b7e6f2a0b37785995e974df31860352c.ppt

- Количество слайдов: 25

by Phy. Met, Inc. www. micropolylubricants. com Phy. Met, Inc.

Phy. Met, Inc. • • • Founded in 1986 USDA and FDA certification in 1989 Agriculture Canada certification in 1991 NSF certification for MPF-0696 – The only solid lubricant to obtain NSF certification ISO 9001: 2000 certified Phy. Met, Inc.

Phy. Met, Inc. Currently approved supplier for: • • AMI Cooper Danaher Dodge FAG Kaydon Mc. Gill • • NSK RBC Rexnord Seal. Master SKF Timken Torrington Phy. Met, Inc.

Micro. Poly Composition • Micro. Poly is a microporous polymer lubricant. It is a mixture of: – Plastics – Oil – Other additives • Micro. Poly is over 50% oil by weight. Phy. Met, Inc.

Micro. Poly is a “Sponge. ” When friction or heat is applied, the “sponge” weeps oil to the surface. This provides constant, consistent lubrication as the bearing rotates. When the bearing is at rest, oil can be reabsorbed by the Micro. Poly. Phy. Met, Inc.

Micro. Poly Applications • • • Ball and roller bearings Linear bearings Ball screws Roller chain lubrication Bushings Wheel flanges Phy. Met, Inc.

All Types of Bearings • • Ball bearing inserts Ball thrust Cam followers Cylindrical roller Double row ball Housed roller • • Needle roller Roller thrust Single row ball Spherical roller Split roller Tapered roller Trolley wheels Phy. Met, Inc.

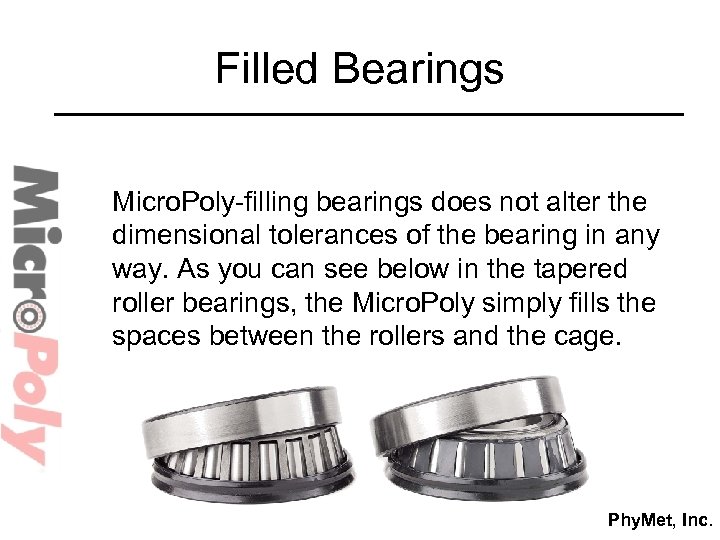

Filled Bearings Micro. Poly-filling bearings does not alter the dimensional tolerances of the bearing in any way. As you can see below in the tapered roller bearings, the Micro. Poly simply fills the spaces between the rollers and the cage. Phy. Met, Inc.

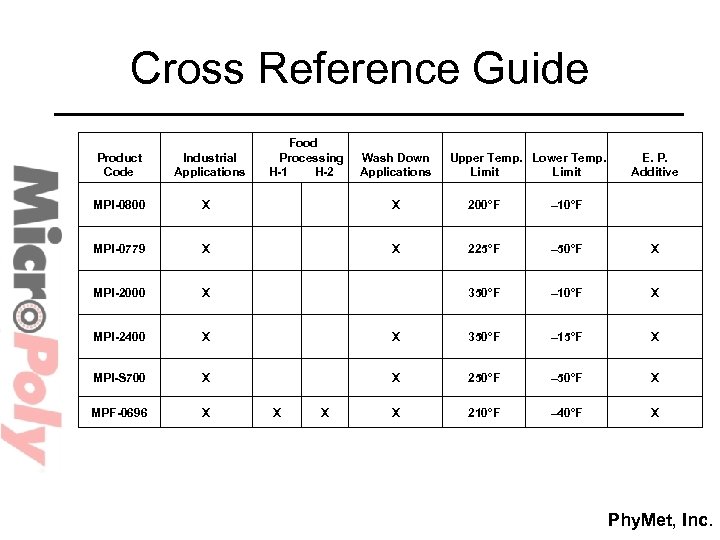

Cross Reference Guide Food Processing H-1 H-2 Product Code Industrial Applications MPI-0800 X X 200°F – 10°F MPI-0779 X X 225°F – 50°F X MPI-2000 X 350°F – 10°F X MPI-2400 X X 350°F – 15°F X MPI-S 700 X X 250°F – 50°F X MPF-0696 X X 210°F – 40°F X X X Wash Down Applications Upper Temp. Lower Temp. Limit E. P. Additive Phy. Met, Inc.

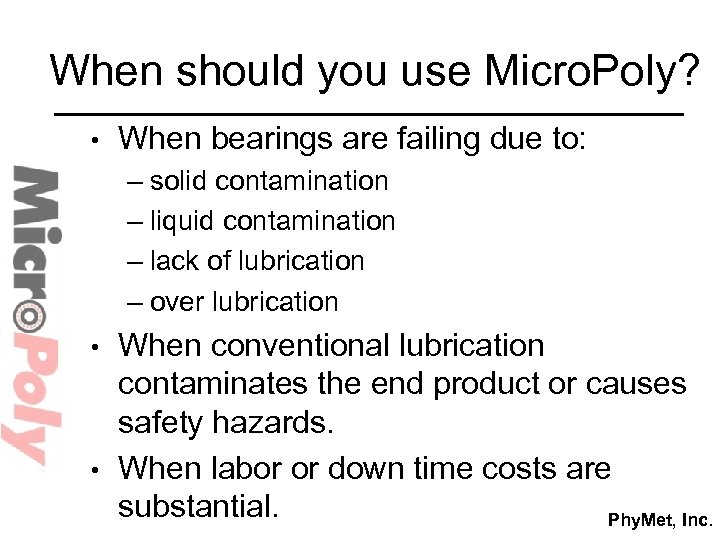

When should you use Micro. Poly? • When bearings are failing due to: – solid contamination – liquid contamination – lack of lubrication – over lubrication • • When conventional lubrication contaminates the end product or causes safety hazards. When labor or down time costs are substantial. Phy. Met, Inc.

Benefits of Micro. Poly Lubrication • • • Reduces costs associated with labor or down time due to bearing failure Reduces contamination Provides a maintenance-free bearing Extends bearing life Improves housekeeping by eliminating the dripping of grease and oil Phy. Met, Inc.

Benefits, cont. • Reduces scrap rate of parts caused by lubrication dripping onto parts • Provides lubrication to difficult to reach applications • In most cases, automatic lubrication systems can be eliminated Phy. Met, Inc.

Micro. Poly vs. Conventional Lubrication • • Grease - about 35% oil suspended in a thickener MPL - over 50% oil Grease - bearing is filled 1/3 to 1/2 full. Overfilling can cause churning. MPL - bearing is filled 100%. More oil is available for lubrication. Due to solid structure, there is no churning. Phy. Met, Inc.

Limitations • • Temperature Limitations – see Cross Reference Guide No direct contact with – Acids – Strong detergents • Speed Limitations All new applications should be reviewed with Phy. Met personnel. Phy. Met, Inc.

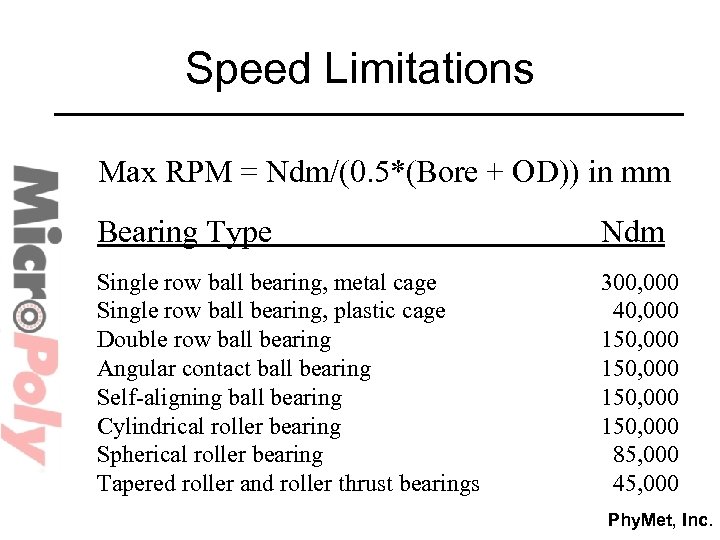

Speed Limitations Max RPM = Ndm/(0. 5*(Bore + OD)) in mm Bearing Type Ndm Single row ball bearing, metal cage Single row ball bearing, plastic cage Double row ball bearing Angular contact ball bearing Self-aligning ball bearing Cylindrical roller bearing Spherical roller bearing Tapered roller and roller thrust bearings 300, 000 40, 000 150, 000 85, 000 45, 000 Phy. Met, Inc.

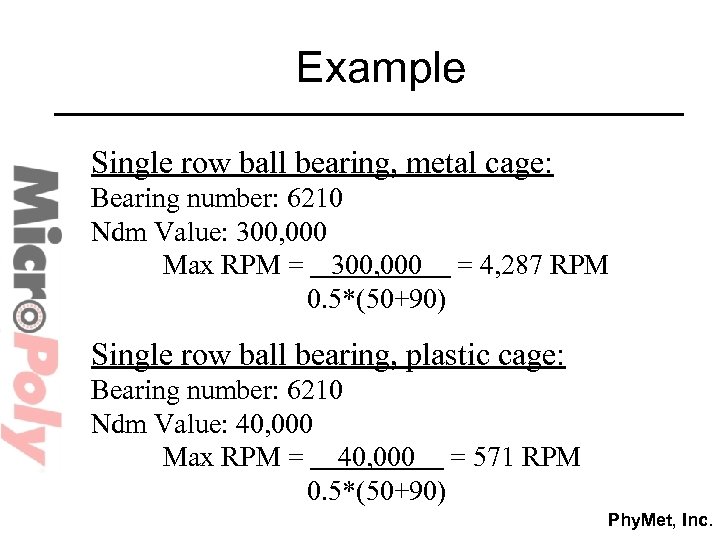

Example Single row ball bearing, metal cage: Bearing number: 6210 Ndm Value: 300, 000 Max RPM = 300, 000 = 4, 287 RPM 0. 5*(50+90) Single row ball bearing, plastic cage: Bearing number: 6210 Ndm Value: 40, 000 Max RPM = 40, 000 = 571 RPM 0. 5*(50+90) Phy. Met, Inc.

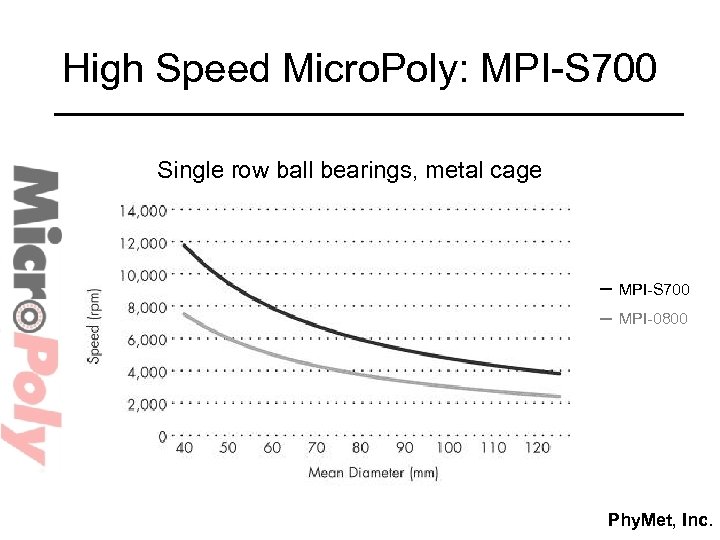

High Speed Micro. Poly: MPI-S 700 Single row ball bearings, metal cage MPI-S 700 MPI-0800 Phy. Met, Inc.

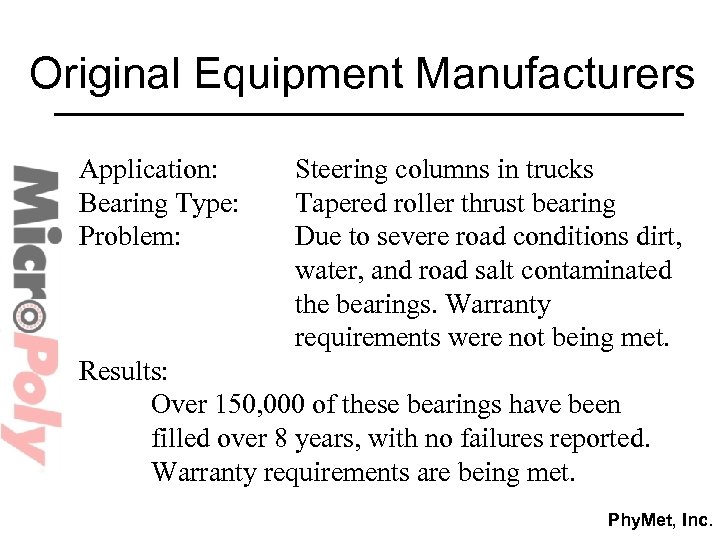

Original Equipment Manufacturers Application: Bearing Type: Problem: Steering columns in trucks Tapered roller thrust bearing Due to severe road conditions dirt, water, and road salt contaminated the bearings. Warranty requirements were not being met. Results: Over 150, 000 of these bearings have been filled over 8 years, with no failures reported. Warranty requirements are being met. Phy. Met, Inc.

Automotive Industry Application: Bearing Type: Conditions: Towmotors, front wheel spindles Tapered roller bearings Heavy load. Bearing life 3 - 12 months. Results: Bearing life extended to 3. 5 years. The automobile company saved $337, 134. Phy. Met, Inc.

Power Generating Industry Application: Bearing Type: Problem: Coal pulverizer grinding wheel Tapered roller bearings Coal dust caused bearing seizure, resulting in the dust igniting. Bearing life 9 months. Results: Bearing life extended to 10 years. Fires were eliminated. The company saves $250, 000 per year. Phy. Met, Inc.

Food Processing Industry Application: Bearing Type: Problem: Feather picker, chicken processing Single row ball bearing Washdown of the bearings with water and detergents causes premature bearing failure. Bearing life 3 -4 weeks. Results: So far bearings have lasted 9 weeks and are still running. Estimated savings $170, 000. Phy. Met, Inc.

Food Processing Industry Application: Bearing Type: Problem: Potato chip sizer UC 205 -16 Ball insert bearing Salt and other seasonings contaminated the bearings. Bearing life was 6 -8 weeks. Downtime costs are $25, 000 per hour. Results: Bearing life has been extended to 18 months. Estimated cost savings over a 6 year period: $4, 000. Phy. Met, Inc.

Metal Processing Industry Application: Bearing Type: Problem: Seal. Master SFT 35 E – 2 7/16” bore Housed ball bearing, 2 -bolt flange Buried in sulfur-contaminated sand. Bearing was contained with an end cap. Temperature 110°F. Bearing life 6 months. Results: Bearing life is now 12 months and the greasing schedule has been reduced. End cap was eliminated. Phy. Met, Inc.

Earth Moving Industry Application: Bearing Type: Problem: Trenching Equipment Guide wheels and idler wheels, 22308 spherical roller bearing (axle bearing), FYRP 2 ½” roller bearing Trenchers run in dusty, dirty, muddy conditions. Dirt and mud are pulled up into the bearings. Results: Life of the idler wheels and axle bearings was extended from one month to one year. Life of the FYRP bearing was extended from 2 months to Phy. Met, Inc. 2 years.

Micro. Poly Lubricants Phy. Met, Inc.

b7e6f2a0b37785995e974df31860352c.ppt