9abd062ae4b2425f7824eab45ee9c6f9.ppt

- Количество слайдов: 19

Cable Harness Testers by Futura Apsol Pvt. Ltd. (Electrodesigners) Pune, India Models Existing PHTM 320 : Tests upto 320 points from 64 points in step of 64 points. PHTM 640 : Tests upto 640 points from 64 points in step of 64 points. All features are similar except enclosure size of tester.

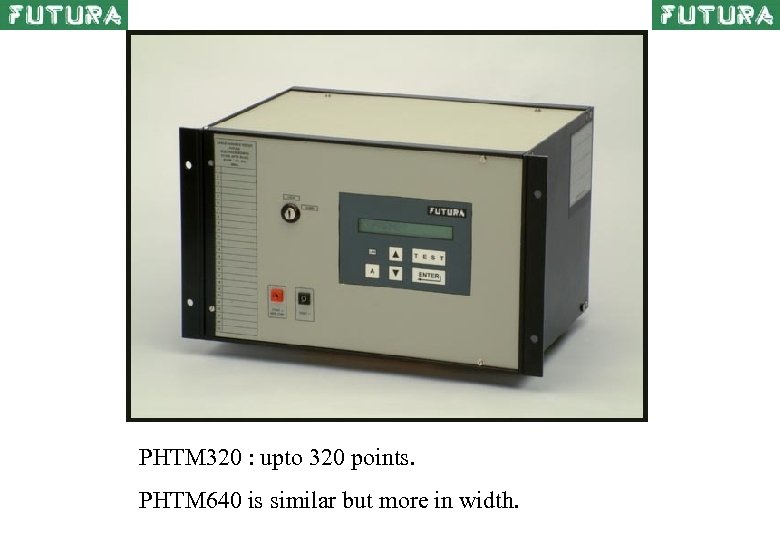

PHTM 320 : upto 320 points. PHTM 640 is similar but more in width.

Package contains • • Tester Serial Cable from PC to tester. Mains cord. Two probes for manual continuity checking. Learn / Lock key. Cable from tester to rig / board. User’s Manual Windows based Software for PC connectivity on CD.

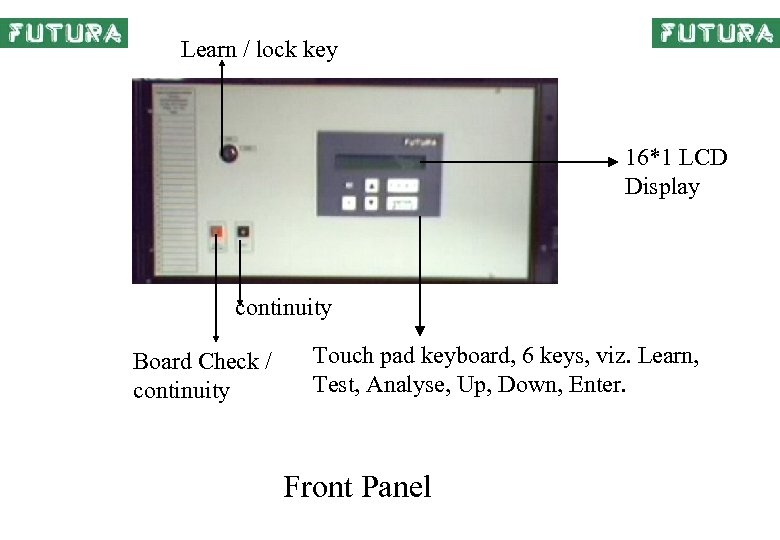

Learn / lock key 16*1 LCD Display continuity Board Check / continuity Touch pad keyboard, 6 keys, viz. Learn, Test, Analyse, Up, Down, Enter. Front Panel

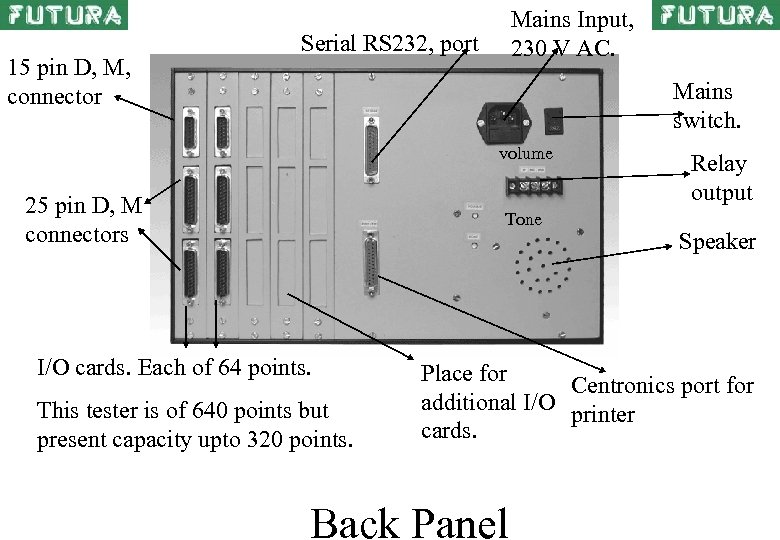

15 pin D, M, connector Mains Input, 230 V AC. Serial RS 232, port Mains switch. volume 25 pin D, M connectors Tone I/O cards. Each of 64 points. This tester is of 640 points but present capacity upto 320 points. Relay output Speaker Place for Centronics port for additional I/O printer cards. Back Panel

Features • It can be connected to PC though RS 232 for downloading harness data, label data, real time etc. • Tester can be connected to any centronics i. e. standard parallel port printer for printing harness data as well as on line labels with date / time /week / month of testing. Label data can be user defined. Selectable on selection of cable / harness. • Bar code reader, selectable on selection of cable / harness. Tests a harness only if scanned bar code label matches with preloaded bar code of maximum 16 characters. Can be made mandatory. • Test mode can be circuit by circuit or all circuits. Default circuit by circuit, selectable on power on.

Testing related Features • All points act as inputs as well as output meaning it does not have from and to concept. Hence wiring of boards is easy. • It can be adopted to any existing boards without disturbing existing wiring. Meaning same board can be used for existing testers as well as Futura’s testers. • All I/O cards are same and have no setting on them. Plugging in a card increases capacity by 64 points. • It has a capacity to store 25/12 (less than 320 points/ 320 – 640 points) different harness data by self learning or from a PC through serial RS 232. • Tester can find out faults such as open and short and very importantly mislocation i. e. interchange. Tester display directly points which are interchanged. It also shows a fault of extra point; a point not In programme but connected to rig. • Two stage testing for fuse insertion • Tester has a relay output on “PASS” of capacity 230 V AC, 5 AMPs, potential free for any application such as stamp printing. • It has a buzzer with tone and volume control.

More Features • Once testing starts; operator need not touch keyboard at all, until special functions are to be carried out. • Test voltage is 5 V DC and current in milliamperes. • It has built in counter, manual continuity checker. • A built in “board checker” facilitates checking and finding faults on rigs, connecting cables, I/O cards and also for periodic calibration or checking. • Storage Memory is of type EEPROM, which is more reliable than Battery Backed memory. • Real Time clock for printing date, time on labels for trace-ability. • A harness can be named. • Pass counter for each harness.

What different features can be offered • In two stage testing, First stage two times testing and second stage one time testing. (Presently both stages tested once. ) • In second stage testing can test only continuity, hence any two points shorted in second state are in programme instead of complete net. (Presently in second stage data, complete net is to be entered but tester also checks for shorting. ) • Large label data by reducing number of harnesses to be tested. (Presently maximum 250 character data is available) • Small beep sound on every fault. Starting of next test on removal of one point instead of complete harness. • Bar code reading can be made mandatory. • Learning from board can be blocked. (Presently Learn is also available)

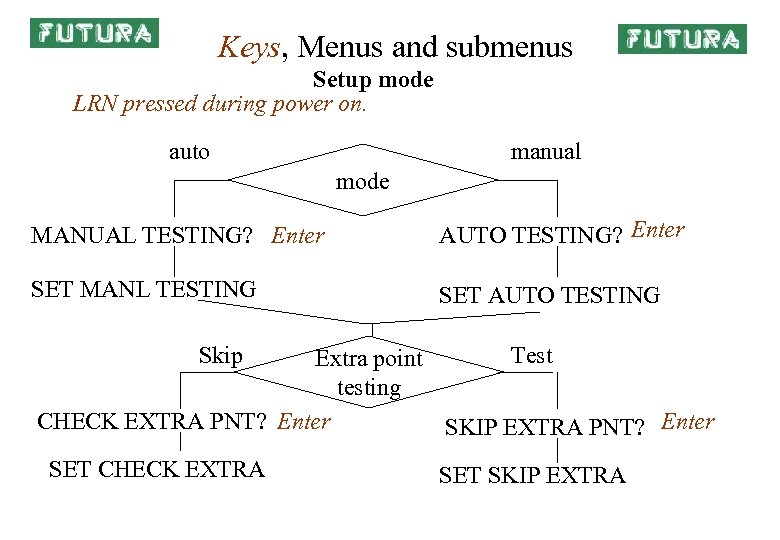

Keys, Menus and submenus Setup mode LRN pressed during power on. auto manual mode MANUAL TESTING? Enter AUTO TESTING? Enter SET MANL TESTING SET AUTO TESTING Skip Test Extra point testing CHECK EXTRA PNT? Enter SKIP EXTRA PNT? Enter SET CHECK EXTRA SET SKIP EXTRA

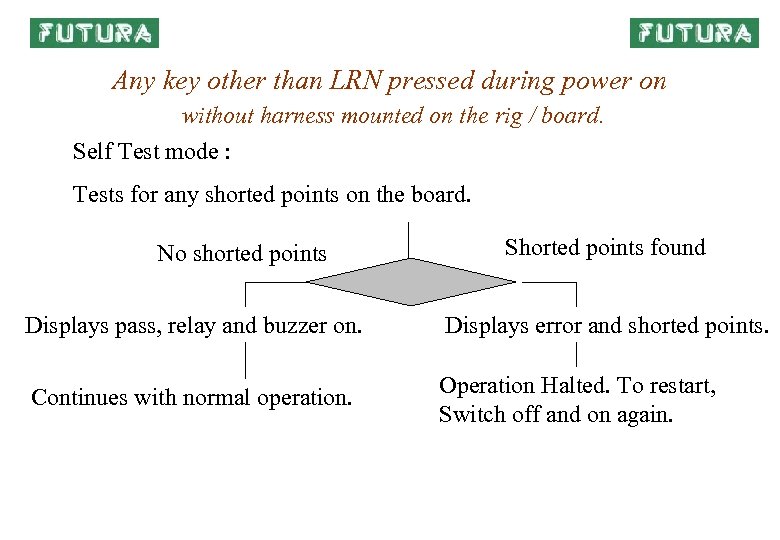

Any key other than LRN pressed during power on without harness mounted on the rig / board. Self Test mode : Tests for any shorted points on the board. No shorted points Shorted points found Displays pass, relay and buzzer on. Displays error and shorted points. Continues with normal operation. Operation Halted. To restart, Switch off and on again.

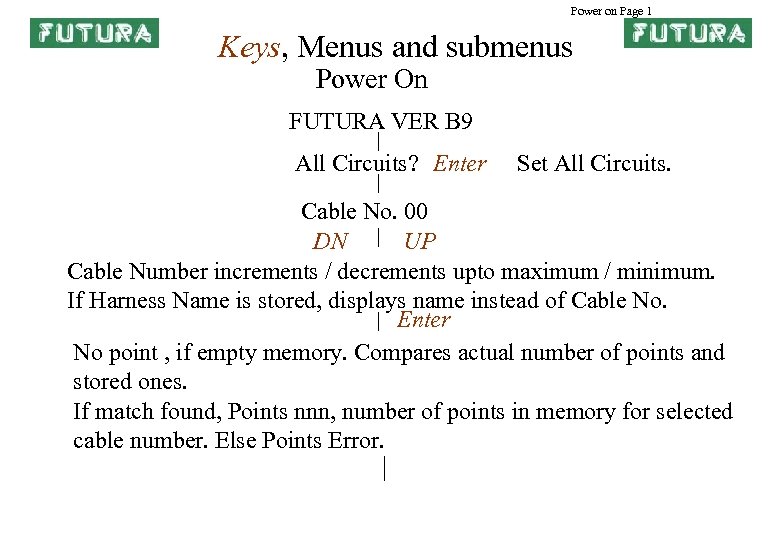

Power on Page 1 Keys, Menus and submenus Power On FUTURA VER B 9 All Circuits? Enter Set All Circuits. Cable No. 00 DN UP Cable Number increments / decrements upto maximum / minimum. If Harness Name is stored, displays name instead of Cable No. Enter No point , if empty memory. Compares actual number of points and stored ones. If match found, Points nnn, number of points in memory for selected cable number. Else Points Error.

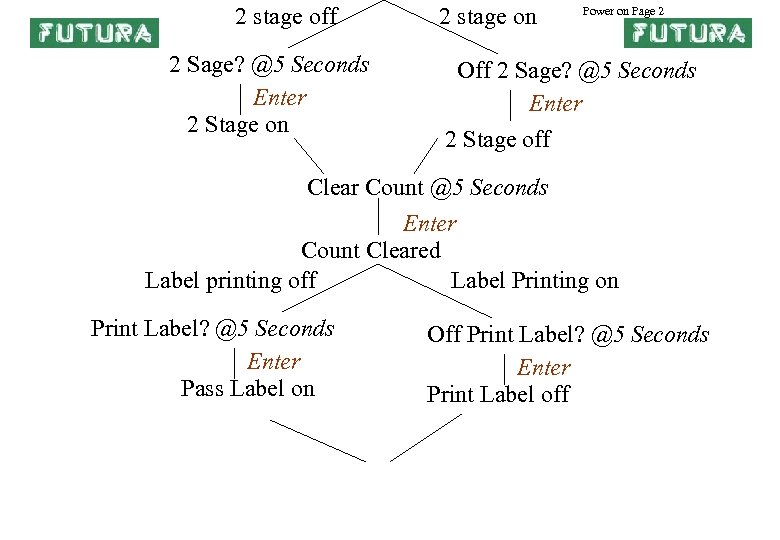

2 stage off 2 Sage? @5 Seconds Enter 2 Stage on 2 stage on Power on Page 2 Off 2 Sage? @5 Seconds Enter 2 Stage off Clear Count @5 Seconds Enter Count Cleared Label printing off Label Printing on Print Label? @5 Seconds Enter Pass Label on Off Print Label? @5 Seconds Enter Print Label off

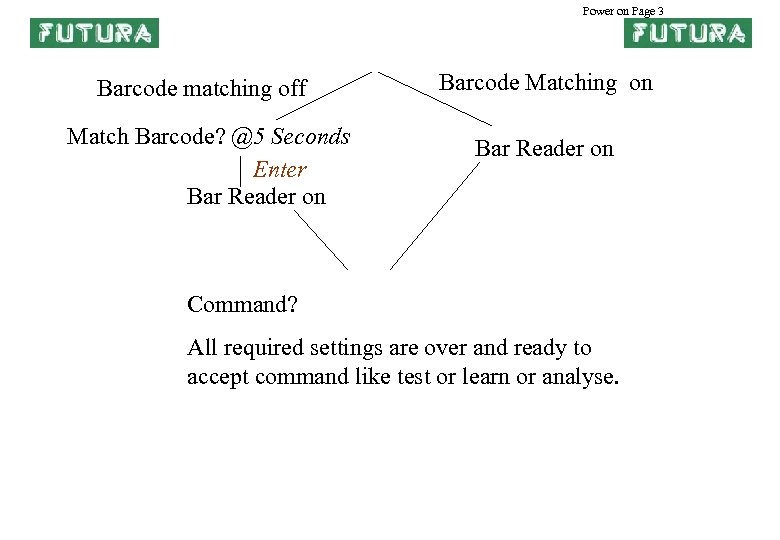

Power on Page 3 Barcode matching off Barcode Matching on Match Barcode? @5 Seconds Enter Bar Reader on Command? All required settings are over and ready to accept command like test or learn or analyse.

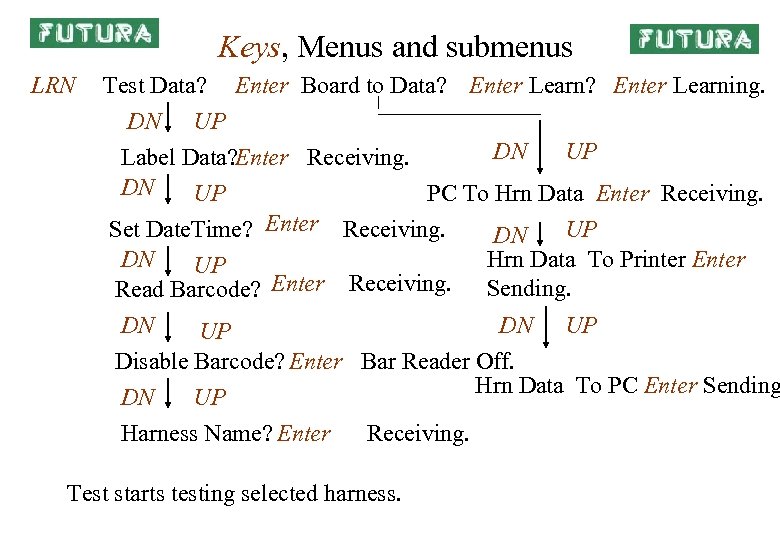

Keys, Menus and submenus LRN Test Data? Enter Board to Data? Enter Learning. DN UP Label Data? Enter Receiving. DN UP PC To Hrn Data Enter Receiving. Set Date. Time? Enter Receiving. UP DN DN Hrn Data To Printer Enter UP Read Barcode? Enter Receiving. Sending. DN DN UP UP Disable Barcode? Enter Bar Reader Off. Hrn Data To PC Enter Sending DN UP Harness Name? Enter Receiving. Test starts testing selected harness.

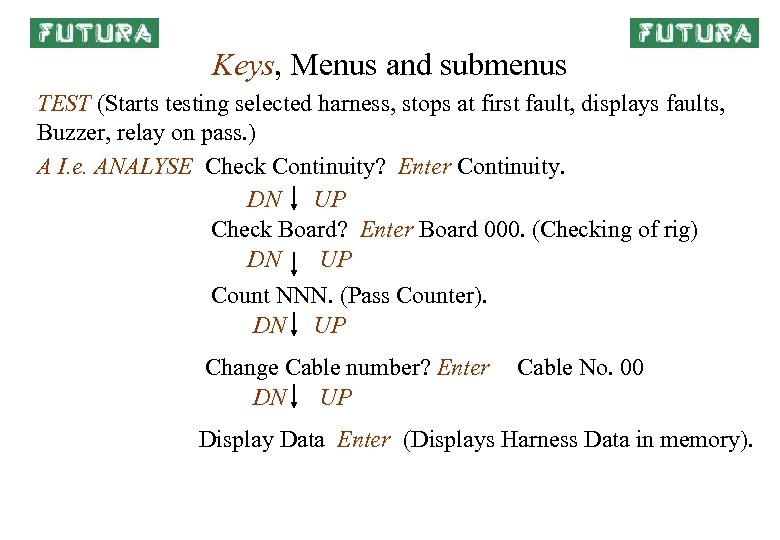

Keys, Menus and submenus TEST (Starts testing selected harness, stops at first fault, displays faults, Buzzer, relay on pass. ) A I. e. ANALYSE Check Continuity? Enter Continuity. DN UP Check Board? Enter Board 000. (Checking of rig) DN UP Count NNN. (Pass Counter). DN UP Change Cable number? Enter DN UP Cable No. 00 Display Data Enter (Displays Harness Data in memory).

Features Under Development / Trials • Tester finds maximum point number and tests only upto that point. Hence increases speed of testing smaller harnesses in tester with more points. • Separate MMI I. e. keyboard, display and keyswitch, connected to main tester through 25 core 3 m. long cable. Improved aesthetic look. Main tester can be kept inside.

Other related products • Solid State Floppy to carry data from PC to tester. At a time 4 datas can be carried. • Harness Assembly Aid for assemblies / subassemblies upto 64 points. (PGT). • One to One continuity checker 6, 48 , 96 circuits. (Clamp Checker). • Customised Automatic Test Equipments such as dashboard assembly Tester, Fan tester, Relay tester, Timer tester etc.

Futura Apsol Pvt. Ltd. 1212/B, Apte Road, Shivajinagar, Pune. Maharashtra. India 411004. Email : sales@futuras. com Website : www. futuras. com Telephone: 91 -20 -2553 1832, 9881138785 Cell : Girish Ranade : 98220 68764.

9abd062ae4b2425f7824eab45ee9c6f9.ppt