BCII-Week 10-Wall Finishes2.ppt

- Количество слайдов: 27

BUILDING CONSTRUCTION II ECM 3154 WEEK 10 INTERNAL CONSTRUCTION AND FINISHES – WALL FINISHES 2 Power. Point® Slides by Zamzarina Bt Md. Judyar Last Updated: © LMS SEGi education group 1

CHAPTER OVERVIEW • Last Updated: This chapter brings the student through the internal construction and finishes for internal walls. © LMS SEGi education group 2

LEARNING OBJECTIVES • Last Updated: To explain the types, functions, methods and performance standards of internal walls as well the various types of wall finishes. © LMS SEGi education group 3

LEARNING OUTCOMES • Last Updated: On completion of this topic, students should be aware of the code requirements for various types of interior walls and select appropriate designs and materials for interior of walls. © LMS SEGi education group 4

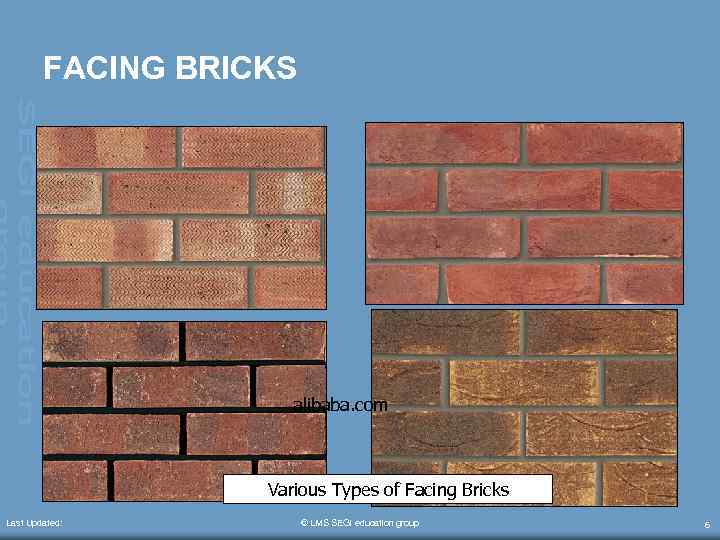

WALL FINISHES • Last Updated: i. Facing Bricks • External brickwork with and exposed face of facing bricks is a self-finish and requires no further treatment. © LMS SEGi education group 5

FACING BRICKS alibaba. com Various Types of Facing Bricks Last Updated: © LMS SEGi education group 6

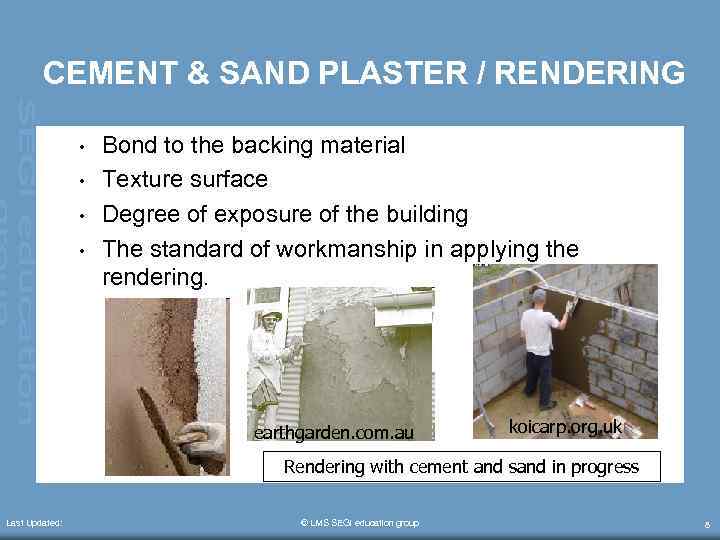

WALL FINISHES (CONT’D) • • Last Updated: ii. Cement & Sand Plaster / Rendering This is a form of plastering using a mixture of cement, lime and sand, applied to the face of a building to give extra protection against the penetration of moisture or to provide a desired texture. The rendering must have the properties of durability, moisture resistance and an acceptable appearance. The factors to be taken into account in achieving the above requirements are: • Mix design © LMS SEGi education group 7

CEMENT & SAND PLASTER / RENDERING • • Bond to the backing material Texture surface Degree of exposure of the building The standard of workmanship in applying the rendering. earthgarden. com. au koicarp. org. uk Rendering with cement and sand in progress Last Updated: © LMS SEGi education group 8

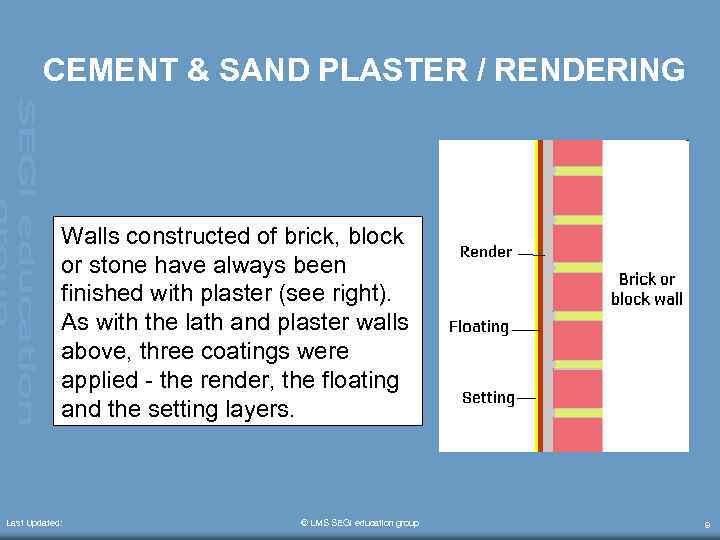

CEMENT & SAND PLASTER / RENDERING Walls constructed of brick, block or stone have always been finished with plaster (see right). As with the lath and plaster walls above, three coatings were applied - the render, the floating and the setting layers. Last Updated: © LMS SEGi education group 9

WALL FINISHES (CONT’D) • • • Last Updated: iii. Plastering The plaster used was a lime plaster, which generally has been superseded by gypsum plaster. The advantages of lime plastering are: • Drying shrinkage, which causes cracking • Slow drying-out process, which can take several weeks, causing delay for the following trades • Need to apply lime plaster in several coats, usually termed render, float and set, to reduce the amount of shrinkage. © LMS SEGi education group 10

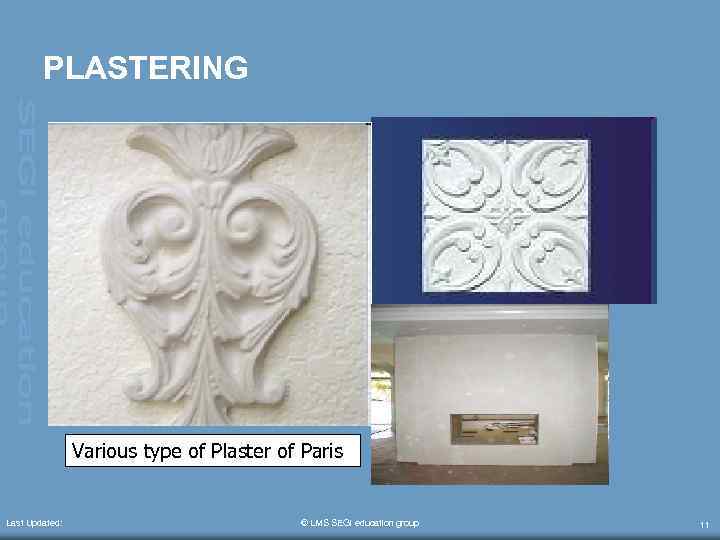

PLASTERING Various type of Plaster of Paris Last Updated: © LMS SEGi education group 11

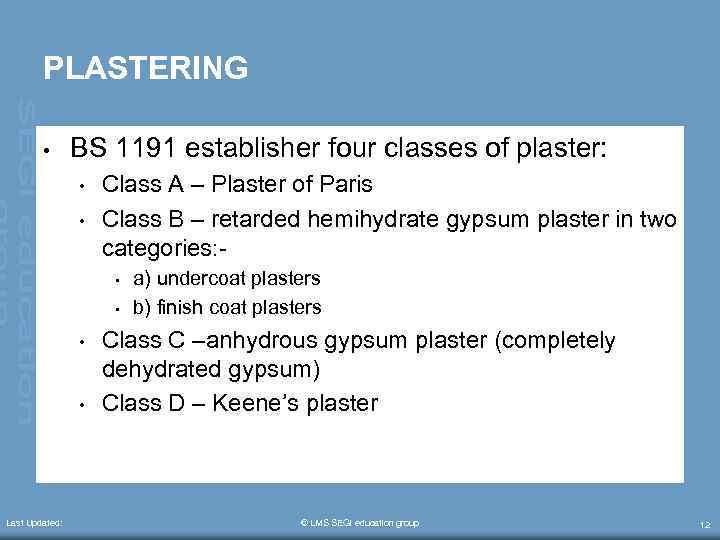

PLASTERING • BS 1191 establisher four classes of plaster: • • Class A – Plaster of Paris Class B – retarded hemihydrate gypsum plaster in two categories: • • Last Updated: a) undercoat plasters b) finish coat plasters Class C –anhydrous gypsum plaster (completely dehydrated gypsum) Class D – Keene’s plaster © LMS SEGi education group 12

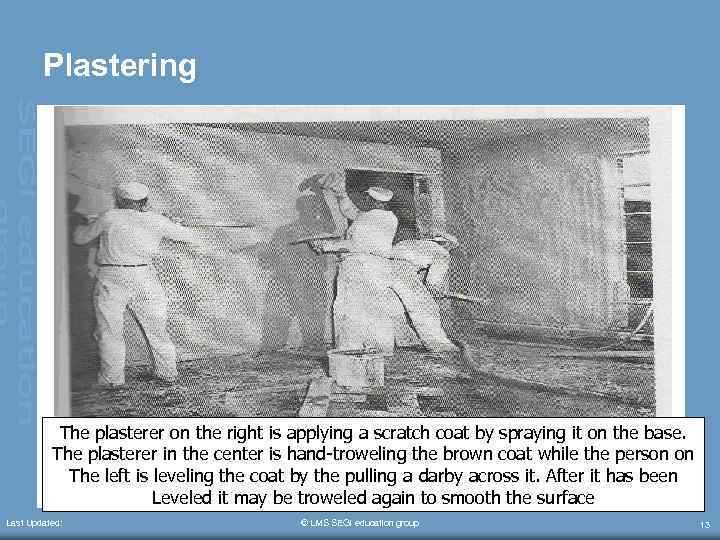

Plastering The plasterer on the right is applying a scratch coat by spraying it on the base. The plasterer in the center is hand-troweling the brown coat while the person on The left is leveling the coat by the pulling a darby across it. After it has been Leveled it may be troweled again to smooth the surface Last Updated: © LMS SEGi education group 13

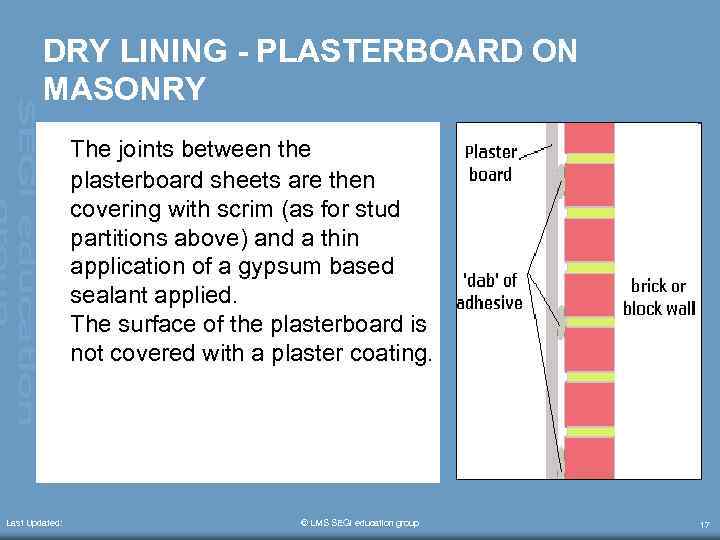

WALL FINISHES (CONT’D) • • • Last Updated: iv. Drylining Technique Dry-lining is a modern, popular, quick alternative to applying plaster on brick, block or stone walls. External walls or internall walls and partitions can be drylined with a variety of materials, which can be selffinished, ready for direct decoration, or have a surface suitable for a single final coat of board finish plaster. Suitable materials are hardboard, chipboard and plasterboard. Plasterboard is simply held in place by numerous 'dabs' of plaster adhesive. © LMS SEGi education group 14

WALL FINISHES (CONT’D) • Last Updated: The masonry wall is covered with a series the adhesive 'dabs' spaced horizontally and vertically about 400 mm (16 inches) apart and then the plasterboard sheeting is pushed onto these 'dabs', pushed up to adjacent sheets and leveled. © LMS SEGi education group 15

WALL FINISHES (CONT’D) • Advantages of drylining • • Last Updated: Speed Reduction in the amount of water used in the construction of building Thus reducing drying out period Increased thermal insulation © LMS SEGi education group 16

DRY LINING - PLASTERBOARD ON MASONRY The joints between the plasterboard sheets are then covering with scrim (as for stud partitions above) and a thin application of a gypsum based sealant applied. The surface of the plasterboard is not covered with a plaster coating. Last Updated: © LMS SEGi education group 17

DRYLINING Drylining the wall Last Updated: © LMS SEGi education group 18

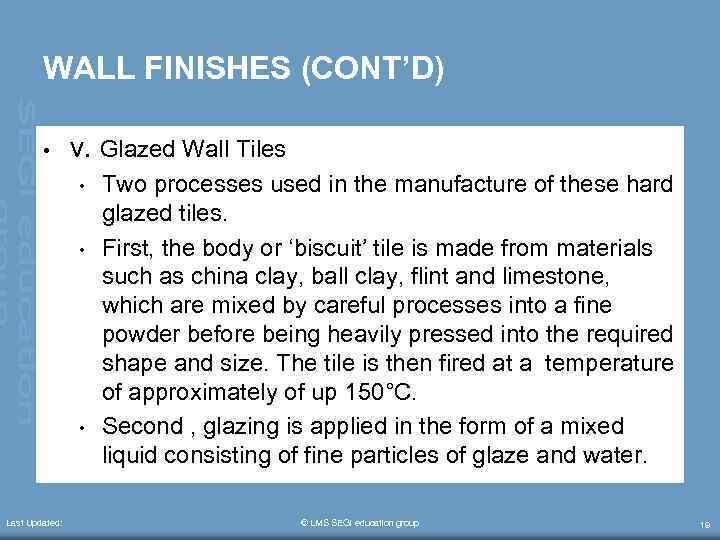

WALL FINISHES (CONT’D) • v. Glazed Wall Tiles • • • Last Updated: Two processes used in the manufacture of these hard glazed tiles. First, the body or ‘biscuit’ tile is made from materials such as china clay, ball clay, flint and limestone, which are mixed by careful processes into a fine powder before being heavily pressed into the required shape and size. The tile is then fired at a temperature of approximately of up 150°C. Second , glazing is applied in the form of a mixed liquid consisting of fine particles of glaze and water. © LMS SEGi education group 19

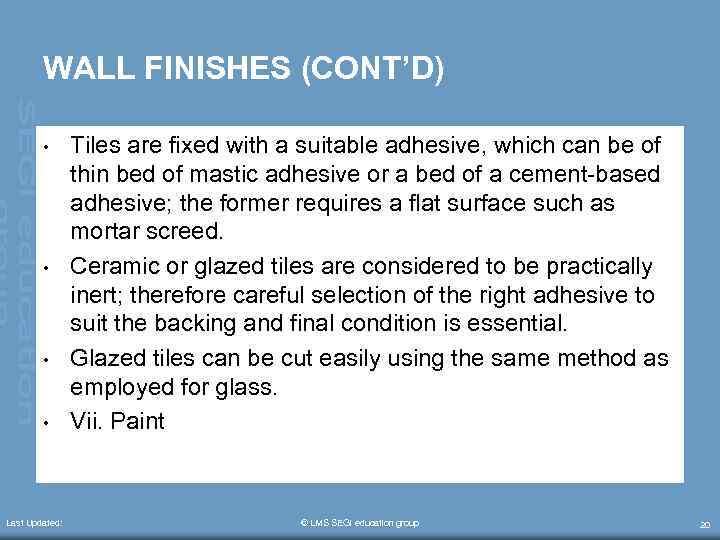

WALL FINISHES (CONT’D) • • Last Updated: Tiles are fixed with a suitable adhesive, which can be of thin bed of mastic adhesive or a bed of a cement-based adhesive; the former requires a flat surface such as mortar screed. Ceramic or glazed tiles are considered to be practically inert; therefore careful selection of the right adhesive to suit the backing and final condition is essential. Glazed tiles can be cut easily using the same method as employed for glass. Vii. Paint © LMS SEGi education group 20

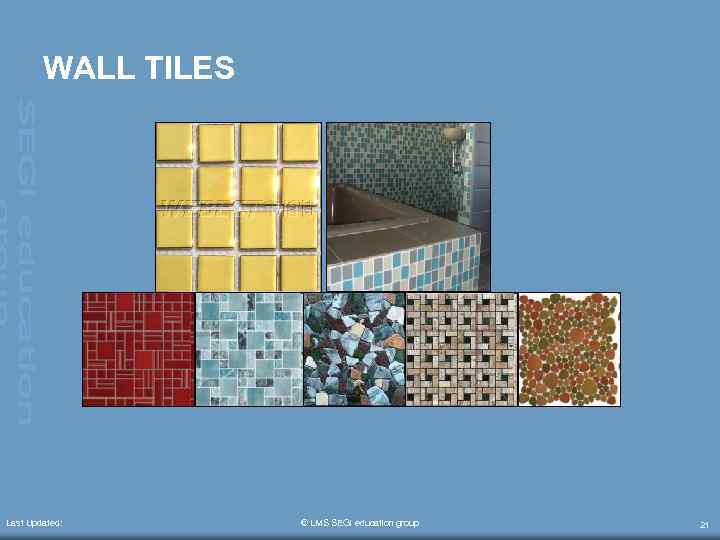

WALL TILES Last Updated: © LMS SEGi education group 21

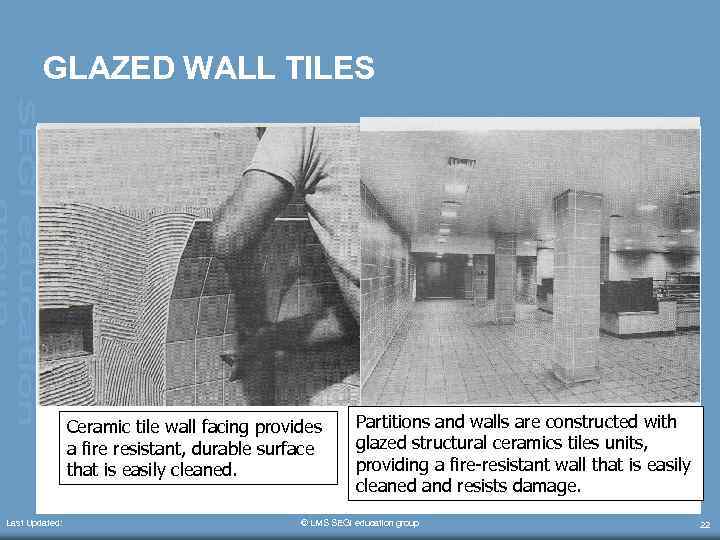

GLAZED WALL TILES Ceramic tile wall facing provides a fire resistant, durable surface that is easily cleaned. Last Updated: Partitions and walls are constructed with glazed structural ceramics tiles units, providing a fire-resistant wall that is easily cleaned and resists damage. © LMS SEGi education group 22

PAINT Last Updated: © LMS SEGi education group 23

QUIZZES 1. Define plastering. ……………………………………………………………… 2. Identify advantages of lime plastering. ……………………………………… Last Updated: © LMS SEGi education group 24

KEY TERMS 1. Low porosity Definition Porosity or void fraction is a measure of the void (i. e. , "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0– 1, or as a percentage between 0– 100%. 2. Ferrous metal Definition A metal that contains iron. The most common ferrous metal is steel. 3. Friable Definition Easily broken into small fragments or reduced to powder Last Updated: 2/18/2018 Updated: © LMS SEGi education group 25

REFERENCES • • Last Updated: Chudley, R. , & Greeno, R. , 2005. Construction Technology, 4 th ed. England: Pearson. Chudley, R. , & Greeno, R. , 2001. Advanced Construction. Technology, 3 rd ed. England: Longman. Spence, W. , D. , 2006. Construction Materials, Methods, and Techniques, 2 nd ed. US: Delmar. constructionphotography. com retrieved 19 th August 2011 © LMS SEGi education group 26

The End. Last Updated: © LMS SEGi education group 27

BCII-Week 10-Wall Finishes2.ppt