Semenko S.O presentation Porto.pptx

- Количество слайдов: 12

BUSINESS – PLAN The model for the decision, modernization and development of metallurgical production S. O. Semenko National Metallurgical Academy of Ukraine semenko 92@mail. ru V. I. Shatokha National Metallurgical Academy of Ukraine Shatokha@metal. nmetau. edu. ua Structural Measures Tempus Project «Support of innovations through improvement of regulatory framework for higher education in Ukraine» 530158 TEMPUS – 1 - 2012 1 – SE-TEMPUSSMHES

Project Summary The are many technologies for reduction greenhouse gases emissions in ferrous metallurgy. This work is designed to help decision-making for the production of steel in accordance with the provisions of the environment on greenhouse gases emissions. The model is designed in Excel and 3 Dmax and it can show real information about greenhouse gases emissions in different metallurgical enterprises.

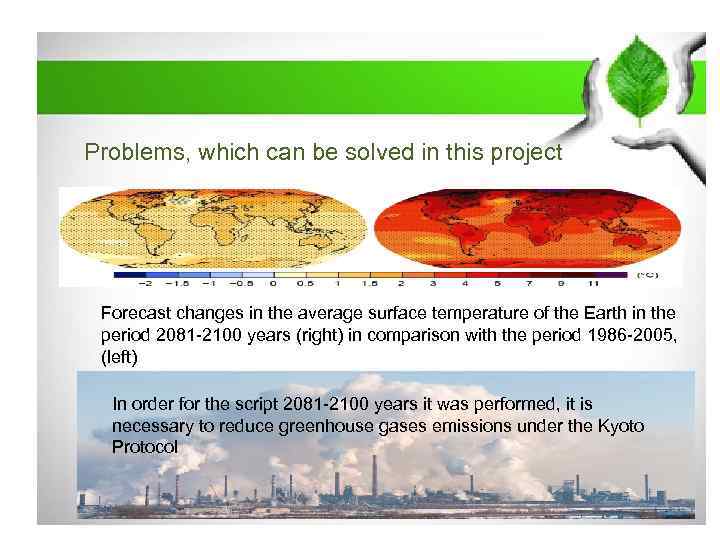

Problems, which can be solved in this project Forecast changes in the average surface temperature of the Earth in the period 2081 -2100 years (right) in comparison with the period 1986 -2005, (left) In order for the script 2081 -2100 years it was performed, it is necessary to reduce greenhouse gases emissions under the Kyoto Protocol

Marketing After the model is complete, it will be proposed on the other plants in the world. Accent: constructing factories and modernization of plants

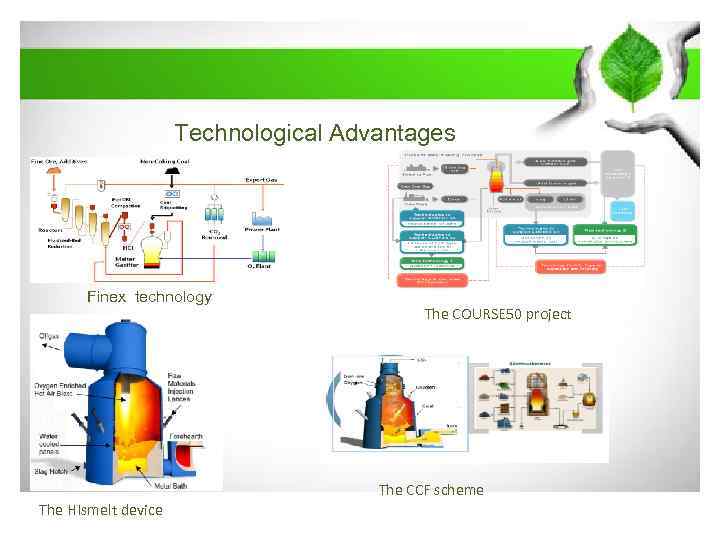

Technological Advantages Finex technology The COURSE 50 project The CCF scheme The HIsmelt device

Market Opportunity This model is relevant for all countries, which signed the Kyoto Protocol Dynamics of CO 2 emissions in the steel industry of some countries in the world, 1990 -2010 years. All of these countries have signed the Kyoto Protocol

The main stages Overview of global developments on greenhouse gases emissions in the steel industry – 01. 11. 2014 – 31. 01. 2015 Calculation of energy and environmental efficiency – 01. 02. 2015 – 01. 03. 2015 The calculation of economic aspects of the new technologies introduction – 03. 2015 – 05. 2015 Creating the model – 05. 2015 – 11. 2015 Model verification by tester – 11. 2015 – 04. 2016

Competition Competitor: 1) P. A. Kokorin – software complex was developed «Information system for inventory and monitoring of greenhouse gases» This model has advantages before the Kokorin’s model: - cheaper price; - more extensive theoretical base; Our competitor has advantage in time and hardware, but our advantage is software design and theoretical base.

Business Model The steel production in Germany on the Tyssen. Krupp company – 7 mil. tons In long term plans – increase to 7. 5 mil. tons The alleged fee for excess CO 2 emission – 20 euro/ton

The change of the production process The blast furnace destruction Construction of CCF device– 150 millions Constuction of HIsmelt – 170 millions The payback period – 5 years

The Team Research team: National Metallurgical Academy of Ukraine Team of business partners The command of 3 D designers from China «Jiatong»

Fund Raising 1. The acquisition of licensed software– 5000$ 2. The payment of 3 D designers – 10000$ 3. The payment of tester services– 10000$ 4. The cost of patenting– 500$

Semenko S.O presentation Porto.pptx