4d05bb11922ed4ee01557125737558ce.ppt

- Количество слайдов: 16

BREBECK COMPOSITE, s. r. o Company Presentation

Company Profile Brebeck Composite s. r. o. (Ltd. ), located in the Czech Republic, is a leading manufacturer of carbon, glass and aramid fiber components. Our core business is supplying the motorsport industry on a global level with highly sophisticated carbon fiber parts. We also produce carbon fiber parts (CFK, GFK) through Pre-preg technology for the automotive industry and other custom orders. Brebeck Composite was founded by Marcel Benda and Thomas Brebeck in Ostrava-Muglinov (CZ) on July 19, 2011. The production facility is located in Ostrava-Senov and spreads over about 2000 m². Brebeck Composite s. r. o. has been certified according to ČSN EN ISO 9001: 2009 since 2012. 2

History 2011 Brebeck Composite was founded 2011 Production launched in Šenov – 1. 000 m 2 2011 Autoclave Scholz #1 installed 2012 ČSN ISO 9001: 2009 Certification recieved 2013 Autoclave Scholz #2 installed 2013 Production expanded up to 1. 300 m 2 2014 Production expanded up to 1. 600 m 2 2015 Autoclave Scholz #3 installed 2016 Production area expanded up to 2. 000 m 2 2016 Strategic partnership with German toolroom (5 -axis milling) 3

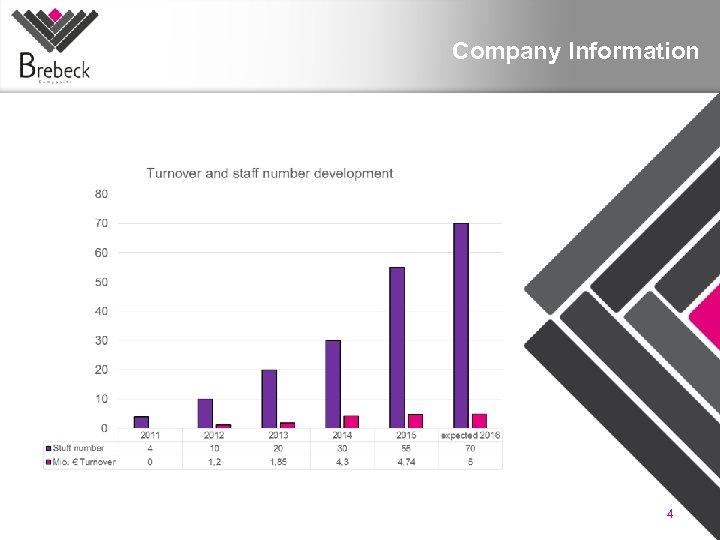

Company Information 4

Certifikation 5

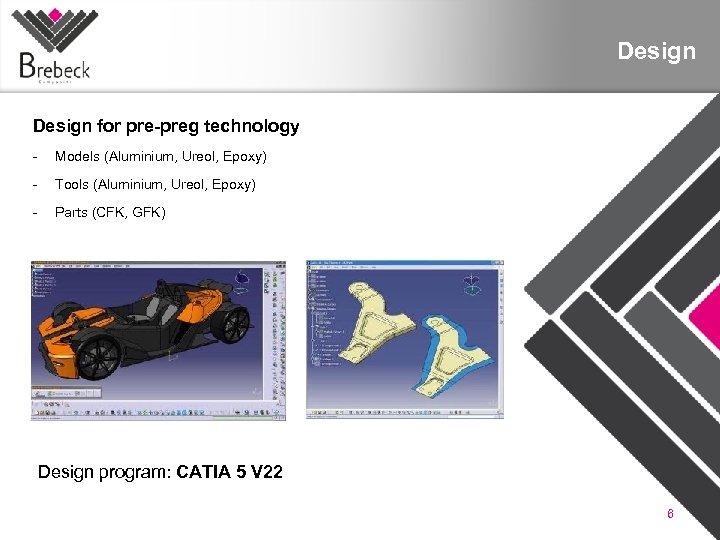

Design for pre-preg technology - Models (Aluminium, Ureol, Epoxy) - Tools (Aluminium, Ureol, Epoxy) - Parts (CFK, GFK) Design program: CATIA 5 V 22 6

Production Area Current: 2. 000 m² Can be expanded up to 3. 500 m² Developement of composite parts Production of composite parts 60 Employees 7

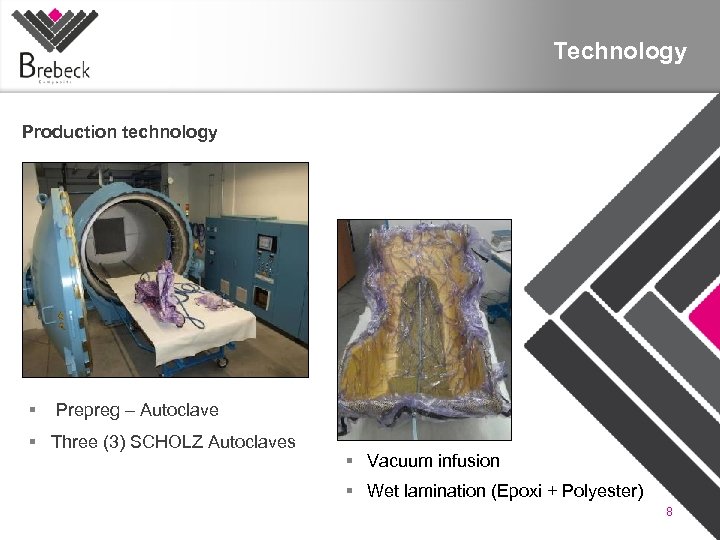

Technology Production technology Prepreg – Autoclave Three (3) SCHOLZ Autoclaves Vacuum infusion Wet lamination (Epoxi + Polyester) 8

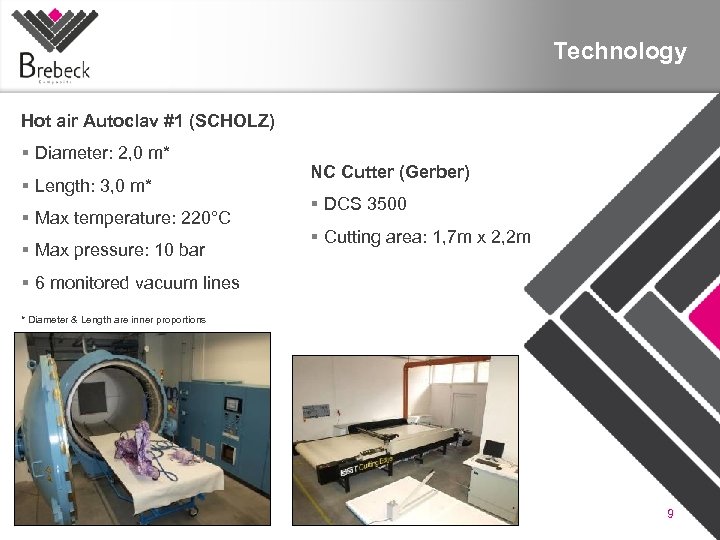

Technology Hot air Autoclav #1 (SCHOLZ) Diameter: 2, 0 m* Length: 3, 0 m* Max temperature: 220°C Max pressure: 10 bar NC Cutter (Gerber) DCS 3500 Cutting area: 1, 7 m x 2, 2 m 6 monitored vacuum lines * Diameter & Length are inner proportions 9

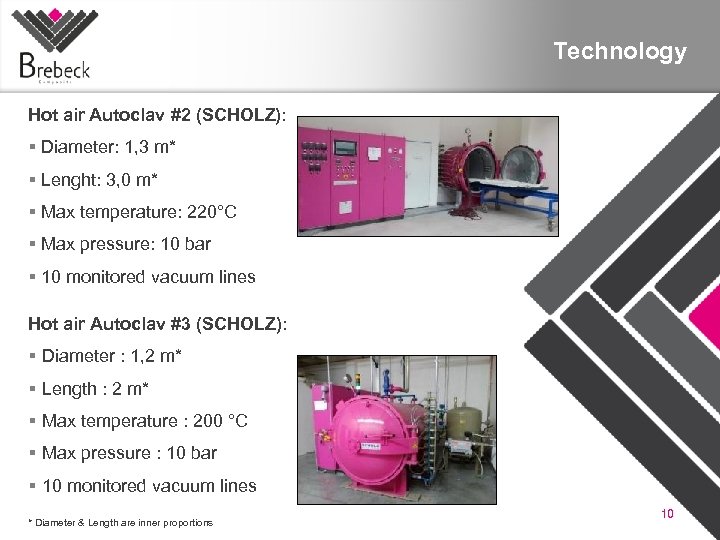

Technology Hot air Autoclav #2 (SCHOLZ): Diameter: 1, 3 m* Lenght: 3, 0 m* Max temperature: 220°C Max pressure: 10 bar 10 monitored vacuum lines Hot air Autoclav #3 (SCHOLZ): Diameter : 1, 2 m* Length : 2 m* Max temperature : 200 °C Max pressure : 10 bar 10 monitored vacuum lines * Diameter & Length are inner proportions 10

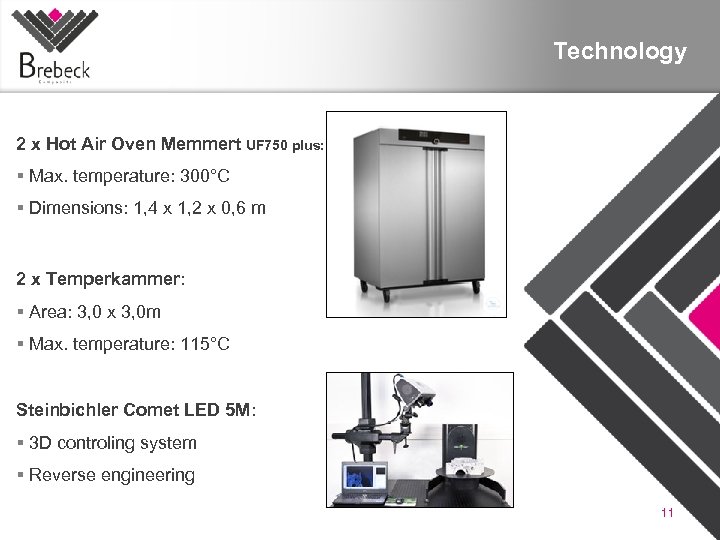

Technology 2 x Hot Air Oven Memmert UF 750 plus: Max. temperature: 300°C Dimensions: 1, 4 x 1, 2 x 0, 6 m 2 x Temperkammer: Area: 3, 0 x 3, 0 m Max. temperature: 115°C Steinbichler Comet LED 5 M: 3 D controling system Reverse engineering 11

Product Line Racing Visual carbon Industrial application • DTM • Motorcycle • Covers • GT 3/GT 4 • Automotive • Technical parts • Le Mans • Design • Dakar 12

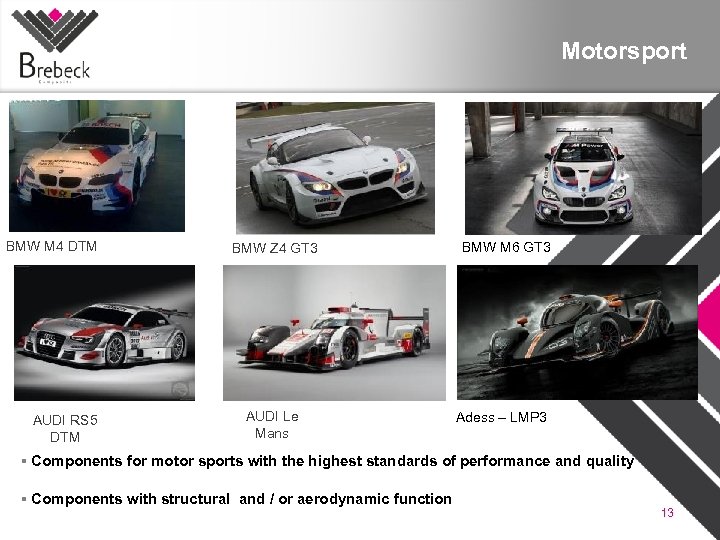

Motorsport BMW M 4 DTM AUDI RS 5 DTM BMW Z 4 GT 3 AUDI Le Mans BMW M 6 GT 3 Adess – LMP 3 Components for motor sports with the highest standards of performance and quality Components with structural and / or aerodynamic function 13

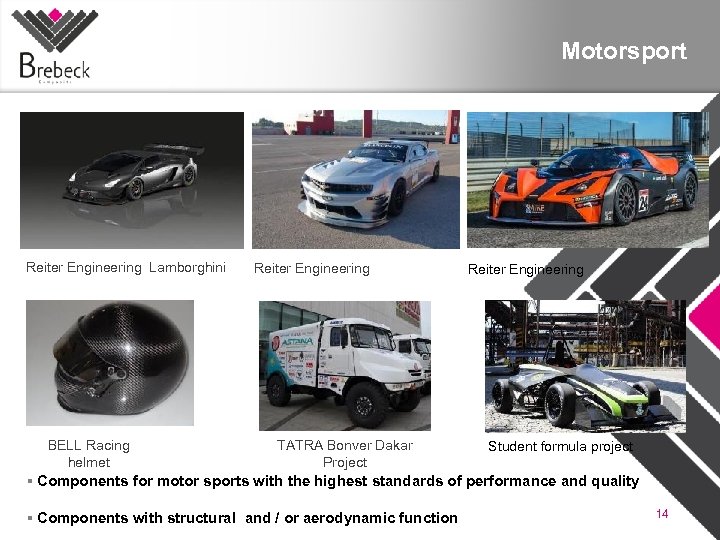

Motorsport Reiter Engineering Lamborghini BELL Racing helmet Reiter Engineering TATRA Bonver Dakar Project Reiter Engineering Student formula project Components for motor sports with the highest standards of performance and quality Components with structural and / or aerodynamic function 14

References P+Z Engineering Gmb. H 15

THANK YOU BREBECK COMPOSITE, s. r. o. Volenska 1718 73934 Senov u Ostravy www. brebeckcomposite. com

4d05bb11922ed4ee01557125737558ce.ppt