b12d2d90d6d4ba6e1d273b8b4dda2d19.ppt

- Количество слайдов: 50

Building Services and System Case Study Lloyds Building 1978 -86, London Richard Rogers MArch 1 Li Yin Kwan, Jess cover

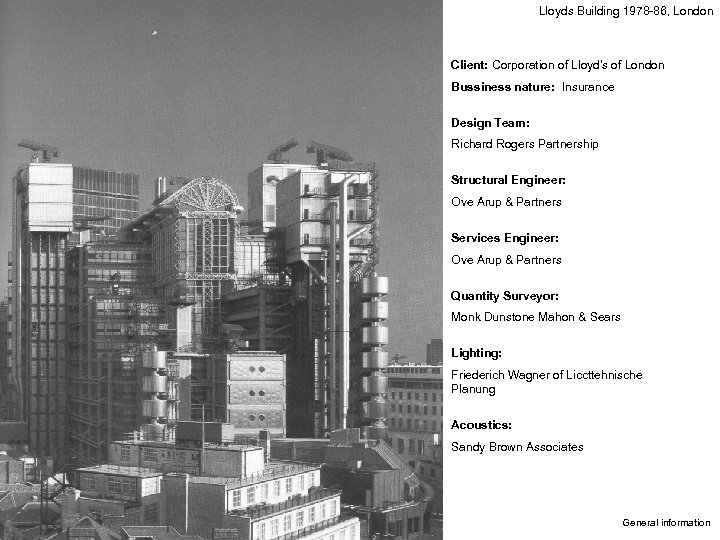

Lloyds Building 1978 -86, London Client: Corporation of Lloyd's of London Bussiness nature: Insurance Design Team: Richard Rogers Partnership Structural Engineer: Ove Arup & Partners Services Engineer: Ove Arup & Partners Quantity Surveyor: Monk Dunstone Mahon & Sears Lighting: Friederich Wagner of Liccttehnische Planung Acoustics: Sandy Brown Associates General information

Site description The Lloyds Building is located on Leadenhall Street in the heart of the financial district of the city of London. The site is awkwardly shaped due to the medieval character of London’s street plan. Typical of medieval streets, the streets surrounding the Lloyds Building are tight and winding, providing a sharp contrast between solid and void, between building and street. site

Lloyds Building 1978 -86, London Description The Lloyds Building, consisting of twelve stories to the north, stepping down to six stories to the south, was a replacement for the previous buildings which Lloyds of London occupied but found to be too small for its continued growth. Presently, the Lloyds Building with its 52, 200 square metres gross area (37, 500 square metres net area) is a 66 percent increase over the Cooper buildings it replaced. "The Room" takes all the area of the ground floor and extends into the upper second, third, and fourth floors. Office spaces take up the remaining upper floors. General information

Requirements The Room – required large open adaptive space Dating back to the 17 th century, Lloyds of London has today transformed itself into a modern market place operating on the principles of a traditional market. Composed of a society of underwriters, each having their individual stall in the Lloyd's market, the efficiency and success of Lloyd's depends on the interaction between individuals and in the contact gained from working in a large open space, an open market, called "The Room". Expansion – continue growth leads to need of expansion and flexible structural and services layout The Corporation of Lloyds of London had already moved several times in attempt to suit its continued growth before acquiring the site on Leadenhall Street in the 1920’s. During the World War II, German bombs flattened the adjacent sites; however, the Cooper building in which Lloyds resided survived. In 1950, Lloyds, foreseeing a further need for expansion bought the surrounding sites and began to build the "new" Lloyds. This new building, completed in 1958, was linked to the 1928 building by a 38 -foot bridge spanning over Lime Street. Continued growth of Lloyds quickly led them to reevaluate their situation and again look for ways to expand. By the 1960 s and 1970 s, the 1958 building was already too small and Lloyds now began to look at 1928 building as a possibility in meeting their expansionist ideals. The 1928 building ultimately became their solution. Although listed (grade II) by the government, it was allowed by the City to be demolished in 1981 in place of the current Lloyds Building, which was completed in 1986. General information

Climatic Summary Latitude: 51 09 N Longitude: 000 11 W Elevation: 62 m London has a relatively cool climate year round. Temperatures range from 22 degrees Celsius in the summer to 0 degrees Celsius in the winter. London receives substantial amounts of precipitation throughout the year. The sky conditions are largely overcast and the wind comes primarily from the southwest with a speed of approximately 10 knots. Considerations -heat loss to outside -Interior temperature Climate

Strategic diagram for services -use of natural light while with insulation -Consideration of the future need of electronics facilities -Growth Strategy

Services Strategy 1 Natural light Strategy 2 Circulation route – staircases & elevators Utilities rooms – generator room, air handling units, water tank, services shaft, lavatories Piping – supply/ return air duct, water supply, drainage, lighting, fire service piping Services

Strategy 1 break 1

Strategy 1 - Natural lighting Stepping Form The Lloyds Building, consisting of twelve stories to the north, stepping down to six stories to the south, sunlight penetration thus utilized. the incorporation of the atrium The atrium was a key feature in the reduction of the loads coming from lighting. The atrium increases in volume and surface area as it progresses toward the south. The office levels increase as the progress northward allowing a large surface area for diffused light coming from the north. A significant amount of natural lighting reaching down into "The Room" demonstrates the success in the design of the atrium. Furthermore, every location in the building is located within 7 meters from a natural source of light. Strategy 1 – natural lighting

Strategy 2 Break 2

Preliminary Sizing of Mechanical Systems Preliminary estimates indicate that the Lloyd's Building with a 500, 000 sq. ft. gross area would require the following sizing in environmental control systems. Cooling capacity: 5250 Mcal/sec Total space for boiler and chilled water plant: 1000 sq. m Space for cooling towers: 110 sq. m Cooling air volume: 148 cu. m/sec Area of main supply or return ducts: 18 sq. m Area of branch supply or return ducts: 29 sq. m Area of fan rooms: 950 sq. m Area of fresh air louvers: 117 sq. m Services data

Served & servant

Strategy 2 – the served and servant It was Kahn’s notion of ‘served’ and ‘servant’ spaces inspired Rogers. In the case of Llyods, servant spaces concentrate in towers. Served zone Servant towers with incorporation of raised flooring system and ceiling viod Strategy 2 – served &

Served zone Servant towers with incorporation of raised flooring system and ceiling void The services towers, 3 of them principally for fire fighting and escape. The other 3 for lifts, lavatories and risers, are the visual expression of the Kahnian doctrine of ‘served and servant spaces’ Servant tower – plan

The towers carry majors plant rooms on top The towers form a flexible framework for the ventilation plant, lifts, service risers and lavatories (all the 33 lavatory units were manufactured and fitted out) attached to them. Four towers carry major plant-rooms, with mains services running vertically down the towers and connected into each level of the building. The largest services duct contained the air-conditioning, with lesser duct for water, drains, power and electronics Main services running vertically down the towers Tower – vertical planning

Typical detailed layout services tower Served zone All the 33 prefabricated lavatory pods were brought to the site on trucks and then hoisted into position prior to linking up to the service risers with ducts for water, drains, power and electronics running vertically down the towers and connected into each level of the building Access and escape routes were provided by means of lifts and staircases The largest services duct contained the airconditioning running vertically down the towers and connected into each level of the building. Tower – detailed layout

Integration integration

Sectional detail – services ALUZINC duct extracting air through light fittings Insulated stainless steel ‘fish tail’ extract duct Anodized aluminum cladding with triple glazing and ventilation cavity Clear double glazed window operable at office 350 mm deep raise floor services plenum 600 x 600 mm lightweight concrete filled steel floor tiles on pedestals Extruded aluminum grille Insulated supply air duct Anodized aluminum sandwich panel, 1 hr FRP Supply ductworks Sprinkler head Silver aluminum light spill ring Extracted ductworks Black painted spun aluminum luminaries shield 440 mm deep service void Raised fl & ceiling void- section deatil

Air conditioning Sub-Air

Air conditioning system ALUZINC duct extracting air through light fittings stale air is extracted from above through the multi-function luminaries The extracted air is passed to the perimeter of the building and forced through the triple-layered exterior glazing – ensuring an almost zero heat loss from the offices during the winter and reducing heat gain in summer. Clear double glazed window operable at office Conditioned air is distributed through a sub-floor plenum into the offices Supply ductworks Extracted ductworks The operable window allows individuals the ability to "acquire" fresh air if the feel it necessary. The placement of the window encourages individuals to work while sitting rather than standing since that is where the views are held. It also allows interior light to be reflected back into the interior during the night and diffuses direct sunlight during the day. The need to take mechanical systems into careful consideration when designing energy conscious builidings is made evident when one compares the overall space that they consume in a building in relation to the human being Air cond. & heat cycle 1

Served zone The largest services duct contained the airconditioning running vertically down the towers and connected into each level of the building. Air cond.

The heat cycle Heat from the return air is collected in the basement sprinkler tanks and re-used. The internal concrete soffits and slabs are ‘heat sinks’, absorbing heat during occupation and being cooled off overnight using naturally chilled night air. This allow cooling to follow a 24 -hour cycle and reduces the peak cooling requirement. Air handling equipment is located at basement level and in four service tower plant-rooms. Air cond. & heat cycle 2

boiler Sub-station generators chillers Air handling plants Lower basement room provided services for lower basement level to G/F level Strategy 2 -lower Basement

Lighting Sub-lighting

Lighting Multi-functioned luminaries triple glazing and ventilation cavity ensuring an almost zero heat loss from the offices during the winter and reducing heat gain in summer. Natural light come through window Every location in the building is located within 7 meters from a natural source of light. Furthermore, a significant amount of natural lighting reaching down into G/F through the atrium demonstrates the success in the design of the atrium. Lighting

Power and electronic Sub-power&ele

Power and electronic 350 mm deep raise floor services plenum housed the power and electronic conduit Power and electronic

Power and electronic Served zone service risers with ducts for water, drains, power and electronics running vertically down the towers and connected into each level of the building Power and electronic

Fire protection Sub-fire

Fire protection Sprinkler system was hold in the ceiling void and sprinkler heads were incorporated into the multifunctioned luminaries Anodized aluminum sandwich panel, 1 hr FRP Sprinkler head Fire protection

Served zone Access and escape routes were provided by means of lifts and staircases Fire protection

Structural system

Description The basic form of the building is that of a large atrium, surmounted by steel and glass arched roof, surrounded by galleries (12 levels of them on the north side) which contain the bulk of the underwriting space and a variable a mount of lettable space, depending on the changing accommodation need of the Llyods market itself. The floors were constructed on reinforced concrete columns on a 10. 8 x 18 metre grid. The load is transferred between the columns and the floor beams by means of a pre-casted bracket. Pre-cast ‘yokes’ cast into inverted U-beam transmit the loads of the floor grid to the perimeter columns via the brackets. The great columns, both the exterior of the building and within the atrium, stand proud of the cladding, increasing the highly articulated ‘Gothic’ effects of Llyods. External cross-braces are actually made of steel tube concrete grid open to view. description

Design of the atrium roof A lightweight contrast to the concrete superstructure of the building Atrium Light steel roof

Columns, Beams and Floors The floors were constructed on reinforced concrete columns on a 10. 8 x 18 metre grid. The load is transferred between the columns and the floor beams by means of a precasted bracket. Pre-cast ‘yokes’ cast into inverted U-beam transmit the loads of the floor grid to the perimeter columns via the brackets. The great columns, both the exterior of the building and within the atrium, stand proud of the cladding, increasing the highly articulated ‘Gothic’ effects of Llyods. External cross-braces are actually made of steel tube concrete grid open to view. By using beams with parallel sides and sharp arises Rogers emphasizes that the floor is a grid not a solid, coffered slab floor and column

‘Yokes’ concrete bracket Main concrete columns In situ concrete was latter substituted. U-beams transfer the loads of the floor grid to the columns via a bracket system The waffle

Pre-cast concrete bracket and ‘yoke’ assemblies Pre-cast concrete bracket yoke assemble

Services supports Axonometrics of the pre-cast concrete ‘kit of parts’ for the sevices towers services support

Sectional detail - structure Pre-cast concrete bracket In situ concrete beam In-situ concrete column 100 mm in situ concrete slab Permanent steel formwork incorporating acoustic panel Painted ductwork support bracket Anodized Aluminum wind bracing section

Photos

photos- Overall

A significant amount of natural lighting reaching down into G/F demonstrates the success in the design of the atrium. Photos –

mains services running vertically down the towers and connected into each level of the building through the raised floor and ceiling void. Photos -connection of the

The layers of structure, services and cladding articulate the elevation photos - services

Servant towers with incorporation of raised flooring system and ceiling void Photos – raised flooring system & ceiling void

photos– in situ concrete column & precast concrete bracket

All the 33 prefabricated lavatory pods were brought to the site on trucks and then hoisted into position prior to linking up to the service riser Photos – prefabricated lav.

Undoubtedly, the Llyods building demonstrated Richard Rogers and his engineers’ very best skill in handling the appropriate building sevices and structural systems. It suits very well of the need of growth And the future development of IT, thus the need of electronics spaces……. It is overwhelming Thanks Mr. Rogers. Llyods taught us a lot. Conclusion

‘ A house is a machine for living in. ’ Le Corbusier However, is that Le Corbusier taught us to design like a machine ? ‘Do not forget architecture. ’ Thanks Mr. Rogers. Llyods taught us a lot. conclusion

b12d2d90d6d4ba6e1d273b8b4dda2d19.ppt