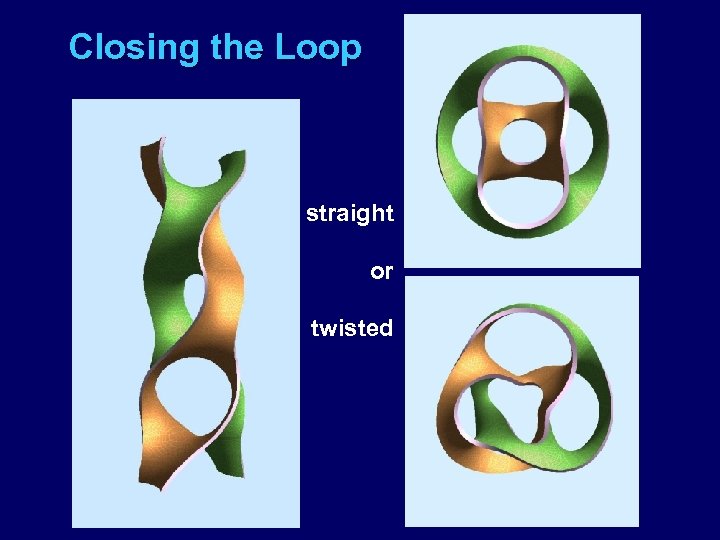

Closing the Loop straight or twisted

Closing the Loop straight or twisted

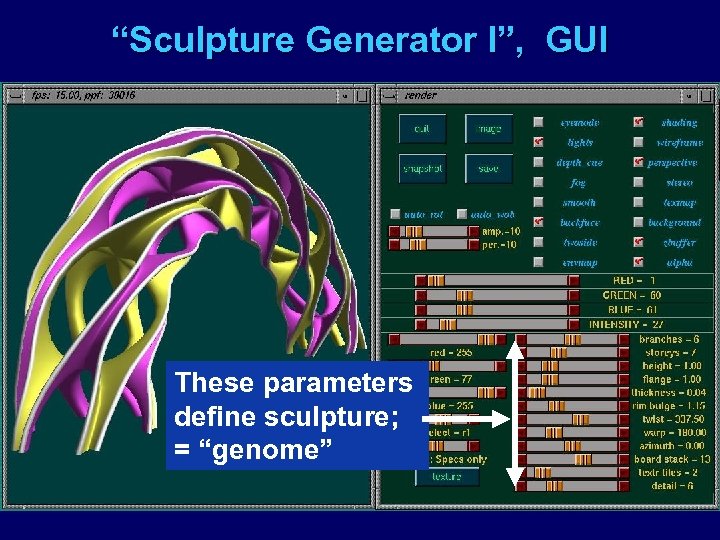

“Sculpture Generator I”, GUI These parameters define sculpture; = “genome”

“Sculpture Generator I”, GUI These parameters define sculpture; = “genome”

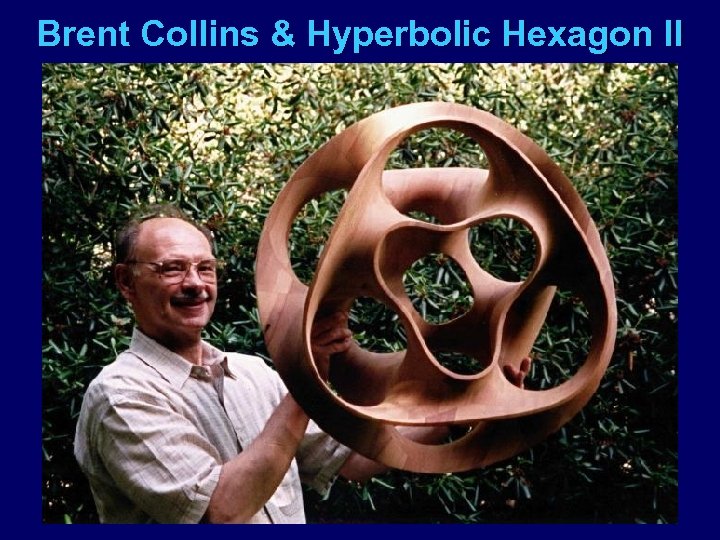

Brent Collins & Hyperbolic Hexagon II

Brent Collins & Hyperbolic Hexagon II

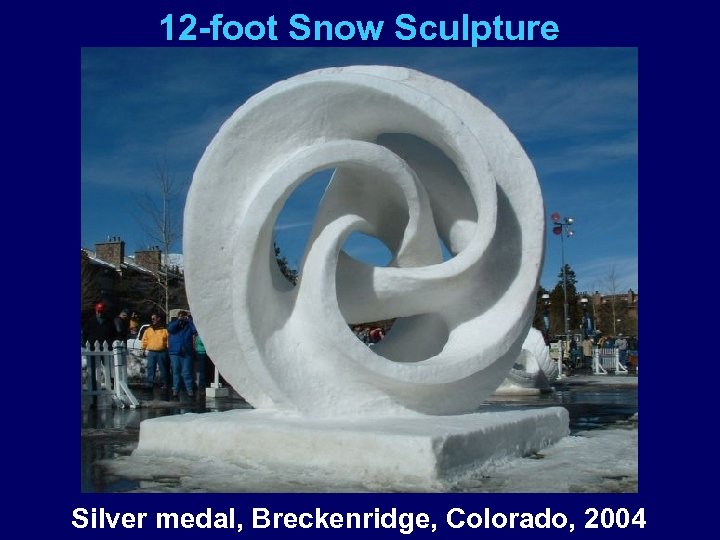

12 -foot Snow Sculpture Silver medal, Breckenridge, Colorado, 2004

12 -foot Snow Sculpture Silver medal, Breckenridge, Colorado, 2004

. . . and a Whole Lot of Plastic Models

. . . and a Whole Lot of Plastic Models

Bronze Sculpture Done by investment casting from FDM original

Bronze Sculpture Done by investment casting from FDM original

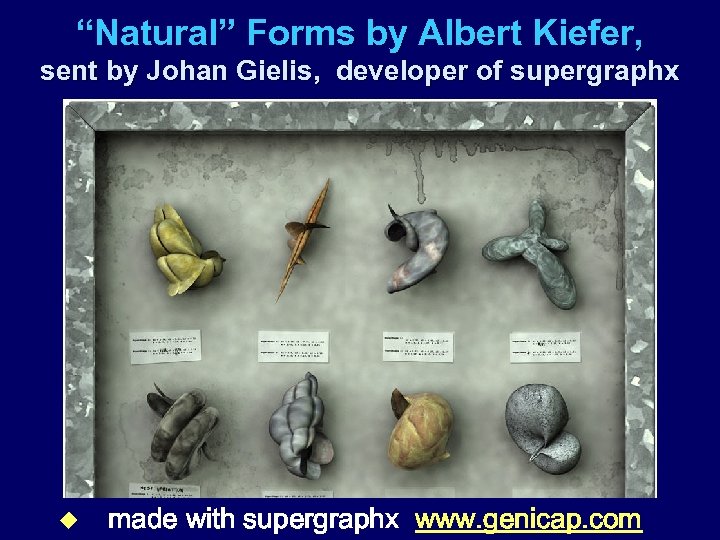

“Natural” Forms by Albert Kiefer, sent by Johan Gielis, developer of supergraphx u made with supergraphx www. genicap. com

“Natural” Forms by Albert Kiefer, sent by Johan Gielis, developer of supergraphx u made with supergraphx www. genicap. com

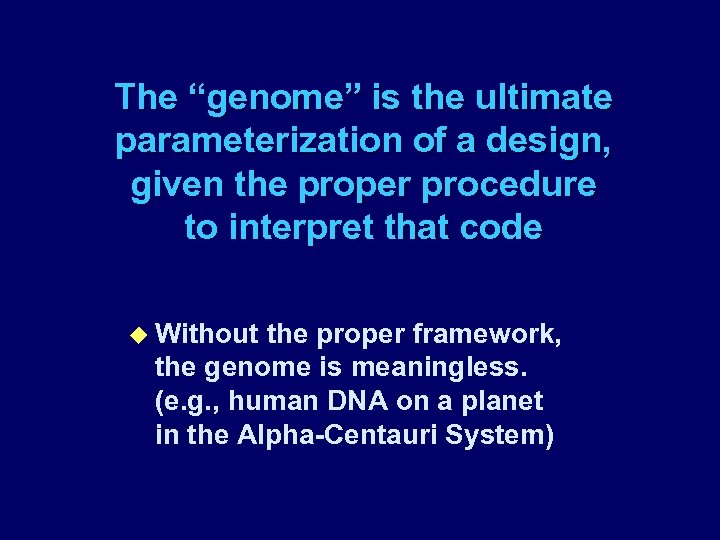

The “genome” is the ultimate parameterization of a design, given the proper procedure to interpret that code u Without the proper framework, the genome is meaningless. (e. g. , human DNA on a planet in the Alpha-Centauri System)

The “genome” is the ultimate parameterization of a design, given the proper procedure to interpret that code u Without the proper framework, the genome is meaningless. (e. g. , human DNA on a planet in the Alpha-Centauri System)

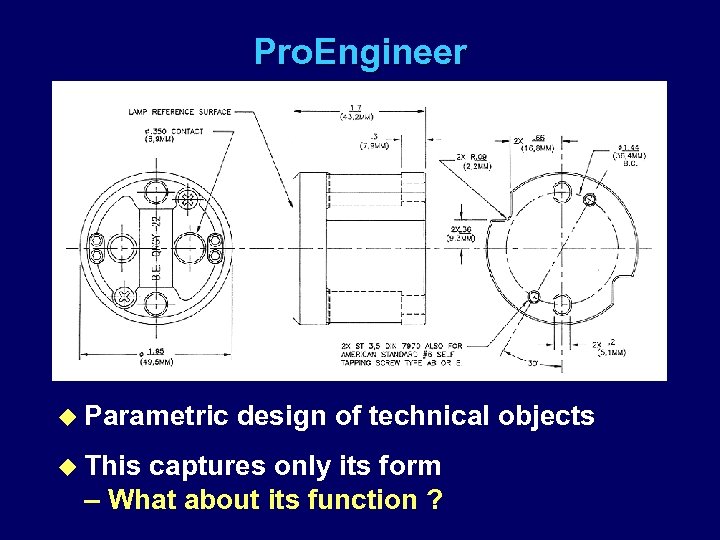

Pro. Engineer u Parametric u This design of technical objects captures only its form – What about its function ?

Pro. Engineer u Parametric u This design of technical objects captures only its form – What about its function ?

What Shape Has the Right Functionality?

What Shape Has the Right Functionality?

How Do We Know What Makes a Good Design With Proper Functionality ? e. g. a comfortable razor ? or a better mouse-trap ? u. Traditional Approach: Trial and Error (T&E)

How Do We Know What Makes a Good Design With Proper Functionality ? e. g. a comfortable razor ? or a better mouse-trap ? u. Traditional Approach: Trial and Error (T&E)

T&E: OK for Early Flying Machines

T&E: OK for Early Flying Machines

T&E: Not OK for Nuclear Power Plants OK ! – this one seems to work !!

T&E: Not OK for Nuclear Power Plants OK ! – this one seems to work !!

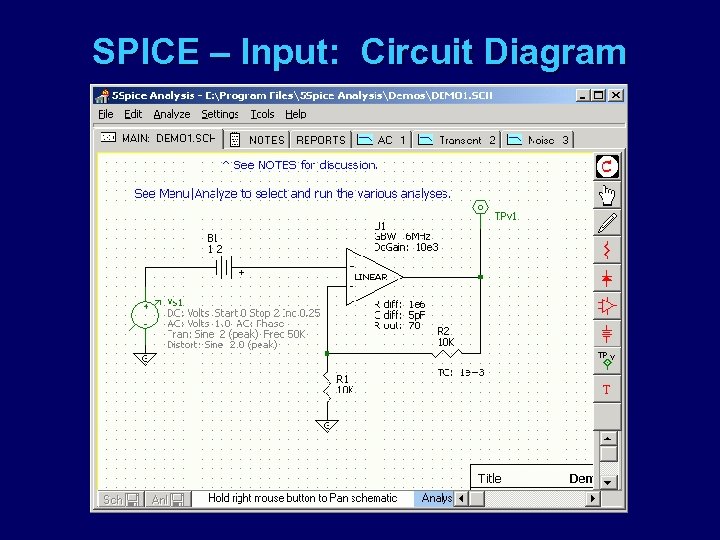

CAD for Design Verification u Do expensive or dangerous experiments on the computer. u Use: u E. g. , calculations, analysis, simulation. . . SPICE (Simulation Program with Integrated Circuit Emphasis), L. W. Nagel and D. O. Pederson (1972)

CAD for Design Verification u Do expensive or dangerous experiments on the computer. u Use: u E. g. , calculations, analysis, simulation. . . SPICE (Simulation Program with Integrated Circuit Emphasis), L. W. Nagel and D. O. Pederson (1972)

SPICE – Input: Circuit Diagram

SPICE – Input: Circuit Diagram

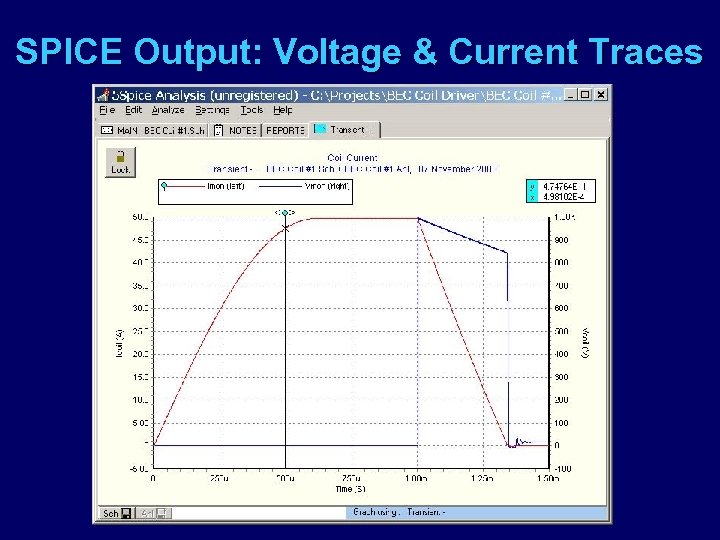

SPICE Output: Voltage & Current Traces

SPICE Output: Voltage & Current Traces

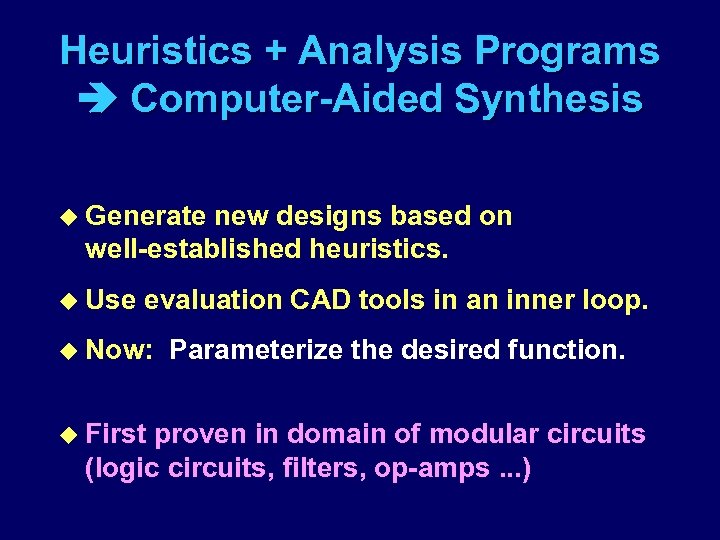

Heuristics + Analysis Programs Computer-Aided Synthesis u Generate new designs based on well-established heuristics. u Use evaluation CAD tools in an inner loop. u Now: u First Parameterize the desired function. proven in domain of modular circuits (logic circuits, filters, op-amps. . . )

Heuristics + Analysis Programs Computer-Aided Synthesis u Generate new designs based on well-established heuristics. u Use evaluation CAD tools in an inner loop. u Now: u First Parameterize the desired function. proven in domain of modular circuits (logic circuits, filters, op-amps. . . )

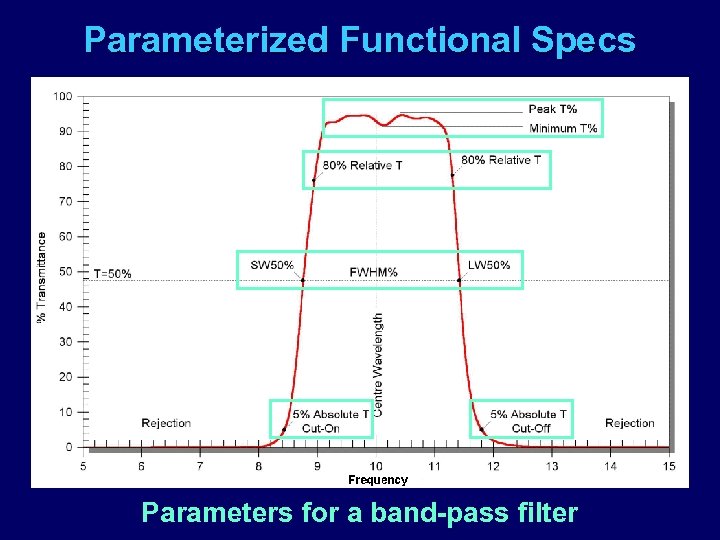

Parameterized Functional Specs Parameters for a band-pass filter

Parameterized Functional Specs Parameters for a band-pass filter

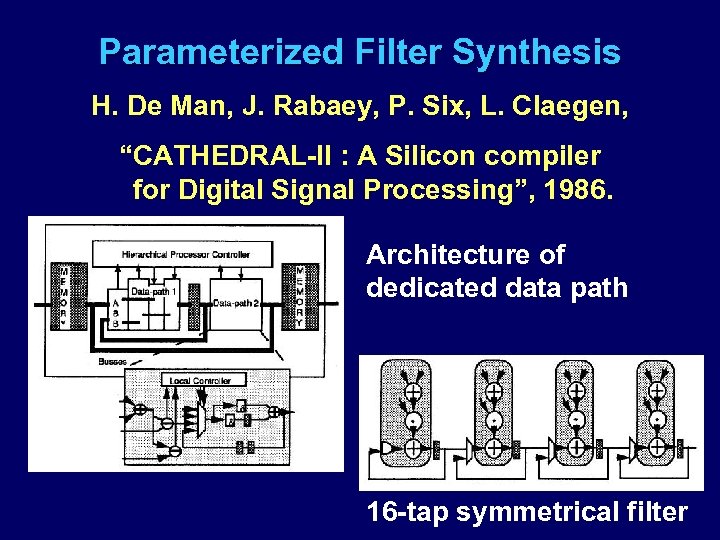

Parameterized Filter Synthesis H. De Man, J. Rabaey, P. Six, L. Claegen, “CATHEDRAL-II : A Silicon compiler for Digital Signal Processing”, 1986. Architecture of dedicated data path 16 -tap symmetrical filter

Parameterized Filter Synthesis H. De Man, J. Rabaey, P. Six, L. Claegen, “CATHEDRAL-II : A Silicon compiler for Digital Signal Processing”, 1986. Architecture of dedicated data path 16 -tap symmetrical filter

Add: Computer-Aided Optimization u Use evaluation CAD tools + a local optimization step as an inner loop in a search procedure.

Add: Computer-Aided Optimization u Use evaluation CAD tools + a local optimization step as an inner loop in a search procedure.

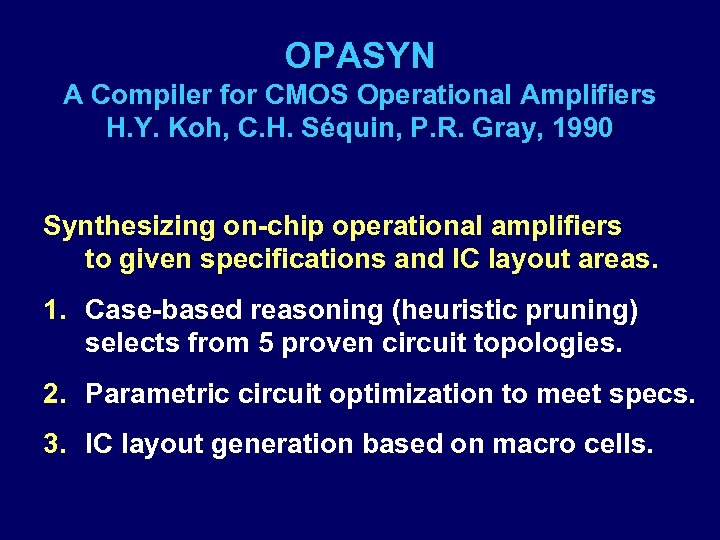

OPASYN A Compiler for CMOS Operational Amplifiers H. Y. Koh, C. H. Séquin, P. R. Gray, 1990 Synthesizing on-chip operational amplifiers to given specifications and IC layout areas. 1. Case-based reasoning (heuristic pruning) selects from 5 proven circuit topologies. 2. Parametric circuit optimization to meet specs. 3. IC layout generation based on macro cells.

OPASYN A Compiler for CMOS Operational Amplifiers H. Y. Koh, C. H. Séquin, P. R. Gray, 1990 Synthesizing on-chip operational amplifiers to given specifications and IC layout areas. 1. Case-based reasoning (heuristic pruning) selects from 5 proven circuit topologies. 2. Parametric circuit optimization to meet specs. 3. IC layout generation based on macro cells.

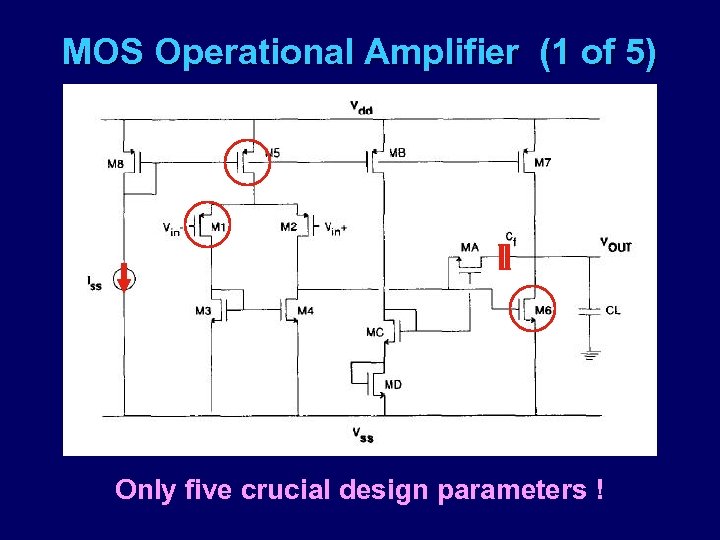

MOS Operational Amplifier (1 of 5) Only five crucial design parameters !

MOS Operational Amplifier (1 of 5) Only five crucial design parameters !

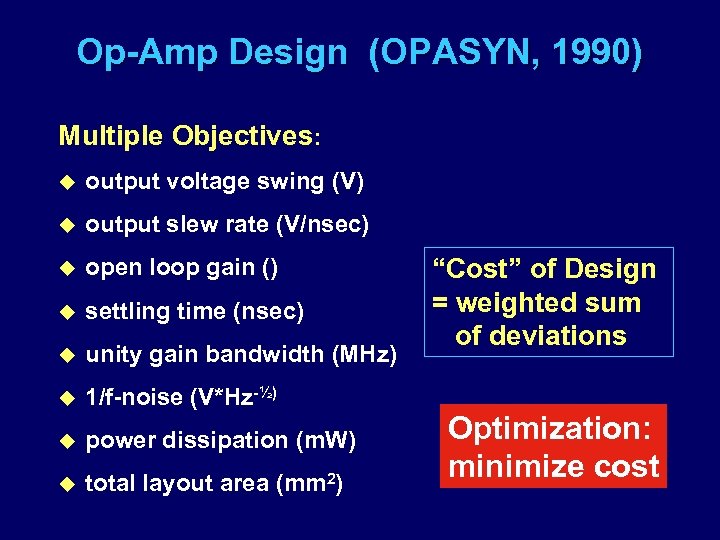

Op-Amp Design (OPASYN, 1990) Multiple Objectives: u output voltage swing (V) u output slew rate (V/nsec) u open loop gain () u settling time (nsec) u unity gain bandwidth (MHz) u 1/f-noise (V*Hz-½) u power dissipation (m. W) u total layout area (mm 2) “Cost” of Design = weighted sum of deviations Optimization: minimize cost

Op-Amp Design (OPASYN, 1990) Multiple Objectives: u output voltage swing (V) u output slew rate (V/nsec) u open loop gain () u settling time (nsec) u unity gain bandwidth (MHz) u 1/f-noise (V*Hz-½) u power dissipation (m. W) u total layout area (mm 2) “Cost” of Design = weighted sum of deviations Optimization: minimize cost

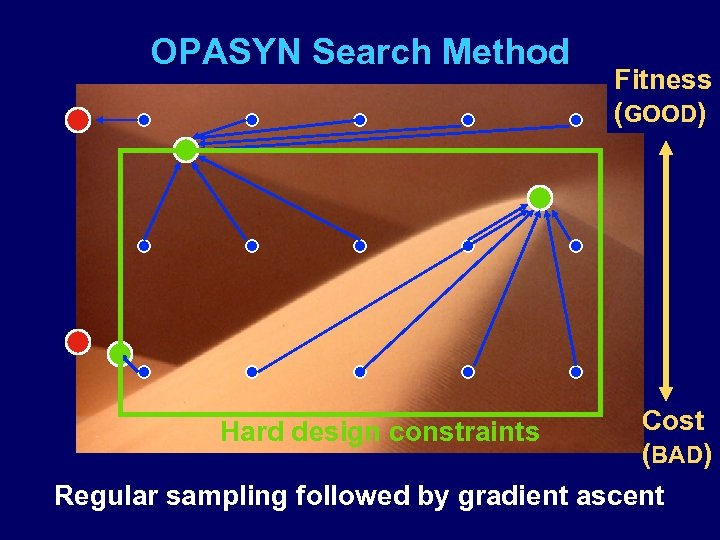

OPASYN Search Method Fitness (GOOD) Cost (BAD) 5 D design-parameter space Regular sampling followed by gradient ascent Hard design constraints

OPASYN Search Method Fitness (GOOD) Cost (BAD) 5 D design-parameter space Regular sampling followed by gradient ascent Hard design constraints

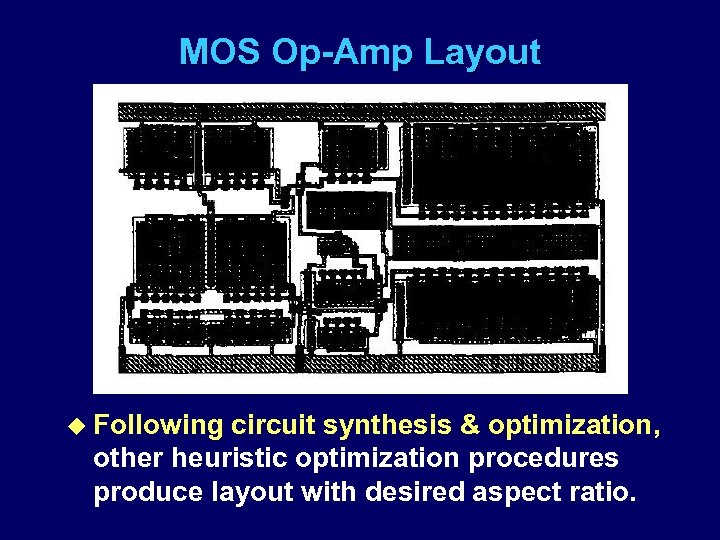

MOS Op-Amp Layout u Following circuit synthesis & optimization, other heuristic optimization procedures produce layout with desired aspect ratio.

MOS Op-Amp Layout u Following circuit synthesis & optimization, other heuristic optimization procedures produce layout with desired aspect ratio.

Synthesis in Established Fields u Filter design and MOS Op-Amp synthesis have well-established engineering practices. u Efficiently parameterized designs as well as robust and efficient design procedures exist. u Experience is captured in special-purpose programs and used for automated synthesis. u But what if we need to design something new in “uncharted engineering territory” ?

Synthesis in Established Fields u Filter design and MOS Op-Amp synthesis have well-established engineering practices. u Efficiently parameterized designs as well as robust and efficient design procedures exist. u Experience is captured in special-purpose programs and used for automated synthesis. u But what if we need to design something new in “uncharted engineering territory” ?

Uncharted Territory u Task: u How Design a robot that climbs trees ! do you get started ? ?

Uncharted Territory u Task: u How Design a robot that climbs trees ! do you get started ? ?

An Important New Phase is Prepended to the Design Process: Idea Generation, Exploration. . .

An Important New Phase is Prepended to the Design Process: Idea Generation, Exploration. . .

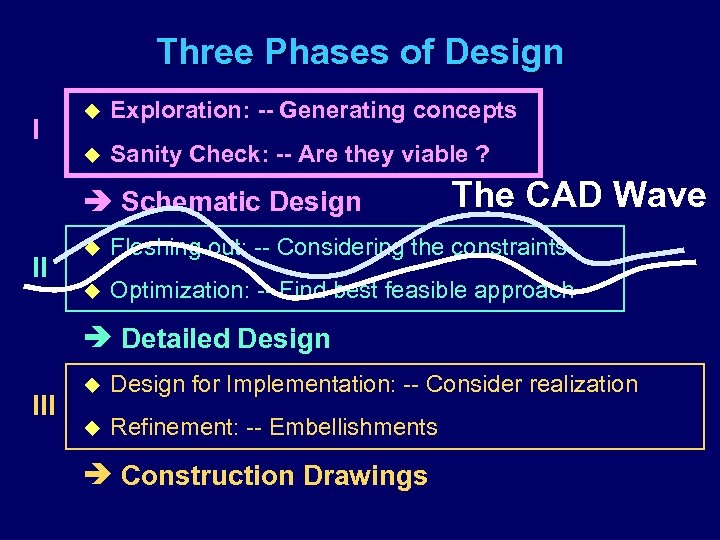

Three Phases of Design Exploration: -- Generating concepts u I u Sanity Check: -- Are they viable ? Schematic Design II The CAD Wave u Fleshing out: -- Considering the constraints u Optimization: -- Find best feasible approach Detailed Design III u Design for Implementation: -- Consider realization u Refinement: -- Embellishments Construction Drawings

Three Phases of Design Exploration: -- Generating concepts u I u Sanity Check: -- Are they viable ? Schematic Design II The CAD Wave u Fleshing out: -- Considering the constraints u Optimization: -- Find best feasible approach Detailed Design III u Design for Implementation: -- Consider realization u Refinement: -- Embellishments Construction Drawings

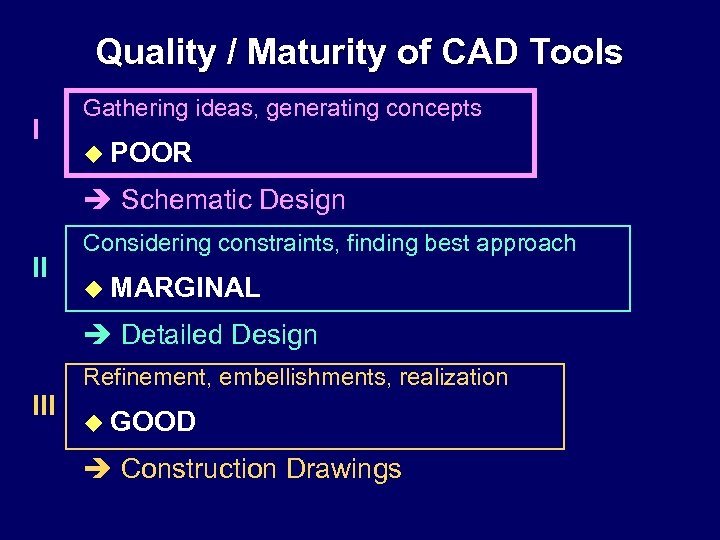

Quality / Maturity of CAD Tools I Gathering ideas, generating concepts u POOR Schematic Design II Considering constraints, finding best approach u MARGINAL Detailed Design III Refinement, embellishments, realization u GOOD Construction Drawings

Quality / Maturity of CAD Tools I Gathering ideas, generating concepts u POOR Schematic Design II Considering constraints, finding best approach u MARGINAL Detailed Design III Refinement, embellishments, realization u GOOD Construction Drawings

Activities in Phase I How do people come up with new ideas ? u Doodles, sketches, brain-storming, make wish-lists, bend wires, carve styrofoam, . . . What CAD tools do we need to help ? u Create novel conceptual prototypes. . . u Evaluate u Show them, rank order them. . . promising ones to user … How do we automate that search ?

Activities in Phase I How do people come up with new ideas ? u Doodles, sketches, brain-storming, make wish-lists, bend wires, carve styrofoam, . . . What CAD tools do we need to help ? u Create novel conceptual prototypes. . . u Evaluate u Show them, rank order them. . . promising ones to user … How do we automate that search ?

“Holey” Fitness Space u Open-ended engineering problems have complicated, higher-dimensional solution / fitness spaces.

“Holey” Fitness Space u Open-ended engineering problems have complicated, higher-dimensional solution / fitness spaces.

Genetic Algorithms u Pursue several design variations in parallel (many “phenotypes” in each generation) u Evaluate their “fitness” (how well they meet the various design objectives “Pareto set”) u Use best designs to “breed” new off-springs (by modifying some genes = “mutation”) (by exchanging genes = “crossover”) u Expectation: Good traits will survive, bad features will be weeded out. . .

Genetic Algorithms u Pursue several design variations in parallel (many “phenotypes” in each generation) u Evaluate their “fitness” (how well they meet the various design objectives “Pareto set”) u Use best designs to “breed” new off-springs (by modifying some genes = “mutation”) (by exchanging genes = “crossover”) u Expectation: Good traits will survive, bad features will be weeded out. . .

How Well Do G. A. Work for Engineering Tasks ? An Experiment: Let ME students design a MEMS resonator u Students u Good (initially) had no IC experience programmers u Excited about Genetic Algorithms

How Well Do G. A. Work for Engineering Tasks ? An Experiment: Let ME students design a MEMS resonator u Students u Good (initially) had no IC experience programmers u Excited about Genetic Algorithms

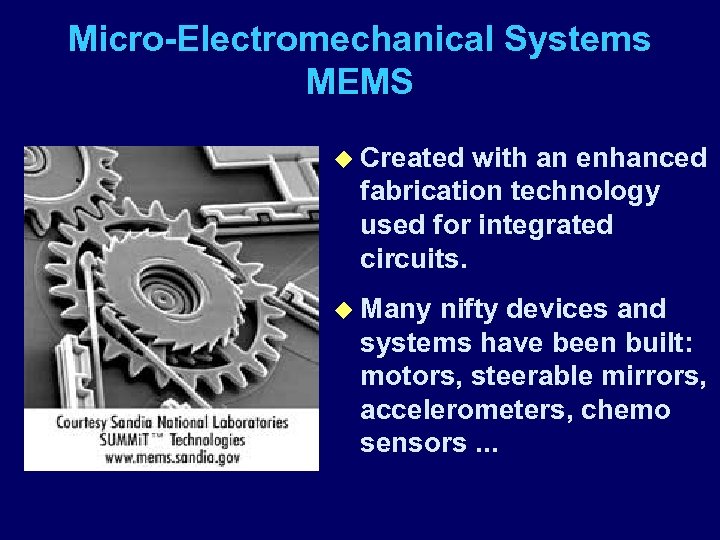

Micro-Electromechanical Systems MEMS u Created with an enhanced fabrication technology used for integrated circuits. u Many nifty devices and systems have been built: motors, steerable mirrors, accelerometers, chemo sensors. . .

Micro-Electromechanical Systems MEMS u Created with an enhanced fabrication technology used for integrated circuits. u Many nifty devices and systems have been built: motors, steerable mirrors, accelerometers, chemo sensors. . .

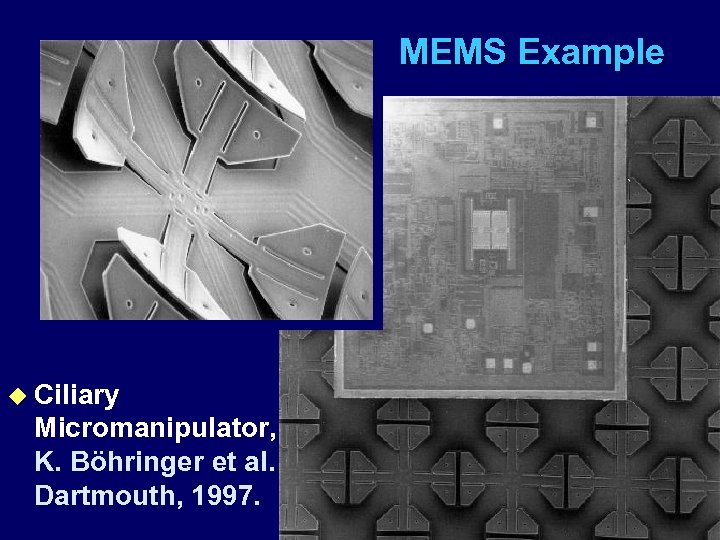

MEMS Example u Ciliary Micromanipulator, K. Böhringer et al. Dartmouth, 1997.

MEMS Example u Ciliary Micromanipulator, K. Böhringer et al. Dartmouth, 1997.

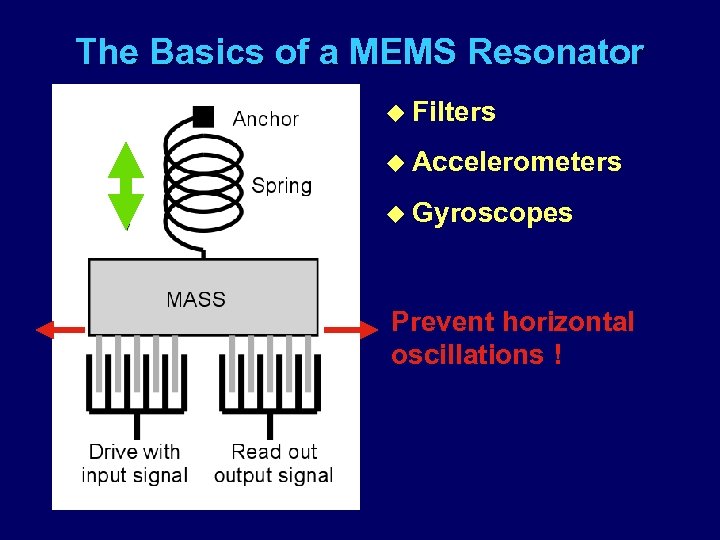

The Basics of a MEMS Resonator u Filters u Accelerometers u Gyroscopes Prevent horizontal oscillations !

The Basics of a MEMS Resonator u Filters u Accelerometers u Gyroscopes Prevent horizontal oscillations !

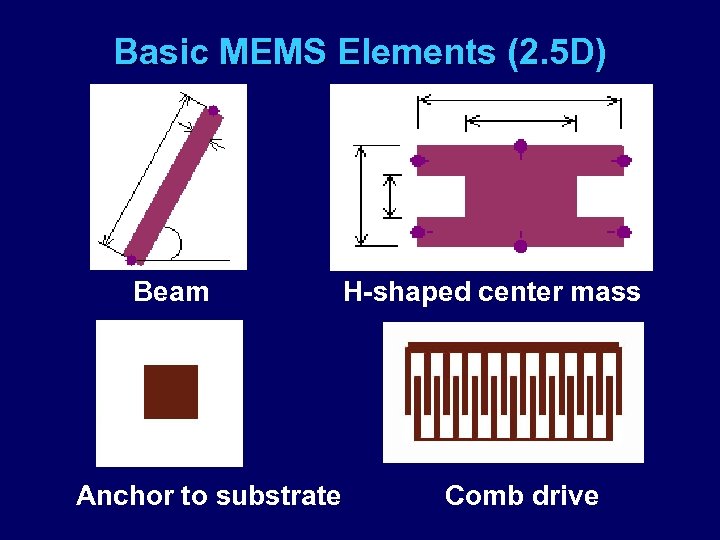

Basic MEMS Elements (2. 5 D) Beam Anchor to substrate H-shaped center mass Comb drive

Basic MEMS Elements (2. 5 D) Beam Anchor to substrate H-shaped center mass Comb drive

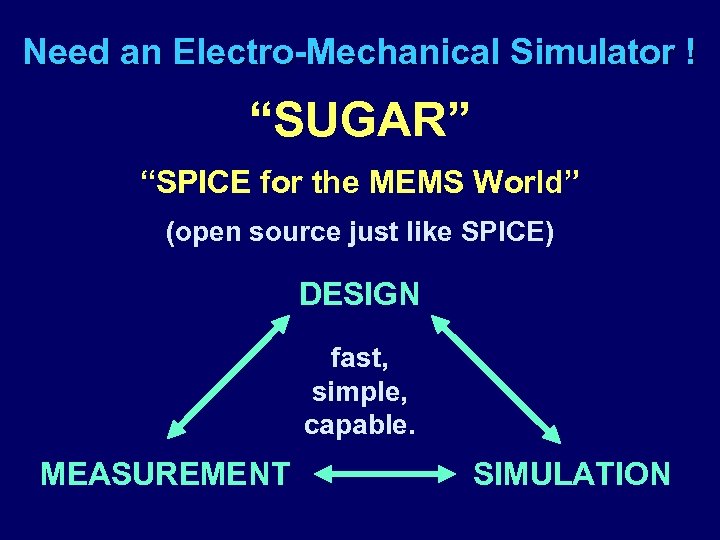

Need an Electro-Mechanical Simulator ! “SUGAR” “SPICE for the MEMS World” (open source just like SPICE) DESIGN fast, simple, capable. MEASUREMENT SIMULATION

Need an Electro-Mechanical Simulator ! “SUGAR” “SPICE for the MEMS World” (open source just like SPICE) DESIGN fast, simple, capable. MEASUREMENT SIMULATION

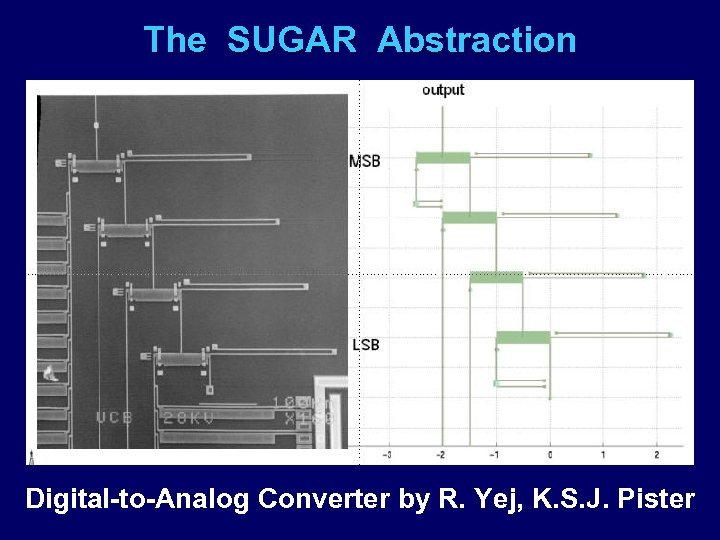

The SUGAR Abstraction Digital-to-Analog Converter by R. Yej, K. S. J. Pister

The SUGAR Abstraction Digital-to-Analog Converter by R. Yej, K. S. J. Pister

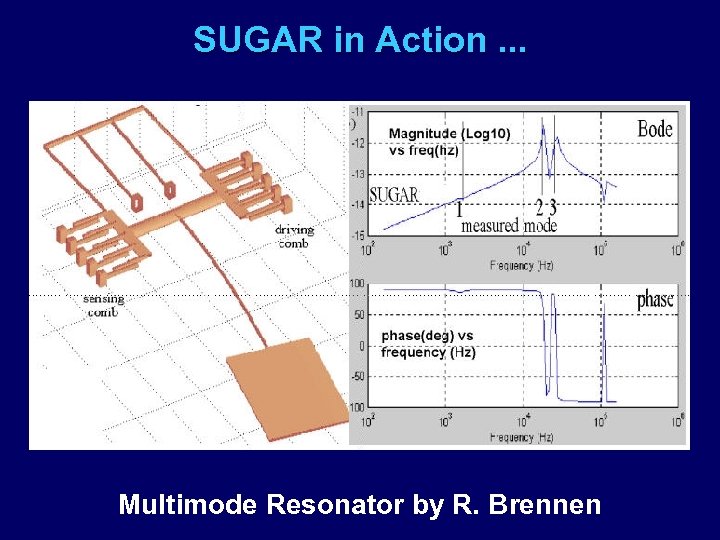

SUGAR in Action. . . Multimode Resonator by R. Brennen

SUGAR in Action. . . Multimode Resonator by R. Brennen

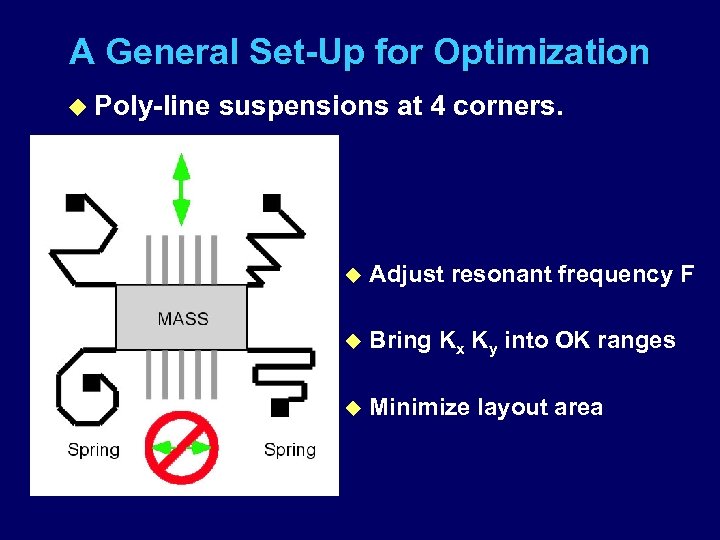

A General Set-Up for Optimization u Poly-line suspensions at 4 corners. u Adjust resonant frequency F u Bring Kx Ky into OK ranges u Minimize layout area

A General Set-Up for Optimization u Poly-line suspensions at 4 corners. u Adjust resonant frequency F u Bring Kx Ky into OK ranges u Minimize layout area

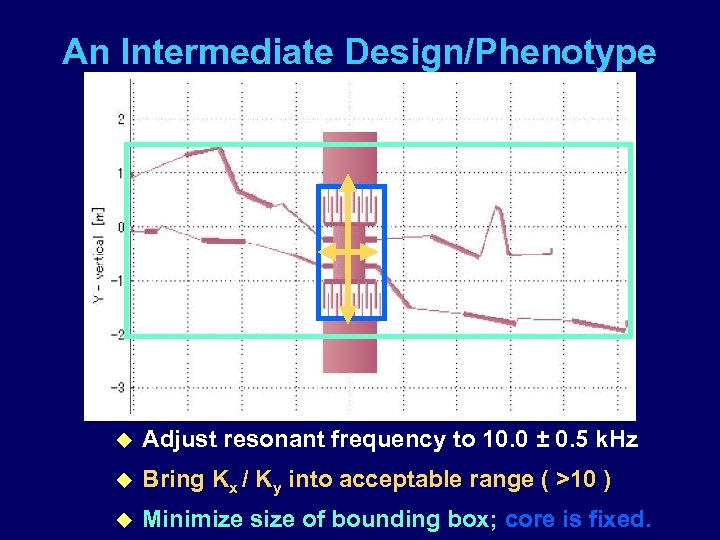

An Intermediate Design/Phenotype u Adjust resonant frequency to 10. 0 ± 0. 5 k. Hz u Bring Kx / Ky into acceptable range ( >10 ) u Minimize size of bounding box; core is fixed.

An Intermediate Design/Phenotype u Adjust resonant frequency to 10. 0 ± 0. 5 k. Hz u Bring Kx / Ky into acceptable range ( >10 ) u Minimize size of bounding box; core is fixed.

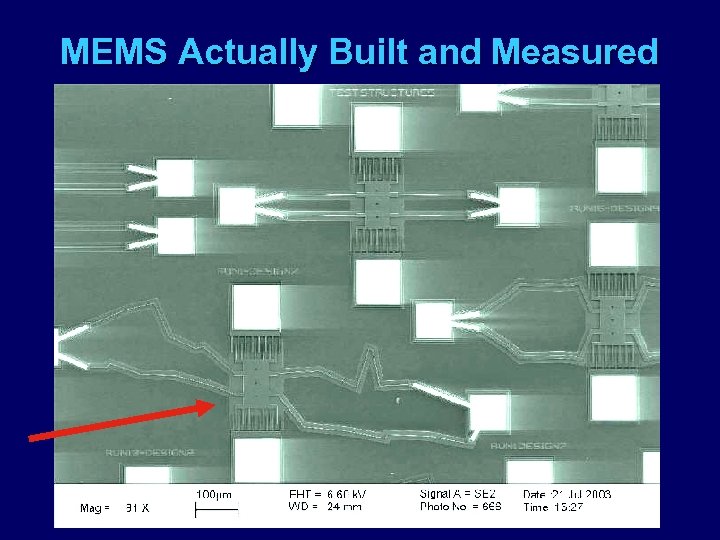

MEMS Actually Built and Measured

MEMS Actually Built and Measured

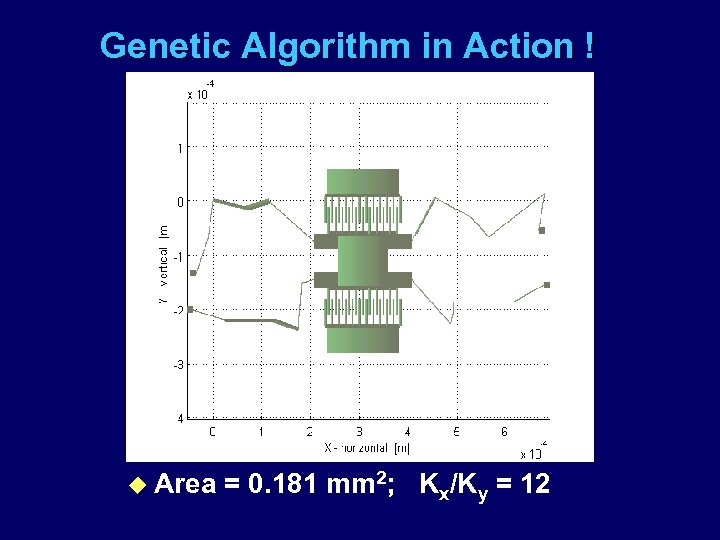

Genetic Algorithm in Action ! u Area = 0. 181 mm 2; Kx/Ky = 12

Genetic Algorithm in Action ! u Area = 0. 181 mm 2; Kx/Ky = 12

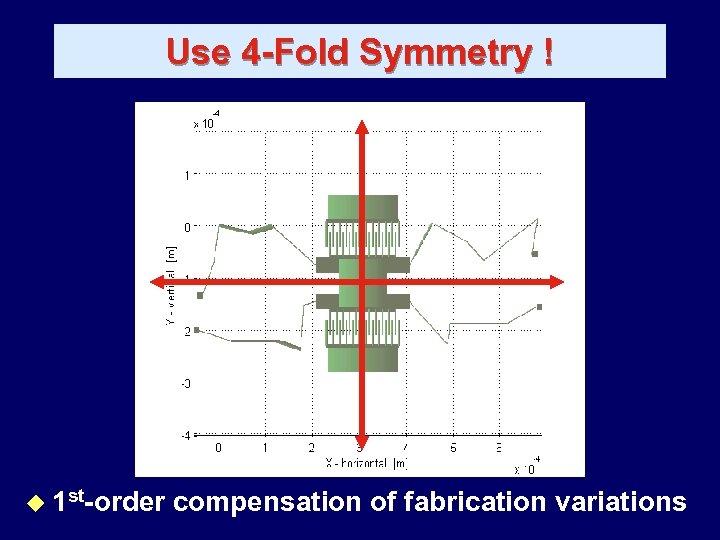

Use 4 -Fold Symmetry ! u 1 st-order compensation of fabrication variations

Use 4 -Fold Symmetry ! u 1 st-order compensation of fabrication variations

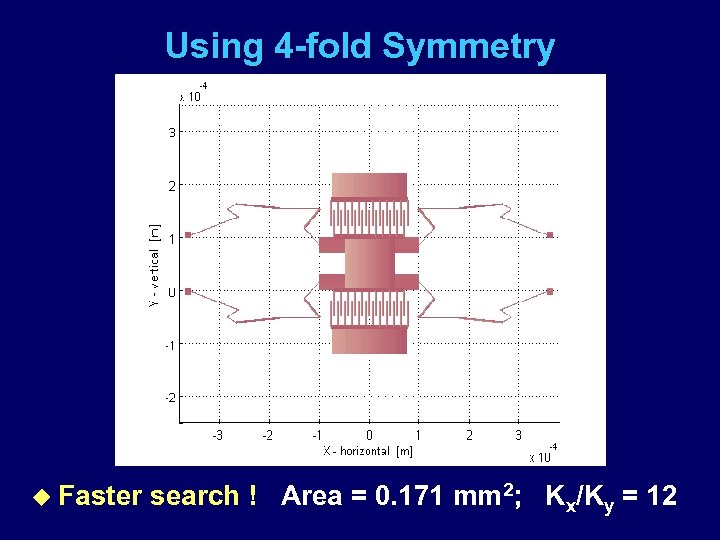

Using 4 -fold Symmetry u Faster search ! Area = 0. 171 mm 2; Kx/Ky = 12

Using 4 -fold Symmetry u Faster search ! Area = 0. 171 mm 2; Kx/Ky = 12

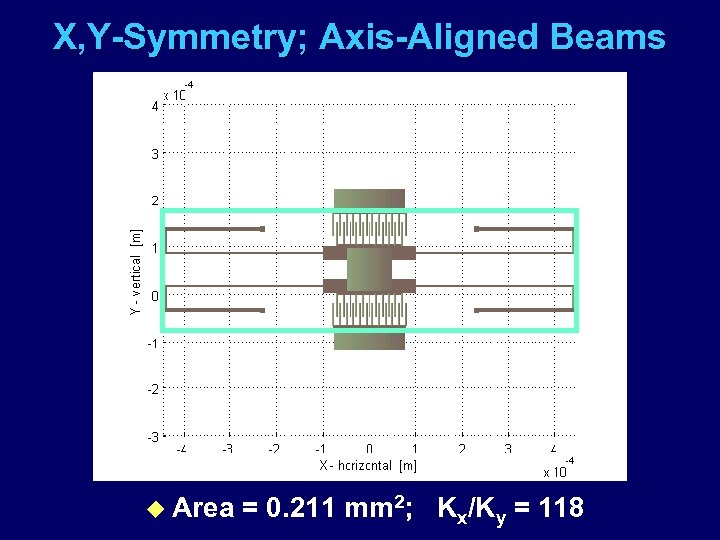

X, Y-Symmetry; Axis-Aligned Beams u Area = 0. 211 mm 2; Kx/Ky = 118

X, Y-Symmetry; Axis-Aligned Beams u Area = 0. 211 mm 2; Kx/Ky = 118

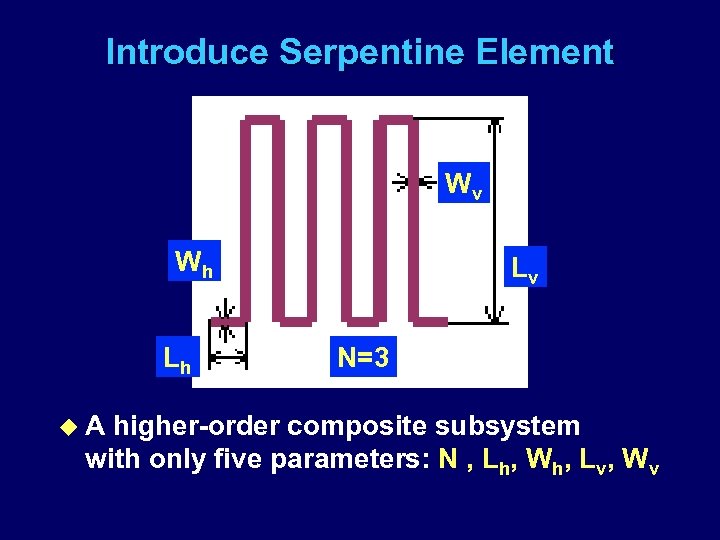

Introduce Serpentine Element Wv Wh Lh u. A Lv N=3 higher-order composite subsystem with only five parameters: N , Lh, Wh, Lv, Wv

Introduce Serpentine Element Wv Wh Lh u. A Lv N=3 higher-order composite subsystem with only five parameters: N , Lh, Wh, Lv, Wv

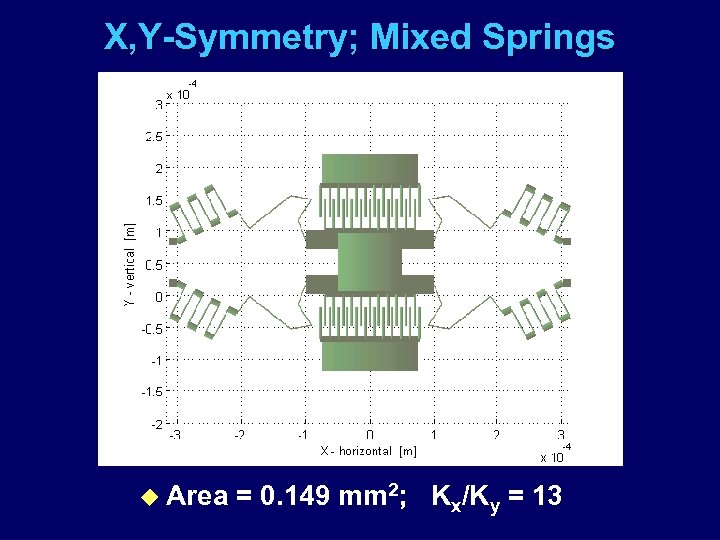

X, Y-Symmetry; Mixed Springs u Area = 0. 149 mm 2; Kx/Ky = 13

X, Y-Symmetry; Mixed Springs u Area = 0. 149 mm 2; Kx/Ky = 13

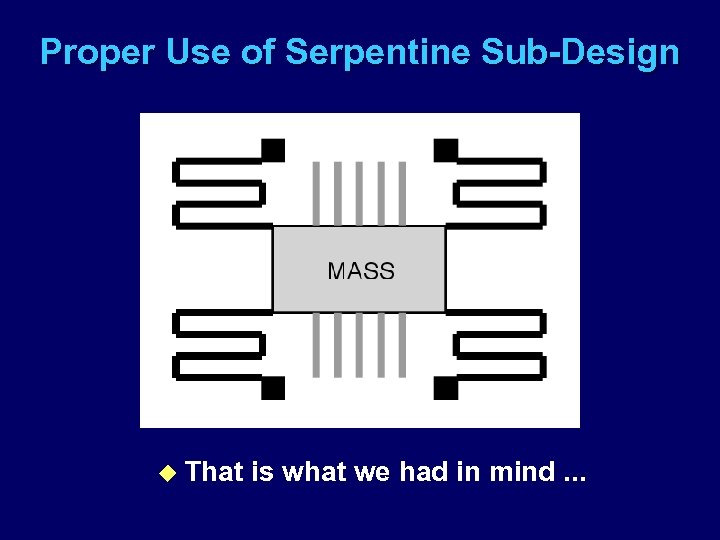

Proper Use of Serpentine Sub-Design u That is what we had in mind. . .

Proper Use of Serpentine Sub-Design u That is what we had in mind. . .

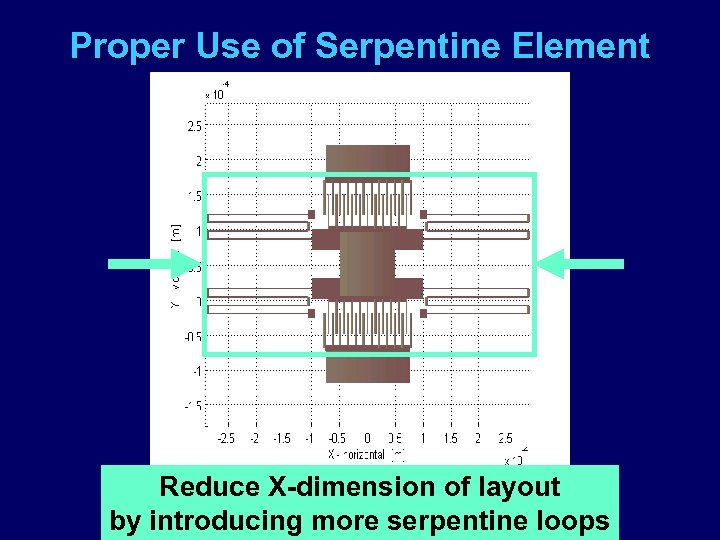

Proper Use of Serpentine Element Reduce 0. 143 mm 2; u Area =X-dimension ofxlayout K /Ky = 11 by introducing more serpentine loops

Proper Use of Serpentine Element Reduce 0. 143 mm 2; u Area =X-dimension ofxlayout K /Ky = 11 by introducing more serpentine loops

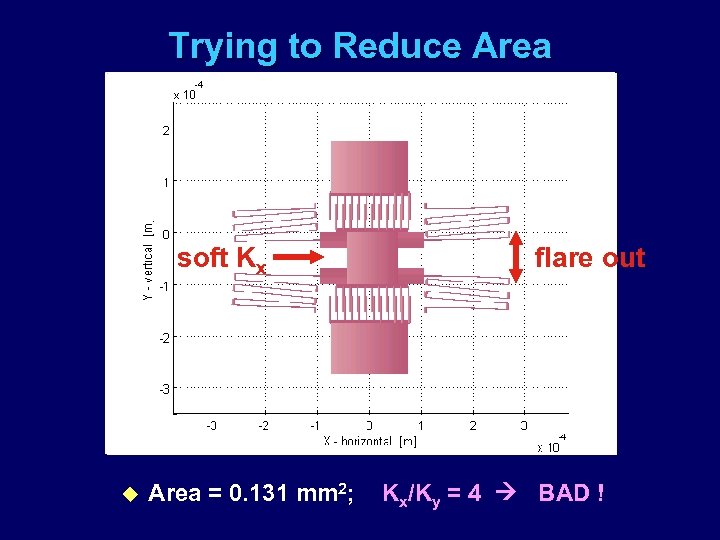

Trying to Reduce Area soft Kx u Area = 0. 131 mm 2; flare out Kx/Ky = 4 BAD !

Trying to Reduce Area soft Kx u Area = 0. 131 mm 2; flare out Kx/Ky = 4 BAD !

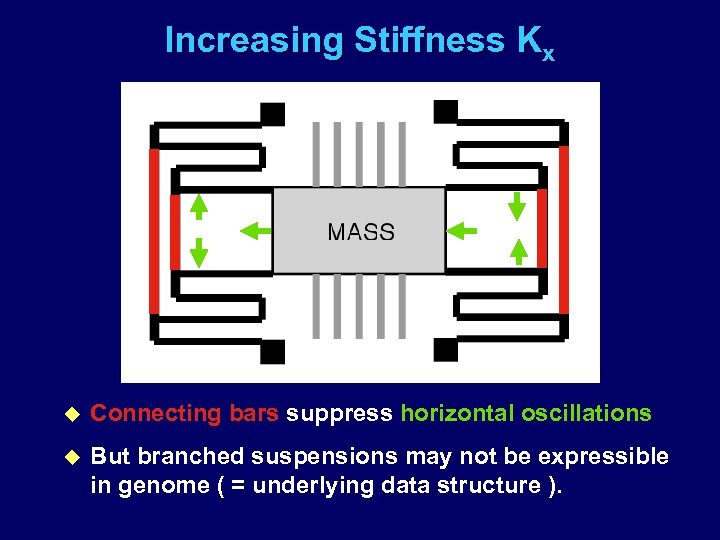

Increasing Stiffness Kx u Connecting bars suppress horizontal oscillations u But branched suspensions may not be expressible in genome ( = underlying data structure ).

Increasing Stiffness Kx u Connecting bars suppress horizontal oscillations u But branched suspensions may not be expressible in genome ( = underlying data structure ).

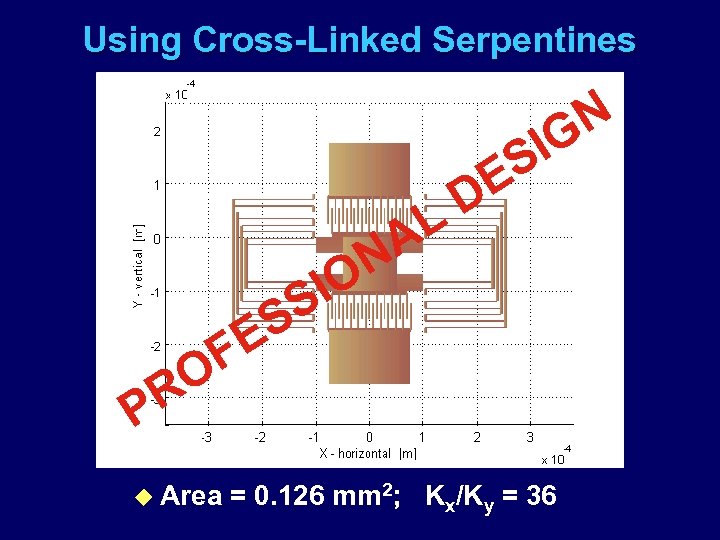

Using Cross-Linked Serpentines N IG S E D L A N S E F O IO S R P u Area = 0. 126 mm 2; Kx/Ky = 36

Using Cross-Linked Serpentines N IG S E D L A N S E F O IO S R P u Area = 0. 126 mm 2; Kx/Ky = 36

What really happened here ? u Major improvement steps came by engineering insights. u Genetic algorithm found good solutions for the newly introduced configurations. u With only few parameters & clear objectives, greedy optimization may be more efficient. u With complex multiple objectives, G. A. may have advantage of parallel exploration.

What really happened here ? u Major improvement steps came by engineering insights. u Genetic algorithm found good solutions for the newly introduced configurations. u With only few parameters & clear objectives, greedy optimization may be more efficient. u With complex multiple objectives, G. A. may have advantage of parallel exploration.

Why Did the G. A. Not Find This ? u Lack of expressibility of genome. u Solution space too large, too rugged. . . u Sampling u Samples is too sparse ! are not driven to local optima.

Why Did the G. A. Not Find This ? u Lack of expressibility of genome. u Solution space too large, too rugged. . . u Sampling u Samples is too sparse ! are not driven to local optima.

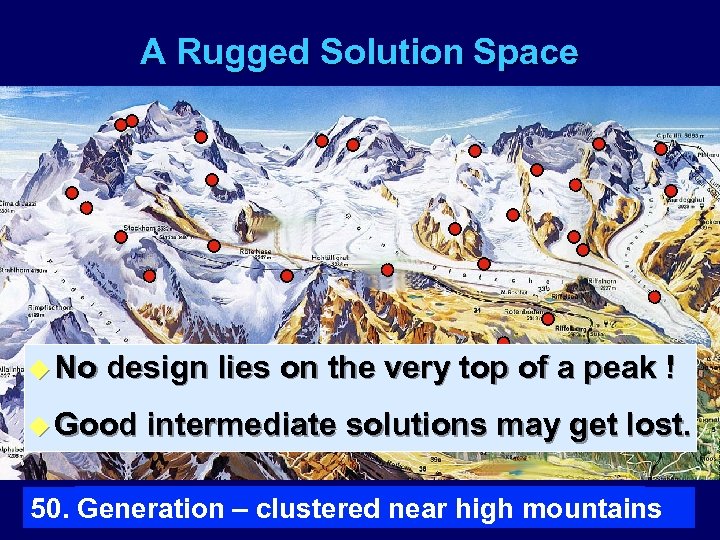

A Rugged Solution Space u No design lies on the very top of a peak ! u Good intermediate solutions may get lost. 20. 1. Generation drifting to high mountains Generation – – a random sampling 50. Generation – clustered nearhigher ground

A Rugged Solution Space u No design lies on the very top of a peak ! u Good intermediate solutions may get lost. 20. 1. Generation drifting to high mountains Generation – – a random sampling 50. Generation – clustered nearhigher ground

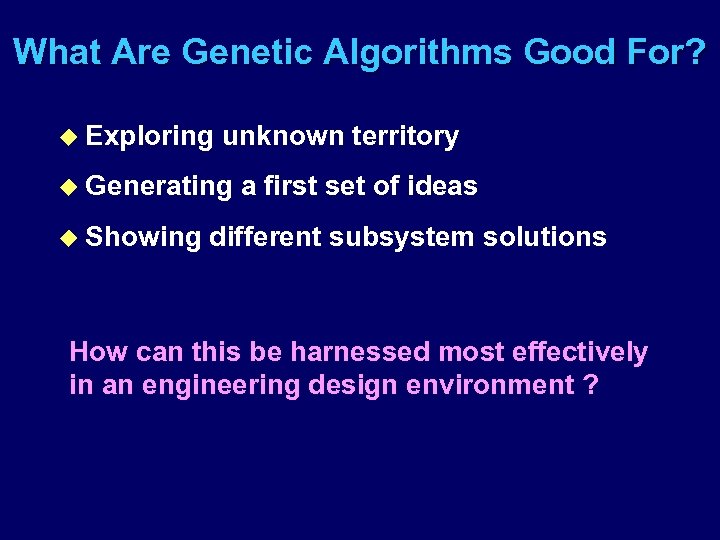

What Are Genetic Algorithms Good For? u Exploring unknown territory u Generating u Showing a first set of ideas different subsystem solutions How can this be harnessed most effectively in an engineering design environment ?

What Are Genetic Algorithms Good For? u Exploring unknown territory u Generating u Showing a first set of ideas different subsystem solutions How can this be harnessed most effectively in an engineering design environment ?

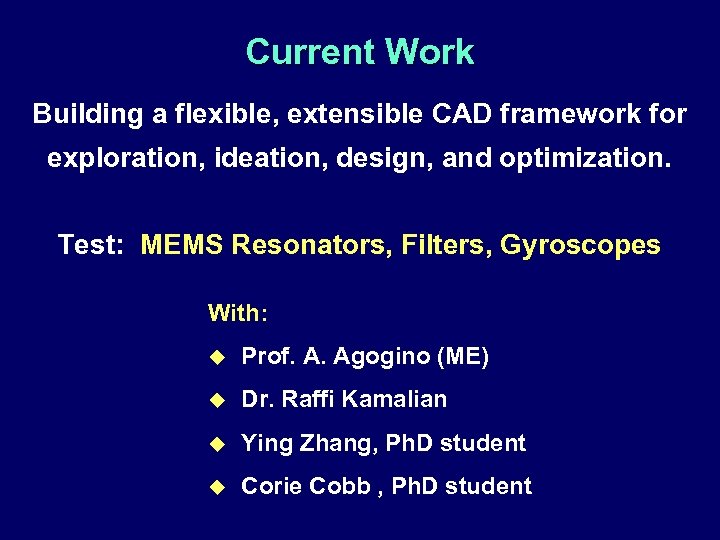

Current Work Building a flexible, extensible CAD framework for exploration, ideation, design, and optimization. Test: MEMS Resonators, Filters, Gyroscopes With: u Prof. A. Agogino (ME) u Dr. Raffi Kamalian u Ying Zhang, Ph. D student u Corie Cobb , Ph. D student

Current Work Building a flexible, extensible CAD framework for exploration, ideation, design, and optimization. Test: MEMS Resonators, Filters, Gyroscopes With: u Prof. A. Agogino (ME) u Dr. Raffi Kamalian u Ying Zhang, Ph. D student u Corie Cobb , Ph. D student

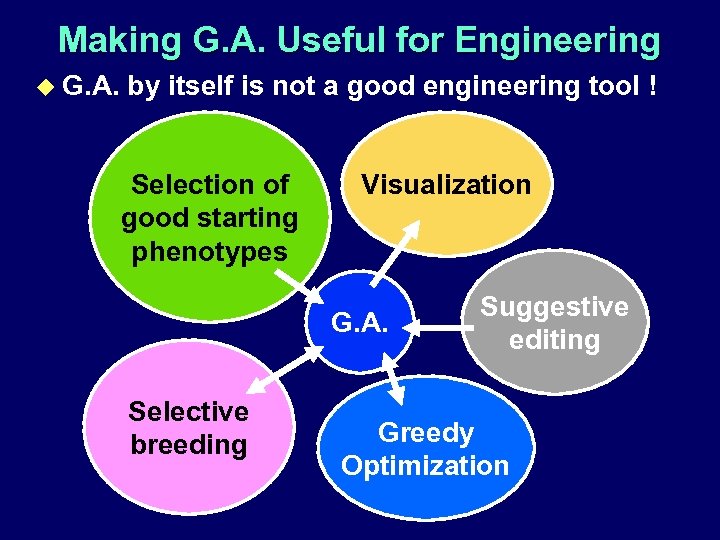

Making G. A. Useful for Engineering u G. A. by itself is not a good engineering tool ! Selection of good starting phenotypes Visualization G. A. Selective breeding Suggestive editing Greedy Optimization

Making G. A. Useful for Engineering u G. A. by itself is not a good engineering tool ! Selection of good starting phenotypes Visualization G. A. Selective breeding Suggestive editing Greedy Optimization

G. A. for Engineering Needs (1): A way to pick promising initial designs, e. g. from: ua case library u classical u internet literature searches u personal advice from experts u sketches, doodles

G. A. for Engineering Needs (1): A way to pick promising initial designs, e. g. from: ua case library u classical u internet literature searches u personal advice from experts u sketches, doodles

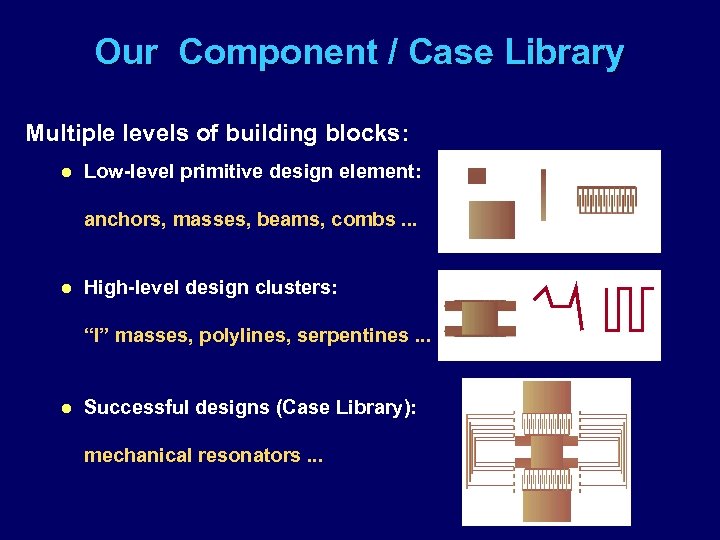

Our Component / Case Library Multiple levels of building blocks: l Low-level primitive design element: anchors, masses, beams, combs. . . l High-level design clusters: “I” masses, polylines, serpentines. . . l Successful designs (Case Library): mechanical resonators. . .

Our Component / Case Library Multiple levels of building blocks: l Low-level primitive design element: anchors, masses, beams, combs. . . l High-level design clusters: “I” masses, polylines, serpentines. . . l Successful designs (Case Library): mechanical resonators. . .

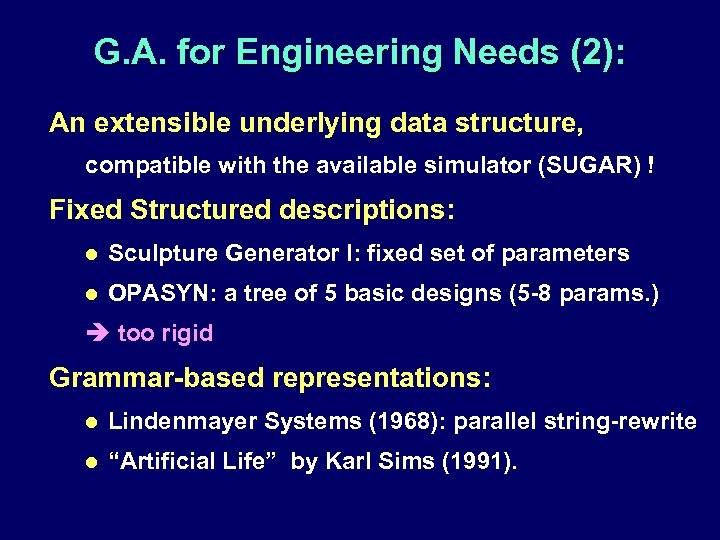

G. A. for Engineering Needs (2): An extensible underlying data structure, compatible with the available simulator (SUGAR) ! Fixed Structured descriptions: l Sculpture Generator I: fixed set of parameters l OPASYN: a tree of 5 basic designs (5 -8 params. ) too rigid Grammar-based representations: l Lindenmayer Systems (1968): parallel string-rewrite l “Artificial Life” by Karl Sims (1991).

G. A. for Engineering Needs (2): An extensible underlying data structure, compatible with the available simulator (SUGAR) ! Fixed Structured descriptions: l Sculpture Generator I: fixed set of parameters l OPASYN: a tree of 5 basic designs (5 -8 params. ) too rigid Grammar-based representations: l Lindenmayer Systems (1968): parallel string-rewrite l “Artificial Life” by Karl Sims (1991).

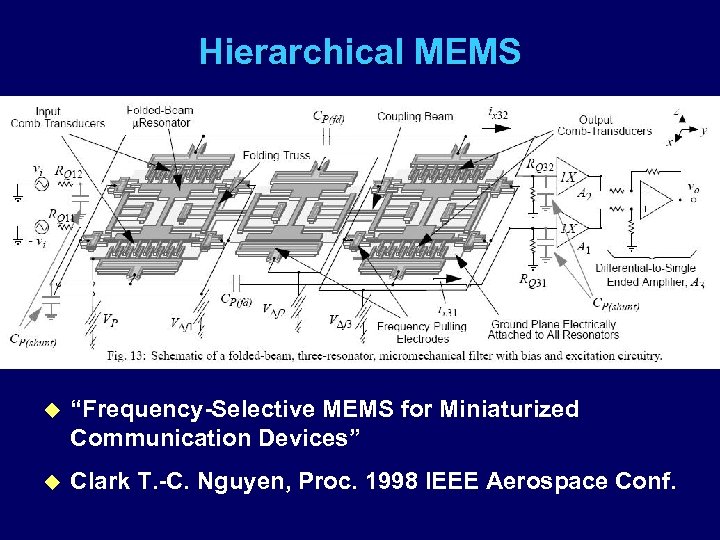

Hierarchical MEMS u “Frequency-Selective MEMS for Miniaturized Communication Devices” u Clark T. -C. Nguyen, Proc. 1998 IEEE Aerospace Conf.

Hierarchical MEMS u “Frequency-Selective MEMS for Miniaturized Communication Devices” u Clark T. -C. Nguyen, Proc. 1998 IEEE Aerospace Conf.

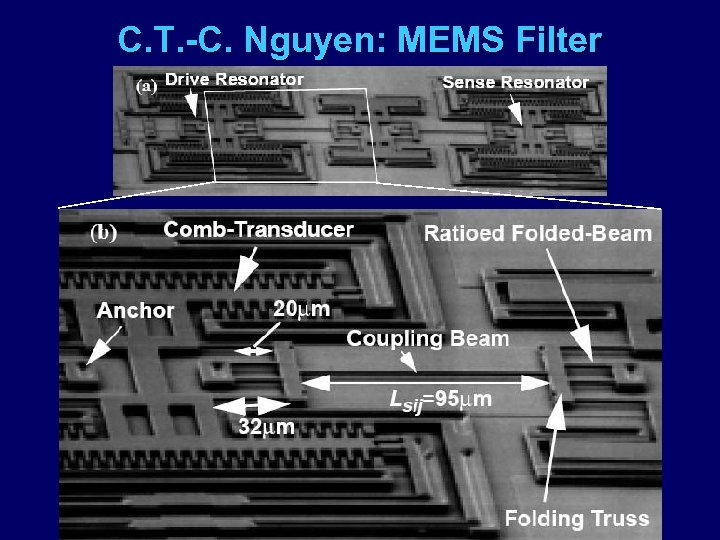

C. T. -C. Nguyen: MEMS Filter

C. T. -C. Nguyen: MEMS Filter

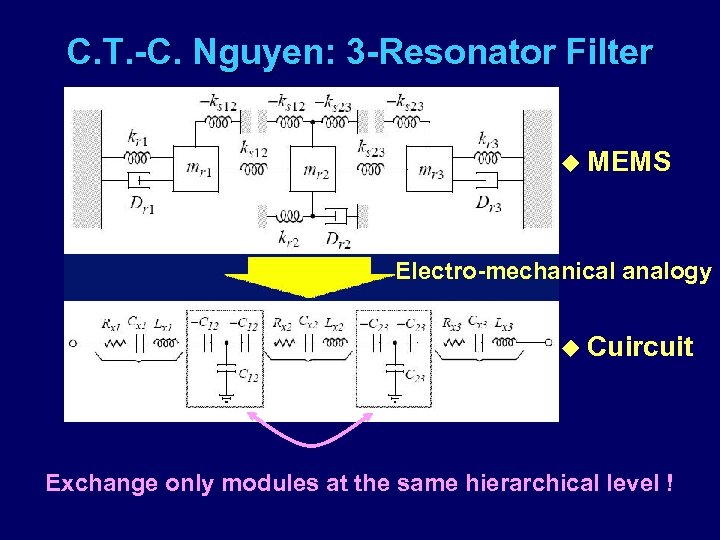

C. T. -C. Nguyen: 3 -Resonator Filter u MEMS Electro-mechanical analogy u Cuircuit Exchange only modules at the same hierarchical level !

C. T. -C. Nguyen: 3 -Resonator Filter u MEMS Electro-mechanical analogy u Cuircuit Exchange only modules at the same hierarchical level !

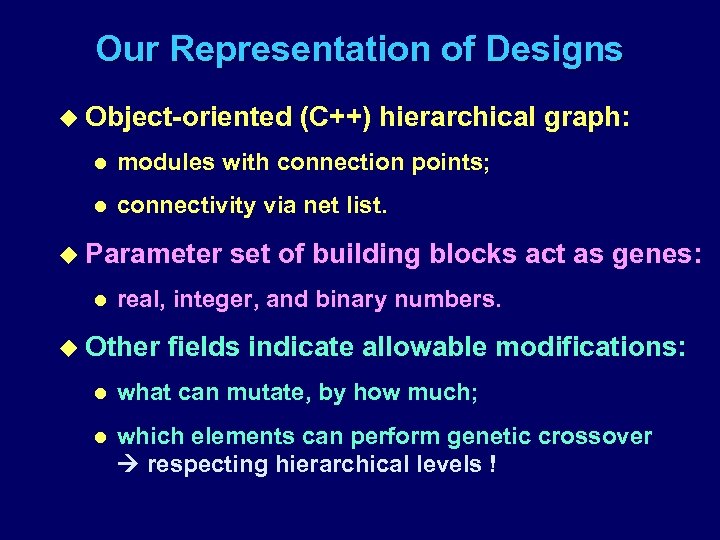

Our Representation of Designs u Object-oriented (C++) hierarchical graph: l modules with connection points; l connectivity via net list. u Parameter l set of building blocks act as genes: real, integer, and binary numbers. u Other fields indicate allowable modifications: l what can mutate, by how much; l which elements can perform genetic crossover respecting hierarchical levels !

Our Representation of Designs u Object-oriented (C++) hierarchical graph: l modules with connection points; l connectivity via net list. u Parameter l set of building blocks act as genes: real, integer, and binary numbers. u Other fields indicate allowable modifications: l what can mutate, by how much; l which elements can perform genetic crossover respecting hierarchical levels !

G. A. for Engineering Needs (3): Efficient ways to predict the functionality and fitness of phenotypes: u simulator u heuristic for the appropriate domain (SUGAR) evaluations based on past experience u visualization for quick human judgment keeping common-sense control !

G. A. for Engineering Needs (3): Efficient ways to predict the functionality and fitness of phenotypes: u simulator u heuristic for the appropriate domain (SUGAR) evaluations based on past experience u visualization for quick human judgment keeping common-sense control !

G. A. for Engineering Needs (4): Ways to improve the evolutionary process: u greedy phenotype optimization u deletion / advancement of special phenotypes u introducing new parameters / constraints u high-lighting of desirable features. . .

G. A. for Engineering Needs (4): Ways to improve the evolutionary process: u greedy phenotype optimization u deletion / advancement of special phenotypes u introducing new parameters / constraints u high-lighting of desirable features. . .

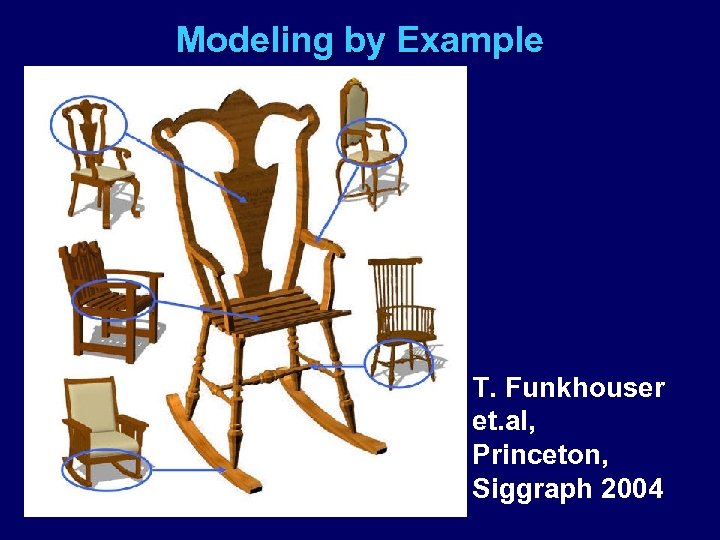

Modeling by Example u T. Funkhouser et. al, Princeton, Siggraph 2004

Modeling by Example u T. Funkhouser et. al, Princeton, Siggraph 2004

G. A. for Engineering Needs (5): Ways to edit individual designs: u sketching a whole new systems topology (this may be a far-out dream. . . ) u selective editing of phenotypes: “story-board” visualization of the sought-after design environment. . .

G. A. for Engineering Needs (5): Ways to edit individual designs: u sketching a whole new systems topology (this may be a far-out dream. . . ) u selective editing of phenotypes: “story-board” visualization of the sought-after design environment. . .

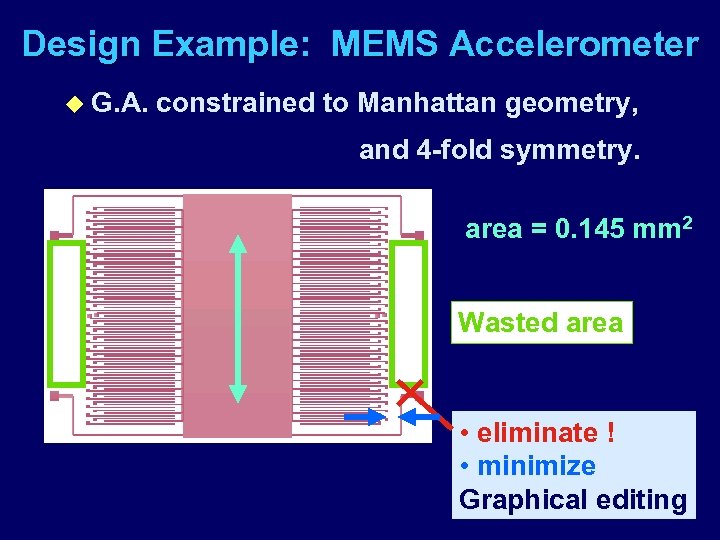

Design Example: MEMS Accelerometer u G. A. constrained to Manhattan geometry, and 4 -fold symmetry. area = 0. 145 mm 2 Wasted area • eliminate ! • minimize Graphical editing

Design Example: MEMS Accelerometer u G. A. constrained to Manhattan geometry, and 4 -fold symmetry. area = 0. 145 mm 2 Wasted area • eliminate ! • minimize Graphical editing

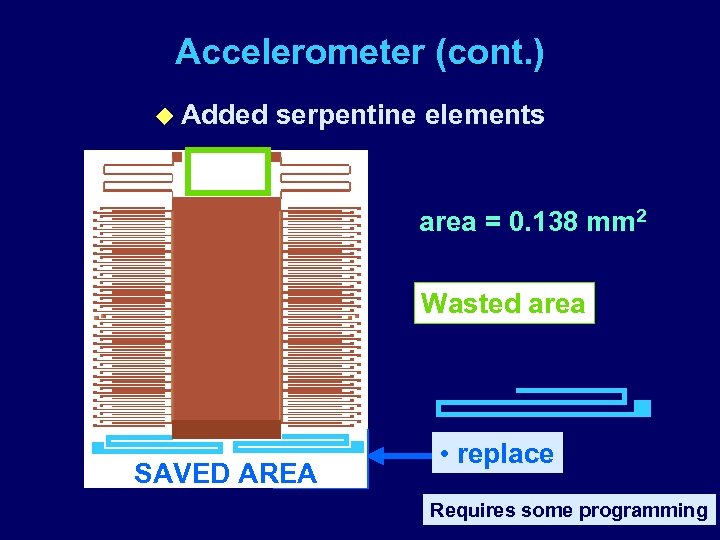

Accelerometer (cont. ) u Added serpentine elements area = 0. 138 mm 2 Wasted area SAVED AREA • replace Requires some programming

Accelerometer (cont. ) u Added serpentine elements area = 0. 138 mm 2 Wasted area SAVED AREA • replace Requires some programming

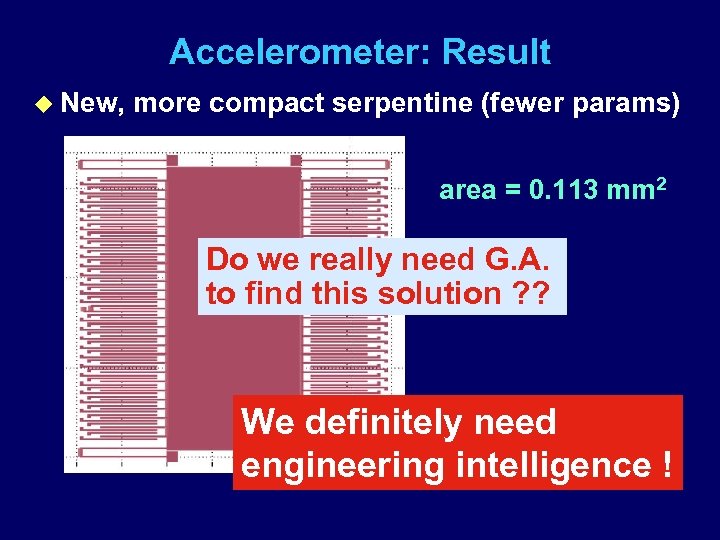

Accelerometer: Result u New, more compact serpentine (fewer params) area = 0. 113 mm 2 Do we really need G. A. to find this solution ? ? We definitely need engineering intelligence !

Accelerometer: Result u New, more compact serpentine (fewer params) area = 0. 113 mm 2 Do we really need G. A. to find this solution ? ? We definitely need engineering intelligence !

Summary u CAD will not become fully automated anytime soon. u Human intelligence will continue to play a key role: l engineering experience l common sense u It must be more tightly integrated into the design process: faster design completion better design results

Summary u CAD will not become fully automated anytime soon. u Human intelligence will continue to play a key role: l engineering experience l common sense u It must be more tightly integrated into the design process: faster design completion better design results

Today’s CAD Environments for Phase I u corresponding state of the art. . .

Today’s CAD Environments for Phase I u corresponding state of the art. . .

CAD Environments of the Future u Phase_1 CAD tools have a long way to go yet ! u Encourage bright young minds to work in this field.

CAD Environments of the Future u Phase_1 CAD tools have a long way to go yet ! u Encourage bright young minds to work in this field.

QUESTIONS ?

QUESTIONS ?

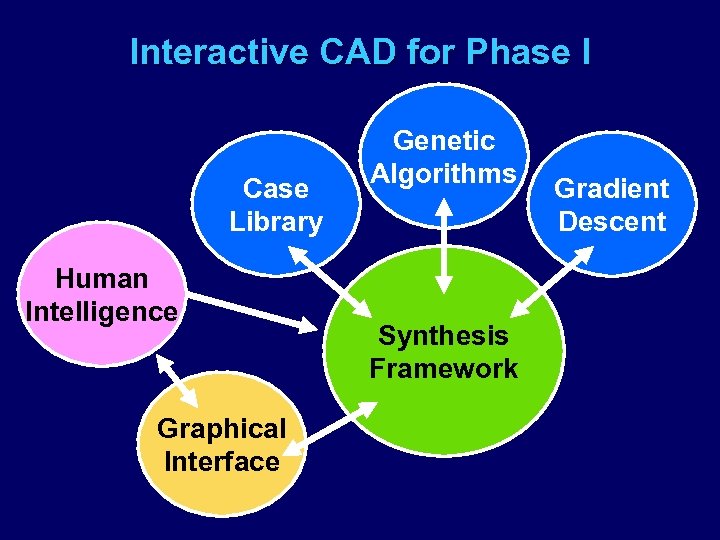

Interactive CAD for Phase I Case Library Human Intelligence Graphical Interface Genetic Algorithms Synthesis Framework Gradient Descent

Interactive CAD for Phase I Case Library Human Intelligence Graphical Interface Genetic Algorithms Synthesis Framework Gradient Descent