f203b210d90e49592d0cc663f2dff021.ppt

- Количество слайдов: 81

BUILDING DYNAMICS: Moisture, Airflows and Construction Technology ITEP Level 2 WX Training Joseph T. Ponessa, Ph. D. Professor Emeritus Housing, Indoor Environments and Health 1

2

Goals n Review basic dynamics of moisture movement, control in buildings n Review basic dynamics of airflows in buildings n Proper management of moisture and airflows provides better buildings and reduces callbacks. --------------------------n Understanding of these mechanisms is essential for diagnostics 3

Objective: how does this fit with weatherization? Weatherization can improve comfort and save money. Downside is ‘inadequate’ ventilation When is ventilation inadequate? n When it is less than prescribed ventilation n When it is inadequate to take care of building excesses – Too much moisture – Excessive pollution sources 4

Overview of Today’s Presentation Building Science n Moisture dynamics; applications in buildings n Airflow mechanisms; applications in buildings 5

Building Science Moisture Dynamics, sources & remedies; Air flows 6

Section I: Moisture Dynamics Outline n Basic moisture science: Vapor & Liquid – Air – vapor – temperature relationships – Relative Humidity – Putting it all together – Psychrometric chart n Vapor movement § Diffusion § Bulk transfer – air flows 7

Moisture Dynamics Outline (cont’d) Basic moisture science (cont. ) n Water movement § Gravity; wind § Capillary action n n Moisture sources Moisture Measurement § Air § Surfaces / solids 8

Moisture Dynamics Water can exist in three states n Vapor n Liquid n Solid 9

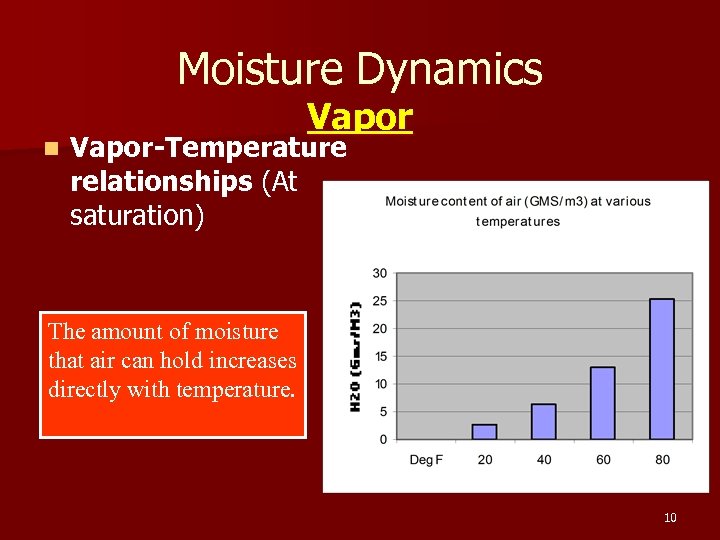

Moisture Dynamics n Vapor-Temperature relationships (At saturation) The amount of moisture that air can hold increases directly with temperature. 10

Moisture Dynamics Vapor (cont. ) n Relative humidity RH is the amount of moisture In the air compared to the total Moisture capacity of air At a given temperature. Expressed as %. Because air’s moistureholding capacity increases with temperature… …for a given amount of moisture in air RH as Temp …and vice versa 11

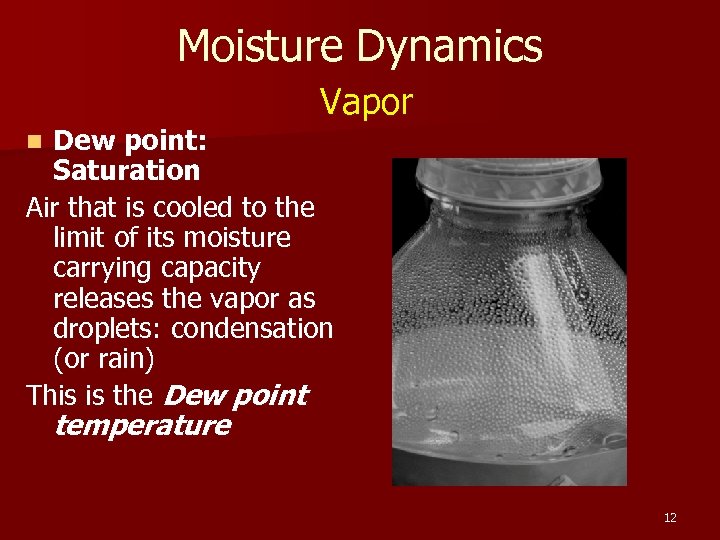

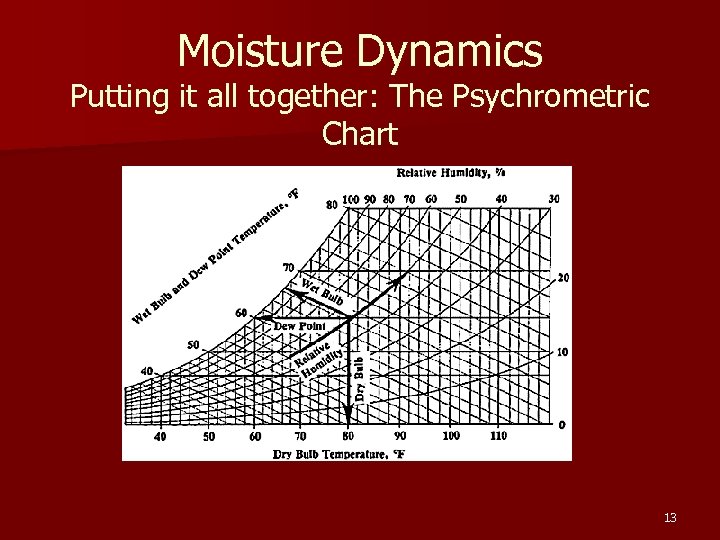

Moisture Dynamics Vapor Dew point: Saturation Air that is cooled to the limit of its moisture carrying capacity releases the vapor as droplets: condensation (or rain) This is the Dew point n temperature 12

Moisture Dynamics Putting it all together: The Psychrometric Chart 13

Moisture Dynamics Vapor n So what does it all mean? Moist air that is cooled down OR… Moist air that meets a cool surface will condense! Wet surfaces that don’t/can’t dry rapidly will produce mold 14

Moisture Dynamics Vapor Transport Vapor transport: how does vapor get from point A to point B? POSSIBLE MECHANISMS n Diffusion n Bulk transport: Airflow Which is more important? 15

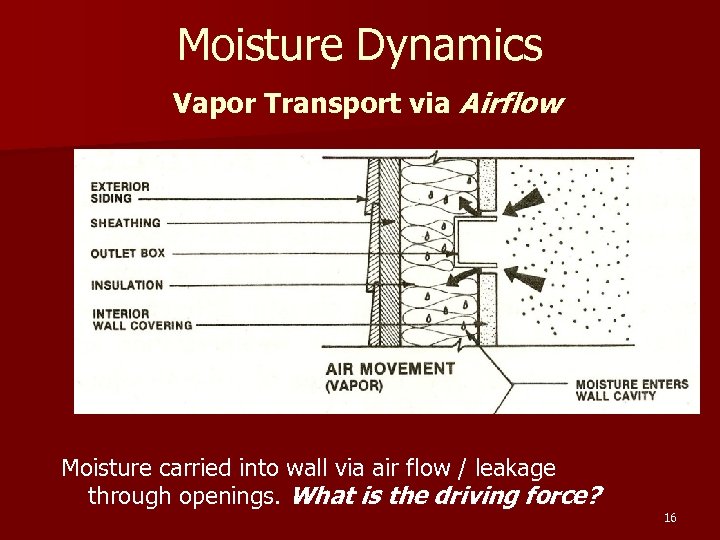

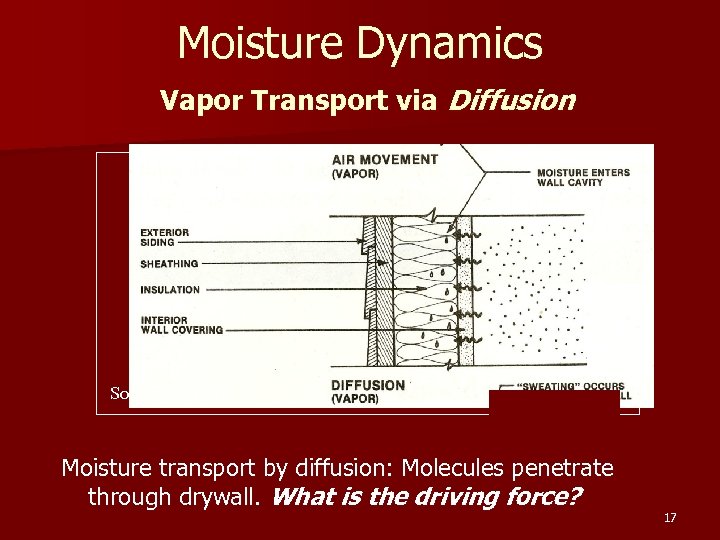

Moisture Dynamics Vapor Transport via Airflow Source: USDOE Moisture carried into wall via air flow / leakage through openings. What is the driving force? 16

Moisture Dynamics Vapor Transport via Diffusion Source: USDOE Moisture transport by diffusion: Molecules penetrate through drywall. What is the driving force? 17

Moisture Dynamics Which mechanism is most important? n Diffusion? n Air transport? 18

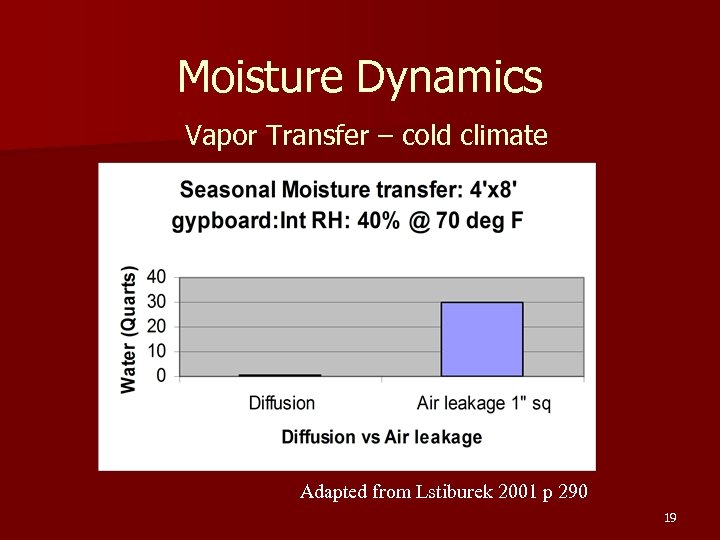

Moisture Dynamics Vapor Transfer – cold climate Adapted from Lstiburek 2001 p 290 19

Moisture Dynamics Diffusion vs. air transport While air transport accounts for bulk of moisture migration in most buildings, there are circumstances when diffusion is most important factor 20

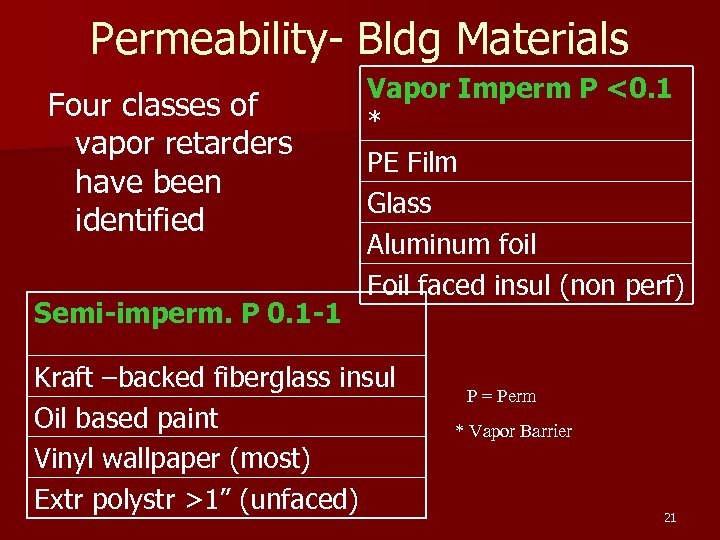

Permeability- Bldg Materials Four classes of vapor retarders have been identified Semi-imperm. P 0. 1 -1 Vapor Imperm P <0. 1 * PE Film Glass Aluminum foil Foil faced insul (non perf) Kraft –backed fiberglass insul Oil based paint Vinyl wallpaper (most) Extr polystr >1” (unfaced) P = Perm * Vapor Barrier 21

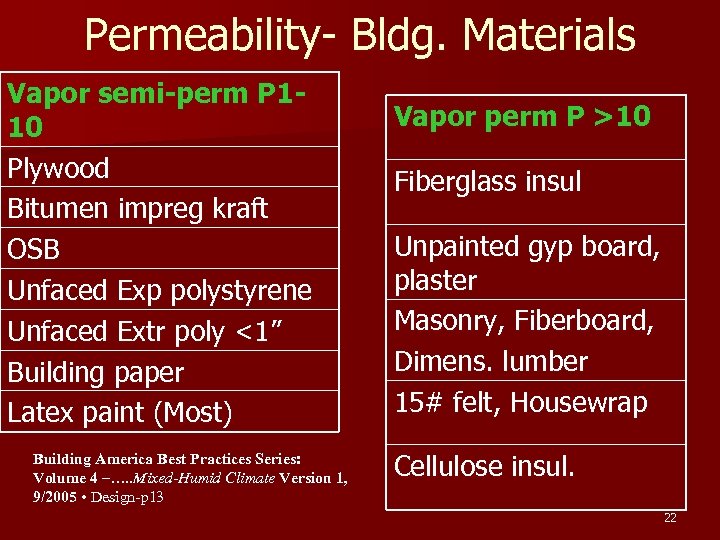

Permeability- Bldg. Materials Vapor semi-perm P 110 Plywood Bitumen impreg kraft OSB Unfaced Exp polystyrene Unfaced Extr poly <1” Building paper Latex paint (Most) Building America Best Practices Series: Volume 4 –…. . Mixed-Humid Climate Version 1, 9/2005 • Design-p 13 Vapor perm P >10 Fiberglass insul Unpainted gyp board, plaster Masonry, Fiberboard, Dimens. lumber 15# felt, Housewrap Cellulose insul. 22

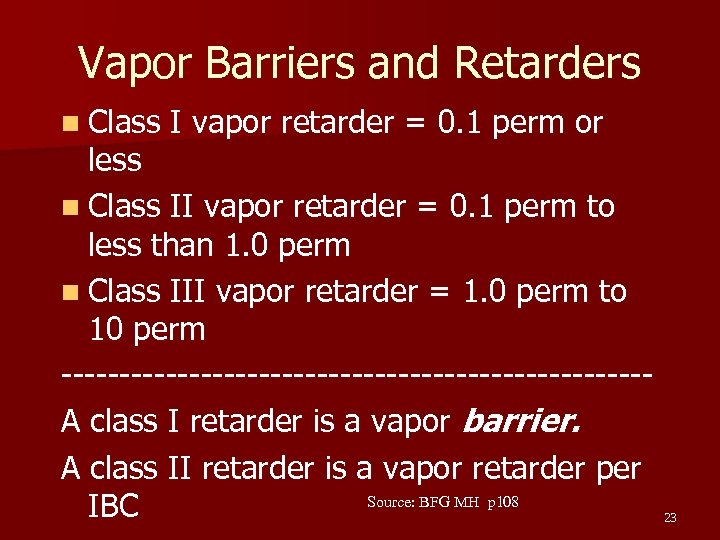

Vapor Barriers and Retarders n Class I vapor retarder = 0. 1 perm or less n Class II vapor retarder = 0. 1 perm to less than 1. 0 perm n Class III vapor retarder = 1. 0 perm to 10 perm -------------------------A class I retarder is a vapor barrier. A class II retarder is a vapor retarder per Source: BFG MH p 108 IBC 23

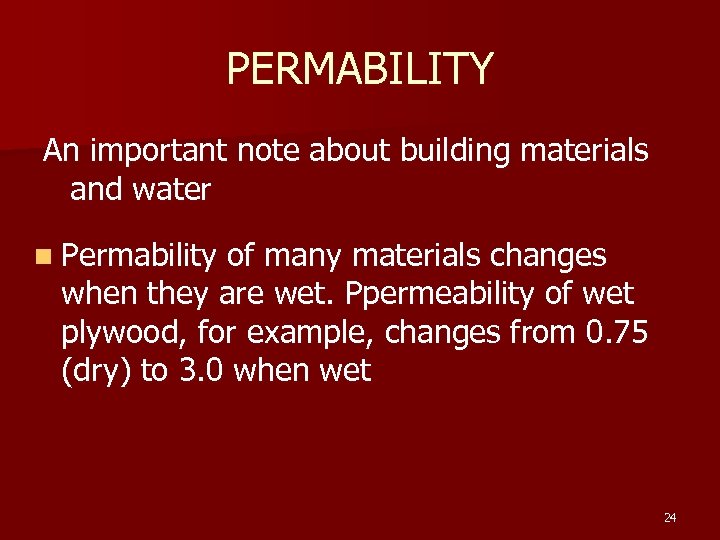

PERMABILITY An important note about building materials and water n Permability of many materials changes when they are wet. Ppermeability of wet plywood, for example, changes from 0. 75 (dry) to 3. 0 when wet 24

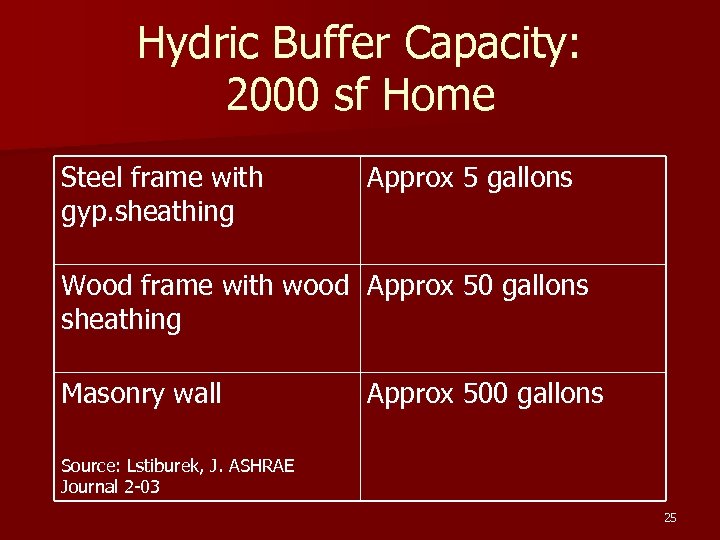

Hydric Buffer Capacity: 2000 sf Home Steel frame with gyp. sheathing Approx 5 gallons Wood frame with wood Approx 50 gallons sheathing Masonry wall Approx 500 gallons Source: Lstiburek, J. ASHRAE Journal 2 -03 25

Questions about vapor transmission/dynamics? While vapor migration and condensation can play an important role in moisture problems, most problems are caused by rainwater 26

Moisture Dynamics Liquid water can flow via n Gravity (or wind pressure) n Capillary action (wicking) = against gravity 27

Moisture Dynamics Liquid Gravity “It flows downhill” Source: Builder Magazine 28

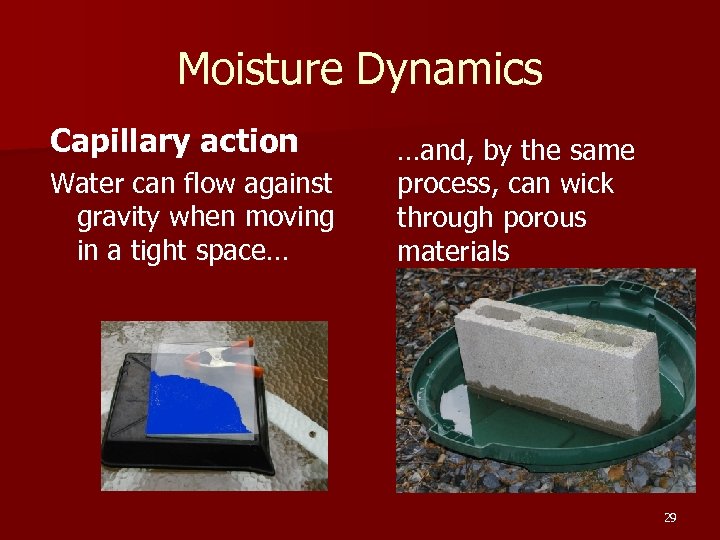

Moisture Dynamics Capillary action Water can flow against gravity when moving in a tight space… …and, by the same process, can wick through porous materials 29

Moisture Dynamics Practical applications n Water can travel up and behind flashing that is not properly dimensioned n Water can diffuse/wick through masonry, adding humidity to spaces and wetting components (e. g. sill plates) 30

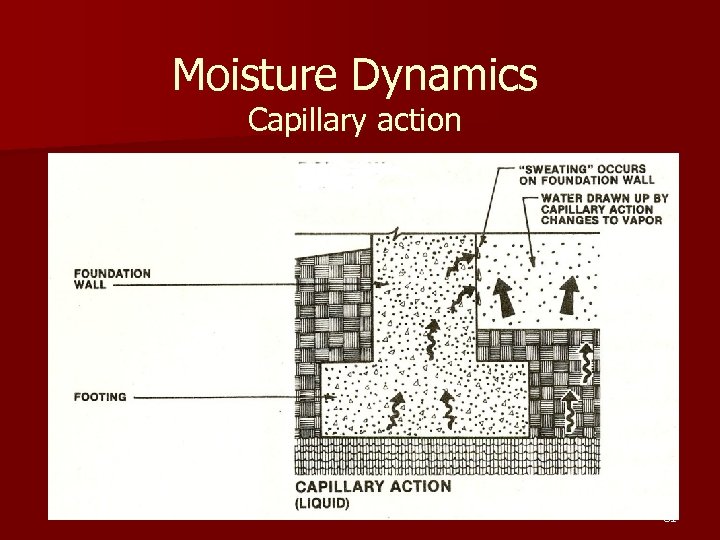

Moisture Dynamics Capillary action Source: USDOE 31

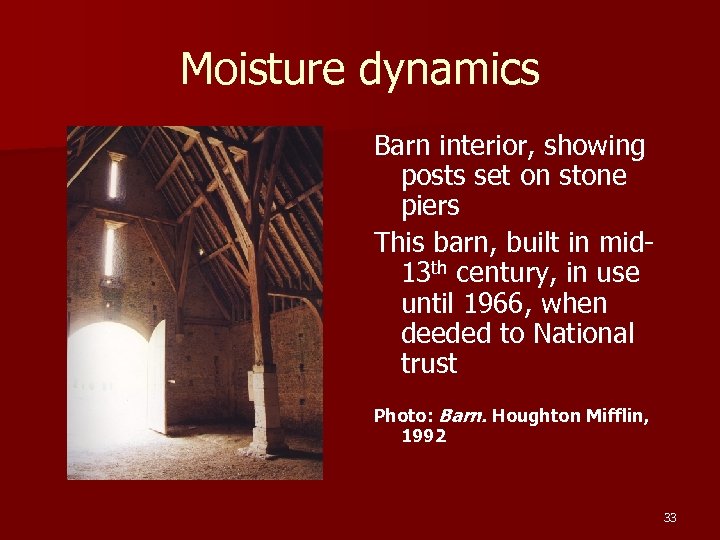

Moisture dynamics Abbey XXX barn grange, Great Coxwell, England Photo: Barn. Houghton Mifflin, 1992. Some builders, at least, have known about capillary action for a long time… 32

Moisture dynamics Barn interior, showing posts set on stone piers This barn, built in mid 13 th century, in use until 1966, when deeded to National trust Photo: Barn. Houghton Mifflin, 1992 33

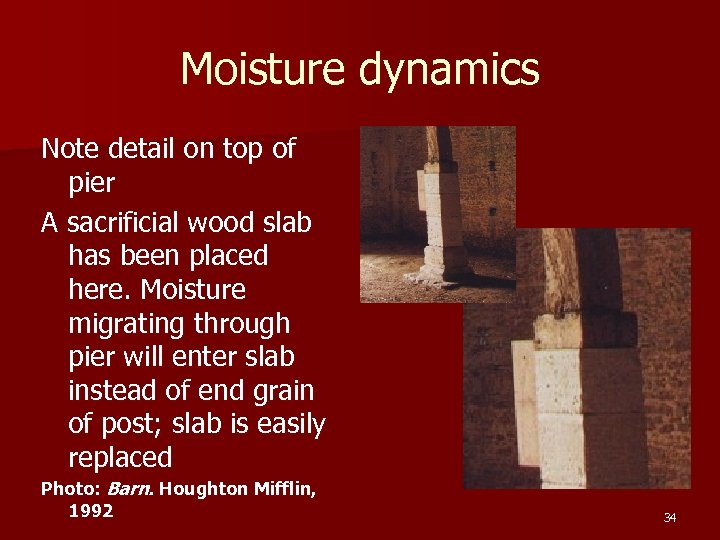

Moisture dynamics Note detail on top of pier A sacrificial wood slab has been placed here. Moisture migrating through pier will enter slab instead of end grain of post; slab is easily replaced Photo: Barn. Houghton Mifflin, 1992 34

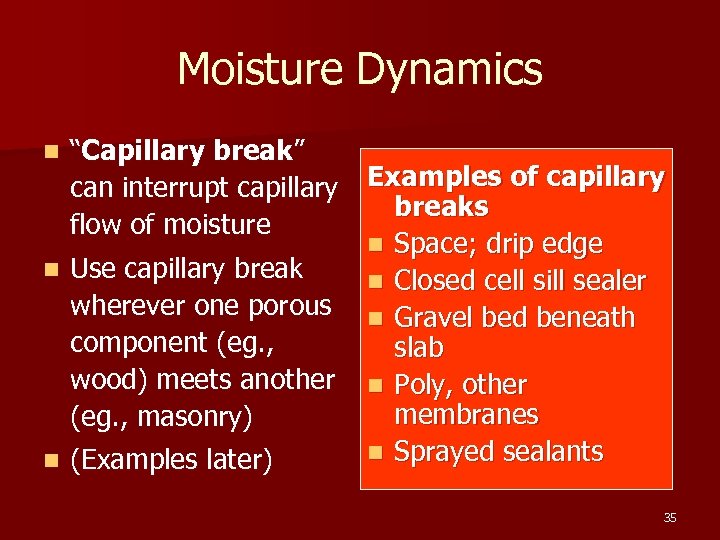

Moisture Dynamics “Capillary break” can interrupt capillary Examples of capillary breaks flow of moisture n Space; drip edge n Use capillary break n Closed cell sill sealer wherever one porous n Gravel bed beneath component (eg. , slab wood) meets another n Poly, other membranes (eg. , masonry) n Sprayed sealants n (Examples later) n 35

Moisture Sources Outline for this section n Plumbing leaks n Rainwater n Groundwater n Humid air (Including embodied water) n Mechanical equipment (Including Combustion equipment) n Occupant practices 36

Moisture Sources: Plumbing leaks n Plumbing leaks should be obvious but can be in concealed spaces, and may involve supply or drain lines n Sweating may sometimes be significant 37

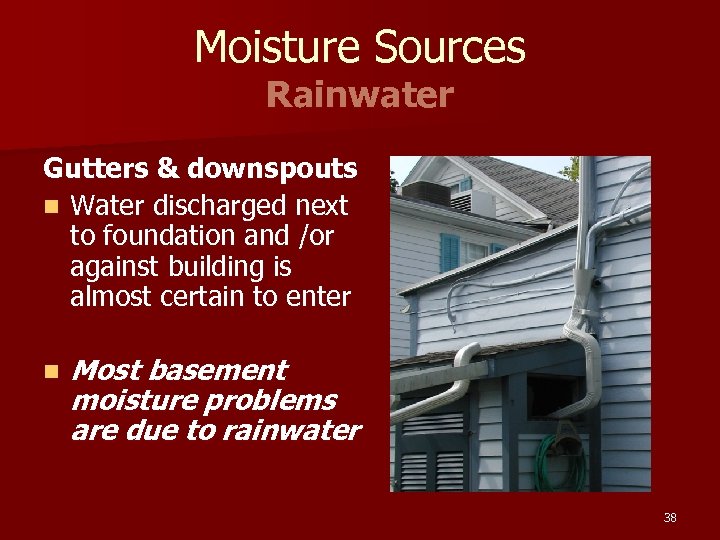

Moisture Sources Rainwater Gutters & downspouts n Water discharged next to foundation and /or against building is almost certain to enter n Most basement moisture problems are due to rainwater 38

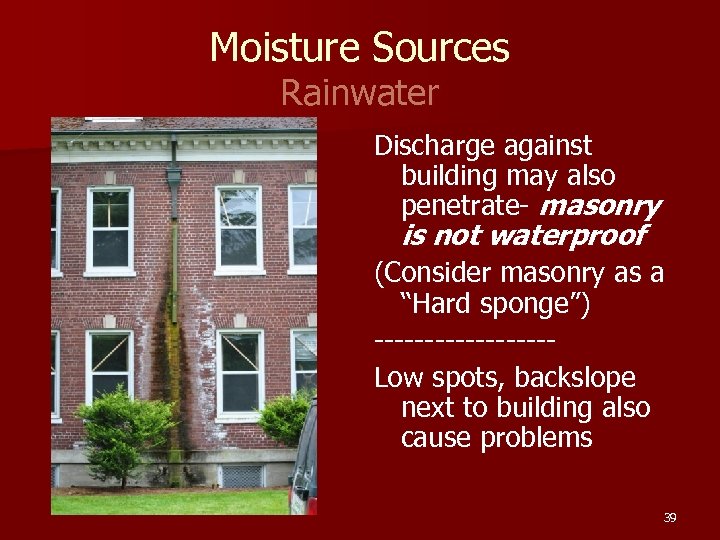

Moisture Sources Rainwater Discharge against building may also penetrate- masonry is not waterproof (Consider masonry as a “Hard sponge”) ---------Low spots, backslope next to building also cause problems 39

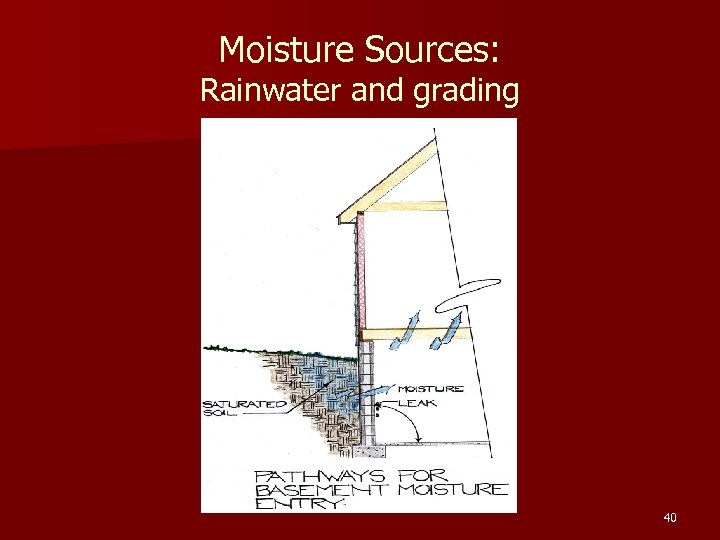

Moisture Sources: Rainwater and grading 40

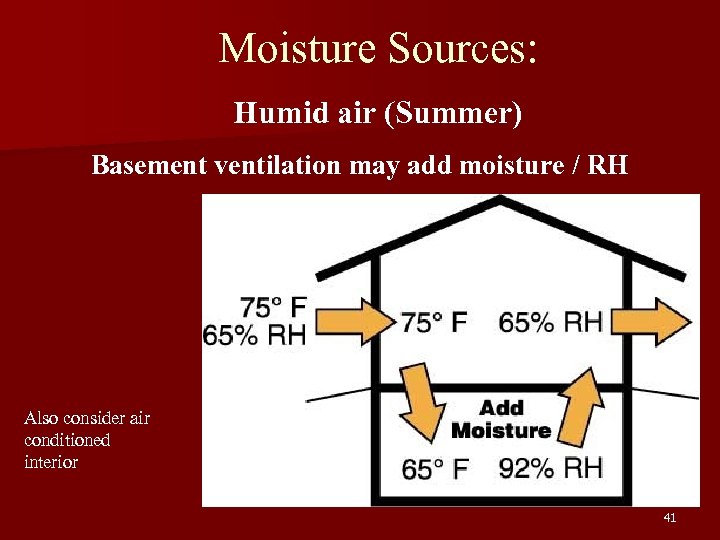

Moisture Sources: Humid air (Summer) Basement ventilation may add moisture / RH Also consider air conditioned interior 41

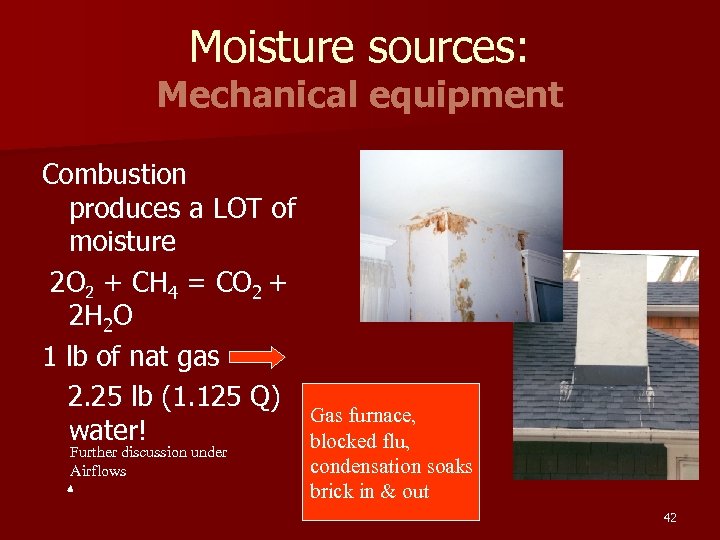

Moisture sources: Mechanical equipment Combustion produces a LOT of moisture 2 O 2 + CH 4 = CO 2 + 2 H 2 O 1 lb of nat gas 2. 25 lb (1. 125 Q) water! Further discussion under Airflows Gas furnace, blocked flu, condensation soaks brick in & out 42

Moisture Sources Embodied moisture – New construction; Several hundred pounds of moisture in concrete, lumber, drywall compound, paint, etc. New building may exhibit moisture problems for months after construction Cold weather construction – Salamander (100 k BTU/h) produces about 1 gal combustion water per hour Occupant practices -Add moisture, too 43

Moisture Measurement Air measurement n Sling psychrometer n Hygrometer (electronic) 44

Moisture Measurement (cont. ) Surface / material measurement n Electronic device (eg Protimeter) Measures moisture content- wood, drywall, masonry 45

Moisture Content in Building Materials Mold growth can begin… n In lumber @16% moisture content (this represents equilibrium @80%RH) n In gypsum sheathing @1% moisture content Source: Lstiburek, ASHRAE Journal, 2/02 46

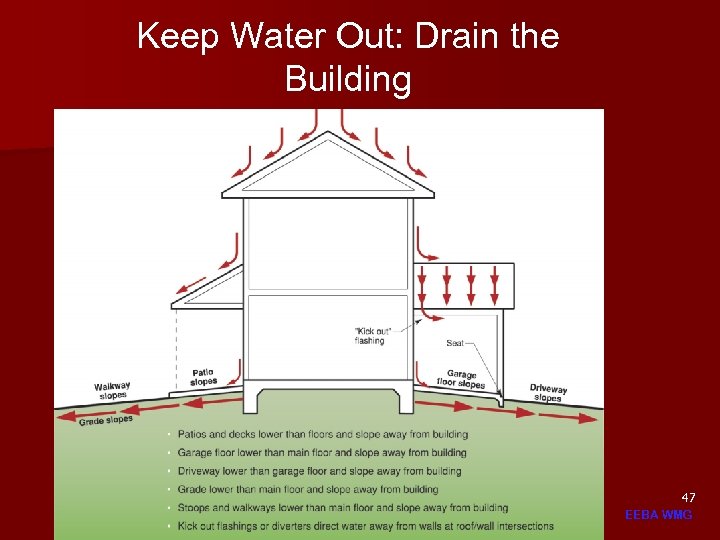

Keep Water Out: Drain the Building 47 EEBA WMG

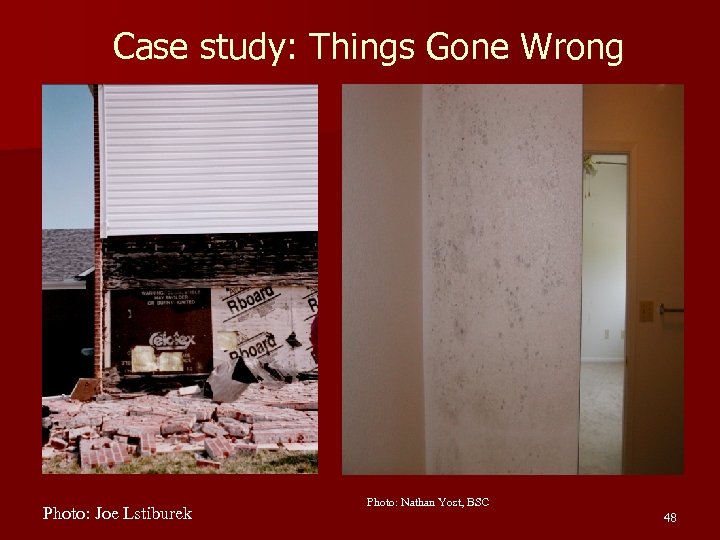

Case study: Things Gone Wrong Photo: Joe Lstiburek Photo: Nathan Yost, BSC 48

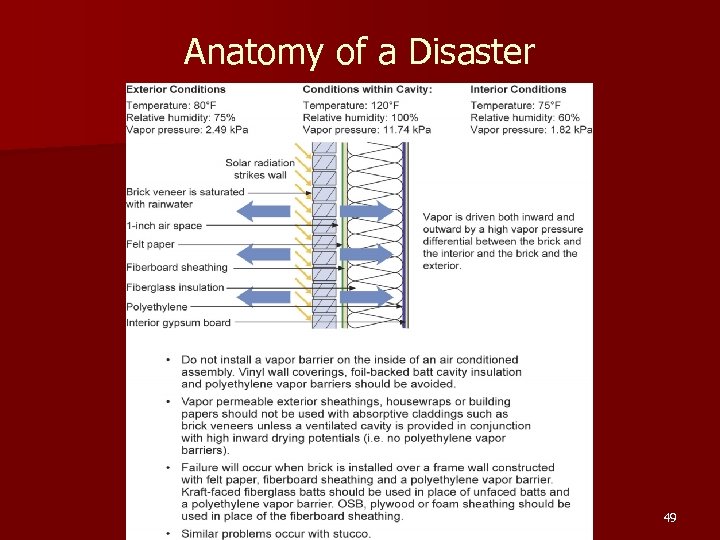

Anatomy of a Disaster 49

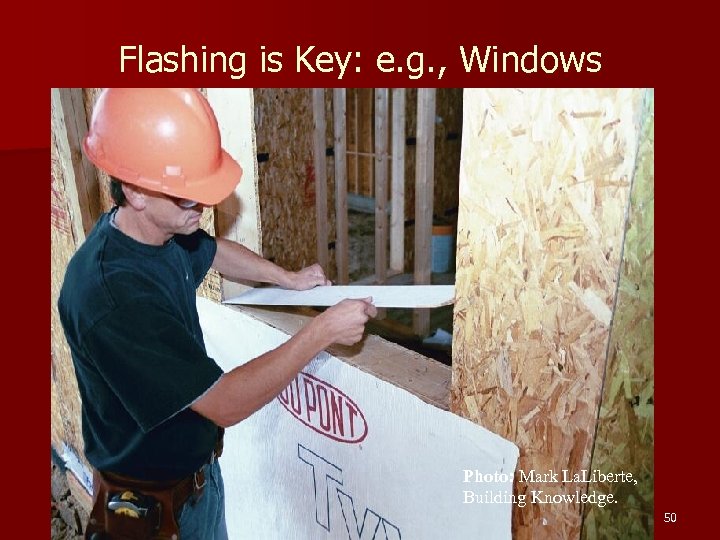

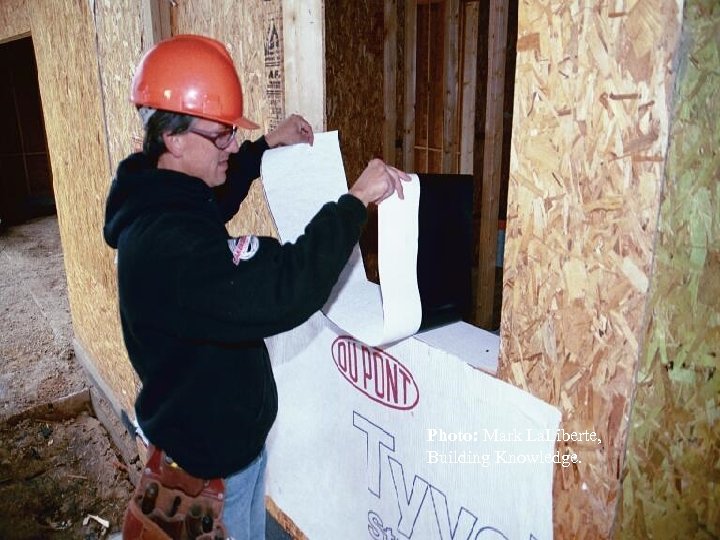

Flashing is Key: e. g. , Windows Photo: Mark La. Liberte, Building Knowledge. 50

Photo: Mark La. Liberte, Building Knowledge. 51

Photo: Mark La. Liberte, Building Knowledge. 52

Photo: Mark La. Liberte, Building Knowledge. 53

Photo: Mark La. Liberte, Building Knowledge. 54

Photo: Mark La. Liberte, Building Knowledge. 55

Photo: Eco. Village Cleveland townhomes, BSC BA project, 2003. 56

Reverse Flashing: A Common Mistake Photo: Mark La. Liberte, Building Knowledge 57

Building moisture: Take-away messages n Building components that get wet must be able to dry out quickly. Assemblies must be able to dry! n If they don’t, mold and other organisms will grow, creating health hazard for occupants and ultimately destroying the building A moisture problem is like a fire: it will not get better with time. It cannot be ignored. Respond promptly! 58

Section II: AIRFLOWS OUTLINE n Air moves according to pressure differences; These can be created by – Temperature differences – Wind – Mechanical equipment 59

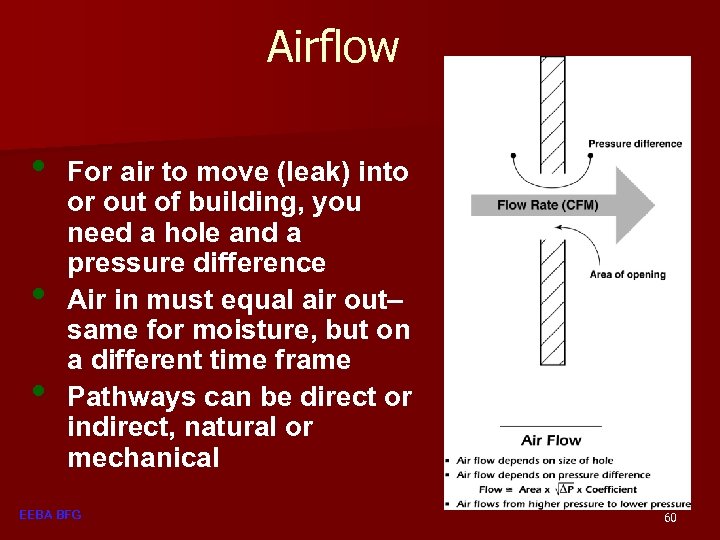

Airflow • • • For air to move (leak) into or out of building, you need a hole and a pressure difference Air in must equal air out– same for moisture, but on a different time frame Pathways can be direct or indirect, natural or mechanical EEBA BFG 60

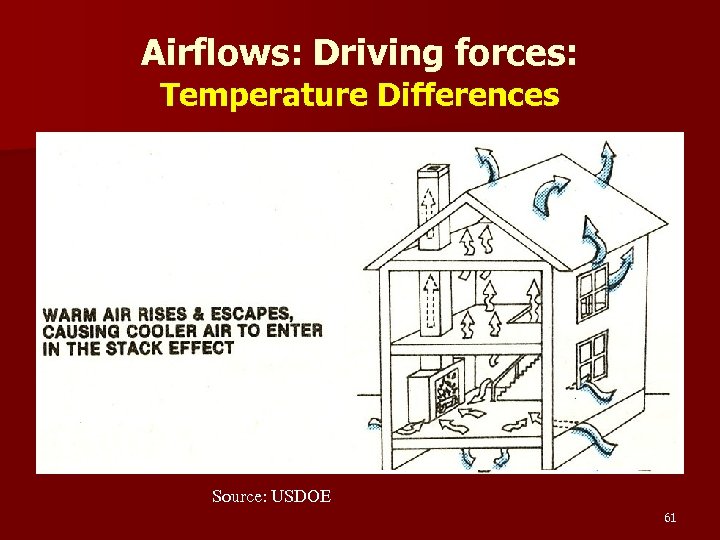

Airflows: Driving forces: Temperature Differences Heating Season: Aka THERMOSIPHONING Source: USDOE 61

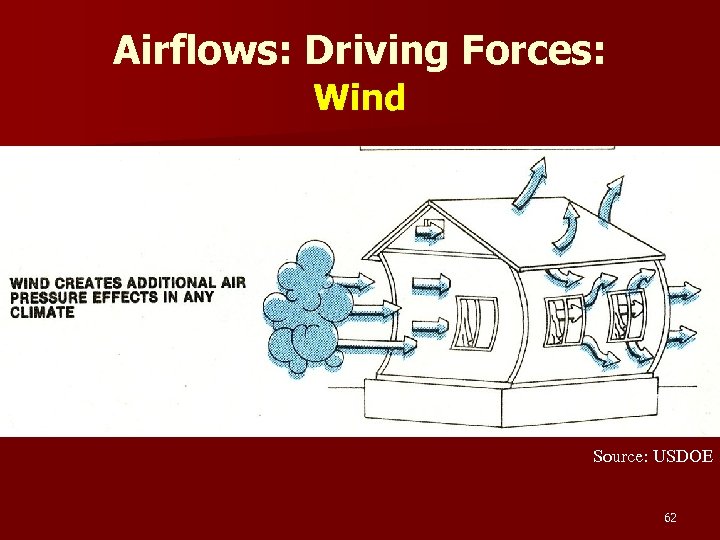

Airflows: Driving Forces: Wind Source: USDOE 62

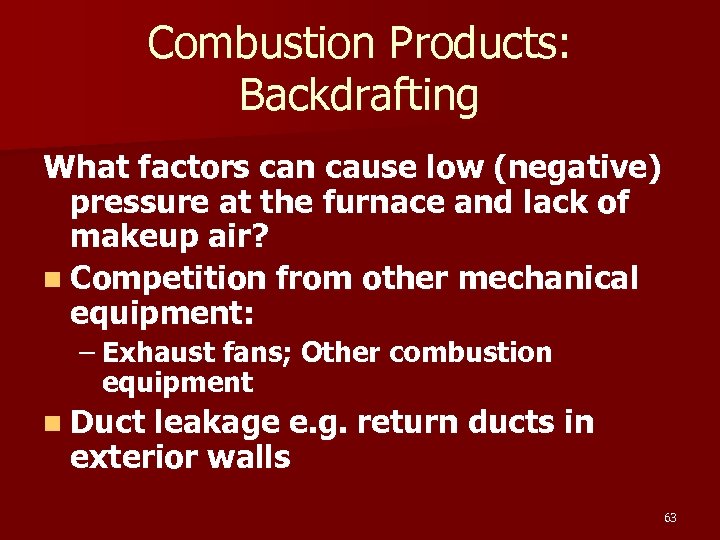

Combustion Products: Backdrafting What factors can cause low (negative) pressure at the furnace and lack of makeup air? n Competition from other mechanical equipment: – Exhaust fans; Other combustion equipment n Duct leakage e. g. return ducts in exterior walls 63

Airflows: Driving forces: Mechanical Equipment Airflows can also be influenced by n Ventilation fans n Furnaces / boilers n Ductwork (leaking) n Major Appliances (dryer, water heater) All of the above can remove air from the conditioned space. What about makeup air? 64

Airflows: Mechanical Equipment Examples Leaking ducts -Can lose as much as 25% of airflow if joints not properly sealed: Energy loss & poss. moisture problem in unconditioned space Furnace -Oil burner draws about 1600 cf of air per hour @ firing rate of 1 GPH Downdraft range vent pulls 400 CFM Who’s gonna win this one? 65

Airflows: Mechanical Equipment Backdrafting Summary n Can affect “atmospheric” equipment (conventional gas furnaces, hot water heaters, dryers, etc. ) n Inadequate air supply or negative pressures in furnace area can introduce combustion gases including moisture into building via reverse flow in “weakest” appliance(s) 66

Providing Fresh Air Best practice to control moisture, pollutants and to save energy n Build a tight building n Tightly seal ducts (anything but duct tape) n Ventilate by design! 67

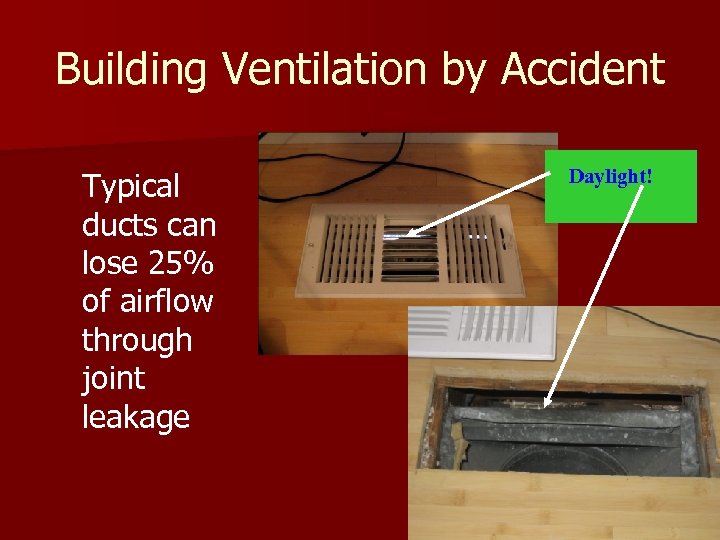

Building Ventilation by Accident Typical ducts can lose 25% of airflow through joint leakage Daylight! 68

…and some ducts lose more than 25% of their airflow! “Needs repair” 69

Typical Ventilation Rates n 100 -year-old house: Two ACH n Energy-conserving house (1970’s)”: 0. 1 ACH) n Estimated optimum, 1980’s: 0. 5 ACH n Present day: ASHRAE’s engineering standard 70

Building Ventilation by Design Various choices n Passive vent open to building n Outside air ducted to air return; dampers, controllers n Sealed combustion equipment reduces need for makeup air 71

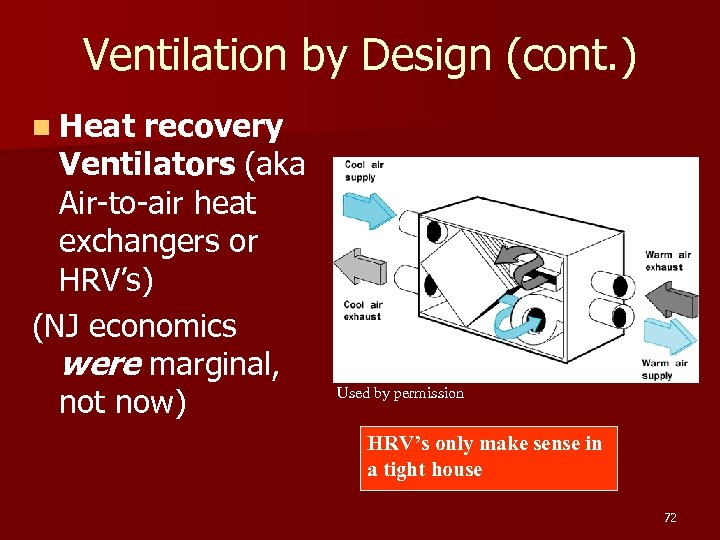

Ventilation by Design (cont. ) n Heat recovery Ventilators (aka Air-to-air heat exchangers or HRV’s) (NJ economics were marginal, not now) (c) Natural Resources Canada. Used by permission HRV’s only make sense in a tight house 72

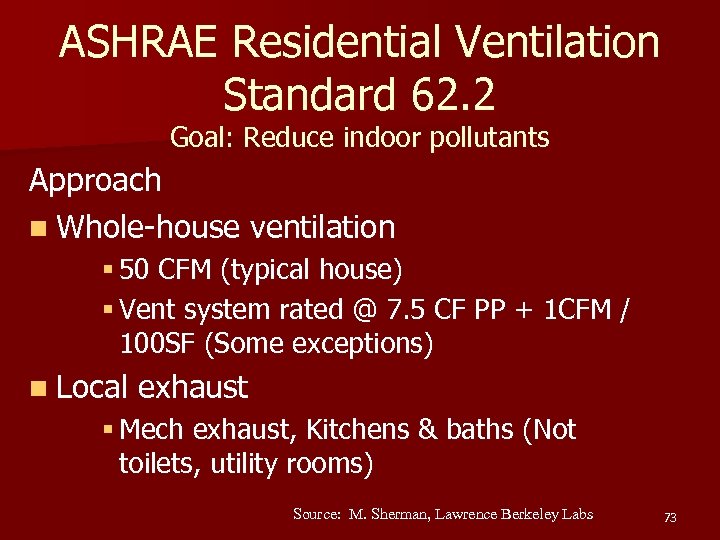

ASHRAE Residential Ventilation Standard 62. 2 Goal: Reduce indoor pollutants Approach n Whole-house ventilation § 50 CFM (typical house) § Vent system rated @ 7. 5 CF PP + 1 CFM / 100 SF (Some exceptions) n Local exhaust § Mech exhaust, Kitchens & baths (Not toilets, utility rooms) Source: M. Sherman, Lawrence Berkeley Labs 73

ASHRAE Residential Ventilation Standard 62. 2 (cont. ) n Source control § Some sources addressed --------------------------Backdraft testing required in some cases Some secondary requirements Some flexibility Lots of controversy 74

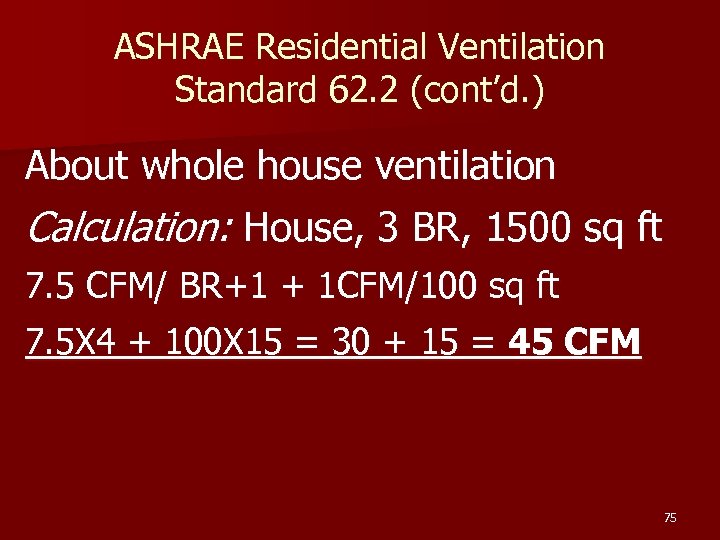

ASHRAE Residential Ventilation Standard 62. 2 (cont’d. ) About whole house ventilation Calculation: House, 3 BR, 1500 sq ft 7. 5 CFM/ BR+1 + 1 CFM/100 sq ft 7. 5 X 4 + 100 X 15 = 30 + 15 = 45 CFM 75

Airflows: Summary Why be concerned about airflows into & out of buildings? 1) Energy transfers (losses) 2) Moisture transport (into bldg or into walls) 3) Pollutant transport (eg radon, ozone, fireplace smoke, particulates, etc. ) And on the plus side, airflows provide 1) Fresh air 2) Replacement/ makeup air n 76

Airflow Dynamics Summary “Nature abhors a vacuum” The law that gases (and other materials) move from a region of high pressure to low pressure is analogous to, and as immutable as the law of gravity Pressures will equilibrate whenever there is a pathway, no matter how small or indirect 77

Airflow Dynamics Summary (cont. ) Amount of air entering (or leaving) through various openings (such as envelope leaks) vs. flue openings depends on relative sizes of openings OR If total envelope leaks are small relative to flue opening(s), some flues may become main sources of makeup air–a problem if flue is active! Direct vent or sealed combustion better 78

Airflows Summary Take Home Message: If building airflow is not balanced – inflow and exhaust not equal - the building will become pressurized or depressurized and bad things can happen. Likewise, pressure differentials can happen within the building. 79

References & Resources for this Section Building Science Corporation wwww. buildingscience. com n BFG: Builders Guide: Mixed Humid Climates. Energy and Environmental Building Association (EEBA): www. eeba. org n Lstiburek, J. Water Management Guide. Energy and Environmental Building Association (EEBA): 2004. www. eeba. org n Building America Best Practices Series: Volume 4. USDOE Building America program: www. buildingamerica. gov n 80

References (cont. ) n Lstiburek, J. Moisture Control for Buildings. ASHRAE Journal, Feb 02, pp 36 -41. HUD Moisture Resistant Homes. March 2006. 125 pp. Available at http: //www. huduser. org/publications/dest ech/moisturehomes. html Or call 1 -800 245 2691, option 1 for hard copy ($5. 00) n 81

f203b210d90e49592d0cc663f2dff021.ppt