C O N N E C T I V I T Y Table of Contents Communications Overview Base System CONI Card and Twisted Pair CONI Card and MINT Digiboard Remote communication to CH devices Base system Intr Section 1 1 -3 1 -6 Section 2 2 -1 2 -2 Multiple Display Multiple display serial connection Multiple display Point to Point Network card Multiple display Local Area Network Ethernet Bridge Sec 3 -1 3 -5 3 -16 3 -20 3 -25 Interfacing with other manufacturers’ Power Monitoring Systems Enhanced Graphics Communication with other kinds of systems Building Management System (BMS), Distributed Control Systems (DCS), Programmable Logic Controllers (PLC) Modbus Gateway Mint Direct interface Special configurations Sec 4 -1 Section 5 5 -1 5 -4 5 -9 5 -21 5 -28 Communication with other manufacturers’ devices and networks Section 6 Enhanced Graphics: Wonderware In. Touch 6 -1 For further information contact Power Management Application Support (PMAS) at 1 -800 -809 -2772 (USA and Canada) or 412 -490 -6814. For referenced documents (IL’s, Application Notes) contact APSC or dial FRED (Fax Retrieval of Engineering Documents) at 412 -494 -3745.

C O N N E C T I V I T Y Table of Contents Communications Overview Base System CONI Card and Twisted Pair CONI Card and MINT Digiboard Remote communication to CH devices Base system Intr Section 1 1 -3 1 -6 Section 2 2 -1 2 -2 Multiple Display Multiple display serial connection Multiple display Point to Point Network card Multiple display Local Area Network Ethernet Bridge Sec 3 -1 3 -5 3 -16 3 -20 3 -25 Interfacing with other manufacturers’ Power Monitoring Systems Enhanced Graphics Communication with other kinds of systems Building Management System (BMS), Distributed Control Systems (DCS), Programmable Logic Controllers (PLC) Modbus Gateway Mint Direct interface Special configurations Sec 4 -1 Section 5 5 -1 5 -4 5 -9 5 -21 5 -28 Communication with other manufacturers’ devices and networks Section 6 Enhanced Graphics: Wonderware In. Touch 6 -1 For further information contact Power Management Application Support (PMAS) at 1 -800 -809 -2772 (USA and Canada) or 412 -490 -6814. For referenced documents (IL’s, Application Notes) contact APSC or dial FRED (Fax Retrieval of Engineering Documents) at 412 -494 -3745.

C O N N E C T I V I T Y Table of Contents Appendix A Cables A-1 Appendix B Dip switch setting (CONI, MINT) B-1 Appendix C Line drivers and media converters settings C-1 Index of Companies Glossary For further information contact Power Management Application Support (PMAS) at 1 -800 -809 -2772 (USA and Canada) or 412 -490 -6814. For referenced documents (IL’s, Application Notes) contact APSC or dial FRED (Fax Retrieval of Engineering Documents) at 412 -494 -3745.

C O N N E C T I V I T Y Table of Contents Appendix A Cables A-1 Appendix B Dip switch setting (CONI, MINT) B-1 Appendix C Line drivers and media converters settings C-1 Index of Companies Glossary For further information contact Power Management Application Support (PMAS) at 1 -800 -809 -2772 (USA and Canada) or 412 -490 -6814. For referenced documents (IL’s, Application Notes) contact APSC or dial FRED (Fax Retrieval of Engineering Documents) at 412 -494 -3745.

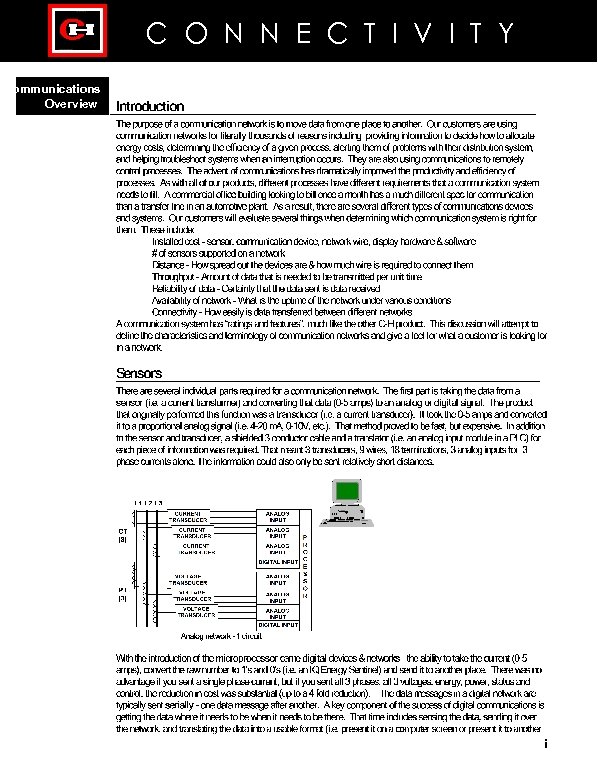

C O N N E C T I V I T Y Communications Overview i

C O N N E C T I V I T Y Communications Overview i

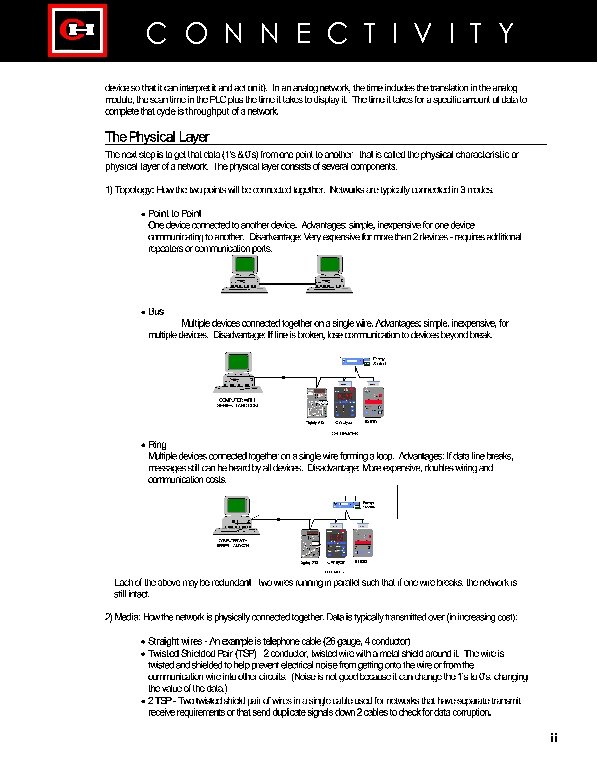

C O N N E C T I V I T Y ii

C O N N E C T I V I T Y ii

C O N N E C T I V I T Y iii

C O N N E C T I V I T Y iii

C O N N E C T I V I T Y iv

C O N N E C T I V I T Y iv

C O N N E C T I V I T Y v

C O N N E C T I V I T Y v

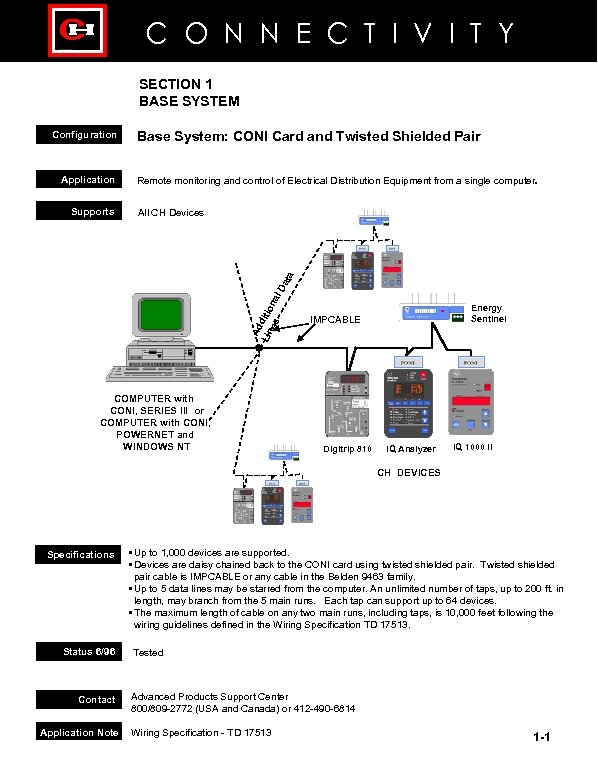

C O N N E C T I V I T Y SECTION 1 BASE SYSTEM Configuration Application . Remote monitoring and control of Electrical Distribution Equipment from a single computer All CH Devices Ad Lin ditio es na l Da ta Supports Base System: CONI Card and Twisted Shielded Pair COMPUTER with CONI, SERIES III or COMPUTER with CONI, POWERNET and WINDOWS NT Energy Sentinel IMPCABLE Digitrip 810 IQ Analyzer IQ 1000 II CH DEVICES Specifications Status 6/96 Contact Application Note • Up to 1, 000 devices are supported. • Devices are daisy chained back to the CONI card using twisted shielded pair. Twisted shielded pair cable is IMPCABLE or any cable in the Belden 9463 family. • Up to 5 data lines may be starred from the computer. An unlimited number of taps, up to 200 ft. in length, may branch from the 5 main runs. Each tap can support up to 64 devices. • The maximum length of cable on any two main runs, including taps, is 10, 000 feet following the wiring guidelines defined in the Wiring Specification TD 17513. Tested Advanced Products Support Center 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 1 -1

C O N N E C T I V I T Y SECTION 1 BASE SYSTEM Configuration Application . Remote monitoring and control of Electrical Distribution Equipment from a single computer All CH Devices Ad Lin ditio es na l Da ta Supports Base System: CONI Card and Twisted Shielded Pair COMPUTER with CONI, SERIES III or COMPUTER with CONI, POWERNET and WINDOWS NT Energy Sentinel IMPCABLE Digitrip 810 IQ Analyzer IQ 1000 II CH DEVICES Specifications Status 6/96 Contact Application Note • Up to 1, 000 devices are supported. • Devices are daisy chained back to the CONI card using twisted shielded pair. Twisted shielded pair cable is IMPCABLE or any cable in the Belden 9463 family. • Up to 5 data lines may be starred from the computer. An unlimited number of taps, up to 200 ft. in length, may branch from the 5 main runs. Each tap can support up to 64 devices. • The maximum length of cable on any two main runs, including taps, is 10, 000 feet following the wiring guidelines defined in the Wiring Specification TD 17513. Tested Advanced Products Support Center 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 1 -1

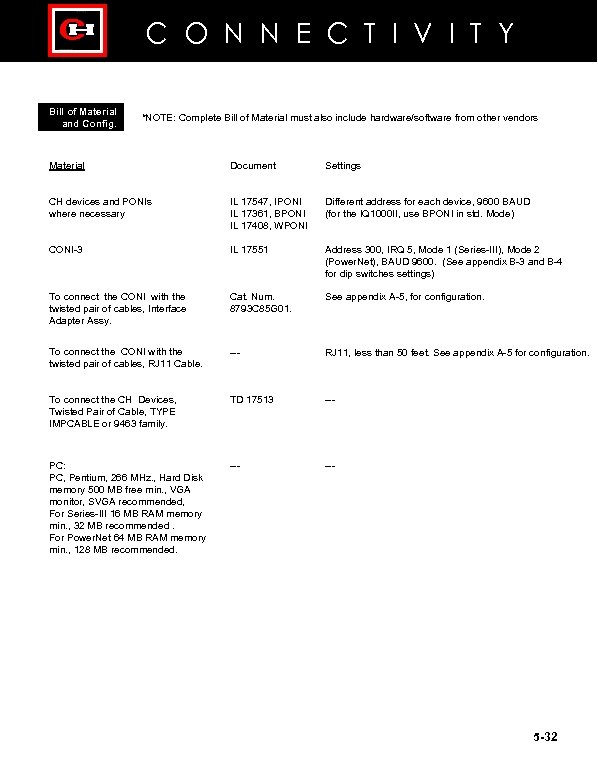

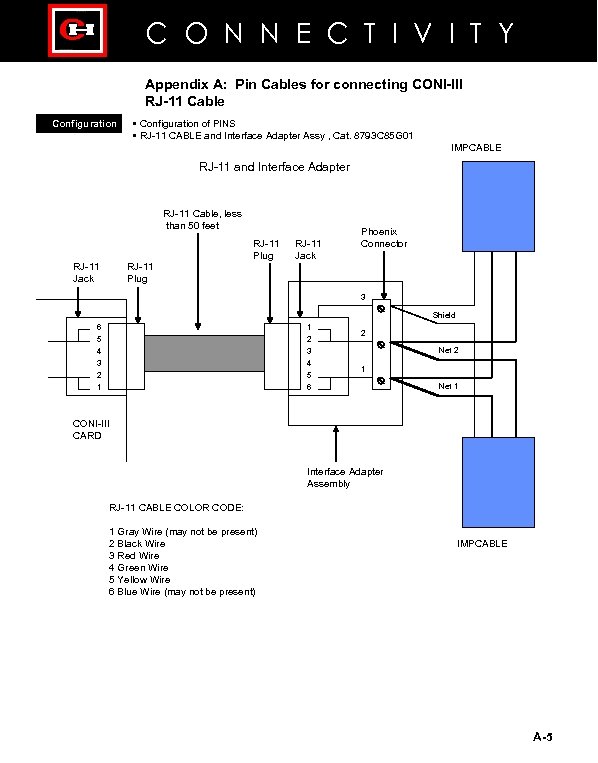

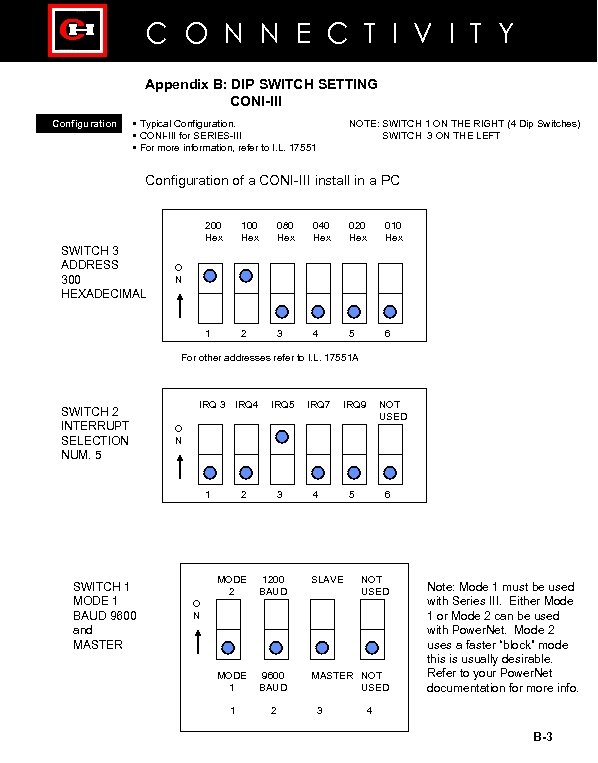

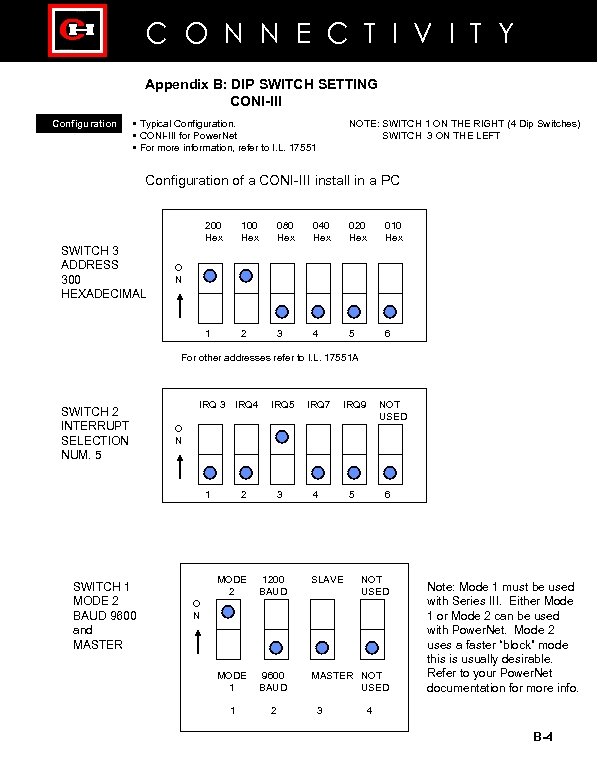

C O N N E C T I V I T Y Configuration Application Base System: CONI Card and Twisted Shielded Pair . Remote monitoring and control of Electrical Distribution Equipment from a single computer Bill of Material and Config. Material Document Settings CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600. (See appendix B-3 and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the CH Devices, Twisted Pair of Cable, TYPE IMPCABLE or 9463 family. TD 17513 --- To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II, use BPONI in std. Mode) PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- --2091 A 90 G 01 ------- --Cat. Num: PNEG or PNED (no graphics) ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net 1 -2

C O N N E C T I V I T Y Configuration Application Base System: CONI Card and Twisted Shielded Pair . Remote monitoring and control of Electrical Distribution Equipment from a single computer Bill of Material and Config. Material Document Settings CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600. (See appendix B-3 and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the CH Devices, Twisted Pair of Cable, TYPE IMPCABLE or 9463 family. TD 17513 --- To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II, use BPONI in std. Mode) PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- --2091 A 90 G 01 ------- --Cat. Num: PNEG or PNED (no graphics) ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net 1 -2

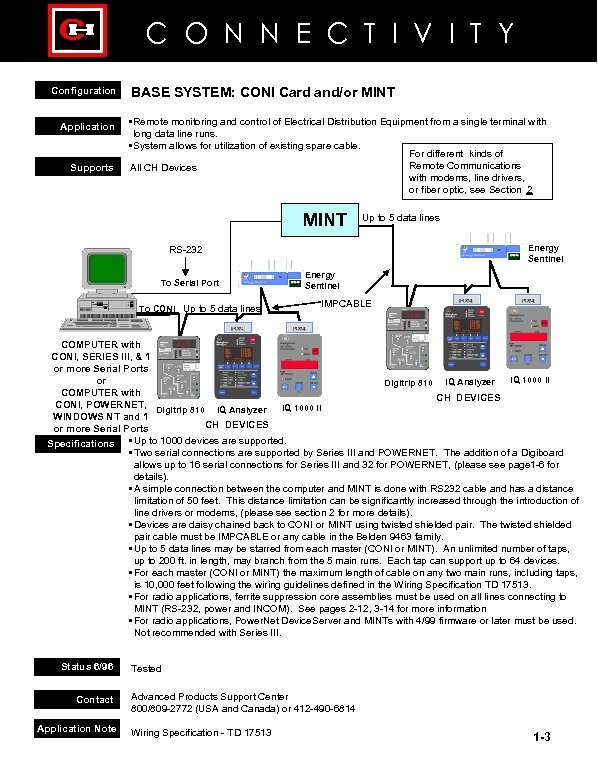

C O N N E C T I V I T Y Configuration Application Supports BASE SYSTEM: CONI Card and/or MINT • Remote monitoring and control of Electrical Distribution Equipment from a single terminal with long data line runs. • System allows for utilization of existing spare cable. For different kinds of Remote Communications All CH Devices with modems, line drivers, or fiber optic, see Section 2 MINT Up to 5 data lines Energy Sentinel RS-232 To Serial Port To CONI Up to 5 data lines Energy Sentinel IMPCABLE COMPUTER with CONI, SERIES III, & 1 or more Serial Ports IQ 1000 II or Digitrip 810 IQ Analyzer COMPUTER with CH DEVICES CONI, POWERNET, Digitrip 810 IQ Analyzer IQ 1000 II WINDOWS NT and 1 CH DEVICES or more Serial Ports Specifications • Up to 1000 devices are supported. • Two serial connections are supported by Series III and POWERNET. The addition of a Digiboard allows up to 16 serial connections for Series III and 32 for POWERNET, (please see page 1 -6 for details). • A simple connection between the computer and MINT is done with RS 232 cable and has a distance limitation of 50 feet. This distance limitation can be significantly increased through the introduction of line drivers or modems, (please section 2 for more details). • Devices are daisy chained back to CONI or MINT using twisted shielded pair. The twisted shielded pair cable must be IMPCABLE or any cable in the Belden 9463 family. • Up to 5 data lines may be starred from each master (CONI or MINT). An unlimited number of taps, up to 200 ft. in length, may branch from the 5 main runs. Each tap can support up to 64 devices. • For each master (CONI or MINT) the maximum length of cable on any two main runs, including taps, is 10, 000 feet following the wiring guidelines defined in the Wiring Specification TD 17513. • For radio applications, ferrite suppression core assemblies must be used on all lines connecting to MINT (RS-232, power and INCOM). See pages 2 -12, 3 -14 for more information • For radio applications, Power. Net Device. Server and MINTs with 4/99 firmware or later must be used. Not recommended with Series III. Status 6/96 Contact Application Note Tested Advanced Products Support Center 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 1 -3

C O N N E C T I V I T Y Configuration Application Supports BASE SYSTEM: CONI Card and/or MINT • Remote monitoring and control of Electrical Distribution Equipment from a single terminal with long data line runs. • System allows for utilization of existing spare cable. For different kinds of Remote Communications All CH Devices with modems, line drivers, or fiber optic, see Section 2 MINT Up to 5 data lines Energy Sentinel RS-232 To Serial Port To CONI Up to 5 data lines Energy Sentinel IMPCABLE COMPUTER with CONI, SERIES III, & 1 or more Serial Ports IQ 1000 II or Digitrip 810 IQ Analyzer COMPUTER with CH DEVICES CONI, POWERNET, Digitrip 810 IQ Analyzer IQ 1000 II WINDOWS NT and 1 CH DEVICES or more Serial Ports Specifications • Up to 1000 devices are supported. • Two serial connections are supported by Series III and POWERNET. The addition of a Digiboard allows up to 16 serial connections for Series III and 32 for POWERNET, (please see page 1 -6 for details). • A simple connection between the computer and MINT is done with RS 232 cable and has a distance limitation of 50 feet. This distance limitation can be significantly increased through the introduction of line drivers or modems, (please section 2 for more details). • Devices are daisy chained back to CONI or MINT using twisted shielded pair. The twisted shielded pair cable must be IMPCABLE or any cable in the Belden 9463 family. • Up to 5 data lines may be starred from each master (CONI or MINT). An unlimited number of taps, up to 200 ft. in length, may branch from the 5 main runs. Each tap can support up to 64 devices. • For each master (CONI or MINT) the maximum length of cable on any two main runs, including taps, is 10, 000 feet following the wiring guidelines defined in the Wiring Specification TD 17513. • For radio applications, ferrite suppression core assemblies must be used on all lines connecting to MINT (RS-232, power and INCOM). See pages 2 -12, 3 -14 for more information • For radio applications, Power. Net Device. Server and MINTs with 4/99 firmware or later must be used. Not recommended with Series III. Status 6/96 Contact Application Note Tested Advanced Products Support Center 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 1 -3

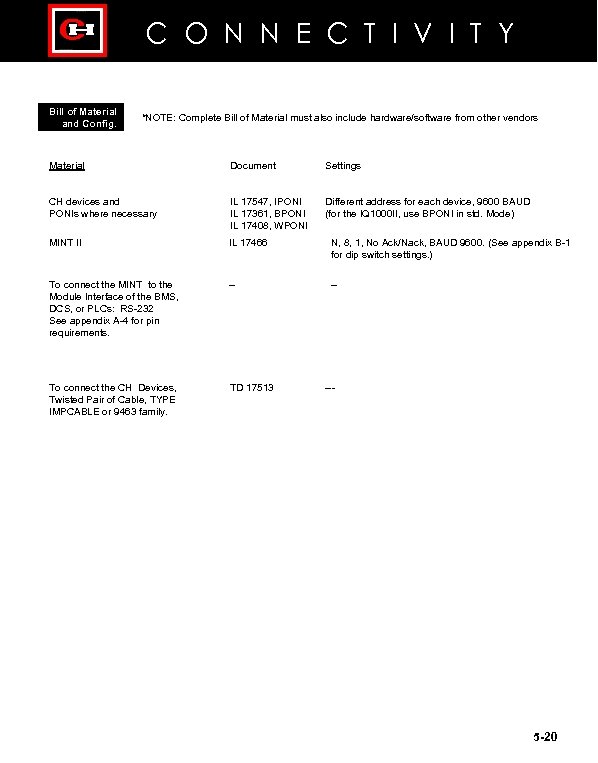

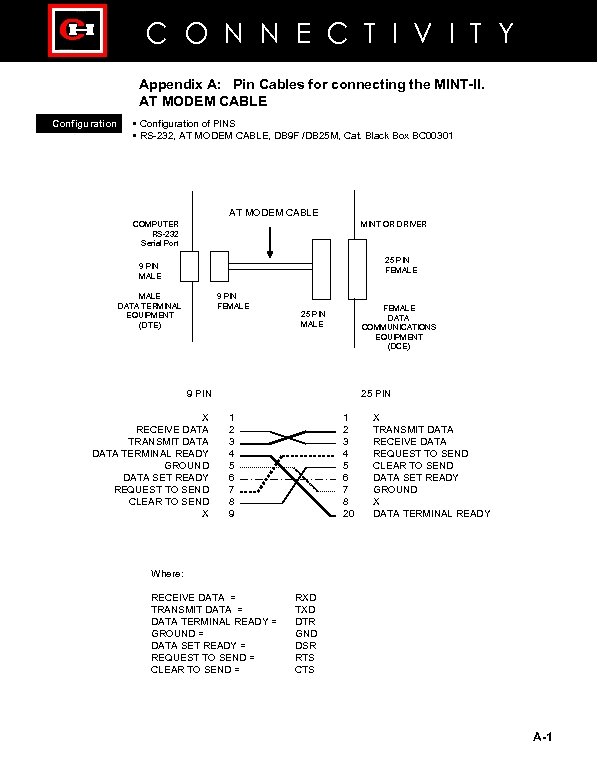

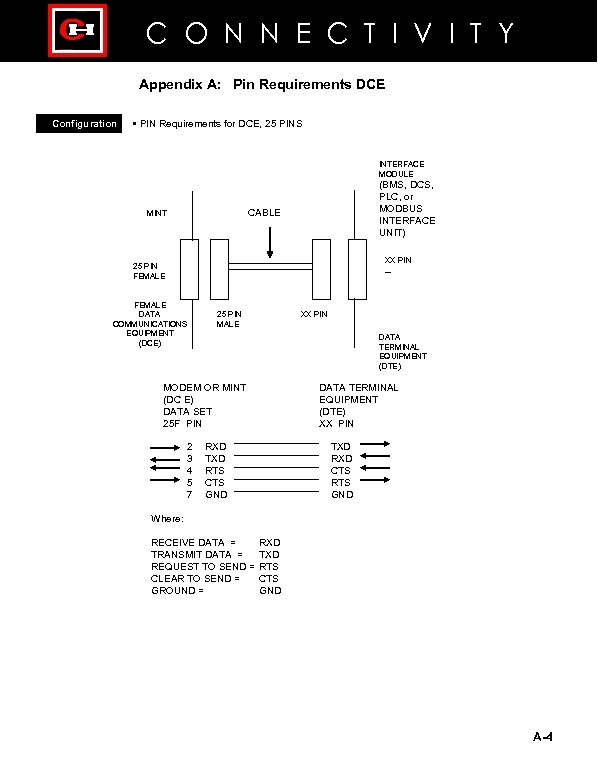

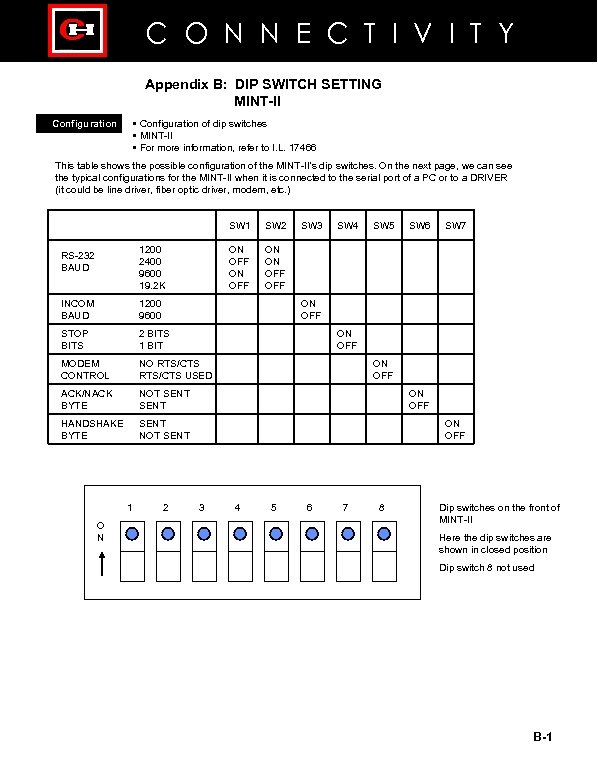

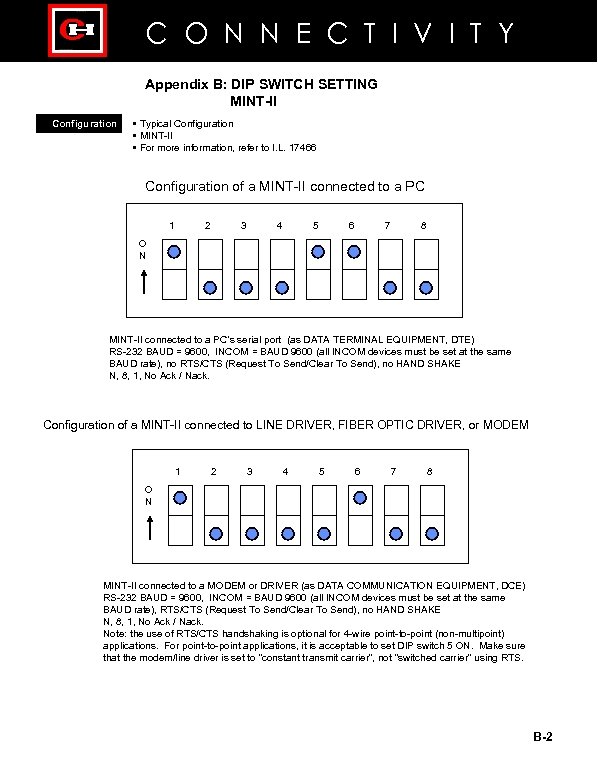

C O N N E C T I V I T Y Configuration Application Base System: CONI Card and/or MINT . Remote monitoring and control of Electrical Distribution Equipment from a single computer Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B-1 for dip switch settings) To connect the MINT to the serial port of a PC, RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 The MINT can be connected to a Line Driver, Fiber Optic Fiber or Modem (less than 50 feet). For remote communication, see section 2. For pin configuration, see appendix A-1 CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600 (See appendix B-3, and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. , Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II, use BPONI in std. Mode) 1 -4

C O N N E C T I V I T Y Configuration Application Base System: CONI Card and/or MINT . Remote monitoring and control of Electrical Distribution Equipment from a single computer Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B-1 for dip switch settings) To connect the MINT to the serial port of a PC, RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 The MINT can be connected to a Line Driver, Fiber Optic Fiber or Modem (less than 50 feet). For remote communication, see section 2. For pin configuration, see appendix A-1 CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600 (See appendix B-3, and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. , Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II, use BPONI in std. Mode) 1 -4

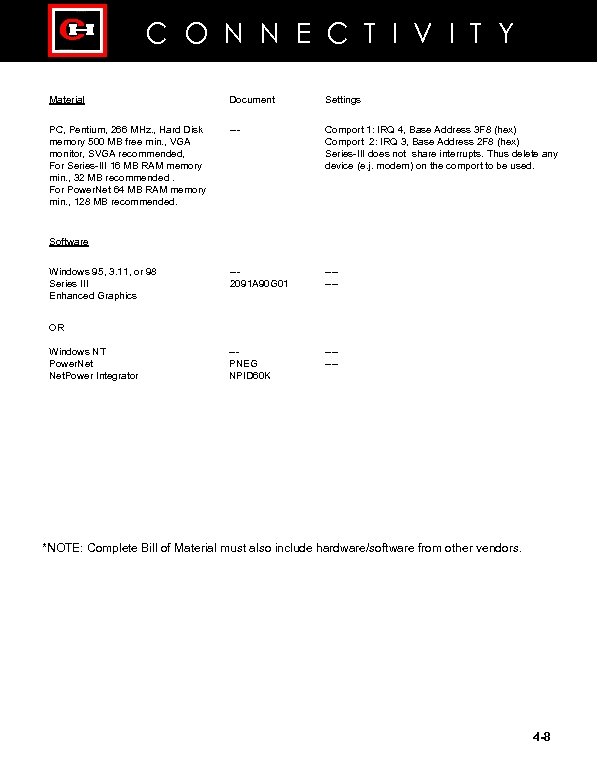

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 1 -5

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 1 -5

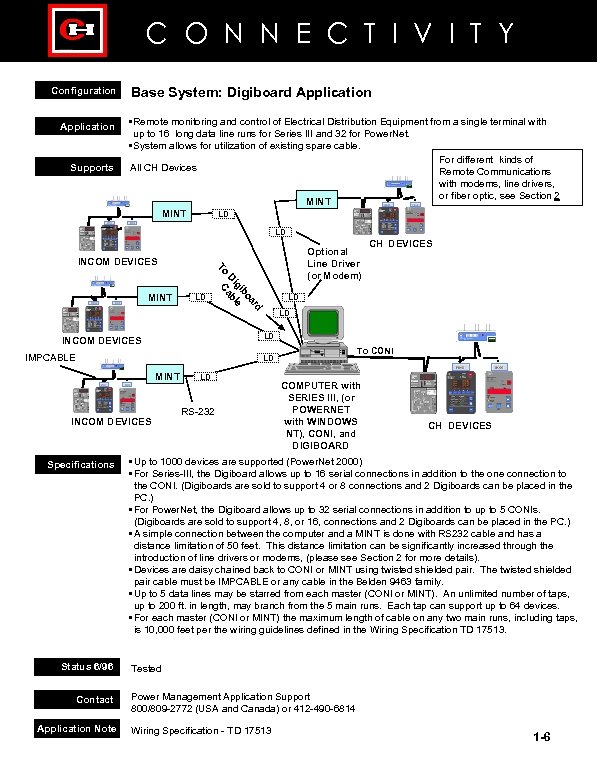

C O N N E C T I V I T Y Configuration Application Supports Base System: Digiboard Application • Remote monitoring and control of Electrical Distribution Equipment from a single terminal with up to 16 long data line runs for Series III and 32 for Power. Net. • System allows for utilization of existing spare cable. For different kinds of All CH Devices Remote Communications with modems, line drivers, or fiber optic, see Section 2 MINT LD LD d ar bo gi le Di ab C MINT To INCOM DEVICES Optional Line Driver (or Modem) LD LD LD INCOM DEVICES IMPCABLE To CONI LD MINT INCOM DEVICES Specifications Status 6/96 Contact Application Note CH DEVICES LD RS-232 COMPUTER with SERIES III, (or POWERNET with WINDOWS NT), CONI, and DIGIBOARD CH DEVICES • Up to 1000 devices are supported (Power. Net 2000) • For Series-III, the Digiboard allows up to 16 serial connections in addition to the one connection to the CONI. (Digiboards are sold to support 4 or 8 connections and 2 Digiboards can be placed in the PC. ) • For Power. Net, the Digiboard allows up to 32 serial connections in addition to up to 5 CONIs. (Digiboards are sold to support 4, 8, or 16, connections and 2 Digiboards can be placed in the PC. ) • A simple connection between the computer and a MINT is done with RS 232 cable and has a distance limitation of 50 feet. This distance limitation can be significantly increased through the introduction of line drivers or modems, (please see Section 2 for more details). • Devices are daisy chained back to CONI or MINT using twisted shielded pair. The twisted shielded pair cable must be IMPCABLE or any cable in the Belden 9463 family. • Up to 5 data lines may be starred from each master (CONI or MINT). An unlimited number of taps, up to 200 ft. in length, may branch from the 5 main runs. Each tap can support up to 64 devices. • For each master (CONI or MINT) the maximum length of cable on any two main runs, including taps, is 10, 000 feet per the wiring guidelines defined in the Wiring Specification TD 17513. Tested Power Management Application Support 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 1 -6

C O N N E C T I V I T Y Configuration Application Supports Base System: Digiboard Application • Remote monitoring and control of Electrical Distribution Equipment from a single terminal with up to 16 long data line runs for Series III and 32 for Power. Net. • System allows for utilization of existing spare cable. For different kinds of All CH Devices Remote Communications with modems, line drivers, or fiber optic, see Section 2 MINT LD LD d ar bo gi le Di ab C MINT To INCOM DEVICES Optional Line Driver (or Modem) LD LD LD INCOM DEVICES IMPCABLE To CONI LD MINT INCOM DEVICES Specifications Status 6/96 Contact Application Note CH DEVICES LD RS-232 COMPUTER with SERIES III, (or POWERNET with WINDOWS NT), CONI, and DIGIBOARD CH DEVICES • Up to 1000 devices are supported (Power. Net 2000) • For Series-III, the Digiboard allows up to 16 serial connections in addition to the one connection to the CONI. (Digiboards are sold to support 4 or 8 connections and 2 Digiboards can be placed in the PC. ) • For Power. Net, the Digiboard allows up to 32 serial connections in addition to up to 5 CONIs. (Digiboards are sold to support 4, 8, or 16, connections and 2 Digiboards can be placed in the PC. ) • A simple connection between the computer and a MINT is done with RS 232 cable and has a distance limitation of 50 feet. This distance limitation can be significantly increased through the introduction of line drivers or modems, (please see Section 2 for more details). • Devices are daisy chained back to CONI or MINT using twisted shielded pair. The twisted shielded pair cable must be IMPCABLE or any cable in the Belden 9463 family. • Up to 5 data lines may be starred from each master (CONI or MINT). An unlimited number of taps, up to 200 ft. in length, may branch from the 5 main runs. Each tap can support up to 64 devices. • For each master (CONI or MINT) the maximum length of cable on any two main runs, including taps, is 10, 000 feet per the wiring guidelines defined in the Wiring Specification TD 17513. Tested Power Management Application Support 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 1 -6

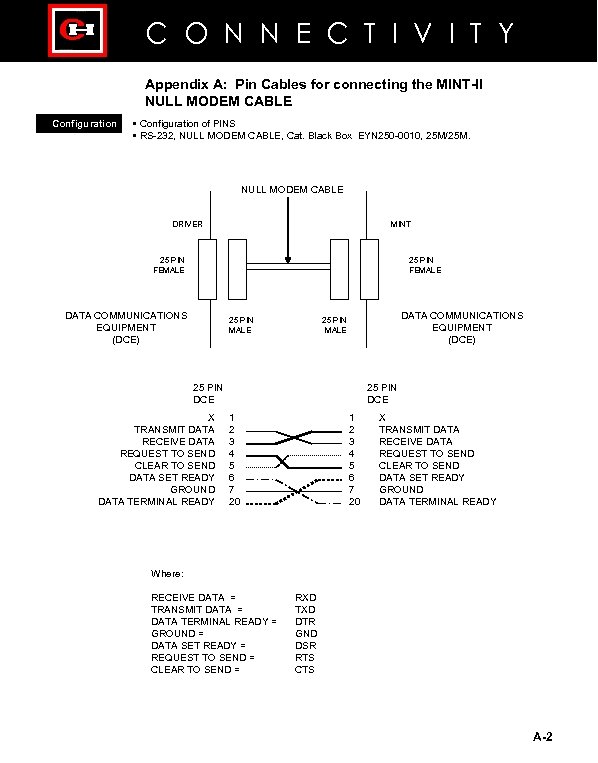

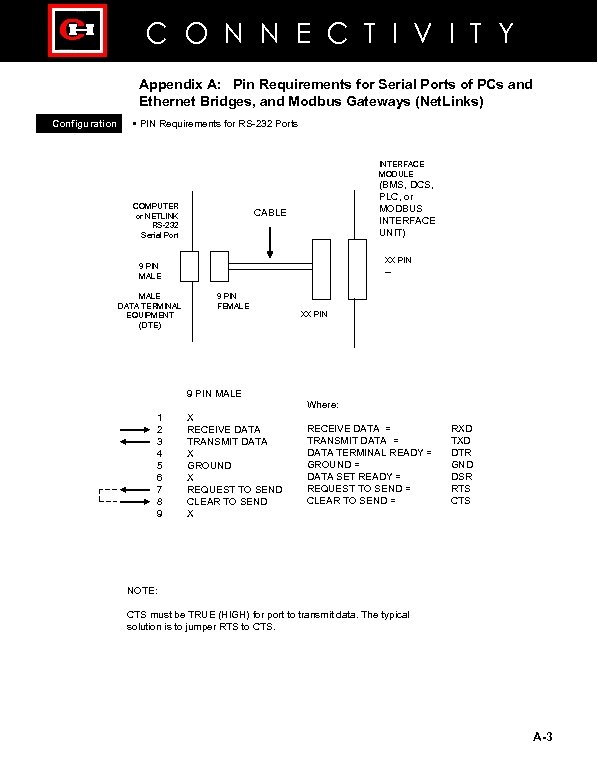

C O N N E C T I V I T Y Configuration Application Base System: Digiboard Application . Remote monitoring and control of Electrical Distribution Equipment from a single computer Bill of Material and Config. Material Document Settings Digiboard: Classic. Board 4 16654 Classic. Board 8 16654 Classic. Board 16 16654 RJ 45 Box (only Power. Net Software) Part Number: 77000435 77000434 70001146 --- Digiboard cable (included with the Digiboard) ----- MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B -1 for dip switch settings) To connect the MINT to Digiboard, RS-232 Null-Modem Cable, 25 M/25 M Black Box Cat. EYN 250 -0010 The MINT can be connected to a Line Driver, Fiber Optic Fiber or Modem (less than 50 feet). For remote communication, see section 2. For pin configuration, see appendix A-2. CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600. (See appendix B-3 and B-4, for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. Cat. Num. 8793 C 85 G 01 See appendix A-5, for configuration. To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 --- To connect the CONI with the twisted pair of cables RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 1 -7

C O N N E C T I V I T Y Configuration Application Base System: Digiboard Application . Remote monitoring and control of Electrical Distribution Equipment from a single computer Bill of Material and Config. Material Document Settings Digiboard: Classic. Board 4 16654 Classic. Board 8 16654 Classic. Board 16 16654 RJ 45 Box (only Power. Net Software) Part Number: 77000435 77000434 70001146 --- Digiboard cable (included with the Digiboard) ----- MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B -1 for dip switch settings) To connect the MINT to Digiboard, RS-232 Null-Modem Cable, 25 M/25 M Black Box Cat. EYN 250 -0010 The MINT can be connected to a Line Driver, Fiber Optic Fiber or Modem (less than 50 feet). For remote communication, see section 2. For pin configuration, see appendix A-2. CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600. (See appendix B-3 and B-4, for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. Cat. Num. 8793 C 85 G 01 See appendix A-5, for configuration. To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 --- To connect the CONI with the twisted pair of cables RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 1 -7

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 1 -8

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 1 -8

C O N N E C T I V I T Y SECTION 2 REMOTE COMMUNICATION TO INCOM DEVICES Application: Basics Remote communication of CH devices to a PC for Monitoring and Controlling. For communicating with our devices from a distance we usually use : • Line Driver Dedicated (non-dial tone) Phone Line connection • Fiber Optic Drivers • Lease Line Modem • Modem (Dial Type Telephone Line) • Radio modems Architecture The Basic Architecture can be: COMPUTER - DRIVER - MEDIA -DRIVER - MINT - CH DEVICES Or COMPUTER - DRIVER - MEDIA DRIVER - CH DEVICES On the next pages, we can see some diagrams that shows these. 2 -1

C O N N E C T I V I T Y SECTION 2 REMOTE COMMUNICATION TO INCOM DEVICES Application: Basics Remote communication of CH devices to a PC for Monitoring and Controlling. For communicating with our devices from a distance we usually use : • Line Driver Dedicated (non-dial tone) Phone Line connection • Fiber Optic Drivers • Lease Line Modem • Modem (Dial Type Telephone Line) • Radio modems Architecture The Basic Architecture can be: COMPUTER - DRIVER - MEDIA -DRIVER - MINT - CH DEVICES Or COMPUTER - DRIVER - MEDIA DRIVER - CH DEVICES On the next pages, we can see some diagrams that shows these. 2 -1

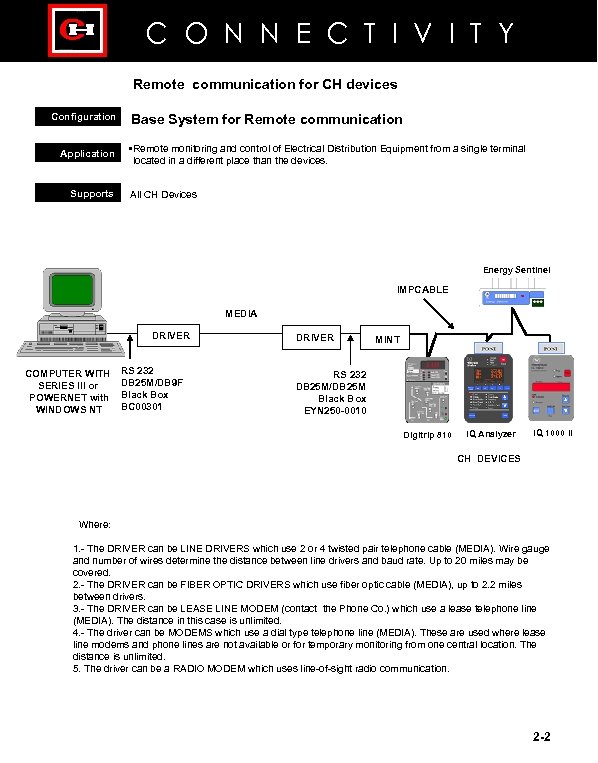

C O N N E C T I V I T Y Remote communication for CH devices Configuration Application Supports Base System for Remote communication • Remote monitoring and control of Electrical Distribution Equipment from a single terminal located in a different place than the devices. All CH Devices Energy Sentinel IMPCABLE MEDIA DRIVER COMPUTER WITH SERIES III or POWERNET with WINDOWS NT RS 232 DB 25 M/DB 9 F Black Box BC 00301 DRIVER MINT RS 232 DB 25 M/DB 25 M Black Box EYN 250 -0010 Digitrip 810 IQ Analyzer IQ 1000 II CH DEVICES Where: 1. - The DRIVER can be LINE DRIVERS which use 2 or 4 twisted pair telephone cable (MEDIA). Wire gauge and number of wires determine the distance between line drivers and baud rate. Up to 20 miles may be covered. 2. - The DRIVER can be FIBER OPTIC DRIVERS which use fiber optic cable (MEDIA), up to 2. 2 miles between drivers. 3. - The DRIVER can be LEASE LINE MODEM (contact the Phone Co. ) which use a lease telephone line (MEDIA). The distance in this case is unlimited. 4. - The driver can be MODEMS which use a dial type telephone line (MEDIA). These are used where lease line modems and phone lines are not available or for temporary monitoring from one central location. The distance is unlimited. 5. The driver can be a RADIO MODEM which uses line-of-sight radio communication. 2 -2

C O N N E C T I V I T Y Remote communication for CH devices Configuration Application Supports Base System for Remote communication • Remote monitoring and control of Electrical Distribution Equipment from a single terminal located in a different place than the devices. All CH Devices Energy Sentinel IMPCABLE MEDIA DRIVER COMPUTER WITH SERIES III or POWERNET with WINDOWS NT RS 232 DB 25 M/DB 9 F Black Box BC 00301 DRIVER MINT RS 232 DB 25 M/DB 25 M Black Box EYN 250 -0010 Digitrip 810 IQ Analyzer IQ 1000 II CH DEVICES Where: 1. - The DRIVER can be LINE DRIVERS which use 2 or 4 twisted pair telephone cable (MEDIA). Wire gauge and number of wires determine the distance between line drivers and baud rate. Up to 20 miles may be covered. 2. - The DRIVER can be FIBER OPTIC DRIVERS which use fiber optic cable (MEDIA), up to 2. 2 miles between drivers. 3. - The DRIVER can be LEASE LINE MODEM (contact the Phone Co. ) which use a lease telephone line (MEDIA). The distance in this case is unlimited. 4. - The driver can be MODEMS which use a dial type telephone line (MEDIA). These are used where lease line modems and phone lines are not available or for temporary monitoring from one central location. The distance is unlimited. 5. The driver can be a RADIO MODEM which uses line-of-sight radio communication. 2 -2

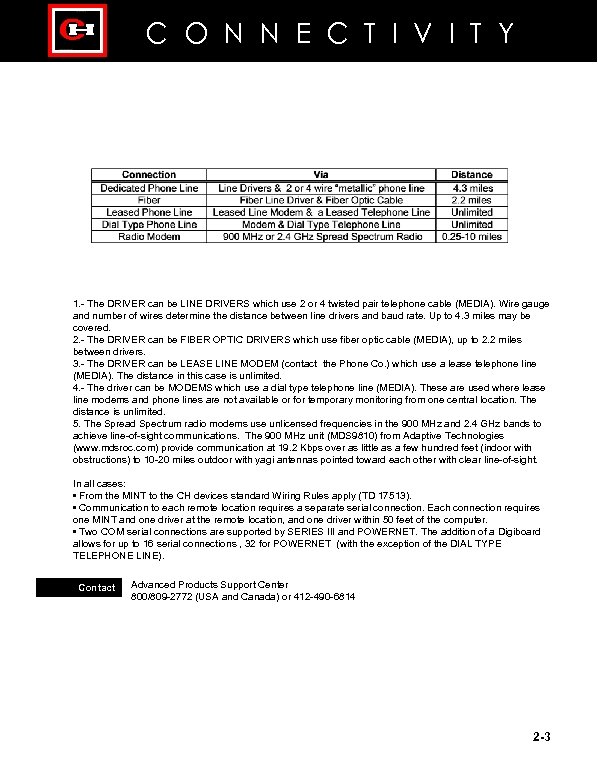

C O N N E C T I V I T Y 1. - The DRIVER can be LINE DRIVERS which use 2 or 4 twisted pair telephone cable (MEDIA). Wire gauge and number of wires determine the distance between line drivers and baud rate. Up to 4. 3 miles may be covered. 2. - The DRIVER can be FIBER OPTIC DRIVERS which use fiber optic cable (MEDIA), up to 2. 2 miles between drivers. 3. - The DRIVER can be LEASE LINE MODEM (contact the Phone Co. ) which use a lease telephone line (MEDIA). The distance in this case is unlimited. 4. - The driver can be MODEMS which use a dial type telephone line (MEDIA). These are used where lease line modems and phone lines are not available or for temporary monitoring from one central location. The distance is unlimited. 5. The Spread Spectrum radio modems use unlicensed frequencies in the 900 MHz and 2. 4 GHz bands to achieve line-of-sight communications. The 900 MHz unit (MDS 9810) from Adaptive Technologies (www. mdsroc. com) provide communication at 19. 2 Kbps over as little as a few hundred feet (indoor with obstructions) to 10 -20 miles outdoor with yagi antennas pointed toward each other with clear line-of-sight. In all cases: • From the MINT to the CH devices standard Wiring Rules apply (TD 17513). • Communication to each remote location requires a separate serial connection. Each connection requires one MINT and one driver at the remote location, and one driver within 50 feet of the computer. • Two COM serial connections are supported by SERIES III and POWERNET. The addition of a Digiboard allows for up to 16 serial connections , 32 for POWERNET (with the exception of the DIAL TYPE TELEPHONE LINE). Contact Advanced Products Support Center 800/809 -2772 (USA and Canada) or 412 -490 -6814 2 -3

C O N N E C T I V I T Y 1. - The DRIVER can be LINE DRIVERS which use 2 or 4 twisted pair telephone cable (MEDIA). Wire gauge and number of wires determine the distance between line drivers and baud rate. Up to 4. 3 miles may be covered. 2. - The DRIVER can be FIBER OPTIC DRIVERS which use fiber optic cable (MEDIA), up to 2. 2 miles between drivers. 3. - The DRIVER can be LEASE LINE MODEM (contact the Phone Co. ) which use a lease telephone line (MEDIA). The distance in this case is unlimited. 4. - The driver can be MODEMS which use a dial type telephone line (MEDIA). These are used where lease line modems and phone lines are not available or for temporary monitoring from one central location. The distance is unlimited. 5. The Spread Spectrum radio modems use unlicensed frequencies in the 900 MHz and 2. 4 GHz bands to achieve line-of-sight communications. The 900 MHz unit (MDS 9810) from Adaptive Technologies (www. mdsroc. com) provide communication at 19. 2 Kbps over as little as a few hundred feet (indoor with obstructions) to 10 -20 miles outdoor with yagi antennas pointed toward each other with clear line-of-sight. In all cases: • From the MINT to the CH devices standard Wiring Rules apply (TD 17513). • Communication to each remote location requires a separate serial connection. Each connection requires one MINT and one driver at the remote location, and one driver within 50 feet of the computer. • Two COM serial connections are supported by SERIES III and POWERNET. The addition of a Digiboard allows for up to 16 serial connections , 32 for POWERNET (with the exception of the DIAL TYPE TELEPHONE LINE). Contact Advanced Products Support Center 800/809 -2772 (USA and Canada) or 412 -490 -6814 2 -3

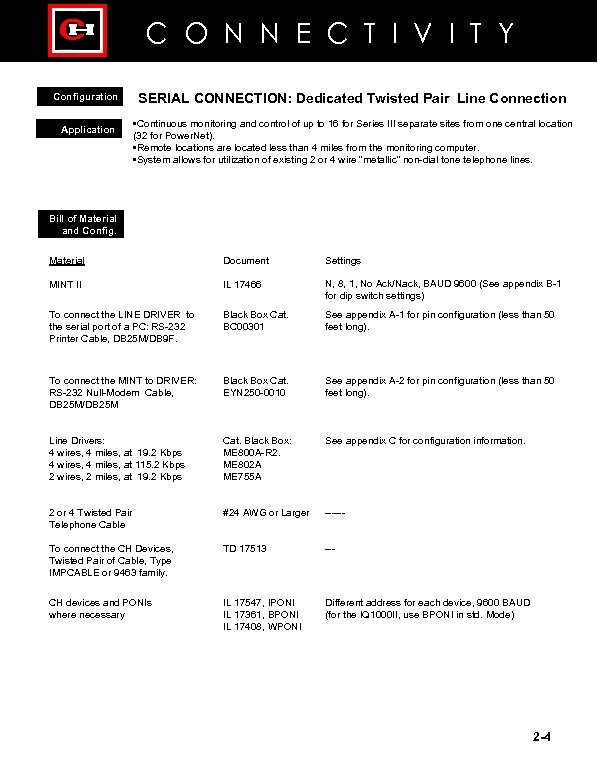

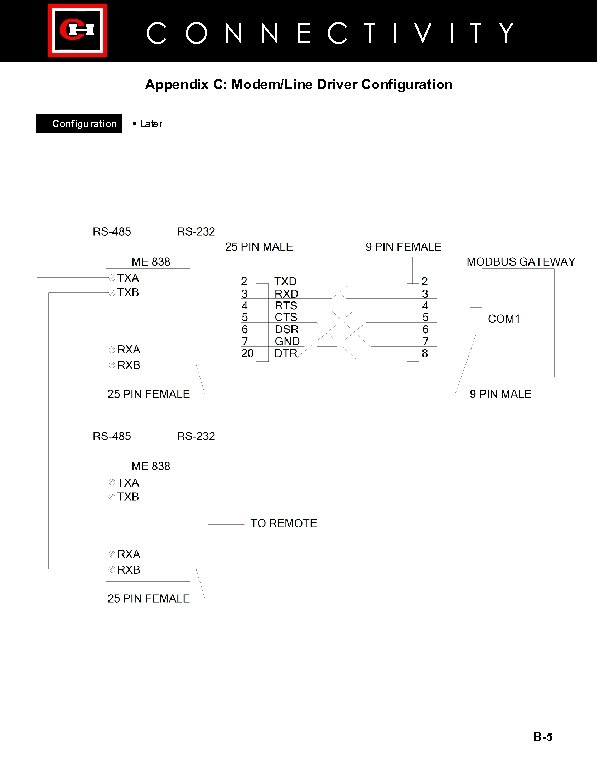

C O N N E C T I V I T Y Configuration Application SERIAL CONNECTION: Dedicated Twisted Pair Line Connection • Continuous monitoring and control of up to 16 for Series III separate sites from one central location (32 for Power. Net). • Remote locations are located less than 4 miles from the monitoring computer. • System allows for utilization of existing 2 or 4 wire “metallic” non-dial tone telephone lines. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600 (See appendix B-1 for dip switch settings) To connect the LINE DRIVER to the serial port of a PC: RS-232 Printer Cable, DB 25 M/DB 9 F. Black Box Cat. BC 00301 See appendix A-1 for pin configuration (less than 50 feet long). To connect the MINT to DRIVER: RS-232 Null-Modem Cable, DB 25 M/DB 25 M Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration (less than 50 feet long). Line Drivers: 4 wires, 4 miles, at 19. 2 Kbps 4 wires, 4 miles, at 115. 2 Kbps 2 wires, 2 miles, at 19. 2 Kbps Cat. Black Box: ME 800 A-R 2. ME 802 A ME 755 A See appendix C for configuration information. 2 or 4 Twisted Pair Telephone Cable #24 AWG or Larger ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II, use BPONI in std. Mode) 2 -4

C O N N E C T I V I T Y Configuration Application SERIAL CONNECTION: Dedicated Twisted Pair Line Connection • Continuous monitoring and control of up to 16 for Series III separate sites from one central location (32 for Power. Net). • Remote locations are located less than 4 miles from the monitoring computer. • System allows for utilization of existing 2 or 4 wire “metallic” non-dial tone telephone lines. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600 (See appendix B-1 for dip switch settings) To connect the LINE DRIVER to the serial port of a PC: RS-232 Printer Cable, DB 25 M/DB 9 F. Black Box Cat. BC 00301 See appendix A-1 for pin configuration (less than 50 feet long). To connect the MINT to DRIVER: RS-232 Null-Modem Cable, DB 25 M/DB 25 M Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration (less than 50 feet long). Line Drivers: 4 wires, 4 miles, at 19. 2 Kbps 4 wires, 4 miles, at 115. 2 Kbps 2 wires, 2 miles, at 19. 2 Kbps Cat. Black Box: ME 800 A-R 2. ME 802 A ME 755 A See appendix C for configuration information. 2 or 4 Twisted Pair Telephone Cable #24 AWG or Larger ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II, use BPONI in std. Mode) 2 -4

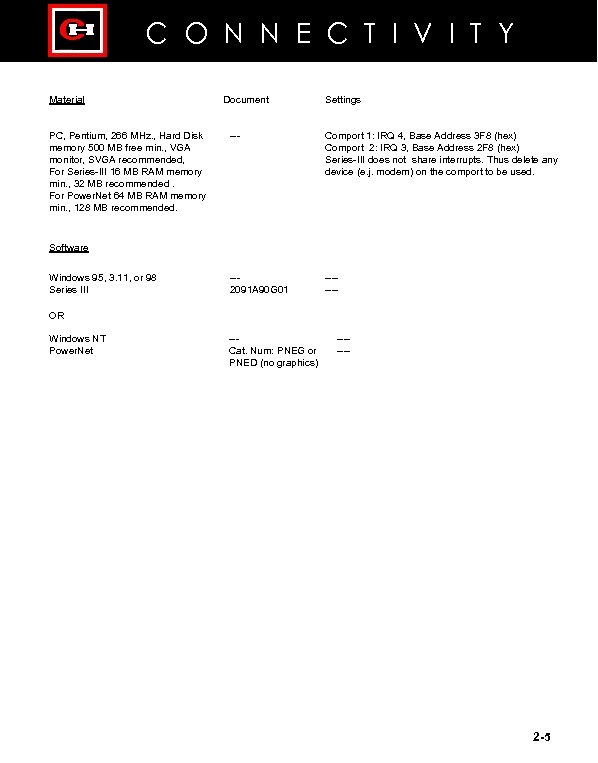

C O N N E C T I V I T Y Material PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. Document Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 2 -5

C O N N E C T I V I T Y Material PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. Document Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 2 -5

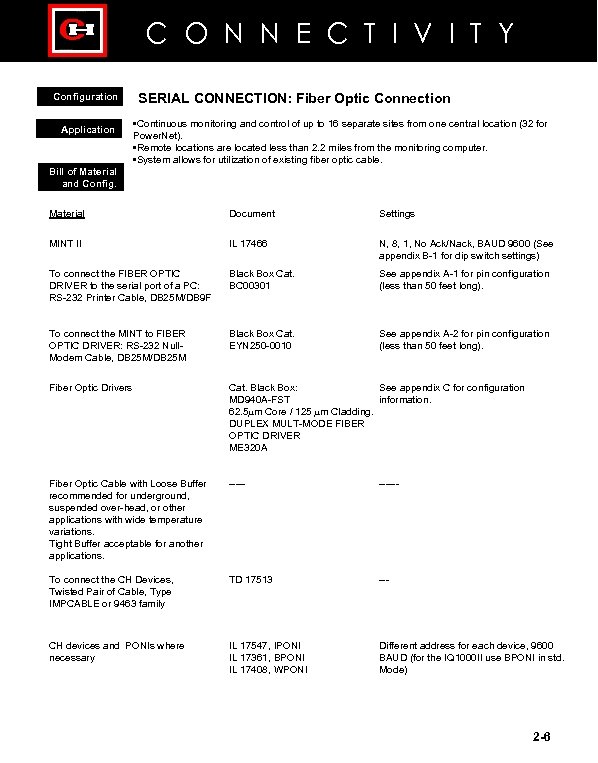

C O N N E C T I V I T Y Configuration Application SERIAL CONNECTION: Fiber Optic Connection • Continuous monitoring and control of up to 16 separate sites from one central location (32 for Power. Net). • Remote locations are located less than 2. 2 miles from the monitoring computer. • System allows for utilization of existing fiber optic cable. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600 (See appendix B-1 for dip switch settings) To connect the FIBER OPTIC DRIVER to the serial port of a PC: RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration (less than 50 feet long). To connect the MINT to FIBER OPTIC DRIVER: RS-232 Null. Modem Cable, DB 25 M/DB 25 M Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration (less than 50 feet long). Fiber Optic Drivers Cat. Black Box: See appendix C for configuration MD 940 A-FST information. 62. 5 m Core / 125 m Cladding. DUPLEX MULT-MODE FIBER OPTIC DRIVER ME 320 A Fiber Optic Cable with Loose Buffer recommended for underground, suspended over-head, or other applications with wide temperature variations. Tight Buffer acceptable for another applications. ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 --- CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 2 -6

C O N N E C T I V I T Y Configuration Application SERIAL CONNECTION: Fiber Optic Connection • Continuous monitoring and control of up to 16 separate sites from one central location (32 for Power. Net). • Remote locations are located less than 2. 2 miles from the monitoring computer. • System allows for utilization of existing fiber optic cable. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600 (See appendix B-1 for dip switch settings) To connect the FIBER OPTIC DRIVER to the serial port of a PC: RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration (less than 50 feet long). To connect the MINT to FIBER OPTIC DRIVER: RS-232 Null. Modem Cable, DB 25 M/DB 25 M Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration (less than 50 feet long). Fiber Optic Drivers Cat. Black Box: See appendix C for configuration MD 940 A-FST information. 62. 5 m Core / 125 m Cladding. DUPLEX MULT-MODE FIBER OPTIC DRIVER ME 320 A Fiber Optic Cable with Loose Buffer recommended for underground, suspended over-head, or other applications with wide temperature variations. Tight Buffer acceptable for another applications. ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 --- CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 2 -6

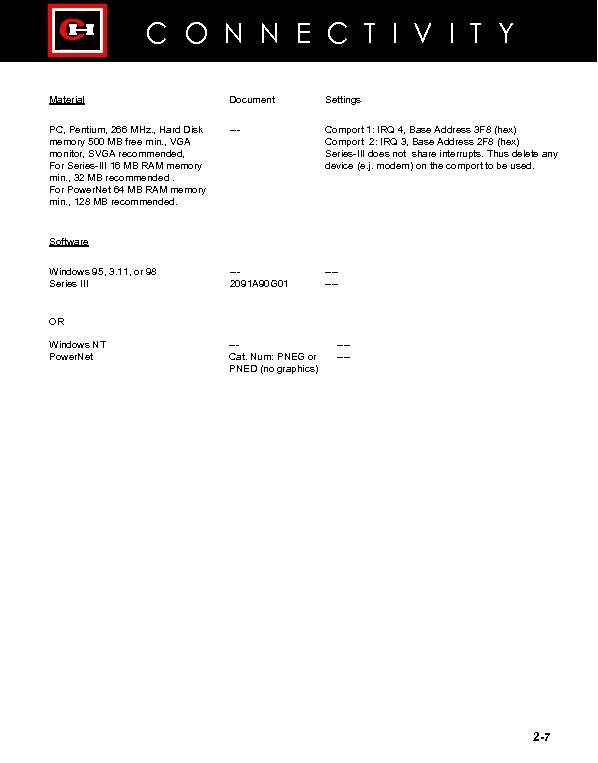

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 2 -7

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 2 -7

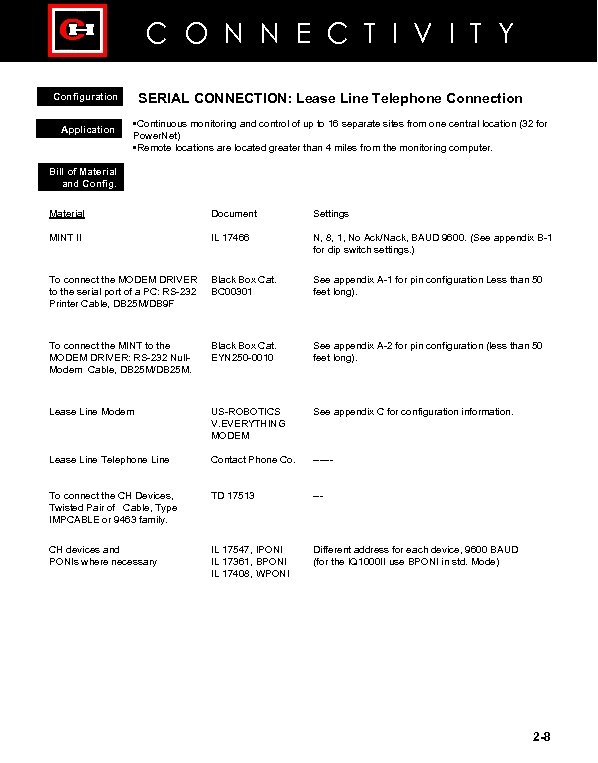

C O N N E C T I V I T Y SERIAL CONNECTION: Lease Line Telephone Connection Configuration Application • Continuous monitoring and control of up to 16 separate sites from one central location (32 for Power. Net) • Remote locations are located greater than 4 miles from the monitoring computer. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B-1 for dip switch settings. ) To connect the MODEM DRIVER to the serial port of a PC: RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration Less than 50 feet long). To connect the MINT to the MODEM DRIVER: RS-232 Null. Modem Cable, DB 25 M/DB 25 M. Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration (less than 50 feet long). Lease Line Modem US-ROBOTICS V. EVERYTHING MODEM See appendix C for configuration information. Lease Line Telephone Line Contact Phone Co. ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 2 -8

C O N N E C T I V I T Y SERIAL CONNECTION: Lease Line Telephone Connection Configuration Application • Continuous monitoring and control of up to 16 separate sites from one central location (32 for Power. Net) • Remote locations are located greater than 4 miles from the monitoring computer. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B-1 for dip switch settings. ) To connect the MODEM DRIVER to the serial port of a PC: RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration Less than 50 feet long). To connect the MINT to the MODEM DRIVER: RS-232 Null. Modem Cable, DB 25 M/DB 25 M. Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration (less than 50 feet long). Lease Line Modem US-ROBOTICS V. EVERYTHING MODEM See appendix C for configuration information. Lease Line Telephone Line Contact Phone Co. ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 2 -8

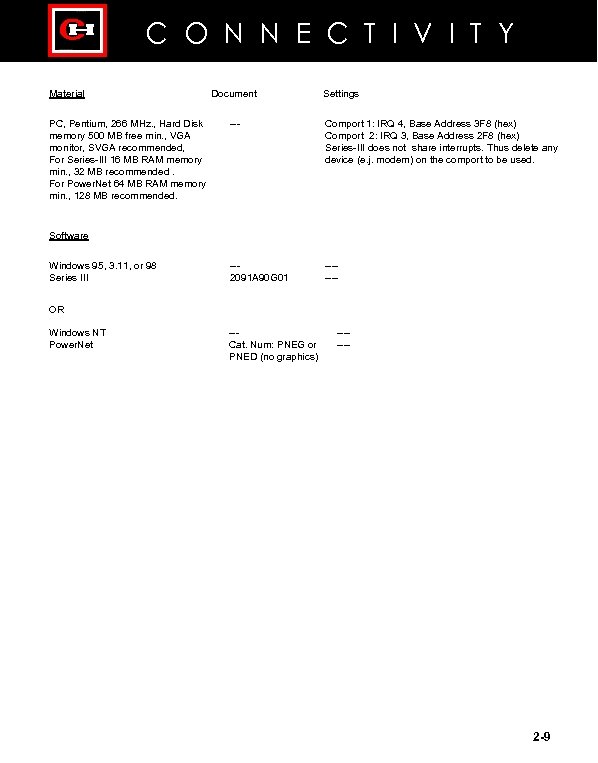

C O N N E C T I V I T Y Material PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. Document Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 2 -9

C O N N E C T I V I T Y Material PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. Document Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 2 -9

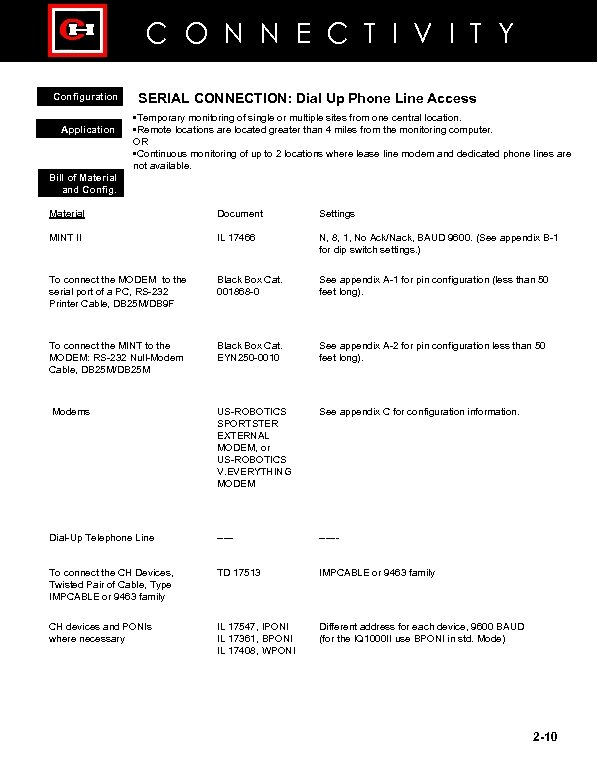

C O N N E C T I V I T Y Configuration Application SERIAL CONNECTION: Dial Up Phone Line Access • Temporary monitoring of single or multiple sites from one central location. • Remote locations are located greater than 4 miles from the monitoring computer. OR • Continuous monitoring of up to 2 locations where lease line modem and dedicated phone lines are not available. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B-1 for dip switch settings. ) To connect the MODEM to the serial port of a PC, RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. 001868 -0 See appendix A-1 for pin configuration (less than 50 feet long). To connect the MINT to the MODEM: RS-232 Null-Modem Cable, DB 25 M/DB 25 M Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration less than 50 feet long). Modems US-ROBOTICS SPORTSTER EXTERNAL MODEM, or US-ROBOTICS V. EVERYTHING MODEM See appendix C for configuration information. Dial-Up Telephone Line ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 IMPCABLE or 9463 family CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 2 -10

C O N N E C T I V I T Y Configuration Application SERIAL CONNECTION: Dial Up Phone Line Access • Temporary monitoring of single or multiple sites from one central location. • Remote locations are located greater than 4 miles from the monitoring computer. OR • Continuous monitoring of up to 2 locations where lease line modem and dedicated phone lines are not available. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B-1 for dip switch settings. ) To connect the MODEM to the serial port of a PC, RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. 001868 -0 See appendix A-1 for pin configuration (less than 50 feet long). To connect the MINT to the MODEM: RS-232 Null-Modem Cable, DB 25 M/DB 25 M Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration less than 50 feet long). Modems US-ROBOTICS SPORTSTER EXTERNAL MODEM, or US-ROBOTICS V. EVERYTHING MODEM See appendix C for configuration information. Dial-Up Telephone Line ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 IMPCABLE or 9463 family CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 2 -10

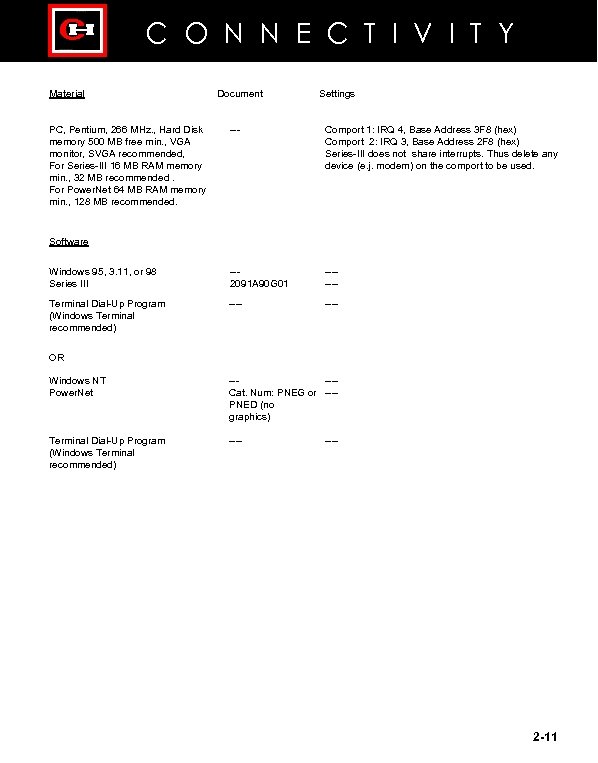

C O N N E C T I V I T Y Material PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. Document Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. Windows 95, 3. 11, or 98 Series III --2091 A 90 G 01 ------- Terminal Dial-Up Program (Windows Terminal recommended) ---- Software OR Windows NT Power. Net -----Cat. Num: PNEG or ---PNED (no graphics) Terminal Dial-Up Program (Windows Terminal recommended) ---- 2 -11

C O N N E C T I V I T Y Material PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. Document Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. Windows 95, 3. 11, or 98 Series III --2091 A 90 G 01 ------- Terminal Dial-Up Program (Windows Terminal recommended) ---- Software OR Windows NT Power. Net -----Cat. Num: PNEG or ---PNED (no graphics) Terminal Dial-Up Program (Windows Terminal recommended) ---- 2 -11

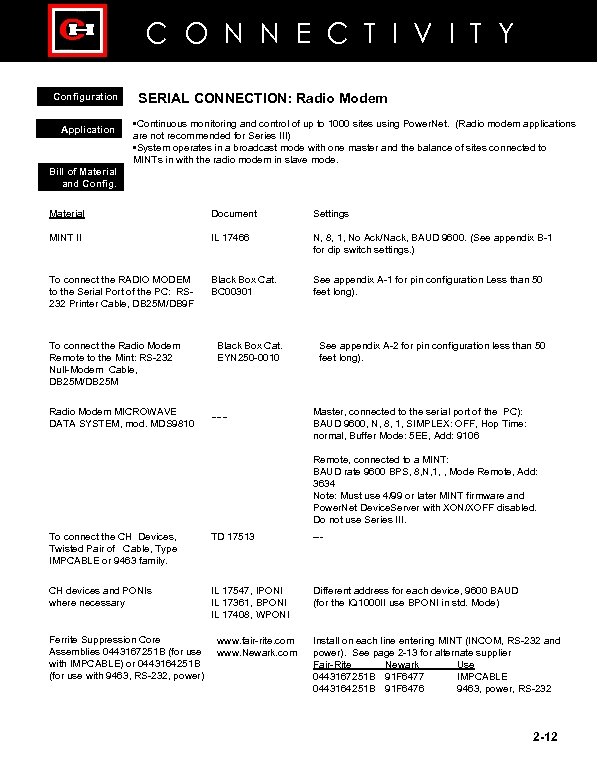

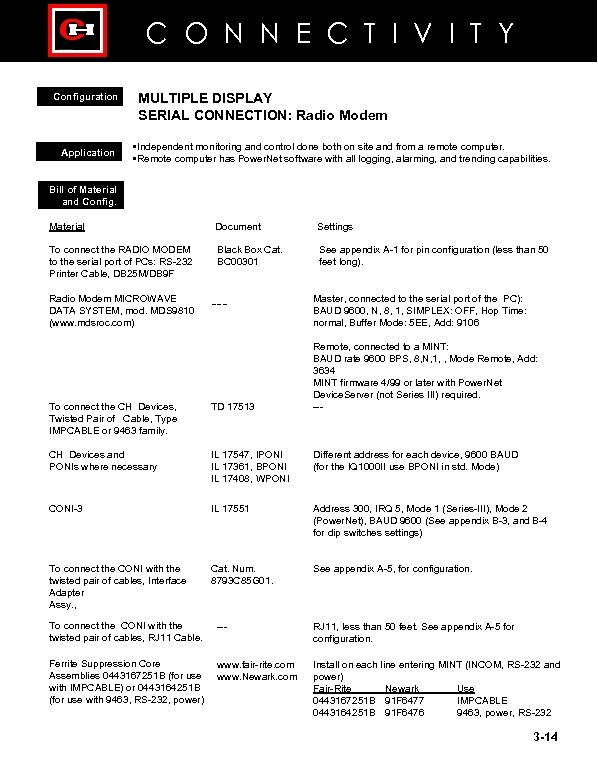

C O N N E C T I V I T Y Configuration Application SERIAL CONNECTION: Radio Modem • Continuous monitoring and control of up to 1000 sites using Power. Net. (Radio modem applications are not recommended for Series III) • System operates in a broadcast mode with one master and the balance of sites connected to MINTs in with the radio modem in slave mode. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B-1 for dip switch settings. ) To connect the RADIO MODEM to the Serial Port of the PC: RS 232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration Less than 50 feet long). To connect the Radio Modem Remote to the Mint: RS-232 Null-Modem Cable, DB 25 M/DB 25 M Radio Modem MICROWAVE DATA SYSTEM, mod. MDS 9810 Black Box Cat. EYN 250 -0010 --- See appendix A-2 for pin configuration less than 50 feet long). Master, connected to the serial port of the PC): BAUD 9600, N, 8, 1, SIMPLEX: OFF, Hop Time: normal, Buffer Mode: 5 EE, Add: 9106 Remote, connected to a MINT: BAUD rate 9600 BPS, 8, N, 1, , Mode Remote, Add: 3634 Note: Must use 4/99 or later MINT firmware and Power. Net Device. Server with XON/XOFF disabled. Do not use Series III. To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) Ferrite Suppression Core Assemblies 0443167251 B (for use with IMPCABLE) or 0443164251 B (for use with 9463, RS-232, power) www. fair-rite. com www. Newark. com Install on each line entering MINT (INCOM, RS-232 and power). See page 2 -13 for alternate supplier Fair-Rite Newark Use 0443167251 B 91 F 6477 IMPCABLE 0443164251 B 91 F 6476 9463, power, RS-232 2 -12

C O N N E C T I V I T Y Configuration Application SERIAL CONNECTION: Radio Modem • Continuous monitoring and control of up to 1000 sites using Power. Net. (Radio modem applications are not recommended for Series III) • System operates in a broadcast mode with one master and the balance of sites connected to MINTs in with the radio modem in slave mode. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600. (See appendix B-1 for dip switch settings. ) To connect the RADIO MODEM to the Serial Port of the PC: RS 232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration Less than 50 feet long). To connect the Radio Modem Remote to the Mint: RS-232 Null-Modem Cable, DB 25 M/DB 25 M Radio Modem MICROWAVE DATA SYSTEM, mod. MDS 9810 Black Box Cat. EYN 250 -0010 --- See appendix A-2 for pin configuration less than 50 feet long). Master, connected to the serial port of the PC): BAUD 9600, N, 8, 1, SIMPLEX: OFF, Hop Time: normal, Buffer Mode: 5 EE, Add: 9106 Remote, connected to a MINT: BAUD rate 9600 BPS, 8, N, 1, , Mode Remote, Add: 3634 Note: Must use 4/99 or later MINT firmware and Power. Net Device. Server with XON/XOFF disabled. Do not use Series III. To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) Ferrite Suppression Core Assemblies 0443167251 B (for use with IMPCABLE) or 0443164251 B (for use with 9463, RS-232, power) www. fair-rite. com www. Newark. com Install on each line entering MINT (INCOM, RS-232 and power). See page 2 -13 for alternate supplier Fair-Rite Newark Use 0443167251 B 91 F 6477 IMPCABLE 0443164251 B 91 F 6476 9463, power, RS-232 2 -12

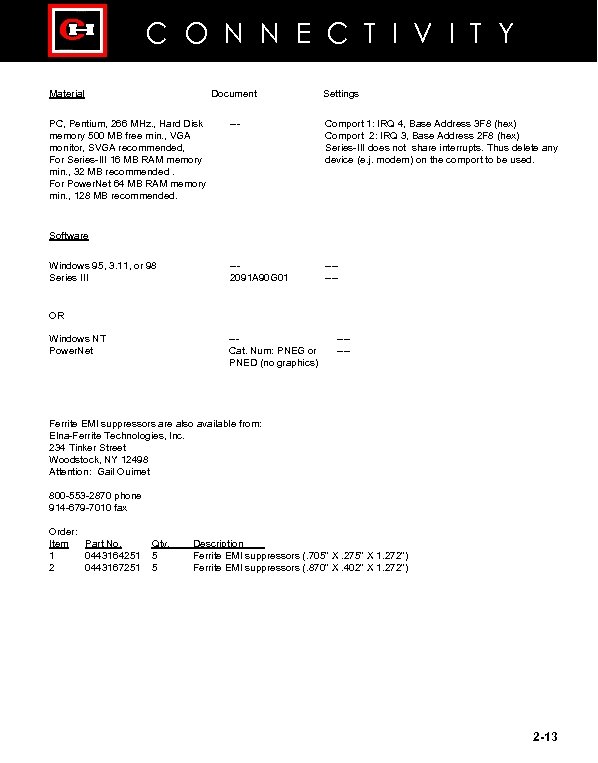

C O N N E C T I V I T Y Material Document PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- Ferrite EMI suppressors are also available from: Elna-Ferrite Technologies, Inc. 234 Tinker Street Woodstock, NY 12498 Attention: Gail Ouimet 800 -553 -2870 phone 914 -679 -7010 fax Order: Item Part No. 1 0443164251 2 0443167251 Qty. 5 5 Description Ferrite EMI suppressors (. 705" X. 275" X 1. 272") Ferrite EMI suppressors (. 870" X. 402" X 1. 272") 2 -13

C O N N E C T I V I T Y Material Document PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- Ferrite EMI suppressors are also available from: Elna-Ferrite Technologies, Inc. 234 Tinker Street Woodstock, NY 12498 Attention: Gail Ouimet 800 -553 -2870 phone 914 -679 -7010 fax Order: Item Part No. 1 0443164251 2 0443167251 Qty. 5 5 Description Ferrite EMI suppressors (. 705" X. 275" X 1. 272") Ferrite EMI suppressors (. 870" X. 402" X 1. 272") 2 -13

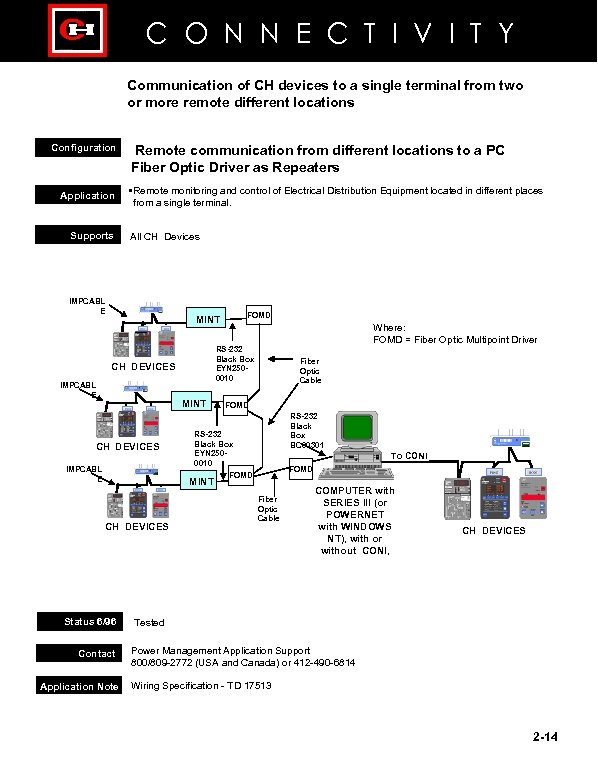

C O N N E C T I V I T Y Communication of CH devices to a single terminal from two or more remote different locations Configuration Application Supports Remote communication from different locations to a PC Fiber Optic Driver as Repeaters • Remote monitoring and control of Electrical Distribution Equipment located in different places from a single terminal. All CH Devices IMPCABL E FOMD MINT RS-232 Black Box EYN 2500010 CH DEVICES IMPCABL E MINT CH DEVICES IMPCABL E Status 6/96 Contact Application Note Fiber Optic Cable FOMD RS-232 Black Box BC 00301 RS-232 Black Box EYN 2500010 MINT CH DEVICES Where: FOMD = Fiber Optic Multipoint Driver To CONI FOMD Fiber Optic Cable COMPUTER with SERIES III (or POWERNET with WINDOWS NT), with or without CONI, CH DEVICES Tested Power Management Application Support 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 2 -14

C O N N E C T I V I T Y Communication of CH devices to a single terminal from two or more remote different locations Configuration Application Supports Remote communication from different locations to a PC Fiber Optic Driver as Repeaters • Remote monitoring and control of Electrical Distribution Equipment located in different places from a single terminal. All CH Devices IMPCABL E FOMD MINT RS-232 Black Box EYN 2500010 CH DEVICES IMPCABL E MINT CH DEVICES IMPCABL E Status 6/96 Contact Application Note Fiber Optic Cable FOMD RS-232 Black Box BC 00301 RS-232 Black Box EYN 2500010 MINT CH DEVICES Where: FOMD = Fiber Optic Multipoint Driver To CONI FOMD Fiber Optic Cable COMPUTER with SERIES III (or POWERNET with WINDOWS NT), with or without CONI, CH DEVICES Tested Power Management Application Support 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 2 -14

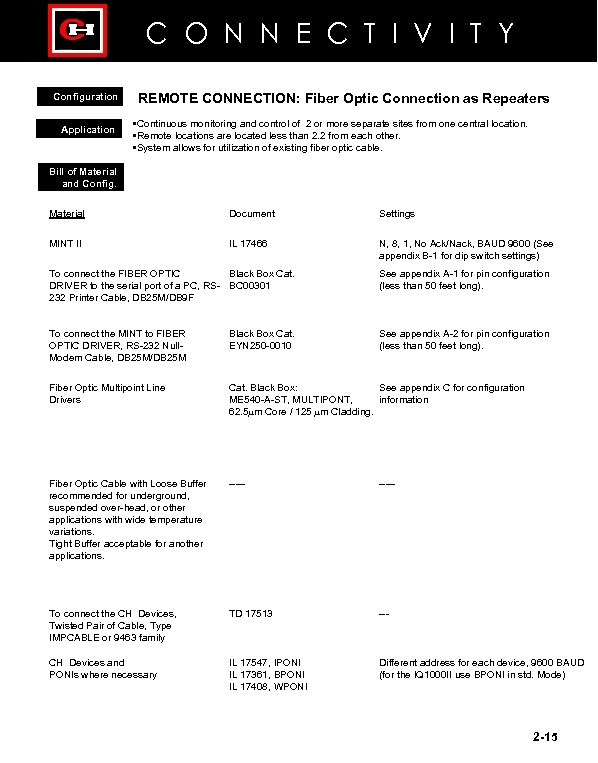

C O N N E C T I V I T Y Configuration Application REMOTE CONNECTION: Fiber Optic Connection as Repeaters • Continuous monitoring and control of 2 or more separate sites from one central location. • Remote locations are located less than 2. 2 from each other. • System allows for utilization of existing fiber optic cable. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600 (See appendix B-1 for dip switch settings) To connect the FIBER OPTIC Black Box Cat. DRIVER to the serial port of a PC, RS- BC 00301 232 Printer Cable, DB 25 M/DB 9 F See appendix A-1 for pin configuration (less than 50 feet long). To connect the MINT to FIBER OPTIC DRIVER, RS-232 Null. Modem Cable, DB 25 M/DB 25 M Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration (less than 50 feet long). Fiber Optic Multipoint Line Drivers Cat. Black Box: See appendix C for configuration ME 540 -A-ST, MULTIPONT, information 62. 5 m Core / 125 m Cladding. Fiber Optic Cable with Loose Buffer recommended for underground, suspended over-head, or other applications with wide temperature variations. Tight Buffer acceptable for another applications. ----- To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 --- CH Devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 2 -15

C O N N E C T I V I T Y Configuration Application REMOTE CONNECTION: Fiber Optic Connection as Repeaters • Continuous monitoring and control of 2 or more separate sites from one central location. • Remote locations are located less than 2. 2 from each other. • System allows for utilization of existing fiber optic cable. Bill of Material and Config. Material Document Settings MINT II IL 17466 N, 8, 1, No Ack/Nack, BAUD 9600 (See appendix B-1 for dip switch settings) To connect the FIBER OPTIC Black Box Cat. DRIVER to the serial port of a PC, RS- BC 00301 232 Printer Cable, DB 25 M/DB 9 F See appendix A-1 for pin configuration (less than 50 feet long). To connect the MINT to FIBER OPTIC DRIVER, RS-232 Null. Modem Cable, DB 25 M/DB 25 M Black Box Cat. EYN 250 -0010 See appendix A-2 for pin configuration (less than 50 feet long). Fiber Optic Multipoint Line Drivers Cat. Black Box: See appendix C for configuration ME 540 -A-ST, MULTIPONT, information 62. 5 m Core / 125 m Cladding. Fiber Optic Cable with Loose Buffer recommended for underground, suspended over-head, or other applications with wide temperature variations. Tight Buffer acceptable for another applications. ----- To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 --- CH Devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) 2 -15

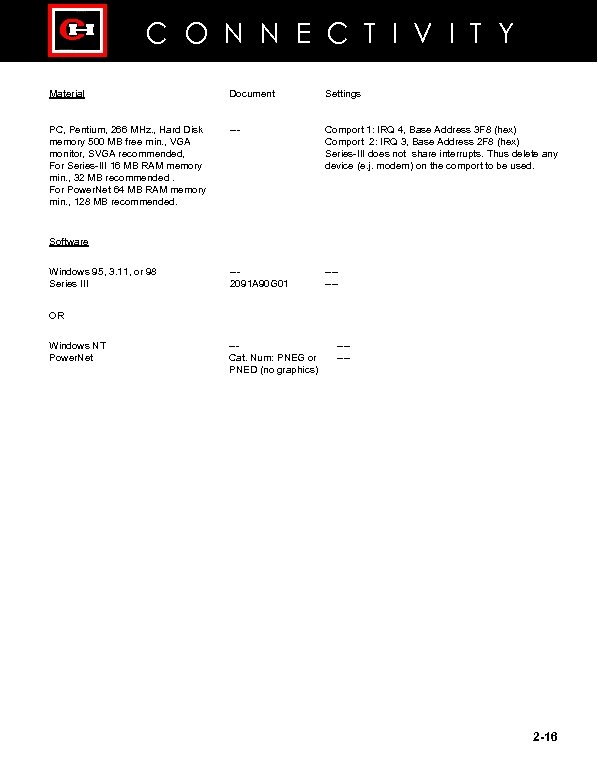

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 2 -16

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 500 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. For Power. Net 64 MB RAM memory min. , 128 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III OR Windows NT Power. Net --Cat. Num: PNEG or PNED (no graphics) ------- 2 -16

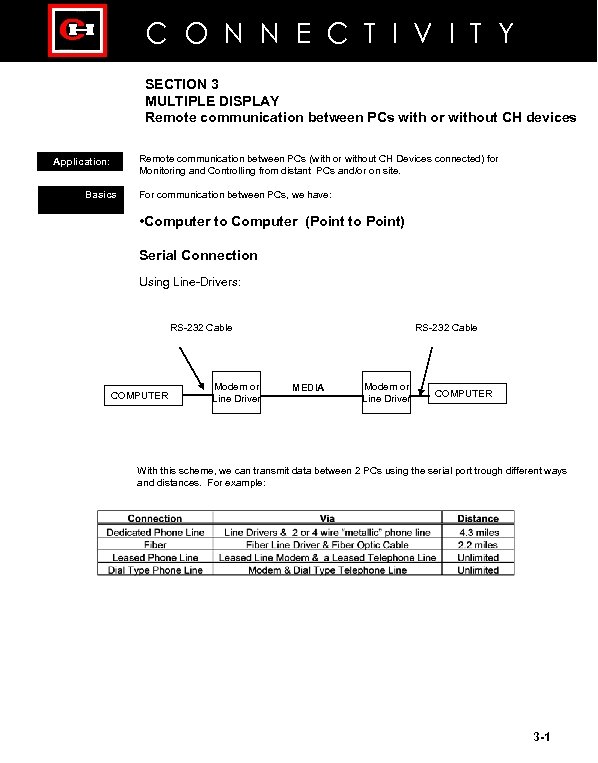

C O N N E C T I V I T Y SECTION 3 MULTIPLE DISPLAY Remote communication between PCs with or without CH devices Remote communication between PCs (with or without CH Devices connected) for Monitoring and Controlling from distant PCs and/or on site. Application: Basics For communication between PCs, we have: • Computer to Computer (Point to Point) Serial Connection Using Line-Drivers: RS-232 Cable COMPUTER Modem or Line Driver RS-232 Cable MEDIA Modem or Line Driver COMPUTER With this scheme, we can transmit data between 2 PCs using the serial port trough different ways and distances. For example: 3 -1

C O N N E C T I V I T Y SECTION 3 MULTIPLE DISPLAY Remote communication between PCs with or without CH devices Remote communication between PCs (with or without CH Devices connected) for Monitoring and Controlling from distant PCs and/or on site. Application: Basics For communication between PCs, we have: • Computer to Computer (Point to Point) Serial Connection Using Line-Drivers: RS-232 Cable COMPUTER Modem or Line Driver RS-232 Cable MEDIA Modem or Line Driver COMPUTER With this scheme, we can transmit data between 2 PCs using the serial port trough different ways and distances. For example: 3 -1

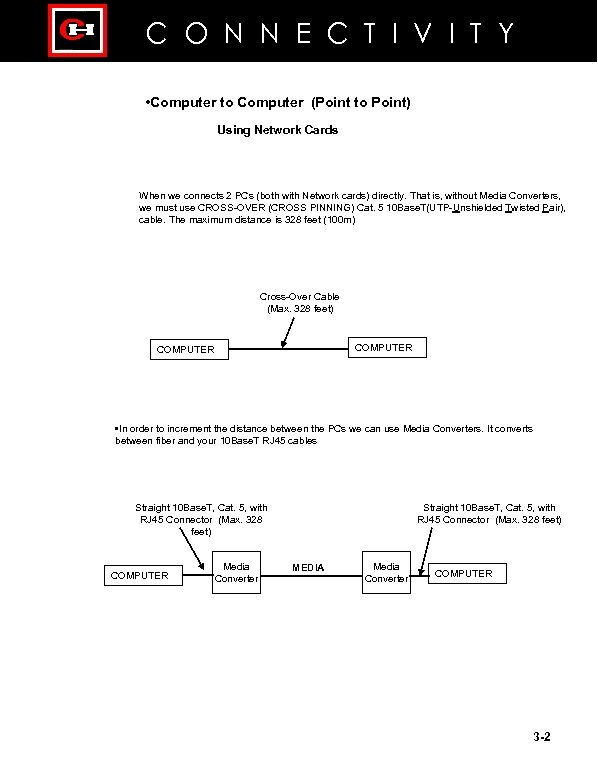

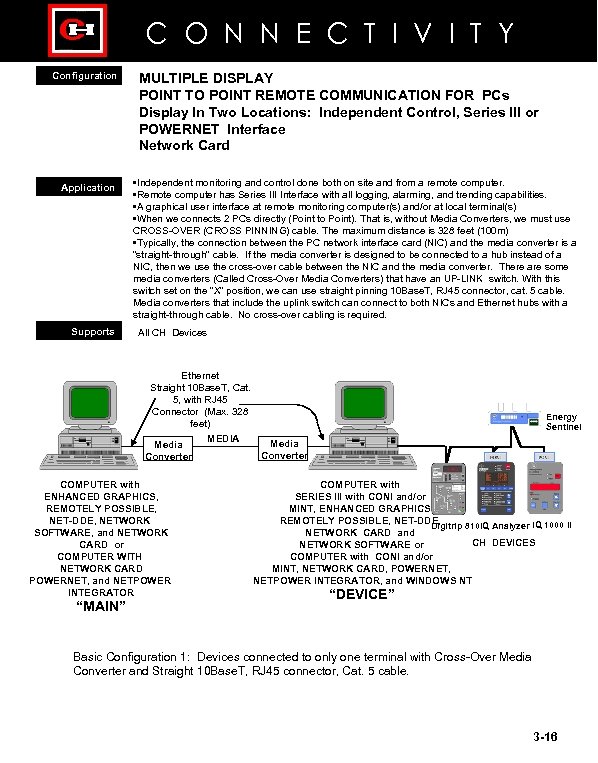

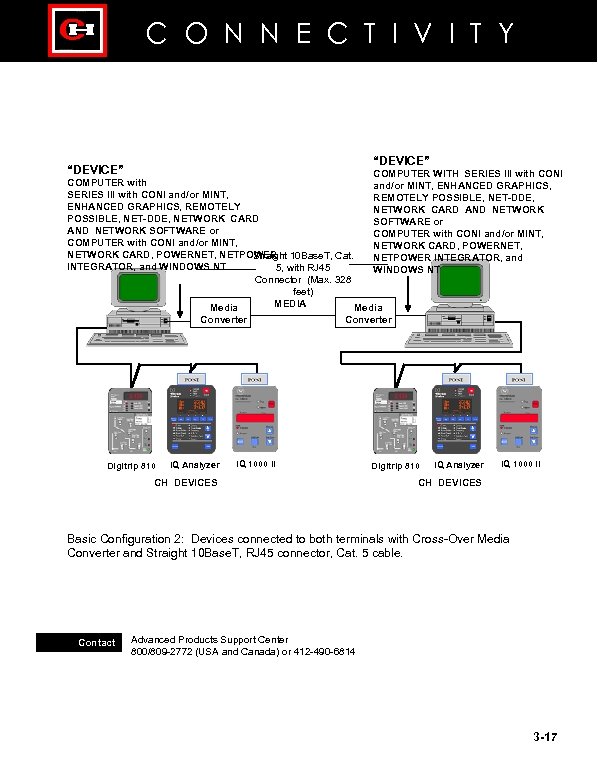

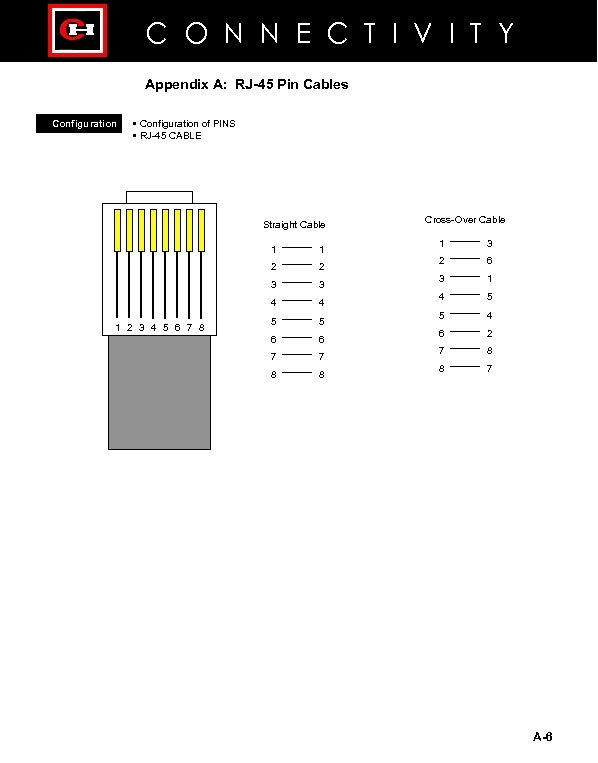

C O N N E C T I V I T Y • Computer to Computer (Point to Point) Using Network Cards When we connects 2 PCs (both with Network cards) directly. That is, without Media Converters, we must use CROSS-OVER (CROSS PINNING) Cat. 5 10 Base. T(UTP-Unshielded Twisted Pair), cable. The maximum distance is 328 feet (100 m) Cross-Over Cable (Max. 328 feet) COMPUTER • In order to increment the distance between the PCs we can use Media Converters. It converts between fiber and your 10 Base. T RJ 45 cables Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) COMPUTER Media Converter Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) MEDIA Media Converter COMPUTER 3 -2

C O N N E C T I V I T Y • Computer to Computer (Point to Point) Using Network Cards When we connects 2 PCs (both with Network cards) directly. That is, without Media Converters, we must use CROSS-OVER (CROSS PINNING) Cat. 5 10 Base. T(UTP-Unshielded Twisted Pair), cable. The maximum distance is 328 feet (100 m) Cross-Over Cable (Max. 328 feet) COMPUTER • In order to increment the distance between the PCs we can use Media Converters. It converts between fiber and your 10 Base. T RJ 45 cables Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) COMPUTER Media Converter Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) MEDIA Media Converter COMPUTER 3 -2

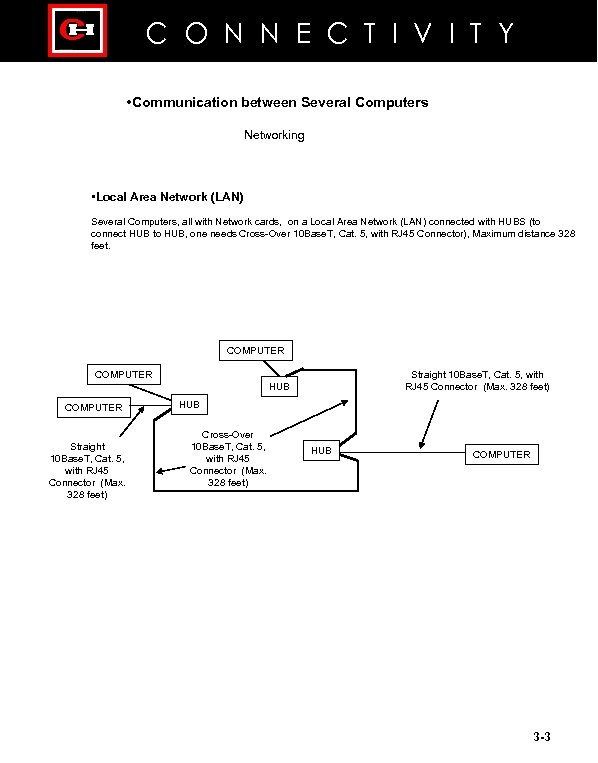

C O N N E C T I V I T Y • Communication between Several Computers Networking • Local Area Network (LAN) Several Computers, all with Network cards, on a Local Area Network (LAN) connected with HUBS (to connect HUB to HUB, one needs Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector), Maximum distance 328 feet. COMPUTER Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) HUB Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) HUB COMPUTER 3 -3

C O N N E C T I V I T Y • Communication between Several Computers Networking • Local Area Network (LAN) Several Computers, all with Network cards, on a Local Area Network (LAN) connected with HUBS (to connect HUB to HUB, one needs Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector), Maximum distance 328 feet. COMPUTER Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) HUB Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) HUB COMPUTER 3 -3

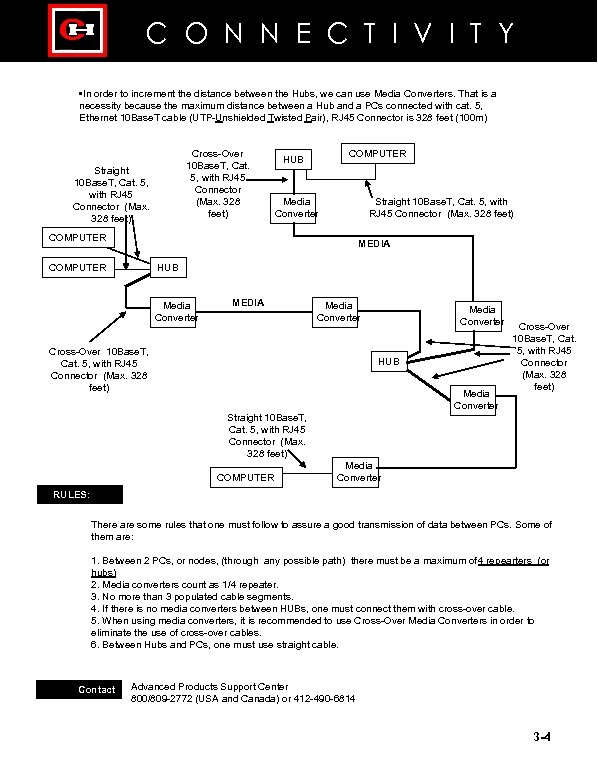

C O N N E C T I V I T Y • In order to increment the distance between the Hubs, we can use Media Converters. That is a necessity because the maximum distance between a Hub and a PCs connected with cat. 5, Ethernet 10 Base. T cable (UTP-Unshielded Twisted Pair), RJ 45 Connector is 328 feet (100 m) Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) COMPUTER HUB Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) Media Converter COMPUTER MEDIA COMPUTER HUB Media Converter MEDIA Media Converter Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) Media Converter HUB Media Converter Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) COMPUTER Media Converter RULES: There are some rules that one must follow to assure a good transmission of data between PCs. Some of them are: 1. Between 2 PCs, or nodes, (through any possible path) there must be a maximum of 4 repearters (or hubs) 2. Media converters count as 1/4 repeater. 3. No more than 3 populated cable segments. 4. If there is no media converters between HUBs, one must connect them with cross-over cable. 5. When using media converters, it is recommended to use Cross-Over Media Converters in order to eliminate the use of cross-over cables. 6. Between Hubs and PCs, one must use straight cable. Contact Advanced Products Support Center 800/809 -2772 (USA and Canada) or 412 -490 -6814 3 -4

C O N N E C T I V I T Y • In order to increment the distance between the Hubs, we can use Media Converters. That is a necessity because the maximum distance between a Hub and a PCs connected with cat. 5, Ethernet 10 Base. T cable (UTP-Unshielded Twisted Pair), RJ 45 Connector is 328 feet (100 m) Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) COMPUTER HUB Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) Media Converter COMPUTER MEDIA COMPUTER HUB Media Converter MEDIA Media Converter Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) Media Converter HUB Media Converter Cross-Over 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) Straight 10 Base. T, Cat. 5, with RJ 45 Connector (Max. 328 feet) COMPUTER Media Converter RULES: There are some rules that one must follow to assure a good transmission of data between PCs. Some of them are: 1. Between 2 PCs, or nodes, (through any possible path) there must be a maximum of 4 repearters (or hubs) 2. Media converters count as 1/4 repeater. 3. No more than 3 populated cable segments. 4. If there is no media converters between HUBs, one must connect them with cross-over cable. 5. When using media converters, it is recommended to use Cross-Over Media Converters in order to eliminate the use of cross-over cables. 6. Between Hubs and PCs, one must use straight cable. Contact Advanced Products Support Center 800/809 -2772 (USA and Canada) or 412 -490 -6814 3 -4

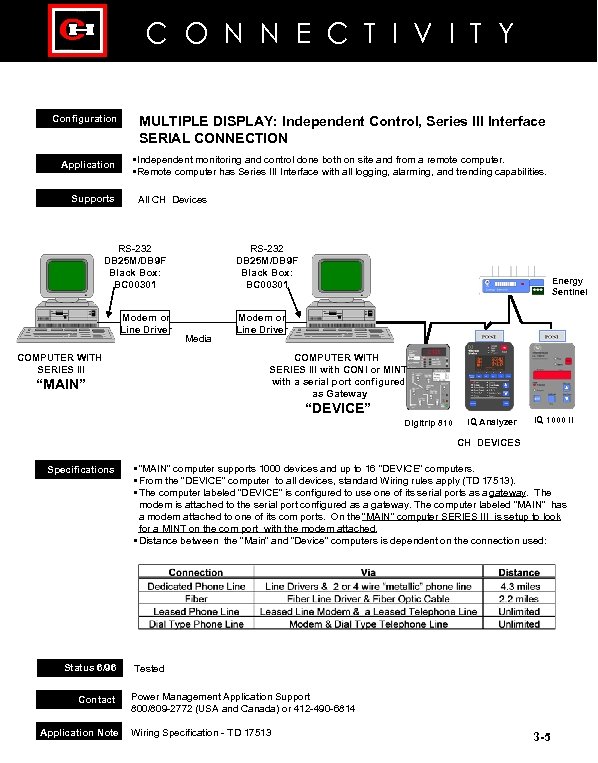

C O N N E C T I V I T Y Configuration Application Supports MULTIPLE DISPLAY: Independent Control, Series III Interface SERIAL CONNECTION • Independent monitoring and control done both on site and from a remote computer. • Remote computer has Series III Interface with all logging, alarming, and trending capabilities. All CH Devices RS-232 DB 25 M/DB 9 F Black Box: BC 00301 Modem or Line Driver COMPUTER WITH SERIES III RS-232 DB 25 M/DB 9 F Black Box: BC 00301 Media Energy Sentinel Modem or Line Driver COMPUTER WITH SERIES III with CONI or MINT with a serial port configured as Gateway “MAIN” “DEVICE” Digitrip 810 IQ Analyzer IQ 1000 II CH DEVICES Specifications Status 6/96 Contact Application Note • “MAIN” computer supports 1000 devices and up to 16 “DEVICE” computers. • From the “DEVICE” computer to all devices, standard Wiring rules apply (TD 17513). • The computer labeled “DEVICE” is configured to use one of its serial ports as a gateway. The modem is attached to the serial port configured as a gateway. The computer labeled “MAIN” has a modem attached to one of its com ports. On the “MAIN” computer SERIES III is setup to look for a MINT on the com port with the modem attached. • Distance between the “Main” and “Device” computers is dependent on the connection used: Tested Power Management Application Support 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 3 -5

C O N N E C T I V I T Y Configuration Application Supports MULTIPLE DISPLAY: Independent Control, Series III Interface SERIAL CONNECTION • Independent monitoring and control done both on site and from a remote computer. • Remote computer has Series III Interface with all logging, alarming, and trending capabilities. All CH Devices RS-232 DB 25 M/DB 9 F Black Box: BC 00301 Modem or Line Driver COMPUTER WITH SERIES III RS-232 DB 25 M/DB 9 F Black Box: BC 00301 Media Energy Sentinel Modem or Line Driver COMPUTER WITH SERIES III with CONI or MINT with a serial port configured as Gateway “MAIN” “DEVICE” Digitrip 810 IQ Analyzer IQ 1000 II CH DEVICES Specifications Status 6/96 Contact Application Note • “MAIN” computer supports 1000 devices and up to 16 “DEVICE” computers. • From the “DEVICE” computer to all devices, standard Wiring rules apply (TD 17513). • The computer labeled “DEVICE” is configured to use one of its serial ports as a gateway. The modem is attached to the serial port configured as a gateway. The computer labeled “MAIN” has a modem attached to one of its com ports. On the “MAIN” computer SERIES III is setup to look for a MINT on the com port with the modem attached. • Distance between the “Main” and “Device” computers is dependent on the connection used: Tested Power Management Application Support 800/809 -2772 (USA and Canada) or 412 -490 -6814 Wiring Specification - TD 17513 3 -5

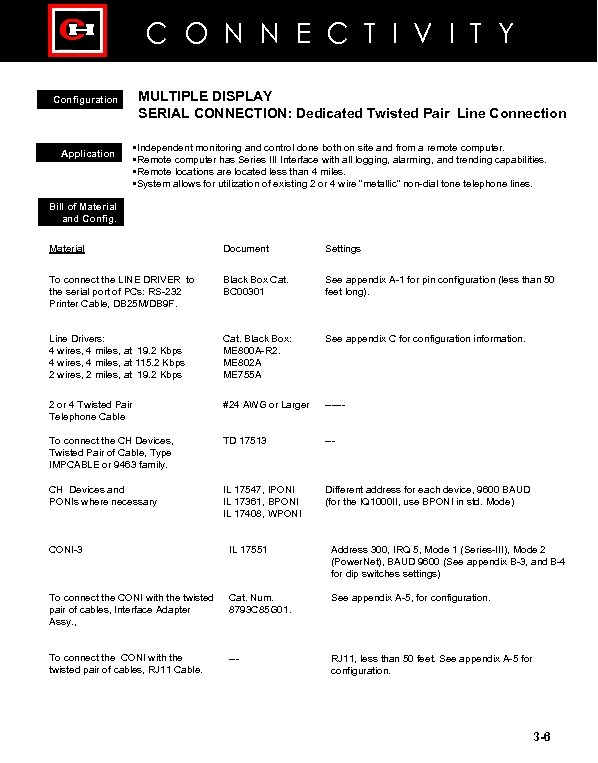

C O N N E C T I V I T Y Configuration Application MULTIPLE DISPLAY SERIAL CONNECTION: Dedicated Twisted Pair Line Connection • Independent monitoring and control done both on site and from a remote computer. • Remote computer has Series III Interface with all logging, alarming, and trending capabilities. • Remote locations are located less than 4 miles. • System allows for utilization of existing 2 or 4 wire “metallic” non-dial tone telephone lines. Bill of Material and Config. Material Document Settings To connect the LINE DRIVER to the serial port of PCs: RS-232 Printer Cable, DB 25 M/DB 9 F. Black Box Cat. BC 00301 See appendix A-1 for pin configuration (less than 50 feet long). Line Drivers: 4 wires, 4 miles, at 19. 2 Kbps 4 wires, 4 miles, at 115. 2 Kbps 2 wires, 2 miles, at 19. 2 Kbps Cat. Black Box: ME 800 A-R 2. ME 802 A ME 755 A See appendix C for configuration information. 2 or 4 Twisted Pair Telephone Cable #24 AWG or Larger ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH Devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II, use BPONI in std. Mode) CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600 (See appendix B-3, and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. , Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. 3 -6

C O N N E C T I V I T Y Configuration Application MULTIPLE DISPLAY SERIAL CONNECTION: Dedicated Twisted Pair Line Connection • Independent monitoring and control done both on site and from a remote computer. • Remote computer has Series III Interface with all logging, alarming, and trending capabilities. • Remote locations are located less than 4 miles. • System allows for utilization of existing 2 or 4 wire “metallic” non-dial tone telephone lines. Bill of Material and Config. Material Document Settings To connect the LINE DRIVER to the serial port of PCs: RS-232 Printer Cable, DB 25 M/DB 9 F. Black Box Cat. BC 00301 See appendix A-1 for pin configuration (less than 50 feet long). Line Drivers: 4 wires, 4 miles, at 19. 2 Kbps 4 wires, 4 miles, at 115. 2 Kbps 2 wires, 2 miles, at 19. 2 Kbps Cat. Black Box: ME 800 A-R 2. ME 802 A ME 755 A See appendix C for configuration information. 2 or 4 Twisted Pair Telephone Cable #24 AWG or Larger ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH Devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II, use BPONI in std. Mode) CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600 (See appendix B-3, and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. , Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. 3 -6

C O N N E C T I V I T Y Material PC, Pentium, 266 MHz. , Hard Disk memory 100 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. Document Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III 3 -7

C O N N E C T I V I T Y Material PC, Pentium, 266 MHz. , Hard Disk memory 100 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. Document Settings --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III 3 -7

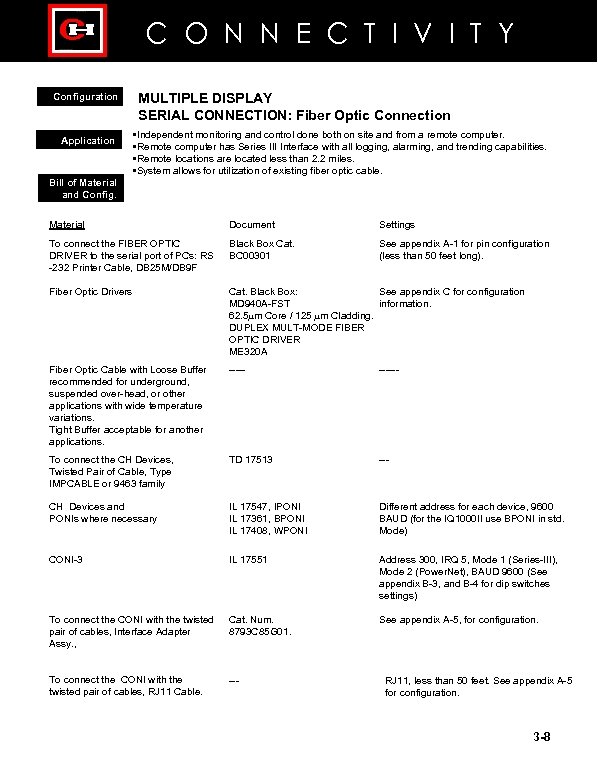

C O N N E C T I V I T Y Configuration Application MULTIPLE DISPLAY SERIAL CONNECTION: Fiber Optic Connection • Independent monitoring and control done both on site and from a remote computer. • Remote computer has Series III Interface with all logging, alarming, and trending capabilities. • Remote locations are located less than 2. 2 miles. • System allows for utilization of existing fiber optic cable. Bill of Material and Config. Material Document Settings To connect the FIBER OPTIC DRIVER to the serial port of PCs: RS -232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration (less than 50 feet long). Fiber Optic Drivers Cat. Black Box: See appendix C for configuration MD 940 A-FST information. 62. 5 m Core / 125 m Cladding. DUPLEX MULT-MODE FIBER OPTIC DRIVER ME 320 A Fiber Optic Cable with Loose Buffer recommended for underground, suspended over-head, or other applications with wide temperature variations. Tight Buffer acceptable for another applications. ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 --- CH Devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600 (See appendix B-3, and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. , Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. 3 -8

C O N N E C T I V I T Y Configuration Application MULTIPLE DISPLAY SERIAL CONNECTION: Fiber Optic Connection • Independent monitoring and control done both on site and from a remote computer. • Remote computer has Series III Interface with all logging, alarming, and trending capabilities. • Remote locations are located less than 2. 2 miles. • System allows for utilization of existing fiber optic cable. Bill of Material and Config. Material Document Settings To connect the FIBER OPTIC DRIVER to the serial port of PCs: RS -232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration (less than 50 feet long). Fiber Optic Drivers Cat. Black Box: See appendix C for configuration MD 940 A-FST information. 62. 5 m Core / 125 m Cladding. DUPLEX MULT-MODE FIBER OPTIC DRIVER ME 320 A Fiber Optic Cable with Loose Buffer recommended for underground, suspended over-head, or other applications with wide temperature variations. Tight Buffer acceptable for another applications. ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family TD 17513 --- CH Devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600 (See appendix B-3, and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. , Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. 3 -8

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 100 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III 3 -9

C O N N E C T I V I T Y Material Document Settings PC, Pentium, 266 MHz. , Hard Disk memory 100 MB free min. , VGA monitor, SVGA recommended, For Series-III 16 MB RAM memory min. , 32 MB recommended. --- Comport 1: IRQ 4, Base Address 3 F 8 (hex) Comport 2: IRQ 3, Base Address 2 F 8 (hex) Series-III does not share interrupts. Thus delete any device (e. j. modem) on the comport to be used. --2091 A 90 G 01 ------- Software Windows 95, 3. 11, or 98 Series III 3 -9

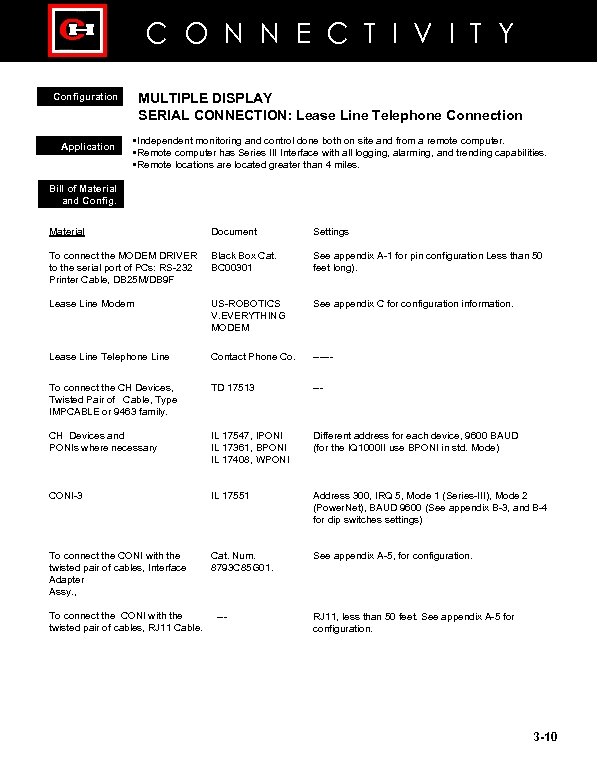

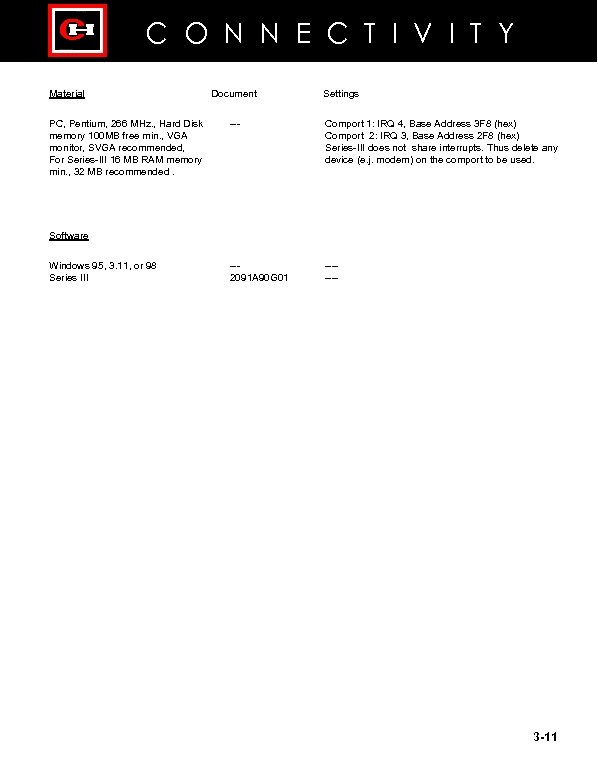

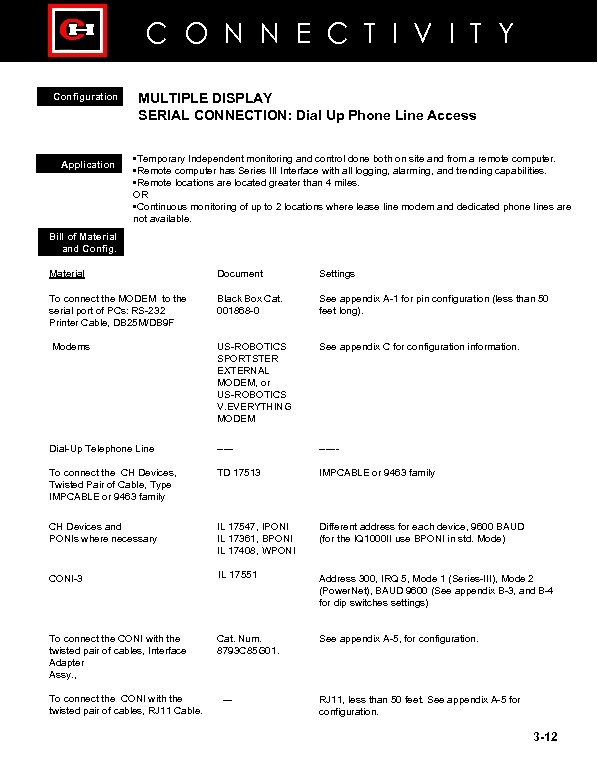

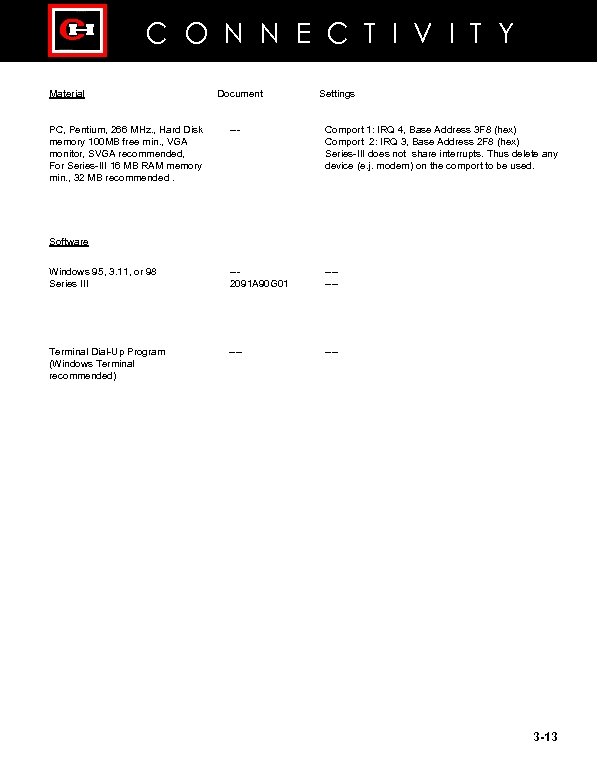

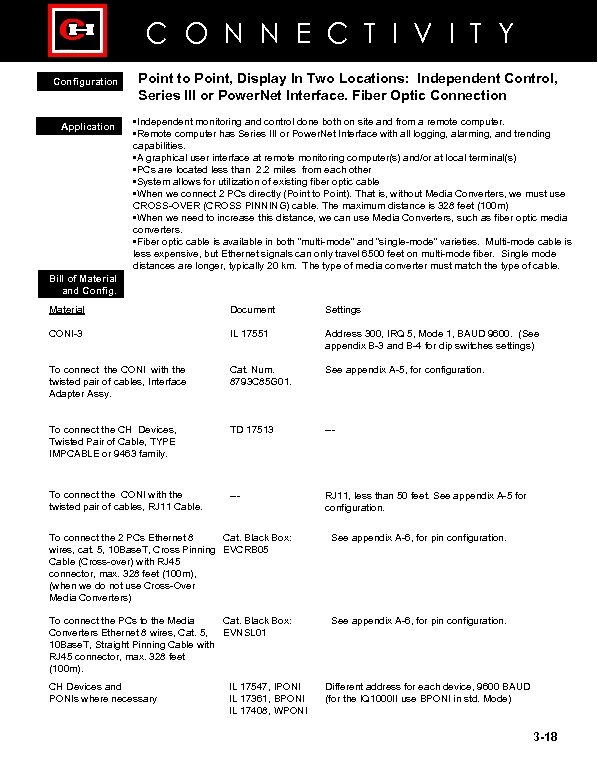

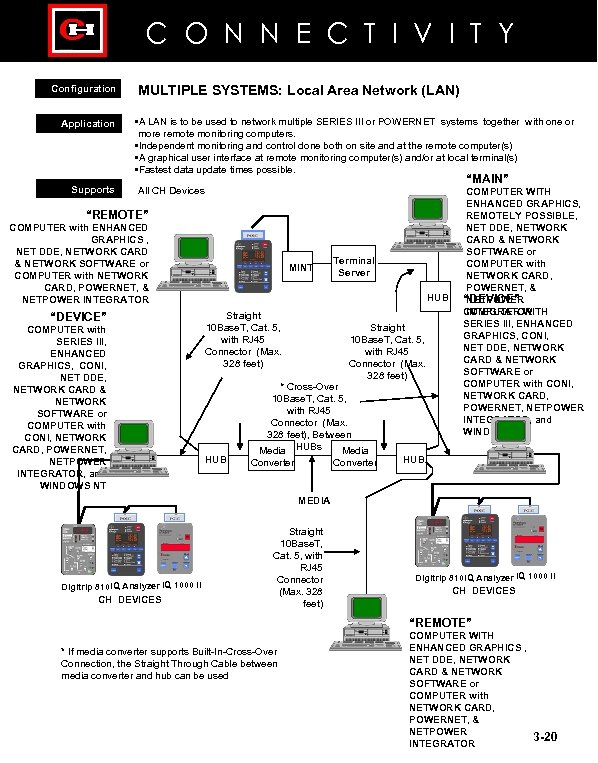

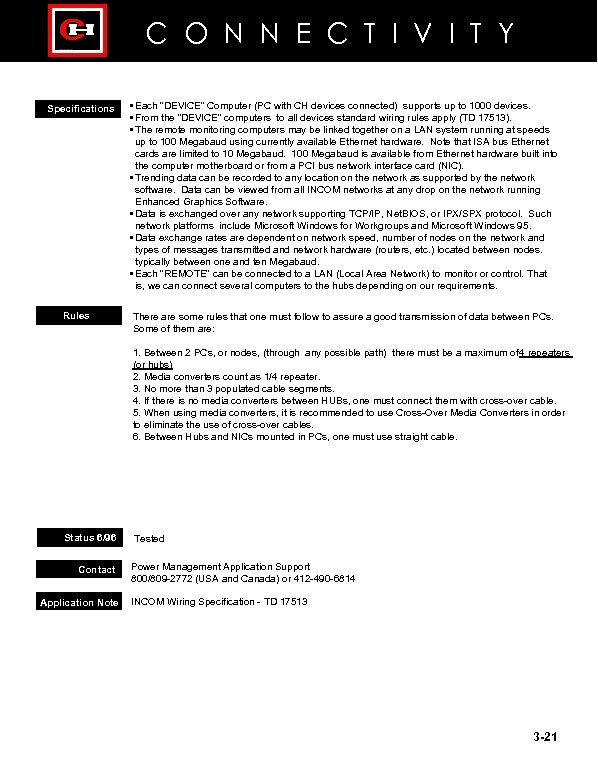

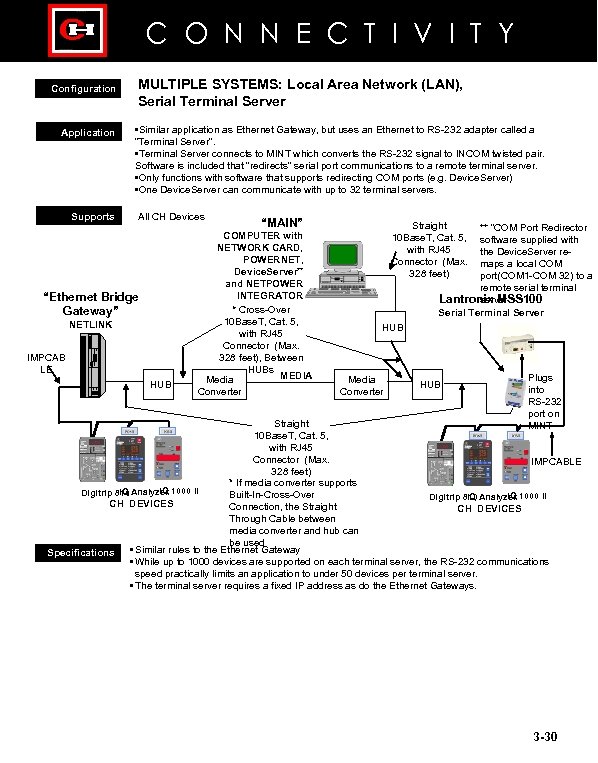

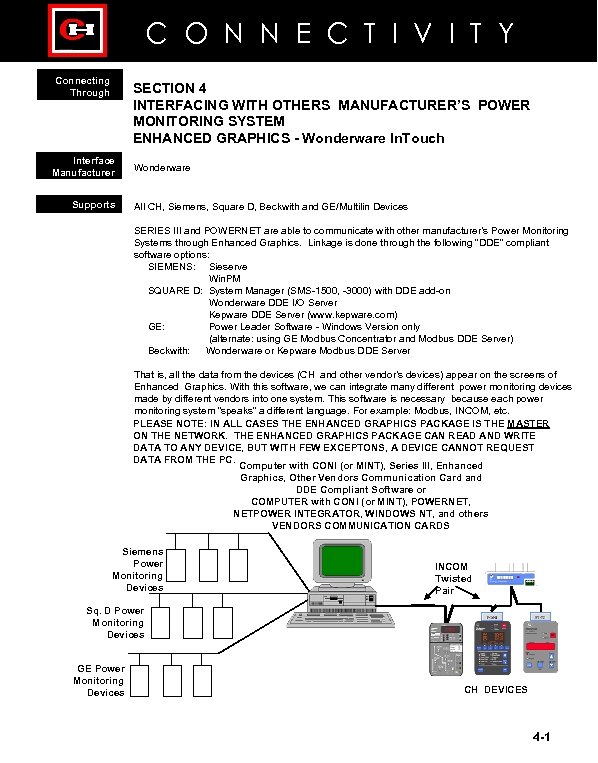

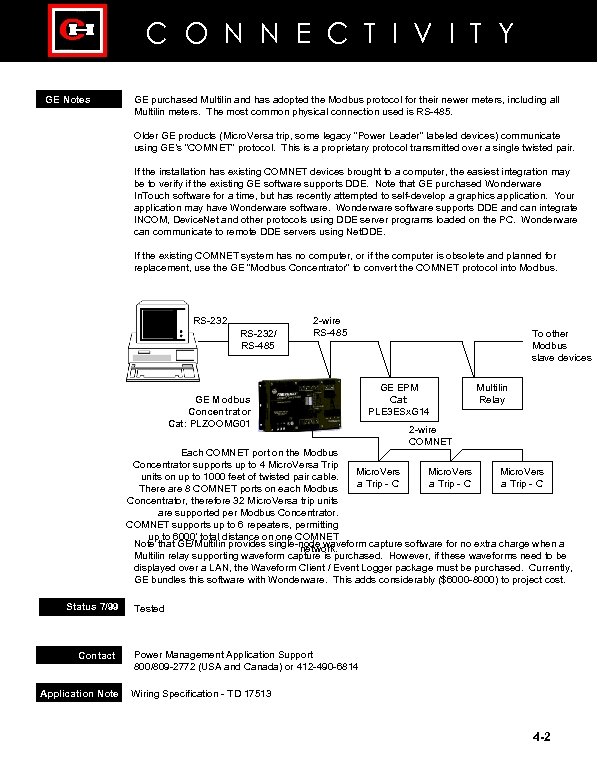

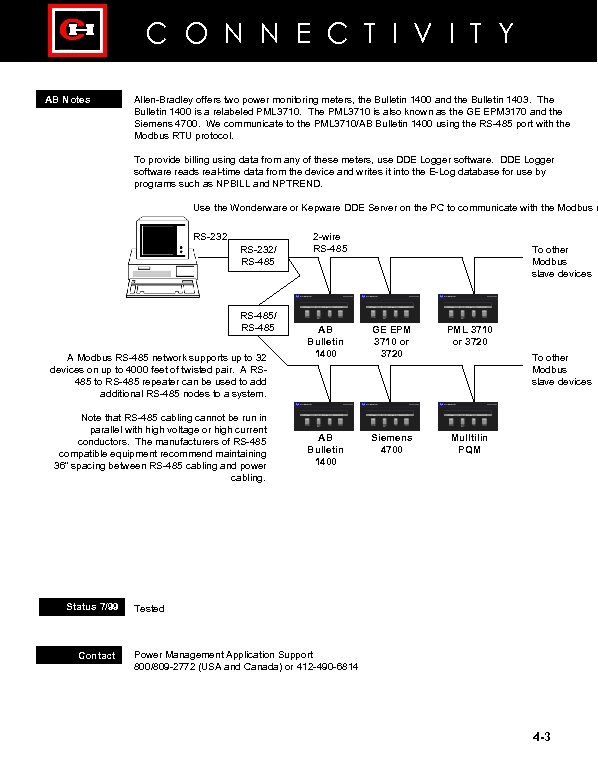

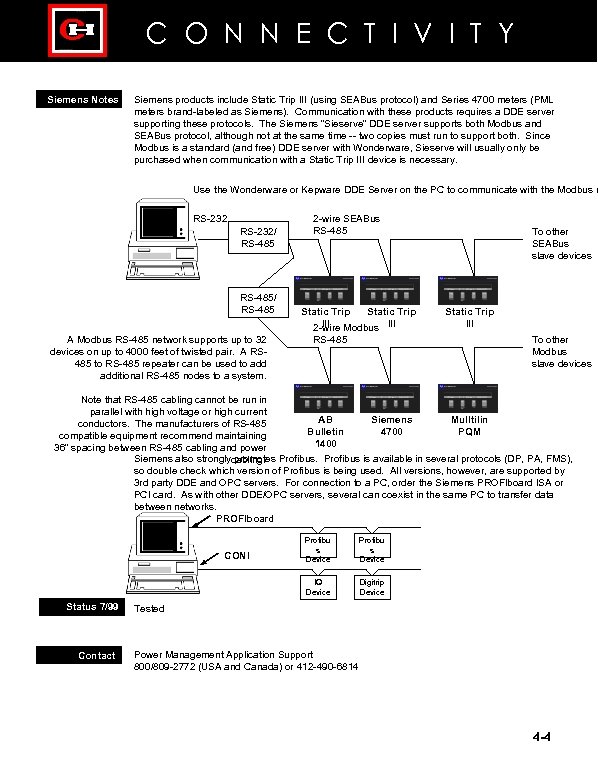

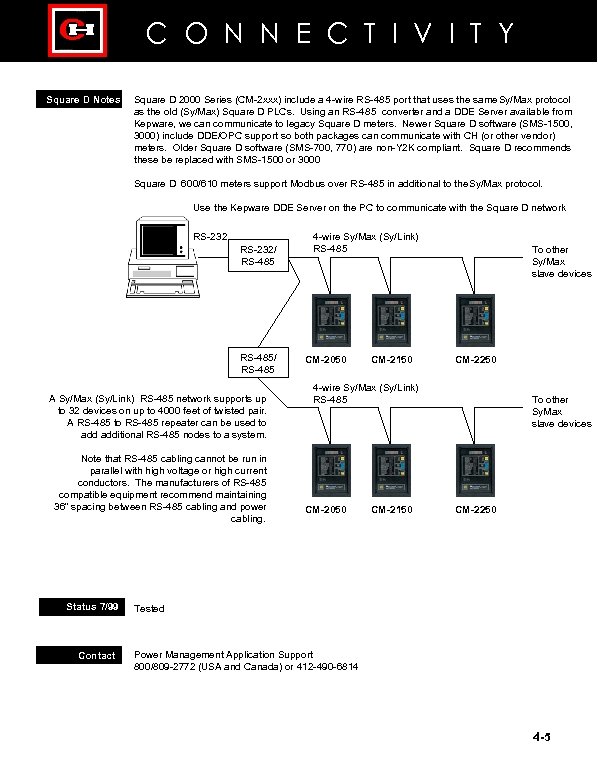

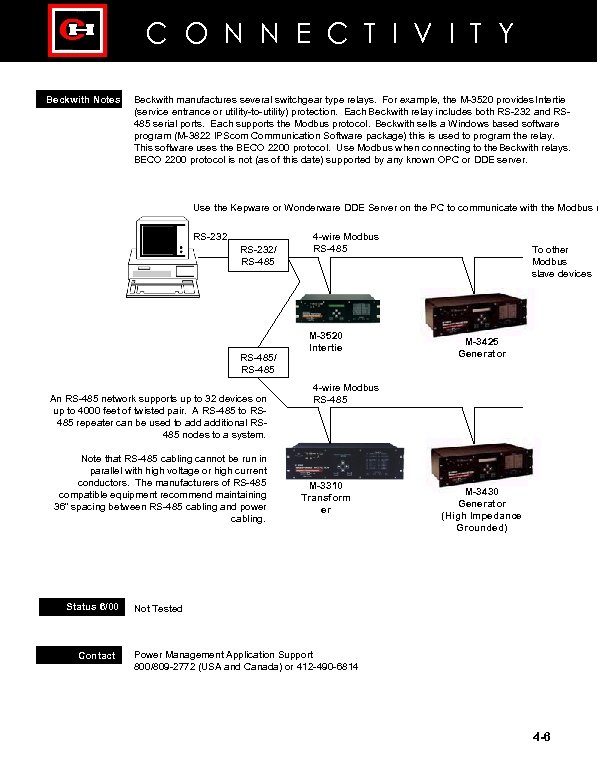

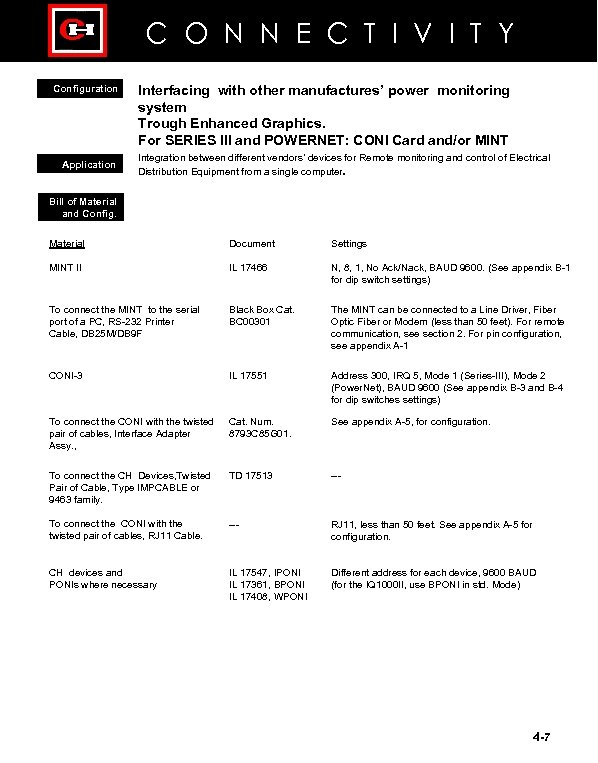

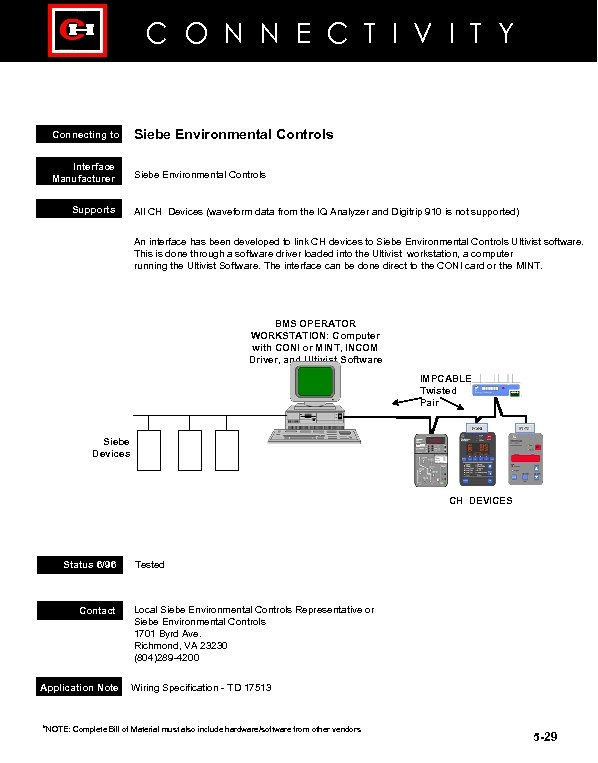

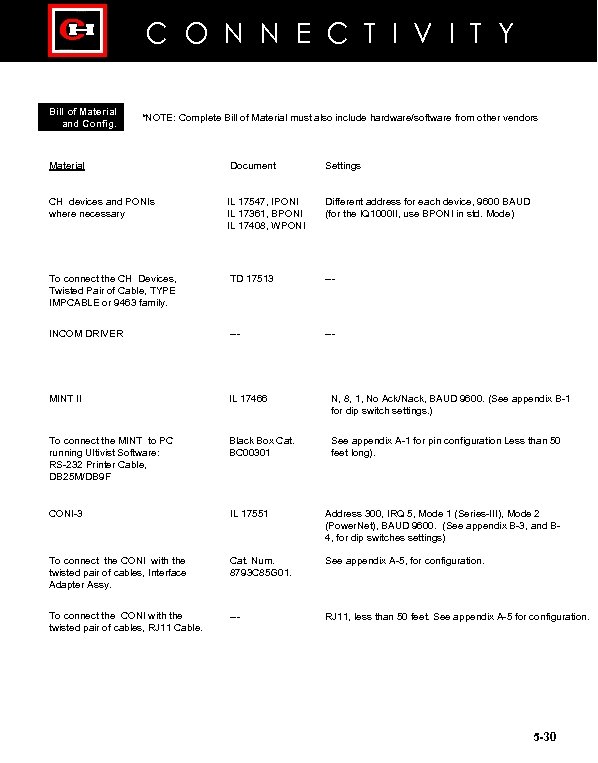

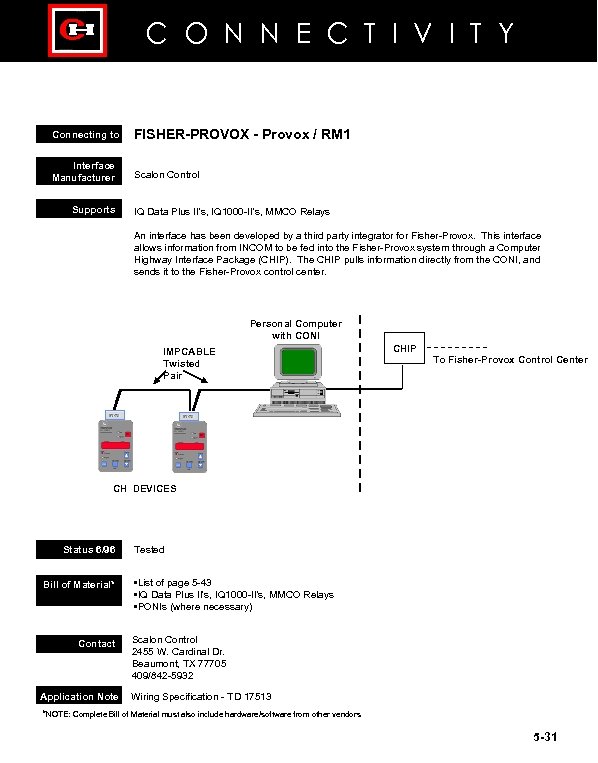

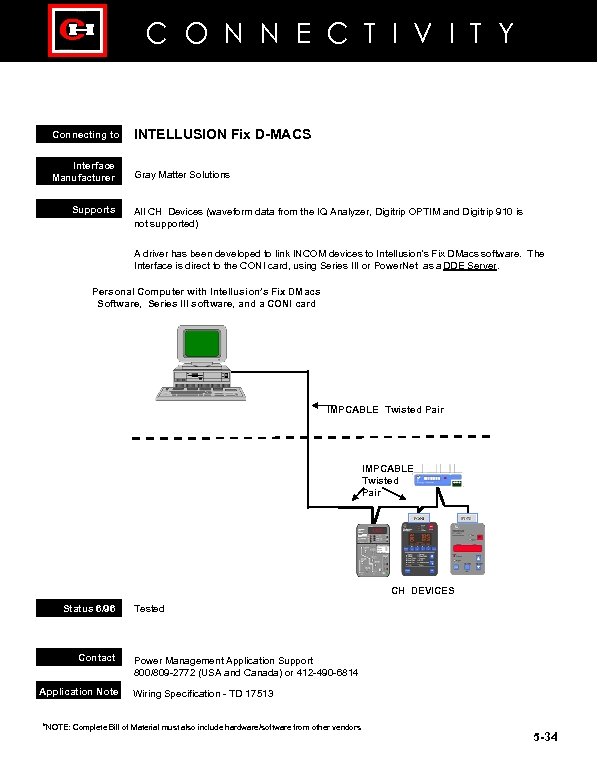

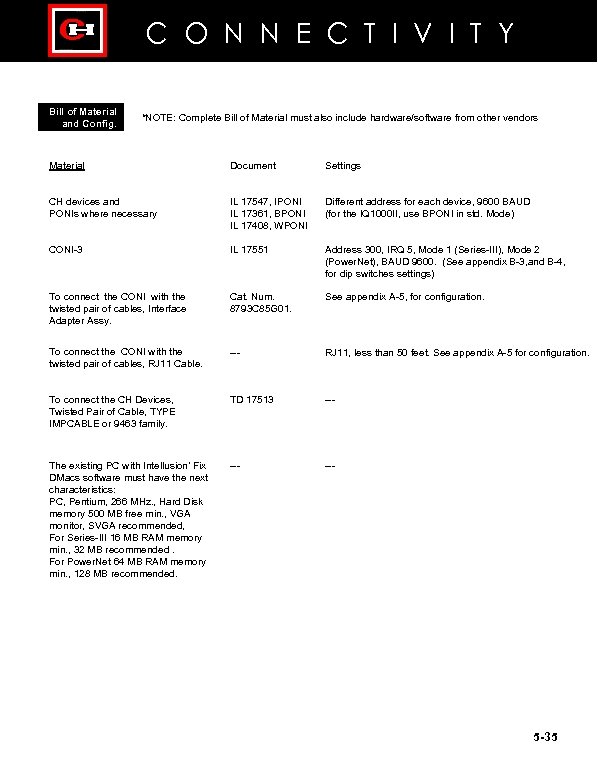

C O N N E C T I V I T Y MULTIPLE DISPLAY SERIAL CONNECTION: Lease Line Telephone Connection Configuration Application • Independent monitoring and control done both on site and from a remote computer. • Remote computer has Series III Interface with all logging, alarming, and trending capabilities. • Remote locations are located greater than 4 miles. Bill of Material and Config. Material Document Settings To connect the MODEM DRIVER to the serial port of PCs: RS-232 Printer Cable, DB 25 M/DB 9 F Black Box Cat. BC 00301 See appendix A-1 for pin configuration Less than 50 feet long). Lease Line Modem US-ROBOTICS V. EVERYTHING MODEM See appendix C for configuration information. Lease Line Telephone Line Contact Phone Co. ------ To connect the CH Devices, Twisted Pair of Cable, Type IMPCABLE or 9463 family. TD 17513 --- CH Devices and PONIs where necessary IL 17547, IPONI IL 17361, BPONI IL 17408, WPONI Different address for each device, 9600 BAUD (for the IQ 1000 II use BPONI in std. Mode) CONI-3 IL 17551 Address 300, IRQ 5, Mode 1 (Series-III), Mode 2 (Power. Net), BAUD 9600 (See appendix B-3, and B-4 for dip switches settings) To connect the CONI with the twisted pair of cables, Interface Adapter Assy. , Cat. Num. 8793 C 85 G 01. See appendix A-5, for configuration. To connect the CONI with the twisted pair of cables, RJ 11 Cable. --- RJ 11, less than 50 feet. See appendix A-5 for configuration. 3 -10