0296a6b14e5b61a9f0f5512b6bc1e759.ppt

- Количество слайдов: 43

Bubble and Slurry columns CHEMICAL REACTION ENGINEERING LABORATORY

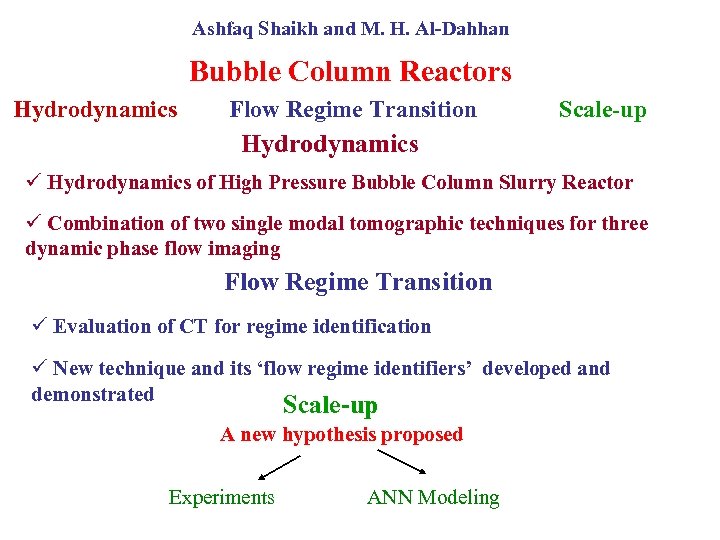

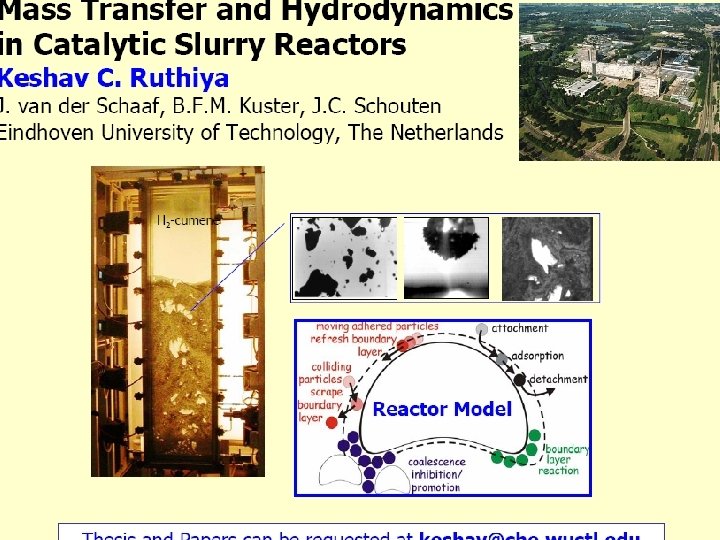

Ashfaq Shaikh and M. H. Al-Dahhan Bubble Column Reactors Hydrodynamics Flow Regime Transition Scale-up Hydrodynamics ü Hydrodynamics of High Pressure Bubble Column Slurry Reactor ü Combination of two single modal tomographic techniques for three dynamic phase flow imaging Flow Regime Transition ü Evaluation of CT for regime identification ü New technique and its ‘flow regime identifiers’ developed and demonstrated Scale-up A new hypothesis proposed Experiments ANN Modeling

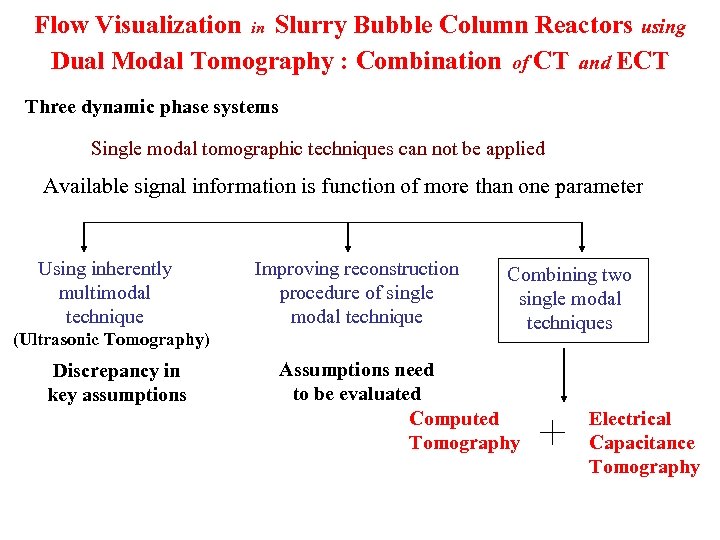

Flow Visualization in Slurry Bubble Column Reactors using Dual Modal Tomography : Combination of CT and ECT Three dynamic phase systems Single modal tomographic techniques can not be applied Available signal information is function of more than one parameter Using inherently multimodal technique (Ultrasonic Tomography) Discrepancy in key assumptions Improving reconstruction procedure of single modal technique Combining two single modal techniques Assumptions need to be evaluated Computed Tomography Electrical Capacitance Tomography

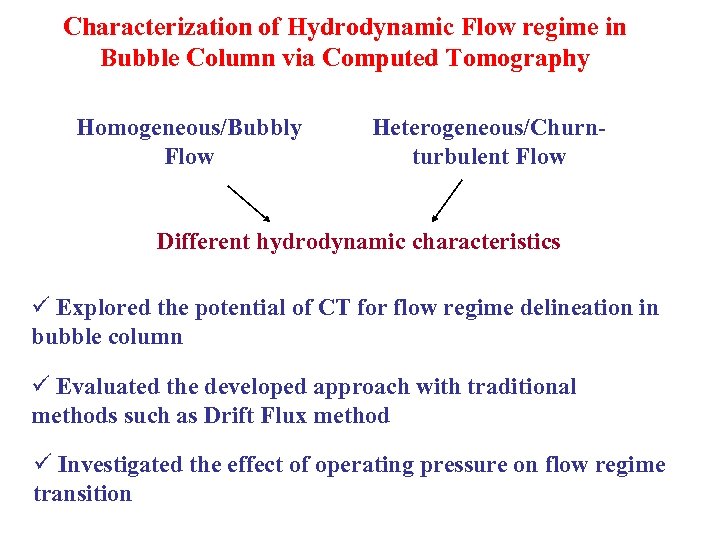

Characterization of Hydrodynamic Flow regime in Bubble Column via Computed Tomography Homogeneous/Bubbly Flow Heterogeneous/Churnturbulent Flow Different hydrodynamic characteristics ü Explored the potential of CT for flow regime delineation in bubble column ü Evaluated the developed approach with traditional methods such as Drift Flux method ü Investigated the effect of operating pressure on flow regime transition

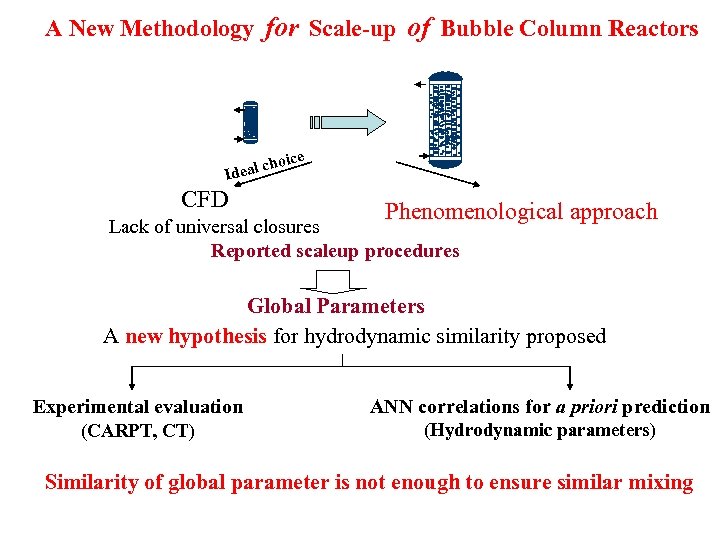

A New Methodology for Scale-up of Bubble Column Reactors ice al cho Ide CFD Phenomenological approach Lack of universal closures Reported scaleup procedures Global Parameters A new hypothesis for hydrodynamic similarity proposed Experimental evaluation ANN correlations for a priori prediction (CARPT, CT) (Hydrodynamic parameters) Similarity of global parameter is not enough to ensure similar mixing

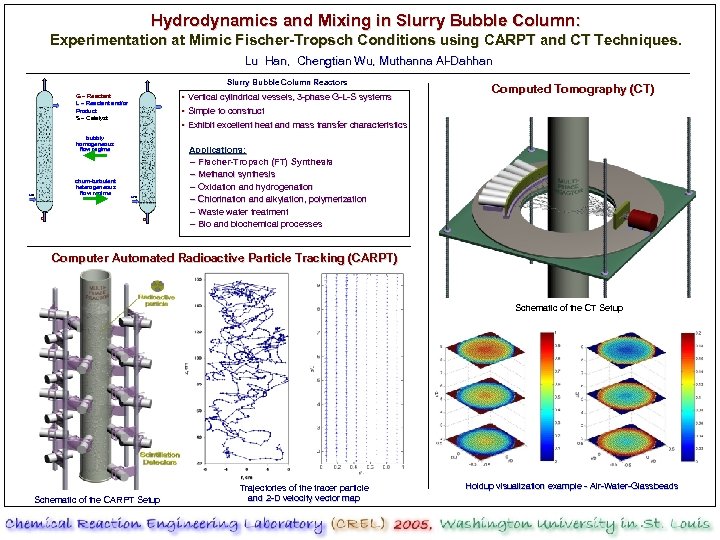

Hydrodynamics and Mixing in Slurry Bubble Column: Experimentation at Mimic Fischer-Tropsch Conditions using CARPT and CT Techniques. Lu Han, Chengtian Wu, Muthanna Al-Dahhan Slurry Bubble Column Reactors • Vertical cylindrical vessels, 3 -phase G-L-S systems • Simple to construct • Exhibit excellent heat and mass transfer characteristics G – Reactant L – Reactant and/or Product S – Catalyst bubbly homogeneous flow regime churn-turbulent heterogeneous flow regime L+S L+ G L+S G Computed Tomography (CT) Applications: – Fischer-Tropsch (FT) Synthesis Fischer-Tropsch – Methanol synthesis – Oxidation and hydrogenation – Chlorination and alkylation, polymerization – Waste water treatment – Bio and biochemical processes Computer Automated Radioactive Particle Tracking (CARPT) Schematic of the CT Setup Schematic of the CARPT Setup Trajectories of the tracer particle and 2 -D velocity vector map Holdup visualization example - Air-Water-Glassbeads

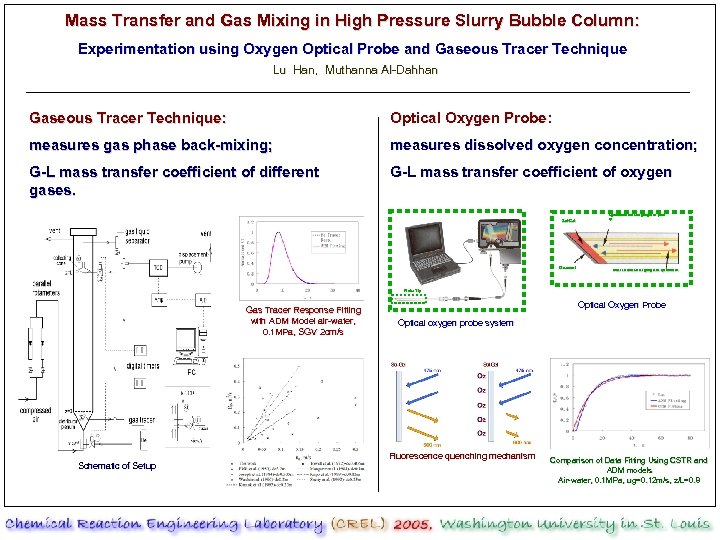

Mass Transfer and Gas Mixing in High Pressure Slurry Bubble Column: Experimentation using Oxygen Optical Probe and Gaseous Tracer Technique Lu Han, Muthanna Al-Dahhan Gaseous Tracer Technique: Optical Oxygen Probe: measures gas phase back-mixing; measures dissolved oxygen concentration; G-L mass transfer coefficient of different gases. G-L mass transfer coefficient of oxygen Sol-Gel Overcoat Light from the blue LED going to the probe tip Collected fluorescence going to the spectrometer Probe Tip Gas Tracer Response Fitting with ADM Model air-water, 0. 1 MPa, SGV 2 cm/s Schematic of Setup Optical Oxygen Probe Optical oxygen probe system Fluorescence quenching mechanism Comparison of Data Fitting Using CSTR and ADM models Air-water, 0. 1 MPa, ug=0. 12 m/s, z/L=0. 8 ug=0. 12 m/s,

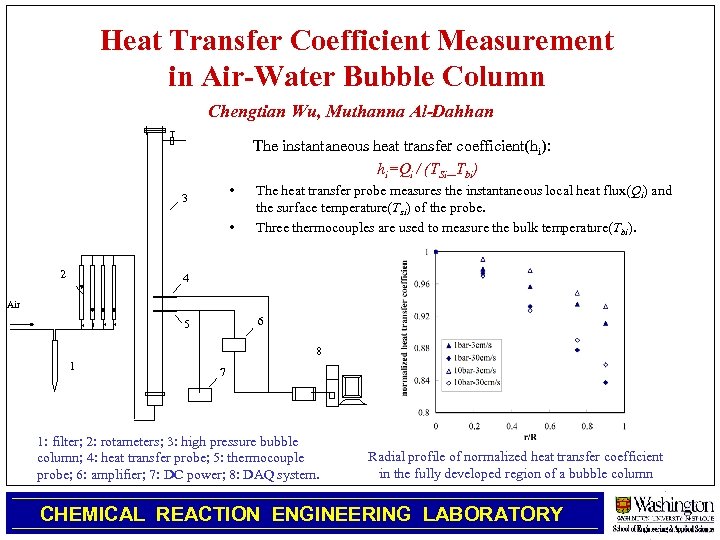

Heat Transfer Coefficient Measurement in Air-Water Bubble Column Chengtian Wu, Muthanna Al-Dahhan The instantaneous heat transfer coefficient(hi): hi=Qi / (TSi—Tbi) • 3 • 2 The heat transfer probe measures the instantaneous local heat flux(Qi) and the surface temperature(Tsi) of the probe. Three thermocouples are used to measure the bulk temperature(Tbi). 4 Air 6 5 8 1 7 1: filter; 2: rotameters; 3: high pressure bubble column; 4: heat transfer probe; 5: thermocouple probe; 6: amplifier; 7: DC power; 8: DAQ system. Radial profile of normalized heat transfer coefficient in the fully developed region of a bubble column CHEMICAL REACTION ENGINEERING LABORATORY

Circulating Fluidized Beds/ Mini Packed bed reactor CHEMICAL REACTION ENGINEERING LABORATORY

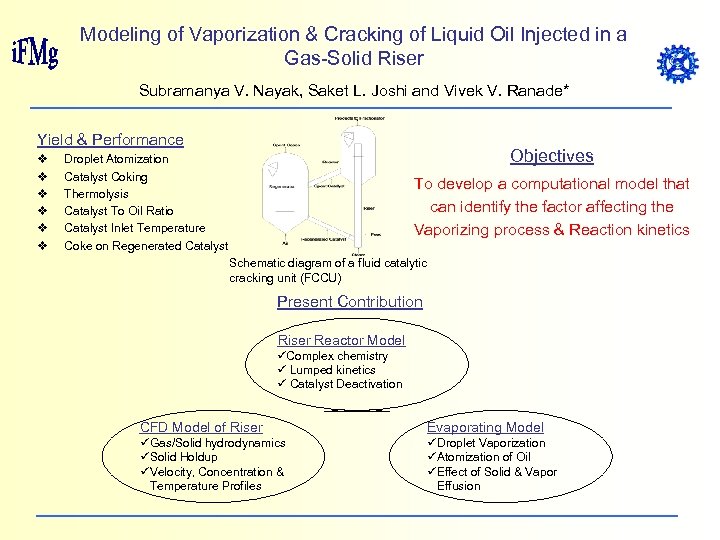

Modeling of Vaporization & Cracking of Liquid Oil Injected in a Gas-Solid Riser Subramanya V. Nayak, Saket L. Joshi and Vivek V. Ranade* Yield & Performance v v v Objectives Droplet Atomization Catalyst Coking Thermolysis Catalyst To Oil Ratio Catalyst Inlet Temperature Coke on Regenerated Catalyst To develop a computational model that can identify the factor affecting the Vaporizing process & Reaction kinetics Schematic diagram of a fluid catalytic cracking unit (FCCU) Present Contribution Riser Reactor Model üComplex chemistry ü Lumped kinetics ü Catalyst Deactivation CFD Model of Riser Evaporating Model üGas/Solid hydrodynamics üSolid Holdup üVelocity, Concentration & Temperature Profiles üDroplet Vaporization üAtomization of Oil üEffect of Solid & Vapor Effusion

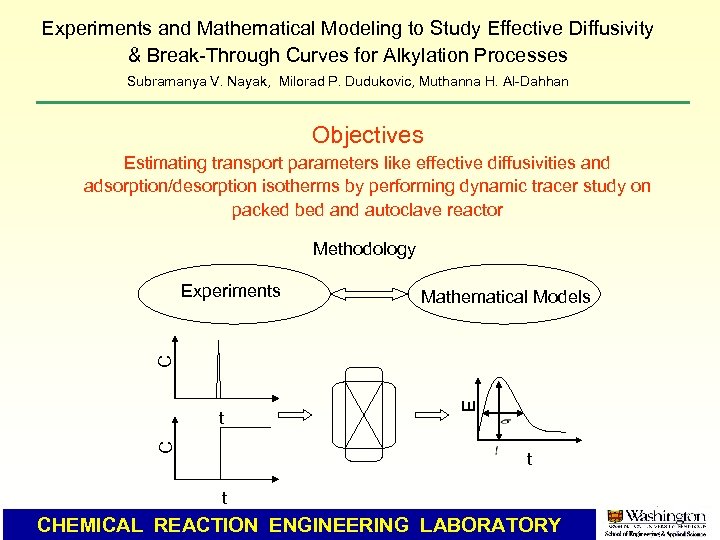

Experiments and Mathematical Modeling to Study Effective Diffusivity & Break-Through Curves for Alkylation Processes Subramanya V. Nayak, Milorad P. Dudukovic, Muthanna H. Al-Dahhan Objectives Estimating transport parameters like effective diffusivities and adsorption/desorption isotherms by performing dynamic tracer study on packed bed and autoclave reactor Methodology Mathematical Models C t E C Experiments t t CHEMICAL REACTION ENGINEERING LABORATORY

Trickle Bed/ Measurement Techniques CHEMICAL REACTION ENGINEERING LABORATORY

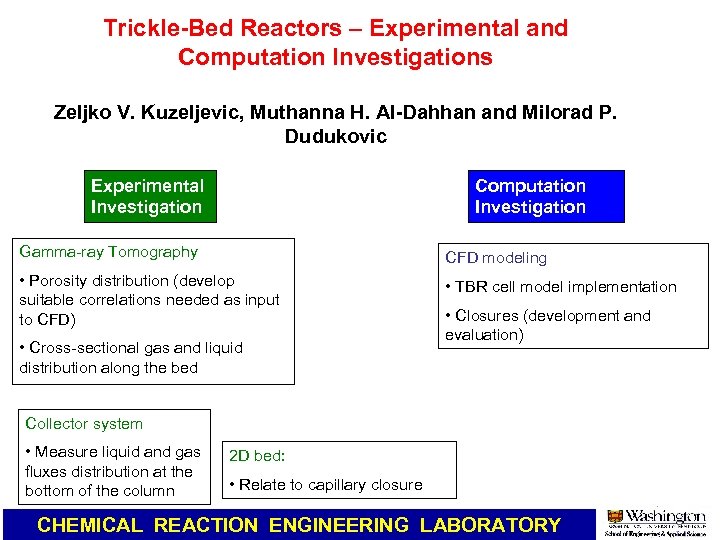

Trickle-Bed Reactors – Experimental and Computation Investigations Zeljko V. Kuzeljevic, Muthanna H. Al-Dahhan and Milorad P. Dudukovic Experimental Investigation Computation Investigation Gamma-ray Tomography CFD modeling • Porosity distribution (develop suitable correlations needed as input to CFD) • TBR cell model implementation • Cross-sectional gas and liquid distribution along the bed • Closures (development and evaluation) Collector system • Measure liquid and gas fluxes distribution at the bottom of the column 2 D bed: • Relate to capillary closure CHEMICAL REACTION ENGINEERING LABORATORY

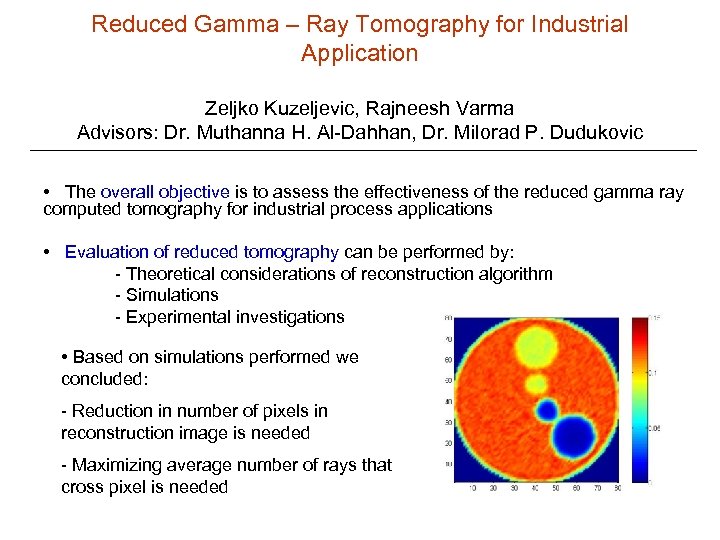

Reduced Gamma – Ray Tomography for Industrial Application Zeljko Kuzeljevic, Rajneesh Varma Advisors: Dr. Muthanna H. Al-Dahhan, Dr. Milorad P. Dudukovic • The overall objective is to assess the effectiveness of the reduced gamma ray computed tomography for industrial process applications • Evaluation of reduced tomography can be performed by: - Theoretical considerations of reconstruction algorithm - Simulations - Experimental investigations • Based on simulations performed we concluded: - Reduction in number of pixels in reconstruction image is needed - Maximizing average number of rays that cross pixel is needed

Liquid Maldistribution in Trickle-Bed Reactors at Elevated Pressure Pierre-Yves Lanfrey (July 2005 – October 2006) TOTAL advisors: Pr. Philippe Tanguy, Jacques Bousquet and Nicolas Dromard. CREL advisors: Pr. Milorad Dudukovic and Muthanna Al-Dahhan. Operating conditions: - real catalyst (porous cylindrical particles), - 10 bar with pre-wetted beds, - uniform gas-liquid distributor, - air-water and air-oil systems. Study of the phase distribution by: - gamma-ray Computed Tomography (CT), - fluids outlet collection. 17

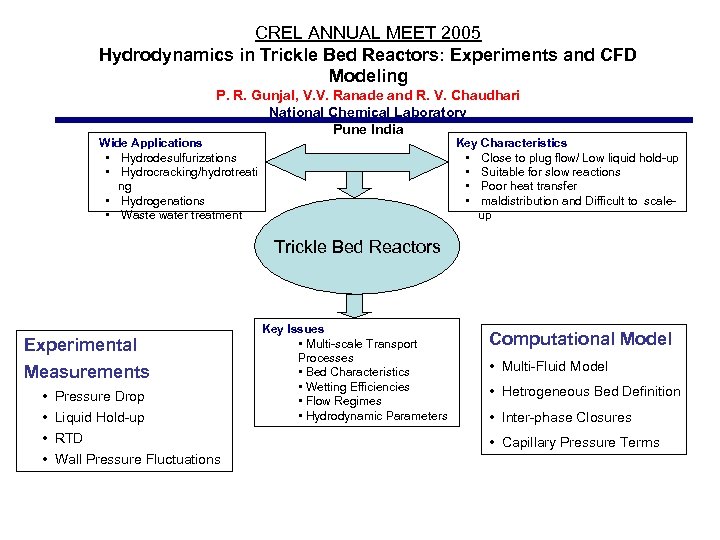

CREL ANNUAL MEET 2005 Hydrodynamics in Trickle Bed Reactors: Experiments and CFD Modeling P. R. Gunjal, V. V. Ranade and R. V. Chaudhari National Chemical Laboratory Pune India Wide Applications • Hydrodesulfurizations • Hydrocracking/hydrotreati ng • Hydrogenations • Waste water treatment Key Characteristics • Close to plug flow/ Low liquid hold-up • Suitable for slow reactions • Poor heat transfer • maldistribution and Difficult to scaleup Trickle Bed Reactors Experimental Measurements • • Pressure Drop Liquid Hold-up RTD Wall Pressure Fluctuations Key Issues • Multi-scale Transport Processes • Bed Characteristics • Wetting Efficiencies • Flow Regimes • Hydrodynamic Parameters Computational Model • Multi-Fluid Model • Hetrogeneous Bed Definition • Inter-phase Closures • Capillary Pressure Terms

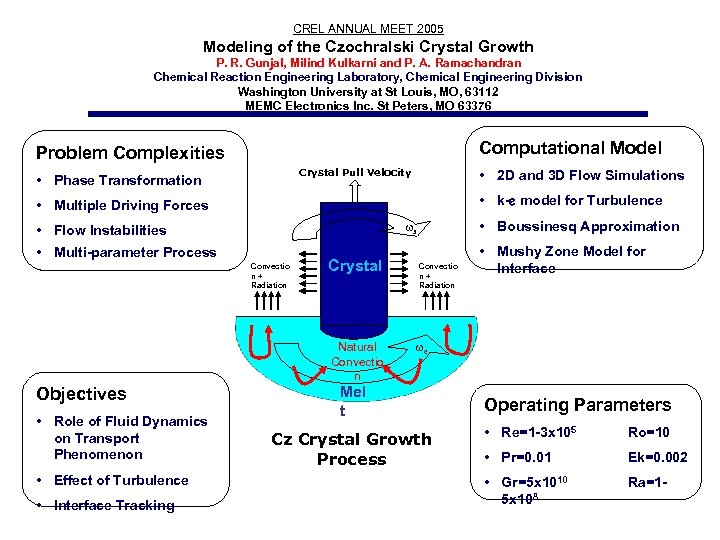

CREL ANNUAL MEET 2005 Modeling of the Czochralski Crystal Growth P. R. Gunjal, Milind Kulkarni and P. A. Ramachandran Chemical Reaction Engineering Laboratory, Chemical Engineering Division Washington University at St Louis, MO, 63112 MEMC Electronics Inc. St Peters, MO 63376 Computational Model Problem Complexities Crystal Pull Velocity • Phase Transformation • 2 D and 3 D Flow Simulations • k-e model for Turbulence • Multiple Driving Forces • Multi-parameter Process Convectio n+ Radiation Crystal Natural Convectio n Objectives • Role of Fluid Dynamics on Transport Phenomenon • Effect of Turbulence • Interface Tracking • Boussinesq Approximation ws • Flow Instabilities Convectio n+ Radiation • Mushy Zone Model for Interface wc Mel t Cz Crystal Growth Process Operating Parameters • Re=1 -3 x 105 Ro=10 • Pr=0. 01 Ek=0. 002 • Gr=5 x 1010 5 x 108 Ra=1 -

Packed bed/ Mixed tanks CHEMICAL REACTION ENGINEERING LABORATORY

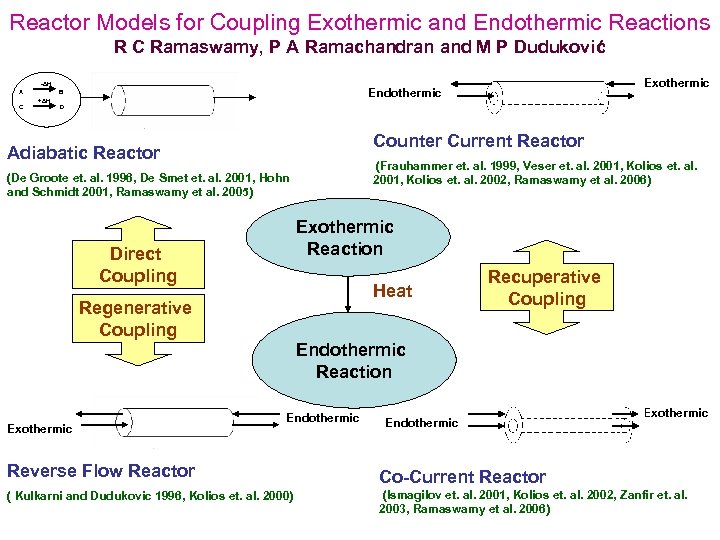

Reactor Models for Coupling Exothermic and Endothermic Reactions R C Ramaswamy, P A Ramachandran and M P Duduković -ΔH A C +ΔH Exothermic Endothermic B D Counter Current Reactor Adiabatic Reactor (Frauhammer et. al. 1999, Veser et. al. 2001, Kolios et. al. 2002, Ramaswamy et al. 2006) (De Groote et. al. 1996, De Smet et. al. 2001, Hohn and Schmidt 2001, Ramaswamy et al. 2005) Exothermic Reaction Direct Coupling Heat Regenerative Coupling Recuperative Coupling Endothermic Reaction Exothermic Endothermic Reverse Flow Reactor ( Kulkarni and Dudukovic 1996, Kolios et. al. 2000) Endothermic Exothermic Co-Current Reactor (Ismagilov et. al. 2001, Kolios et. al. 2002, Zanfir et. al. 2003, Ramaswamy et al. 2006)

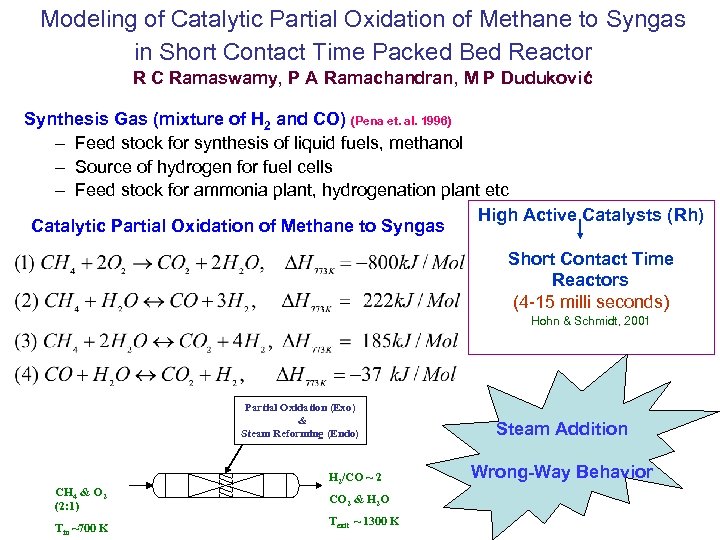

Modeling of Catalytic Partial Oxidation of Methane to Syngas in Short Contact Time Packed Bed Reactor R C Ramaswamy, P A Ramachandran, M P Duduković Synthesis Gas (mixture of H 2 and CO) (Pena et. al. 1996) – Feed stock for synthesis of liquid fuels, methanol – Source of hydrogen for fuel cells – Feed stock for ammonia plant, hydrogenation plant etc High Active Catalysts (Rh) Catalytic Partial Oxidation of Methane to Syngas Short Contact Time Reactors (4 -15 milli seconds) Hohn & Schmidt, 2001 Partial Oxidation (Exo) & Steam Reforming (Endo) CH 4 & O 2 (2: 1) Tin ~700 K H 2/CO ~ 2 CO 2 & H 2 O Texit ~ 1300 K Steam Addition Wrong-Way Behavior

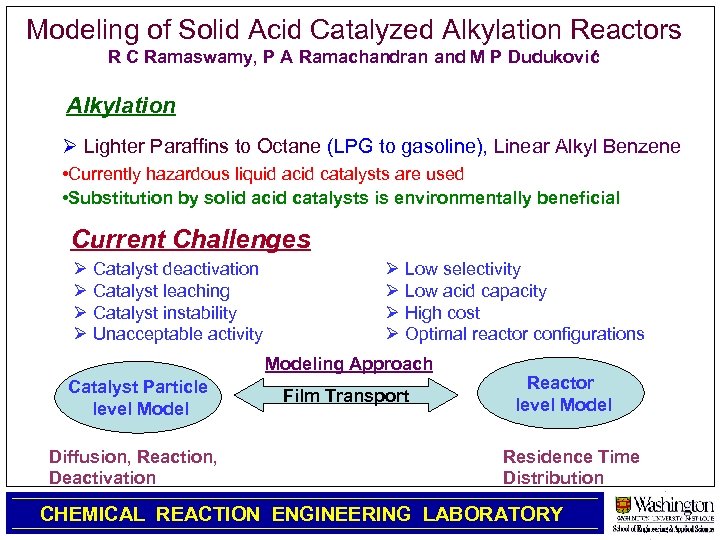

Modeling of Solid Acid Catalyzed Alkylation Reactors R C Ramaswamy, P A Ramachandran and M P Duduković Alkylation Ø Lighter Paraffins to Octane (LPG to gasoline), Linear Alkyl Benzene • Currently hazardous liquid acid catalysts are used • Substitution by solid acid catalysts is environmentally beneficial Current Challenges Ø Catalyst deactivation Ø Catalyst leaching Ø Catalyst instability Ø Unacceptable activity Ø Low selectivity Ø Low acid capacity Ø High cost Ø Optimal reactor configurations Modeling Approach Catalyst Particle level Model Diffusion, Reaction, Deactivation Film Transport Reactor level Model Residence Time Distribution CHEMICAL REACTION ENGINEERING LABORATORY

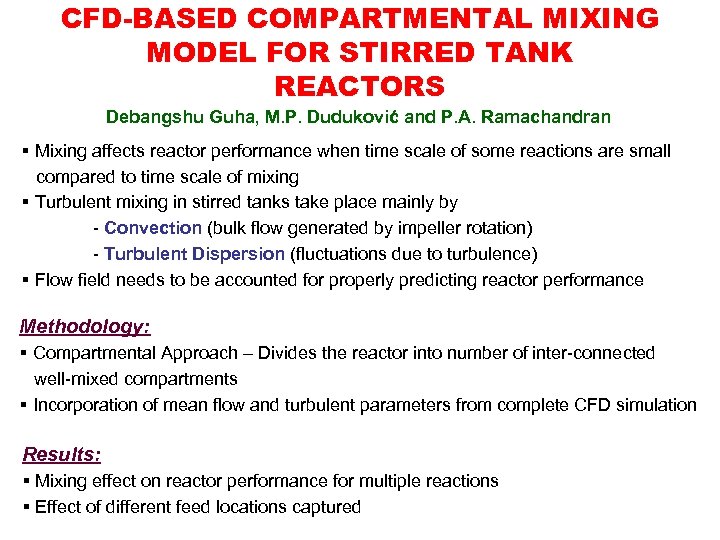

CFD-BASED COMPARTMENTAL MIXING MODEL FOR STIRRED TANK REACTORS Debangshu Guha, M. P. Duduković and P. A. Ramachandran § Mixing affects reactor performance when time scale of some reactions are small compared to time scale of mixing § Turbulent mixing in stirred tanks take place mainly by - Convection (bulk flow generated by impeller rotation) - Turbulent Dispersion (fluctuations due to turbulence) § Flow field needs to be accounted for properly predicting reactor performance Methodology: § Compartmental Approach – Divides the reactor into number of inter-connected well-mixed compartments § Incorporation of mean flow and turbulent parameters from complete CFD simulation Results: § Mixing effect on reactor performance for multiple reactions § Effect of different feed locations captured

Processes and mini and micro reactors CHEMICAL REACTION ENGINEERING LABORATORY

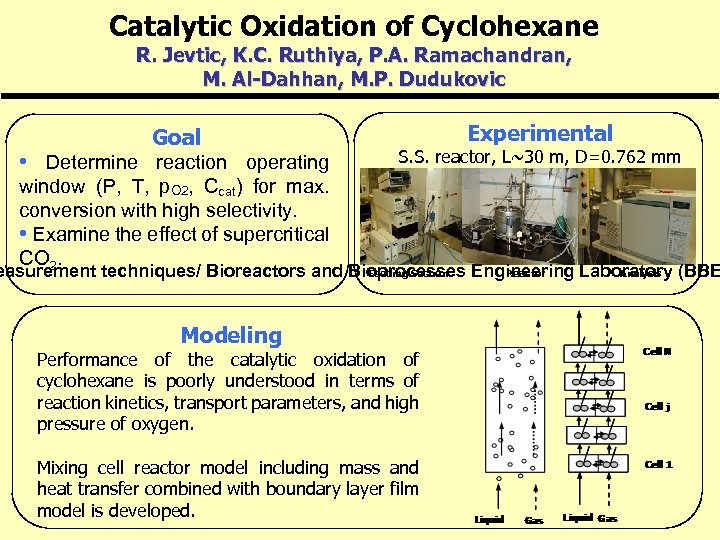

Catalytic Oxidation of Cyclohexane R. Jevtic, K. C. Ruthiya, P. A. Ramachandran, M. Al-Dahhan, M. P. Dudukovic Goal • Determine reaction operating Experimental S. S. reactor, L~30 m, D=0. 762 mm window (P, T, p. O 2, Ccat) for max. conversion with high selectivity. • Examine the effect of supercritical CO 2. easurement techniques/ Bioreactors and Bioprocesses Engineering Laboratory (BBE Feeding Section Reactor Analysis Modeling Performance of the catalytic oxidation of cyclohexane is poorly understood in terms of reaction kinetics, transport parameters, and high pressure of oxygen. Mixing cell reactor model including mass and heat transfer combined with boundary layer film model is developed.

The Integrated Struvite-CANON System Fan Mei, Sarah Dryden, Biplab Mukherjee, Lars T. Angenent Objectives: Design a technology to reduce nitrogen concentration from anaerobic sludge digestion centrate at the New York City Department of Environmental Protection (NYCDEP) wastewater facilities. Study the effects of Several factors on the system: acceptable effluent concentrations, costs, value-added products, and design stability. Accomplishments: 1. 2. 3. 4. 5. Reduce the effluent nitrogen levels to the allowable limit Create a marketable product with revenues that compensate for the cost of all chemical additives in the process Reduce phosphorous levels in the effluent Reduce struvite-scaling formation within piping Dramatically reduce the amount of required aeration Chemical Reaction Engineering Laboratory

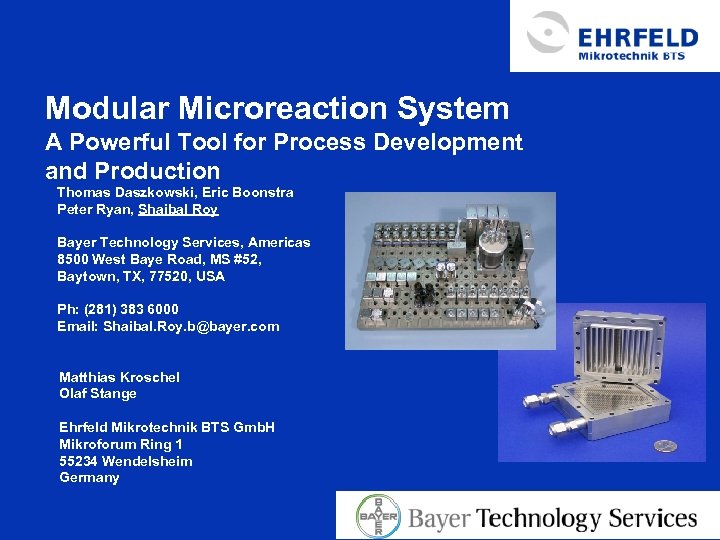

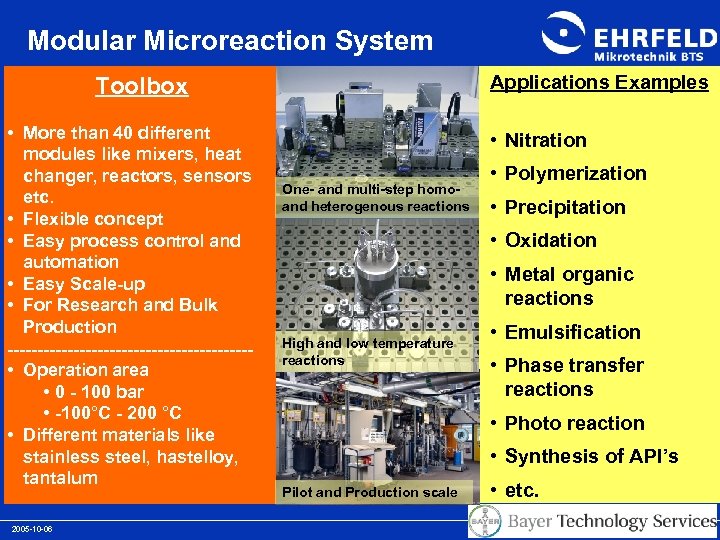

Modular Microreaction System A Powerful Tool for Process Development and Production Thomas Daszkowski, Eric Boonstra Peter Ryan, Shaibal Roy Bayer Technology Services, Americas 8500 West Baye Road, MS #52, Baytown, TX, 77520, USA Ph: (281) 383 6000 Email: Shaibal. Roy. b@bayer. com Matthias Kroschel Olaf Stange Ehrfeld Mikrotechnik BTS Gmb. H Mikroforum Ring 1 55234 Wendelsheim Germany

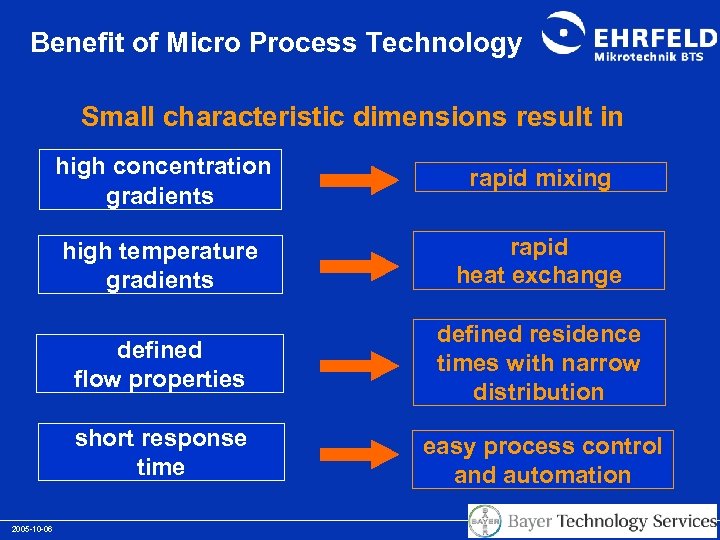

Benefit of Micro Process Technology Small characteristic dimensions result in high concentration gradients high temperature gradients rapid heat exchange defined flow properties defined residence times with narrow distribution short response time 2005 -10 -06 rapid mixing easy process control and automation

Modular Microreaction System Applications Examples Toolbox • More than 40 different modules like mixers, heat changer, reactors, sensors etc. • Flexible concept • Easy process control and automation • Easy Scale-up • For Research and Bulk Production -------------------- • Operation area • 0 - 100 bar • -100°C - 200 °C • Different materials like stainless steel, hastelloy, tantalum 2005 -10 -06 • Nitration One- and multi-step homoand heterogenous reactions • Polymerization • Precipitation • Oxidation • Metal organic reactions High and low temperature reactions • Emulsification • Phase transfer reactions • Photo reaction • Synthesis of API’s Pilot and Production scale • etc.

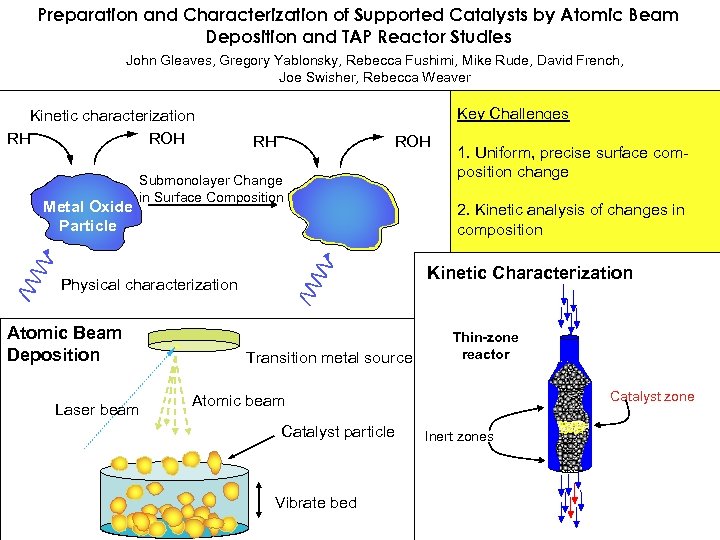

Preparation and Characterization of Supported Catalysts by Atomic Beam Deposition and TAP Reactor Studies John Gleaves, Gregory Yablonsky, Rebecca Fushimi, Mike Rude, David French, Joe Swisher, Rebecca Weaver Kinetic characterization RH ROH Metal Oxide Particle Key Challenges RH ROH Submonolayer Change in Surface Composition Laser beam 2. Kinetic analysis of changes in composition Kinetic Characterization Physical characterization Atomic Beam Deposition 1. Uniform, precise surface composition change Transition metal source Thin-zone reactor Catalyst zone Atomic beam Catalyst particle Vibrate bed Inert zones

Measurement techniques/ Bioreactors and Bioprocesses Engineering Laboratory (BBEL) CHEMICAL REACTION ENGINEERING LABORATORY

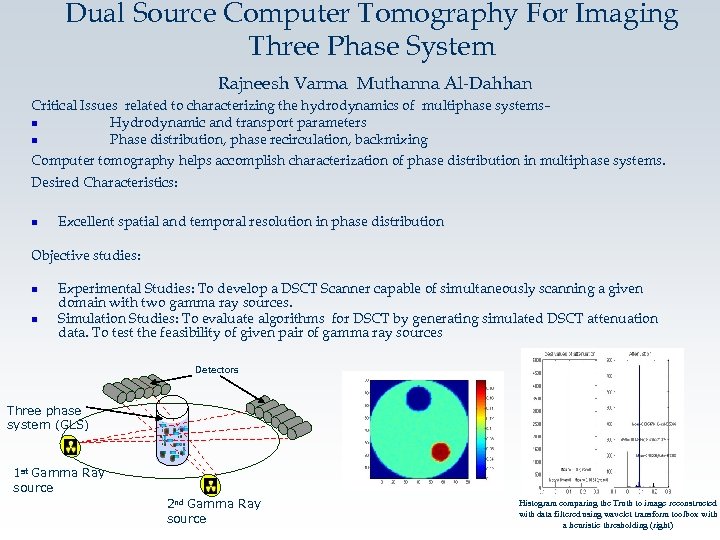

Dual Source Computer Tomography For Imaging Three Phase System Rajneesh Varma Muthanna Al-Dahhan Critical Issues related to characterizing the hydrodynamics of multiphase systems– n Hydrodynamic and transport parameters n Phase distribution, phase recirculation, backmixing Computer tomography helps accomplish characterization of phase distribution in multiphase systems. Desired Characteristics: n Excellent spatial and temporal resolution in phase distribution Objective studies: n n Experimental Studies: To develop a DSCT Scanner capable of simultaneously scanning a given domain with two gamma ray sources. Simulation Studies: To evaluate algorithms for DSCT by generating simulated DSCT attenuation data. To test the feasibility of given pair of gamma ray sources Detectors Three phase system (GLS) 1 st Gamma Ray source 2 nd Gamma Ray source Histogram comparing the Truth to image reconstructed with data filtered using wavelet transform toolbox with a heuristic thresholding (right)

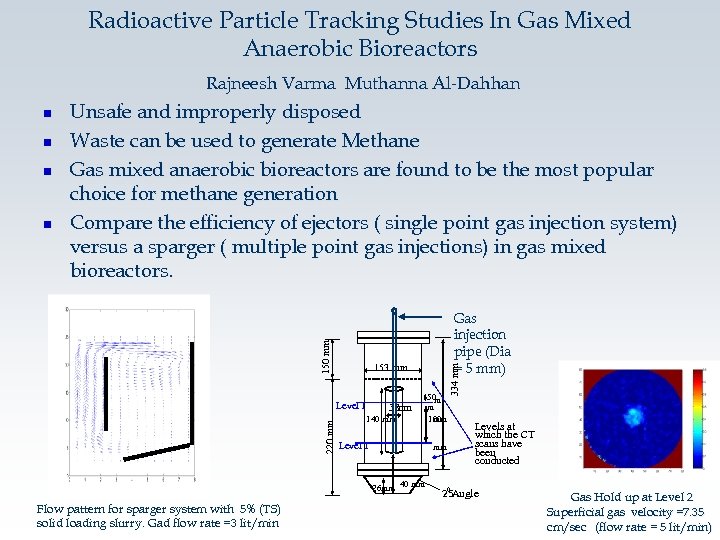

Radioactive Particle Tracking Studies In Gas Mixed Anaerobic Bioreactors Rajneesh Varma Muthanna Al-Dahhan n n 150 mm n Unsafe and improperly disposed Waste can be used to generate Methane Gas mixed anaerobic bioreactors are found to be the most popular choice for methane generation Compare the efficiency of ejectors ( single point gas injection system) versus a sparger ( multiple point gas injections) in gas mixed bioreactors. 153 mm 220 mm Level 1 38 mm 140 mm Level 1 50 m m 100 mm mm 26 mm 40 mm Flow pattern for sparger system with 5% (TS) solid loading slurry. Gad flow rate =3 lit/min Gas injection pipe (Dia = 5 mm) 334 mm n Levels at which the CT scans have been conducted 0 25 Angle Gas Hold up at Level 2 Superficial gas velocity =7. 35 cm/sec (flow rate = 5 lit/min)

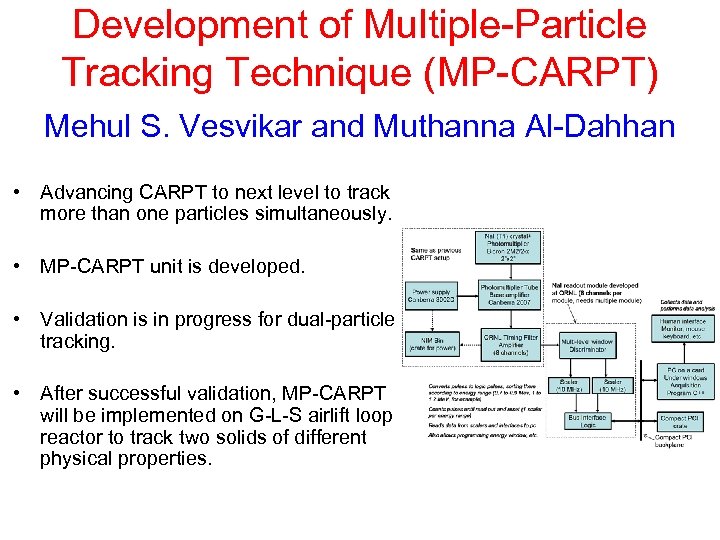

Development of Multiple-Particle Tracking Technique (MP-CARPT) Mehul S. Vesvikar and Muthanna Al-Dahhan • Advancing CARPT to next level to track more than one particles simultaneously. • MP-CARPT unit is developed. • Validation is in progress for dual-particle tracking. • After successful validation, MP-CARPT will be implemented on G-L-S airlift loop reactor to track two solids of different physical properties.

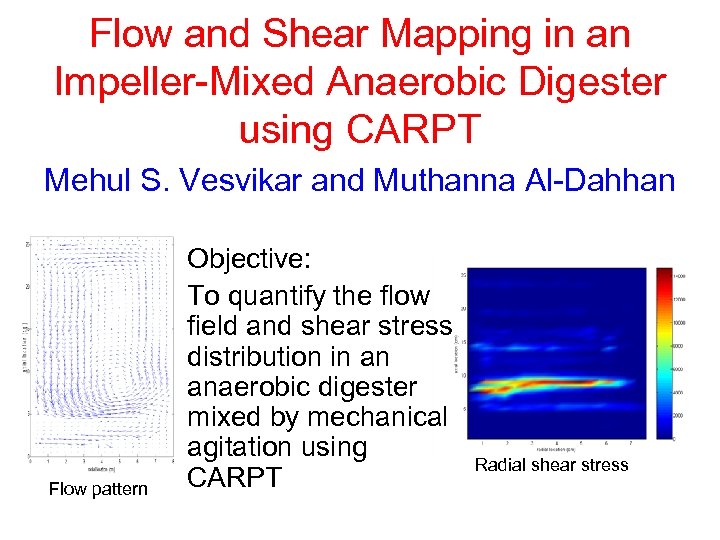

Flow and Shear Mapping in an Impeller-Mixed Anaerobic Digester using CARPT Mehul S. Vesvikar and Muthanna Al-Dahhan Flow pattern Objective: To quantify the flow field and shear stress distribution in an anaerobic digester mixed by mechanical agitation using CARPT Radial shear stress

Performance Study of a Pilot Scale Anaerobic Digester Mehul S. Vesvikar, Abhijeet Borole, Thomas Klasson, Khursheed Karim and Muthanna Al-Dahhan • Impact of reactor scale and mixing on the performance of anaerobic digesters. • Importance of scale of operation in experiments for obtaining reliable results.

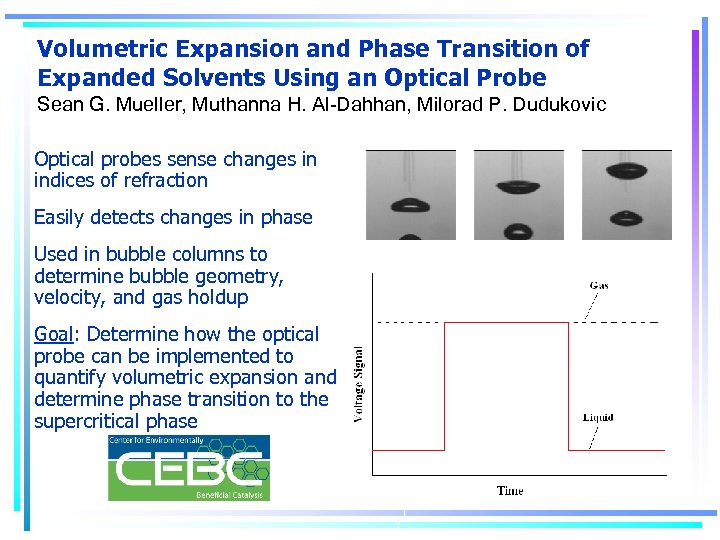

Volumetric Expansion and Phase Transition of Expanded Solvents Using an Optical Probe Sean G. Mueller, Muthanna H. Al-Dahhan, Milorad P. Dudukovic Optical probes sense changes in indices of refraction Easily detects changes in phase Used in bubble columns to determine bubble geometry, velocity, and gas holdup Goal: Determine how the optical probe can be implemented to quantify volumetric expansion and determine phase transition to the supercritical phase

Multiphase Reactors Modeling CHEMICAL REACTION ENGINEERING LABORATORY

User Friendly Modules for Modeling Multiphase Reactors C. Tunca, S. V. Mehul, R. C. Ramaswamy, A. Shaikh, M. P. Dudukovic, P. A. Ramachandran v A series of user friendly simulation packages have been developed for selected multiphase reactors and specific processes. v The simulation packages cover the key concepts in reactor design. One can assess the effect of catalyst parameters, operating conditions, reactor scale-up, etc. on the reactor performance. The poster presentation will demonstrate alkylation and methanol synthesis process simulations.

Potential new technologies using PI tools Dr. Radu V. Vladea Bioethanol- Conventional vs. New Process Biodiesel – Current vs. New Process Ethoxylation/ Propoxylation - Conventional vs. New Process Monoethylene Glycol – Conventional vs. New Process

Washington University and ECI Present: Bioenergy I: From Concept to Commercial Processes March 5 -10, 2006 Tomar, Portugal Theme I: Theme III: Theme IV: Theme V: Bioethanol and butanol production and technical development Biogas (methane) and biohydrogen process Biodiesel and biorefinery integration Microbial fuel cells Biomass thermal conversion (gasification, pyrolysis, biopower), syngas, methanol Theme VI: Related environmental issues, policies, economic considerations (including embodied energy involved in producing bioenergy) November 1, 2005 November 30, 2005 Deadline for abstract submission Notification of acceptance Conference Chairs: Dr. Muthanna Al-Dahhan, Professor/Co-Director, Washington University Dr. Kevin Hicks, Research Leader, USDA Dr. Charles A. Abbas, Director, Archer Daniels Midland Company Website: http: //www. engconfintl. org/6 aebody. html

Completed Thesis, 2004 -2005 ØSolids Flow Mapping in Gas-Solid Risers -Satish Bhusarapu ØModeling the Fluid Dynamics of Bubble Column Flows -Peng Chen ØAnalyzing and Modeling of Airlift Photobioreactors for Microalgal and Cyanobacteria Cultures -Hu-Ping Luo ØCatalytic Wet Oxidation Over Pillared Clay In Packed Bed Reactors: Experiments and Modeling -Jing Guo ØBubble Velocity, Size and Interfacial Area Measurements in Bubble Columns -Junli Xue ØFlow Distribution and Performance Studies of Gas-Liquid Monolith Reactor -Shaibal Roy ØThe effect of shear on the performance and microbial ecology of anaerobic digesters treating cow manure from dairy farms. -Rubecca Hoffman CHEMICAL REACTION ENGINEERING LABORATORY

0296a6b14e5b61a9f0f5512b6bc1e759.ppt