136decab30428a7341c919b0a8f62580.ppt

- Количество слайдов: 32

Business Development and Carbon Capture: Future Technologies for Green Energy Christopher W. Jones Georgia Institute of Technology School of Chemical & Biomolecular Engineering Atlanta, GA 30332, USA Forum on Green Entrepreneurship Athens, Greece Tuesday, July 8, 2008

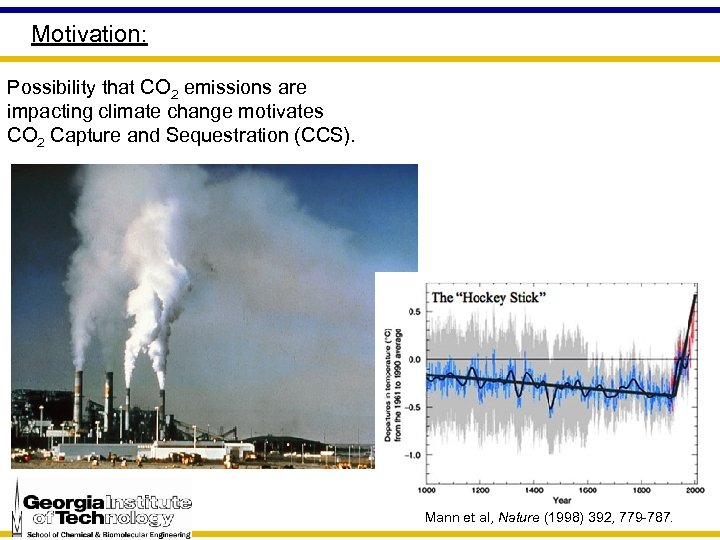

Motivation: Possibility that CO 2 emissions are impacting climate change motivates CO 2 Capture and Sequestration (CCS). Mann et al, Nature (1998) 392, 779 -787.

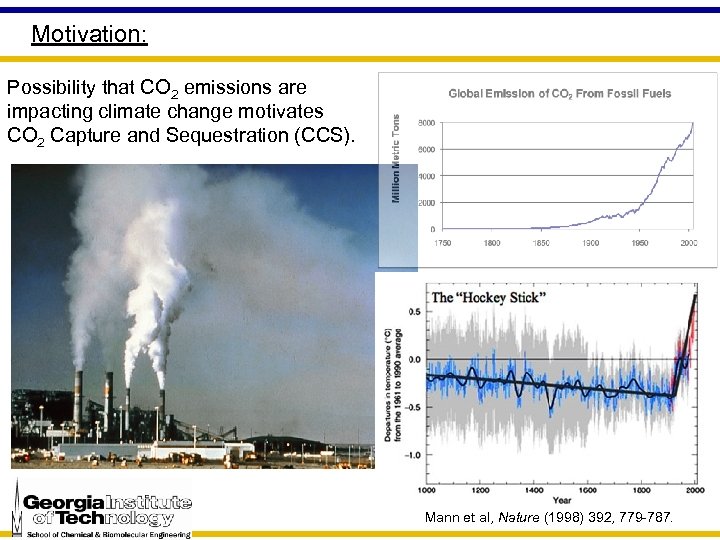

Motivation: Possibility that CO 2 emissions are impacting climate change motivates CO 2 Capture and Sequestration (CCS). Mann et al, Nature (1998) 392, 779 -787.

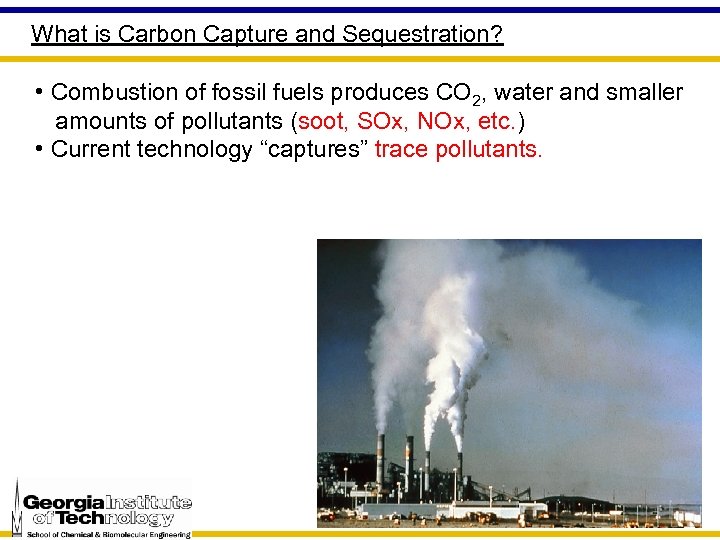

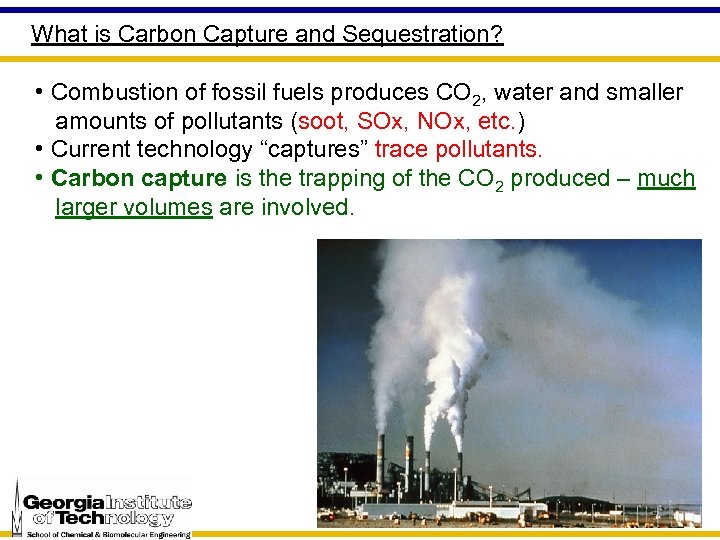

What is Carbon Capture and Sequestration? • Combustion of fossil fuels produces CO 2, water and smaller amounts of pollutants (soot, SOx, NOx, etc. )

What is Carbon Capture and Sequestration? • Combustion of fossil fuels produces CO 2, water and smaller amounts of pollutants (soot, SOx, NOx, etc. ) • Current technology “captures” trace pollutants.

What is Carbon Capture and Sequestration? • Combustion of fossil fuels produces CO 2, water and smaller amounts of pollutants (soot, SOx, NOx, etc. ) • Current technology “captures” trace pollutants. • Carbon capture is the trapping of the CO 2 produced – much larger volumes are involved.

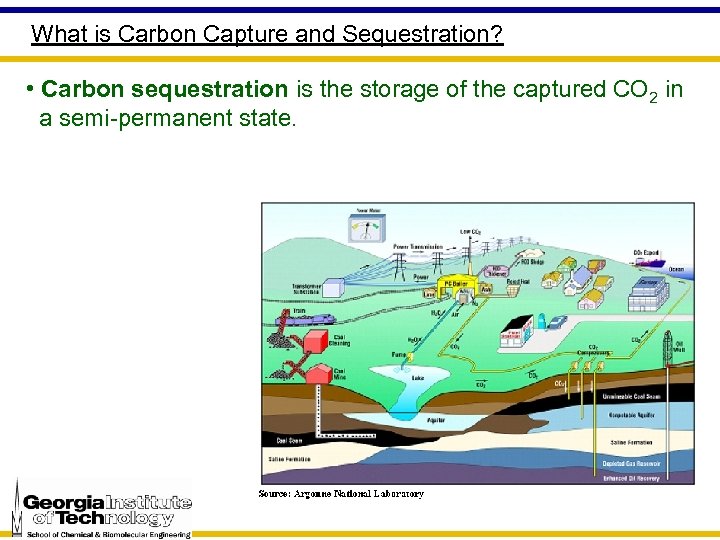

What is Carbon Capture and Sequestration? • Carbon sequestration is the storage of the captured CO 2 in a semi-permanent state.

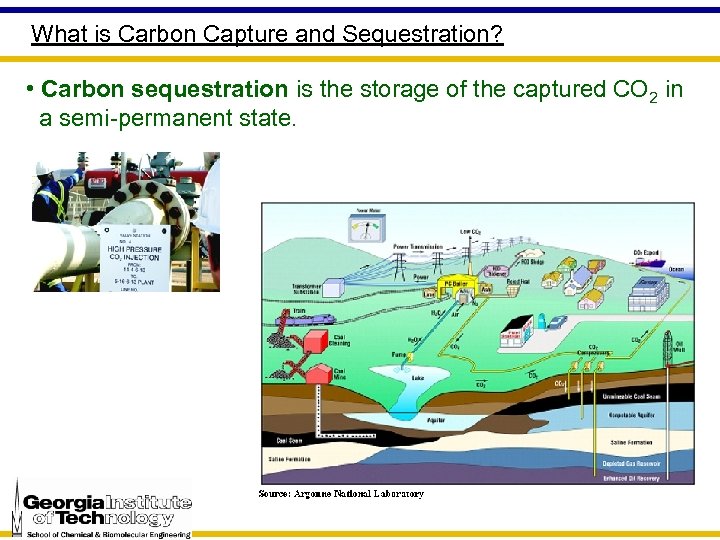

What is Carbon Capture and Sequestration? • Carbon sequestration is the storage of the captured CO 2 in a semi-permanent state.

Business Opportunities in CCS: • Mature technology exists today that can allow CO 2 capture – “liquid amine absorption” – but it is expensive and inefficient.

Business Opportunities in CCS: • Mature technology exists today that can allow CO 2 capture – “liquid amine absorption”– but it is expensive and inefficient. • Implementation of standard technology with coal-fired power plants for CCS in the USA would lead to ~50 -100% increase in the cost of electricity.

Business Opportunities in CCS: • Mature technology exists today that can allow CO 2 capture – “liquid amine absorption”– but it is expensive and inefficient. • Implementation of standard technology with coal-fired power plants for CCS in the USA would lead to ~50 -100% increase in the cost of electricity. • Most of the cost is associated with capture, not sequestration.

Business Opportunities in CCS: • Mature technology exists today that can allow CO 2 capture – “liquid amine absorption” – but it is expensive and inefficient. • Implementation of standard technology with coal-fired power plants for CCS in the USA would lead to ~50 -100% increase in the cost of electricity. • Most of the cost is associated with capture, not sequestration. • Thus, new technology is needed that allows for more cost-effective CO 2 capture.

Georgia Tech CO 2 Capture Program: Vision: Develop paradigm-shifting technology that can drastically reduce the cost of CO 2 capture from flue gas streams.

Georgia Tech CO 2 Capture Program: Vision: Develop paradigm-shifting technology that can drastically reduce the cost of CO 2 capture from flue gas streams. Approach: Combine cutting-edge new CO 2 -adsorbing materials with new efficient processing approaches.

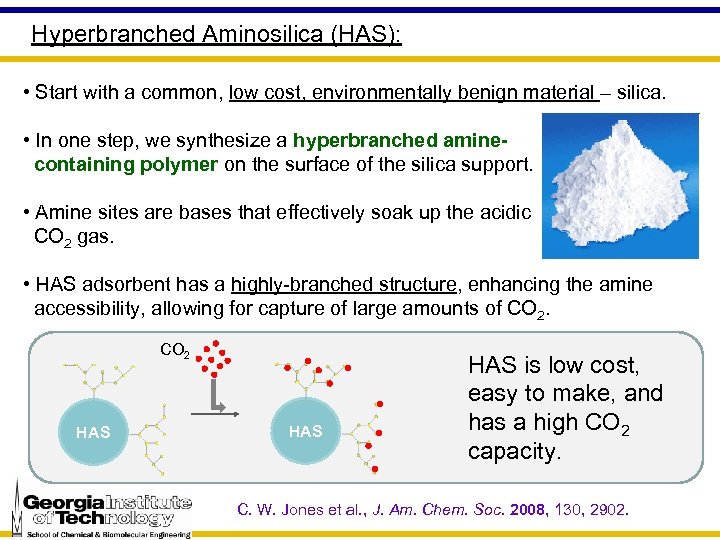

Georgia Tech CO 2 Capture Program: Vision: Develop paradigm-shifting technology that can drastically reduce the cost of CO 2 capture from flue gas streams. Approach: Combine cutting-edge new CO 2 -adsorbing materials with new efficient processing approaches. Working with the US National Energy Technology Laboratory, we have developed a promising new material – a hyperbranched aminosilica material – that is: (i) low in cost (ii) easy to make (iii) has a very high CO 2 capacity.

Hyperbranched Aminosilica (HAS): • Start with a common, low cost, environmentally benign material – silica.

Hyperbranched Aminosilica (HAS): • Start with a common, low cost, environmentally benign material – silica. • In one step, we synthesize a hyperbranched aminecontaining polymer on the surface of the silica support. • Amine sites are bases that effectively soak up the acidic CO 2 gas.

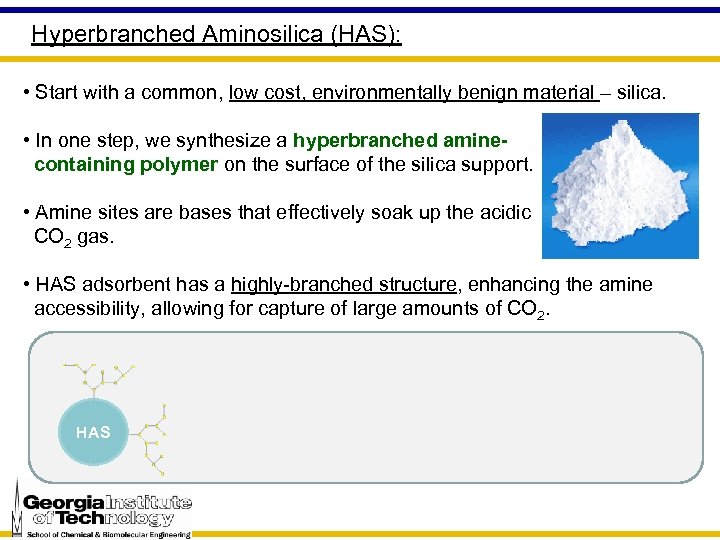

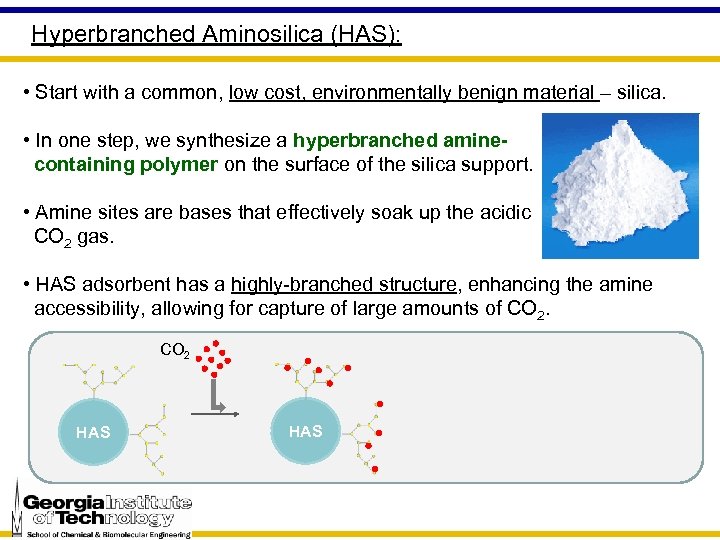

Hyperbranched Aminosilica (HAS): • Start with a common, low cost, environmentally benign material – silica. • In one step, we synthesize a hyperbranched aminecontaining polymer on the surface of the silica support. • Amine sites are bases that effectively soak up the acidic CO 2 gas. • HAS adsorbent has a highly-branched structure, enhancing the amine accessibility, allowing for capture of large amounts of CO 2. HAS

Hyperbranched Aminosilica (HAS): • Start with a common, low cost, environmentally benign material – silica. • In one step, we synthesize a hyperbranched aminecontaining polymer on the surface of the silica support. • Amine sites are bases that effectively soak up the acidic CO 2 gas. • HAS adsorbent has a highly-branched structure, enhancing the amine accessibility, allowing for capture of large amounts of CO 2 HAS

Hyperbranched Aminosilica (HAS): • Start with a common, low cost, environmentally benign material – silica. • In one step, we synthesize a hyperbranched aminecontaining polymer on the surface of the silica support. • Amine sites are bases that effectively soak up the acidic CO 2 gas. • HAS adsorbent has a highly-branched structure, enhancing the amine accessibility, allowing for capture of large amounts of CO 2 HAS HAS is low cost, easy to make, and has a high CO 2 capacity. C. W. Jones et al. , J. Am. Chem. Soc. 2008, 130, 2902.

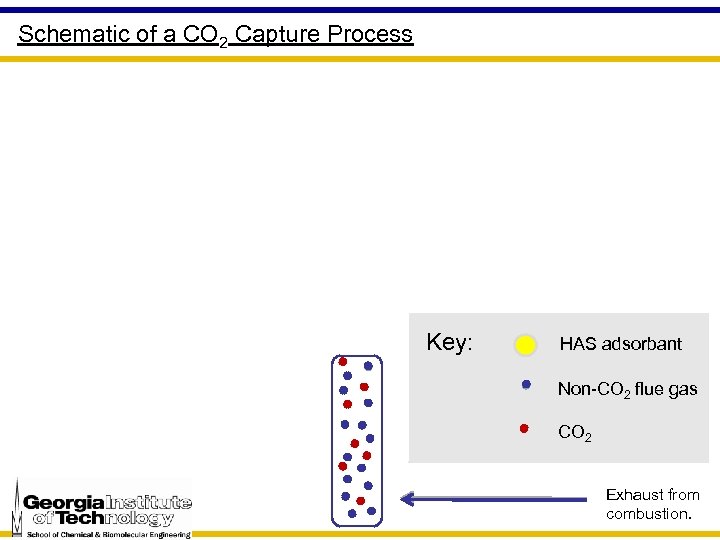

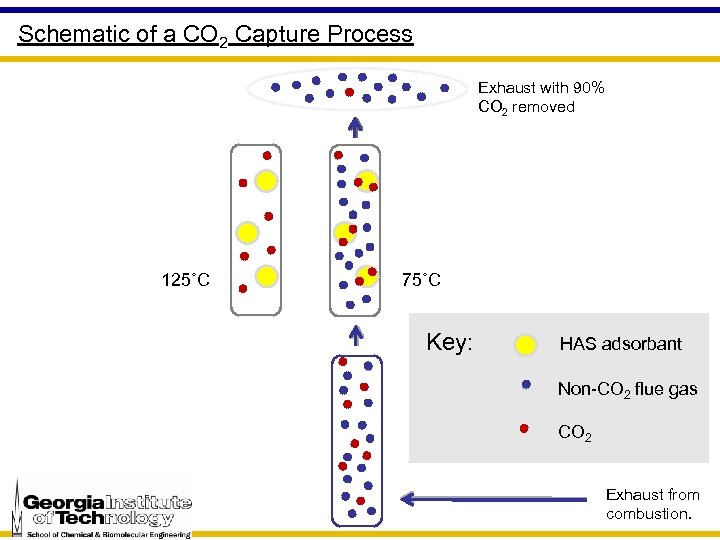

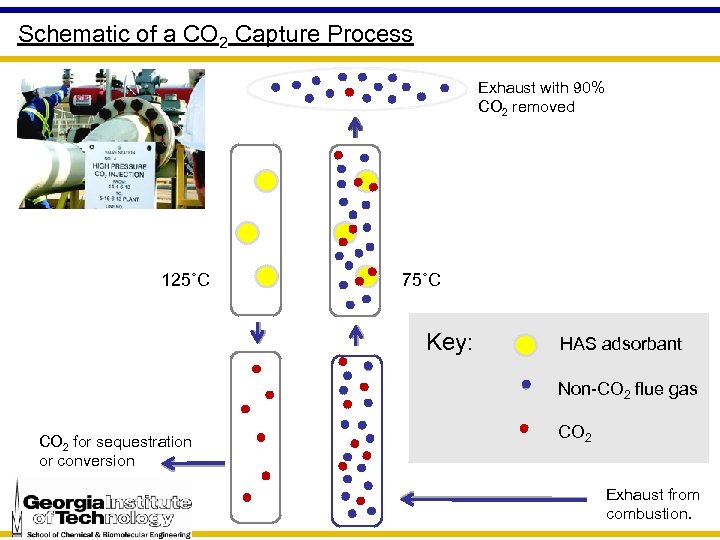

Schematic of a CO 2 Capture Process Key: HAS adsorbant Non-CO 2 flue gas CO 2 Exhaust from combustion.

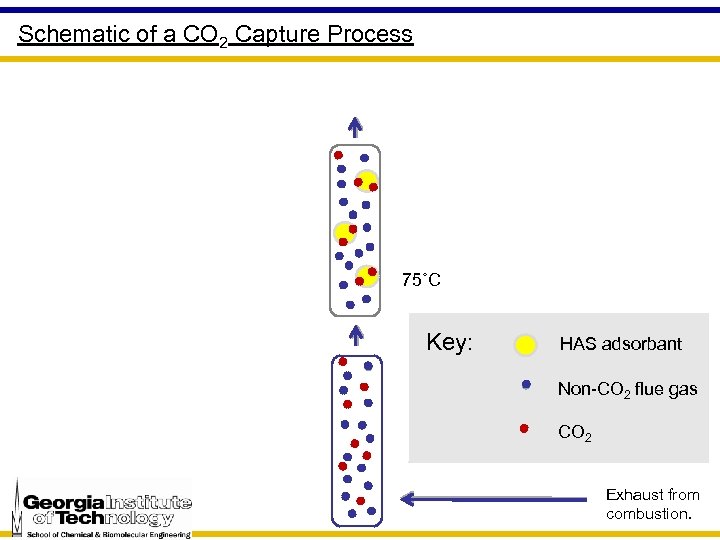

Schematic of a CO 2 Capture Process 75˚C Key: HAS adsorbant Non-CO 2 flue gas CO 2 Exhaust from combustion.

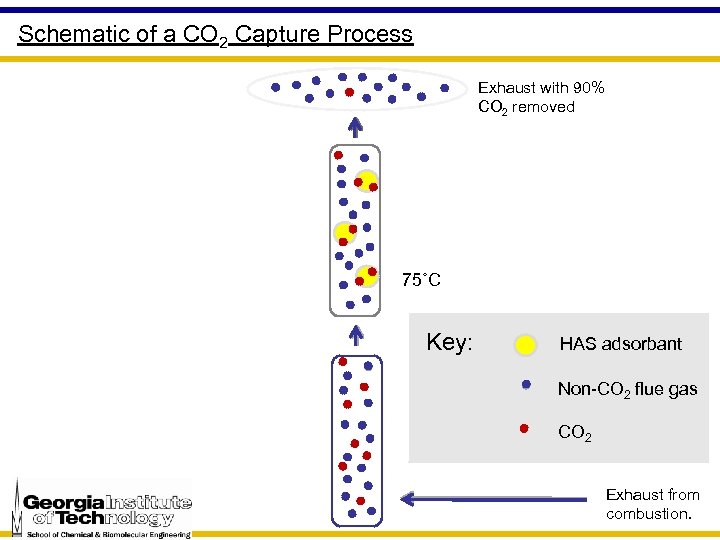

Schematic of a CO 2 Capture Process Exhaust with 90% CO 2 removed 75˚C Key: HAS adsorbant Non-CO 2 flue gas CO 2 Exhaust from combustion.

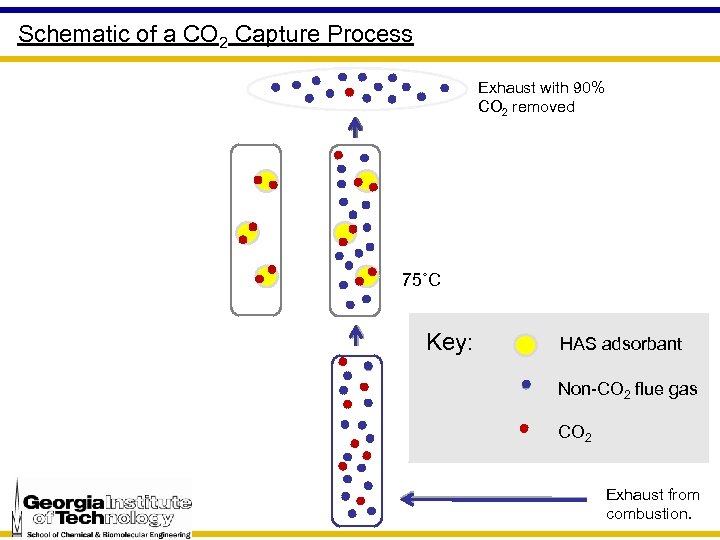

Schematic of a CO 2 Capture Process Exhaust with 90% CO 2 removed 75˚C Key: HAS adsorbant Non-CO 2 flue gas CO 2 Exhaust from combustion.

Schematic of a CO 2 Capture Process Exhaust with 90% CO 2 removed 125˚C 75˚C Key: HAS adsorbant Non-CO 2 flue gas CO 2 Exhaust from combustion.

Schematic of a CO 2 Capture Process Exhaust with 90% CO 2 removed 125˚C 75˚C Key: HAS adsorbant Non-CO 2 flue gas CO 2 for sequestration or conversion CO 2 Exhaust from combustion.

Business Opportunities in CCS: Sequestration vs. Utilization -- very few large scale utilization strategies 1) Enhanced Oil Recovery – EOR: -- use pressurized CO 2 to allow secondary recovery of hard to access crude oil -- some CO 2 remains underground

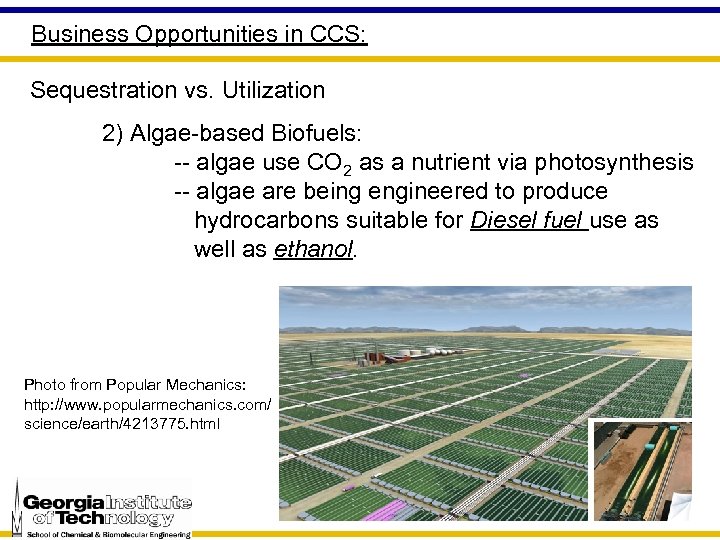

Business Opportunities in CCS: Sequestration vs. Utilization 2) Algae-based Biofuels: -- algae use CO 2 as a nutrient via photosynthesis -- algae are being engineered to produce hydrocarbons suitable for Diesel fuel use as well as ethanol. Photo from Popular Mechanics: http: //www. popularmechanics. com/ science/earth/4213775. html

Conclusions: There are numerous business opportunities in both CO 2 capture and sequestration/utilization. New GT hyperbranched aminosilica sorbent has: 1. Very high capacity 2. Multi-cycle stability 3. Simple, low cost, scalable design promising for commercial application. Current work seeks to develop a new process for implementation of HAS materials in post-combustion CO 2 capture in collaboration with our research partners: US Department of Energy - National Energy Technology Laboratory

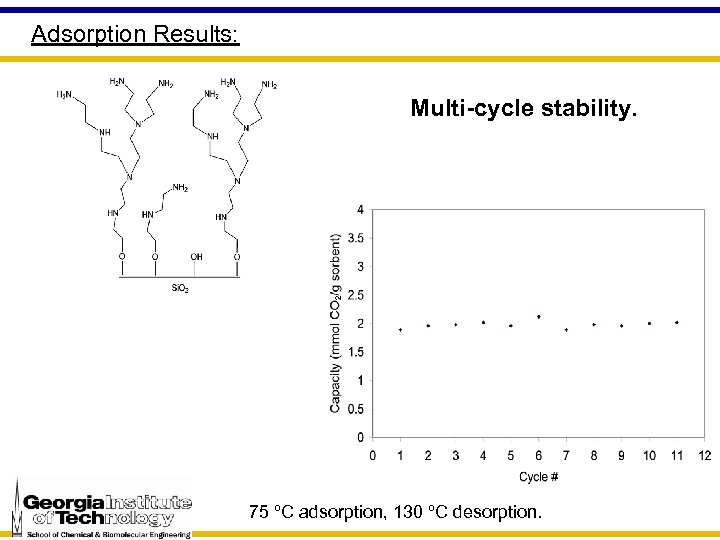

Adsorption Results: Multi-cycle stability. 75 ºC adsorption, 130 ºC desorption.

136decab30428a7341c919b0a8f62580.ppt