3264536f442981a2b5278080715c67aa.ppt

- Количество слайдов: 19

Cable and Low Frequency Cable Assemblies Kelly Wolff – Product Marketer kpwolff@mmm. com Ph: 512 -984 -3172 Electronics

Markets Cable is used in almost all electronic markets where there is a need to transition either data or power over a length that exceeds the reach of standard connectors. v Gaming Machines v Automated Test and Measurement v Medical v High Vibration Applications v Banking & Retail v Security Electronics v v v Audio & Video Military Computing Networking Equipment Communications Equipment Life Sciences Industrial Controls

Channels to Market Almost all of the cable that we produce is incorporated into cable assemblies which are used to transition signal and power in electronic systems. A large portion of the cable 3 M produces today is consumed via cable assembly and harness manufacturers. ESD sells cable to a variety of OEM’s, Contract Manufacturers and Cable/Harness manufacturers (Subcontractors). Close to 70% of all cable is sold through our distribution channel, the balance is sold directly to the previously mentioned channels. Electronics

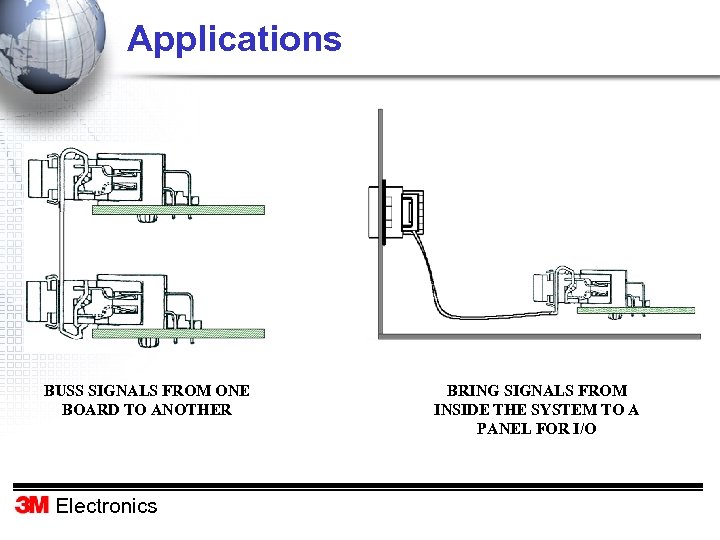

Applications BUSS SIGNALS FROM ONE BOARD TO ANOTHER Electronics BRING SIGNALS FROM INSIDE THE SYSTEM TO A PANEL FOR I/O

Application Cable type is selected based on the electrical and mechanical needs of the application. Cable serves as the medium for transmitting signals from one point to another. Cable Selection Criteria for an Assembly: Signal Speed Electrical Characteristics Connector Pitch Shielding requirements Ruggedness Flexibility Regulatory Electronics

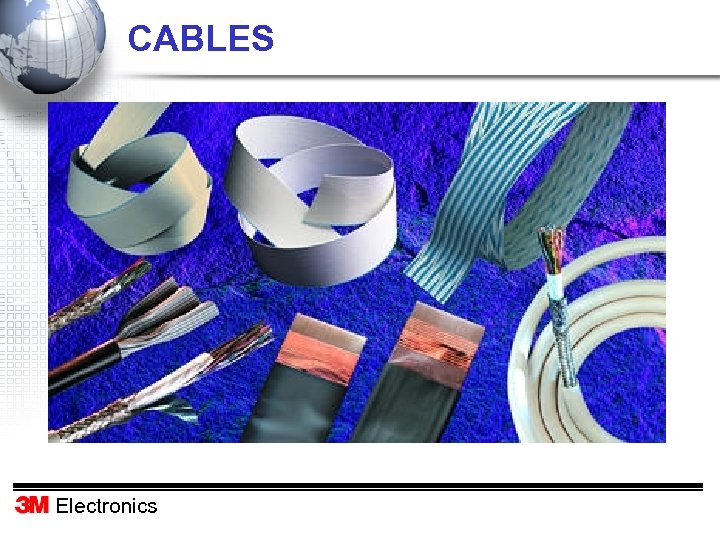

CABLES Electronics

Cable Offering v Round Conductor Flat Cable (including color coded & Power Cable) v Extended Flex Life Flat Cable v Twisted Pair Flat Cable v Ground Plane Cable v Shielded/Jacketed, Flat Cable v Pleated Foil Cable v Round Shielded/Jacketed, Flat Cable v Round Shielded/Jacketed, Discrete Wire Cable v Halogen Free Cable v Cable Accessories (Clamps, Clips, Shields, Jackets, Ties) Electronics

Cable – Features & Benefits v Wide variety of flat and round cable solutions v Innovative shielding solutions for mass termination v Custom manufacturing capability with ability to provide quick turn v Multiple packaging options- roll size, splice free, custom twist and flat v Compatible with 3 M wiremount connectors v 81% of sku’s have LT of 14 days or less, with many sku’s in stock Electronics

Competition v Tyco / Madison v Hitachi v Amphenol/Spectra-Strip v Molex v Belden v Gore Competitive Situation v v Move to lower cost manufacturing in Asia Longer Lead times Offer higher speed cables/ wider variety Rising Copper Prices/ Frequent Price Changes Electronics

Cable v. How We Win ØSales Rep involvement ØSolve a problem ØQuality product ØQuick response and delivery ØCompetitive Pricing Electronics

Success Stories v RND Ø 3659 and 3759 cable Ø Orignally lost business to Hitachi with original disty due to pricing and lack of support Ø Due to sales rep involvement with account and help with solving a problem they were having in another application, rep was able to get the chance to re-quote this business Ø With competitive pricing, short lead times, and different disty, was able to win back business v YC Cable Ø Ø 30 K ft of 3600 cable needed asap at competitve price (total EAU 60 K) Was able to offer discounted price higher than meet comp First 10 K feet to ship w/i 1 wk Customer is placing full order of 60 K this week Electronics

MOLDED ASSEMBLIES Electronics

Assembly Offerings v 2 mm 2 M Series Ø 2 -row Sockets Ø 2 -row PCBs v. 100” 1 M Series Ø 2 -row Sockets Ø 2 -row PCBs Ø 2 -row DIPs v Various Flat Ribbon Cables Ø 26 and 28 AWG Ø Solid or Stranded Electronics

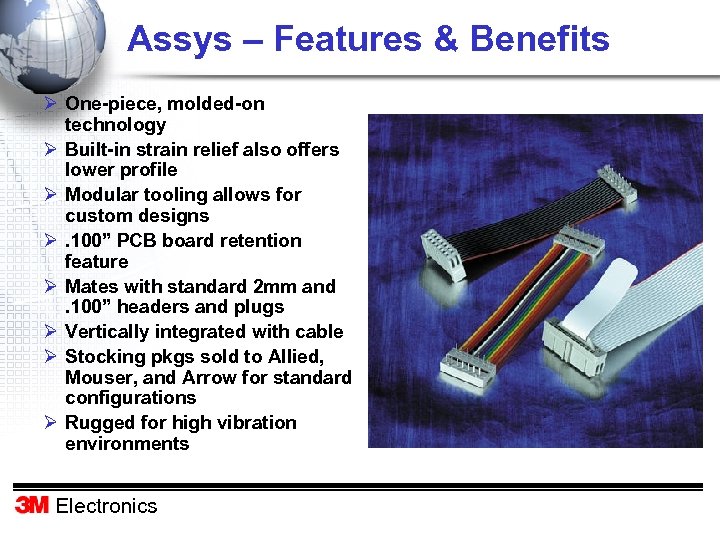

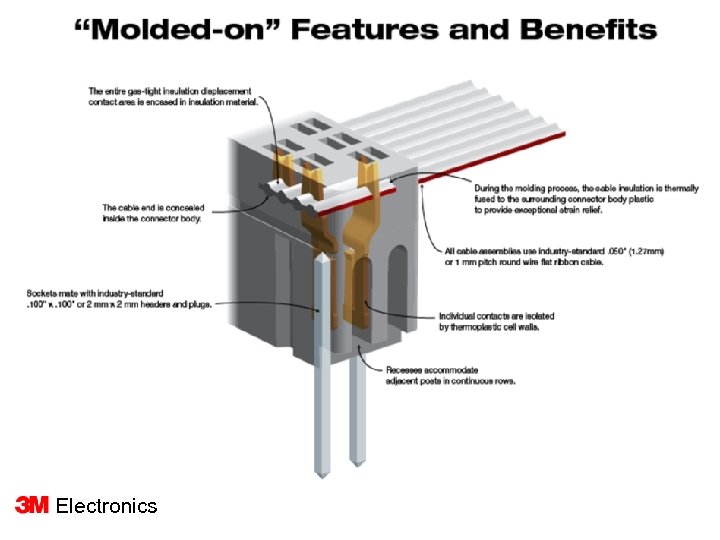

Assys – Features & Benefits Ø One-piece, molded-on technology Ø Built-in strain relief also offers lower profile Ø Modular tooling allows for custom designs Ø. 100” PCB board retention feature Ø Mates with standard 2 mm and. 100” headers and plugs Ø Vertically integrated with cable Ø Stocking pkgs sold to Allied, Mouser, and Arrow for standard configurations Ø Rugged for high vibration environments Electronics

Electronics

Competition v Moldtech (Black Silver®, not global, . 100” molded only) v Samtec (press-on only) v Any CM, value-add disty or harness shop that has the tooling Competitive Situation v Commodity products of the electronics industry therefore “perceived” as low end of supply chain v Orders go to lowest bidder and shortest lead time v Low cost Asian suppliers v Custom assemblies have more value, therefore can get higher pricing but technical support, service, and delivery are still key v US Competition can deliver samples and production orders quicker Electronics

Assembly v. How We Win ØSales Rep involvement ØProvide a custom configuration that solves a problem ØRuggedness of molded design ØPricing is secondary but still competitive Electronics

Success Stories v Crown Int’l Ø Ø Ø Audio Industry – Speakers & Amplifiers Was using Molex but had poor quality Molded design was the right solution Cost effective enough They are replacing with 3 M across the board v ITT Ø Airport Towers Ø Samtec solution was breaking Ø Offered them the molded w/ pull tab feature v Network Car Ø GPS systems for trucking industry Ø Existing press-on solution out of China was having termination disengagements in the field and moisture exposure issues Ø Quick turn press-on sample with jacket out of Austin Ø Molded design with jacketed cable at competitive price Electronics

Questions? ? Electronics

3264536f442981a2b5278080715c67aa.ppt