0b4331bd8fd2a49395729a071b2948a9.ppt

- Количество слайдов: 14

Business Planning and Execution Mr. Don Tison 28 March, 2012

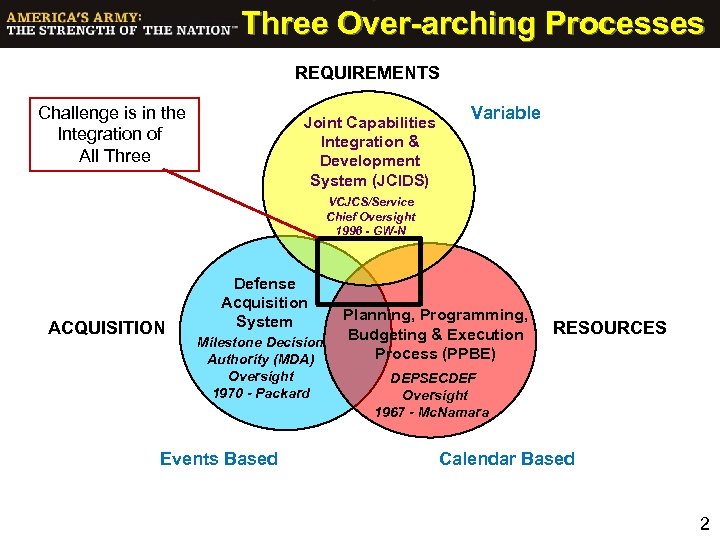

Three Over-arching Processes REQUIREMENTS Challenge is in the Integration of All Three Joint Capabilities Integration & Development System (JCIDS) Variable VCJCS/Service Chief Oversight 1996 - GW-N ACQUISITION Defense Acquisition System Milestone Decision Authority (MDA) Oversight 1970 - Packard Events Based Planning, Programming, Budgeting & Execution Process (PPBE) RESOURCES DEPSECDEF Oversight 1967 - Mc. Namara Calendar Based 2

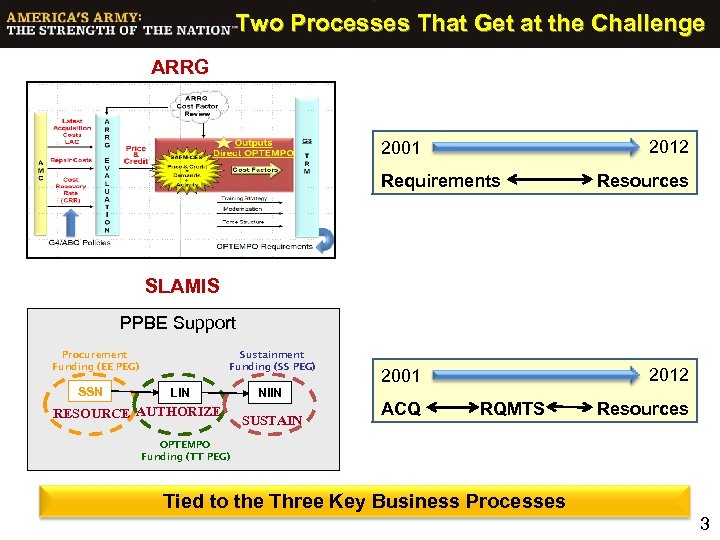

Two Processes That Get at the Challenge ARRG 2012 2001 Requirements Resources SLAMIS PPBE Support Procurement Funding (EE PEG) SSN Sustainment Funding (SS PEG) LIN RESOURCE AUTHORIZE NIIN SUSTAIN 2012 2001 ACQ RQMTS Resources OPTEMPO Funding (TT PEG) Tied to the Three Key Business Processes 3

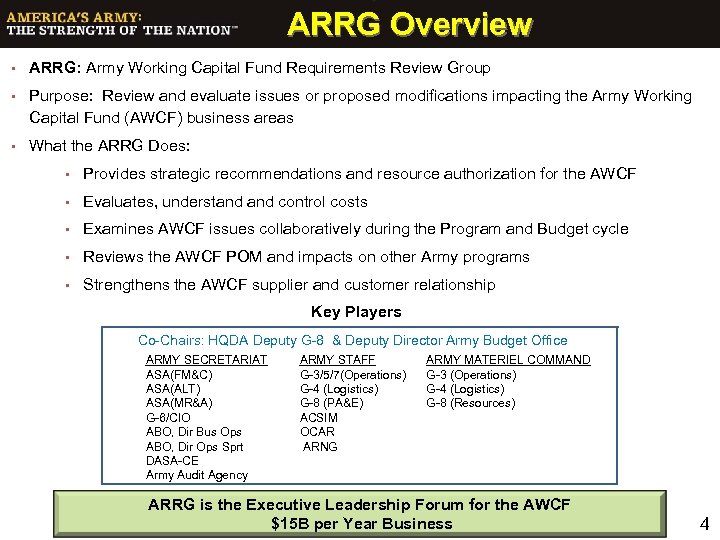

ARRG Overview • ARRG: Army Working Capital Fund Requirements Review Group • Purpose: Review and evaluate issues or proposed modifications impacting the Army Working Capital Fund (AWCF) business areas • What the ARRG Does: • Provides strategic recommendations and resource authorization for the AWCF • Evaluates, understand control costs • Examines AWCF issues collaboratively during the Program and Budget cycle • Reviews the AWCF POM and impacts on other Army programs • Strengthens the AWCF supplier and customer relationship Key Players Co-Chairs: HQDA Deputy G-8 & Deputy Director Army Budget Office ARMY SECRETARIAT ASA(FM&C) ASA(ALT) ASA(MR&A) G-6/CIO ABO, Dir Bus Ops ABO, Dir Ops Sprt DASA-CE Army Audit Agency ARMY STAFF G-3/5/7(Operations) G-4 (Logistics) G-8 (PA&E) ACSIM OCAR ARNG ARMY MATERIEL COMMAND G-3 (Operations) G-4 (Logistics) G-8 (Resources) ARRG is the Executive Leadership Forum for the AWCF $15 B per Year Business 4

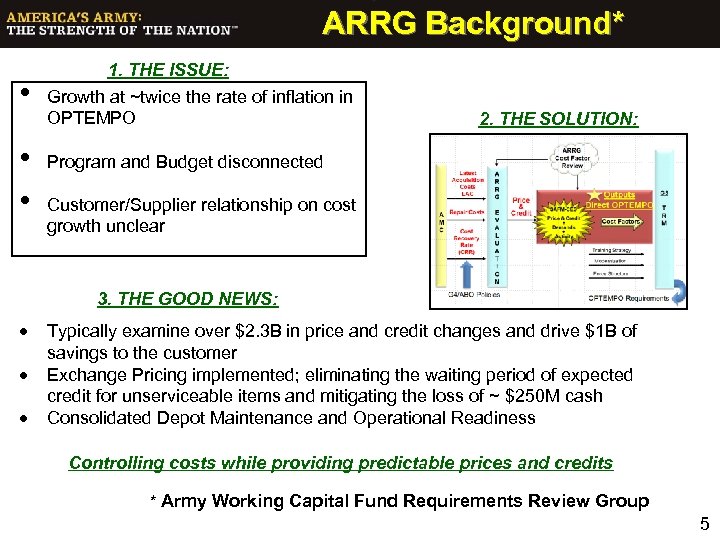

ARRG Background* • • • 1. THE ISSUE: Growth at ~twice the rate of inflation in OPTEMPO 2. THE SOLUTION: Program and Budget disconnected Customer/Supplier relationship on cost growth unclear 3. THE GOOD NEWS: · · · Typically examine over $2. 3 B in price and credit changes and drive $1 B of savings to the customer Exchange Pricing implemented; eliminating the waiting period of expected credit for unserviceable items and mitigating the loss of ~ $250 M cash Consolidated Depot Maintenance and Operational Readiness Controlling costs while providing predictable prices and credits * Army Working Capital Fund Requirements Review Group 5

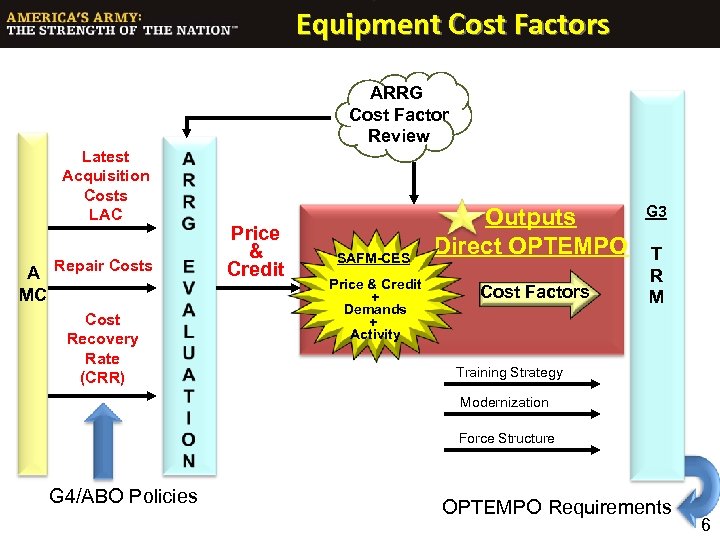

Equipment Cost Factors ARRG Cost Factor Review Latest Acquisition Costs LAC A MC Repair Costs Cost Recovery Rate (CRR) Price & Credit SAFM-CES Price & Credit + Demands + Activity Outputs Direct OPTEMPO Cost Factors G 3 T R M Training Strategy Modernization Force Structure G 4/ABO Policies OPTEMPO Requirements 6

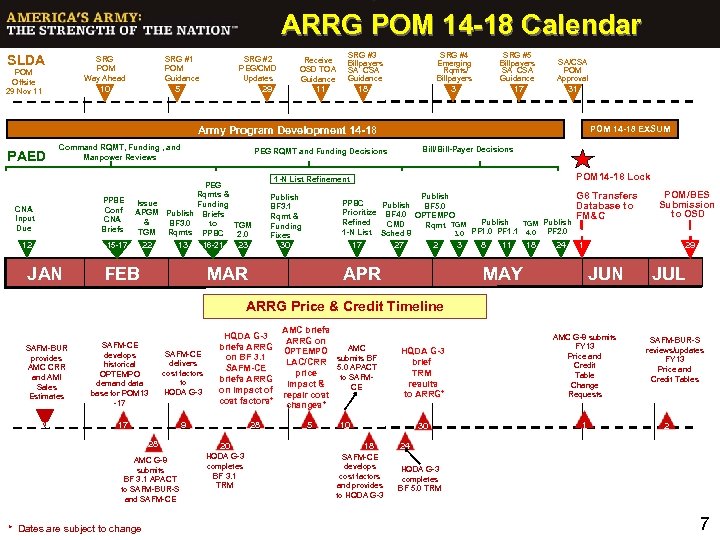

ARRG POM 14 -18 Calendar SLDA SRG POM Way Ahead POM Offsite 29 Nov 11 SRG #1 POM Guidance 10 SRG #2 PEG/CMD Updates 5 Receive OSD TOA Guidance 29 SRG #3 Billpayers SA CSA Guidance SRG #4 Emerging Rqmts/ Billpayers SRG #5 Billpayers SA CSA Guidance SA/CSA POM Approval 18 3 17 31 11 POM 14 -18 EXSUM Army Program Development 14 -18 PAED Command RQMT, Funding , and Manpower Reviews PEG Rqmts & PPBE Issue Funding Conf APGM Publish Briefs CNA & BF 3. 0 to TGM Briefs TGM Rqmts PPBC 2. 0 15 -17 16 -21 22 13 23 CNA Input Due 12 JAN FEB Bill/Bill-Payer Decisions PEG RQMT and Funding Decisions POM 14 -18 Lock 1 -N List Refinement Publish PPBC Publish BF 5. 0 Prioritize BF 4. 0 OPTEMPO Publish Refined TGM Publish CMD Rqmt TGM PF 2. 0 1 -N List Sched 8 3. 0 PF 1. 1 4. 0 Publish BF 3. 1 Rqmt & Funding Fixes 30 17 MAR 27 2 APR 3 8 11 18 24 G 8 Transfers Database to FM&C POM/BES Submission to OSD 1 MAY 29 JUN JUL ARRG Price & Credit Timeline SAFM-BUR provides AMC CRR and AMI Sales Estimates 25 SAFM-CE develops historical OPTEMPO demand data base for POM 13 -17 SAFM-CE delivers cost factors to HQDA G-3 17 9 28 AMC G-8 submits BF 3. 1 APACT to SAFM-BUR-S and SAFM-CE * Dates are subject to change HQDA G-3 briefs ARRG on BF 3. 1 SAFM-CE briefs ARRG on impact of cost factors* 28 20 HQDA G-3 completes BF 3. 1 TRM AMC briefs ARRG on AMC OPTEMPO submits BF LAC/CRR 5. 0 APACT price to SAFMimpact & CE repair cost changes* 5 HQDA G-3 brief TRM results to ARRG* AMC G-8 submits FY 13 Price and Credit Table Change Requests 30 1 10 18 SAFM-CE develops cost factors and provides to HQDA G-3 SAFM-BUR-S reviews/updates FY 13 Price and Credit Tables 2 24 HQDA G-3 completes BF 5. 0 TRM 7

Some ARRG Successes • FY 05: Consolidated Depot Maintenance and Ordnance Activity Groups eliminating redundant efforts preparing separate budget submissions • FY 07: Evaluated over $50 B of OPTEMPO requirements, examined $2. 3 B of Price & Credit changes and drove $1 B of customer savings • FY 09: MRAP FY 11 -15 Sustainment. ARRG initiated actions to migrate MRAP into base funding, and actions that led to Army decisions to retain ~19 K of the most effective and supportable MRAP variants. • FY 10: ARRG initiated actions resulting in Aviation component reliability improving for 19 of 25 top cost drivers, with a projected $630 M return on investment over 10 years. • FY 10: ARRG guidance on developing cost factors resulted in a $1. 2 B cost avoidance for POM 12 -16, with a reduction in FY 12 demands of $229. 8 M • FY 11: For POM 13 -17, the ARRG evaluated over $10 B of annual OPTEMPO requirements and drove savings through demand adjustments and improved cost estimation • Reduced the AWCF cost recovery rate from 15. 9% to $14. 1%. This reduced OPTEMPO costs by $55. 5 M, passing along savings to AWCF customers • Collective ARRG analysis generated a $1. 3 B reduction in OPTEMPO requirements 8

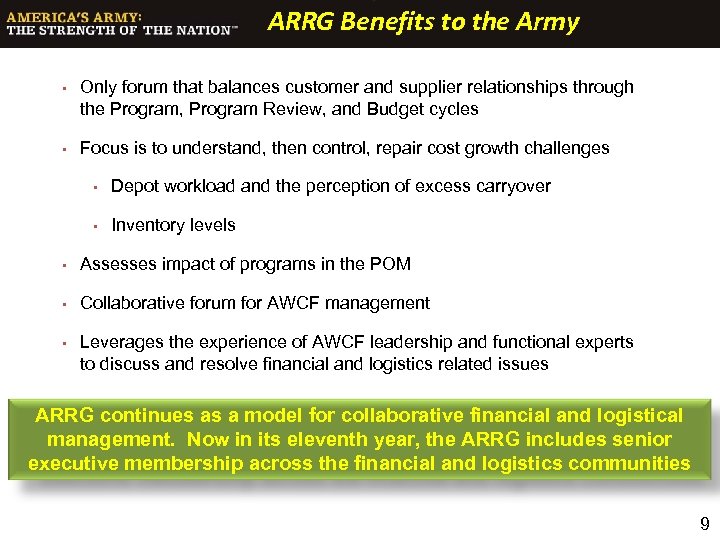

ARRG Benefits to the Army • Only forum that balances customer and supplier relationships through the Program, Program Review, and Budget cycles • Focus is to understand, then control, repair cost growth challenges • Depot workload and the perception of excess carryover • Inventory levels • Assesses impact of programs in the POM • Collaborative forum for AWCF management • Leverages the experience of AWCF leadership and functional experts to discuss and resolve financial and logistics related issues ARRG continues as a model for collaborative financial and logistical management. Now in its eleventh year, the ARRG includes senior executive membership across the financial and logistics communities 9

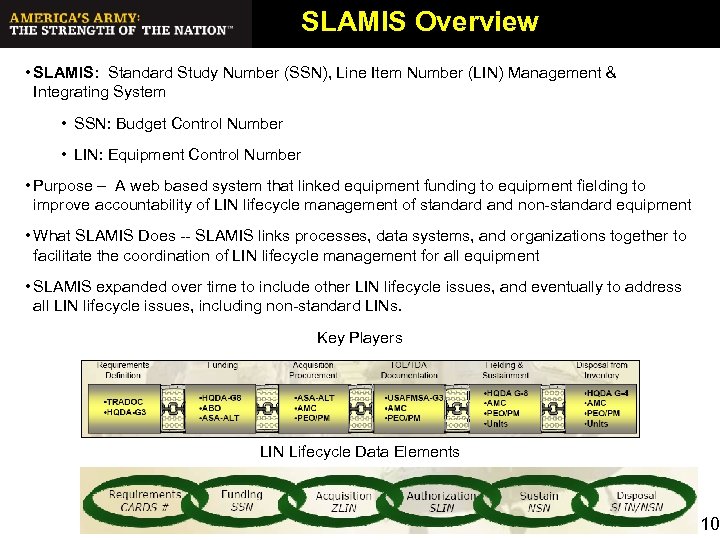

SLAMIS Overview • SLAMIS: Standard Study Number (SSN), Line Item Number (LIN) Management & Integrating System • SSN: Budget Control Number • LIN: Equipment Control Number • Purpose – A web based system that linked equipment funding to equipment fielding to improve accountability of LIN lifecycle management of standard and non-standard equipment • What SLAMIS Does -- SLAMIS links processes, data systems, and organizations together to facilitate the coordination of LIN lifecycle management for all equipment • SLAMIS expanded over time to include other LIN lifecycle issues, and eventually to address all LIN lifecycle issues, including non-standard LINs. Key Players LIN Lifecycle Data Elements 10

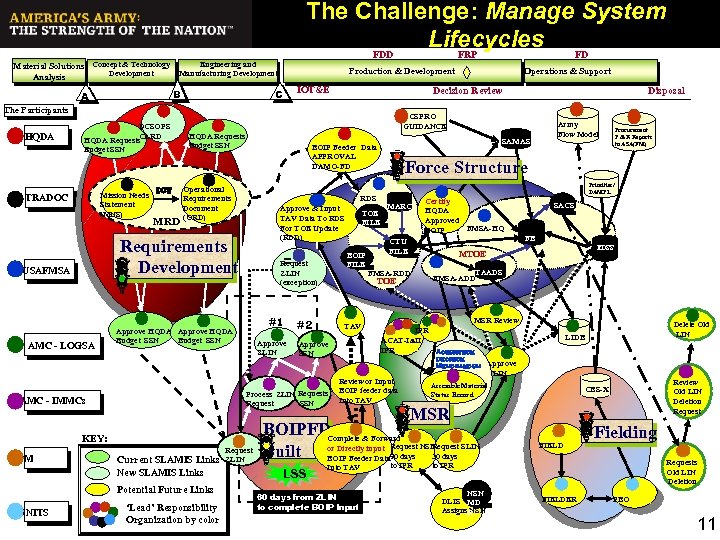

The Challenge: Manage System Lifecycles FD FDD FRP Engineering and Material Solutions Concept & Technology Development Manufacturing Development Analysis B A Production & Development C IOT&E HQDA Mission Needs ICT Statement (MNS) TRADOC MRD DCSPRO GUIDANCE HQDA Requests Budget SSN AMC - LOGSA Operational Requirements Document (ORD) KEY: PM Approve ZLIN #2 TAV Approve SSN Request ZLIN Links. ZLIN Current SLAMIS New SLAMIS Links ‘Lead’ Responsibility Organization by color MARC Certify HQDA Approved FMSA-HQ BOIP CTU FILE FMSA-RDD 60 days from ZLIN to complete BOIP Input FB EDSS TAADS FMSA-ADD MSR Review IPR ACAT-I&II IPR Review or Input BOIP feeder data Into TAV SACS MTOE to IPR Delete Old LIN LIDB Acquisition Decision Memorandum Approve SLIN Assemble Material Status Record MSR BOIPFD Complete & Forward Request Built or Directly input Request NSN days SLIN 30 BOIP Feeder Data 90 days LSS Procurement P & R Reports to ASA(FM) Force Structure TOE Process ZLIN Requests SSN Request Potential Future Links UNITS = Request ZLIN (exception) #1 TOE FILE BOIP FILE Army Flow Model Priorities/ DAMPL RDS Approve & Input TAV Data To RDS For TOE Update (RDD) Approve HQDA Budget SSN AMC - IMMCs SAMAS BOIP Feeder Data APPROVAL DAMO-FD Requirements Development USAFMSA Disposal Decision Review The Participants DCSOPS CARD HQDA Requests Budget SSN Operations & Support Review Old LIN Deletion Request CBS-X FIELD Fielding Requests Old LIN Deletion to IPR NSN DLIS MD Assigns. R NSN FIELDER PBO 11

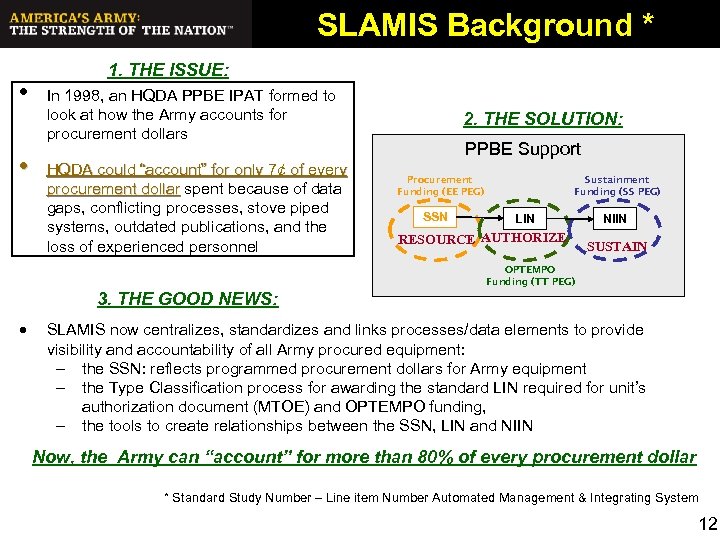

SLAMIS Background * • • 1. THE ISSUE: In 1998, an HQDA PPBE IPAT formed to look at how the Army accounts for procurement dollars HQDA could “account” for only 7¢ of every procurement dollar spent because of data gaps, conflicting processes, stove piped systems, outdated publications, and the loss of experienced personnel 2. THE SOLUTION: PPBE Support Procurement Funding (EE PEG) SSN Sustainment Funding (SS PEG) LIN RESOURCE AUTHORIZE NIIN SUSTAIN OPTEMPO Funding (TT PEG) 3. THE GOOD NEWS: · SLAMIS now centralizes, standardizes and links processes/data elements to provide visibility and accountability of all Army procured equipment: – the SSN: reflects programmed procurement dollars for Army equipment – the Type Classification process for awarding the standard LIN required for unit’s authorization document (MTOE) and OPTEMPO funding, – the tools to create relationships between the SSN, LIN and NIIN Now, the Army can “account” for more than 80% of every procurement dollar * Standard Study Number – Line item Number Automated Management & Integrating System 12

SLAMIS – Benefits to the Army • Integrates relational data for managing major items throughout their life cycle Requiring Funding Procuring Fielding Accounting Sustaining Disposing • Integrates with key Logistics, Acquisition, and financing requirements systems • Improves programming and budgeting decisions for procurement and sustainment • Highlights gaps and friction between major management systems • Provides framework to resolve emerging life-cycle management issues • Provides linkage for tracking rapid transition of items from non-standard to standard 13

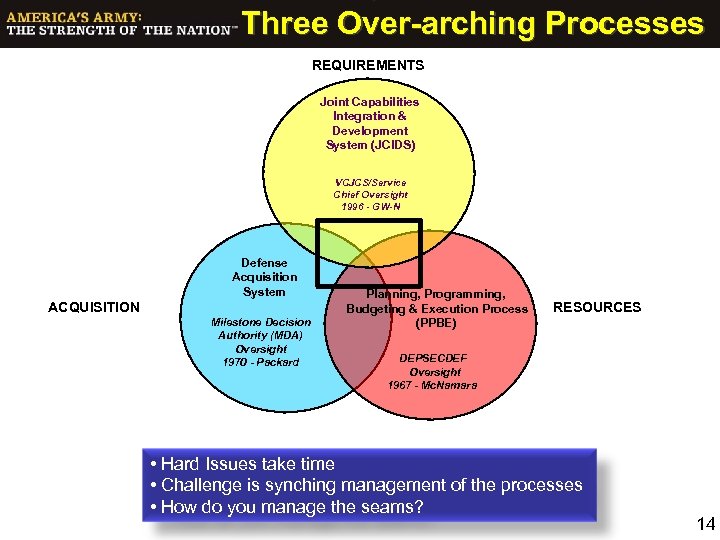

Three Over-arching Processes REQUIREMENTS Joint Capabilities Integration & Development System (JCIDS) VCJCS/Service Chief Oversight 1996 - GW-N Defense Acquisition System ACQUISITION Milestone Decision Authority (MDA) Oversight 1970 - Packard Planning, Programming, Budgeting & Execution Process (PPBE) RESOURCES DEPSECDEF Oversight 1967 - Mc. Namara • Hard Issues take time • Challenge is synching management of the processes • How do you manage the seams? 14

0b4331bd8fd2a49395729a071b2948a9.ppt