BCII-Week 2-Floor2.ppt

- Количество слайдов: 39

BUILDING CONSTRUCTION II ECM 3154 WEEK 2 FLOOR – PART 2 Power. Point® Slides by Zamzarina Bt Md. Judyar Last Updated: © LMS SEGi education group 1

CHAPTER OVERVIEW • Last Updated: This chapter brings the student through the upper floor made of different materials including timber, reinforced concrete cast in situ, precast concrete, steel and composite. © LMS SEGi education group 2

LEARNING OBJECTIVES To highlight: • The materials used of upper floor. • The construction process of concrete, cast in-situ, pre cast and various types of reinforced concrete floors. • The advantages and disadvantages of each type of floor • The drawing plan of the various types of upper floors. Last Updated: © LMS SEGi education group 3

LEARNING OUTCOME On completion of this topic, students should be able: • To describe the floor finishes related to concrete floors • To read the drawing plan of the various types of upper floors. Last Updated: © LMS SEGi education group 4

UPPER FLOOR Last Updated: © LMS SEGi education group 5

TIMBER FLOOR / TIMBER SLAB TIMBER UPPER FLOORS The first floor timber joist Last Updated: © LMS SEGi education group theselfbuildblog. com 6

Precast Concrete Floor Last Updated: © LMS SEGi education group 7

PRECAST CONCRETE FLOOR • Last Updated: Advantages of Precast Concrete floor is a) Doesn’t need formwork b) Time taken for concrete to cure in the formwork can be eliminated c) Better quality control d) Doesn’t need many workers as in in-situ concrete construction e) Fast completion of construction project © LMS SEGi education group 8

PRECAST CONCRETE FLOOR • • • Last Updated: Long spans available with precast concrete flooring systems reduce the number of secondary beam required and maximize the column free space. Fire resistance ratings normally between 1 & 2 hours Among the things that need to be considered before considering any system of precast concrete flooring are: • Maximum span • Sound insulation • Nature of support • Thermal insulation properties © LMS SEGi education group 9

PRECAST CONCRETE FLOOR • • • Last Updated: Weight of units Fire resistance of units Thickness of units Speed of construction Amount of temporary support required © LMS SEGi education group 10

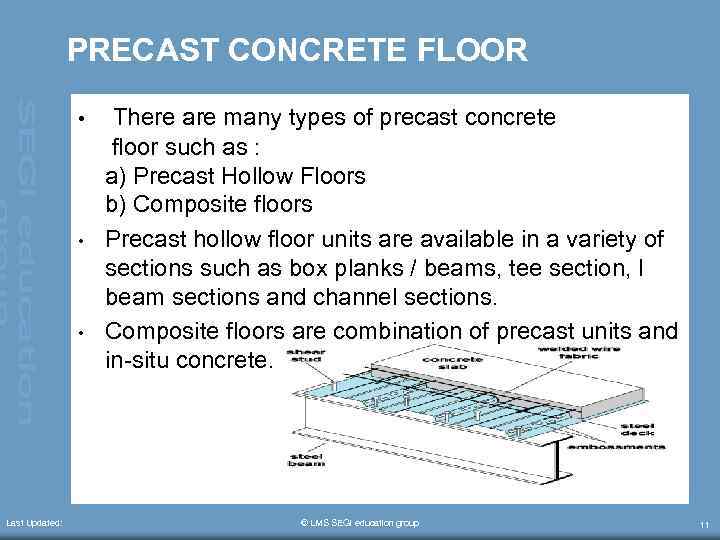

PRECAST CONCRETE FLOOR • • • Last Updated: There are many types of precast concrete floor such as : a) Precast Hollow Floors b) Composite floors Precast hollow floor units are available in a variety of sections such as box planks / beams, tee section, I beam sections and channel sections. Composite floors are combination of precast units and in-situ concrete. © LMS SEGi education group 11

precaststructure. com concretec. ae Precast Hollow Slab Last Updated: © LMS SEGi education group 12

PRECAST HOLLOW FLOORS • • • Last Updated: More economic compared to in-situ floor due to reduction in volume of concrete used, weight of reinforcement and size of foundation. Cheaper than composite In-situ concrete is not required Units are self centering so, no need temporarysupport Construction period is shorter © LMS SEGi education group 13

COMPOSITE FLOORS • • Last Updated: Combination of precast units and in situ concrete. Precast units that are usually prestressed / reinforced with high yield bars are used to provide the strength of the floor with the smallest depth practicable At the same time, act as permanent formwork to the insitu topping that provides the compressive strength required. Composite floors will act in the same manner as in-situ floor so it can be designed for more complex loadings © LMS SEGi education group 14

ustudy. in bricks-n-mortar. com Composite Floors Last Updated: © LMS SEGi education group 15

REINFORCED CONCRETE SLAB / FLOOR • • • Last Updated: In- Situ construction Flat Slab Flat Plate Slab Waffle Slab / Honeycomb Floors Beam Floor Slab © LMS SEGi education group 16

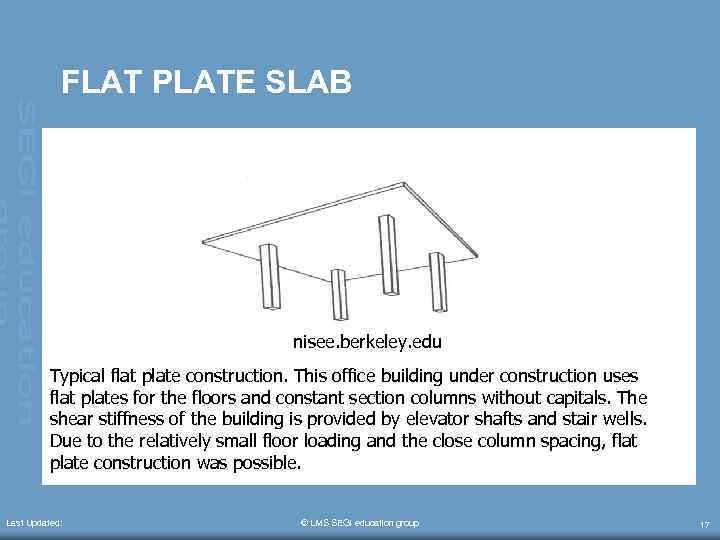

FLAT PLATE SLAB nisee. berkeley. edu Typical flat plate construction. This office building under construction uses flat plates for the floors and constant section columns without capitals. The shear stiffness of the building is provided by elevator shafts and stair wells. Due to the relatively small floor loading and the close column spacing, flat plate construction was possible. Last Updated: © LMS SEGi education group 17

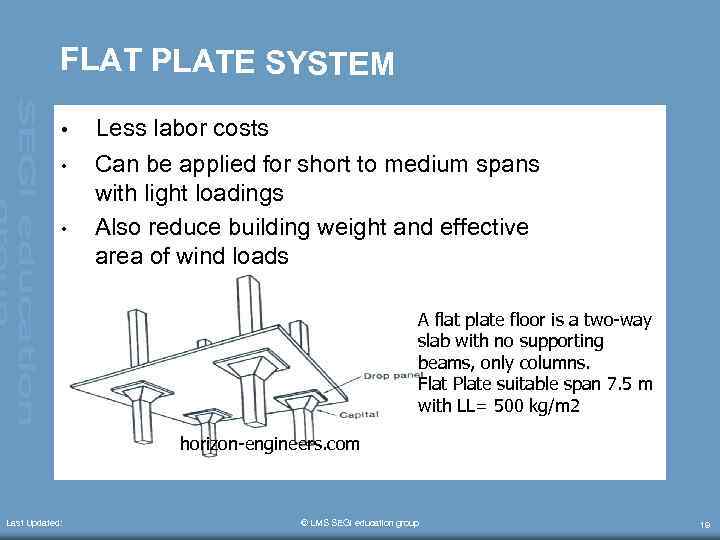

FLAT PLATE SYSTEM • • • Last Updated: Simple construction Flat plate construction can minimize storey height (piping, wall cladding, elevators etc) in areas with absolute height restrictions. Low storey heights due to shallow floor Spans < 20 ft (residential & light commercial) Flat ceilings (reduced finishing cost) Have the simplest formwork © LMS SEGi education group 18

FLAT PLATE SYSTEM • • • Less labor costs Can be applied for short to medium spans with light loadings Also reduce building weight and effective area of wind loads A flat plate floor is a two-way slab with no supporting beams, only columns. Flat Plate suitable span 7. 5 m with LL= 500 kg/m 2 horizon-engineers. com Last Updated: © LMS SEGi education group 19

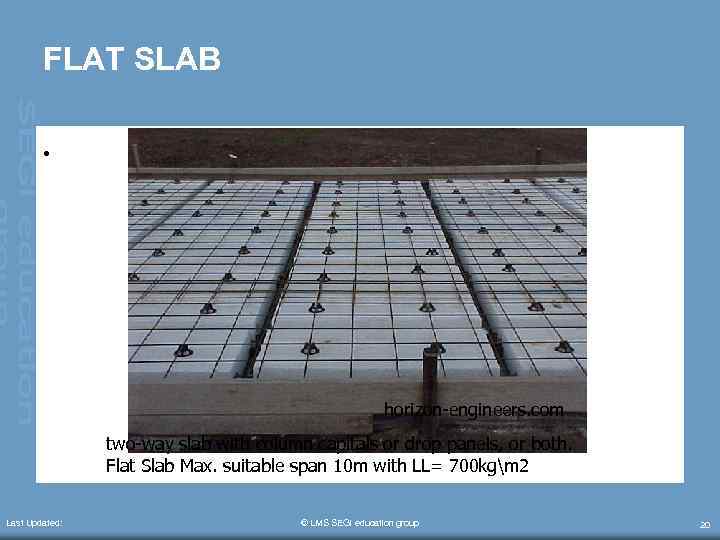

FLAT SLAB • horizon-engineers. com two-way slab with column capitals or drop panels, or both. Flat Slab Max. suitable span 10 m with LL= 700 kgm 2 Last Updated: © LMS SEGi education group 20

FLAT SLAB • • Last Updated: Reduce slab displacement Increased slab shear resistance This system provide relatively a flat ceilings (reduce finishing cost) Low storey heights due to shallow floor Medium span with light loading Spans 20 to 40 ft Live load > 100 psf (garage, warehouses) © LMS SEGi education group 21

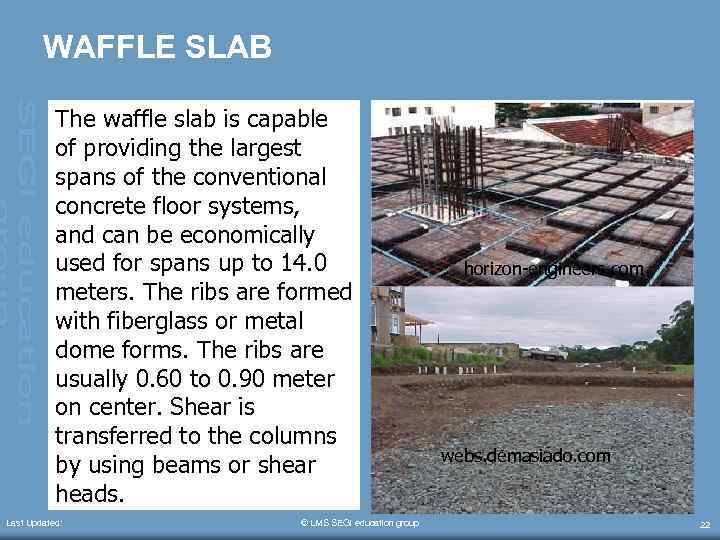

WAFFLE SLAB The waffle slab is capable of providing the largest spans of the conventional concrete floor systems, and can be economically used for spans up to 14. 0 meters. The ribs are formed with fiberglass or metal dome forms. The ribs are usually 0. 60 to 0. 90 meter on center. Shear is transferred to the columns by using beams or shear heads. Last Updated: © LMS SEGi education group horizon-engineers. com webs. demasiado. com 22

WAFFLE SLAB • • • Last Updated: Used as alternative to an in-site flat slab or a beam and slab suspended floor This is because it requires less concrete, less reinforcement and can be used to reduce the number of beams and columns required with the resultant savings on foundations. Moulds are very strong, lightweight & capable of supporting all the normal loads encountered in building works. © LMS SEGi education group 23

• • Last Updated: Spans >30 ft Use prefabricated standard forms special moulds are placed at certain distance skilled workers are needed & need less steel © LMS SEGi education group 24

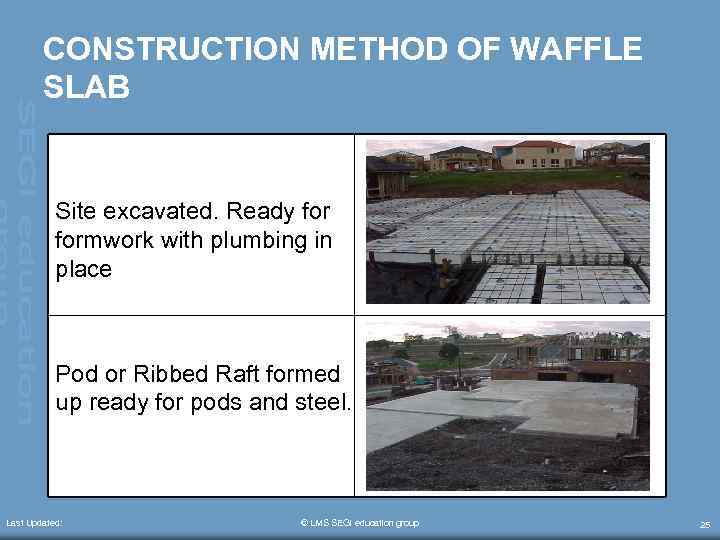

CONSTRUCTION METHOD OF WAFFLE SLAB Site excavated. Ready formwork with plumbing in place Pod or Ribbed Raft formed up ready for pods and steel. Last Updated: © LMS SEGi education group 25

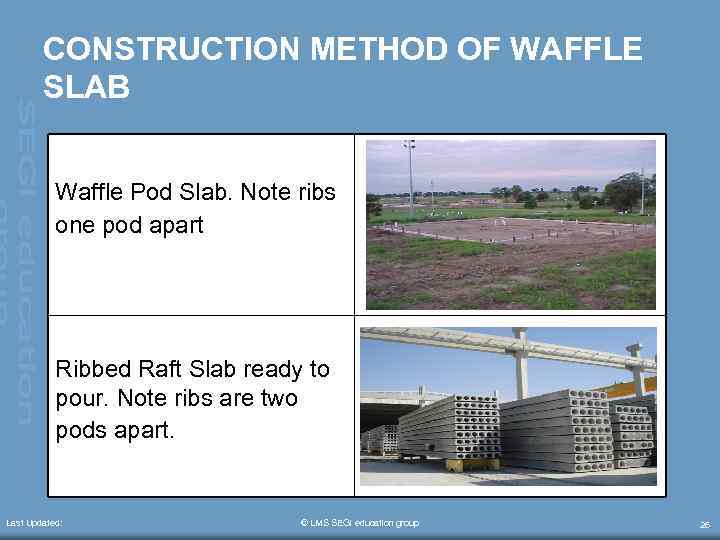

CONSTRUCTION METHOD OF WAFFLE SLAB Waffle Pod Slab. Note ribs one pod apart Ribbed Raft Slab ready to pour. Note ribs are two pods apart. Last Updated: © LMS SEGi education group 26

CONSTRUCTION METHOD OF WAFFLE SLAB Finished product. Last Updated: © LMS SEGi education group 27

SLAB DESIGN • • Last Updated: One Way Slab Two Way Slab - Require less steel - Few two slabs built in the area of high labor costs - Suitable for minimizing deflections © LMS SEGi education group 28

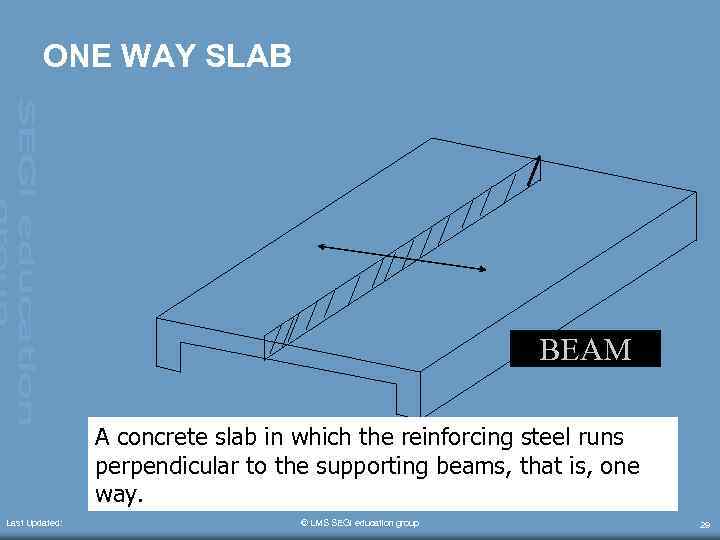

ONE WAY SLAB BEAM A concrete slab in which the reinforcing steel runs perpendicular to the supporting beams, that is, one way. Last Updated: © LMS SEGi education group 29

arch. hku. hk A concrete slab supported by beams along all four edges and reinforced with steel bars arranged perpendicularly. Two Way Slab Last Updated: © LMS SEGi education group 30

TYPES OF SLAB PROBLEM Damp Or Wet Floor Slab Cracking Of The Slab Cold Floor Last Updated: © LMS SEGi education group 31

CRACKING OF THE SLAB : CAUSES • • Last Updated: Poor construction techniques and practices Differential / Uneven settlement Inadequate structural strength of concrete Improper placement of reinforcing & mesh © LMS SEGi education group 32

Cracking Of The Slab Last Updated: © LMS SEGi education group 33

DAMP OR WET FLOOR SLAB : CAUSES • • Last Updated: Moisture migration through the slab Poor site drainage © LMS SEGi education group 34

QUIZZES 1. 2. Last Updated: List any Three (3) advantages of pre-cast concrete. a. ………………… b. ………………… c. ………………… Compare one way slab and two way slab. © LMS SEGi education group 35

KEY TERMS a. Compressive strength Definition Compressive strength is the capacity of a material or structure to withstand axially directed pushing forces. When the limit of compressive strength is reached, materials are crushed. Concrete can be made to have high compressive strength, e. g. many concrete structures have compressive strengths in excess of 50 MPa, whereas a material such as soft sandstone may have a compressive strength as low as 5 or 10 MPa. b. The rib Definition The ribs are forming elements of the building structure. Last Updated: © LMS SEGi education group 36

REFERENCES • • Last Updated: Chudley, Roy, Greeno, Roger (2007), Construction. Technology, 4 th Edition, Pearson Jack Stroud Foster (2007), Structure and Fabric Part 1, 7 th Edition, Pearson/ Prentice Hall Barry, R. (1998), The Construction of Building Vol 1, 7 th Edition, Blackwell Science Ivor H. Seeley (1995), Building Technology, 5 th Edition, Palgrave Macmillan. © LMS SEGi education group 37

References • • • theselfbuildblog. com retrieved 4 th August 2011 concretec. ae retrieved 4 th August 2011 precaststructure. com retrieved 4 th August 2011 • ustudy. in retrieved 4 th August 2011 bricks-n-mortar. com retrieved 4 th August 2011 • nisee. berkeley. edu retrieved 4 th August 2011 • • horizon-engineers. com retrieved 4 th August 2011 webs. demasiado. com retrieved 4 th August 2011 • arch. hku. hk retrieved 4 th August 2011 • Last Updated: © LMS SEGi education group 38

THE END Last Updated: © LMS SEGi education group 39

BCII-Week 2-Floor2.ppt