d307bff82b737e458026ca268a6bbaff.ppt

- Количество слайдов: 37

Business Trends Affecting Mc. Allen & Reynosa

City of Mc. Allen The City of Mc. Allen and M. E. D. C. work with Global Companies planning a strategic move or expansion to service their industry from a cost competitive market.

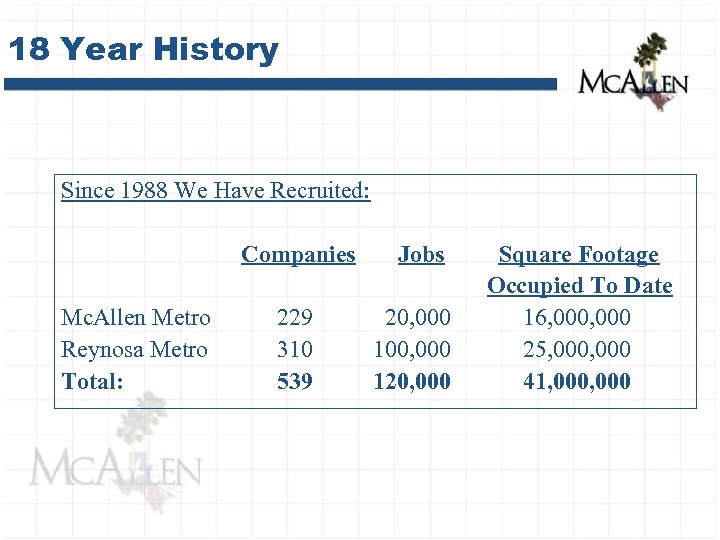

18 Year History Since 1988 We Have Recruited: Companies Mc. Allen Metro Reynosa Metro Total: 229 310 539 Jobs 20, 000 100, 000 120, 000 Square Footage Occupied To Date 16, 000 25, 000 41, 000

International Relationships The City of Mc. Allen & M. E. D. C. maintains a strong international relationship with Mexico. We work closely with Mexican officials in Reynosa, Tamaulipas, to attract new investment, develop infrastructure, enhance workforce education and training, and promote the construction of worker housing.

International Clients CANADA: EMU Plastics Progressive Molded Product Windsor Mold CHINA: GERMANY: Ganzhou China/Import Export Autech Draexlmaier Landis & Gyr Siemens Energy Siemens VDO Kern Liebers FINLAND: Unomedical, Inc. Nokia Mobile Phones Perlos Inc. ENGLAND: FRANCE: DENMARK: BSN Medical TI Group Automotive Systems Cinch Connectors Hutchinson Automotive Pechiney Plastics Valeo Electornics KOREA: LG Electronics (Zenith)

International Clients ITALY: Haemotronic JAPAN: Alcom Alps Automotive Bigston Corporation Fujitsu Ten GSW JVC Matsushita Electronic Mikuni Panasonic Service Company Sharp Shin Etsu Polymers MEXICO: Galvotec Alloys Sabritas Select Elastics NORWAY: Kongsberg Automotive SWITZERLAND: Siemens-Landis & Gyr SWEDEN: Atlas Copco Group Kuehne & Nagel TAIWAN: King’s Prosperity Industries UNITED STATES: Bissell, Inc. Black & Decker Brunswick C. R. Bard Corning Scientific Delphi Automotive Eaton Corporation Emerson Escalade Sports Hoffman Engineering Jabil Johnson Controls Kimball Maytag R. R. Donnelly Symbol Technologies TRW

Mc. Allen Residents

Reynosa Residents TI Automotive Symbol Technologies Draexlmaier Corning Cable Systems Delphi Fujitsu Ten ARC Automotive Mikuni

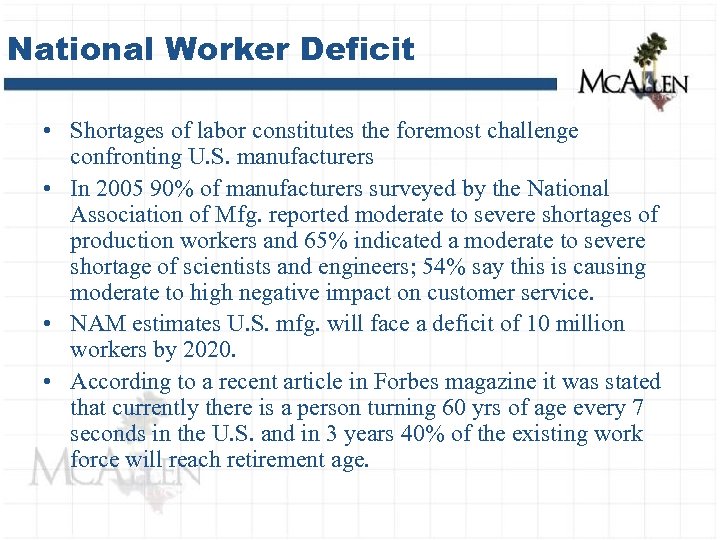

National Worker Deficit • Shortages of labor constitutes the foremost challenge confronting U. S. manufacturers • In 2005 90% of manufacturers surveyed by the National Association of Mfg. reported moderate to severe shortages of production workers and 65% indicated a moderate to severe shortage of scientists and engineers; 54% say this is causing moderate to high negative impact on customer service. • NAM estimates U. S. mfg. will face a deficit of 10 million workers by 2020. • According to a recent article in Forbes magazine it was stated that currently there is a person turning 60 yrs of age every 7 seconds in the U. S. and in 3 years 40% of the existing work force will reach retirement age.

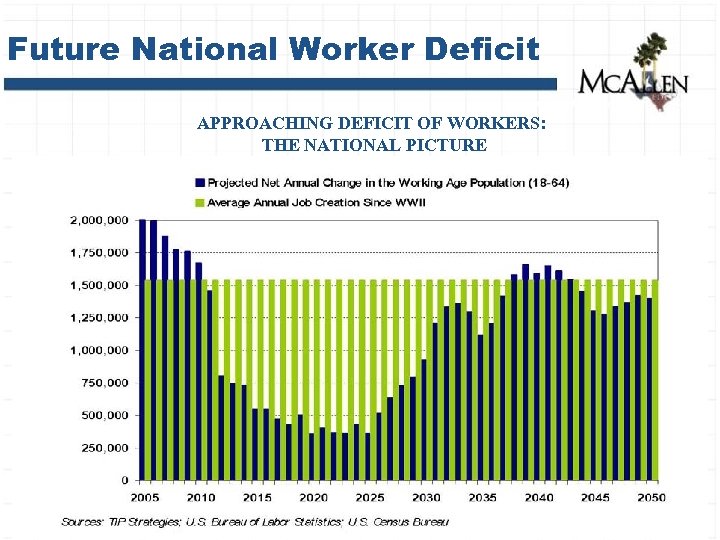

Future National Worker Deficit APPROACHING DEFICIT OF WORKERS: THE NATIONAL PICTURE

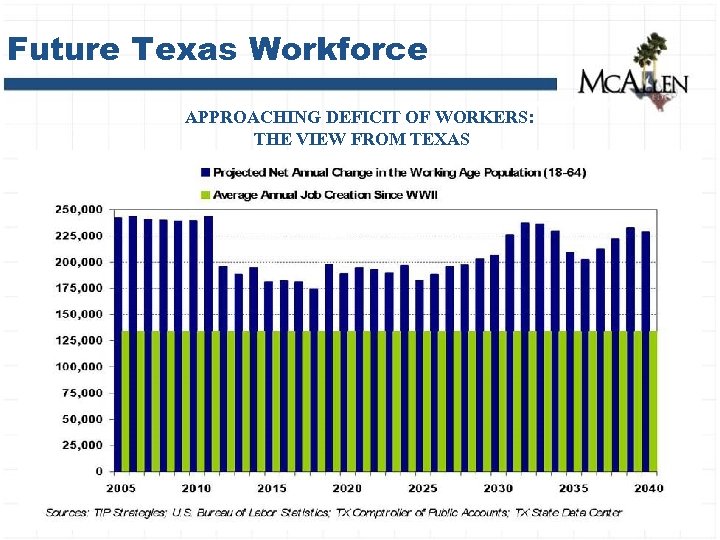

Future Texas Workforce APPROACHING DEFICIT OF WORKERS: THE VIEW FROM TEXAS

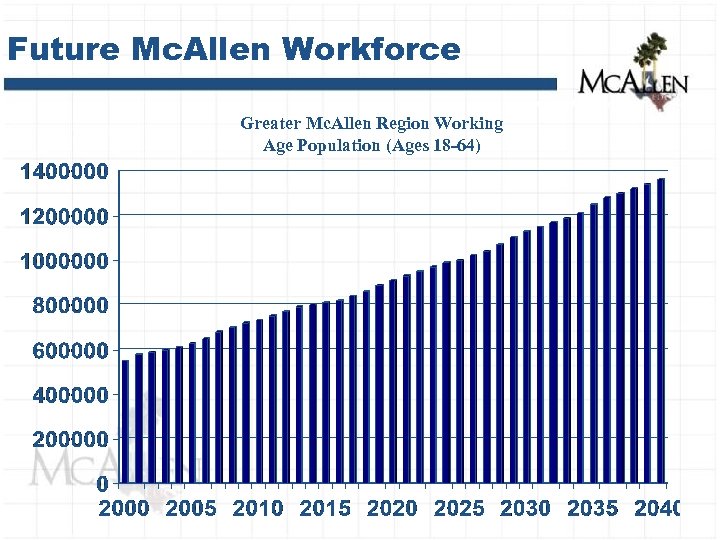

Future Mc. Allen Workforce Greater Mc. Allen Region Working Age Population (Ages 18 -64)

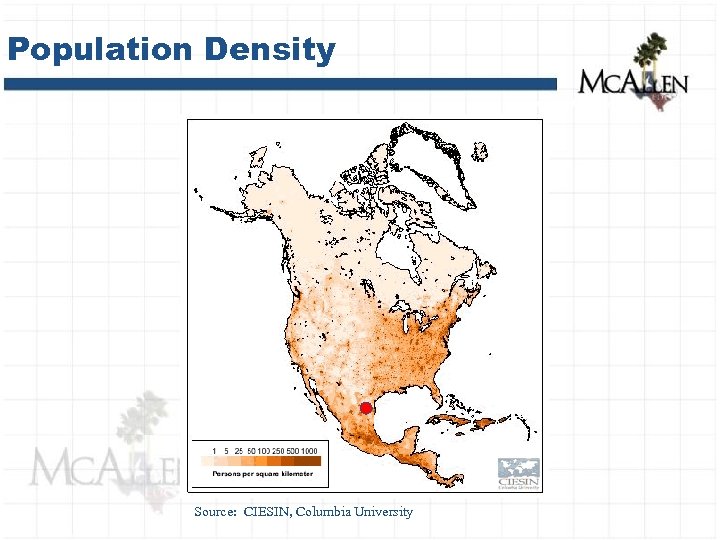

Population Density Source: CIESIN, Columbia University

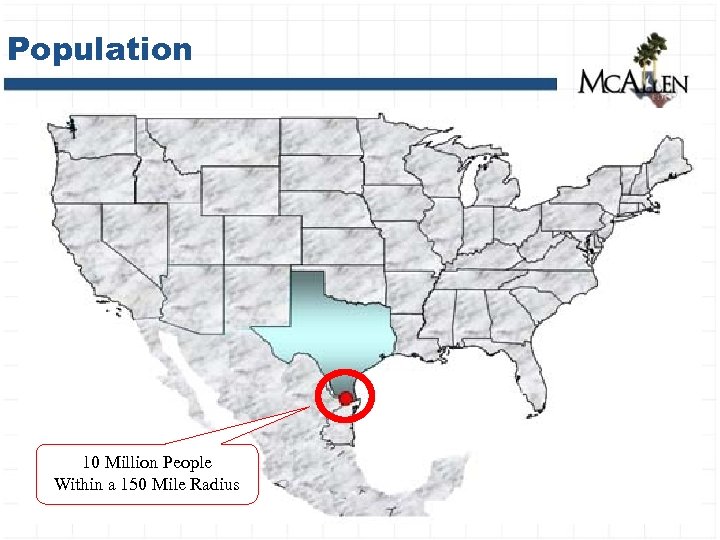

Population 10 Million People Within a 150 Mile Radius

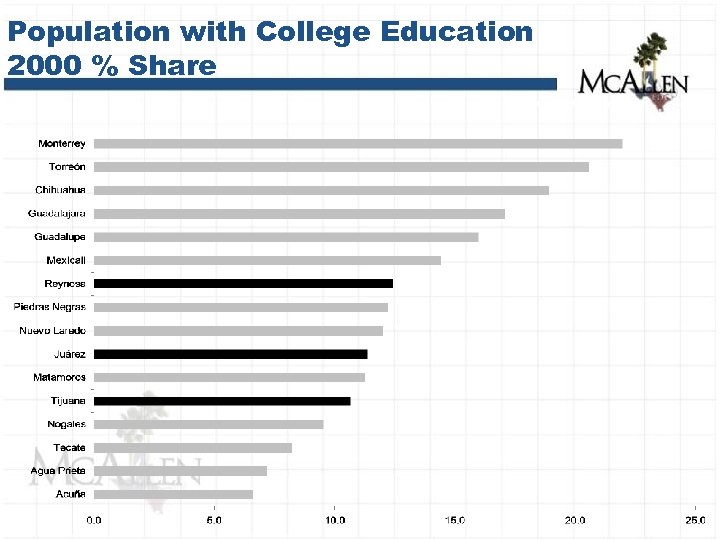

Population with College Education 2000 % Share

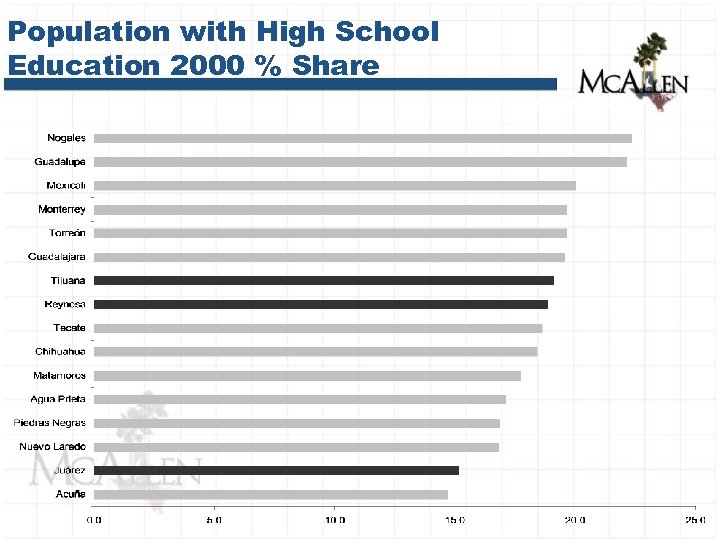

Population with High School Education 2000 % Share

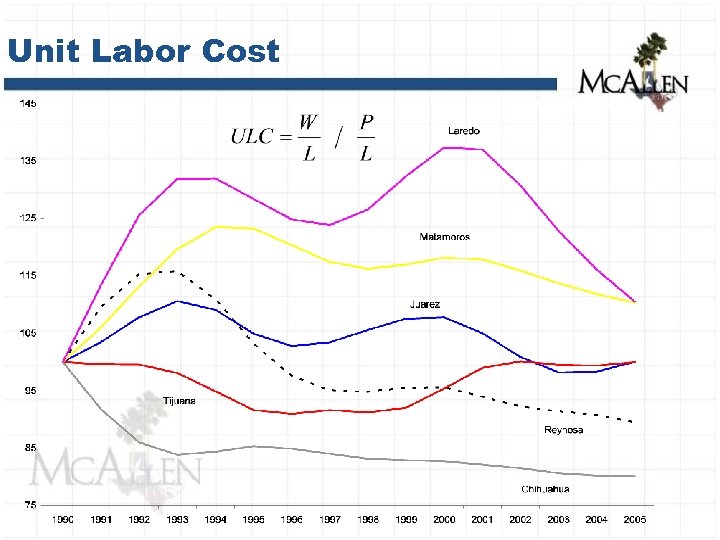

Unit Labor Cost

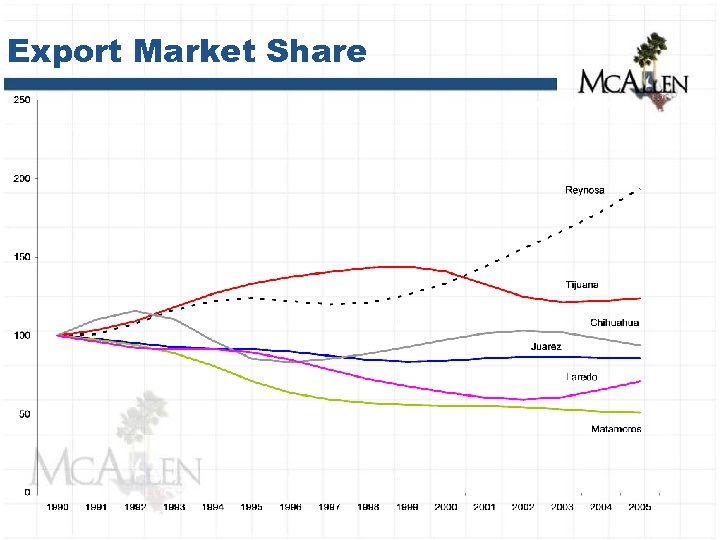

Export Market Share

Manufacturing Trends – Speed to Market and Customization • Companies have found a way to compete with low cost areas outside North America by encouraging customers to custom order with a short turn around time (24 -72 hours) • Increases customer satisfaction, reduces finished goods inventory, increases margins

This fundamentally changes how companies compete in the Global Marketplace • Past Minimum Requirements • Cost control, Total quality, Continuous Improvement • Future Current Requirements • Flexibility • Collaboration • Boundary spanning organization, and • Rapid response Extended Production Enterprise

Rapid Response Manufacturing Center

Viper Pro SLA System

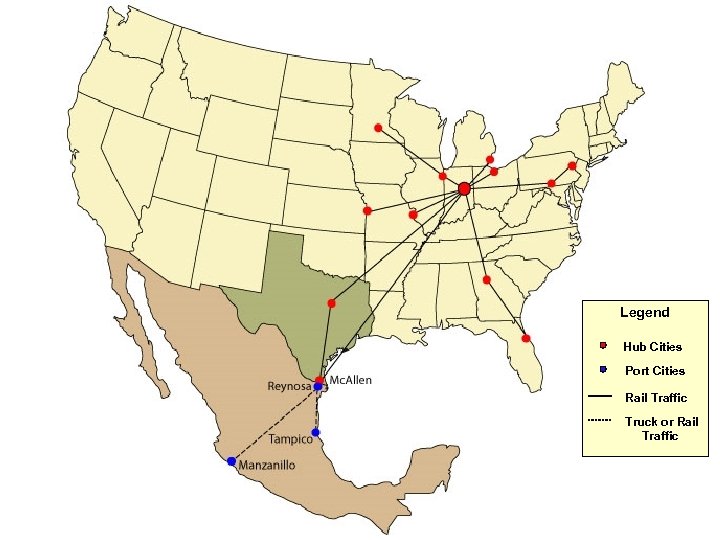

Emerging New Global Logistic Routes/Distribution Trends New Global Shipping Routes • 25% cost reduction over traditional routes • Avg 3 day reduction over traditional routes • Distribution of globally produced products from one point • Makes Texas the “ 3 rd Coast” Distance from Reynosa To: Miles Km Monterrey 140 225 Manzanillo 833 1341 Altamira 316 508 Mexico City 636 1024 Provides direct connection from one of the largest Cities in the world to the population centers of Texas.

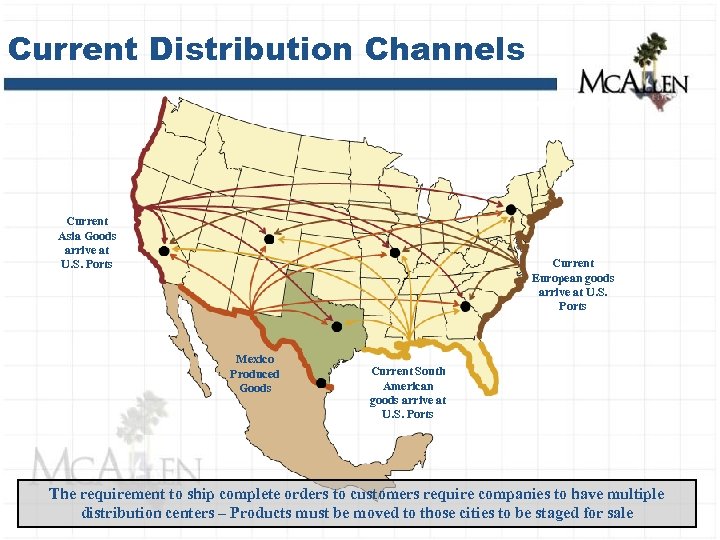

Current Distribution Channels Current Asia Goods arrive at U. S. Ports Current European goods arrive at U. S. Ports Mexico Produced Goods Current South American goods arrive at U. S. Ports The requirement to ship complete orders to customers require companies to have multiple distribution centers – Products must be moved to those cities to be staged for sale

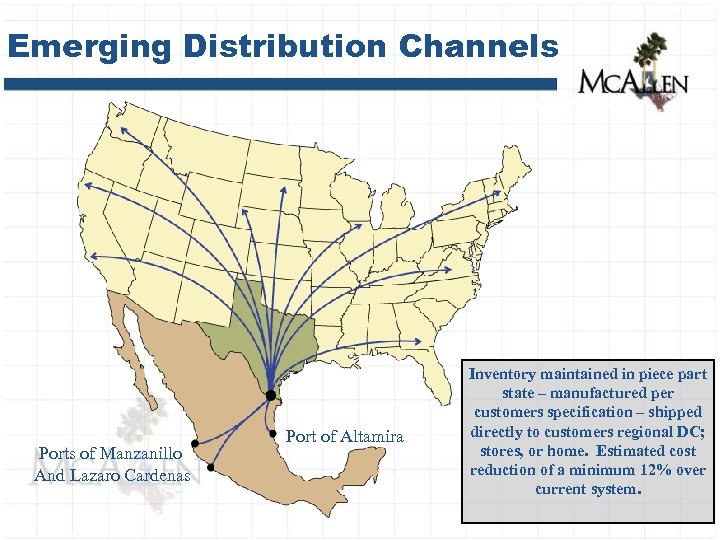

Emerging Distribution Channels Ports of Manzanillo And Lazaro Cardenas Port of Altamira Inventory maintained in piece part state – manufactured per customers specification – shipped directly to customers regional DC; stores, or home. Estimated cost reduction of a minimum 12% over current system.

Regional Multi. Modal Center for South Texas

Project Description • Procure funding to construct a Regional-Multi Modal Center adjacent to the Mc. Allen Foreign Trade Zone, and only minutes from the Pharr/Hidalgo ports of entry, and the soon to be constructed Anzalduas Bridge. • Funds will be used to build upon existing infrastructure and to improve the flow of Northbound goods through Hidalgo County to major U. S. population centers throughout the U. S. .

Strategic Objective • Establish a Regional Multi-Modal Center to achieve the following: • Improve the cost competitiveness of our local manufacturers • Minimize wear and tear on Texas and national highways • Reduce fuel consumption • Reduce truck emissions • Create Direct and Indirect jobs for our community • Establish alternate mode of transport for auto assembly plants • Support efforts to establish south Texas as a major North American • logistics and distribution hub with global access through Mexico ports (3 rd Coast concept)

What is Bi-Modal Transportation? • Enhanced motor carrier • Non-conventional intermodal

Road Railer Technology Contractors will pick up loaded trailers from shippers and take them to a train assembly terminal in the Mc. Allen Foreign Trade Zone

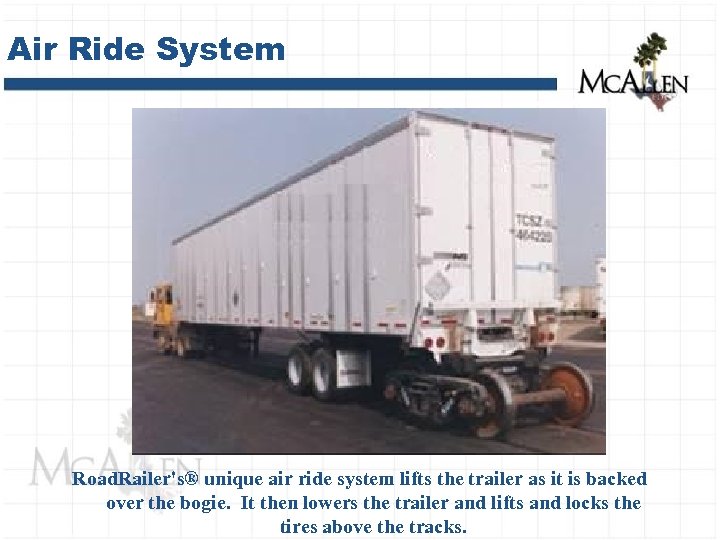

Air Ride System Road. Railer's® unique air ride system lifts the trailer as it is backed over the bogie. It then lowers the trailer and lifts and locks the tires above the tracks.

Local Delivery Contractors hookup and deliver trailers, providing premium service for their customers.

Multi-Use Facility Immediate: - Road Railer assembly facility - Cross docking - Equipment Storage / Maintenance Long Term: - “Double Stack” container services - RVSC overflow / Constructive Placement - Container Freight Station

Ware Rd Military Highwa y 23 rd St FTZ Proposed Site

Legend Hub Cities Port Cities Rail Traffic Truck or Rail Traffic

Reynosa, Mexico Del Norte Industrial hway deral Hig y Fe Monterre Villa Florida Industrial Anzalduas International Trade Bridge 2007 Proposed Assembly Plant Site Intermodal Yard State Highway Sharyland Plantation Existing Rail N

d307bff82b737e458026ca268a6bbaff.ppt